Patents

Literature

150results about How to "Avoid sticking in" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

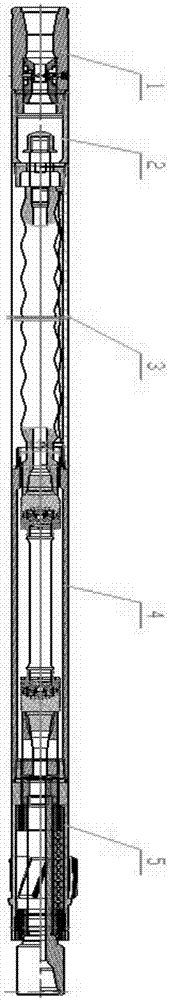

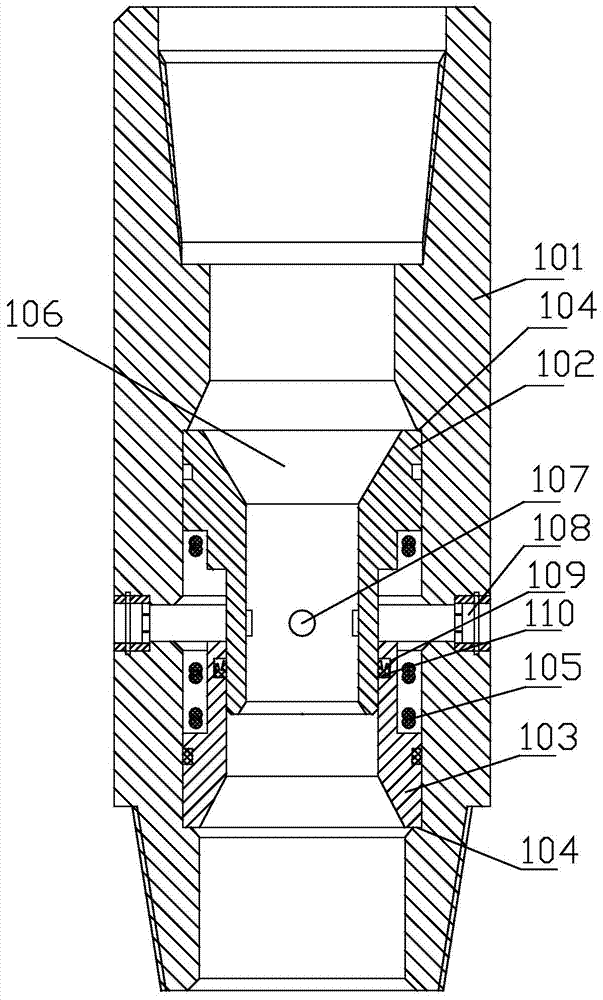

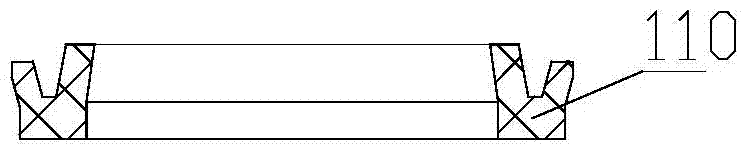

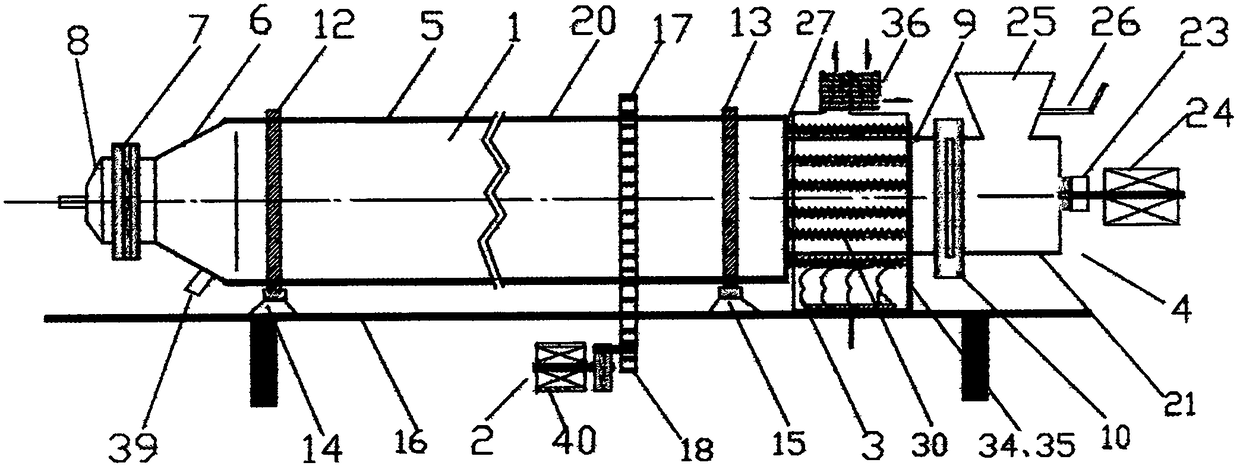

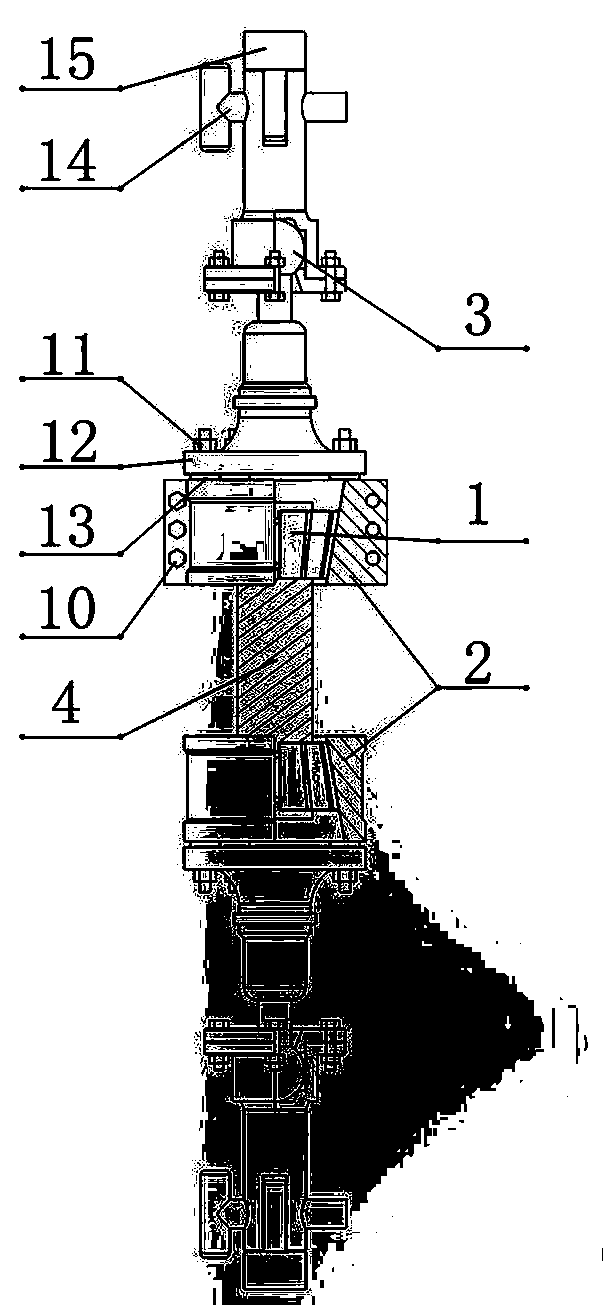

Efficient positive displacement motor drill under well

An efficient positive displacement motor under a well comprises a bypass valve assembly, a falling prevention joint, a motor joint, a universal joint assembly and a bearing joint assembly. The efficient positive displacement motor under the well is simple in structure, convenient to use, stable in operation under the well, safe, reliable, high in complete machine efficiency, capable of outputting larger torque, long in working time and service life, suitable for drilling needs of various complex wells at the present, free of piercing leakage and high in working reliability. A streamlined flow channel enables water conservancy losses of a main flow channel to be reduced, turn-off force is large, the defects of the interference effect and tooth form distortion of the conjugation curvature of a traditional single-screw machine type positive displacement motor are overcome, a universal shaft operates flexibly, energy efficiency is high, the universal shaft can work in the environments where no sand grain exists, and drilling fluid erosion exists, the service life is long, and mechanism strength is high.

