Patents

Literature

53results about How to "Good chilling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lost wax shell-based negative pressure dry sand and iron shot chilling vibrational casting process method

InactiveCN102240778AHigh strengthReduce the number of hanging coatsFoundry mouldsFoundry coresWaxHigh density

The invention discloses a lost wax shell-based negative pressure dry sand and iron shot chilling vibrational composite casting process method. The method is characterized by comprising the following steps of: feeding a shell manufactured by a lost wax process into a chilling sand box; loading steel shots in the gap between the shell and the chilling sand box; feeding the chilling sand box into a sand box with a vacuumized negative pressure model; fully filling dry sand between the chilling sand box and the sand box with the vacuumized negative pressure model; paving a plastic film; placing a pouring cup; and pouring under the simultaneous vacuumizing and vibrating condition. By the method, the strength of molding sand is high, a chilling effect is good, the process characteristics of lost foam casting and hot investment casting are combined, the defect of foam-gasified carbon special for the lost foam casting is overcome, the chilling effect of the iron shots is fully exerted, the pouring is performed under the vibration condition, and alloy grains are refined, so that wear-resisting castings have higher density, hardness and wear resistance.

Owner:HUBEI GENGLIAN WEAR RESISTANT MATERIALS TECH

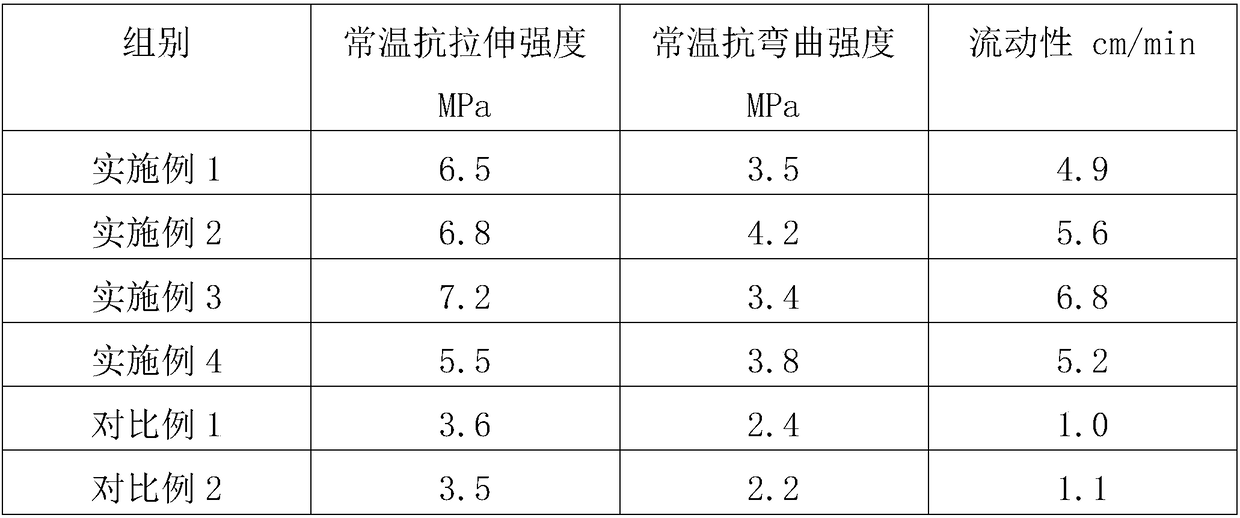

High-temperature wear-resisting coating for casting and preparation method thereof

ActiveCN104325067AHigh refractorinessLow thermal conductivityFoundry mouldsFoundry coresWear resistantSuspending Agents

The invention discloses a high-temperature wear-resisting coating for casting and a preparation method thereof. The coating comprises the following components: a fireproof material, a carrier, a bonding agent, a suspension agent and an auxiliary agent. The invention further designs the preparation method of the high-temperature wear-resisting coating for casting. The preparation method comprises the following steps: putting the suspension agent and the carrier into a dispersion machine and uniformly agitating; then adding the fireproof material and continually agitating; and slowly adding the bonding agent and the auxiliary agent in sequence under an agitating state; and agitating uniformly to obtain the high-temperature wear-resisting coating for casting. The high-temperature wear-resisting coating for casting is low in price, and is clean and is free from pollution; the preparation method is simple and the coating is high temperature resistant and wear resistant and is not easy to release; and a die for casting can be protected and the quality of a casting piece can be improved.

Owner:YANCHENG AOTONG TESCO FOUNDRY CO LTD

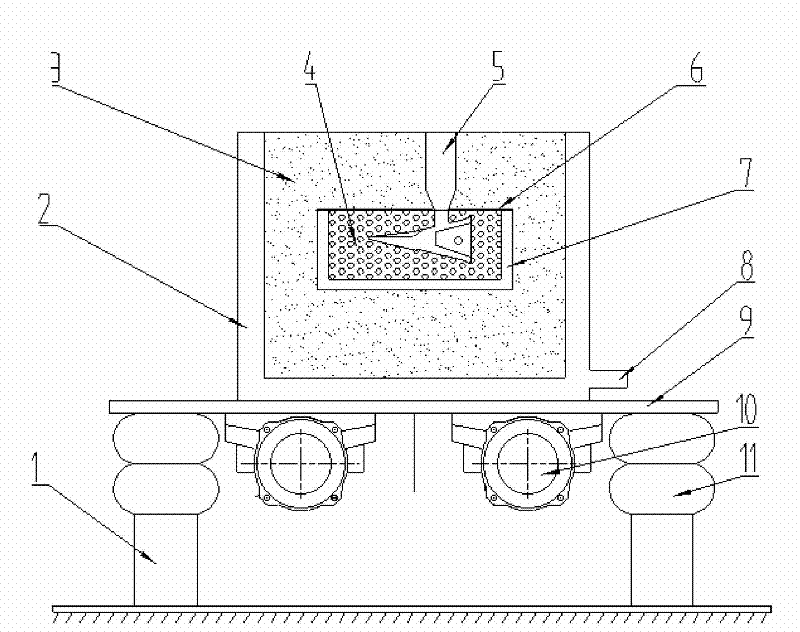

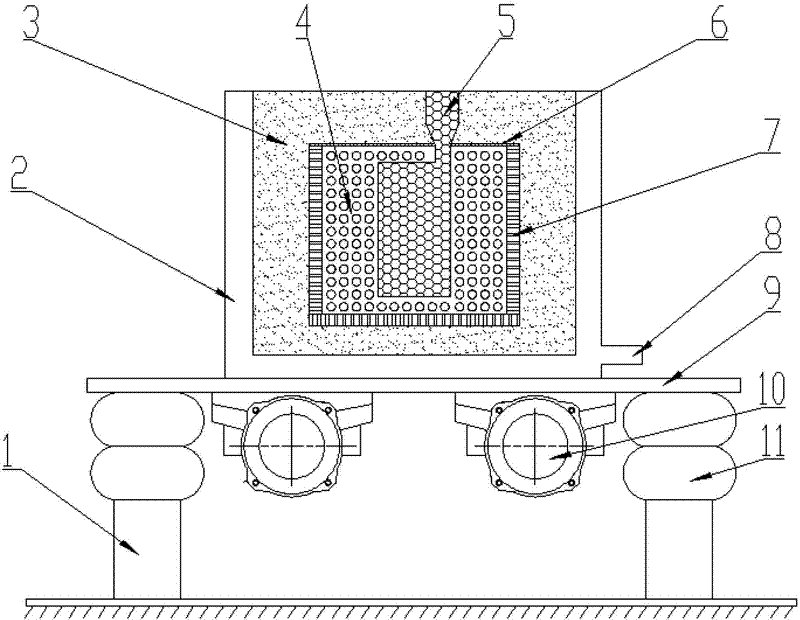

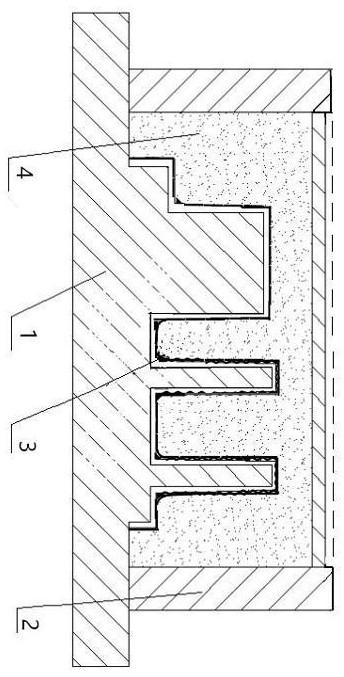

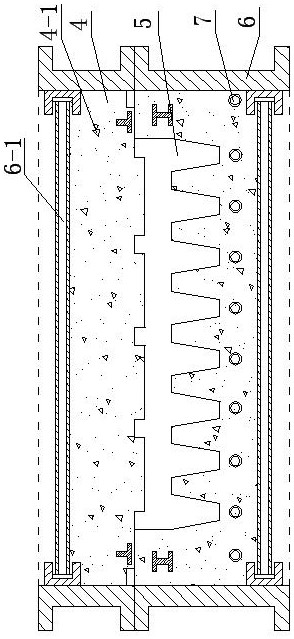

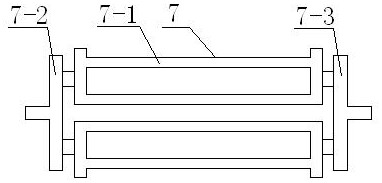

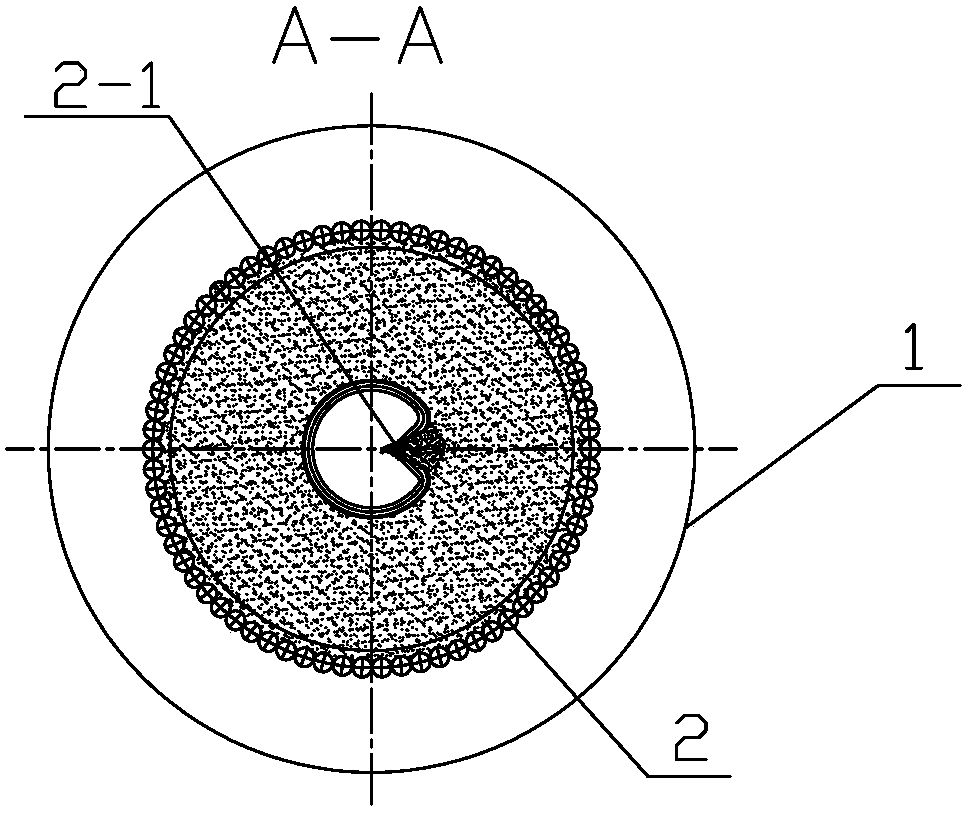

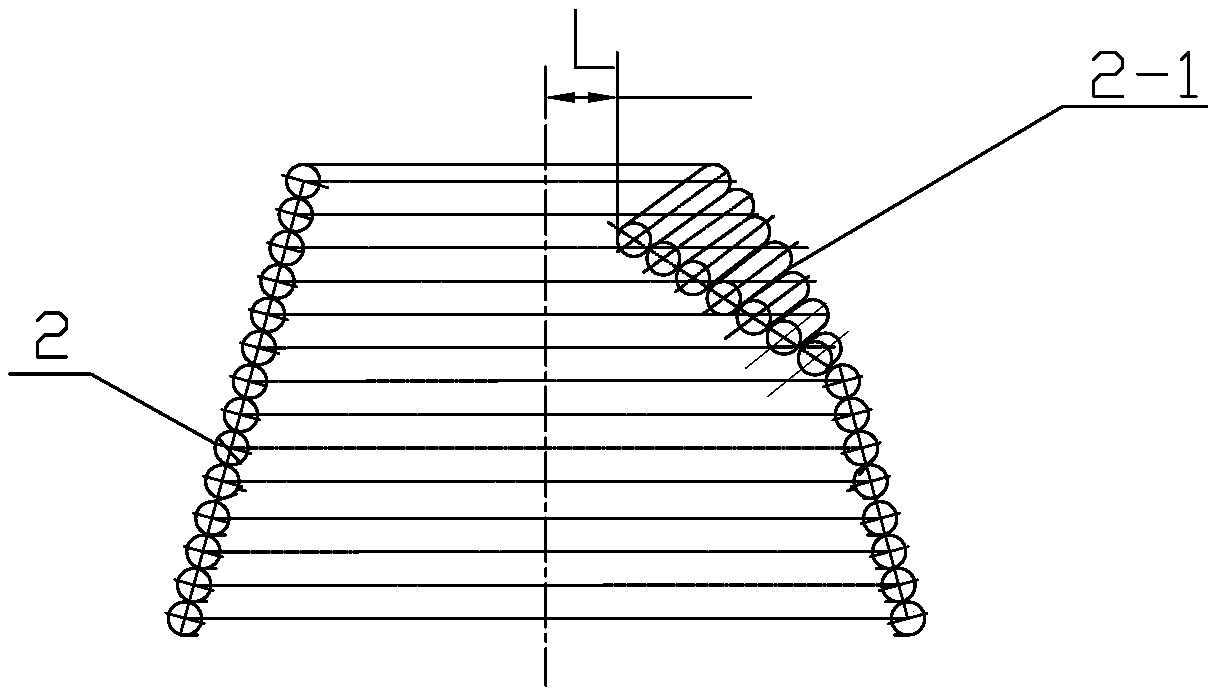

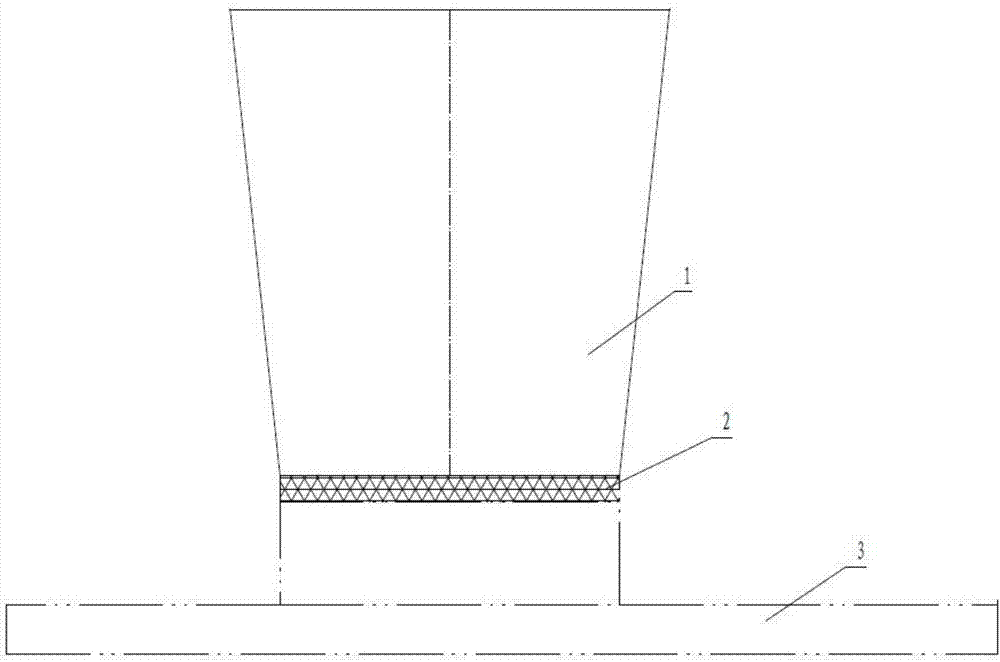

Casting process method combining steel-shot chilling and vibratory pouring based on disappearing die

InactiveCN102371339ASolve the slow cooling rateImprove toughnessFoundry mouldsFoundry coresVacuum pumpingDry sand

The invention discloses a casting process method combining steel-shot chilling and vibratory pouring based on a disappearing die. The casting process method combining steel-shot chilling and vibratory pouring based on the disappearing die is characterized in that a manufactured foam model is placed into a chilling sand box, steel shots are also placed at the position of a clearance between the foam model and the chilling sand box, then the chilling sand box is placed into a sand box with a vacuum-pumping negative-pressure model, dry sand is filled between the chilling sand box and the sand box with the vacuum-pumping negative-pressure model, a plastic film is laid, a sprue cup is placed, and finally, the operation of pouring is carried out under the condition that the operations of vacuumpumping and vibrating are simultaneously carried out. According to the casting process method combining steel-shot chilling and vibratory pouring based on the disappearing die, the circular use of the steel shots and the sand is realized, the problem of lower cooling speed of a cast in the casting of the disappearing die is thoroughly solved, the problems of bulky crystal grains, uncompacted tissues and the like, which are easy to occur in the casting of a traditional disappearing die, are avoided, the toughness and the compactness of the tissues of the cast are enhanced, the use quantity of alloy elements, such as Cr, Mo and the like, is lowered, the service life of a wear-resisting cast is ensured, the batch production of a product is realized, the rejection rate is reduced, and the manpower cost is lowered.

