Hot-charging hot-delivery casting method adopting graphite mold

A graphite mold, hot charging and hot delivery technology, which is used in casting molding equipment, casting molds, heat treatment furnaces, etc., can solve problems such as the inability to realize the production line casting bucket teeth, the low production efficiency of the production process, and the overall poor wear resistance of the bucket teeth. , to achieve the effect of environmental protection, accurate size and convenient demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The following description illustrates specific embodiments of the invention sufficiently to enable those skilled in the art to practice and reproduce it.

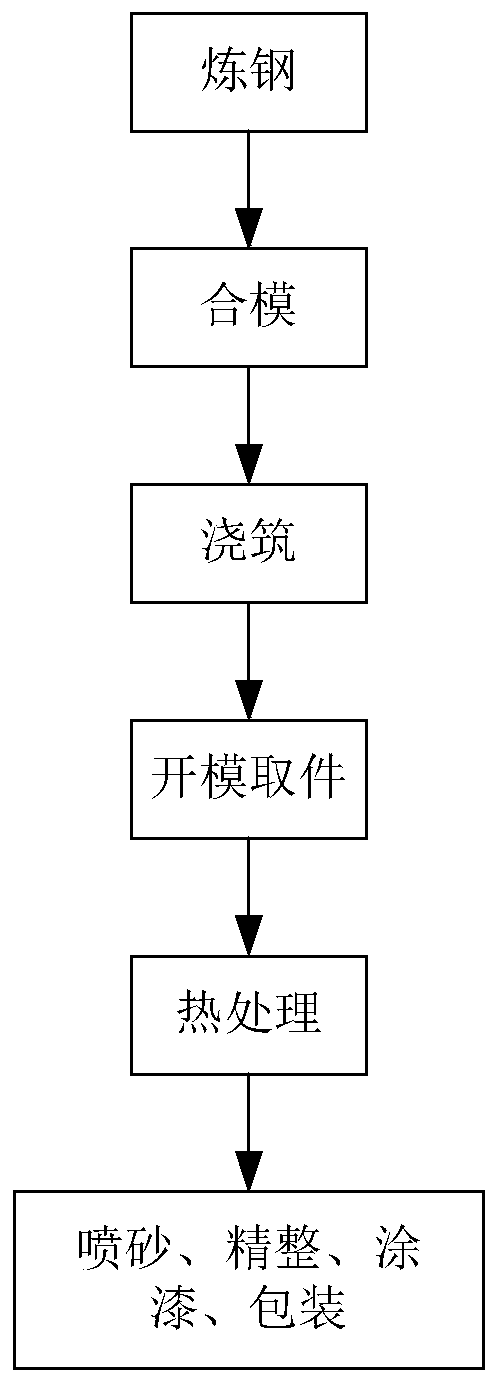

[0060] Such as figure 1 Shown is the flow chart of the hot charging and hot delivery casting method adopting graphite mold in the present invention.

[0061]The hot charging and hot sending casting method adopting graphite mould, specifically comprises the following steps:

[0062] Step 1: Smelting molten steel, the temperature of molten steel is greater than 1300°C;

[0063] The molten steel adopts alloy steel of Cr and Mn elements.

[0064] Step 2: Assemble the graphite mold, pour molten steel into the graphite mold;

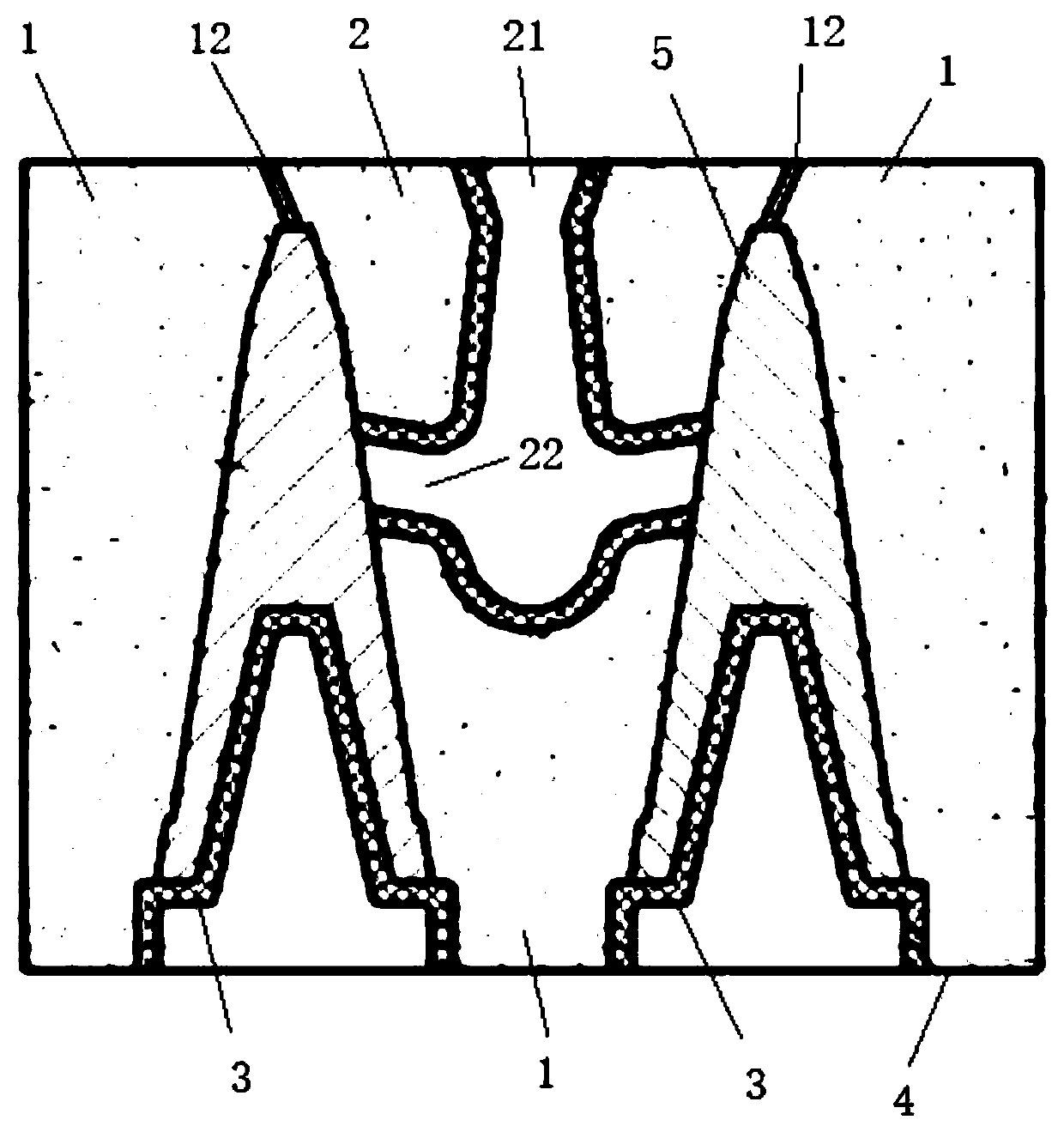

[0065] Such as figure 2 Shown is a schematic view of the longitudinal section of the graphite mold in the present invention.

[0066] The structure of the graphite mold includes: a mold body 1, a first sandbox 2, a second sandbox 3, and a mold case 4. The mold body 1 is provided with two cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com