Owner:QINGDAO JINJIANGYUAN IND EQUIP CO LTD

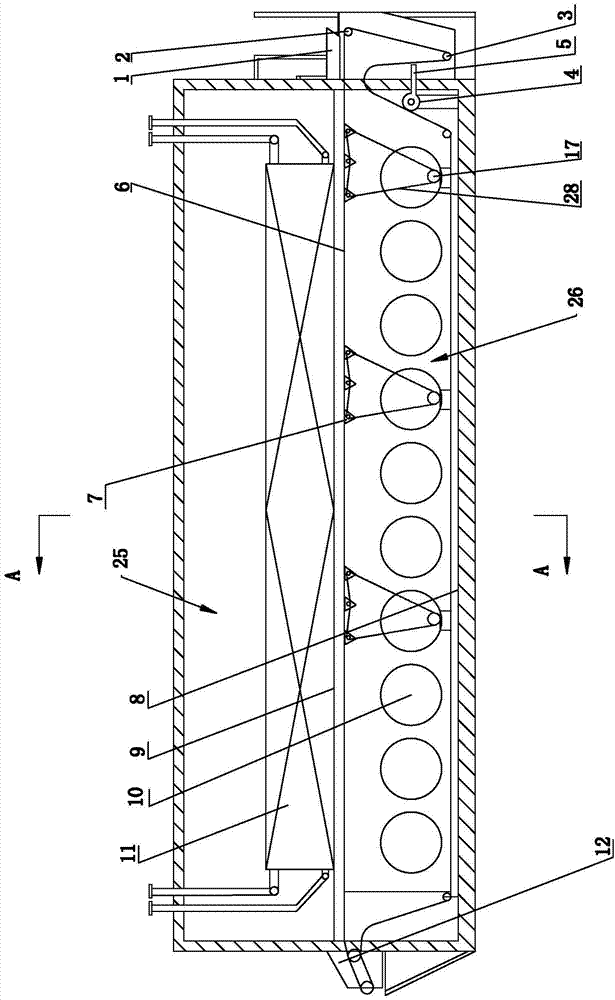

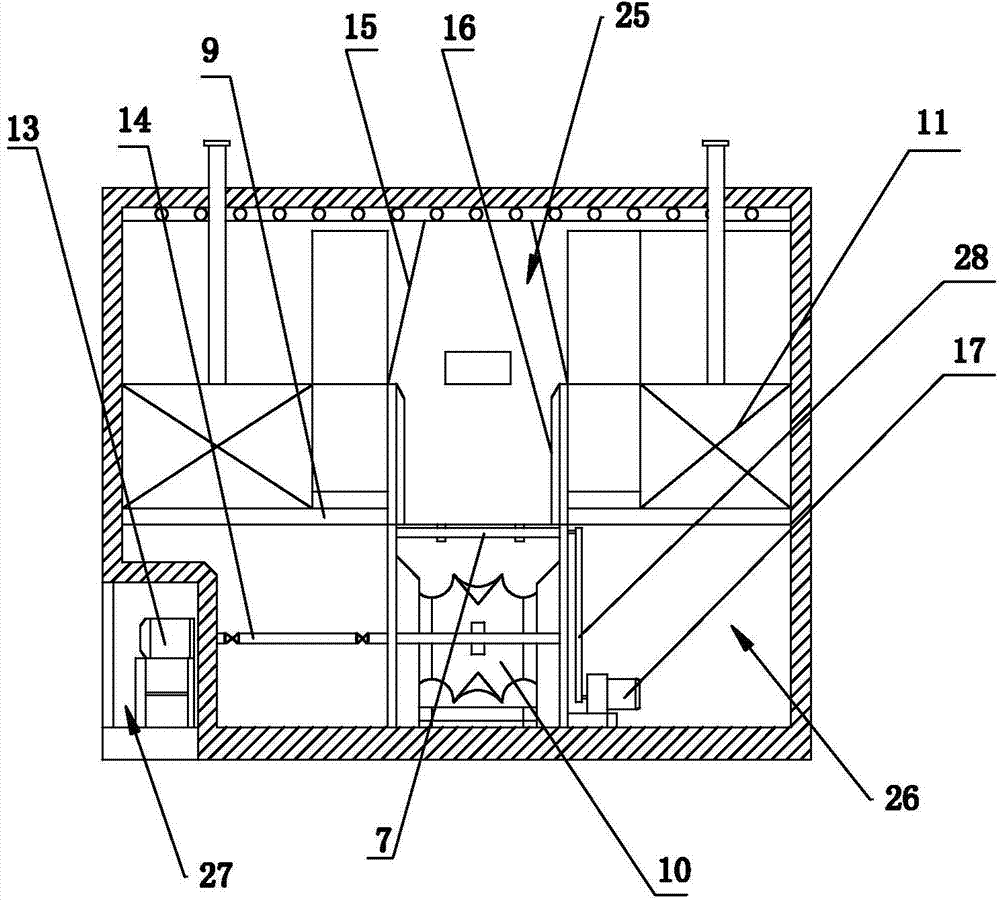

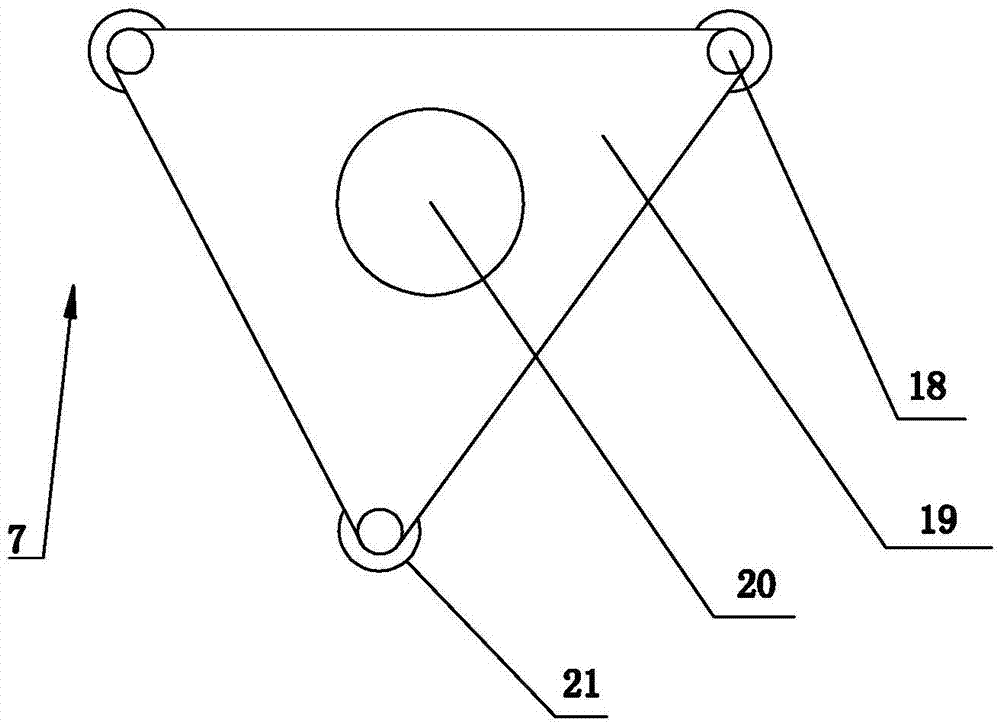

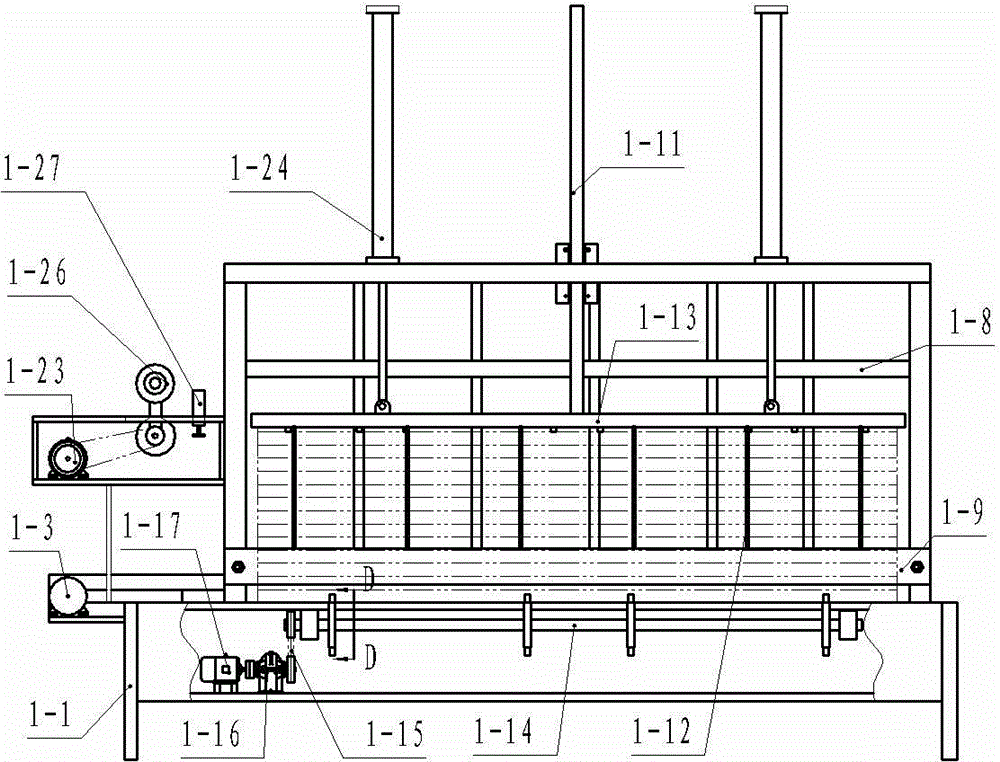

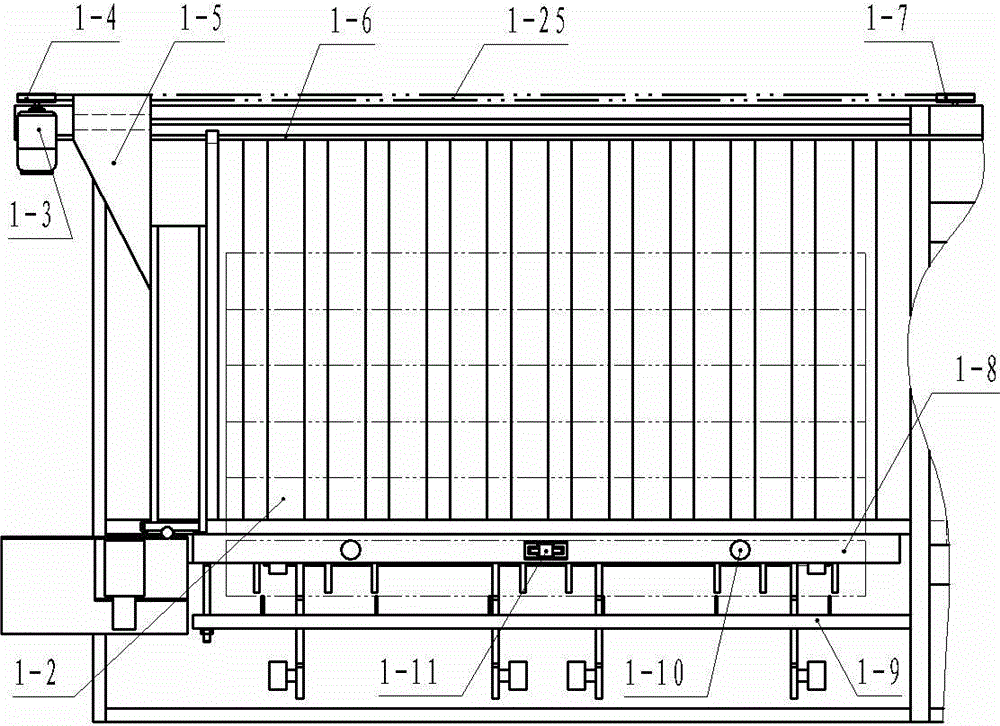

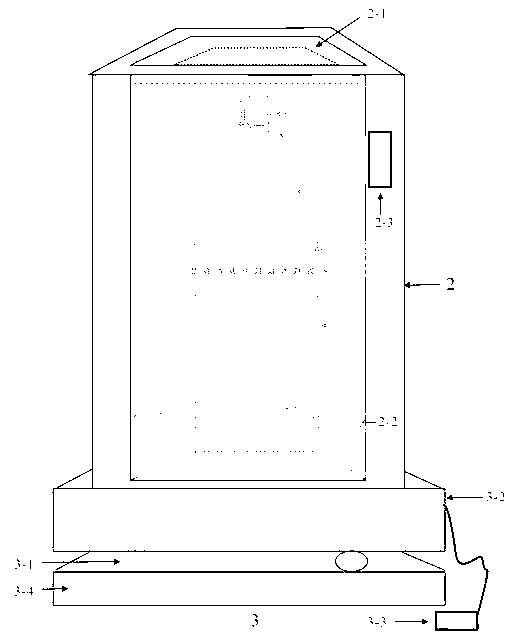

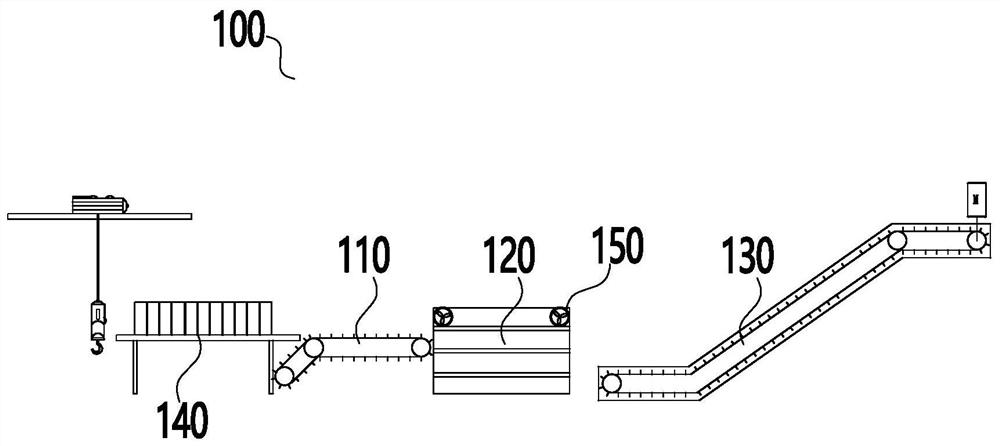

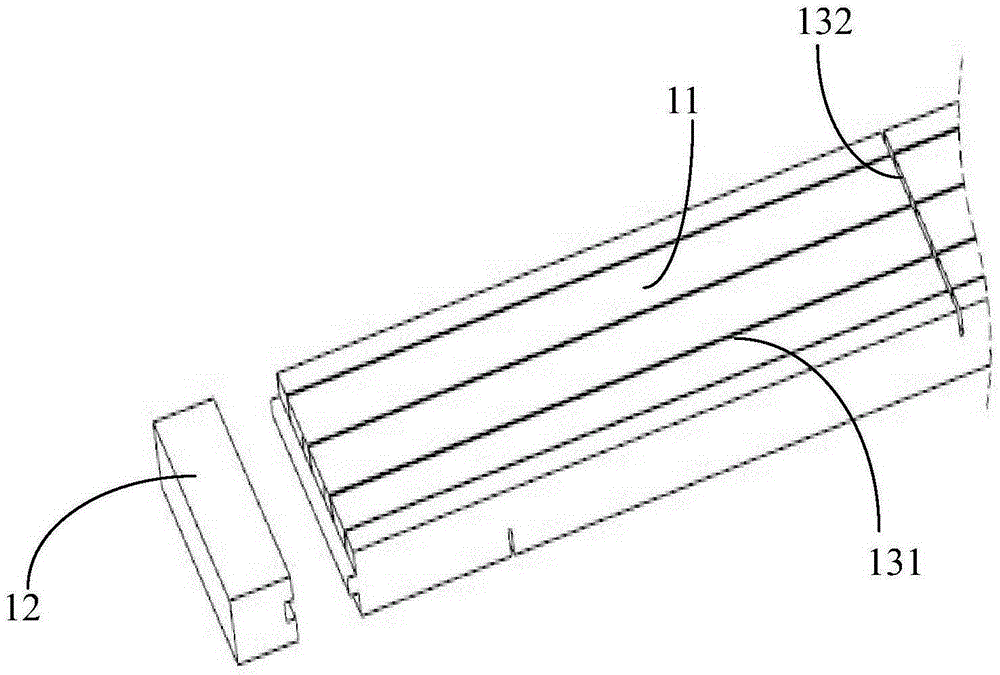

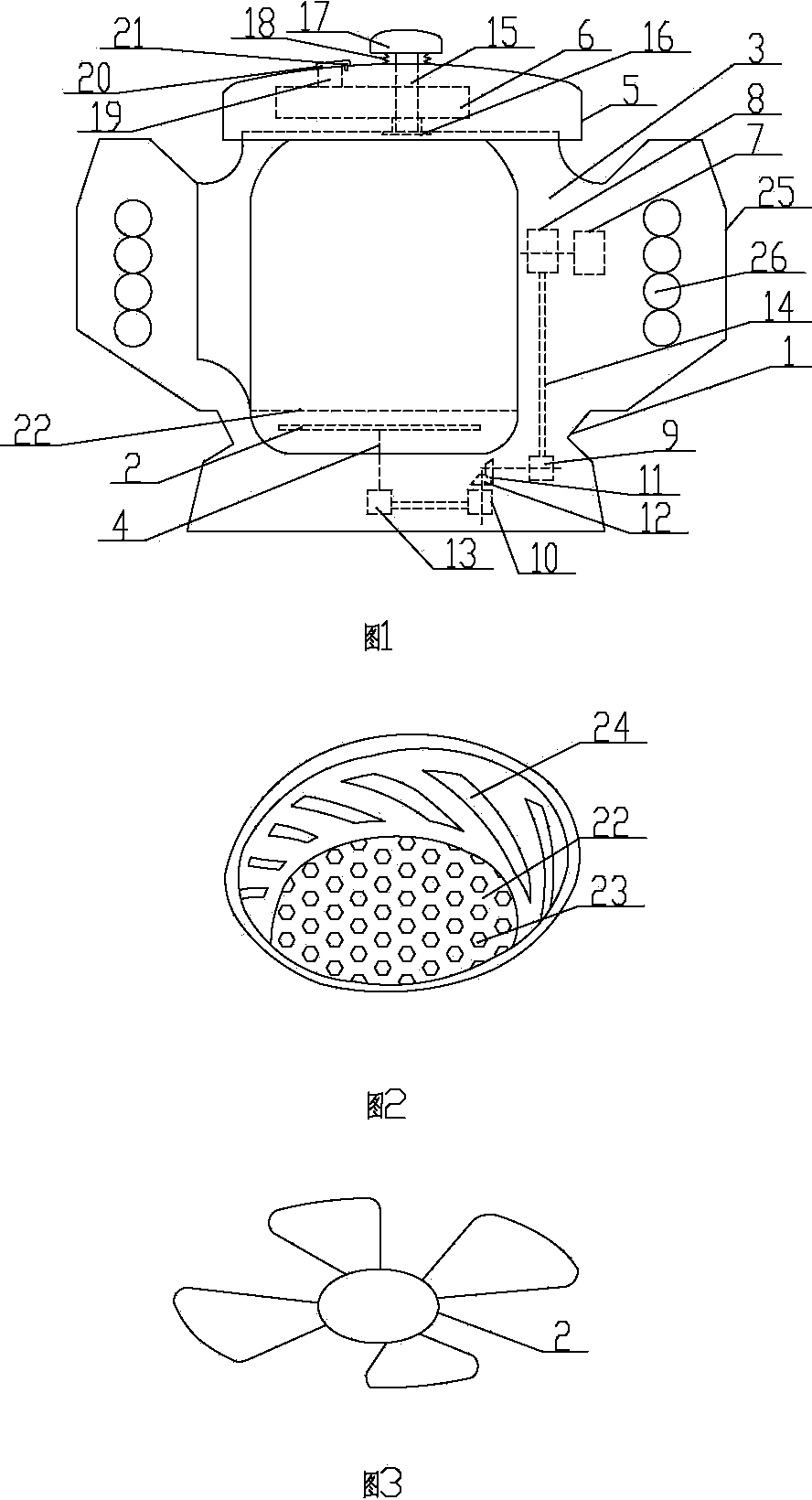

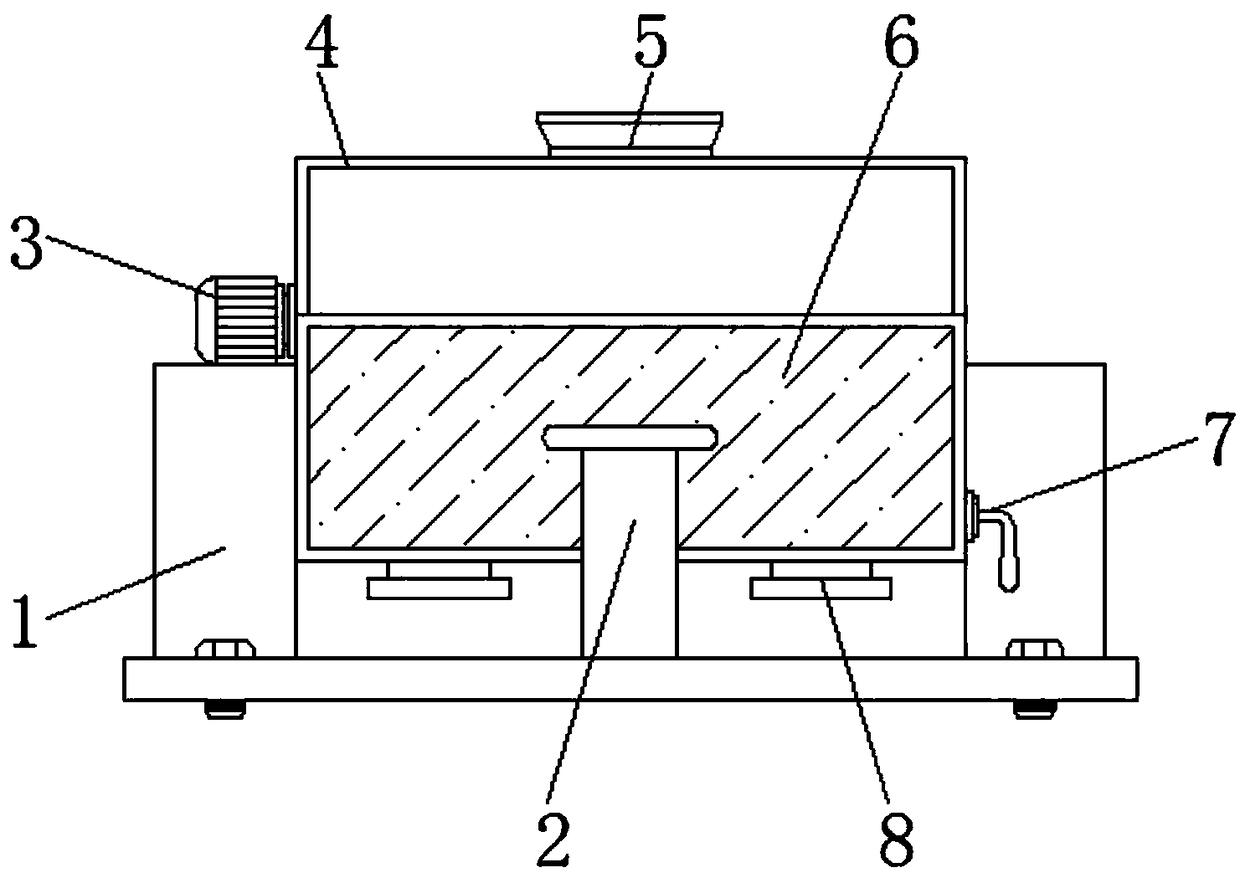

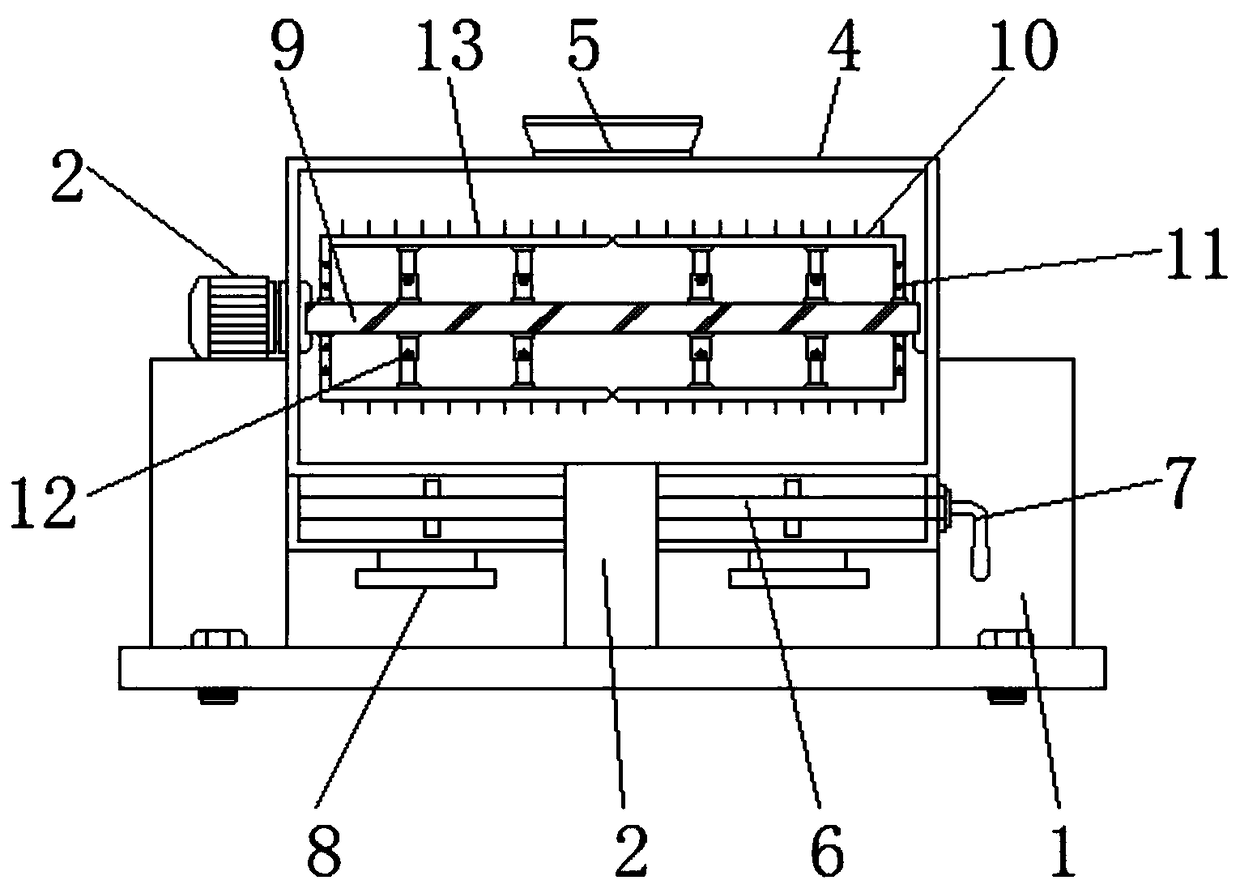

Instant freezer

ActiveCN103791671AReduce loadTake advantage ofLighting and heating apparatusStationary refrigeration devicesCold airEngineering

The invention discloses an instant freezer and belongs to the technical field of instant freezing equipment. The instant freezer comprises a freezer body, a freezing chamber and an air supply chamber provided with a cold air blowing device are arranged in the freezer body, a conveying belt is arranged in the position corresponding to the cold air blowing device around the air supply chamber, and a power chamber used for installation of a first power device is arranged outside the freezer body. The two ends of the conveying belt extend out of the inlet end and the outlet end of the freezer body, and a normal temperature heating device which is communicated with the power chamber and used for heating the conveying belt is arranged at the inlet end of the freezer body. Heat in the power chamber acts on the conveying belt through the normal temperature heating device, so that the temperature of the body of the conveying belt is raised, the function of the cold air blowing device is utilized in an auxiliary mode, fluidized instant freezing is achieved, the problem of adhering between goods and adhering between the goods and the conveying belt is avoided, the single rate of the goods and normal conveying of the conveying belt are guaranteed, and the production efficiency and the product quality are improved. Meanwhile, the first power device is externally arranged, the refrigerating capacity is fully utilized, the load of the freezer is reduced, and the purpose of energy conservation is achieved.

Owner:绿特国创(潍坊)节能科技有限公司

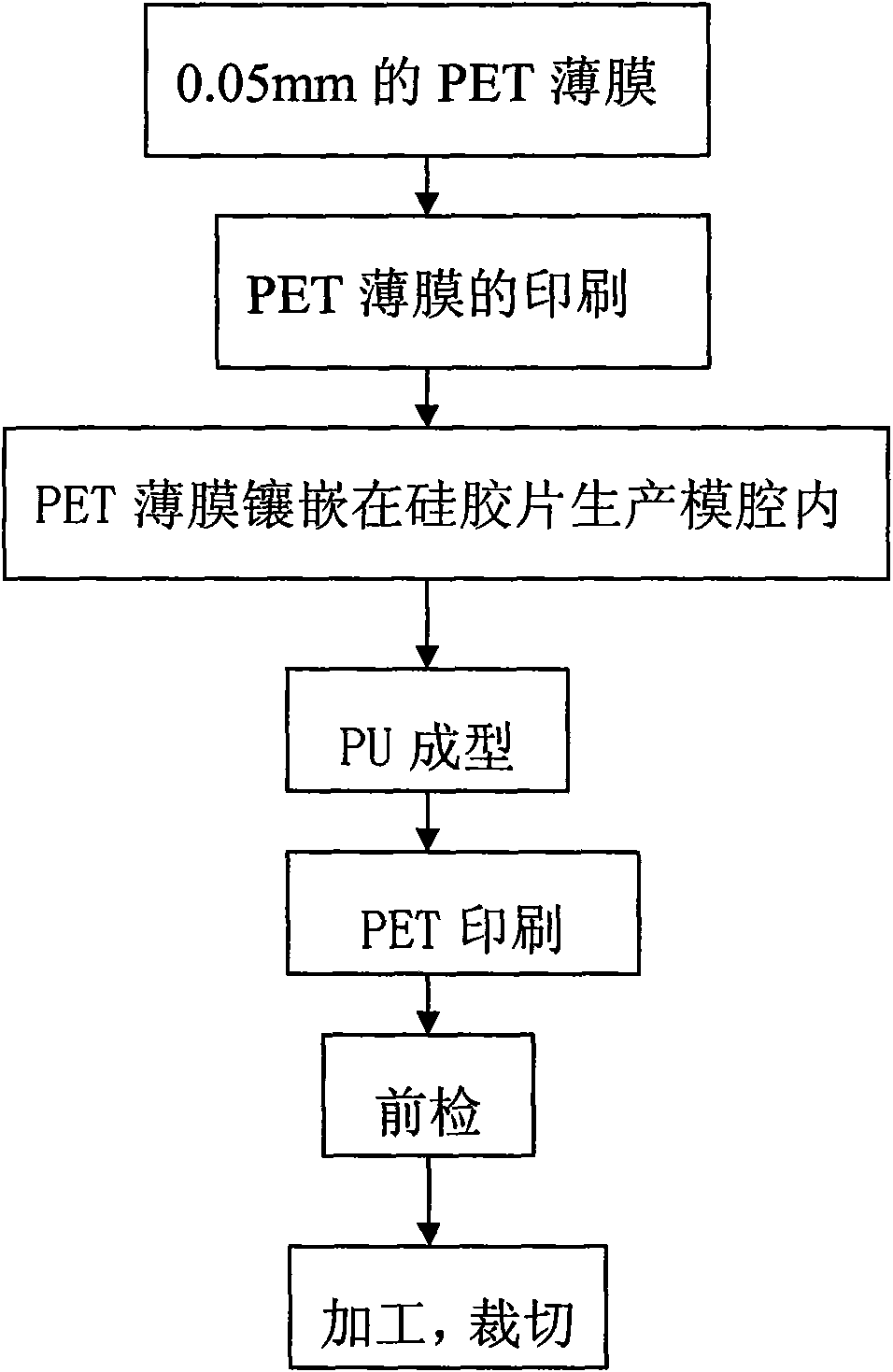

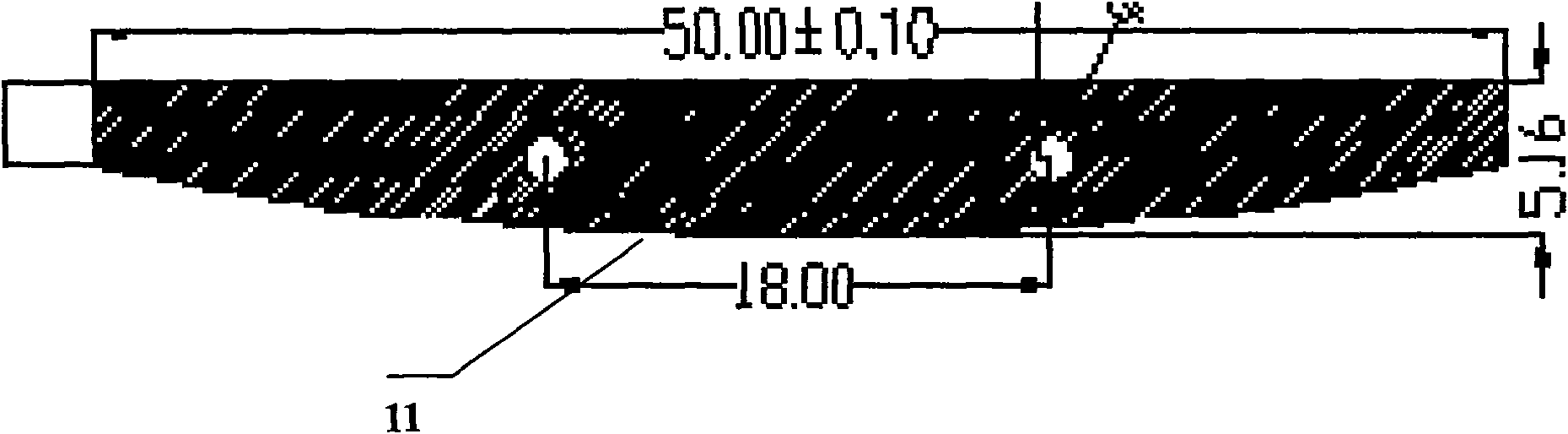

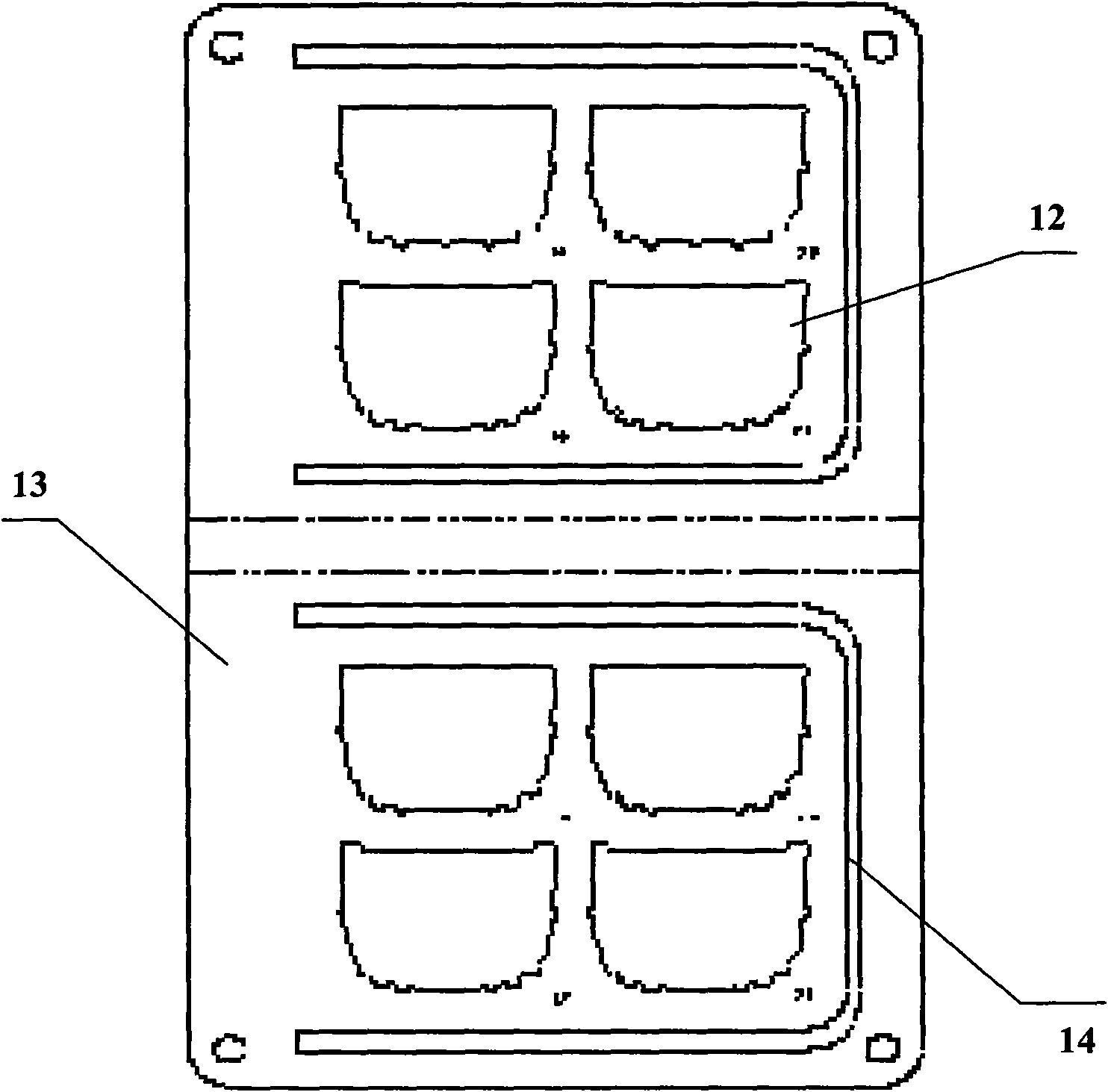

Production process of uv transfer printing molded key device

InactiveCN101609754AThe demand is moderateAchieve double-sided moldingElectric switchesPunchingUltraviolet lights

The invention discloses a production process of a uv transfer printing molded key device, which includes the following steps of: solidifying glue in a mold cavity by ultraviolet light of a uv lamp and adhering the glue to a film; positioning a key structure on a double-sided glue assembly base according to a positioning hole, with the front face of the key structure facing upwards; tearing out a D-type double-sided release paper glue layer, and positioning the release paper glue layer facing downwards on the key structure according to the positioning hole; tearing sponge off the release paper, and placing the sponge with the glue layer facing downwards and a laser etched production brochure number facing upwards into a sponge assembly base; positioning the key stuck with the D-type double-sided glue and the sponge facing downwards on the assembly base according to the positioning hole; tearing off C-type double-sided glue yellow release paper, positioning transparent release paper facing downwards on the assembly base according to the positioning hole with automatic turnover and assembly, and flat-pressing and tightly compressing the C-type double-sided glue on the back of the key; and after silica gel is prepared, sheathing the silica gel on the base by using a pressing fixture, flat-pressing and tightly compressing the silica gel on a punching machine for one time, and putting the base on an ejection fixture for ejecting out the molded key device.