Owner:HUBEI GENGLIAN WEAR RESISTANT MATERIALS TECH

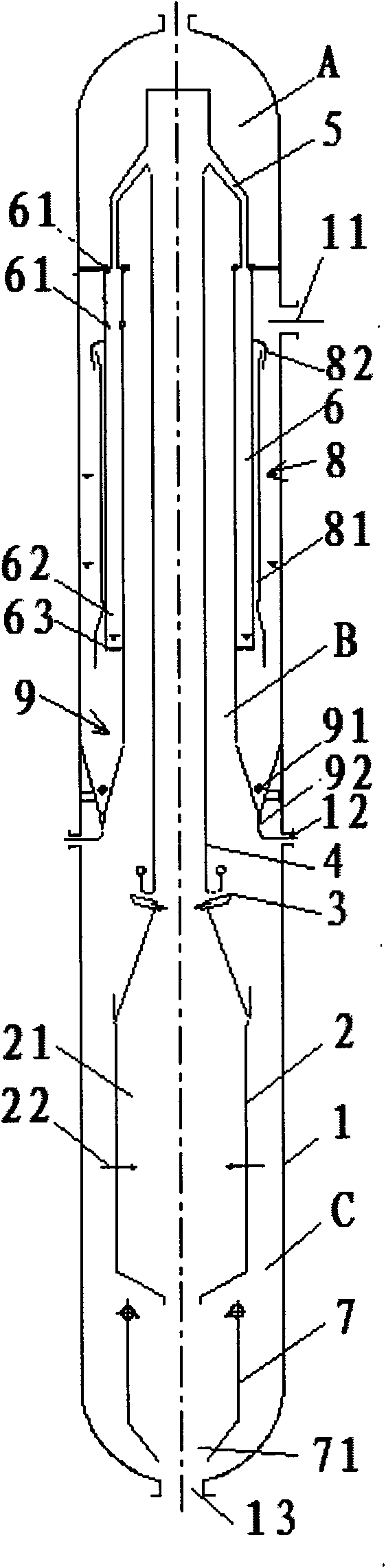

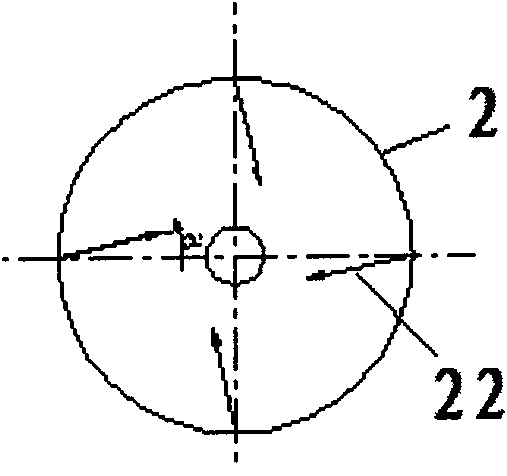

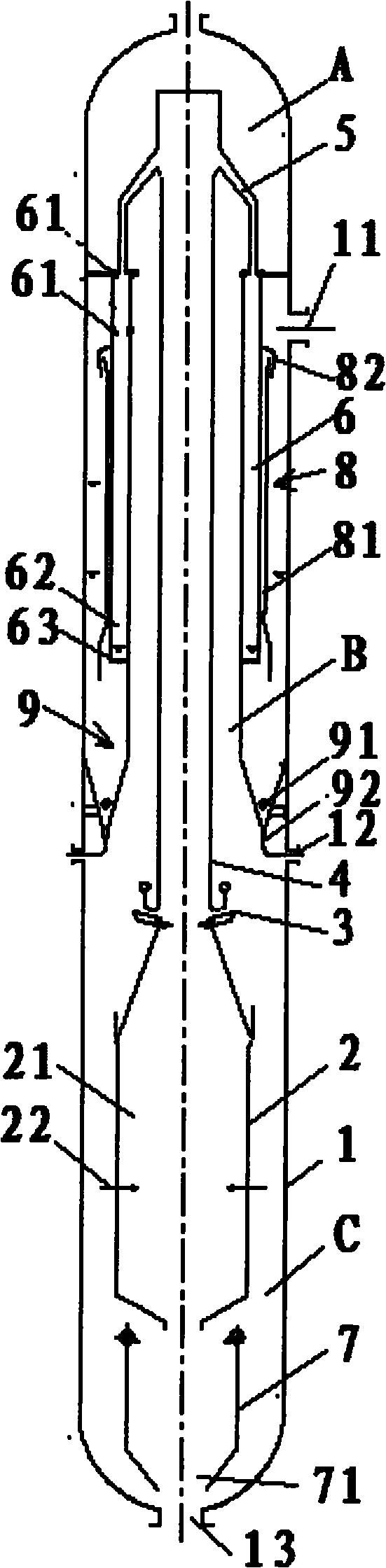

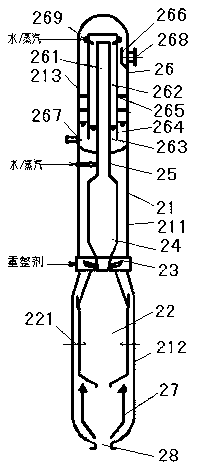

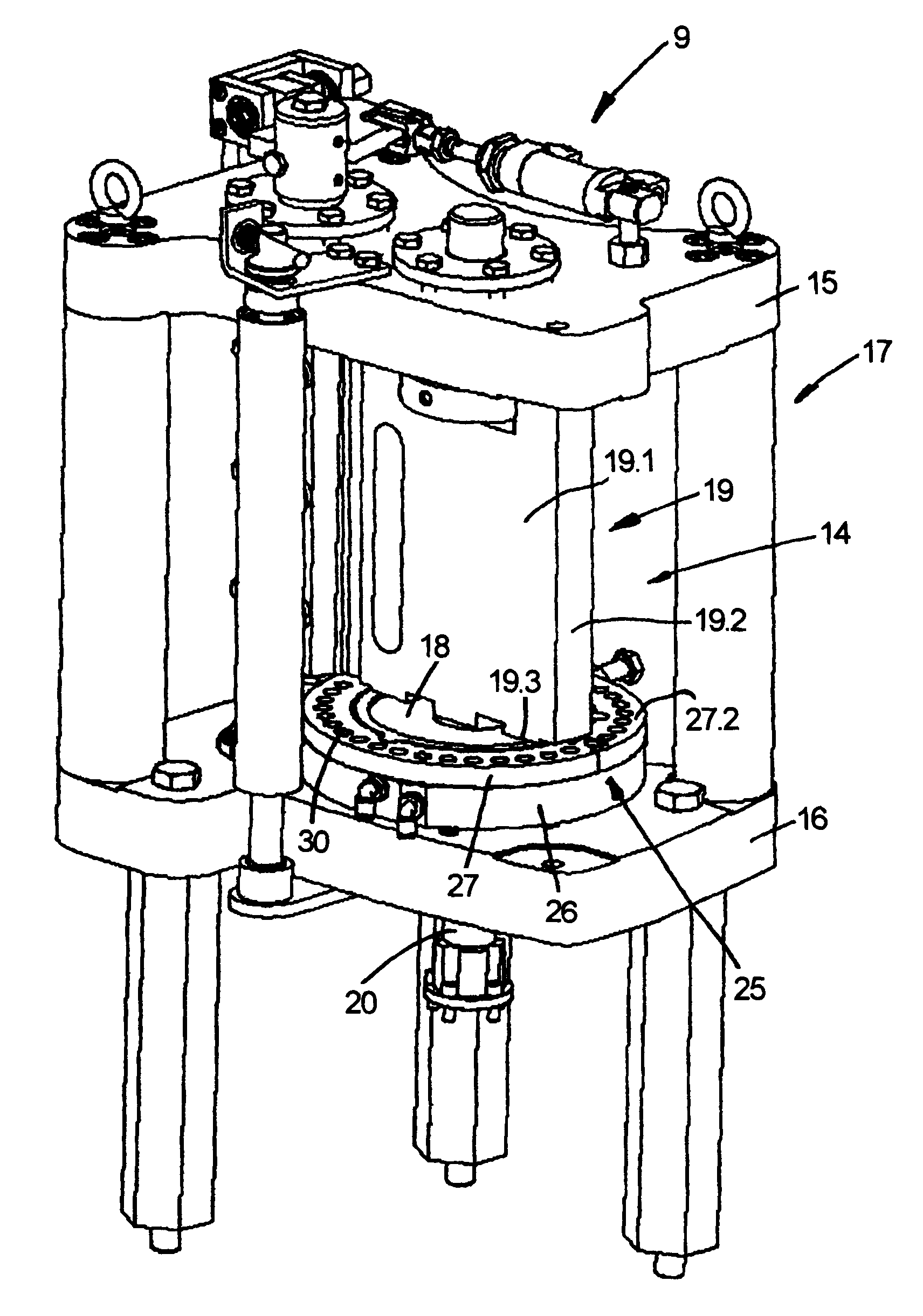

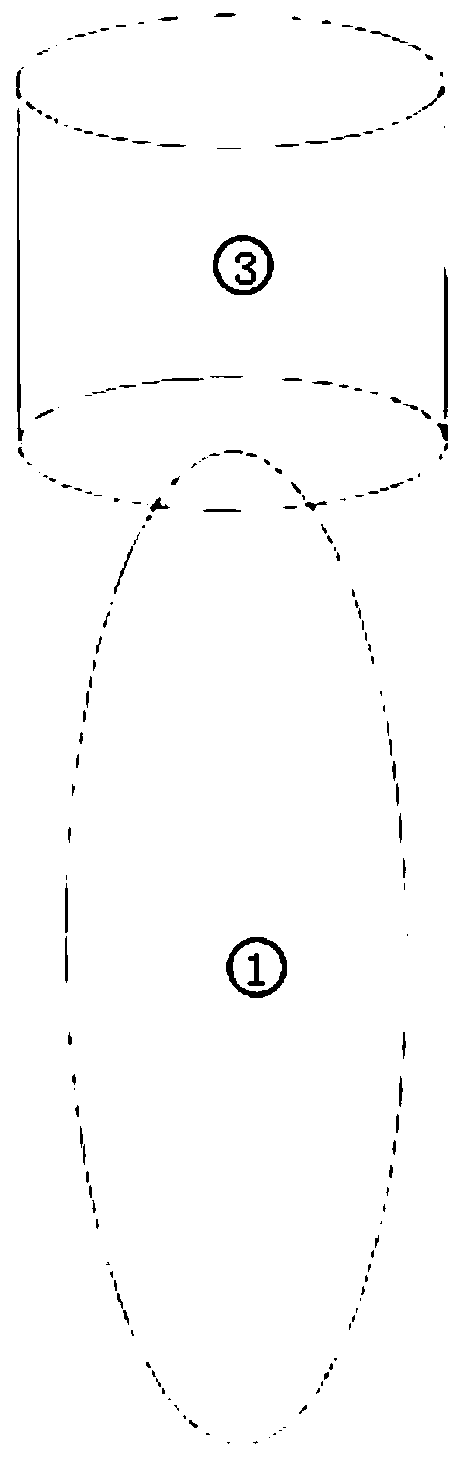

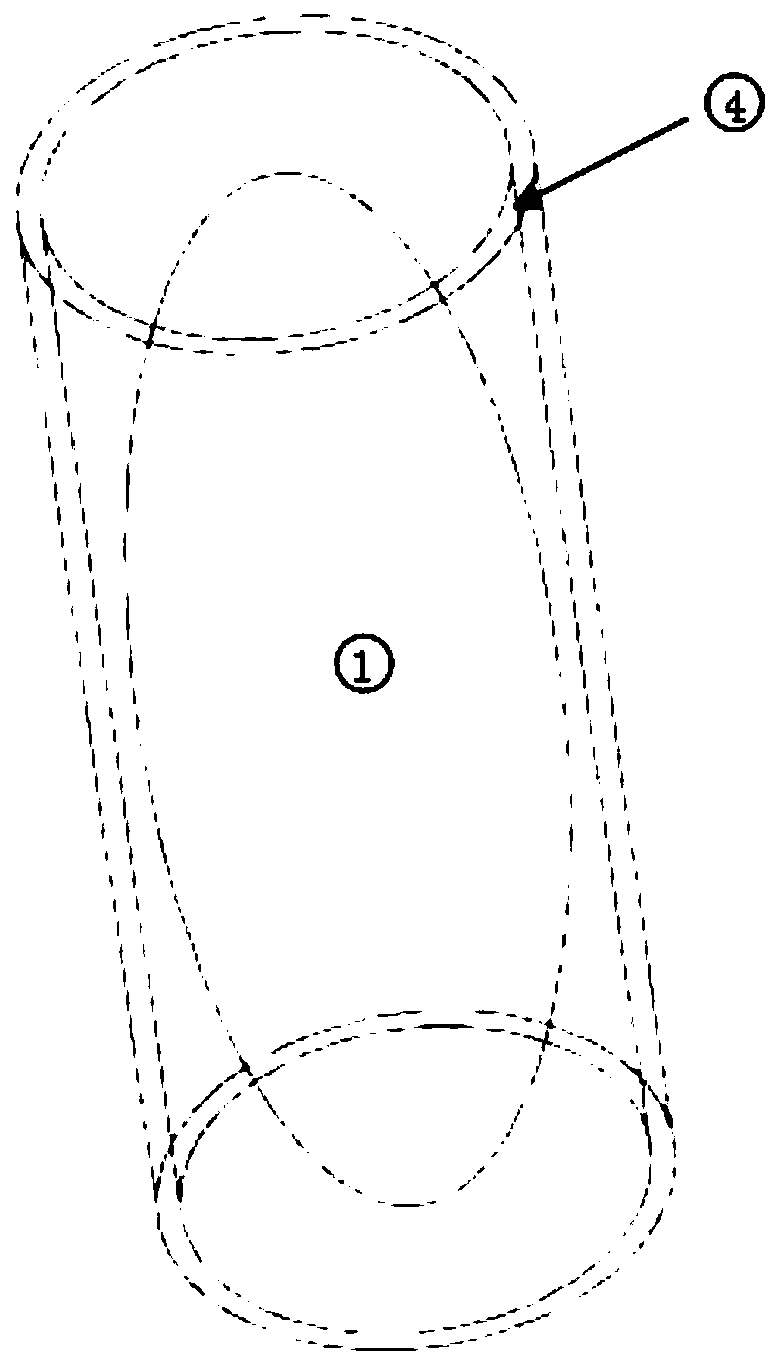

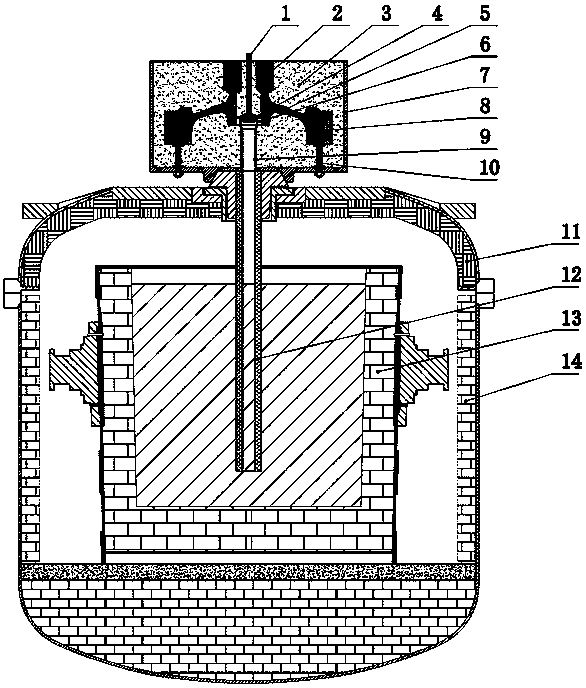

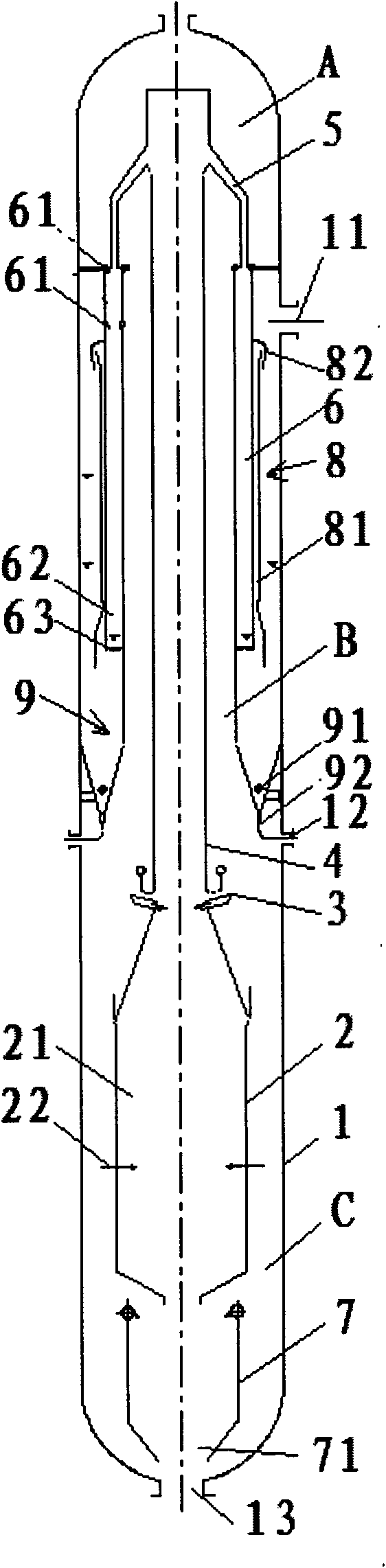

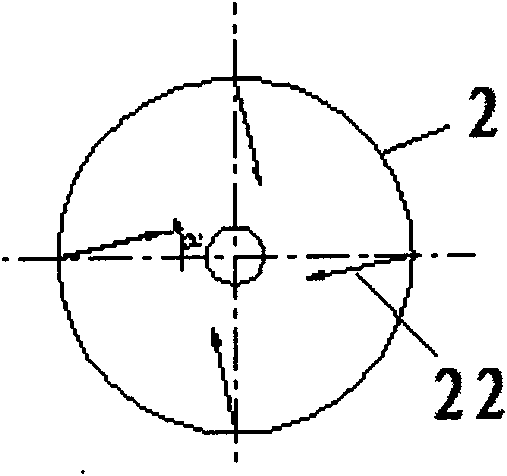

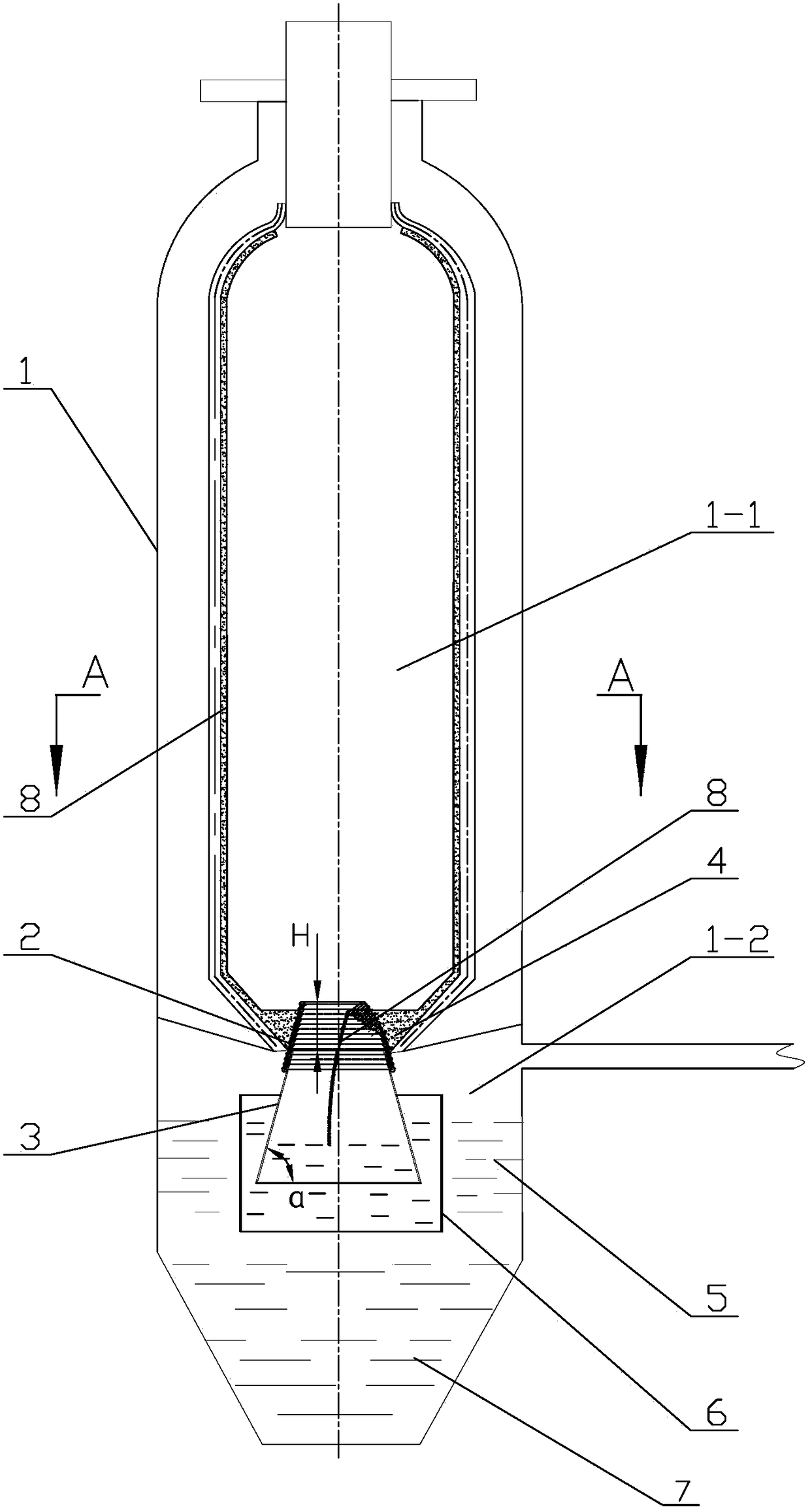

Tower-type powdered coal pressure gasification device with chilling process

ActiveCN101885991ALower the altitudeIncrease catch rateGranular/pulverulent flues gasificationSlagEngineering

The invention discloses a tower-type powdered coal pressure gasification device with a chilling process. The device comprises a pressure shell, and a gasification unit and a steam / water or dust-free gas chilling unit which are hung in the pressure shell. The device is characterized in that the gasification unit is arranged below the steam / water or dust-free gas chilling unit coaxially; the gasification unit comprises a reaction chamber and four nozzles arranged near the bottom of the reaction chamber at interval; the device of the invention also comprises a cooling channel and a returning chamber which are in coaxial arrangement with the gasification unit or the steam / water or dust-free gas chilling unit, and a chilling chamber and a slag pool; the cooling channel is arranged above the steam / water or dust-free gas chilling unit; the returning chamber is arranged on the top of the cooling channel; the chilling chamber is arranged around the cooling channel; the slag pool is arranged below the gasification unit; and the pressure shell is provided with a synthesis gas outlet, a grey water exhaust port and a slag-discharging hole. By using the device of the invention, dust and slag generated by gasification can be effectively separated and processed and the problem of performing thermal compensation to the entire equipment is effectively solved.

