3D printing graphite contoured chill and preparation method thereof

A 3D printing and graphite technology, which is used in manufacturing, additive processing of mixtures of solid materials and liquid materials, and additive processing. It can solve the problem of high production costs, achieve low production costs, prevent adhesion, and reduce production costs. and the effect of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

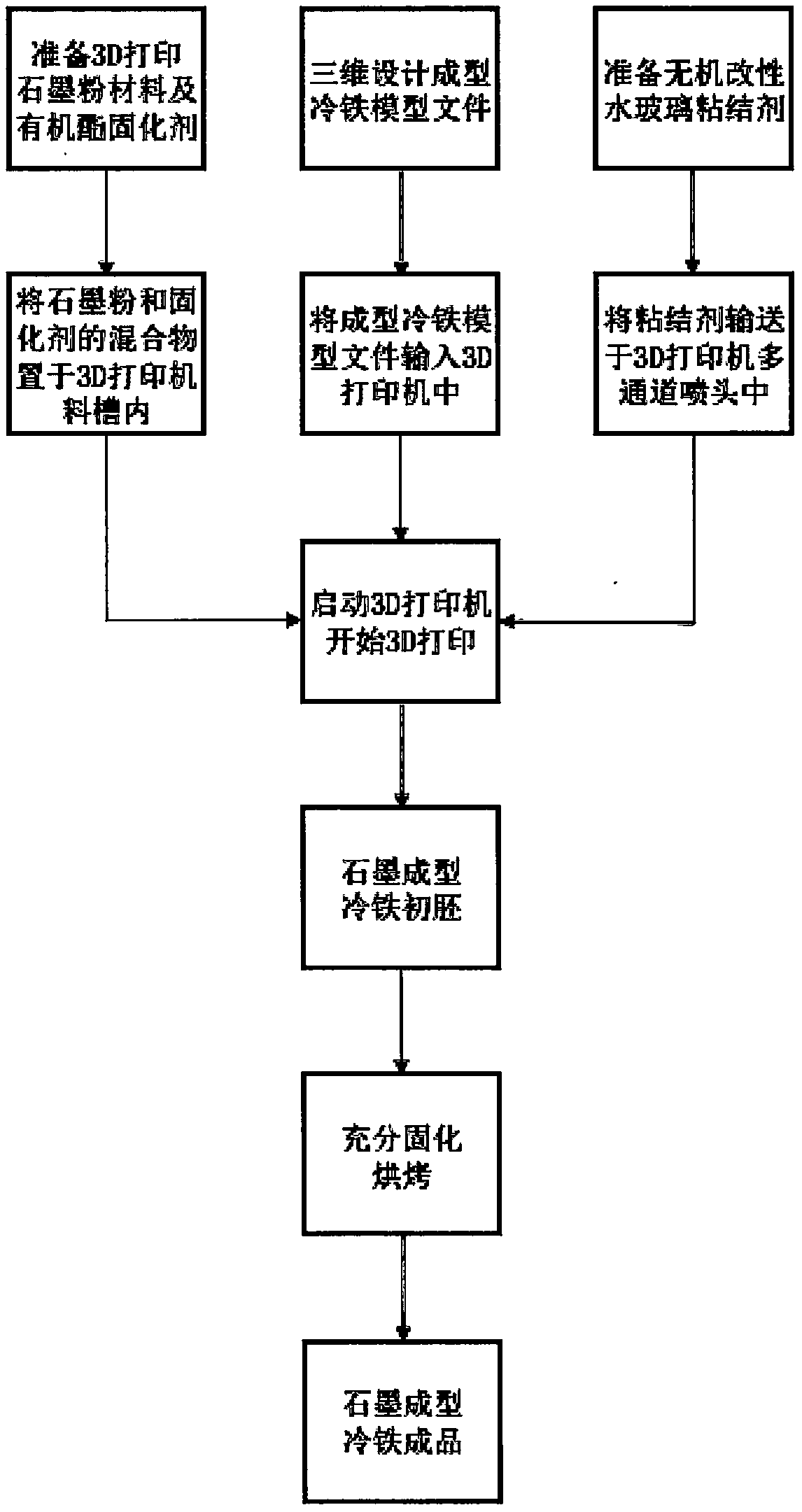

[0024] (1) Provide 3D printing raw materials, that is, 3D printing high-purity graphite powder, inorganic modified water glass binder, and organic ester curing agent;

[0025] (2) A 3DP printer is provided, the automatic mixture of the 3D printing graphite powder and curing agent in step 1 is placed in the 3D printer trough, and the binder in step 1 is delivered to the multi-channel nozzle of the 3D printer;

[0026] (3) Use computer-aided design software to draw the three-dimensional structure model of A forming cold iron;

[0027] (4) start the 3D printer, import the three-dimensional structure model file of the A molding cold iron in the 3D printer, and make the 3D printer start to print, adopt three-dimensional jet printing (3DP) technology process during printing, multi-layer stacking obtains the graphite forming cold Iron primordial;

[0028] (5) Form the graphite-formed cold iron embryo in step 4, fully solidify, and bake (baking temperature 200°C, baking time 1.5 hour...

Embodiment 2

[0030] (1) Provide 3D printing raw materials, that is, 3D printing high-purity graphite powder, inorganic modified water glass binder, and organic ester curing agent;

[0031] (2) A 3DP printer is provided, the automatic mixture of the 3D printing graphite powder and curing agent in step 1 is placed in the 3D printer trough, and the binder in step 1 is delivered to the multi-channel nozzle of the 3D printer;

[0032] (3) Use computer-aided design software to draw the three-dimensional structural model of B-shaped cold iron;

[0033] (4) start the 3D printer, import the three-dimensional structure model file of the B forming cold iron in the 3D printer, and make the 3D printer start to print, adopt three-dimensional jet printing (3DP) technology process during printing, multi-layer stacking obtains the graphite forming cold Iron primordial;

[0034] (5) Form the cold iron blank from the graphite in step 4, fully solidify and bake (baking temperature 200°C, baking time 2 hours)...

Embodiment 3

[0036] (1) Provide 3D printing raw materials, that is, 3D printing high-purity graphite powder, inorganic modified water glass binder, and organic ester curing agent;

[0037] (2) A 3DP printer is provided, the automatic mixture of the 3D printing graphite powder and curing agent in step 1 is placed in the 3D printer trough, and the binder in step 1 is delivered to the multi-channel nozzle of the 3D printer;

[0038] (3) Use computer-aided design software to draw a three-dimensional structural model of C-shaped cold iron;

[0039] (4) start the 3D printer, import the three-dimensional structure model file of the C forming cold iron in the 3D printer, and make the 3D printer start to print, adopt three-dimensional jet printing (3DP) technology process during printing, multi-layer stacking obtains the graphite forming cold Iron primordial;

[0040] (5) Form the graphite-formed cold iron embryo in step 4, fully solidify and bake (baking temperature 225°C, baking time 1.5 hours) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com