Owner:东莞星海丰电子有限公司

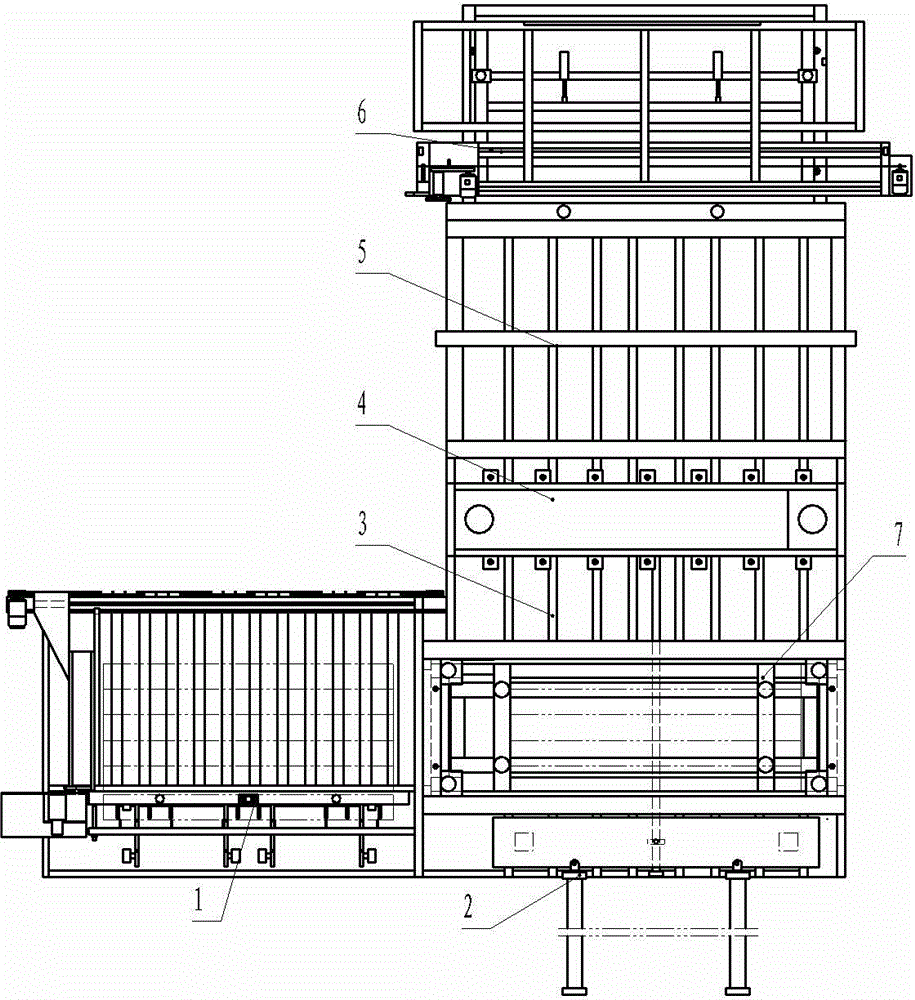

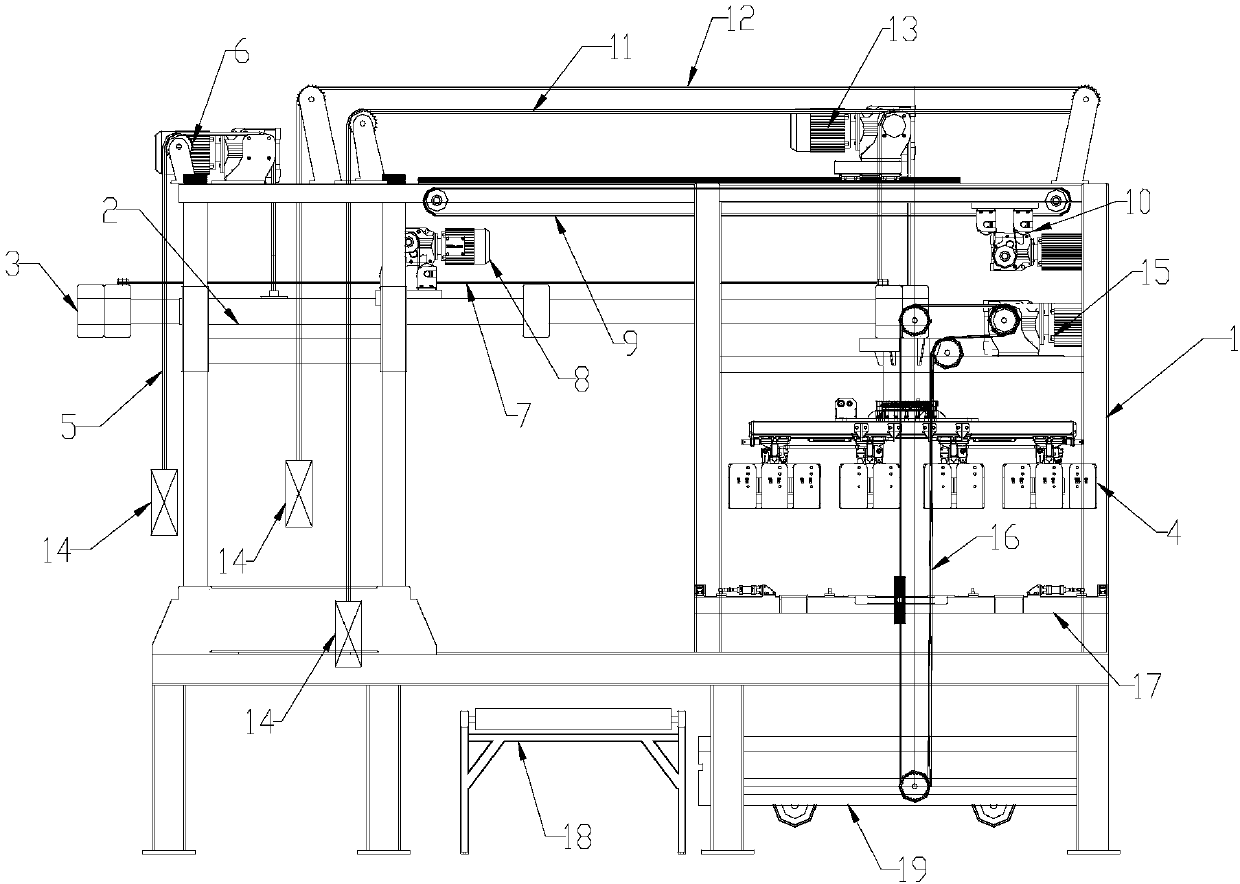

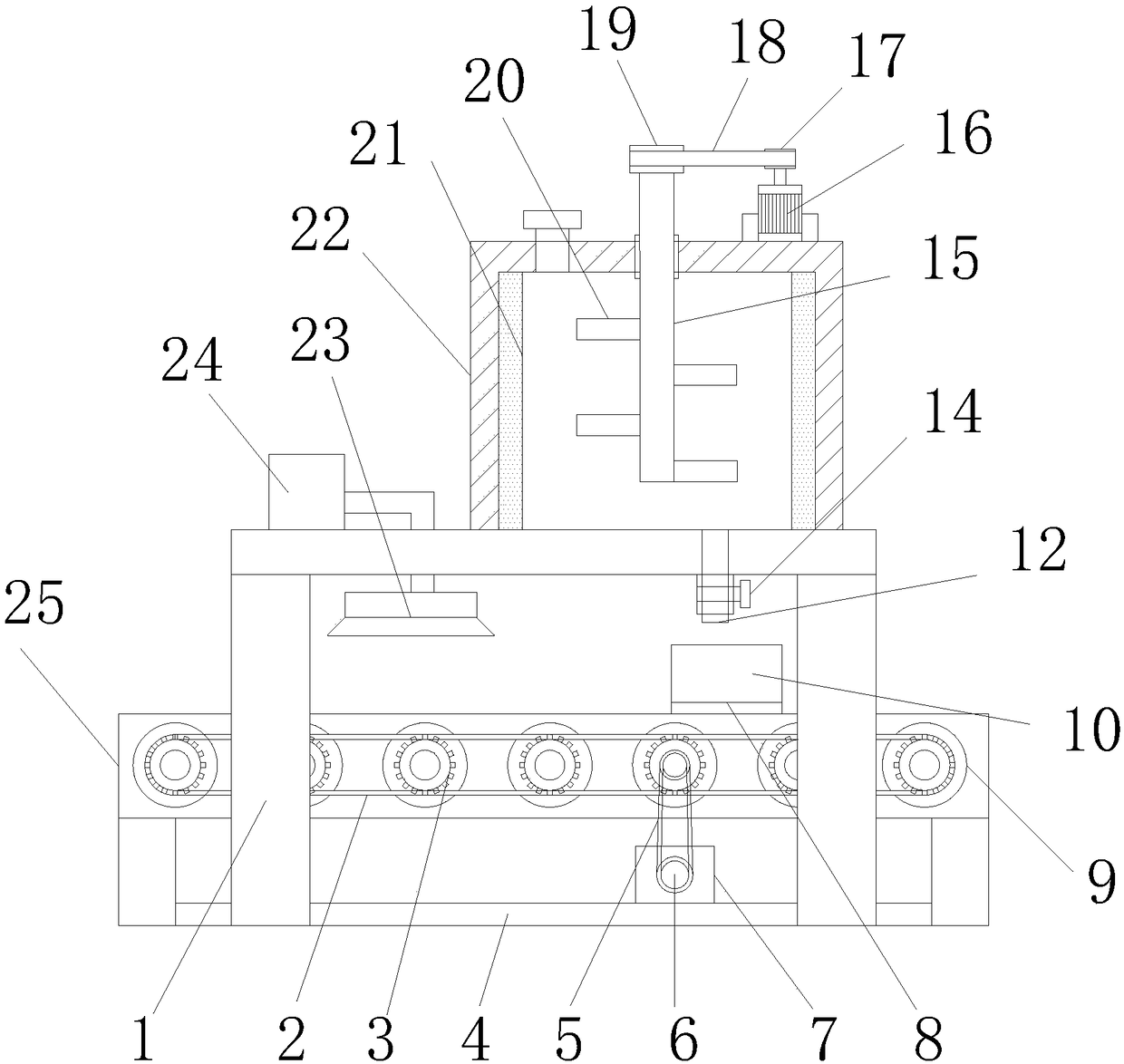

Board jointing machine

The invention discloses a board jointing machine and relates to the technical field of wood-working machine manufacture. The board jointing machine comprises a machine frame which is provided with a board jointing bench and a board pushing device which is arranged at one end of the board jointing bench; a leveling device, a pressurizing device and a cutting board discharging device which is sequentially connected with the board pushing device are arranged on the board jointing bench of the machine frame; a board pressing device is arranged between the board pushing device and the leveling device; one side of the board pressing device is provided with a feeding board pushing device; the feeding board pushing device comprises a material bench which is provided with supporting feet; a batten storage frame is arranged on the material bench; a batten pushing device is arranged below the batten storage frame on the supporting feet; the material bench, which is arranged on one side of the batten storage frame, is provided with a slide rail extends into a framework and a feeding trolley walks on the slide rail; the feeding trolley is connected with a first power machine. Compared with the prior art, the board jointing machine can solve the problem that the existing board jointing machine is easy to cause buckling deformation and irregular surface when performs board jointing.

Owner:LIUZHOU WUXIN WOOD WORKING MACHINERY

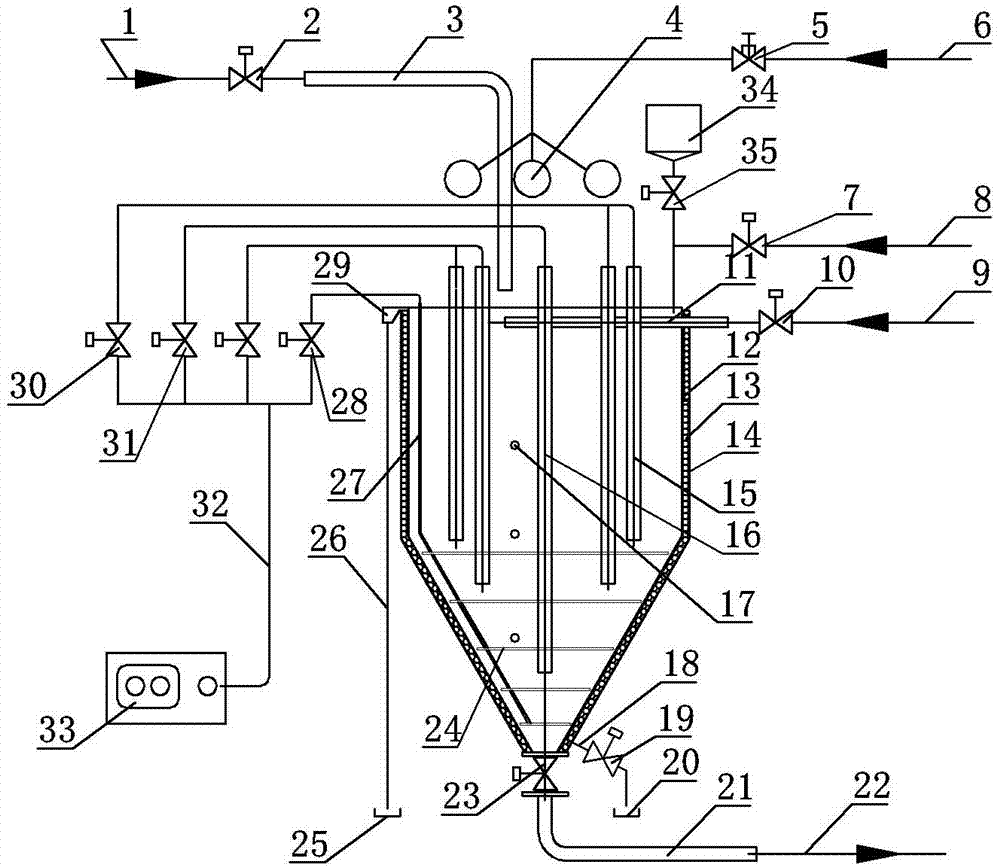

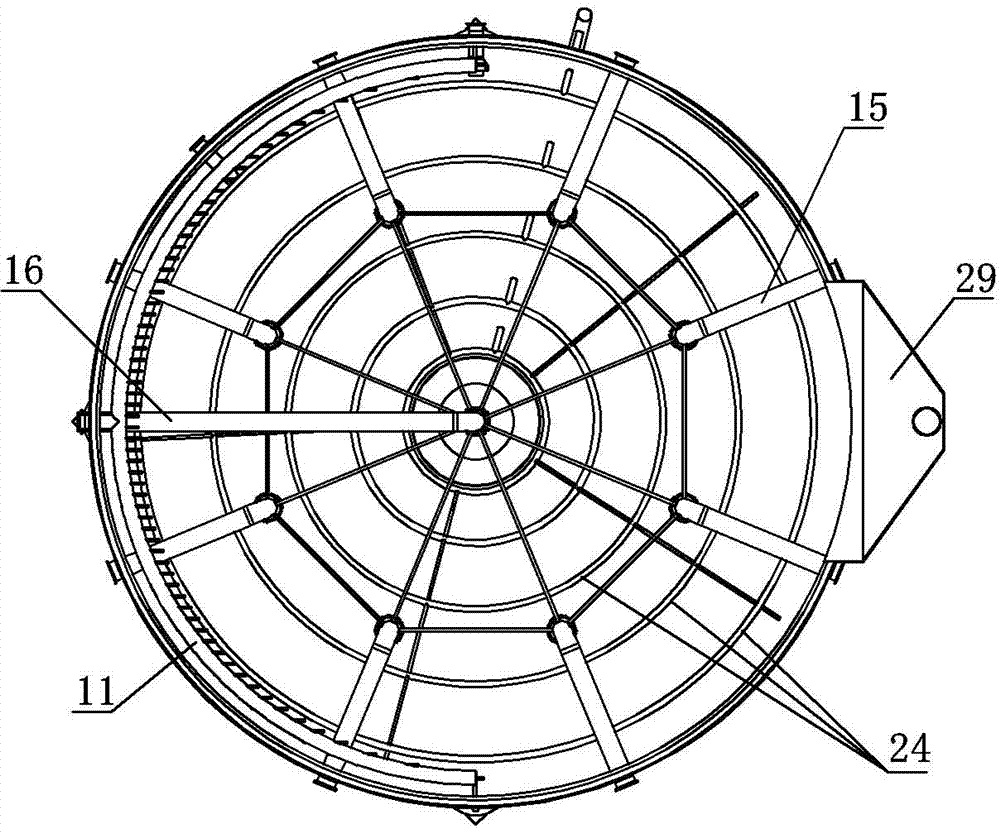

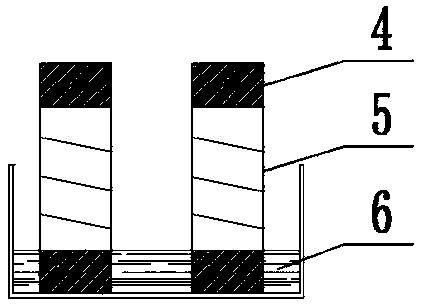

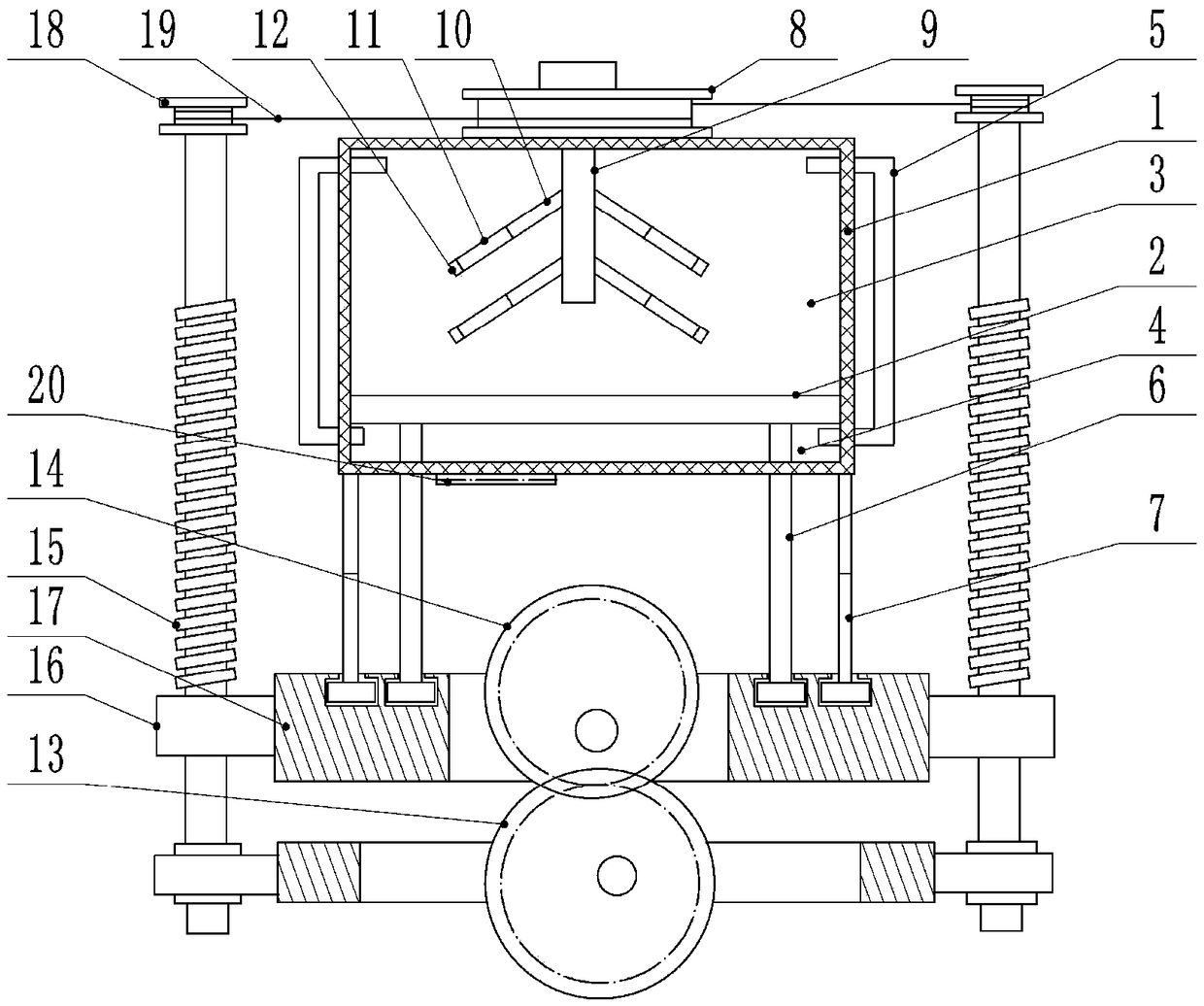

Full-automatic integrated cleaning, soaking and sprouting device of seeds

ActiveCN104206069AFirmly connectedRealize industrial automation productionGerminating apparatusPharmaceutical industrySmall footprint

A full-automatic integrated cleaning, soaking and sprouting device of seeds relates to a sprouting industrially producing device for corn, beans, rice (unpolished rice), wheat and the like. Produced sprouted product can be applied in the fields of bio-enzyme extraction, fermented foods, infant foods, geriatric foods, health-caring foods, beverages and the like, and the fields of agricultural production and pharmaceutical industry. In the device, three functions, including cleaning, soaking and sprouting, are integrated in one container, is high in automatic degree, is low in energy consumption, is less in occupied area, is low in production cost, and is high in efficiency. The device includes a pot body of which a top is in an opening type and a bottom is in a taper shape, a material feeding system, a water supply system, a gas supply system, a sewage discharging system, a draining system, a material output system, a cleaning and disinfecting agent supply system and a sensor system.