Owner:中国船舶集团有限公司第七一一研究所

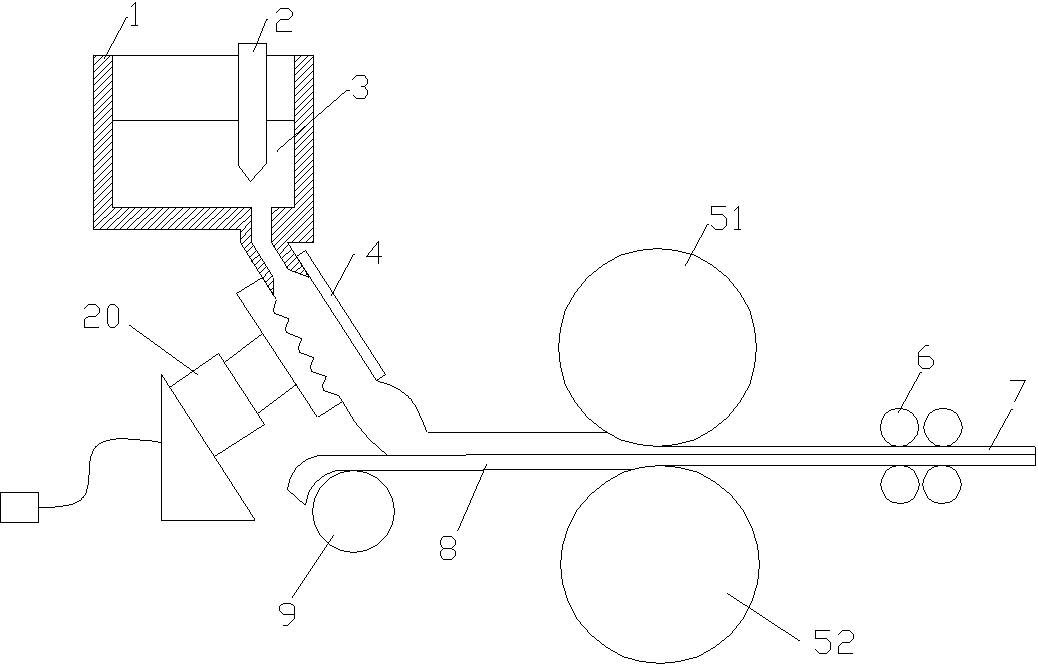

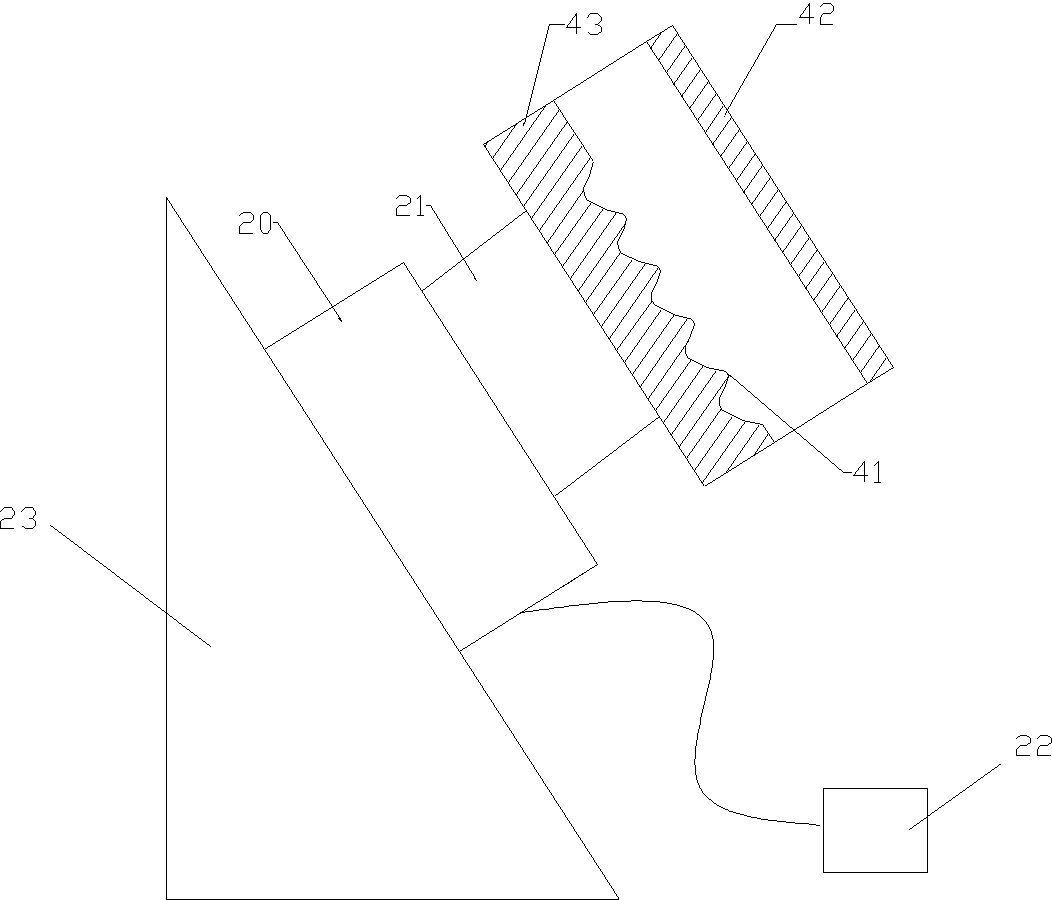

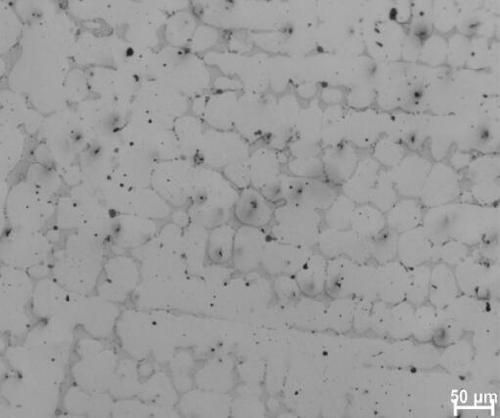

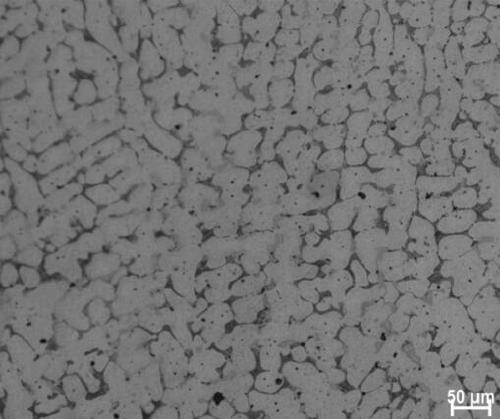

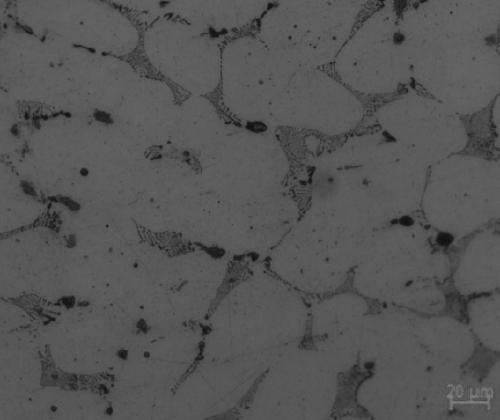

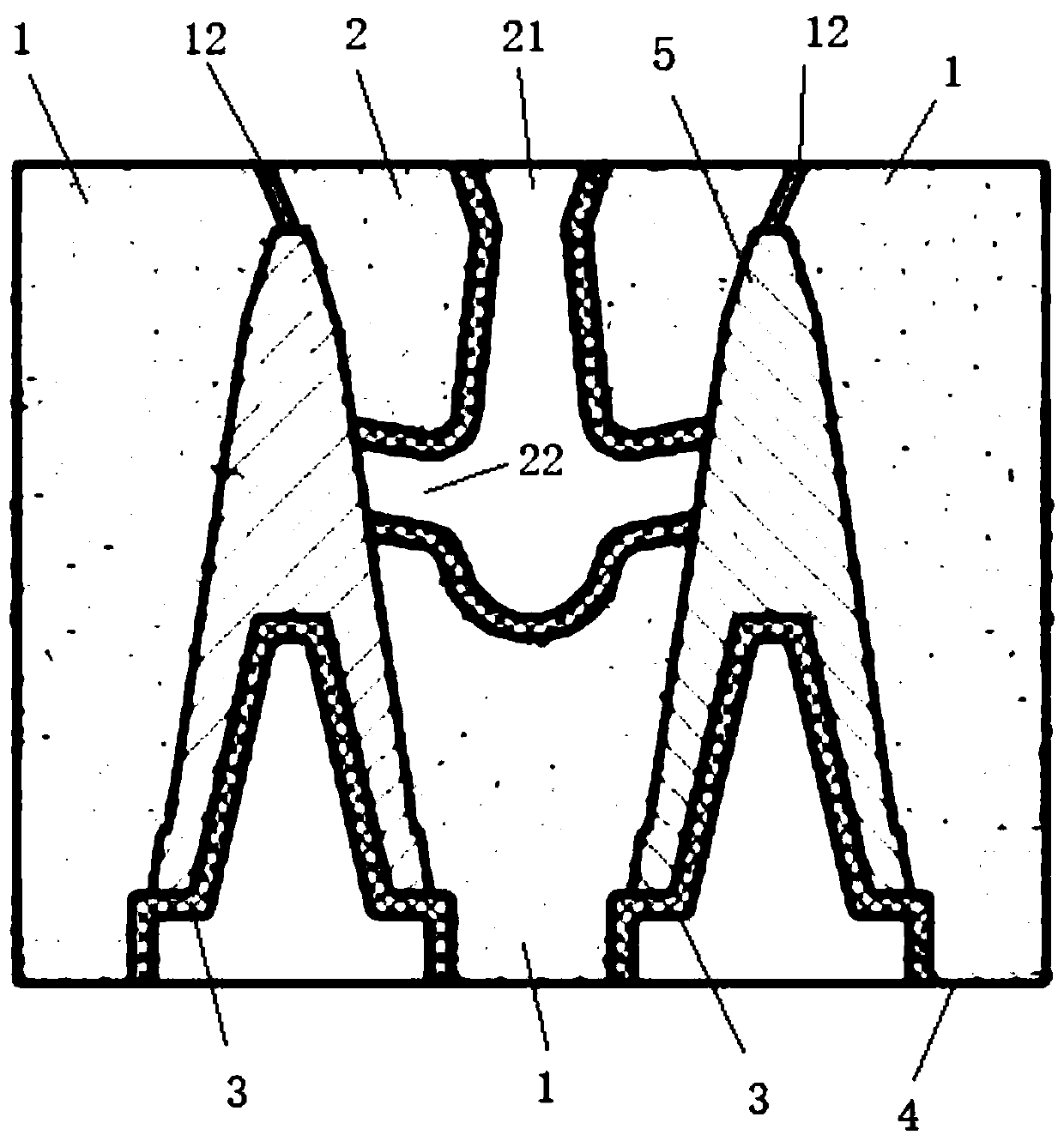

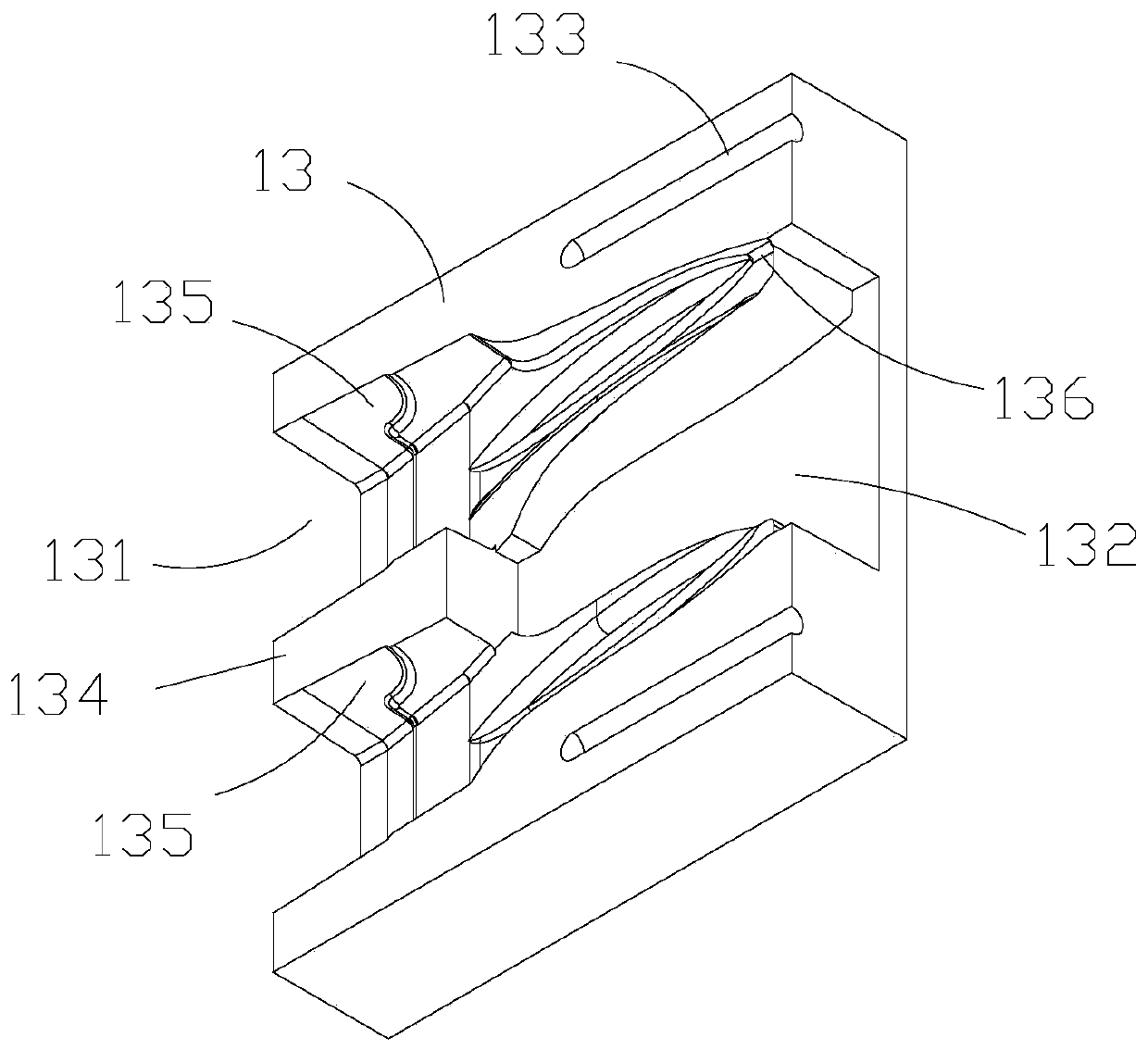

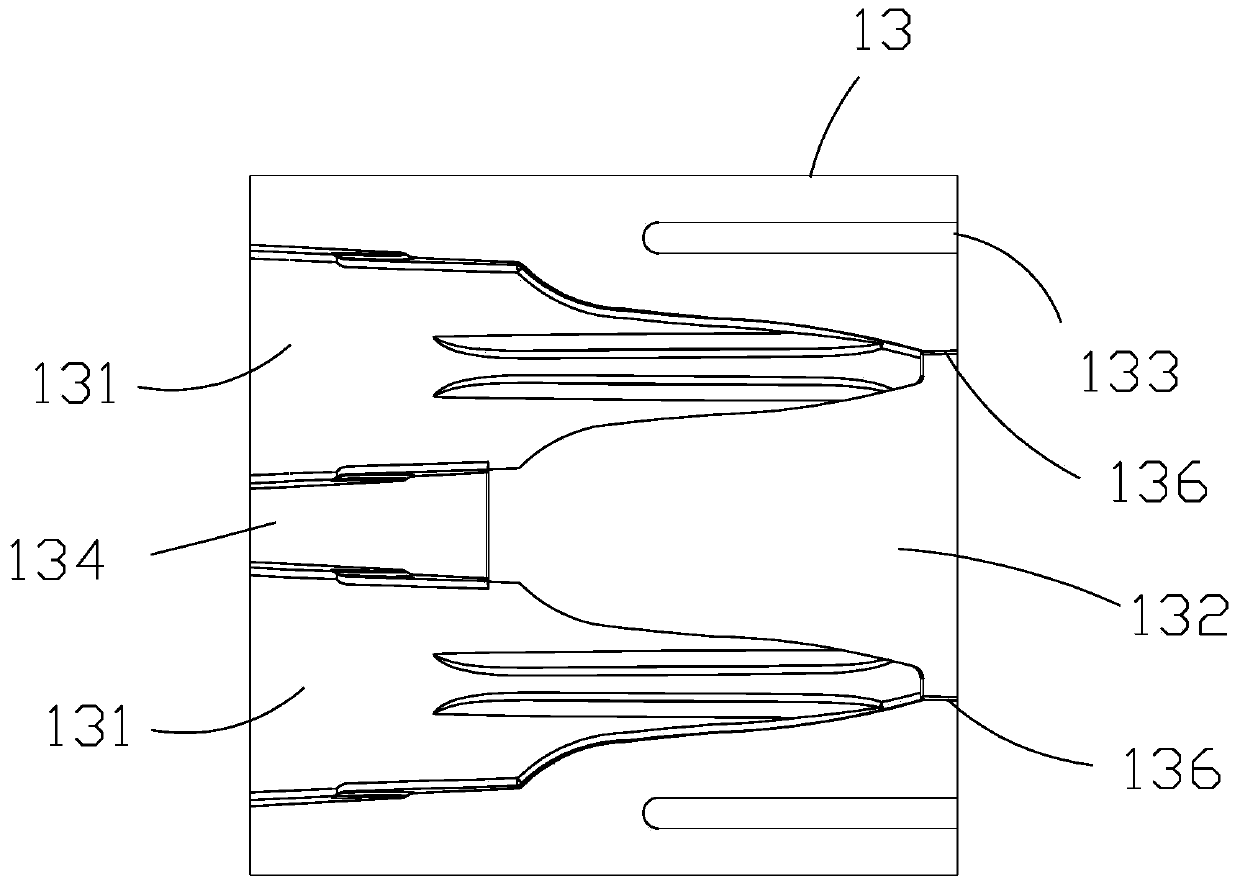

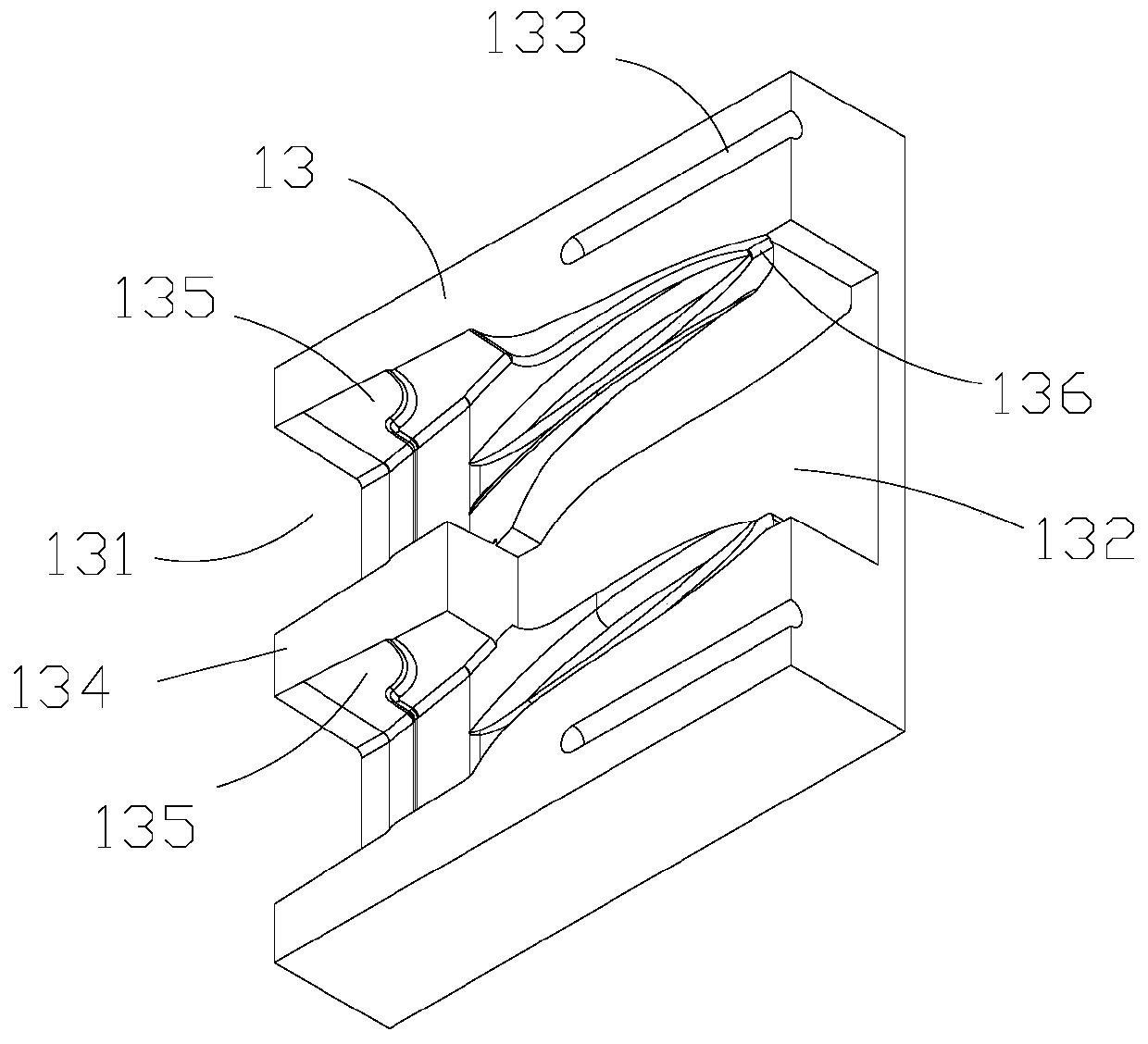

Semi-solid slurrying device and composite board manufacturing device using semi-solid slurrying device

The invention relates to the technical field of semi-solid slurrying, in particular to a semi-solid slurrying device and a composite board manufacturing device using the semi-solid slurrying device. The semi-solid slurrying device comprises a runner communicated with a liquid storage tank, obliquely arranged from top to bottom and used for molten metal to flow through, wherein the runner is provided with the contact surface in contact with the molten metal, strip-shaped protrusions parallelly distributed from top to bottom are arranged on the contact surface, grooves are formed among adjacent strip-shaped protrusions, the length directions of the strip-shaped protrusions are perpendicular to the flowing direction of the molten metal. By adopting the semi-solid slurrying device, the kish problem of the contact surface of the runner is greatly solved, high-quality semi-solid slurry produced by the semi-solid slurrying device can form metallurgical bonding with a solid heterogeneous material, and further the technical problem that interface metallurgical bonding is difficult to achieve by adopting a traditional composite board manufacturing process is further effectively overcome.

Owner:HENAN UNIV OF SCI & TECH

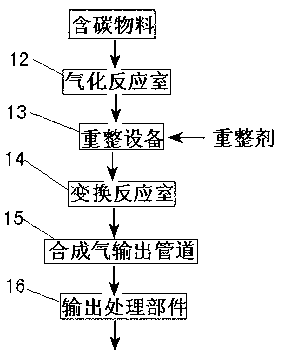

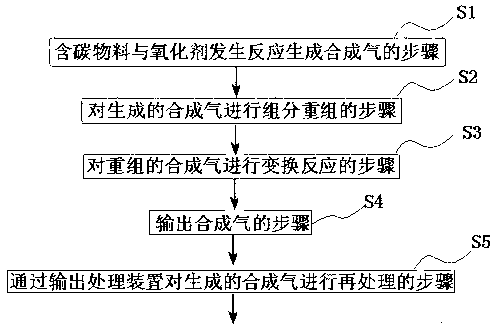

Gasification-reforming transformation reformer of carbonic materials and method of preparing hydrogen-rich syngas

InactiveCN103242906AIncrease conversion rateIncrease contentGranular/pulverulent flues gasificationSyngasHydrogen content

The invention discloses a gasification-reforming transformation reformer of carbonic materials. The gasification-reforming transformation reformer is characterized by comprising a gasification reaction chamber, reforming equipment, a transformation reaction chamber and a syngas output pipeline, wherein the gasification reaction chamber is provided with at least one nozzle; the reforming equipment is arranged at the output end of the gasification reaction chamber; the transformation reaction chamber is arranged at the output end of the reforming equipment; and the syngas output pipeline is connected with the output end of the transformation reaction chamber. The invention further discloses a method of preparing hydrogen-rich syngas. The method comprises the following steps: generating a gasification reaction (first reaction) on a carbonic material and an oxidant in the gasification reaction chamber to generate a syngas containing main ingredients of carbon monoxide and hydrogen under a high-temperature high-pressure environment, reforming the gasified syngas to proper temperature and ingredients through a reforming agent, generating a transformation reaction (second reaction) on the syngas in the transformation reaction chamber to fully generate carbon monoxide transformation reaction so as to improve the transformation rate of the carbon monoxide, thereby greatly reducing the carbon monoxide content in the syngas and increasing the hydrogen content to prepare hydrogen-rich syngas.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

