Semi-solid slurrying device and composite board manufacturing device using semi-solid slurrying device

A semi-solid, composite plate technology, applied in the field of semi-solid pulping device and composite plate preparation equipment, can solve the problem of easy solidification shell of molten metal, and achieve the effect of increasing nucleation rate, good quality and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

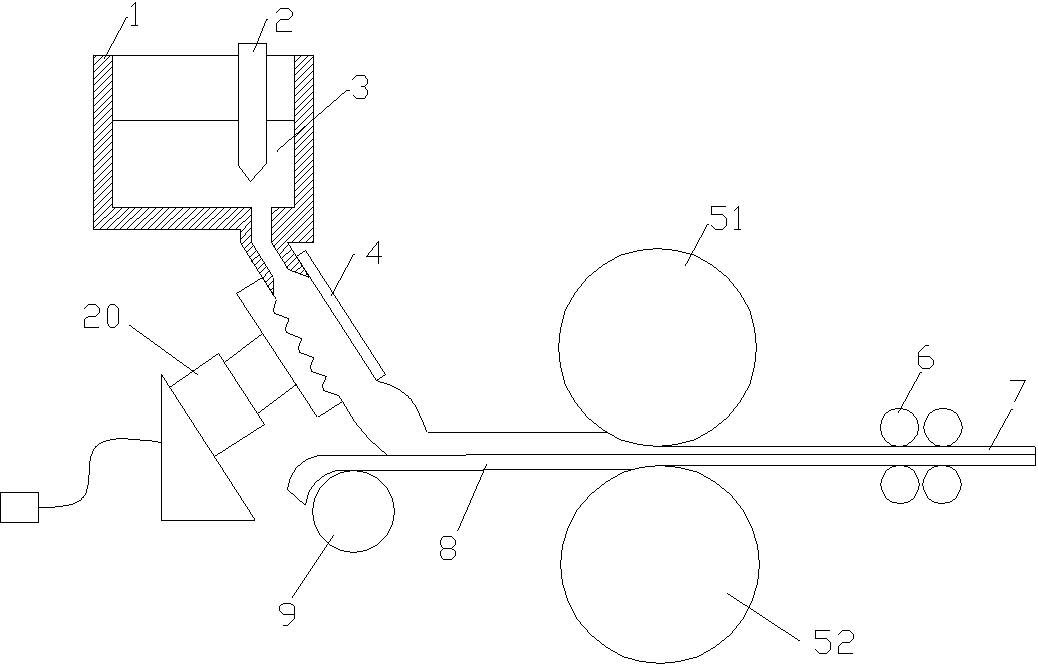

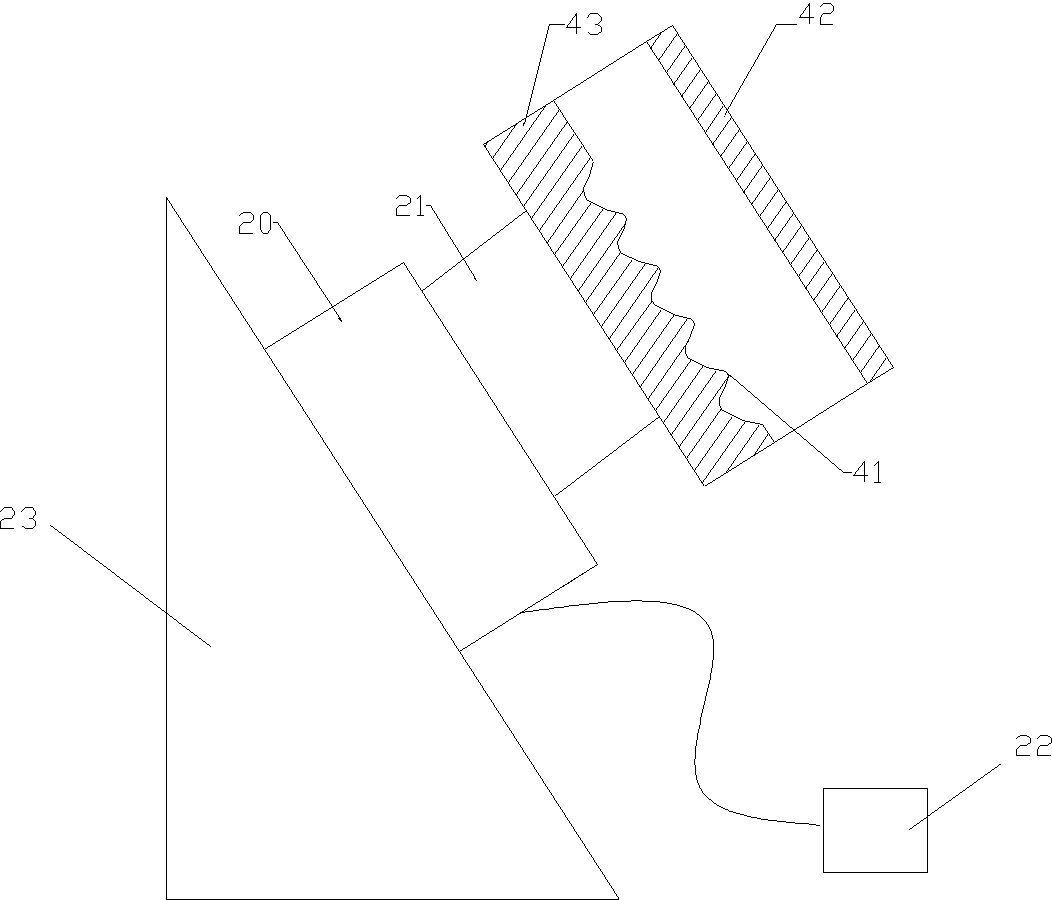

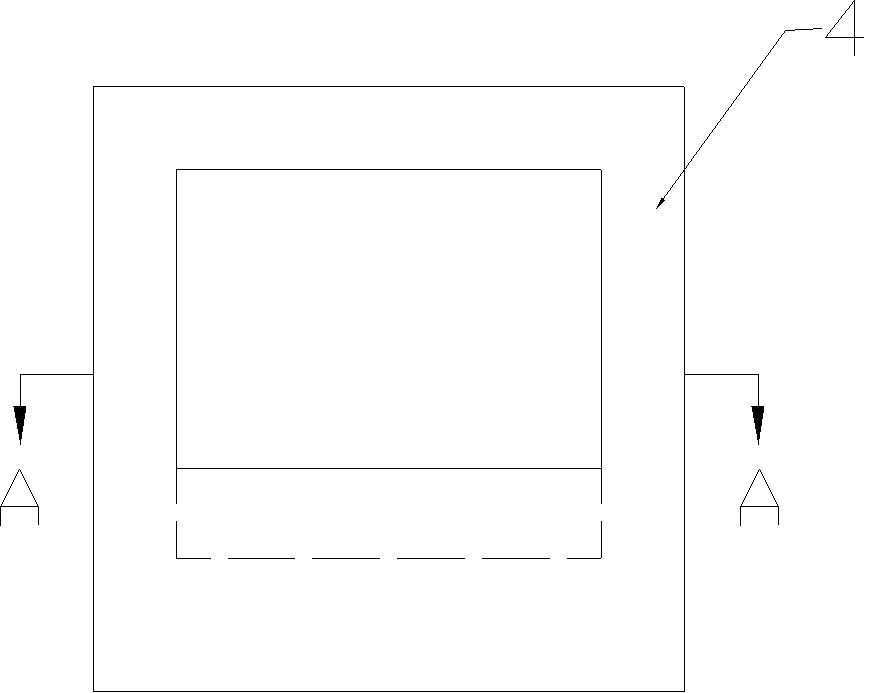

[0024] Embodiment 1 of the composite board preparation equipment of the present invention, such as Figure 1-4 Shown: composite board preparation equipment, including a semi-solid pulping device, the lower part of the semi-solid pulping device is provided with a preheating roller 9 for conveying the board, and one side of the preheating roller 9 is sequentially arranged along the moving direction of the board. The upper roll 51 and the lower roll 52 arranged in pairs for rolling the semi-solid liquid and the plate together, and the traction mechanism 6 for pulling the plate to move. The semi-solid pulping device includes a liquid storage tank 1, which is provided with a stirring rod 2 for stirring the molten metal, and the bottom of the liquid storage tank 1 is provided with an opening for the molten metal to flow out. The semi-solid pulping device also includes a In the flow channel 4 connected with the liquid storage tank and arranged obliquely from top to bottom for the mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com