Owner:LIAONING PROSPECTIVE BIOTECH

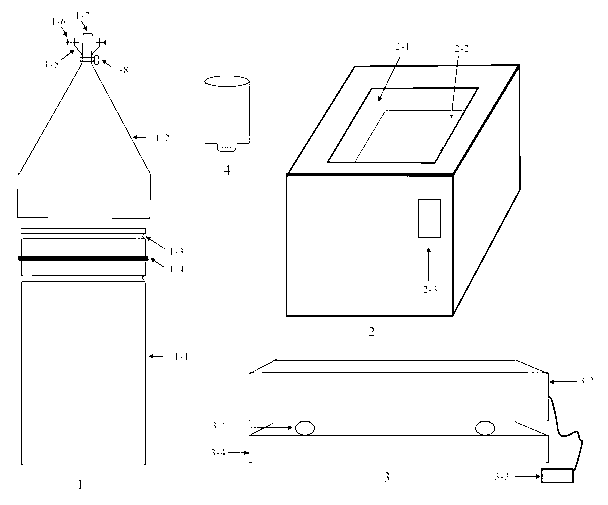

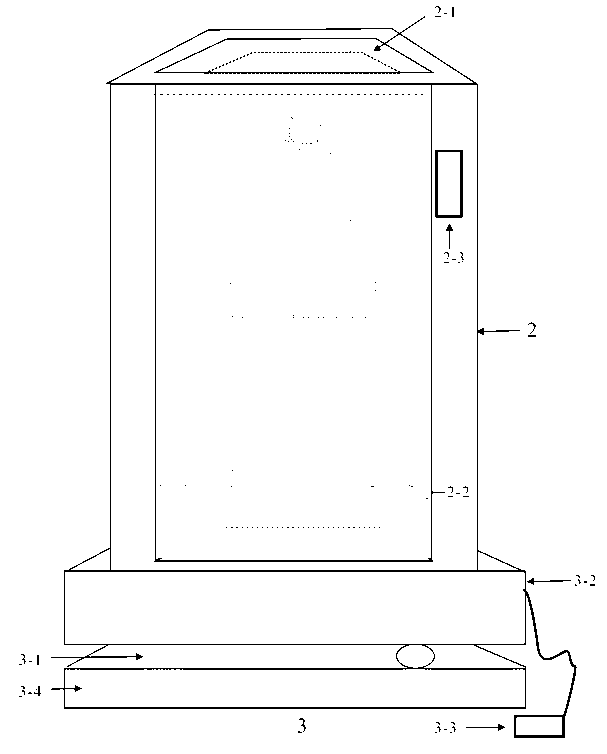

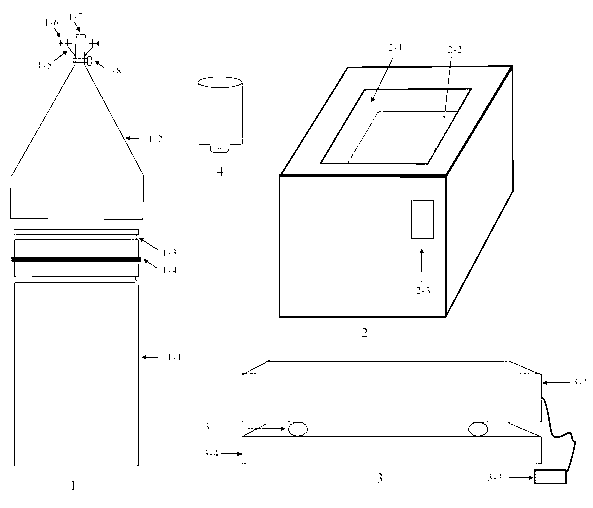

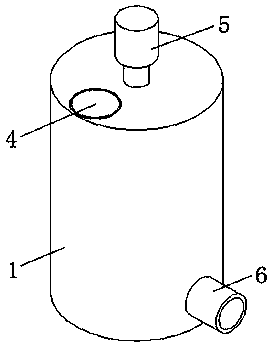

Collecting system of core gas in core gas hydrate drilling field

The invention provides a collecting system of core gas in a natural gas hydrate drilling field. The collecting system comprises an air collector, a water bath thermotank, a vibration table and a gas collecting bottle, wherein the water bath thermotank is arranged on the vibration table; the air collector comprises a tank body and a tank body cover, wherein the tank body and the tank body cover are separable, and the tank boy is in seal connection with the tank body cover; and when the collecting system is adopted to collect the core gas, the tank body filled with a core sample is in seal connection with the tank body cover when the water bath thermotank is positioned in a constant temperature saturated salt water environment, and the gas collecting bottle is connected with a gas collecting outlet of the tank body cover under the constant temperature saturated salt water environment. The collecting system provided by the invention has the advantages that the processes of packaging the aquo-complex core sample, releasing the gas, collecting the gas, collecting gas in an oscillation manner and sealing and storing the gas are finished once, a series of pilot processes are simplified, and the work efficiency of gas collection is greatly improved.

Owner:OIL & GAS SURVEY CGS

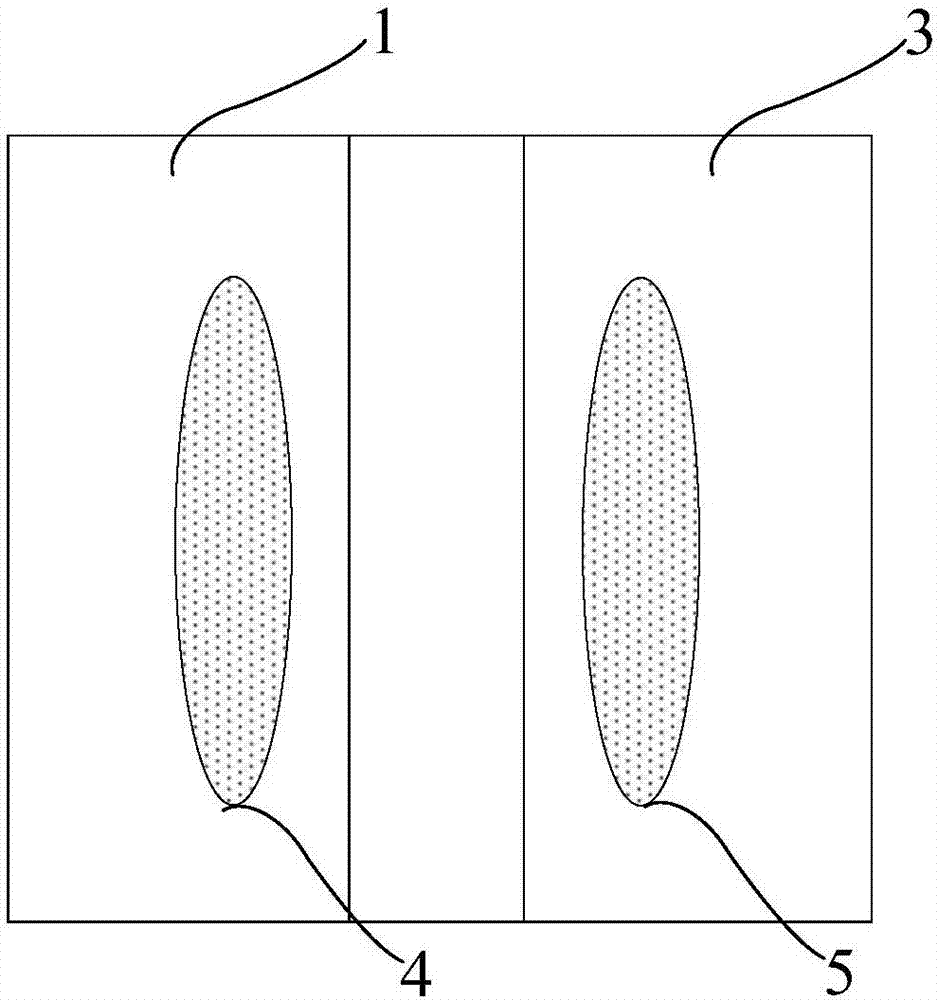

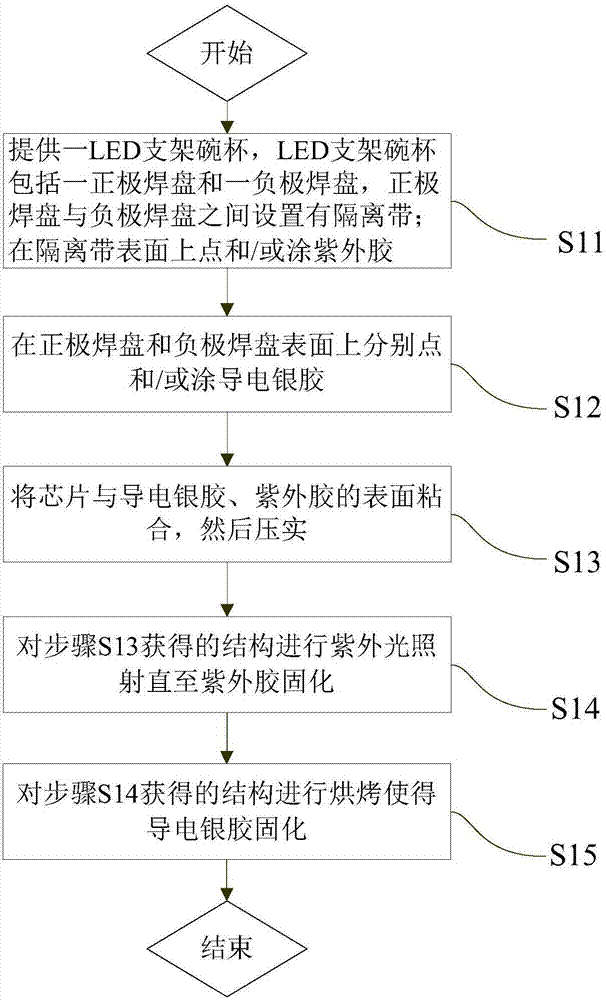

Method for avoiding die-bonding electric leakage of flip chip

InactiveCN107464873APrevent leakageAvoid sticking inSolid-state devicesSemiconductor devicesCooking & bakingUltraviolet

The invention provides a method for avoiding die-bonding electric leakage of a flip chip. The method comprises the following steps of S11, providing an LED bracket bowl cup, wherein the LED bracket bowl cup comprises a positive electrode bonding pad and a negative electrode bonding pad, and an isolation band is placed between the positive electrode bonding pad and the negative electrode bonding pad; and dispensing and / or coating the surface of the isolation band with ultraviolet adhesive; S12, dispensing and / or coating the surfaces of the positive electrode bonding pad and the negative electrode bonding pad with conductive silver adhesive separately; S13, enabling the chip to be glued with the surfaces of the conductive silver adhesive and the ultraviolet adhesive, and then performing tight compression; S14, performing ultraviolet irradiation on the structure obtained in the step S13; and S15, performing baking of the structure obtained in the step S14. By setting the ultraviolet adhesive between the conductive silver adhesive on the surfaces of the positive electrode bonding pad and the negative electrode bonding pad, contact between the two parts of the conductive silver adhesive is blocked, thereby further avoiding the possibilities of electric leakage or even short circuit caused by die bonding; and by adoption of the ultraviolet adhesive for gluing the chip, the problems of insufficient adhesive force of the chip and increased hole rate can be avoided.

Owner:合肥彩虹蓝光科技有限公司

High efficient and environmental friendly cutting seedling method of vine plants

The invention provides a high efficient and environmental friendly cutting seedling method of vine plants. The method comprises the steps of substrate preparation, scion preparation, cutting treatment, cutting, substrate placement, full exposure atomizing management and seedling exercising and germinating. After the method is adopted for cutting propagation, the period is short, the operation is convenient, the rooting rate is high, the shape of the cutting substrate is controllable, transportation and application are facilitated, and cutting seedlings produced by adopting the method are wide in application range, and can be both applied to conventional greening and three-dimensional greening.

Owner:HANGZHOU LANDSCAPING

Collecting method of core gas in natural gas hydrate drilling field

InactiveCN103217317ASimple and fast operationGood sealingWithdrawing sample devicesProduction rateGas cylinder

The invention relates to a collecting method of core gas in a natural gas hydrate drilling field. The collecting method comprises the following steps of: (1) step 1, cleaning a collected core sample in the drilling field and placing the cleaned core sample in an air collector, and fully filling saturated salt water and discharging air in the air collector under the thermostatic waterbath condition of an air chamber; step 2, selecting a gas collecting bottle the size of which is matched with the gas production rate of a core, and when the saturated salt water is filled in the thermostatic waterbath, connecting a bottle port of the gas collecting bottle with a gas collecting outlet of the air collector; and step 3, collecting release gas of the core sample under the gas condition set by the air chamber is in within the pre-set time, then screwing down a bottle cover of the gas collecting bottle under the thermostatic waterbath, and finishing the collection of the release gas of the core sample. The collecting method provided by the invention has the advantages that the processes of packaging the aquo-complex core sample, releasing the gas, collecting the gas, collecting gas in an oscillation manner and sealing and storing the gas are finished once, a series of pilot processes are simplified, and the work efficiency of gas collection is greatly improved.

Owner:OIL & GAS SURVEY CGS

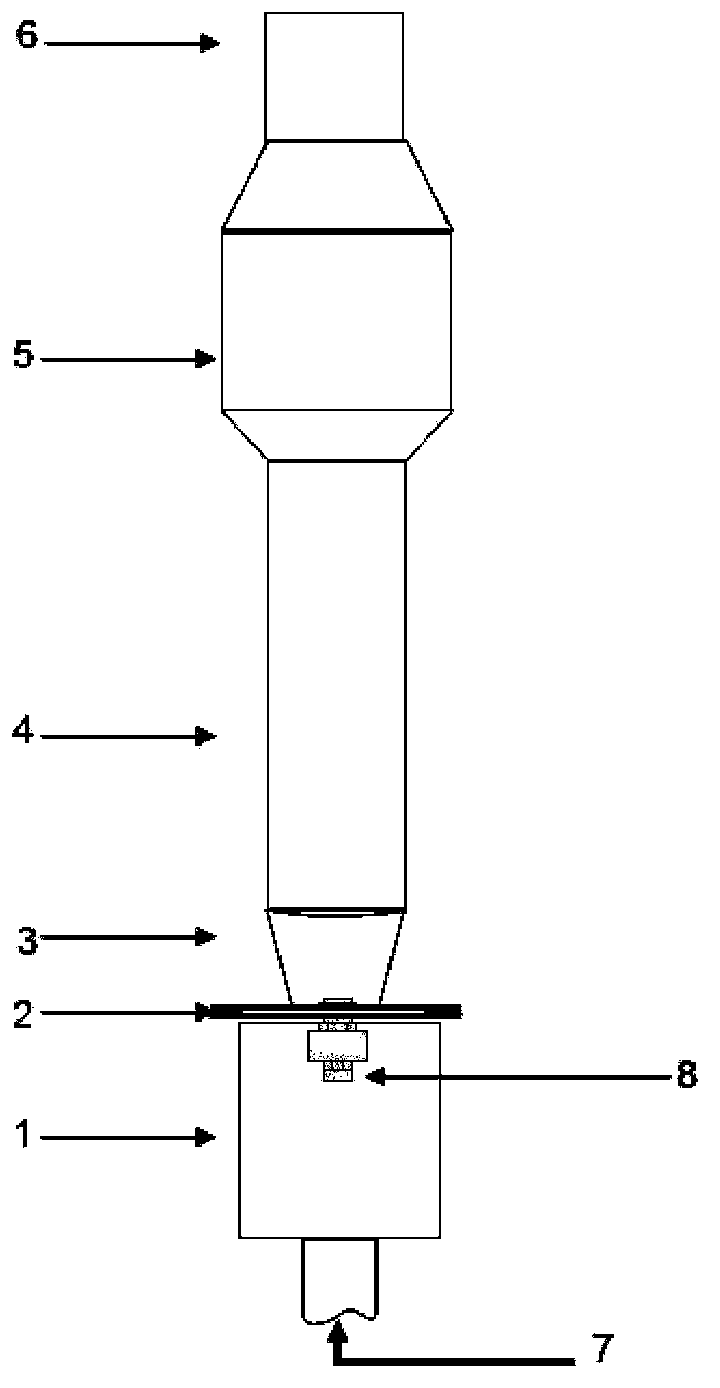

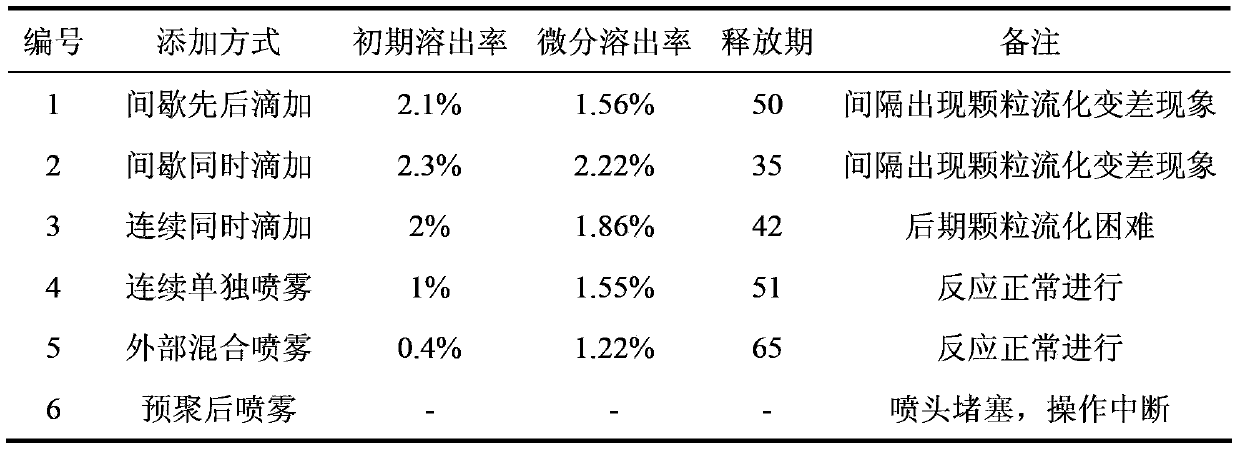

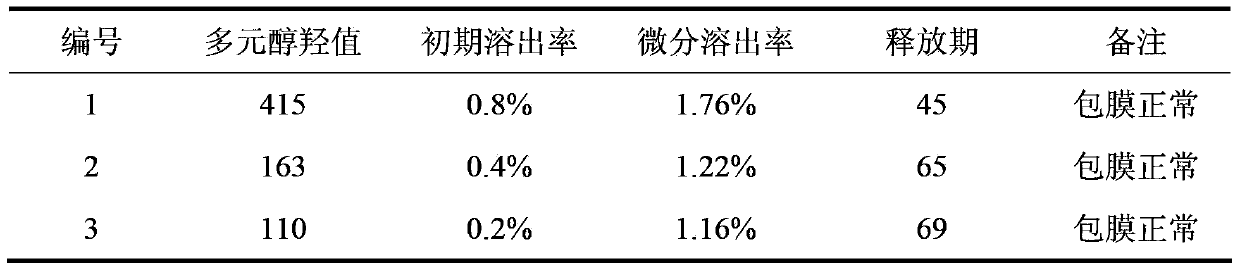

Production method for polyurethane enveloped controlled release fertilizer

The invention relates to a production method for polyurethane enveloped controlled release fertilizer. The production method comprises the following steps: preheating granulated fertilizer in a fluidized bed in a fluidizing state; atomizing liquid paraffin, and pretreating the surface of the granulated fertilizer; mixing polyatomic alcohol and isocyanate in a nozzle, atomizing the mixture fast, and spraying the mixture onto the surface of the granulated fertilizer; controlling material adding speeds to ensure that polyurethane reaction can be fulfilled fast; adding liquid paraffin and carrying out surface anti-sticking treatment after the filling of reaction materials. According to the invention, the fluidized bed is adopted as enveloping equipment, polyatomic alcohol and isocyanate are used for spraying and enveloping after being premixed, and the adding speeds are regulated in a matched manner, so that the whole enveloping reaction process is fast and continuous. The production method can improve the polyurethane enveloping efficiency to a relatively large extent, and ensure relatively stable and reliable quality of the enveloped fertilizer due to continuous reaction.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

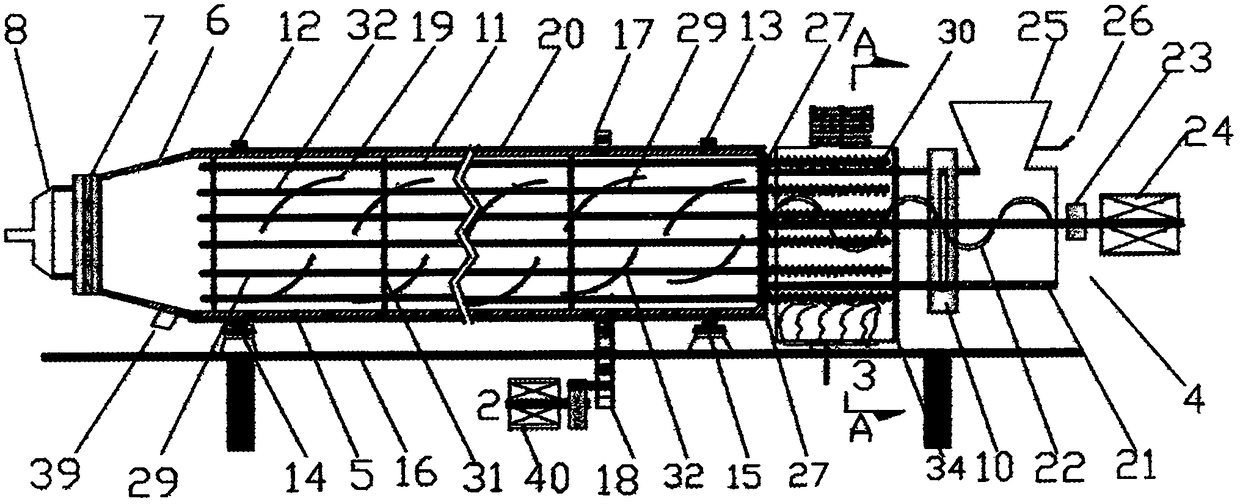

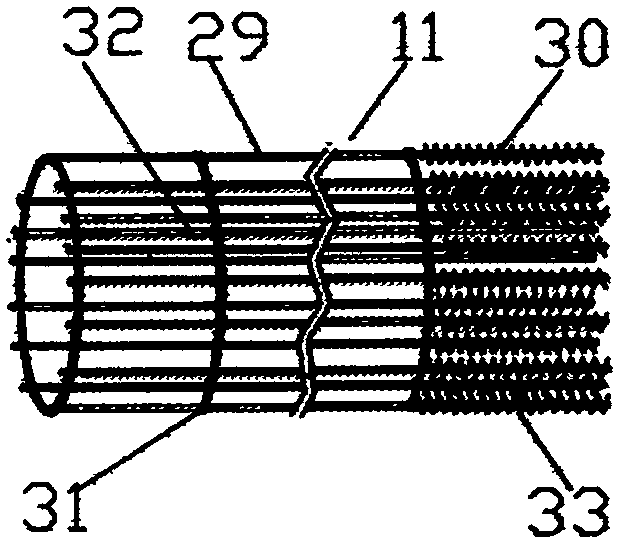

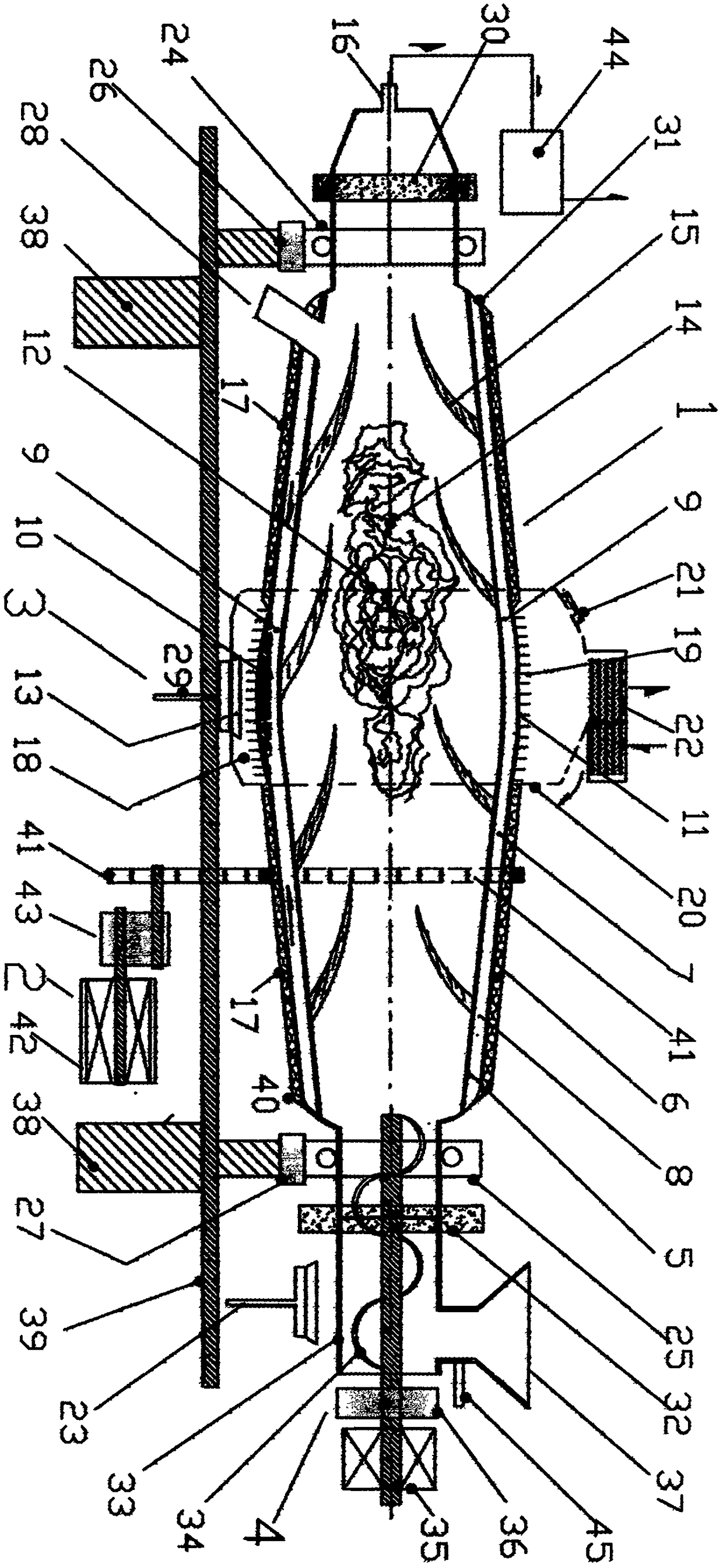

Rotary high-temperature superconducting-tube pyrogasification furnace for garbage

InactiveCN109423339AHigh pyrolysis gasification efficiencyImprove thermal conductivityGasification processes detailsRotary drum/kiln gasifiersFurnace temperatureSocial benefits

The invention relates to a rotary high-temperature superconducting-tube pyrogasification furnace for garbage. The rotary high-temperature superconducting-tube pyrogasification furnace is composed of four parts, i.e., a circular cylinder rotary furnace body, a rotary furnace body driver, a heater and a feeding machine. The rotary high-temperature superconducting-tube pyrogasification furnace is characterized in that the inner wall of the circular cylinder rotary furnace body is filled with metal stirring plates and a high-temperature mouse-cage-type superconducting heat transmitter. The heateruses gas produced by the cracking furnace for heating the superconducting-tube evaporation section of the high-temperature mouse-cage-type superconducting heat transmitter in the exterior of the furnace body, and generated radiant heat can be rapidly transmitted to garbage stirred in the furnace via high-temperature superconducting heat-transmitting pipes, thereby completing rapid, high-efficiencyand continuous pyrogasification of the garbage. The pyrogasification furnace provided by the invention has high temperature and balanced furnace temperature, so the dangers of bonding, bulging, block-forming and coking of the garbage caused by local overheating in the furnace are effectively solved, the generation of flue gas is avoided, pollution of harmful substances released by cracked substances to the environment are shielded, and the generation of dioxin is suppressed; and solid residues produced after cracking can be used as a chemical raw material for manufacturing of active carbon, and social benefits and economic benefits are significantly improved.