Vein-proof additive for casting and preparing method thereof

InactiveCN110000328ARelieve thermal expansionAvoid Veining DefectsFoundry mouldsFoundry coresPyrophylliteMineral particles

The invention relates to a vein-proof additive for casting and a preparing method thereof. The vein-proof additive comprises 5-15% of special mold sand, 8-25% of silicate particles, 30-55% of lithiumcontaining mineral particles, 8-20% of titanium containing mineral particles and 8-20% of iron oxide powder, wherein the special mold sand comprises at least one of zircon sand, chromite sand, olivinesand and ceramsite; the silicate particles are of a layered structure and comprise at least one of shale, pyrophyllite and mica; the lithium containing mineral particles comprise at least one of spodumene, amblygonite and petalite; the titanium containing mineral particles comprise at least one of ilmenite, rutile, anatase titanium dioxide, brookite and leucoxene; and the iron oxide powder comprises iron oxide black and iron oxide red. On account of the common vein casting flaws of resin sand castings, the invention provides the vein-proof additive product which has a remarkable vein-proof effect, is low in cost and does not affect the strength of sand cores.

Owner:GANSU KOCEL CHEM

Preparation method of 3D printing precoated sand and made 3D printing precoated sand

ActiveCN108296425AHigh strengthImprove bindingAdditive manufacturing apparatusFoundry mouldsChemical LinkagePolymer science

The invention relates to a preparation method of 3D printing precoated sand and the made 3D printing precoated sand. The precoated sand is prepared through the following steps that quartz sand, silicasand and chromite sand are mixed, and are calcined in a high temperature furnace after being soaked with an acid solution, and crude sand is obtained through cooling; the crude sand, a coupling agentand a catalytic agent are added into a material mixer, a first mixture is obtained after high-speed stirring, then the first mixture, a first adhesion agent and a lubricating agent are added into thematerial mixer, the first adhesion agent and a second adhesion agent are replenished after high-speed stirring, then stirring is performed, and modified crude sand is obtained through cooling and screening; and the modified crude sand, a high temperature resistant agent, a toughening agent, a lubricating agent and a curing agent are stirred after being mixed in a sand mixer, screening is performed after cooling, and then the 3D printing precoated sand is obtained. According to the preparation method of the 3D printing precoated sand and the made 3D printing precoated sand, the acrylate type adhesion agents are used for modifying the crude sand, the crude sand and the adhesion agents are made to be connected through chemical bonds, the strength of the precoated sand is improved, the precoated sand can be used for making products high in strength requirement, and the applicable range of the 3D printing precoated sand is widened.

