A cold iron production process

A manufacturing process and cold iron technology, which is applied in the direction of manufacturing tools, metal processing equipment, casting molding equipment, etc., can solve the problems of casting quality problems, prone to pores and cracks, short service life of cold iron, etc., to avoid shrinkage cavities and defects, improve the chilling effect, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

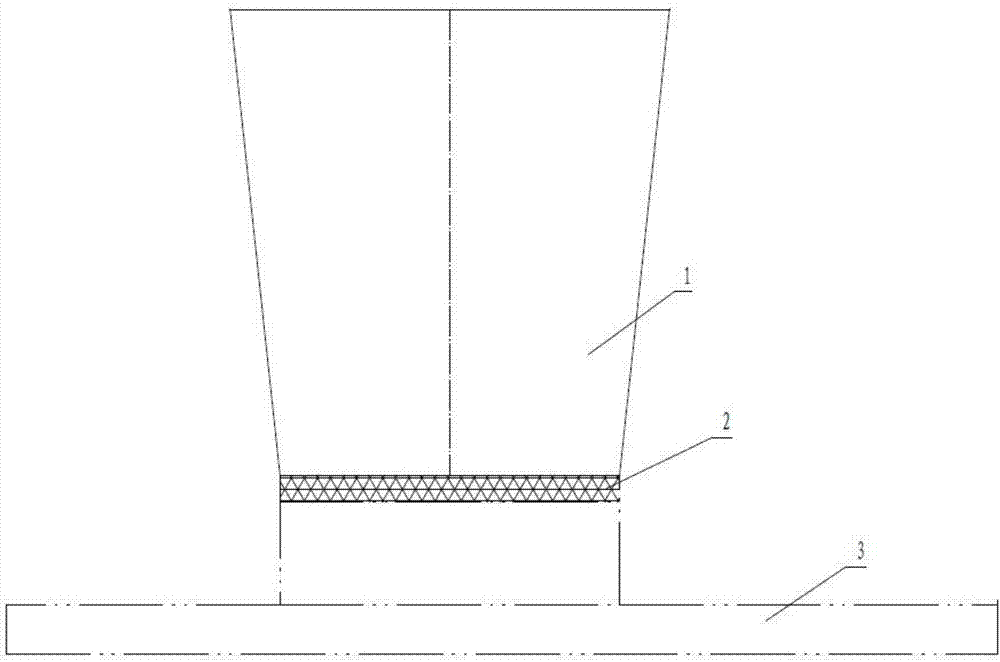

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0028] A kind of cold iron manufacturing process described in a preferred embodiment of the present invention, first prepare acrylic concave-convex orange-shaped paint, clean the surface of the cold iron, after removing burrs and dirt, paint on the surface of the cold iron and the casting. Acrylic concave-convex orange-shaped paint, dry the painted cold iron, and shape the cold iron after drying to chill the casting. Acrylic concave-convex orange paint has high hardness, good adhesion, impact resistance and solvent resistance, and good three-proof performance, which can well protect the contact surface of the cold iron and prolong the service life of the cold iron.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com