Owner:西安美润环保工程技术有限公司 +1

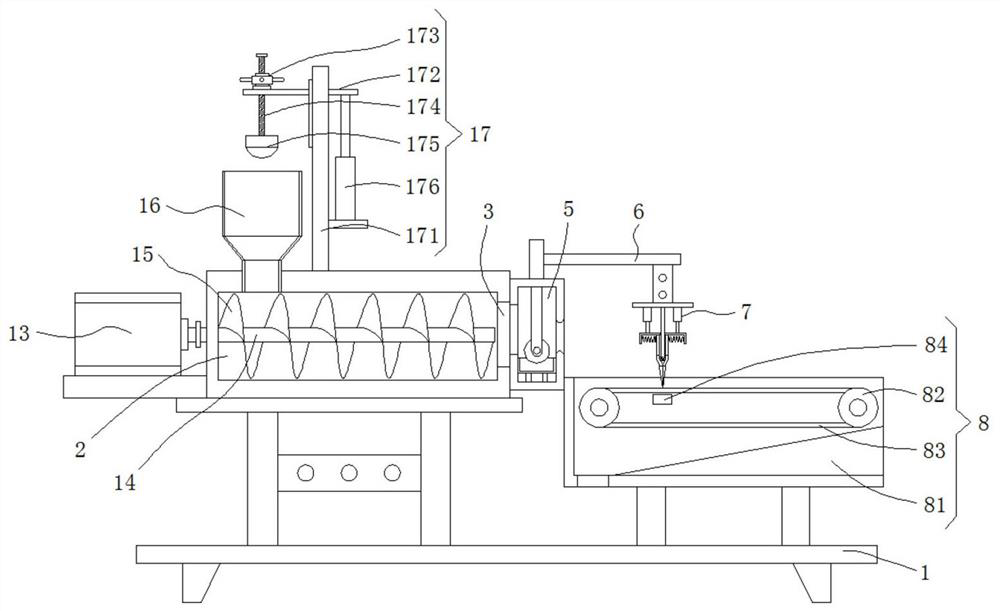

Noodle processing and extruding device with cutting function

InactiveCN112544652AAvoid sticking and knottingAvoid sticking inDough shaping and cutting apparatusDough extruding machinesStructural engineeringMechanical engineering

The present invention provides a noodle processing and extruding device with cutting function. The noodle processing and extruding device comprises a base, wherein one side of a top of the base is fixedly connected with a cavity through a supporting table, an extruding plate is arranged on one side of an interior of the cavity, a through opening is formed in the extruding plate, a movable frame isarranged on one side of the cavity, a supporting frame is fixedly connected to a top of the movable frame, a cutting assembly is fixedly connected to one side of a bottom of the supporting frame, andthe cutting assembly comprises a fixing plate. The device does not require workers to manually cut, improves convenience of operation, saves physical strength, facilitates better subsequent processing, improves cutting effect through arrangement of two cutting blocks, can move cut ends of the noodles to both sides, effectively avoid bonding phenomenon of the cut noodles, and does not require additional components, thereby reducing cost of equipment.

Owner:十堰市益客迅人力资源有限公司

Bipyramid rotary superconducting waste cracking furnace

InactiveCN109424963AConducive to continuous cracking and gasificationLarge capacity reductionIncinerator apparatusActivated carbonFlue gas

The invention discloses a bipyramid rotary superconducting waste cracking furnace which is composed of a bipyramid superconducting isothermal rotary furnace body, a rotary furnace body driver, a heater and a feeding machine. The bipyramid rotary superconducting waste cracking furnace is characterized in that the bipyramid superconducting isothermal rotary furnace body is a bipyramid composite pipeisothermal superconducting rotary furnace body with two small ends and a thick middle composed of a metal inner pipe and a metal outer pipe which are concentric, the thick portion in the furnace bodyis a superconducting working medium heating pool, and a circumferential heating zone provided with heat exchange sheets is arranged on the periphery of the heating pool. The heater heats the furnacebody outside the furnace body through self-produced gas of the waste cracking furnace, produced radiant heat is rapidly and evenly transferred to waste in the rotary furnace through the circumferential heating zone, the heating pool and the bipyramid composite pipe isothermal superconducting rotary furnace body, and therefore the waste is rapidly and efficiently cracked and gasified. By means of the cracking furnace, the risk that bonding, bulging, blocking and coking are caused by local overheating of waste in the furnace is avoided, flue gas is prevented from being produced, pollution of harmful substances released by cracked materials to environment is avoided, dioxin emission is effectively restrained, and environment is protected; and cracked solid waste can be used as activated carbon for preparing chemical raw materials, and the overall economic benefits are obvious.

Owner:西安美润环保工程技术有限公司 +1

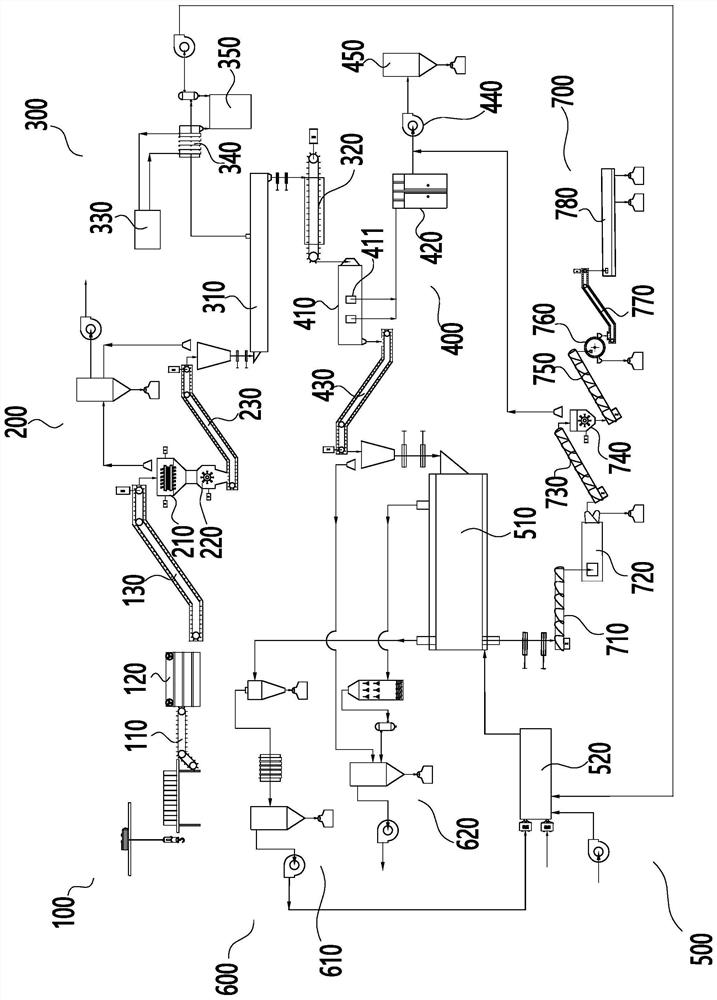

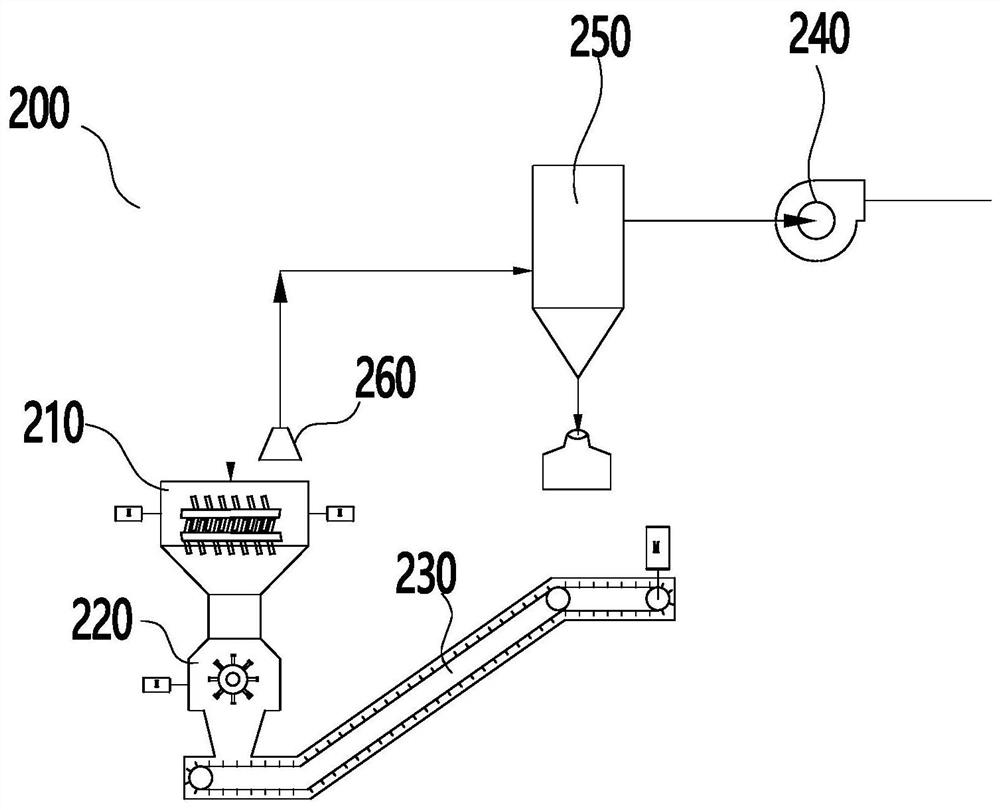

Waste power battery single body full-component recovery system

PendingCN111842410AReduce turnoverAvoid sticking inHuman health protectionCombination devicesElectrolytic agentPower battery

The invention discloses a waste power battery single body full-component recovery system which comprises a single body discharge system, a crushing system, an electrolyte recovery system, a diaphragmrecovery system, a cracking system, a tail gas purification system and a separation system. Electrolyte, diaphragm paper, battery powder and metal materials in batteries can be recovered in a full-component manner. The waste power batteries are subjected to working procedures of discharge, crushing, electrolyte recovery, diaphragm paper recovery, cracking, separation and the like to obtain final products. All the working procedures of the whole system are connected in a head and tail manner, continuous production can be achieved, material circulation is reduced, and labor and consumption costare reduced remarkably. The batteries can be recovered in a full-component manner. The batteries are crushed after being discharged, and the technology is safe and reliable. After diaphragms and the electrolyte in battery crushed materials are removed, then the cracking technology is adopted for treating the battery crushed materials, the cracking reaction is easier, the problem of material bonding caused by diaphragm melting is effectively avoided, and powder of positive and negative anodes of the batteries are separated more thoroughly.

Owner:HUNAN BRUNP RECYCLING TECH +2

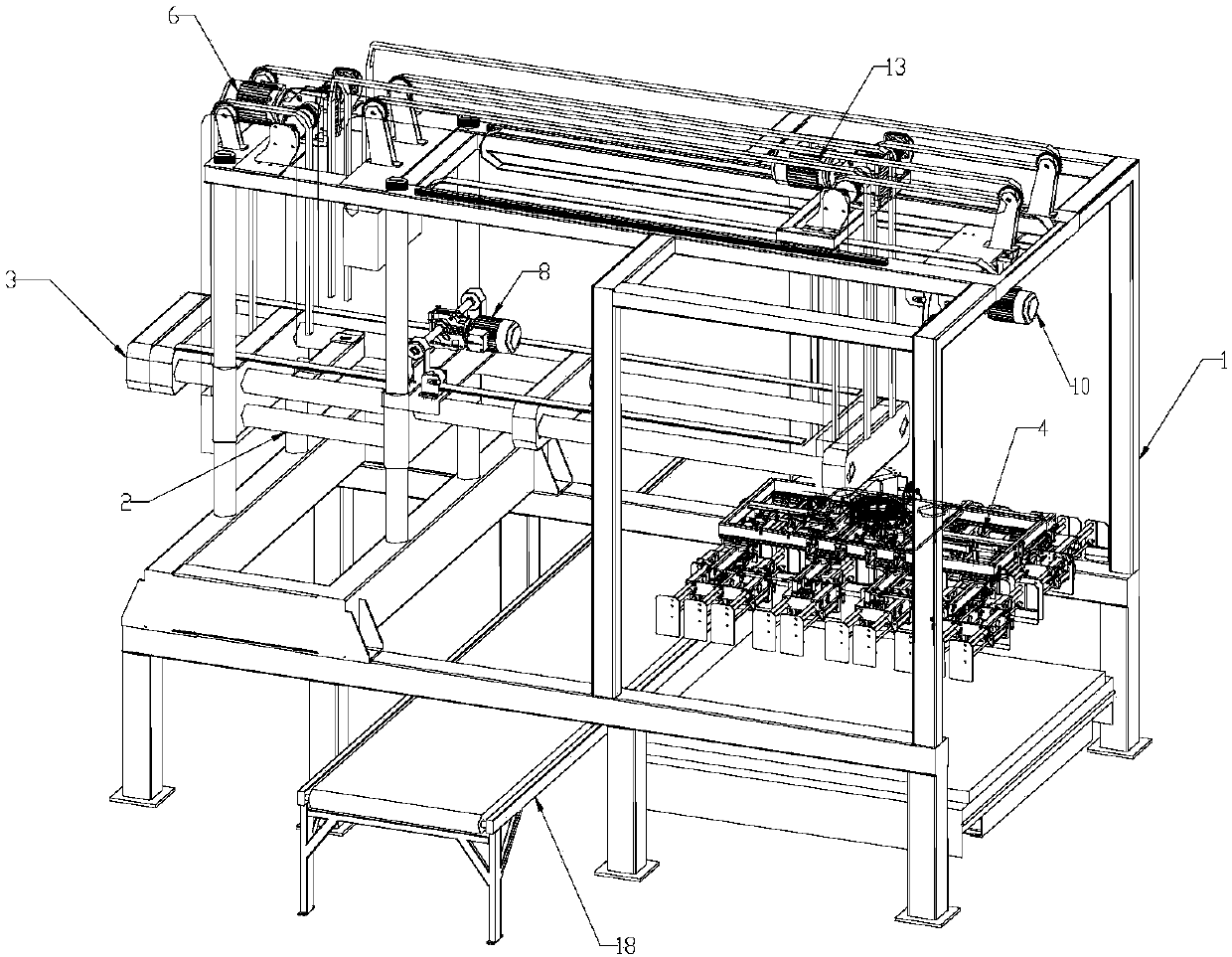

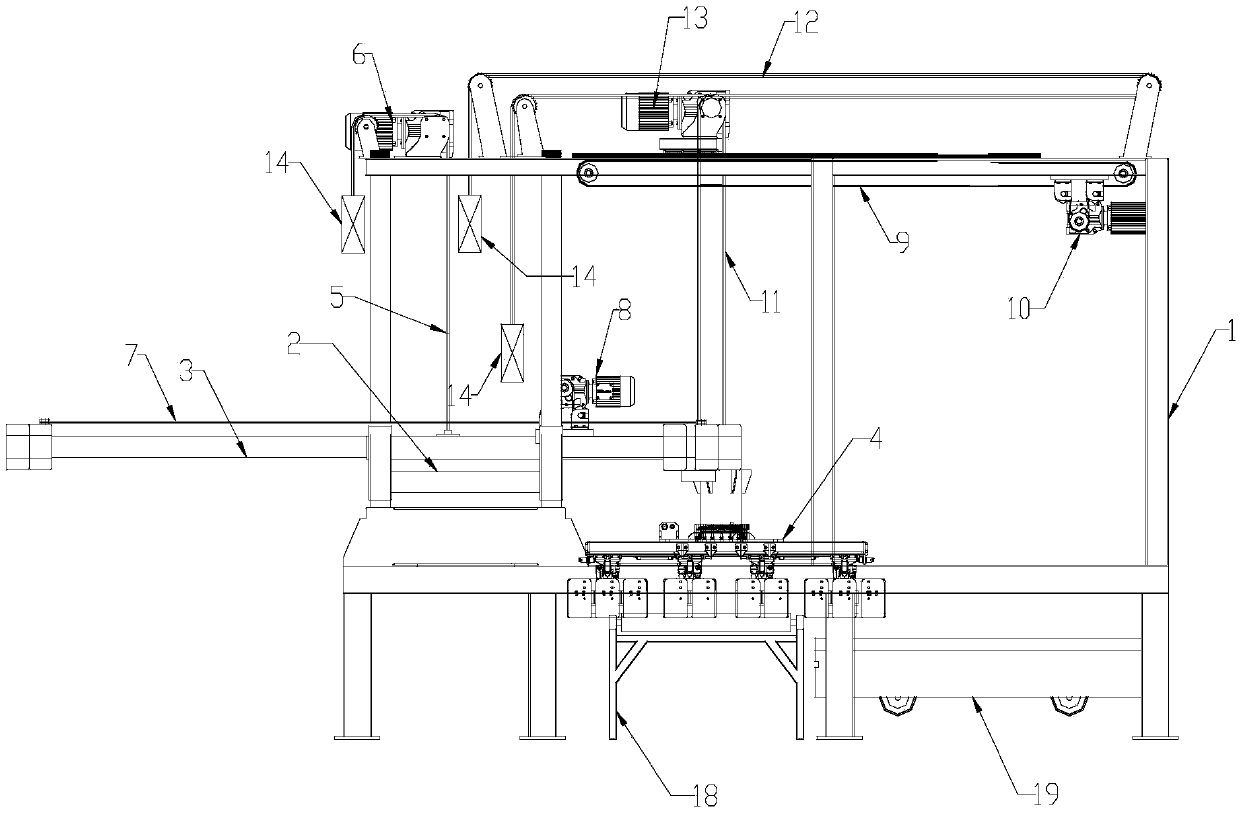

Brick discharging and green brick piling dual-purpose device

PendingCN107640579AIncrease contact surfaceIncrease clamping forceStacking articlesDe-stacking articlesEngineeringDual purpose

The invention discloses a brick discharging and green brick piling dual-purpose device which comprises a framework, a lifting frame, a transverse movable frame, and a brick discharging and green brickpiling chuck. The brick discharging and green brick piling chuck is connected with an end of the transverse movable frame, the transverse movable frame is arranged in the lifting frame, the lifting frame is arranged on a side of the framework and is connected with a lifting motor by a lifting synchronous belt, the lifting motor is arranged on the top of the framework, and a transverse synchronousbelt is arranged on the transverse movable frame and is connected with a transverse movable motor; an auxiliary transverse synchronous belt is arranged on the top of the framework and is connected with a synchronous transverse movable motor, the bottom of a synchronous lifting motor is connected with the auxiliary transverse synchronous belt by connecting sliders, and the synchronous lifting motor is connected with the brick discharging and green brick piling chuck by auxiliary lifting synchronous belts. The brick discharging and green brick piling dual-purpose device has the advantages thatthe brick discharging and green brick piling dual-purpose device has a green brick piling function and an automatic brick discharging function, accordingly, two links with the maximum hand labor amounts in brickyards can be taken into consideration, the labor intensity of workers can be relieved to a great extent, and the production efficiency can be improved.