Owner:LIUZHOU LIUJING TECH CO LTD

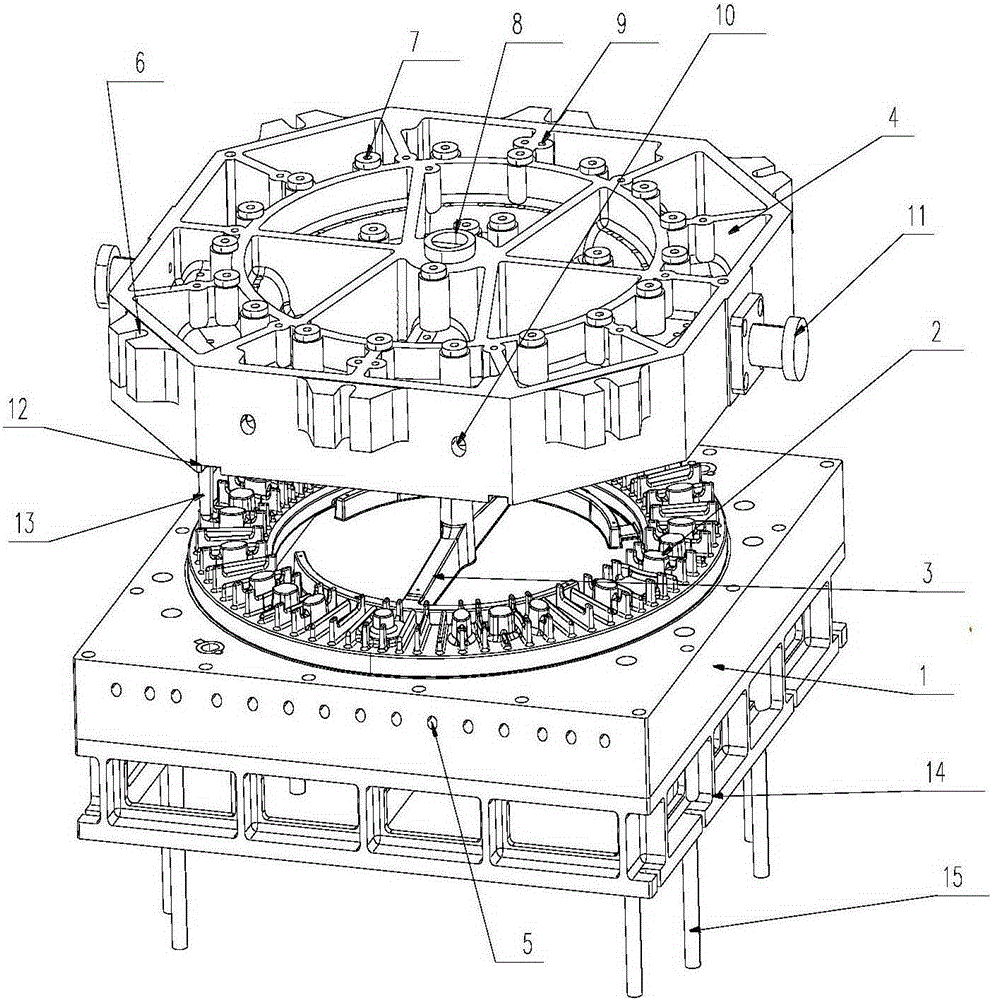

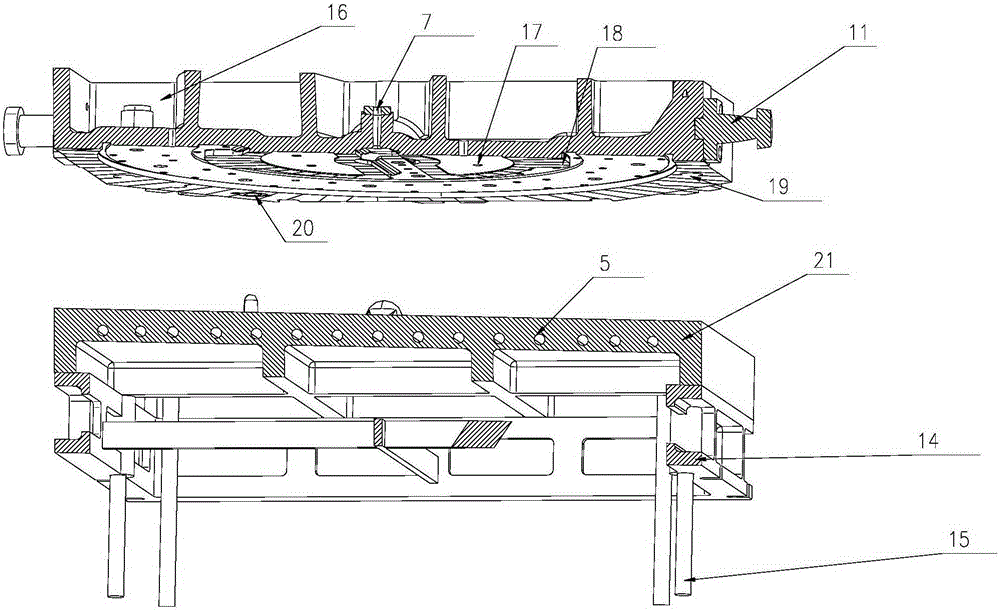

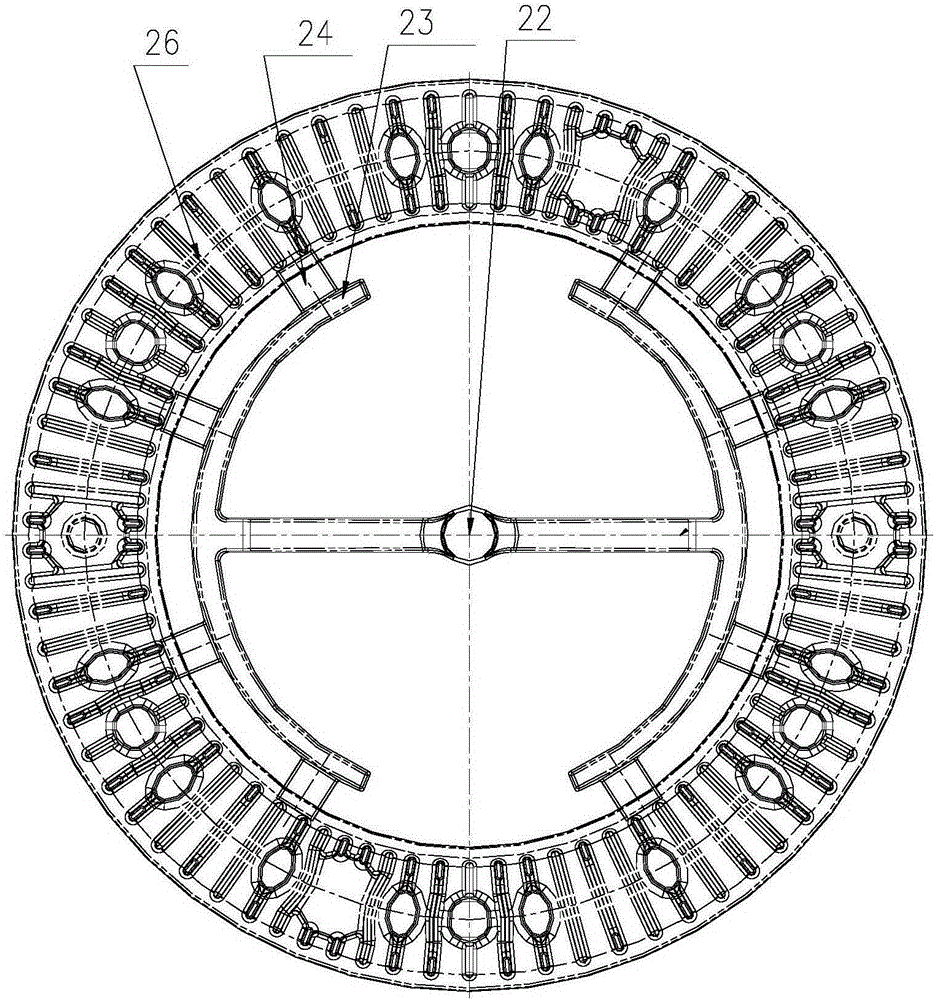

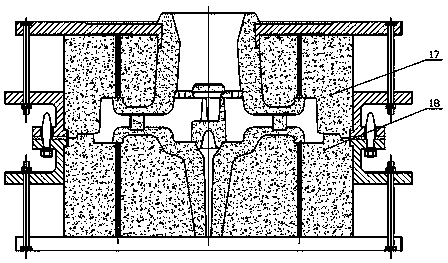

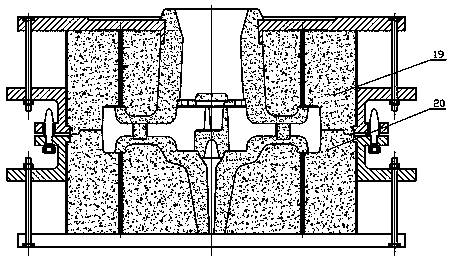

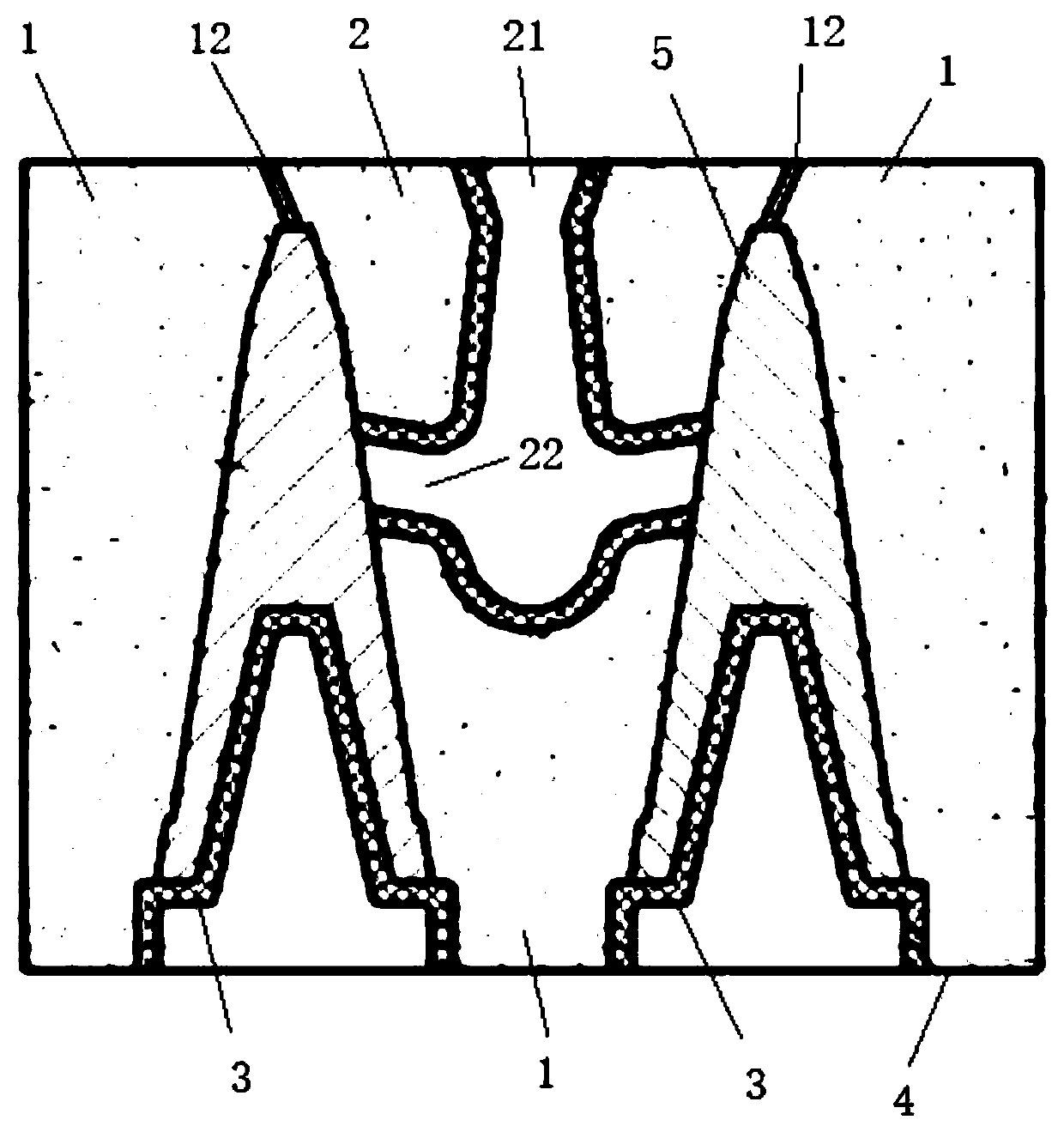

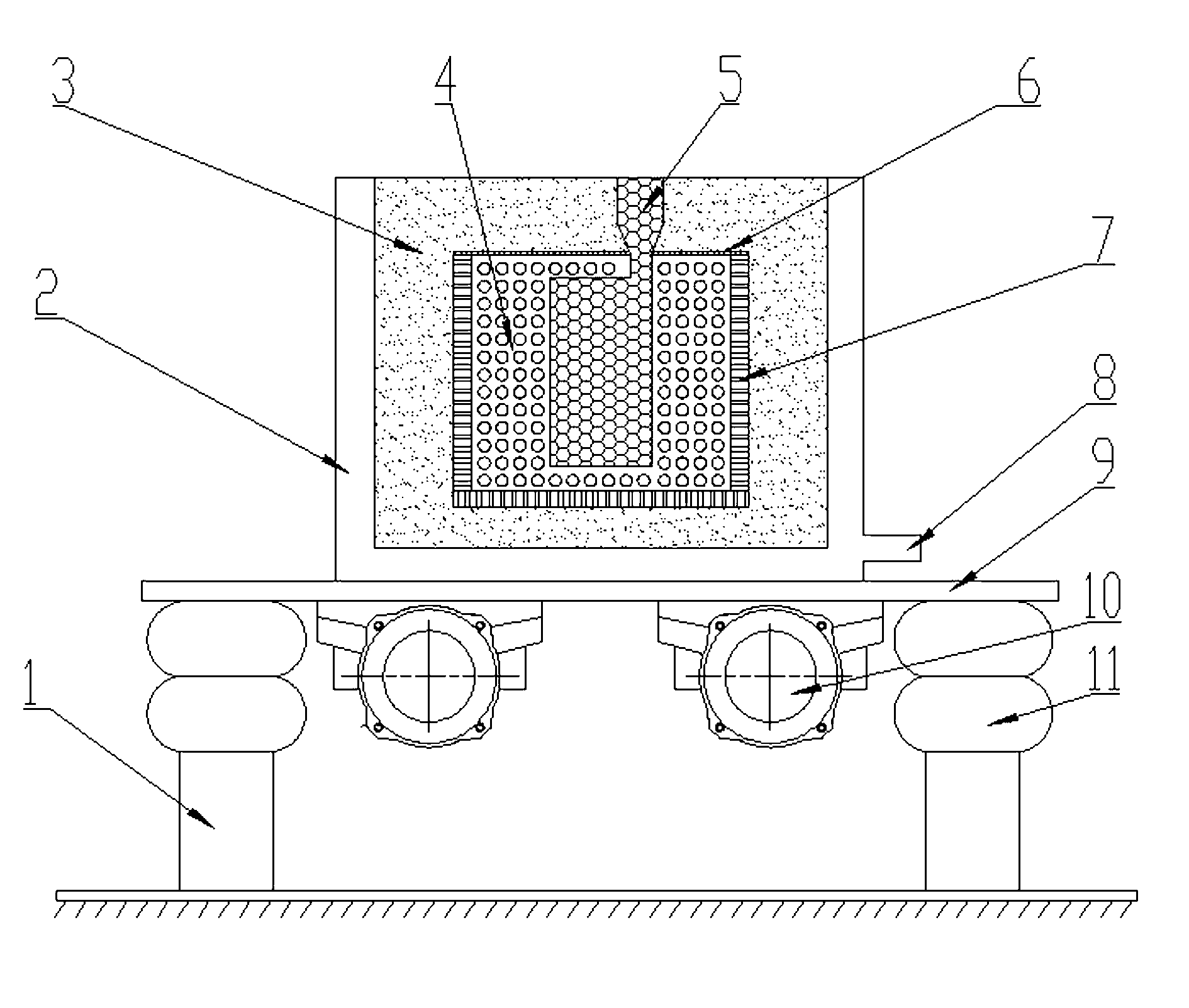

Sand-coated iron mold casting device for friction rings of brake discs for high-speed rails and casting technology

ActiveCN105328122AReduce the amount of turning operationsImprove surface qualityFoundry mouldsFoundry coresCastingElectric heating

The invention discloses a sand-coated iron mold casting device for friction rings of brake discs for high-speed rails and a casting technology. The sand-coated iron mold casting device comprises an upper mold modeling device and a lower mold modeling device. The upper mold modeling device comprises an upper mold plate, the upper mold plate is provided with an upper pattern of a round ring shape, a pouring system is arranged at the part, in the middle hole of the upper pattern, of the upper mold plate, an upper sand box is arranged above the upper mold plate in a matched mode, and electric heating rods horizontally arranged are installed in the upper mold plate. The lower mold modeling device comprises a lower mold plate, a lower sand box is arranged above the lower mold plate in a matched mode, and the electric heating rods horizontally arranged are installed in the lower mold plate. The chilling effect of sand-coated iron molds on molten liquid is good, and the friction performance of products is greatly improved; the turning amount of brake disc castings is small, and the yield of the technology can reach 80%; the surface quality of the brake disc castings is high, and flash burrs are avoided. According to the technology and the casting device, the qualified brake disc castings can be successfully produced, the domestic gap is filled in, and the market requirement is met.

Owner:JINAN FOUNDRY PATTERN +1

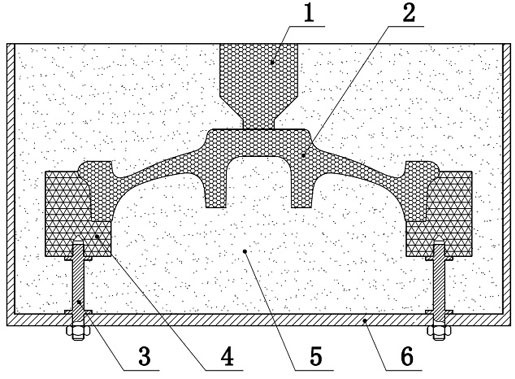

Gravity casting technique for crane wheel by hanging sand linings on graphite molds

InactiveCN107866532AGraphite has a high thermal conductivityGood chilling effectFoundry mouldsFoundry coresSodium silicateW-box

The invention discloses a gravity casting technique for a crane wheel by hanging sand linings on graphite molds. The gravity casting technique comprises the specific steps that the upper box graphitemold provided with an upper box top plate, an upper box pouring jacket and an upper bolt, and a lower box graphite mold provided with fixed square steel, a lower box pouring jacket and a lower bolt are prepared; after baking is conducted to the set temperature, the sodium silicate-bonded sand upper box sand lining and the sodium silicate-bonded sand lower box sand lining are made in a shot mode through a sand shooter, and the set flow of CO2 is blown in for hardening demolding; the upper box sand lining and the lower box sand lining are reserved on the upper box graphite mold and the lower boxgraphite mold through sand hanging grooves correspondingly, a rim graphite core is placed at the rim part of the lower box graphite mold, a technical hole sand core and a central core which are madeof resin sand are placed at the lower box sand lining, and a rain core and a floating core which are made of resin sand are placed at the upper box sand lining; and after box closing, the wheel is poured through a bottom pouring ladle. The problems that in a traditional crane wheel casting production technique, the surface quality of a wheel is poor, the dimensional precision is low, internal quality uniformity is poor, and large-batch efficient production is quite difficult to achieve are solved.

