Tower-type powdered coal pressure gasification device with chilling process

A pressurized gasification and chilling technology, which is applied in the gasification of granular/powdered fuels, the manufacture of combustible gases, and the petroleum industry. It can solve the problems of complex manufacturing and installation, long manufacturing cycle, and lower calorific value of raw materials. Solve the overall thermal compensation problem, reduce the difficulty of manufacturing and installation, and strengthen the effect of air-water mixing intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

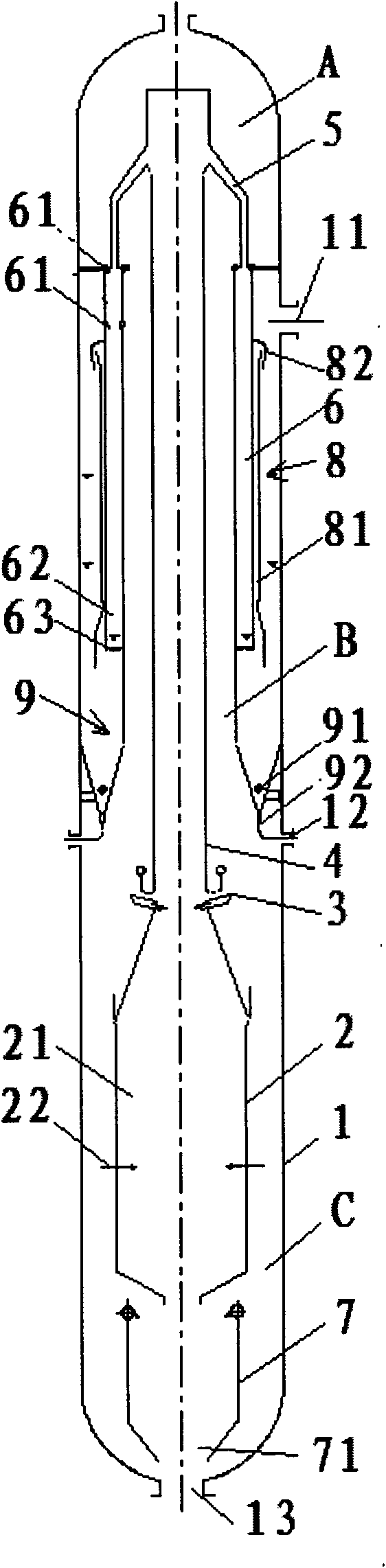

[0023] The invention is a device for gasifying dry coal powder and simultaneously quenching the high-temperature syngas after gasification, mainly including: a pressure shell and a gasification unit suspended in the pressure shell, steam / water or non-gasification It consists of a dust gas quenching unit, a cooling channel arranged coaxially with the pressure shell, a return chamber and an immersion quenching chamber coaxially arranged with the cooling channel, and a slag pool directly below the gasification unit. An annular gap is reserved between the pressure shell and the gasification unit, and an annular gap is reserved between the cooling channel and the water bath quenching chamber, which is convenient for installation and maintenance.

[0024] In order to better understand the present invention, the following will be described in detail through specific implementation cases in conjunction with the accompanying drawings:

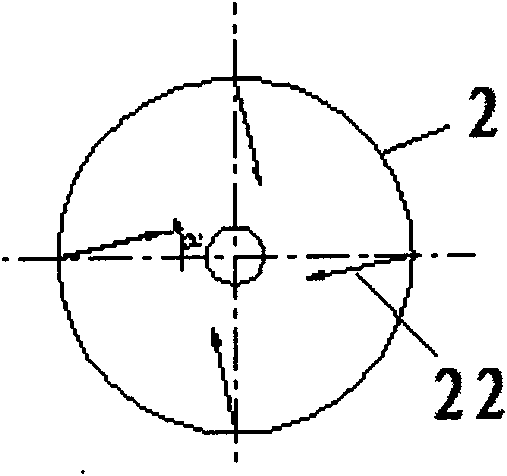

[0025] see figure 1 , figure 2 . The tower-ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com