Owner:ZIYANG JINGGONG MECHANICS

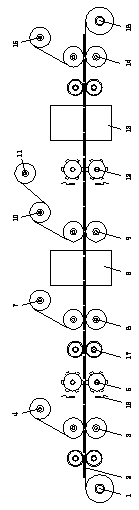

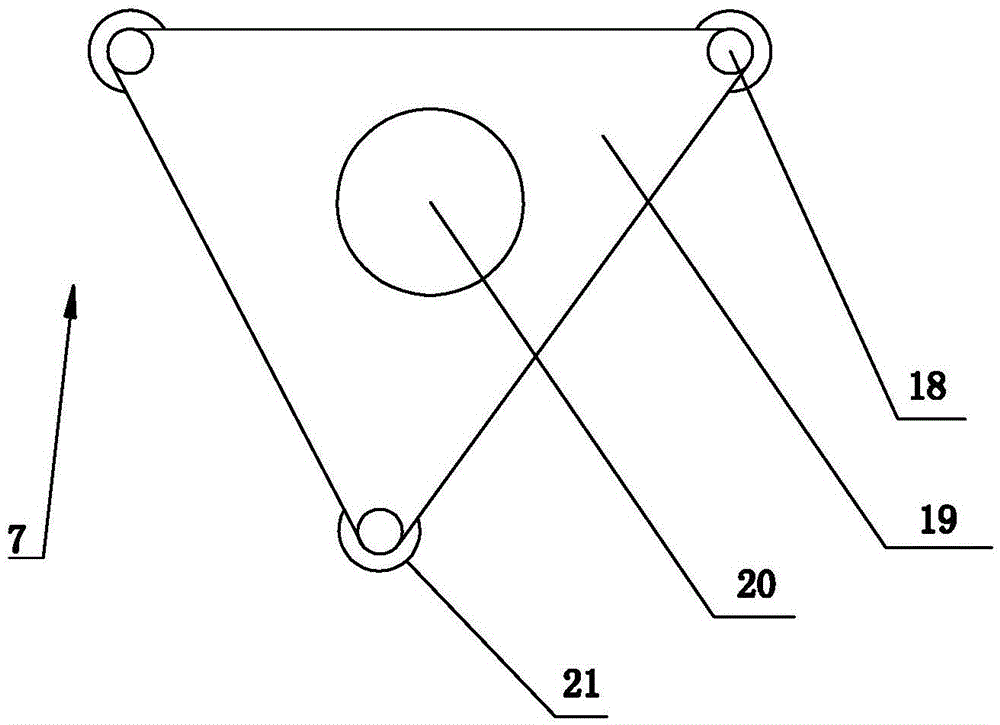

Manual graphene film asynchronous die cutting device

InactiveCN109366612AChange spacingSave human effortLamination ancillary operationsControlling laminationEngineeringGraphene

The invention discloses a manual graphene film asynchronous die cutting device which comprises a pay-off roller and a take-up roller. First doubling rollers distributed in pairs are arranged on the right side of the pay-off roller, a PET film pay-off roller is arranged above the first doubling rollers, the right sides of the first doubling rollers are provided with first die cutting hobs distributed in pairs, the right sides of the first die cutting hobs are provided with second doubling rollers distributed in pairs, a double faced adhesive tape pay-of roller is arranged above the second doubling rollers, a first asynchronous stripping mechanism is arranged on the right sides of the second doubling rollers, and the right side of the first asynchronous stripping mechanism is provided with third doubling rollers distributed in pairs. On the basis of existing technology, a guide transmission mechanism and the stripping mechanism which are convenient to adjust are arranged, the device canadapt to products with different specifications, is good in adaptability and easy to adjust, materials are labor are saved, and the production efficiency is improved.

Owner:SUZHOU KANRONICS ELECTRONICS TECH CO LTD

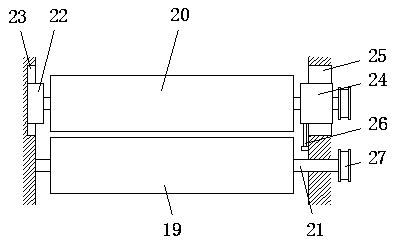

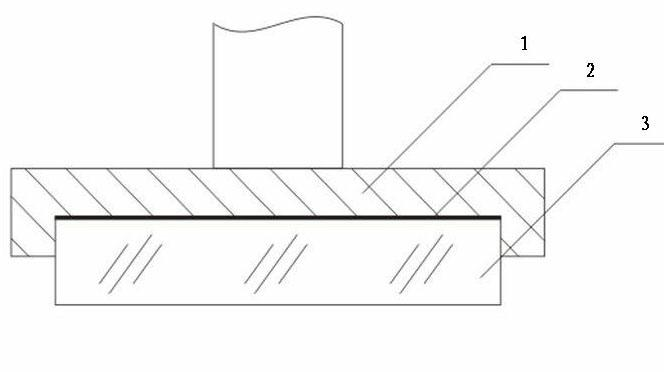

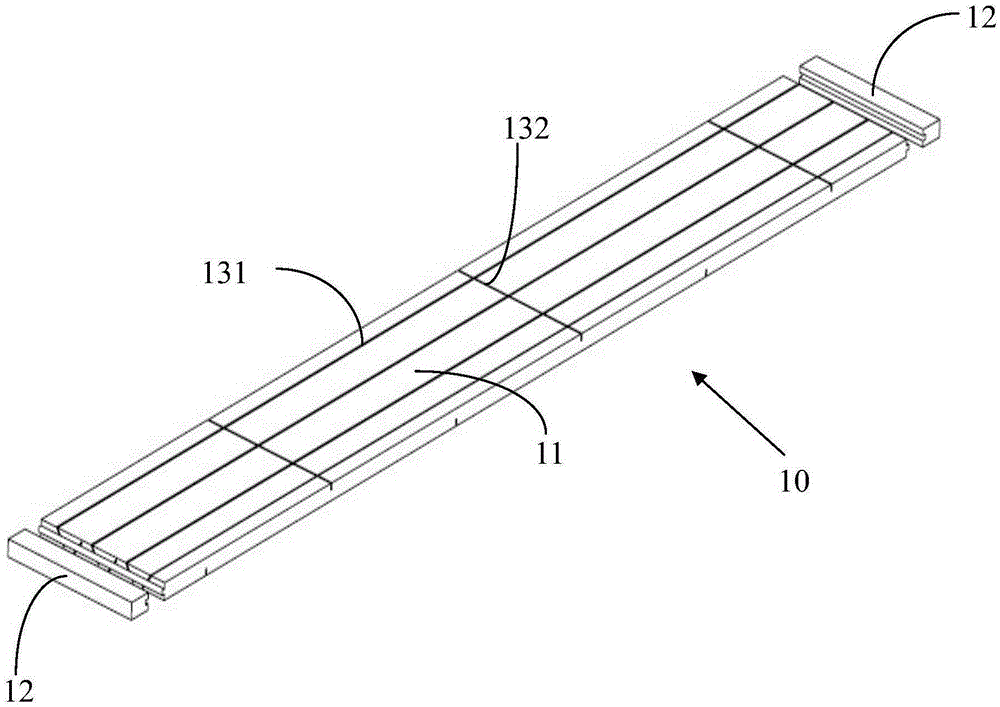

Machine and method for grinding and polishing ultra-long and ultra-thin quartz plate

InactiveCN102554764AGuaranteed smoothTo achieve the purpose of grindingLapping machinesWork carriersEngineeringMaterials science

The invention discloses a machine for grinding and polishing an ultra-long and ultra-thin quartz plate, which comprises a grinding disc. A cover die is arranged above the grinding disc; a workpiece placing slot is arranged on the cover die; the bottom of the workpiece placing slot is provided with a gasket; the cover die is fixedly connected on a translational shaft by a connecting rod; the translational shaft is connected with a guide rail which moves back and forth through a sliding block; and the translational shaft and the guide rail are connected with a motor respectively through a transmitting mechanism. The invention further discloses a process for grinding and polishing the ultra-long and ultra-thin quartz plate. The machine is suitable for grinding the ultra-long and ultra-thin quartz plate, is convenient to use, has a more reasonable structure, strong applicability and high use efficiency and can guarantee the quality and the rate of finished products effectively. The process for grinding and polishing the ultra-long and ultra-thin quartz plate is easy to operate and can guarantee the rate of finished products and the production efficiency.

Owner:蔡桂芳

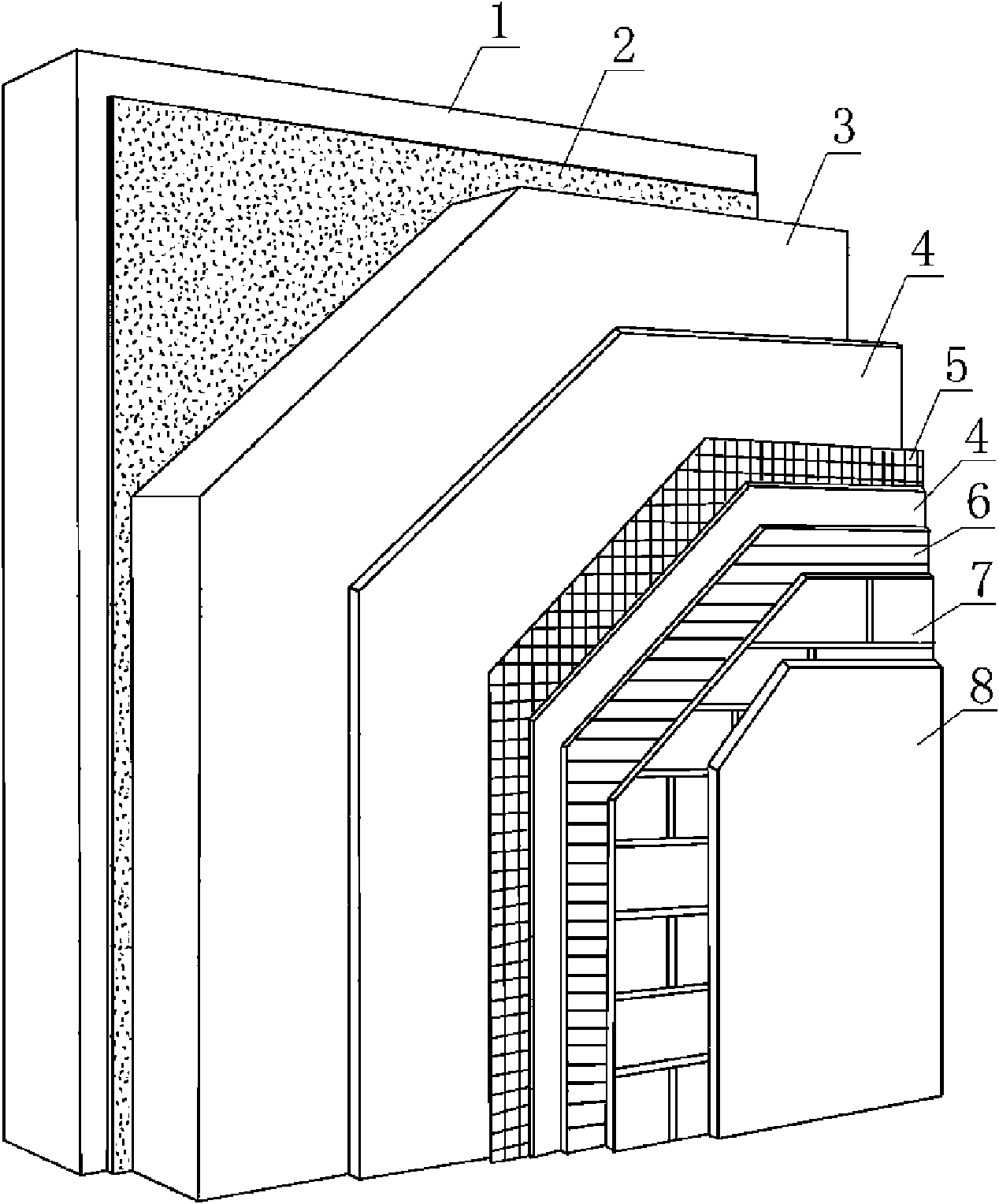

Heat preserving and water proof decoration system outside the external wall and construction method thereof

InactiveCN101550730AGood wall decorationSolve the problem of water seepageCovering/liningsBuilding insulationsFiberUltraviolet

A heat preserving and water proof decoration system outside the external wall and its construction method, which is characterized in that the external side of wall permanently connects with bonding mortar bed, heat-insulating layer and anti-crack mortar bed in sequence, and the external side of the anti-crack mortar bed permanently connects with alkali-resistant waterproof layer, facing mortar bed and anti-soil waterproof layer in sequence, wherein there clips fabric grid reinforcement in the anti-crack mortar bed. The system can discretionarily deploy colors and patterns through facing mortar bed and the decoration effect of wall surface is good. The alkali-resistant waterproof layer and the outermost anti-soil waterproof layer form two waterproof layers, which accounts for the water penetration problem by the water pervading into the cement space of anti-crack mortar bed, can prevent the anti-crack mortar bed from cement alkalizing and prevent desquamation between layer and layer. The anti-soil waterproof layer can keep the appearance of the facing layer by preventing the dust falling onto the surface of facing mortar bed, and has the function of ultraviolet resistance.

Owner:北京立高科技股份有限公司

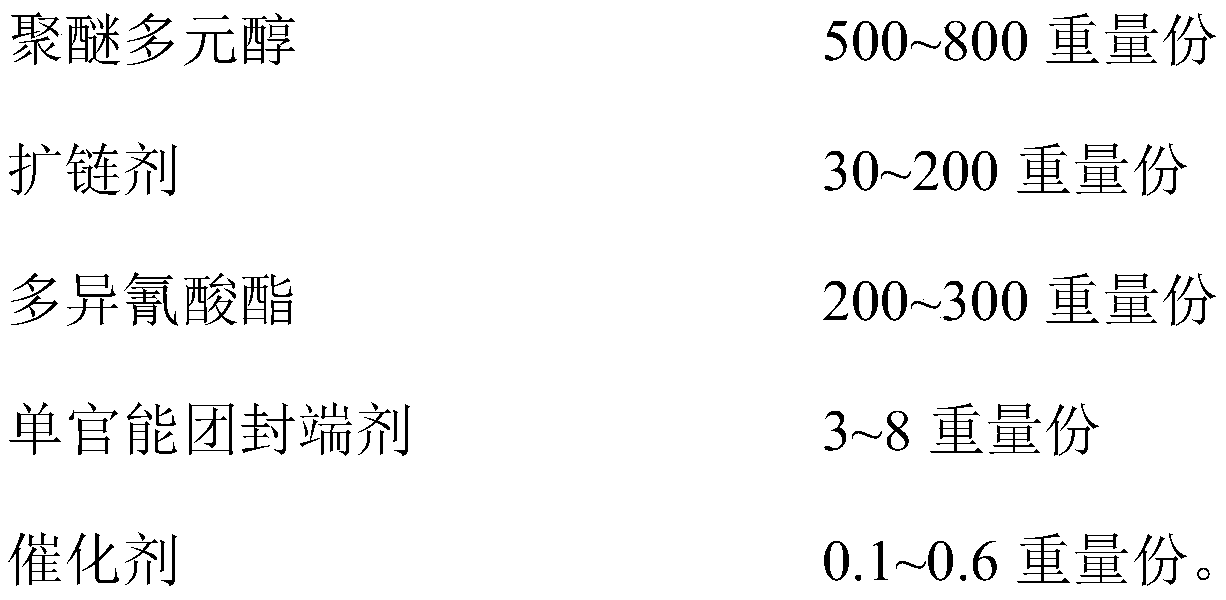

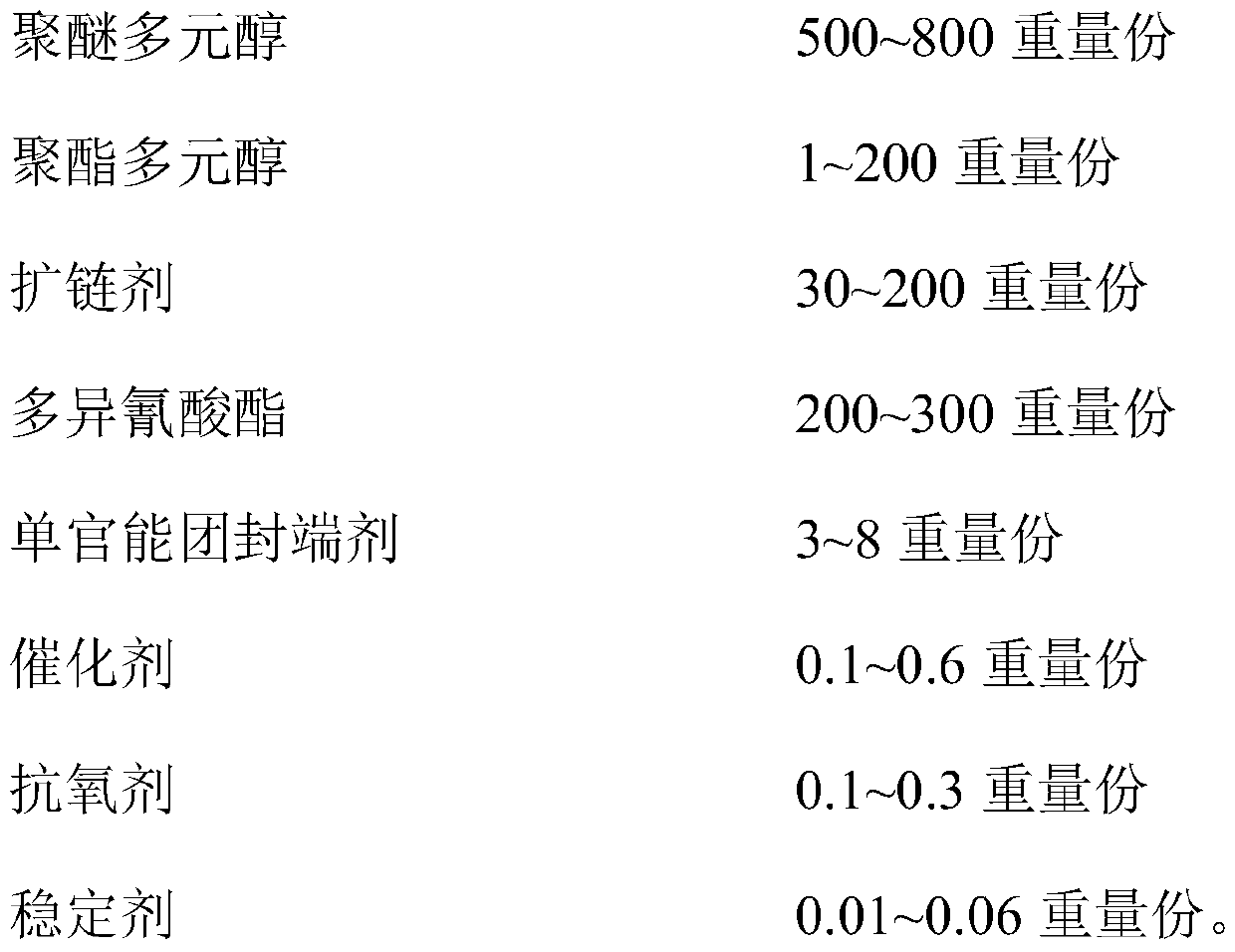

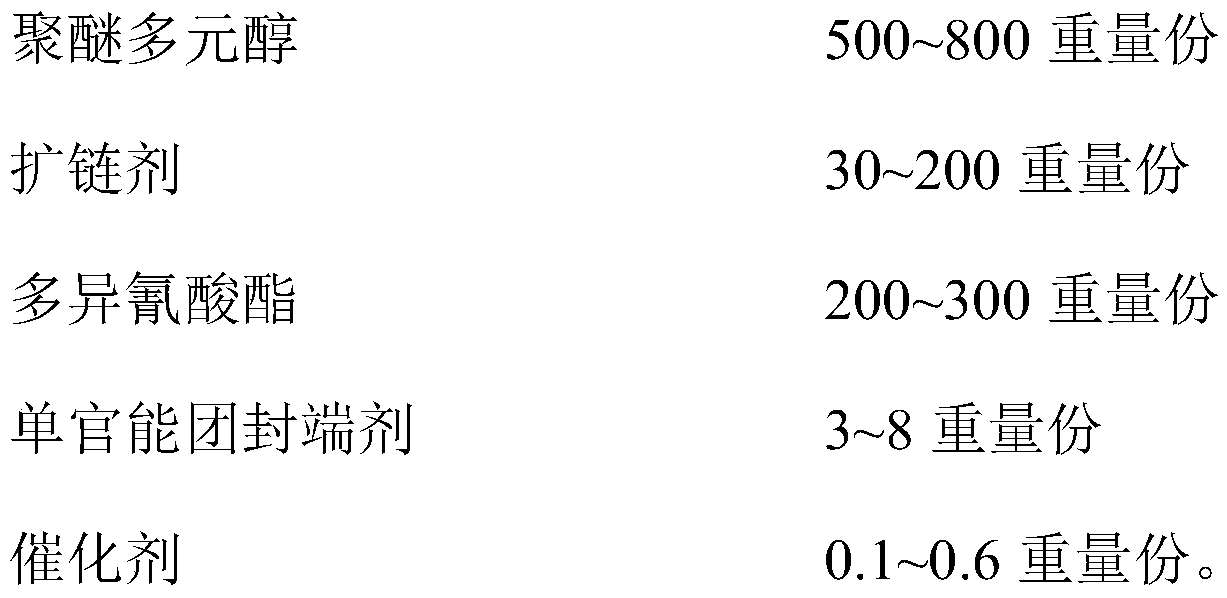

Moisture-curable polyurethane hot melt adhesive as well as preparation method and application thereof

ActiveCN110964475ASuitable viscosityAppropriate strengthPolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention provides a moisture-curable polyurethane hot melt adhesive as well as a preparation method and application thereof. The moisture-curable polyurethane hot melt adhesive is prepared from the following raw material components in parts by weight: 500 to 800 parts by weight of polyether polyol, 30 to 200 parts by weight of a chain extender, 200 to 300 parts by weight of polyisocyanate, 3to 8 parts by weight of a monofunctional end-capping reagent and 0.1 to 0.6 part by weight of a catalyst, the monofunctional end-capping reagent can block part of NCO groups in a system, so that the hot melt adhesive still keeps certain viscosity after being cured and converted into a solid state, and can be stably bonded with nylon taffeta, thereby avoiding infirm bonding caused by volume changein the curing process of a polyurethane system and improving the curing effect of the polyurethane system. The bonding strength and the bonding stability are obviously improved. The moisture-curable polyurethane hot melt adhesive has proper viscosity and initial bonding strength and relatively high final bonding strength and bonding stability, and can fully meet the requirement for compounding nylon taffeta fabrics.