Owner:信阳同合车轮有限公司

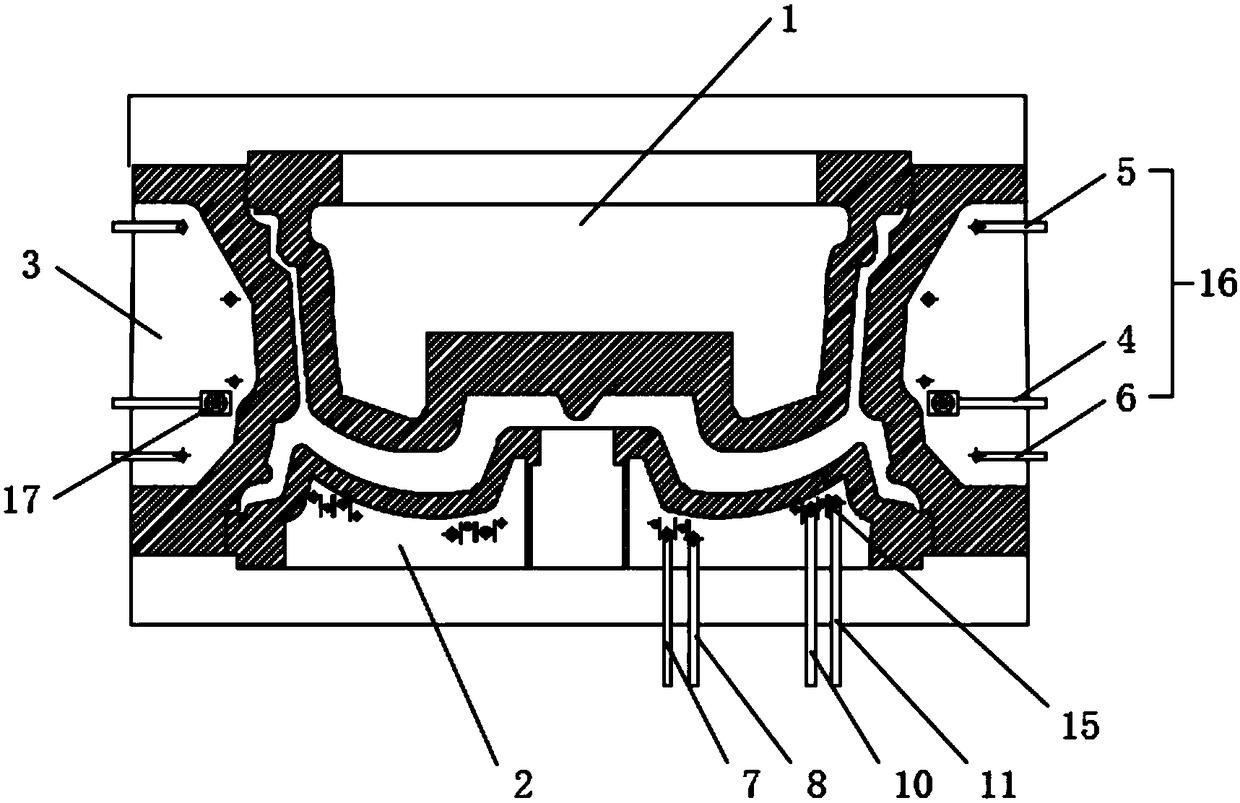

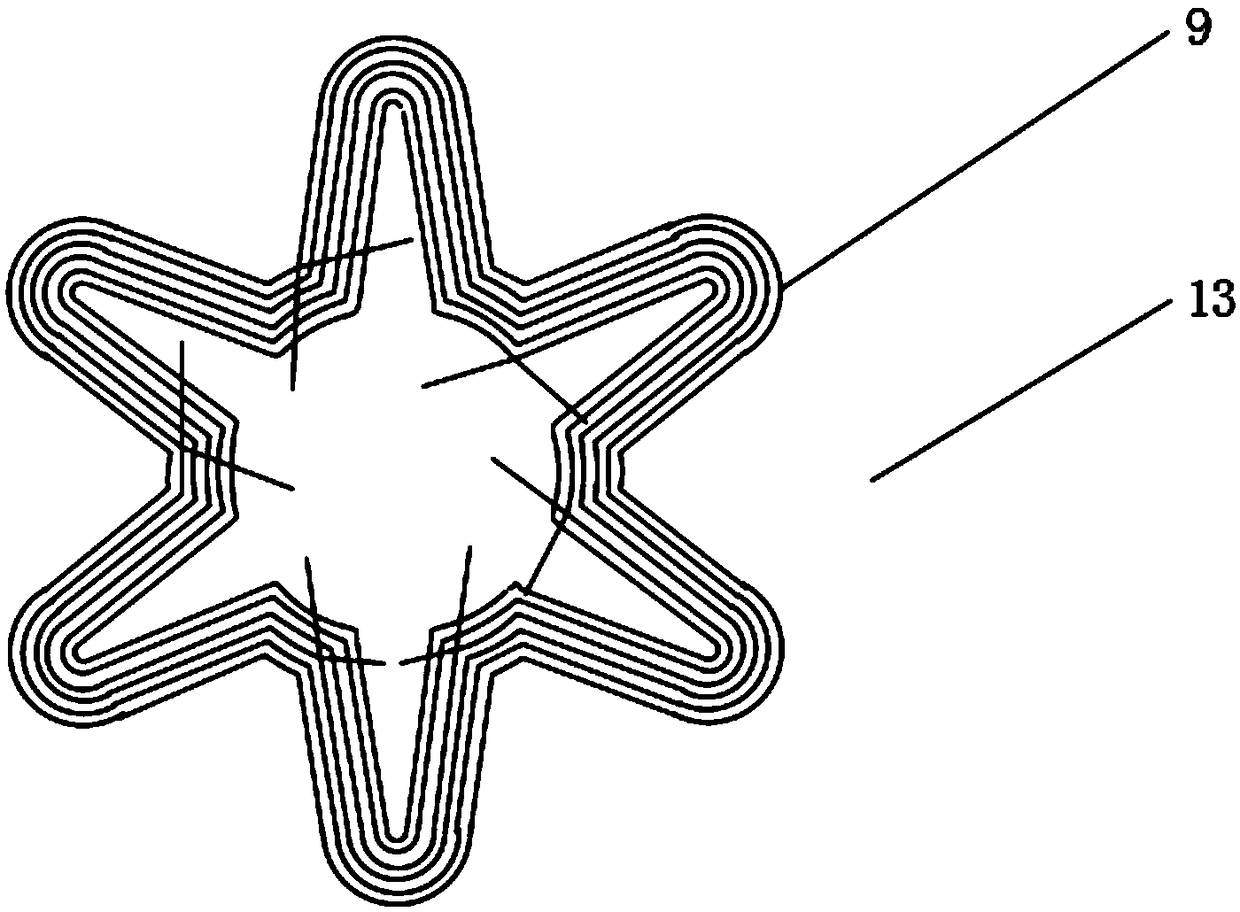

Mixed cooling low-pressure wheel hub mold

The invention discloses a mixed cooling low-pressure wheel hub mold. The mixed cooling low-pressure wheel hub mold comprises an upper mold body, a lower mold body and side mold bodies, and the upper mold body, the lower mold body and the two side mold bodies can jointly form a casting mold for casting a wheel hub in an enclosing mode; a wheel rim water cooling mechanism is arranged in each side mold body, each wheel rim water cooling mechanism comprises a flow dividing pipe, an upper flow guiding pipe and a lower flow guiding pipe, and the upper flow guiding pipes and the lower flow guiding pipes communicate with the flow dividing pipes through three-way pipes; and a wheel spoke air cooling mechanism, a wheel spoke water cooling mechanism and a diaphragm medium are arranged in the lower mold body. According to the mixed cooling low-pressure wheel hub mold, the wheel hub mold is cooled by adopting a water cooling and air cooling mixed mode, the cooling speed is high, and the achieved chilling effect is better; and pipe arranging structures in the lower mold body and the side mold bodies are overall planned according to the thickness of all parts of the wheel hub, therefore, the cooling speed of all the parts of the wheel hub is more similar, the wheel hub can be overall molded, and the phenomena that the junctions of wheel spokes and a wheel rim have large shrinkage holes and wheel rim shrinkage defects due to the fact that shrinkage compensation is insufficient are avoided.

Owner:重庆众异特巧匠模具科技有限公司

Pre-coated sand of cold iron for steel casting and preparation method of pre-coated sand

ActiveCN108971417AGood chilling effectFast cooling rateFoundry mouldsFoundry coresSurface oxidationSlag

The invention discloses pre-coated sand of cold iron for a steel casting and a preparation method of the pre-coated sand. The pre-coated sand is prepared from the following raw materials: chromite sand, phenolic resin, a curing agent, a lubricant and a coupling agent. The pre-coated sand of the cold iron for the steel casting, disclosed by the invention, is used for accelerating the cooling of thecasting and has a chilling effect; the surface of the cold iron with the pre-coated sand prepared by the invention has high smooth finish and the pre-coated sand can be directly used for the cold iron; surface oxidization is not caused, the slag hole defect of the casting is avoided and dip coating of coating is reduced; the defect that water in the coating is not completely removed so that the casting has gas pores is avoided; the cold iron for the steel casting is collapsed at high temperature and is not stuck with the casting.

Owner:南阳仁创砂业科技有限公司

Precoated sand with sand adhesion prevention characteristic and used for high manganese steel and preparation method and application thereof

InactiveCN110340277AGood high temperature strength and chillingReduce instabilityFoundry mouldsFoundry coresOxideConstruction aggregate

The invention relates to precoated sand with a sand adhesion prevention characteristic and used for high manganese steel and a preparation method and application thereof. The precoated sand with the sand adhesion prevention characteristic and used for the high manganese steel comprises base aggregate, first reinforcement aggregate, second reinforcement aggregate, binder, a curing agent and lubricant. The base aggregate is silica sand. The first reinforcement aggregate comprises ferroferric oxide or / and chromite sand. The second reinforcement aggregate is magnesia. The precoated sand has good high temperature resistant strength and chilling performance, a sand core does not need to be coated with paint, and in this way, the precoated sand has a sand adhesion prevention function when used for a high manganese steel casting. The casting cast in the sand core prepared by the preparation method does not need polishing after casting, unstable factors in the production process are reduced greatly, the yield of castings is increased greatly, cost of a casting enterprise can be lowered, production efficiency of the casting enterprise can be improved, and the precoated sand can be used in the foundry industry on a large scale.

Owner:江阴天润造型材料科技有限公司

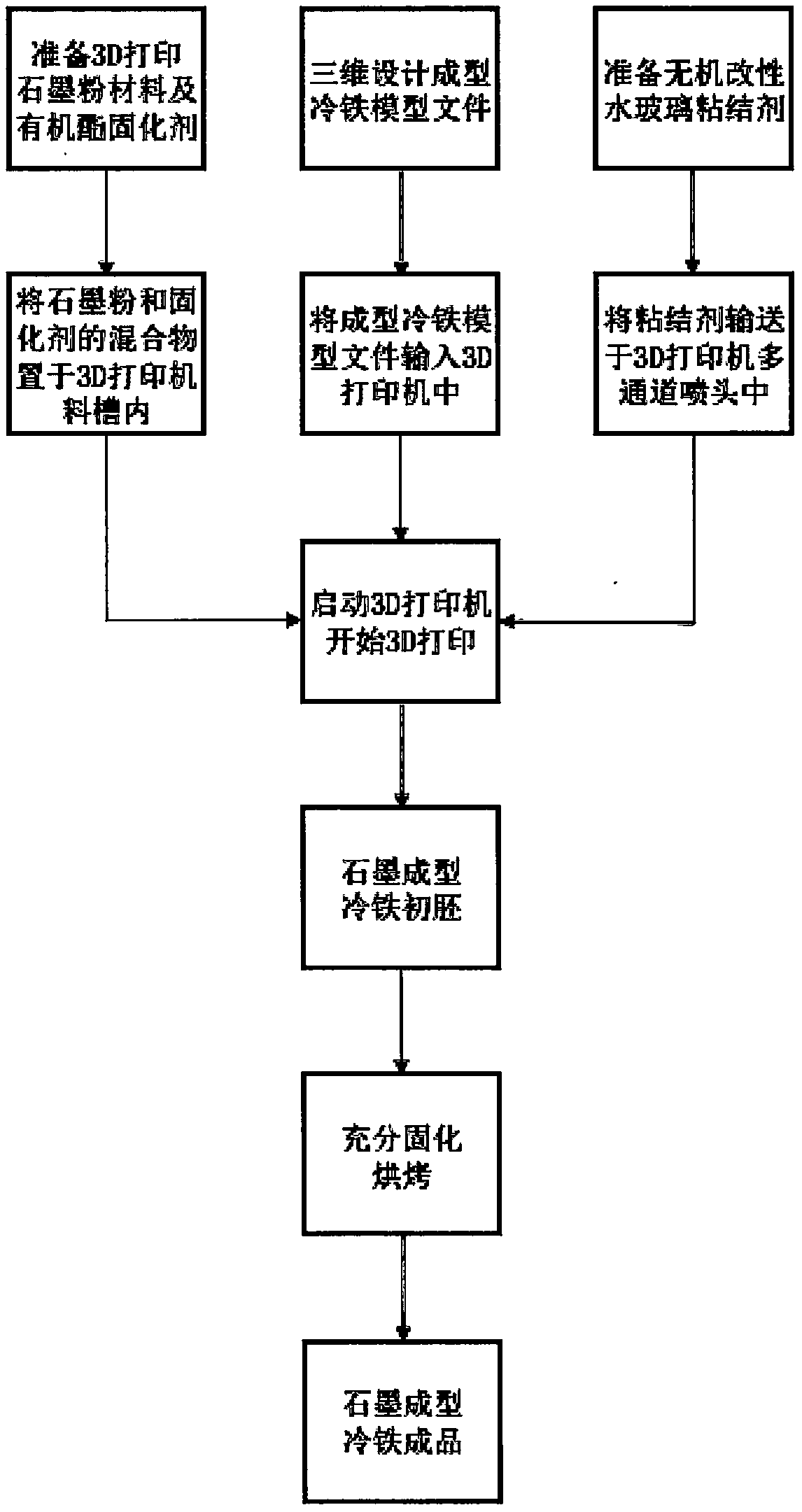

3D printing graphite contoured chill and preparation method thereof

InactiveCN109774130AGood chilling effectAvoid sticking inAdditive manufacturing apparatusAdditive mnaufacturing with solid and fluidPaper documentGraphite

The invention discloses a 3D printing graphite contoured chill and a preparation method thereof, and relates to 3D printing forming methods. The 3D printing graphite contoured chill and the preparation method thereof are characterized in that inorganic modified water glass is treated as an adhering agent; an organic ester curing agent is treated as a hardening agent; graphite powder is treated asa printing forming material; a three-dimensional design contoured chill model document is input a 3D printer; a powder bed based three-dimensional jet printing (3DP) technology is carried out to printa three-dimensional entity in a multi-layer overlapping manner so as to obtain a primary graphite contoured chill blank; the primary graphite contoured chill blank is fully cured and roasted to obtain the 3D printing graphite contoured chill product. The formation technology is simple; industrial production is easily carried out; the market prospect is wide; the problems of cumbersome manufacturing process of the contoured chill in casting, difficult numerical control processing and short production period can be solved; in addition, the graphite chill chilling effect is good, so that a castcan be prevented from chill adhering and air pore defects; the production cost is decreased; the cast yield and the production efficiency can be improved; in addition, an organic adhering agent is applied to the 3D printing technology, the performance is stable, the energy is saved, the environment is protected, and the production cost is low.

Owner:KEHUA HLDG

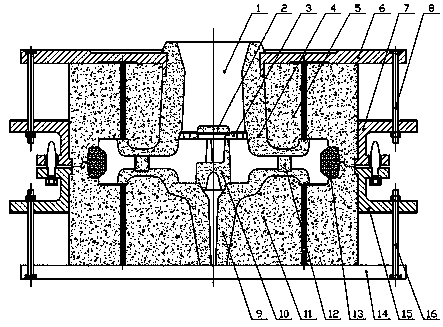

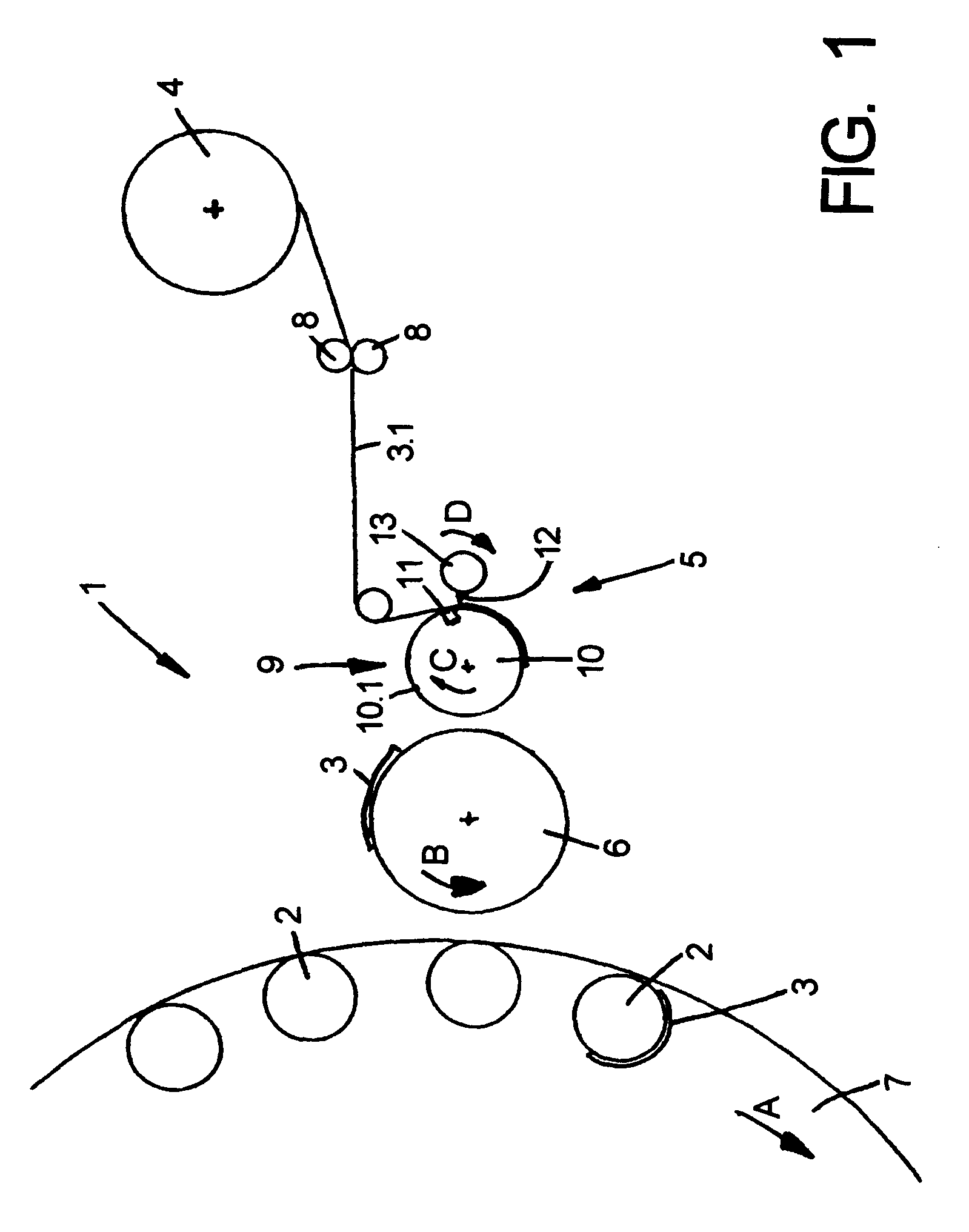

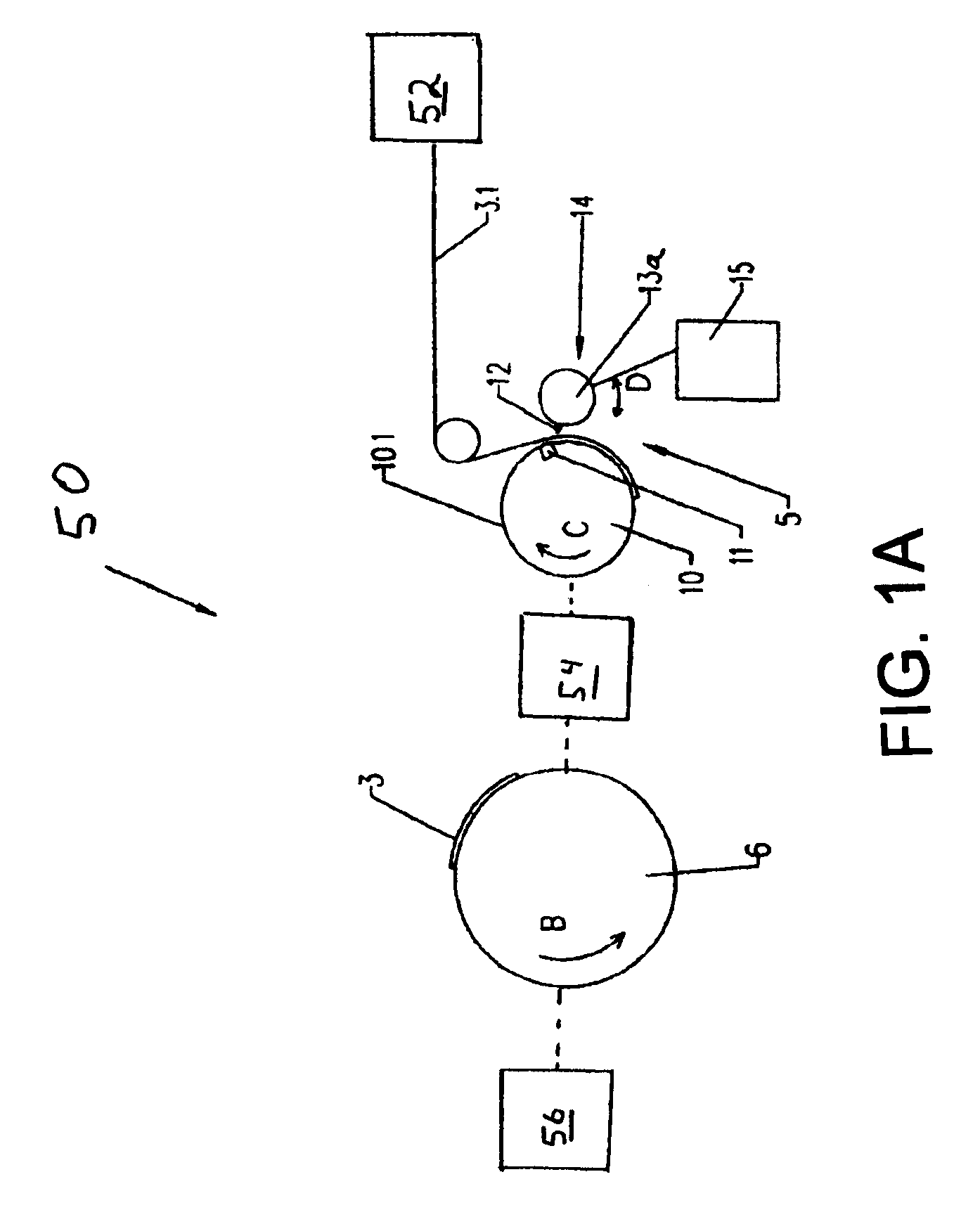

Beverage bottling or container filling plant having a beverage bottle or container labeling machine, and a beverage bottle or container labeling machine having a vacuum drum

ActiveUS20090260712A1High heat conductivityGood chilling effectSolid materialLiquid materialTrademarkEngineering

Beverage bottling or container filling plant having a beverage bottle or container labeling machine, and a beverage bottle or container labeling machine having a vacuum drum. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

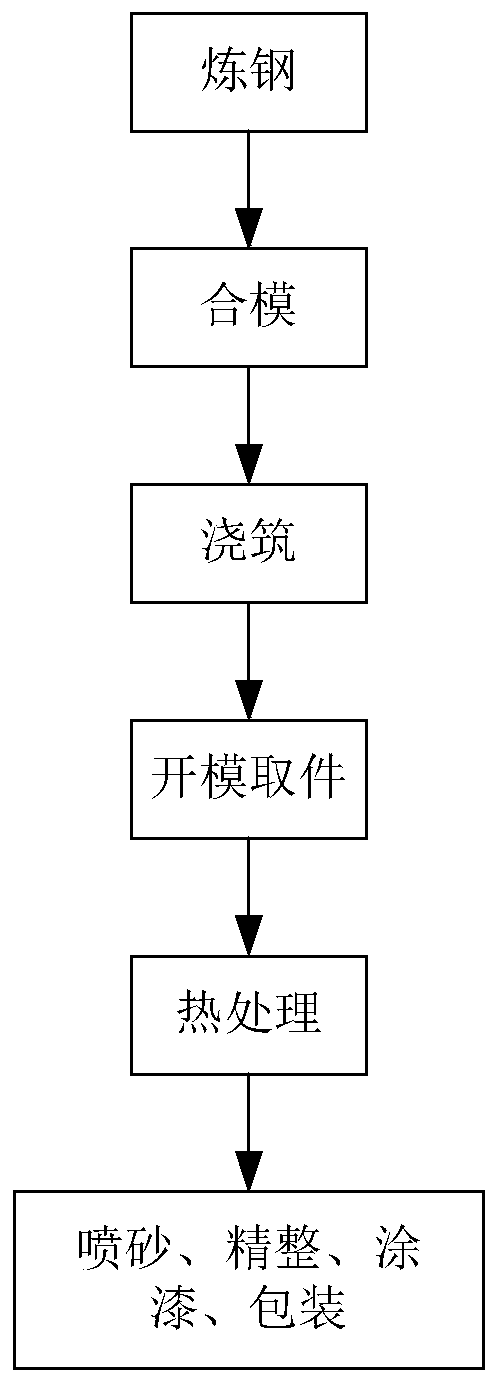

A thin-wall heat-resistant steel exhaust manifold casting method

The invention discloses a thin-walled heat resistant steel exhaust gas manifold casting method, and belongs to the technical field of heat resistant steel exhaust gas manifold casting. The casting method comprises the following steps of core manufacturing, modeling, smelting, pouring and sand shakeout. Through the reasonable design of the amount of molten iron entering a pouring channel and the section ratio of each unit in a pouring system and strict control of the iron mold sand covering layer thickness, the mold cavity exhaust gas system and pouring temperature and the sand shankout box opening time, the thickness of the prepared exhaust gas manifold is 3.2-3.6mm, the wall is thin, the grain size level is 5.5, and the technical property reaches the required index. The prepared exhaust gas manifold has the thin wall and low weight, is stable in property, solves the problem that a common wet sand technology is difficult to form, effectively lowers the integral weight, and achieves light-weight design of an engine.

Owner:西峡飞龙特种铸造有限公司 +1

Preparing method of high-performance easy-to-demold resin sand for nodular cast iron

InactiveCN110860647AEasy reunionSuperior oxygen storage and release functionFoundry mouldsFoundry coresPyrophylliteFirming agent

The invention discloses a preparing method of high-performance easy-to-demold resin sand for nodular cast iron. The resin sand is prepared from 40-50 parts of forsterite powder, 3-5 parts of silica sol, 1-3 parts of boron glass powder, 0.01-0.02 part of sodium lignin sulfonate, 5-9 parts of pyrophyllite powder, 2-4 parts of phenolic resin powder, 5-8 parts of pyrite powder, 4-7 parts of gypsum powder, 2-4 parts of epoxy resin powder, 0.3-0.5 part of samarium oxide, 1-3 parts of alumina whiskers, 1-3 parts of a graphene PVA emulsion, 2-4 parts of boron nitride, 1-3 parts of ferric oxide, 1-2 parts of silicon carbide, 1-3 parts of fused alumina zirconia powder, 0.2-0.5 part of cerium oxide and 0.4-0.8 part of a vulcanizing agent. According to the resin sand, through the reasonable cooperation of the components, the content of resin and a curing agent is reduced, the performance of the resin sand is improved, the ash content and water content of the resin sand are reduced, and therefore the quality of a casting is improved, the gas volume is reduced, meanwhile the quality of reclaimed sand is improved, and good circulation is formed.

Owner:和县华顺铸造有限公司

Internal chill process for improving shrinkage porosity of vermicular iron cylinder head

InactiveCN111468695AEffective improvementReduce volumeFoundry mouldsFoundry coresCylinder headCarbon steel

The invention discloses an internal chill process for improving shrinkage porosity of a vermicular iron cylinder head. The internal chill process comprises the following steps that the internal chillis used for chilling from the inside of a casting hot spot when the vermicular iron cylinder head is produced, wherein the internal chill needs to be placed in a cavity and kept fixed during casting,and the internal chill and molten iron can be fused into a whole during pouring; the internal chill is fused with the casting and is removed during machining; the internal chill is placed in a bolt hole part and inserted into a sand core base to be fixed; the internal chill is placed in a fuel injector hole, is wrapped in a sand core during sand shooting, and is fused with the molten iron into a whole during pouring; and the internal chill is made of low-carbon steel. According to the internal chill process, the internal chill made of the low-carbon steel is fixed to the center of the hot spotpart in a certain modes, chilling is directly conducted from the center part where shrinkage porosity is likely to occur, the action effect is high, and the chilling effect is good; compared with chillers currently used in the industry, the internal chill is smaller in size, lighter in weight and more convenient to use in the production process and transport in a logistics mode.

Owner:CHINA FIRST AUTOMOBILE +1

A kind of coated sand of cold iron for steel castings and its preparation method

ActiveCN108971417BGood chilling effectFast cooling rateFoundry mouldsFoundry coresSurface finishSlag