Owner:SHANGHAI HUIDE TECH CO LTD

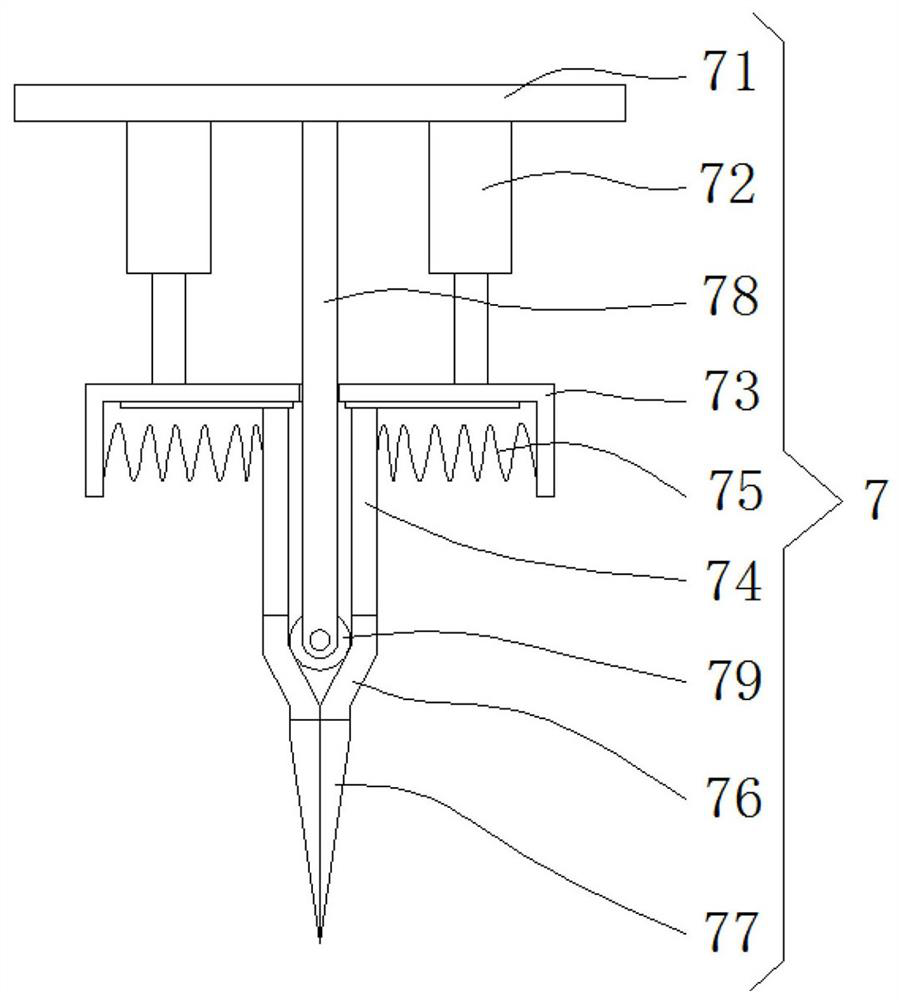

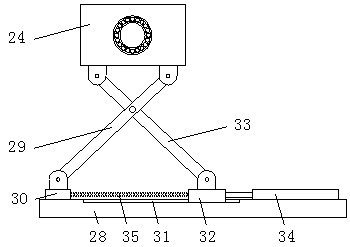

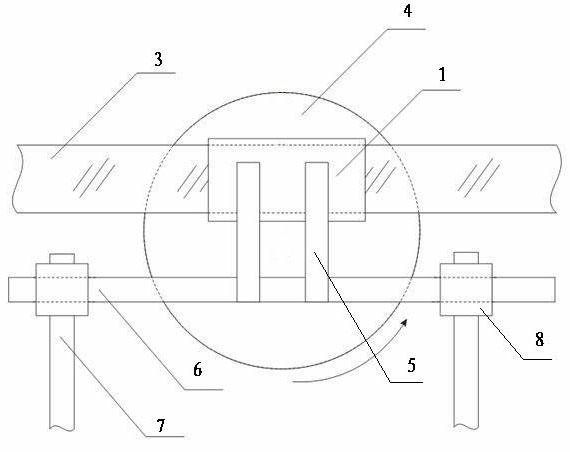

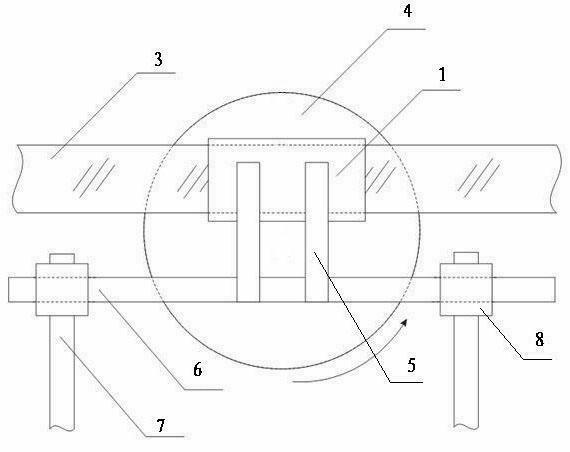

Jointing coal rock direct tensile test device and jointing coal rock direct tensile test method

ActiveCN104111197AAvoid Coal Sample DamageAvoid stress concentrationPreparing sample for investigationMaterial strength using tensile/compressive forcesCoalEnvironmental geology

The invention relates to a jointing coal rock direct tensile test device and a jointing coal rock direct tensile test method. The jointing coal rock direct tensile test device comprises clamping body taper sleeves, a spherical joint and a tensile testing machine, wherein both ends of a coal sample are respectively tightly sleeved by the clamping body taper sleeves, each clamping body taper sleeve is connected with the corresponding spherical joint, and the spherical joint is connected with the tensile testing machine; each clamping body taper sleeve is formed by sleeving a taper sleeve out of an annular wedge-shaped sleeve, and the annular wedge-shaped sleeve comprises twelve clamping bodies, spring joints and rubber gaskets; the adjacent clamping bodies are sequentially connected end to end through the spring joints to form the annular wedge-shaped sleeve, the outer surfaces of the clamping bodies are in arc shapes, the longitudinal sections of the clamping bodies are in trapezoidal shapes, and the inner surfaces of the clamping bodies are provided with the rubber gaskets; one ends of the spring joints are provided with connecting plates, and the other ends of the spring joints are provided with connecting columns; the top ends of the connecting columns are provided with axial center grooves, and two side walls of the center grooves are provided with pin holes; the spring joints are fixedly connected with the tensile testing machine through the center grooves. The jointing coal rock direct tensile test device disclosed by the invention can effectively prevent the coal sample from being damaged due to excessive pressure of a clamp on the coal sample and reduces the influence of stress concentration on a test result.

Owner:平湖市精艺机械制造厂

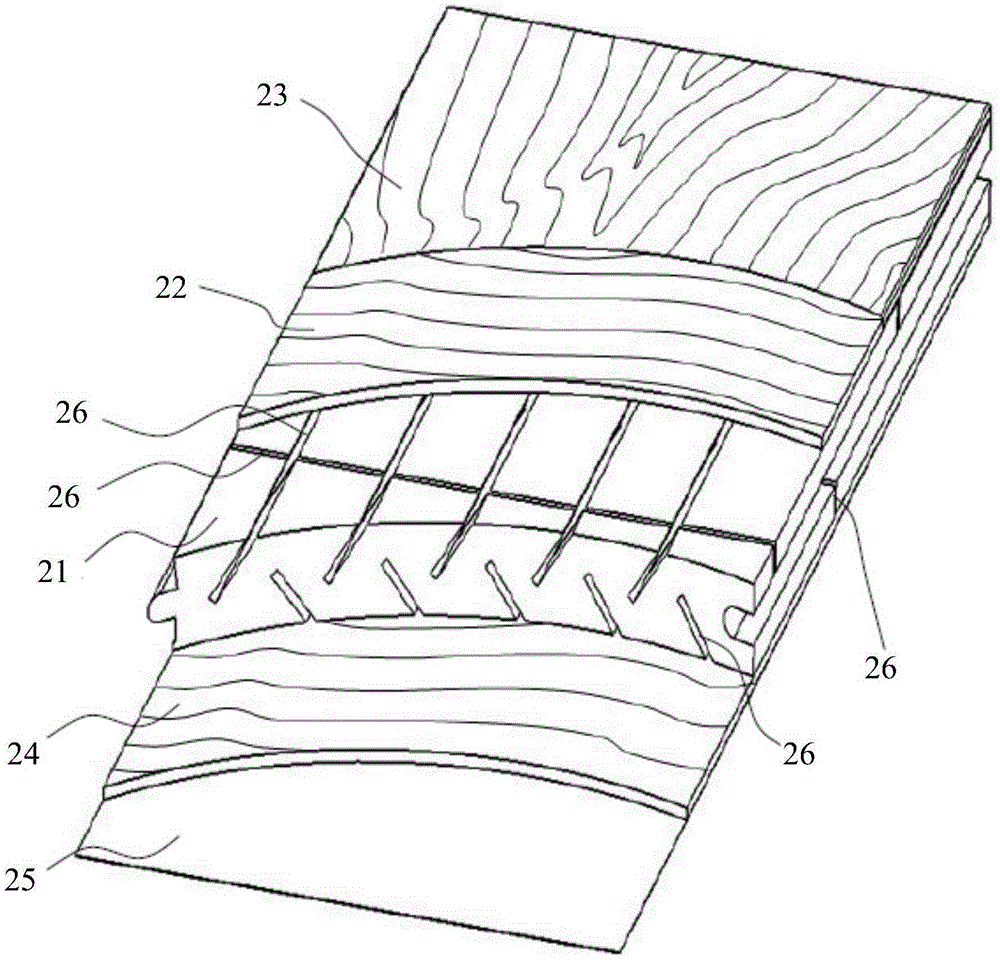

Groove-type cross-band veneer, and sheet material prepared from groove-type cross-band veneer

InactiveCN105252834AImprove protectionAccelerate evaporationWood layered productsFiberInternal stress

The invention discloses a groove-type cross-band veneer, and a sheet material prepared from the groove-type cross-band veneer. The groove-type cross-band veneer comprises a cross-band veneer main body, wherein the surface of the cross-band veneer main body is provided with grooves; and connecting edgings arranged on the end surfaces of the cross-band veneer main body; the connecting edgings are also provided with splicing structures used for splicing with adjacent groove-type cross-band veneers. According to a preparation method, the surface of the cross-band veneer main body is provided with the grooves so as to cut connection of surface fiber of the cross-band veneer main body, reduce superposition of buckling deformation of the surface of the cross-band veneer main body, and help to release internal stress of the cross-band veneer main body; the end surface of the cross-band veneer main body are provided with the connecting edgings, the connecting edgings are provided with the splicing structures used for splicing via cutting, and connection of the cross-band veneer main bodies is realized via the connecting edgings, so that cutting of the end surfaces of the cross-band veneer main body is avoided, and the end surfaces of the cross-band veneer main body is protected from being damaged.

Owner:张家铭 +1

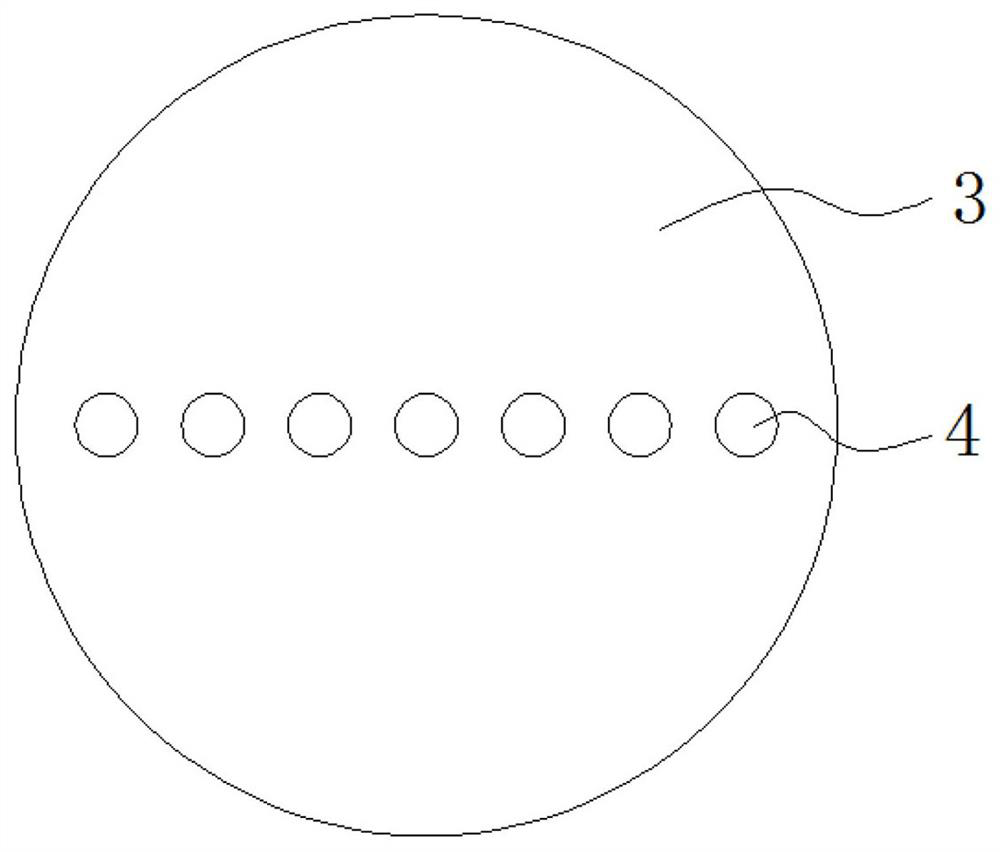

Punching mechanism for honeycomb paper core automatic production line

The invention relates to a perforating mechanism for automotic production line of honeycomb paper core, which comprises a frame, an upper compression roller and a lower compression roller; the upper and lower compression rollers can be arranged on the frame in a rotary way and a paper feeding channel is arranged between the upper compression roller and the lower compression roller; roll needles are densely distributed on the roller surface of the lower compression roller. Due to the perforating mechanism arranged on the automotive production line of the honeycomb core, air holes are uniformly distributed on the surface of each single piece of paper at the same time of compound forming of the honeycomb paper core; when the two-time hot pressing is carried out, the air with heat-moisture can be discharged from various air holes so as to effectively prevent defects of the foaming and unfirm bonding on the surface of the honeycomb paper core and ensure the quality of the finished product. In addition, the tension of the paper can be caused to be eliminated when the honeycomb paper core is stretched by arranging the air holes on the paper core, so as to ensure that the processed paper board is smoother.