Owner:南阳仁创砂业科技有限公司

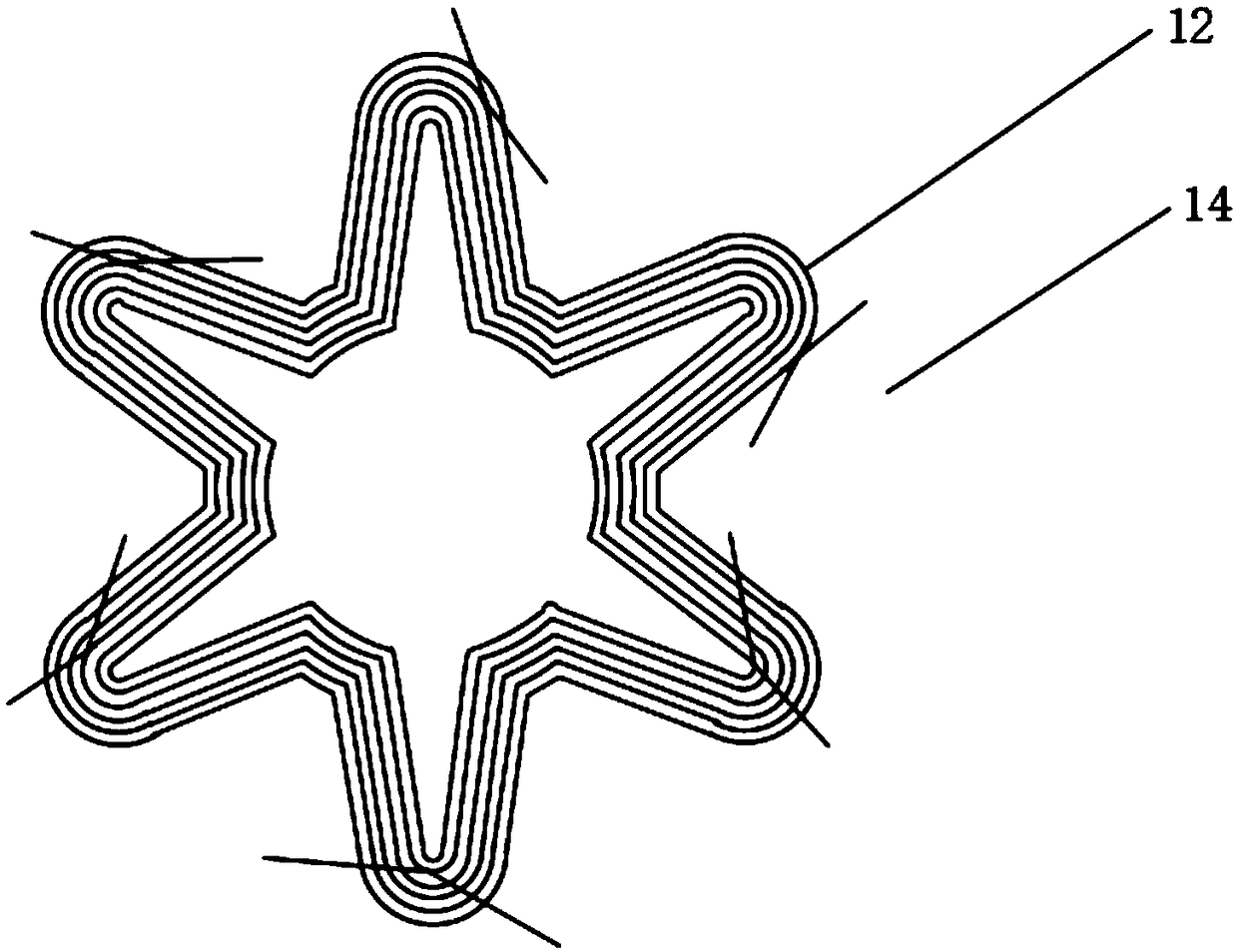

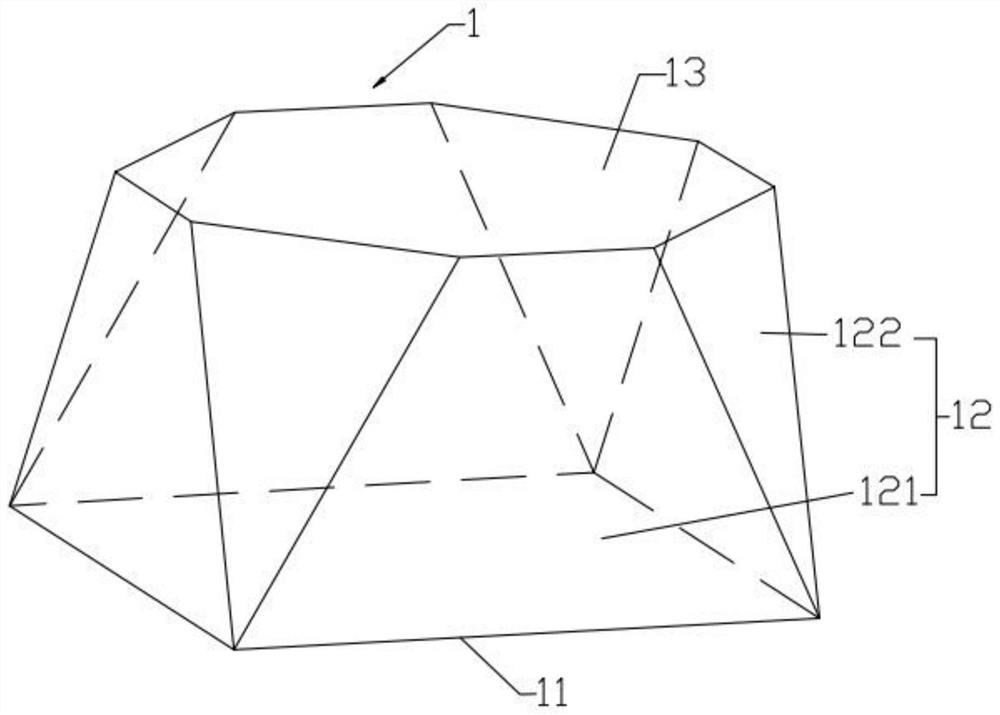

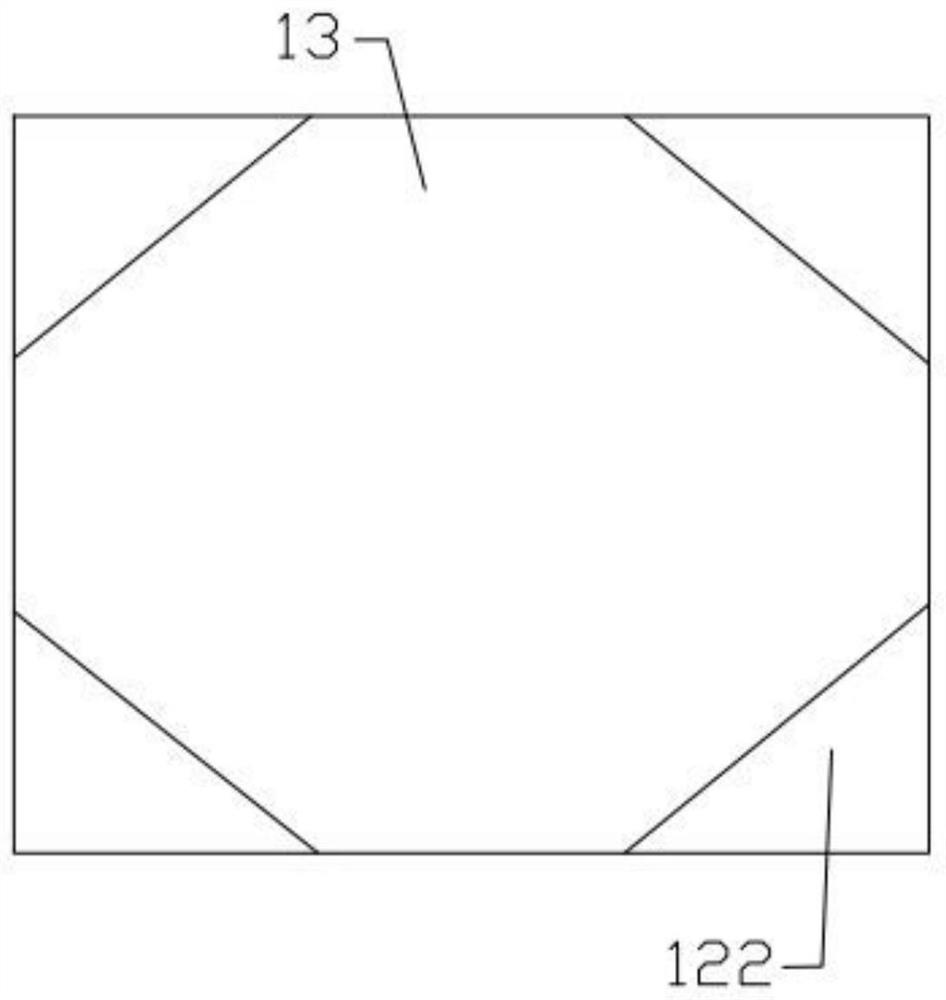

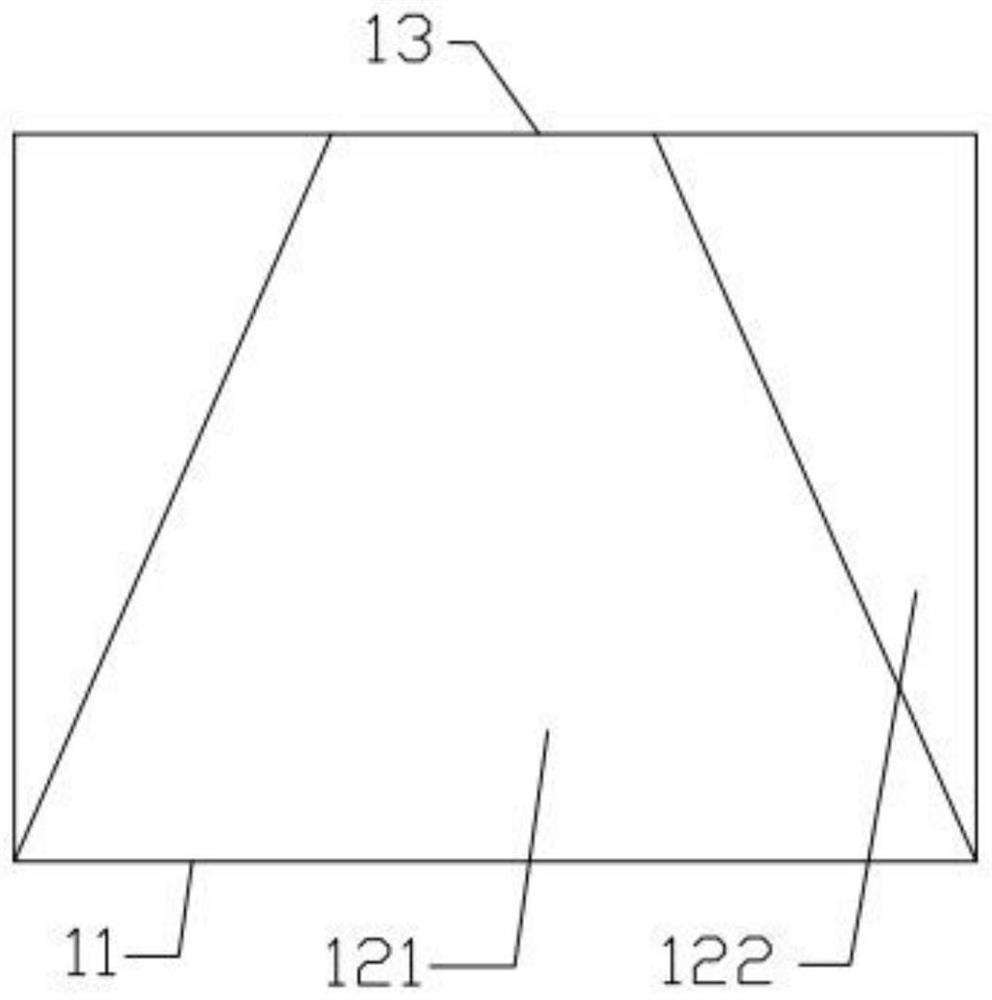

Novel chilling block for casting

The invention discloses a novel chilling block for casting. The chilling block is provided with a bottom surface, a top surface and side surfaces, wherein the bottom surface is used for being in contact (including direct contact and indirect contact) with the surface of a casting, the bottom surface and the top surface are connected (including direct connection and indirect connection) through the side surfaces, and the cross section area of the chilling block is gradually reduced from the bottom surface to the top surface. The novel chilling block is simple and ingenious in structure and easy to machine, the corresponding technical effect can be effectively achieved, the chilling effect at the edge junction is gently transited, and the situation that the casting cracks at the edge of the chilling block is effectively avoided. Besides, due to a polygon structure, the heat dissipation area is enlarged, the conduction of heat energy is improved, the chilling effect of the chilling block is improved, the product quality of the casting is ensured, and the quality of the casting is improved.

Owner:SHANGHAI HULIN HEAVY IND

Lost foam-graphite chilling-antigravity casting process for railway cast-steel wheels

InactiveCN107584086AReduce consumptionSolve the regeneration problemFoundry mouldsFoundry coresEcological environmentDry sand

The invention discloses a lost foam-graphite chilling-antigravity casting process for railway cast-steel wheels. The lost foam-graphite chilling-antigravity casting process integrates lost foam casting technology, graphite chilling casting technology and antigravity casting technology into one. According to the process, a graphite ring ready to mold is fixed in a lost foam casting sandbox via bolts; prepared and molded riser foam and wheel foam patterns are bonded with an assembly of an ingate, a casting pipe, a stopper plug and a stopper rod and are then put in the graphite ring; the lost foam casting sandbox is filled with dry sand and is then connected with a negative pressure device after vibration compaction; the sandbox is put on the top of the cover of a prepared pressure tank; a riser tube arranged on the cover of the pressure tank is communicated with the casting pipe; a steel ladle is arranged in the pressure tank; the riser tube is inserted into the steel ladle; air or inertgas is pressed in the pressure tank; and wheel casting is carried out. The lost foam-graphite chilling-antigravity casting process provided by the invention overcomes the problems of the low recoveryand utilization rate of sodium silicate sand in conventional production processes for railway cast-steel wheels, influence of high waste-sand discharge on surrounding ecological environment and secondary oxidation of molten steel caused by casting of bottom-pouring ladles.

Owner:信阳同合车轮有限公司

Tower-type powdered coal pressure gasification device with chilling process

ActiveCN101885991BLower the altitudeIncrease catch rateGranular/pulverulent flues gasificationSlagProcess engineering

The invention discloses a tower-type powdered coal pressure gasification device with a chilling process. The device comprises a pressure shell, and a gasification unit and a steam / water or dust-free gas chilling unit which are hung in the pressure shell. The device is characterized in that the gasification unit is arranged below the steam / water or dust-free gas chilling unit coaxially; the gasification unit comprises a reaction chamber and four nozzles arranged near the bottom of the reaction chamber at interval; the device of the invention also comprises a cooling channel and a returning chamber which are in coaxial arrangement with the gasification unit or the steam / water or dust-free gas chilling unit, and a chilling chamber and a slag pool; the cooling channel is arranged above the steam / water or dust-free gas chilling unit; the returning chamber is arranged on the top of the cooling channel; the chilling chamber is arranged around the cooling channel; the slag pool is arranged below the gasification unit; and the pressure shell is provided with a synthesis gas outlet, a grey water exhaust port and a slag-discharging hole. By using the device of the invention, dust and slag generated by gasification can be effectively separated and processed and the problem of performing thermal compensation to the entire equipment is effectively solved.

Owner:中国船舶集团有限公司第七一一研究所

Water glass fiber reinforced plastic sand casting mold and preparation method

ActiveCN113695513AIncrease heat storageImprove thermal conductivityFoundry mouldsFoundry coresGlass fiberSand casting

The invention relates to casting, in particular to a water glass fiber reinforced plastic sand casting mold and a preparation method. According to the water glass reinforced plastic sand casting mold, crude sand is steel sand, and the steel sand is bonded and shaped through water glass. The preparation method of the water glass fiber reinforced plastic sand casting mold comprises the following steps: A, sand preparation; b, preparing of a model and a sand box; c, sand mixing; d, modeling; d, casting mold hardening; and E, demolding. The cast steel grit is high in heat storage coefficient and heat conductivity coefficient, the chilling capacity is enhanced, and the obtained casting is fine in crystal structure, compact in texture, excellent in mechanical property, high in production efficiency and low in production cost; and the steel grit is recycled, compared with mineral sand, consumption of natural resources is reduced, generation of a large amount of solid waste sand is avoided, and energy conservation and environmental protection are achieved.

Owner:王绍勤

Graphite mold for casting and assembling method thereof

InactiveCN110000333AImprove heat resistanceReduce expansionFoundry mouldsFoundry coresGraphiteMaterials science

The invention discloses a graphite mold for casting. The graphite mold for casting comprises a mold body, first sand boxes, second sand boxes and a mold sleeve; the mold body, the first sand boxes, the second sand boxes are positioned in the mold sleeve; a cavity is formed in the mold body, and an exhaust hole is formed in the top end of the mold cavity; the first sand boxes are positioned on theside part of the mold cavity, the first sand boxes are provided with a branch runner and a main runner, and an opening of the main runner is positioned at the top end of the first sand boxes; and oneend of the branch runner is connected with the middle part of the cavity, the other end of the branch runner is in communication with the main runner, and the second sand boxes are positioned at the lower part of the cavity. The graphite mold can be repeatedly used, the heat conductivity of graphite can be utilized, so that castings 5 can be quickly cooled.

Owner:BAOTOU SHENRUI SPECIAL ALLOY

Hot-charging hot-delivery casting method adopting graphite mold

InactiveCN110000336AImprove casting efficiencyReduce heat lossFoundry mouldsFurnace typesGraphiteHeat losses

The invention discloses a hot-charging hot-delivery casting method adopting a graphite mold. The method comprises the following steps that when surface temperature of a casting in the mold is reducedto 1000-1100 DEG C, the mold is taken and the casting is taken out; and the casting in a heat treatment temperature interval is subjected to heat treatment, and at the moment, the temperature of the casting is 900-1000 DEG C. According to the method, the casting processing efficiency can be improved, so that the heat loss in the processing process can be reduced, and meanwhile, the performance offlimsy materials can be easily improved.

Owner:BAOTOU SHENRUI SPECIAL ALLOY

Casting process method combining steel-shot chilling and vibratory pouring based on disappearing die

InactiveCN102371339BSolve the slow cooling rateImprove toughnessFoundry mouldsFoundry coresVacuum pumpingDry sand

The invention discloses a casting process method combining steel-shot chilling and vibratory pouring based on a disappearing die. The casting process method combining steel-shot chilling and vibratory pouring based on the disappearing die is characterized in that a manufactured foam model is placed into a chilling sand box, steel shots are also placed at the position of a clearance between the foam model and the chilling sand box, then the chilling sand box is placed into a sand box with a vacuum-pumping negative-pressure model, dry sand is filled between the chilling sand box and the sand box with the vacuum-pumping negative-pressure model, a plastic film is laid, a sprue cup is placed, and finally, the operation of pouring is carried out under the condition that the operations of vacuumpumping and vibrating are simultaneously carried out. According to the casting process method combining steel-shot chilling and vibratory pouring based on the disappearing die, the circular use of the steel shots and the sand is realized, the problem of lower cooling speed of a cast in the casting of the disappearing die is thoroughly solved, the problems of bulky crystal grains, uncompacted tissues and the like, which are easy to occur in the casting of a traditional disappearing die, are avoided, the toughness and the compactness of the tissues of the cast are enhanced, the use quantity of alloy elements, such as Cr, Mo and the like, is lowered, the service life of a wear-resisting cast is ensured, the batch production of a product is realized, the rejection rate is reduced, and the manpower cost is lowered.

Owner:HUBEI GENGLIAN WEAR RESISTANT MATERIALS TECH

Lost Foam Graphite Chilled Gravity Casting Process for Railway Cast Steel Wheels

ActiveCN107570669BReduce consumptionSolve the regeneration problemFoundry mouldsFoundry coresDry sandEngineering

Owner:信阳同合车轮有限公司

A kind of slag gasification furnace with slagging device

ActiveCN106085507BSimple structureReduce manufacturing costGasification processes detailsCombustible gas productionCombustion chamberSlag

A melt-slag gasifier with slag discharging device relates to a melt-slag gasifier. In the prior art, a slag-tapping port of a gasifier is easily blocked by slags and accordingly the gasifier cannot smoothly discharge slags, and there is the problem that the gasification surface cannot normally operate because of burning loss of a quenching ring at the slag-tapping port of the entrained flow gasifier and a downcomer. The interior of the melt-slag gasifier is successively divided into a combustion chamber and a quenching chamber from top to bottom; a water cooling coil is disposed in the melt-slag gasifier body, and forms a conical barrel through coiling of a water cooling pipe from top to bottom, the top end of the water cooling coil is disposed in the combustion chamber, the bottom end of the water cooling coil is disposed in the quenching chamber, the combustion chamber and the quenching chamber are communicated through the water cooling coil, the outer wall at the top end of the water cooling coil is provided with a notch, and an annular melt-slag storage groove is formed between the outer wall of the water cooling coil and the inner wall at the bottom of the combustion chamber; and the downcomer is disposed in the quenching chamber, the upper end of the downcomer is communicated with the water cooling coil, and the lower end of the downcomer is inserted into cooling water of the quenching chamber. The device is applied to the field of coal gasification.

Owner:HARBIN INST OF TECH

Anticorrosive chlorinated rubber coating and production process for same

InactiveCN109054513AIncrease wettabilityImprove adhesionFireproof paintsRubber derivative coatingsEpoxyPolymer science

The invention discloses an anticorrosive chlorinated rubber coating, which is prepared from the following components: chloroprene rubber, chlorinated rubber, a refractory material, a dispersant, dimethylbenzene, fluorocarbon resin, organic silicone modified epoxy resin, Songxiashui, baryta powder, vermiculite powder, a surfactant, a binder, a plasticizer, micaceous iron oxide and composite rare earth. The invention also discloses a production process for the anticorrosive chlorinated rubber coating. The production process is simple and easy, the produced anticorrosive material is high in anticorrosive performance and protection performance, the service life of the anticorrosive material is prolonged, and the cost is reduced.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

A cold iron production process

ActiveCN105598364BExtended service lifeNot easy to drill outFoundry mouldsFoundry coresComing outFire resistance

The invention relates to a chilling block preparation process. The contact face of a chilling block is coated with acrylic acid concave-convex orange-grained paint and then is dried, so that an extremely firm protective film can be formed on the contact face after the paint is cured. The paint is extremely high in fire resistance, so that water of sand in a casting can be prevented from coming out of the paint, so as to realize strong protection and control, therefore, the service life of the chilling block is prolonged, and the quality of the casting is guaranteed.

Owner:LIYANG XINLI MASCH CASTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com