Owner:HONICEL HONEYCOMB MATERIAL HLDG LTD

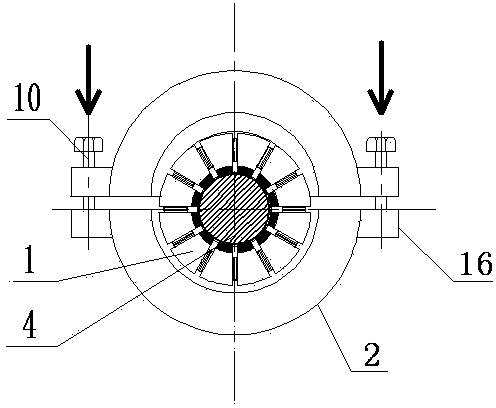

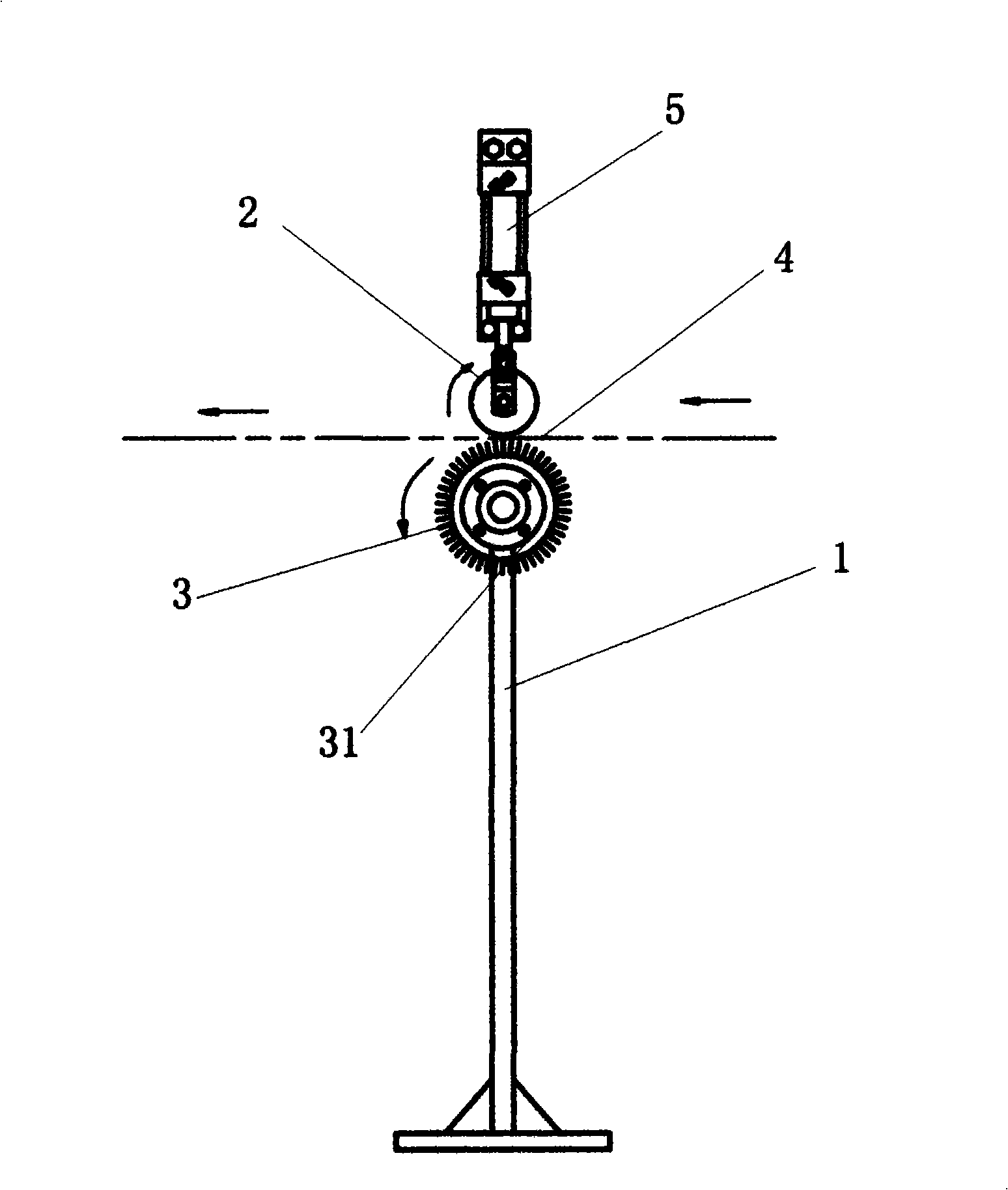

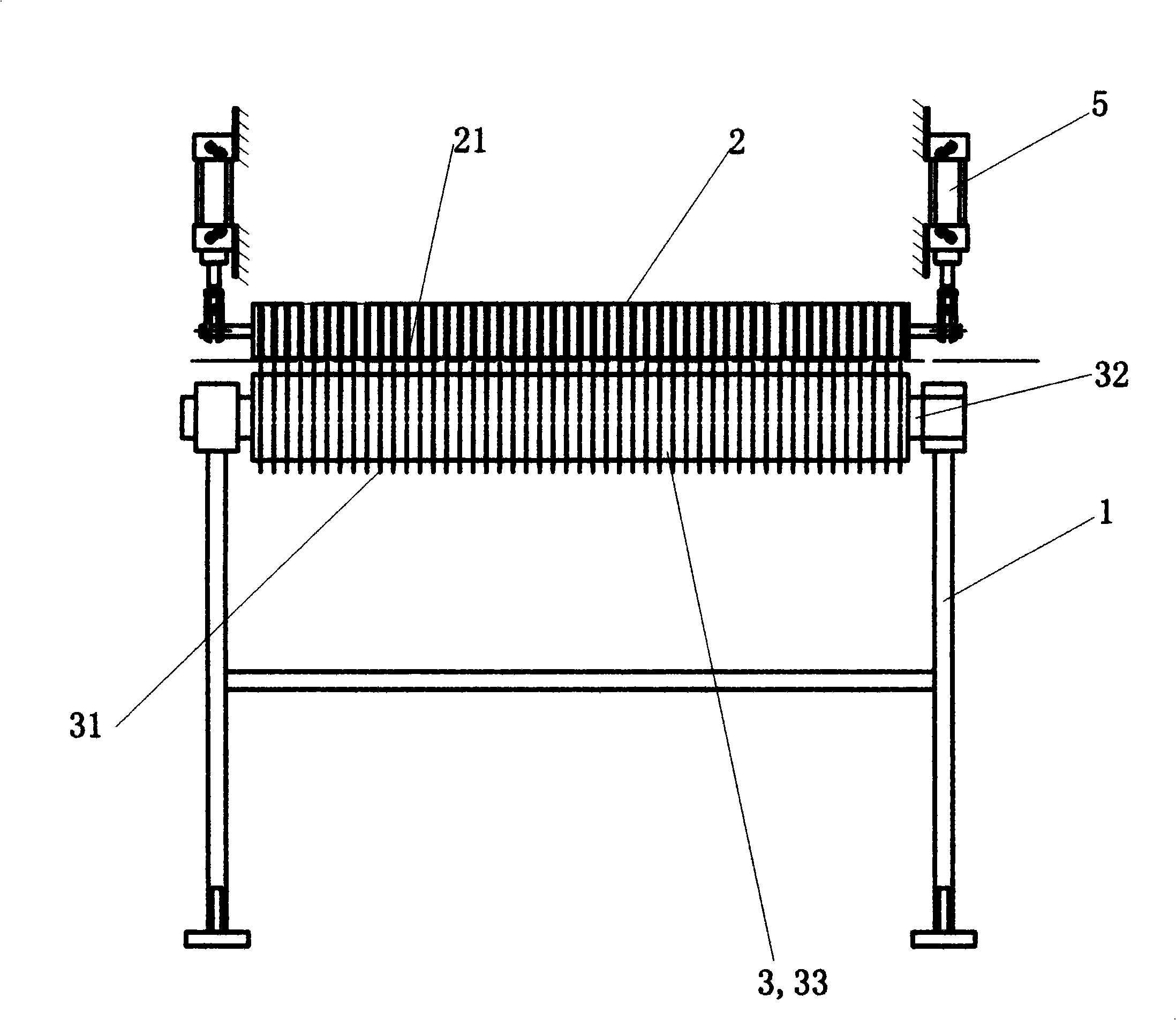

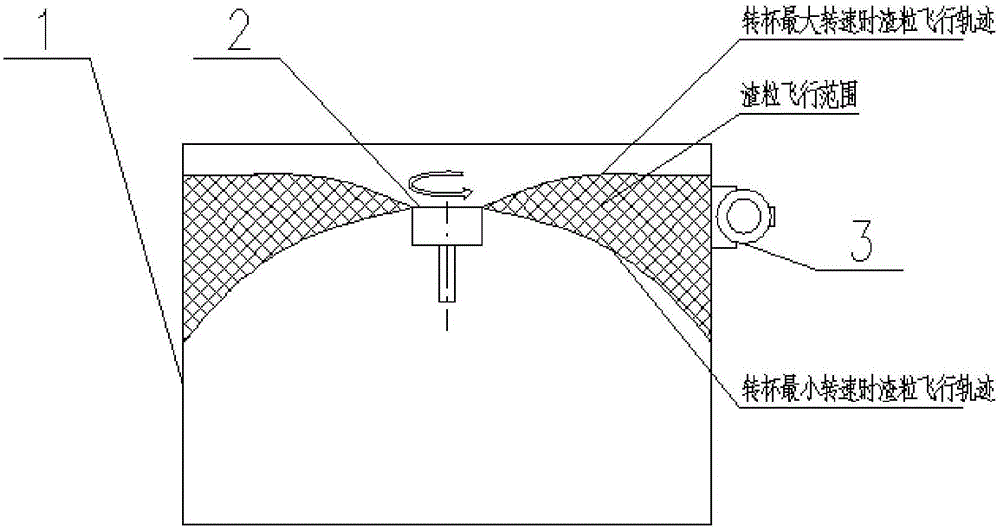

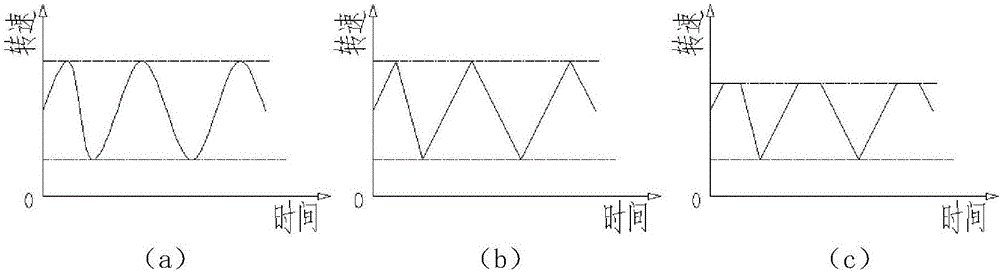

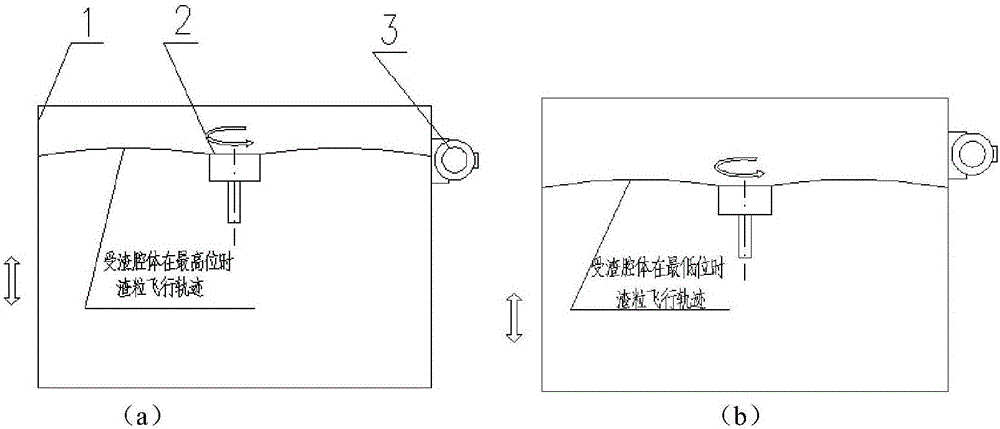

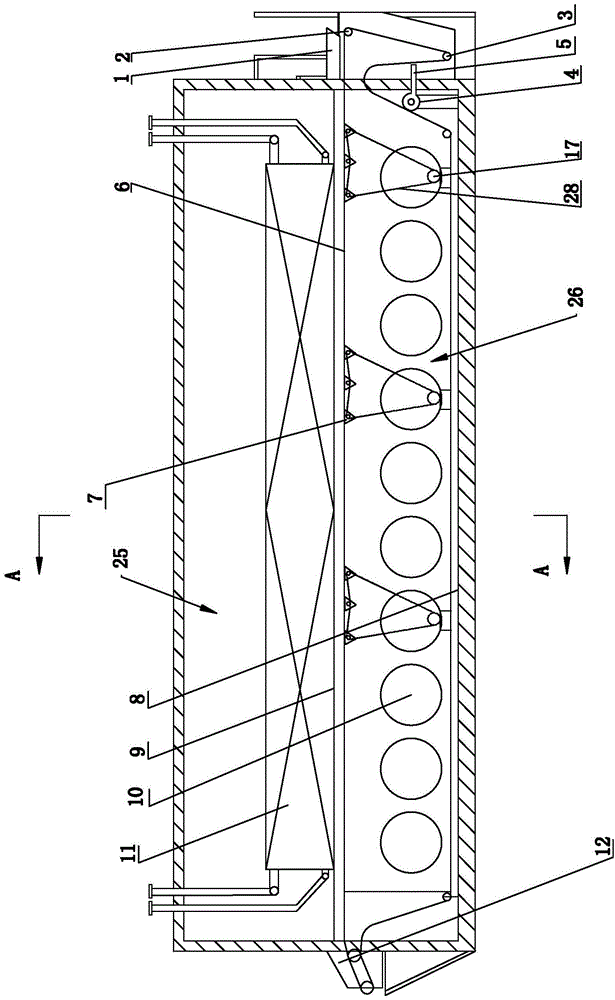

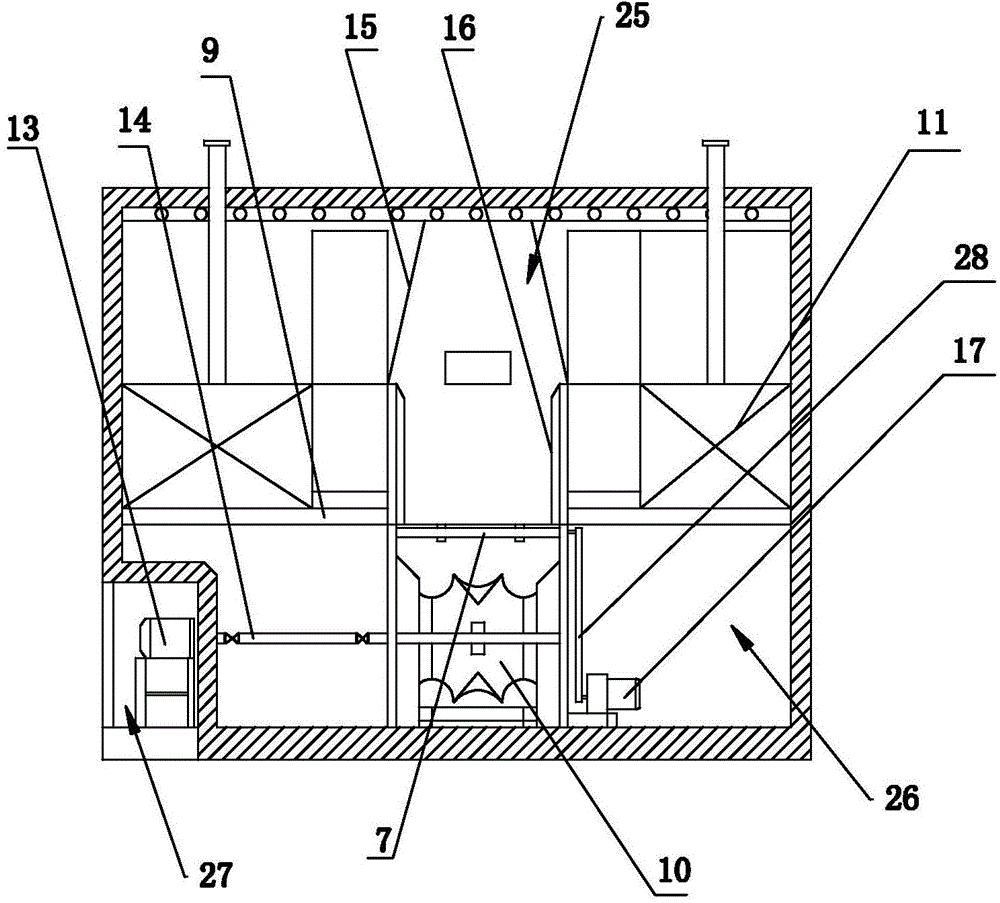

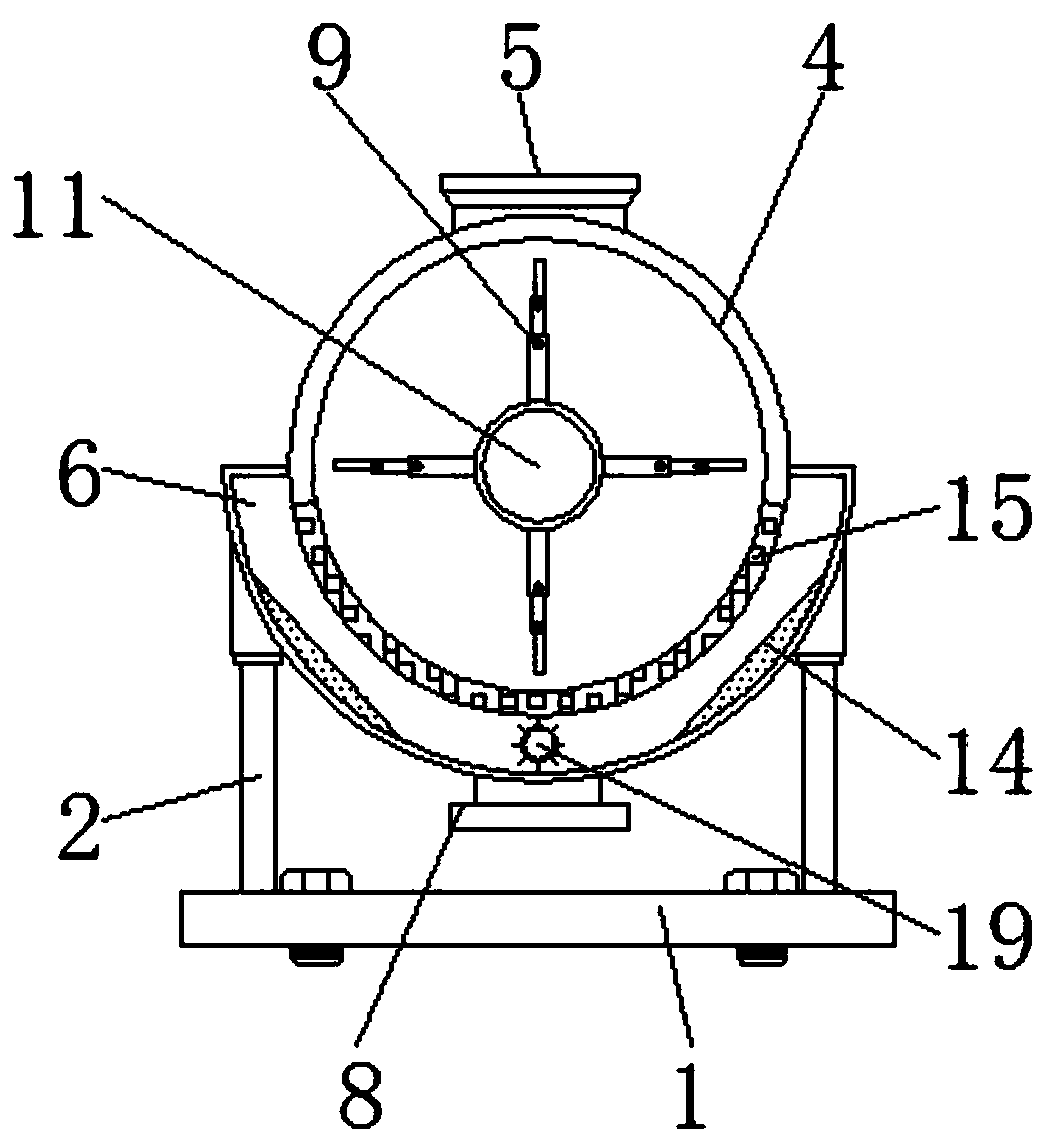

Method and system for improving performance of metallurgical slag dry-process pelletizing device

ActiveCN106191348AAvoid stickingAvoid clumpingRecycling and recovery technologiesElectricityMetallurgical slag

The invention discloses a method and a system for improving the performance of a metallurgical slag dry-process pelletizing device and belongs to the technical field of metallurgy energy saving. The pelletizing device comprises a slag collecting cavity vertically arranged and a rotating cup located in the center in a hollow cavity of the slag collecting cavity. According to the method, slag pelletization is carried out by utilizing the periodical variation of the rotating speed of the rotating cup and / or the vertical height of the slag collecting cavity with time. The system comprises the pelletizing device, a variable-frequency motor, an electric-hydraulic push rod and a controller, wherein the variable-frequency motor is fixedly connected with the rotating cup through a vertical rotating shaft, the electric-hydraulic push rod is fixedly connected with the slag collecting cavity, and the controller and the variable-frequency motor are electrically connected with the electric-hydraulic push rod. When slag pelletization is carried out, the positions that pelletized slag particles hit the wall surface of the slag collecting cavity periodically vary, so that bonding or hardening caused by the concentrated hitting of the slag particles on the wall surface is effectively avoided.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD

Freezer

ActiveCN103791671BReduce loadTake advantage ofLighting and heating apparatusStationary refrigeration devicesCold airQuick Freeze

The invention discloses an instant freezer and belongs to the technical field of instant freezing equipment. The instant freezer comprises a freezer body, a freezing chamber and an air supply chamber provided with a cold air blowing device are arranged in the freezer body, a conveying belt is arranged in the position corresponding to the cold air blowing device around the air supply chamber, and a power chamber used for installation of a first power device is arranged outside the freezer body. The two ends of the conveying belt extend out of the inlet end and the outlet end of the freezer body, and a normal temperature heating device which is communicated with the power chamber and used for heating the conveying belt is arranged at the inlet end of the freezer body. Heat in the power chamber acts on the conveying belt through the normal temperature heating device, so that the temperature of the body of the conveying belt is raised, the function of the cold air blowing device is utilized in an auxiliary mode, fluidized instant freezing is achieved, the problem of adhering between goods and adhering between the goods and the conveying belt is avoided, the single rate of the goods and normal conveying of the conveying belt are guaranteed, and the production efficiency and the product quality are improved. Meanwhile, the first power device is externally arranged, the refrigerating capacity is fully utilized, the load of the freezer is reduced, and the purpose of energy conservation is achieved.

Owner:绿特国创(潍坊)节能科技有限公司

Pouring equipment for brake drum in brake

InactiveCN108405839AStir wellAvoid sticking inMolten metal supplying equipmentsEngineeringElectromagnetic valve

The invention discloses pouring equipment for a brake drum in a brake. The pouring equipment for the brake drum comprises a fixing frame and a stirring shell. The right side of the upper portion of the fixing frame is fixedly provided with a stirring shell. The left side of the upper portion of the stirring shell is provided with a feed port. The middle of the interior of the stirring shell is provided with a stirring shaft. The upper end of the stirring shaft penetrates the stirring shell to be provided with a driven wheel. The driven wheel is rotationally connected with a first drive device,and the first drive device is located on the right side of the top end of the stirring shell. The inner wall of the stirring shell is fixedly provided with a heating panel. The lower portion of the stirring shell is provided with a discharge port. The discharge port penetrates the fixing frame to be provided with an electromagnetic valve. The left side of the upper portion of the fixing frame isprovided with an air cooling device. The middle of the interior of the fixing frame is provided with a conveyor belt. The upper portion of the conveyor belt is provided with a die box in a sliding manner. A weight sensor is arranged below the die box. The pouring equipment is simple in structure, high in practicality, good in pouring effect, high in production efficiency and beneficial to large-scale production for an enterprise.

Owner:广德盛源电器有限公司

Dumpling boiling machine

The invention relates to the technical field of dumpling cooking devices, and relates to a dumpling boiling machine. The dumpling boiling machine comprises a pot body and a helical blade, wherein a mounting cavity is defined between the inner side and the outer side of the pot body; a driving device capable of driving the helical blade to rotate is fixedly mounted in the mounting cavity; the upper part of a rotating shaft of the driving device is placed on the inner side of the pot body; the lower part of the rotating shaft of the driving device is mounted in the mounting cavity in a sealing manner; the helical blade is fixedly mounted at the upper part of the rotating shaft; a pot cover is mounted at the upper end of the pot body. The dumpling boiling machine is reasonable and compact in structure, and convenient to use; during a process of boiling dumplings, the helical blade and the driving device can avoid the phenomenon that the dumplings in the pot are spliced and stuck on the pot, and avoid damage to the dumplings by stirring; stirring the dumplings in the boiling pot by manual power is not needed; heat injury of hands by steam during the dumpling stirring process is prevented effectively; a dapping device can avoid direct contact of hands and steam; heat injury of hands by steam during a dapping process is prevented effectively.

Owner:马宏江

Cooling device used for wine brewing

InactiveCN108913412AAvoid bondingAvoid repeated hitsAlcoholic beverage preparationControl engineeringChain conveyor

The invention relates to the technical field of wine brewing, and discloses a cooling device used for wine brewing. The cooling device comprises a cooling tank and a pushing mechanism used for controlling the cooling tank to rotate, wherein the cooling tank is connected with a cooling mechanism, the pushing mechanism comprises a fixed eccentric gear which is rotatably arranged, lead screws are rotatably arranged on the outer side of the fixed eccentric gear, each lead screw is sleeved with a sliding sleeve, a rack is fixedly connected to the sliding sleeves, annular sliding rails are arrangedon the rack, the cooling tank is fixedly connected with telescopic support rods, the support rods are connected in the sliding rails in a sliding manner, shaft rods are fixedly arranged on the coolingtank, the shaft rods are rotatably connected to the circle center parts of the sliding rails, and torsional springs are connected between the shaft rods and the rack; and a movable eccentric gear meshed with the fixed eccentric gear is further rotatably arranged on the rack, one end of each lead screw is fixedly provided with a reel, a steel wire rope winds each reel, a spool is fixedly arrangedon the cooling tank, and one end, far away from each reel, of the corresponding steel wire rope is fixed to the spool. With the cooling device used for wine brewing, the problem that the cooling of the existing chain conveyer for rice is nonuniform and insufficient is solved.

Owner:遵义市永胜金属设备有限公司

Crushing and mixing system for production of mixed feed additives

PendingCN108435367AUniform powderAvoid sticking inFeeding-stuffTransportation and packagingHybrid typeFeed additive

The invention discloses a crushing and mixing system for production of mixed feed additives. The crushing and mixing system comprises a base, a rotating shaft and material guide plates, the upper portion of the rotating shaft is connected with smashing blades through automatic telescopic rods and manual telescopic rods, and brushes are arranged above the smashing blades; a material storage main body is fixed outside the material guide plates, a material mixing shaft is arranged in the middle of the material storage main body, and discharging ports are formed in the upper portion of the material storage main body; and a rotating sleeve and a material mixing rod are arranged above the material mixing shaft correspondingly, and baffles are fixedly arranged above the rotating sleeve. The crushing and mixing system for the production of the mixed feed additives is provided with a system main body with the discharging ports, so that the feed additives which are crushed and preliminarily mixed inside the system main body can enter the interior of the storage main body through the discharging ports for storage, so that the crushed feed additive powder can be more uniform.

Owner:江西东旺动物微生物有限公司

Stirring device for processing sheet jelly

InactiveCN108704524AReasonable structural designTo achieve anti-sticking effectRotary stirring mixersTransportation and packagingEngineeringElectromagnet

The invention discloses a stirring device for processing sheet jelly. The stirring device comprises a stirring cylinder, an anti-adhesion material scraping ring and a first electromagnet, wherein a feeding hole is formed in one side of the top end surface of the stirring cylinder, a motor is arranged at the center of the top end surface of the stirring cylinder, an output end of the motor penetrates through the inner side of the top end surface of the stirring cylinder and is connected to a rotating shaft through a bolt, stirring blades are welded to the lower part of the surface of the rotating shaft, stirring rods are welded to the upper part, above the stirring blades, of the rotating shaft, and N groups of the stirring blades and the stirring rods are respectively welded; and the anti-adhesion material scraping ring is arranged on the inner wall of the stirring cylinder, two groups of through slots are symmetrically formed in the middle of the inner wall of the stirring cylinder, and sliding rails are formed in one end surfaces, facing towards the vertical central axis of the stirring cylinder, of the through slots. The stirring device for processing the sheet jelly is reasonable in design and can be widely popularized and used, and a material adhesion effect can be effectively prevented.

Owner:耒阳市金谷农产品加工厂

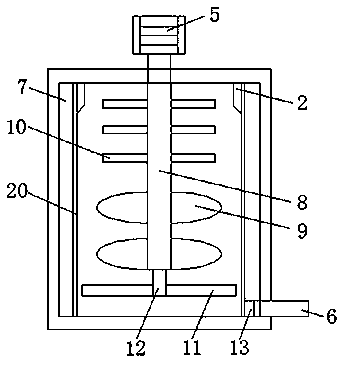

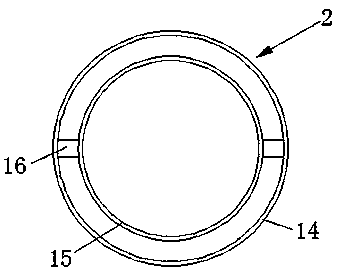

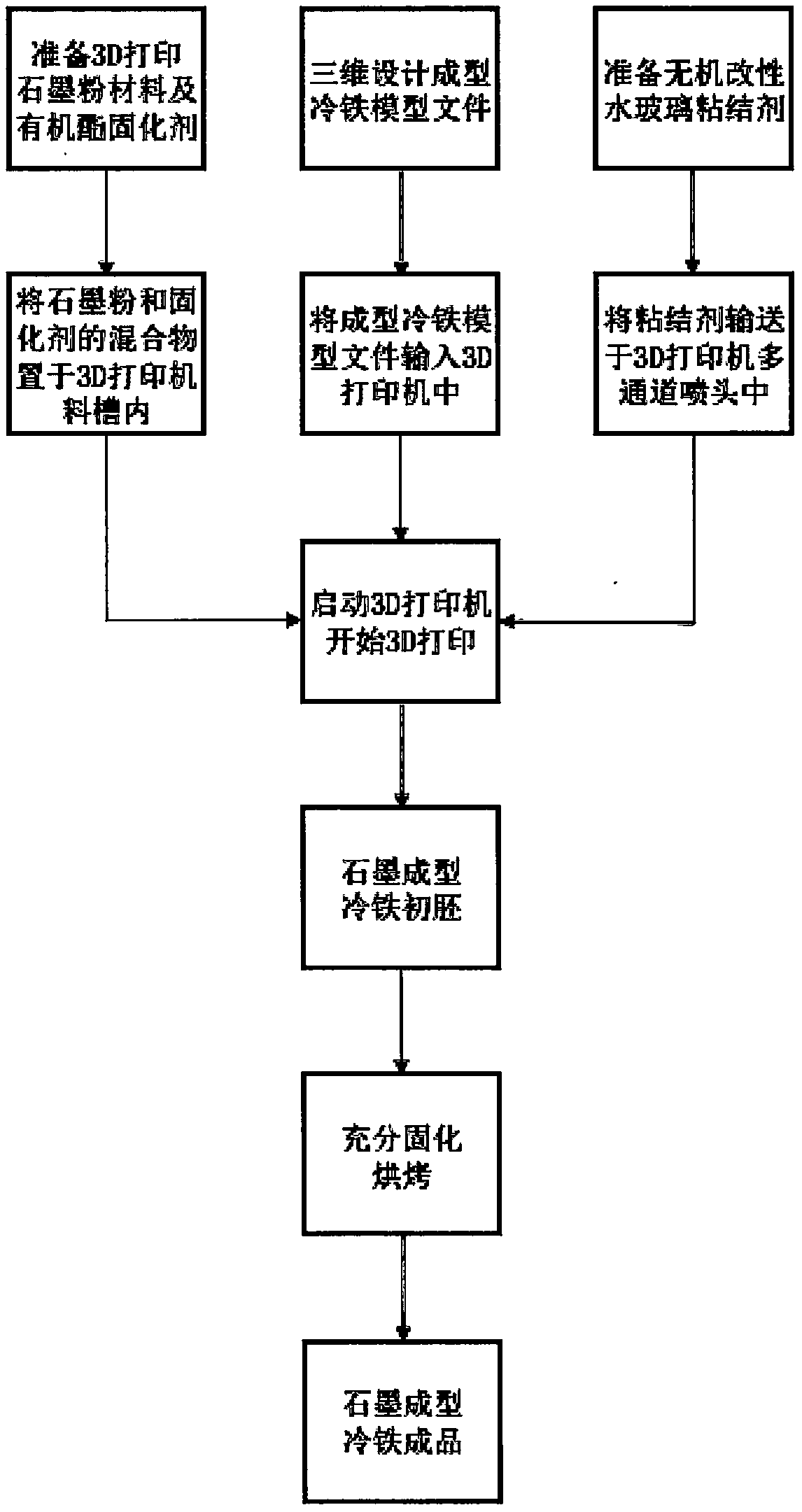

3D printing graphite contoured chill and preparation method thereof

InactiveCN109774130AGood chilling effectAvoid sticking inAdditive manufacturing apparatusAdditive mnaufacturing with solid and fluidPaper documentGraphite

The invention discloses a 3D printing graphite contoured chill and a preparation method thereof, and relates to 3D printing forming methods. The 3D printing graphite contoured chill and the preparation method thereof are characterized in that inorganic modified water glass is treated as an adhering agent; an organic ester curing agent is treated as a hardening agent; graphite powder is treated asa printing forming material; a three-dimensional design contoured chill model document is input a 3D printer; a powder bed based three-dimensional jet printing (3DP) technology is carried out to printa three-dimensional entity in a multi-layer overlapping manner so as to obtain a primary graphite contoured chill blank; the primary graphite contoured chill blank is fully cured and roasted to obtain the 3D printing graphite contoured chill product. The formation technology is simple; industrial production is easily carried out; the market prospect is wide; the problems of cumbersome manufacturing process of the contoured chill in casting, difficult numerical control processing and short production period can be solved; in addition, the graphite chill chilling effect is good, so that a castcan be prevented from chill adhering and air pore defects; the production cost is decreased; the cast yield and the production efficiency can be improved; in addition, an organic adhering agent is applied to the 3D printing technology, the performance is stable, the energy is saved, the environment is protected, and the production cost is low.

Owner:KEHUA HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com