Patents

Literature

30results about How to "Fluidized state is good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

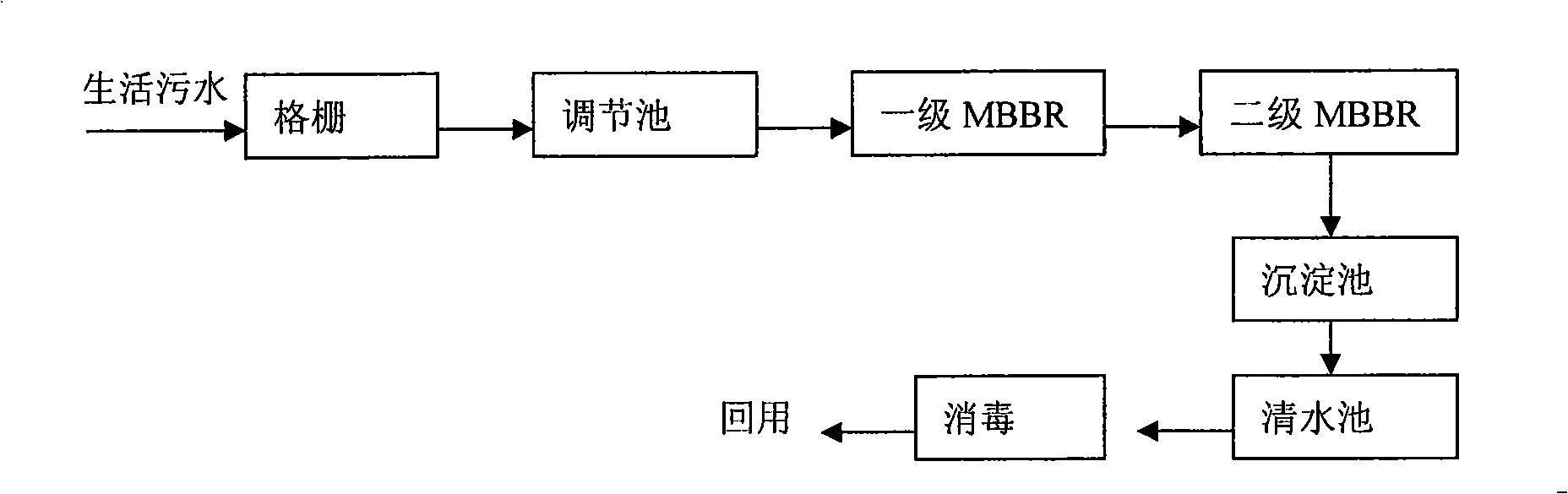

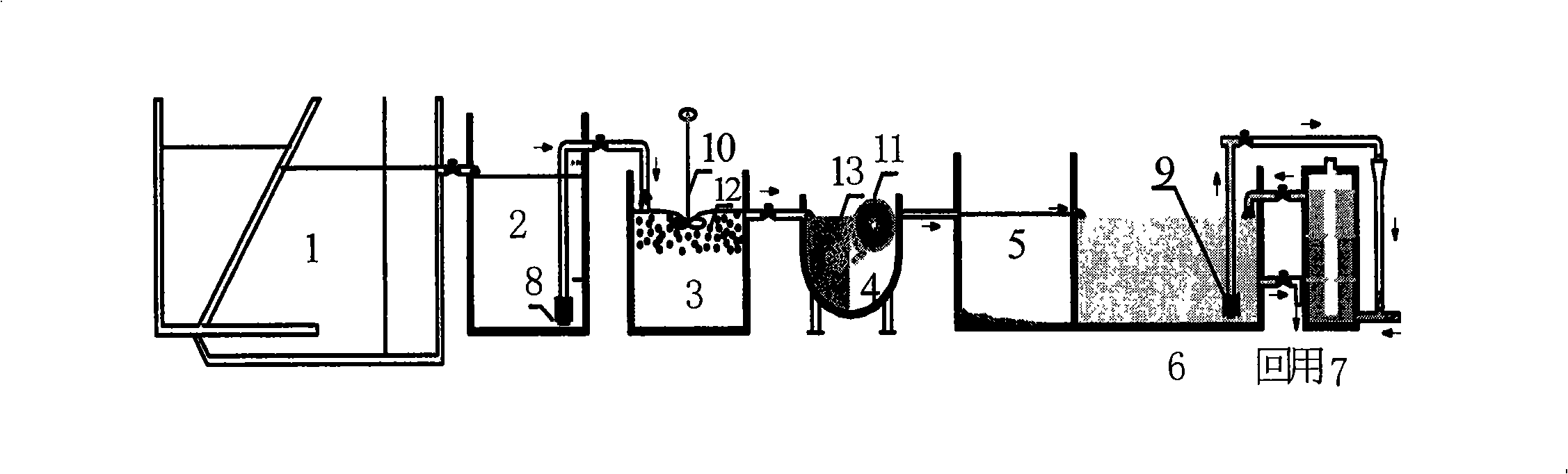

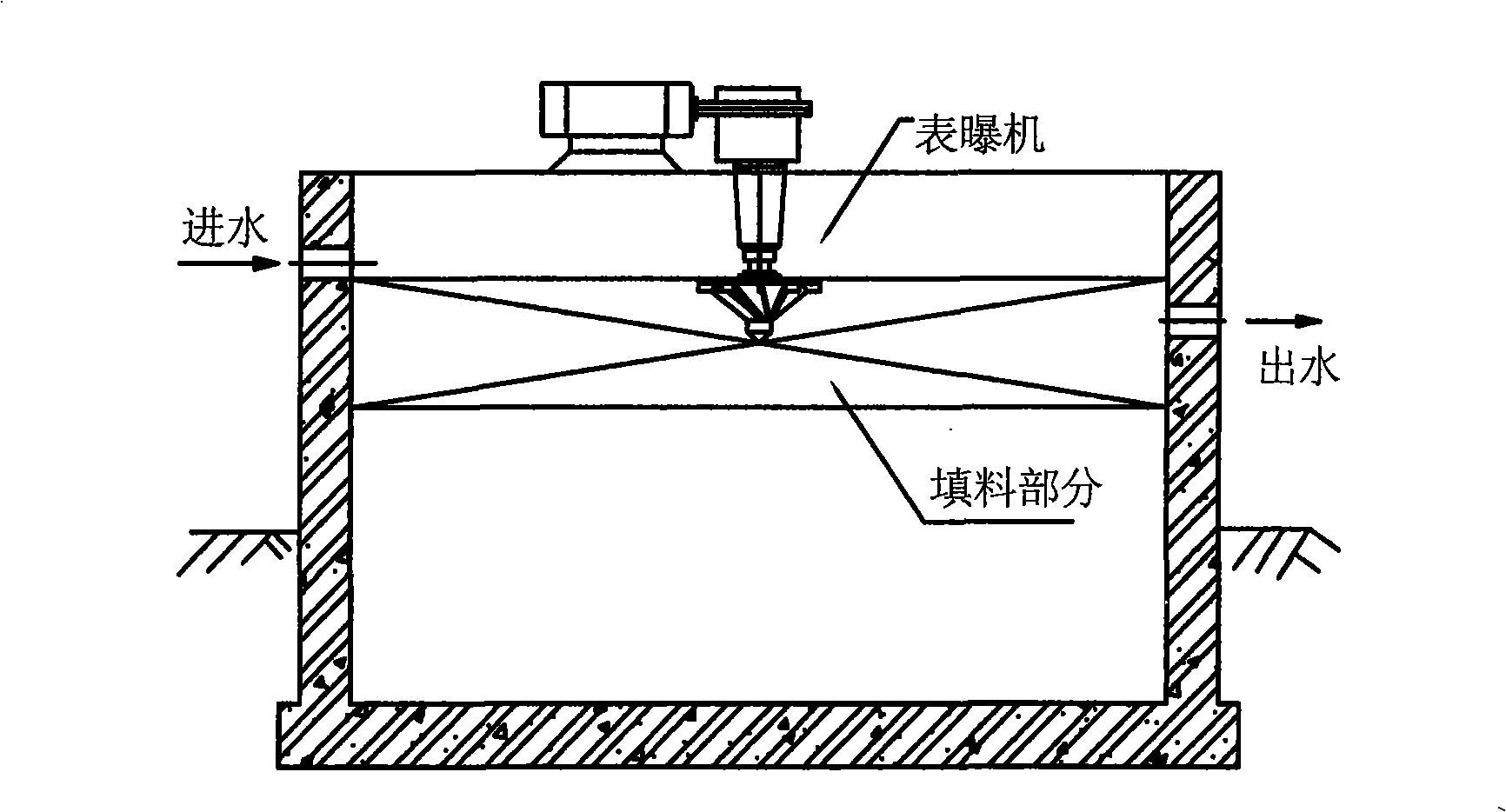

Water treatment system in two-stage moving bed biomembrane reactor

InactiveCN101402487AEasy to handleStrong resistance to shock loadsSustainable biological treatmentBiological water/sewage treatmentAutomatic controlSludge

The invention belongs to the field of water treatment, and relates to a two-stage moving bed biomembrane reactor medium water treatment system. The two-stage moving bed biomembrane reactor medium water treatment system is characterized in that the whole process adopts a programmable PLC automatic control system; the main treatment structure is two-stage cascade connected moving bed biomembrane reactors; and the concrete process flow is as follows: domestic sewage or sewage with similar water quality enters a regulating pond through grates and then enters a first-stage MBBR reactor and a second-stage MBBR reactor in turn by pump lifting; and then the water is outputted into a depositing pond, enters a clear water pond and is reused for flushing toilet or as landscape water after cyclic ultraviolet sterilization. The two-stage moving bed biomembrane reactor medium water treatment system has the advantages that: 1 the system has good medium water treatment effects, stronger resistance to shock load and stable outputted water quality; 2 the system has simple and convenient operating management, a small floor area, convenient maintenance and little excessive sludge; and the system adopts the PLC automatic control system with high automatic degree; 3 the system adopts a mechanical aeration mode, thereby bringing about low energy consumption and good oxygenation performance without an independent blower; 4 the system adopts a cyclic ultraviolet sterilization mode without any medicament added during the whole process, thereby avoiding the secondary pollution; and 5 the system has a wide application range.

Owner:UNIV OF SCI & TECH BEIJING

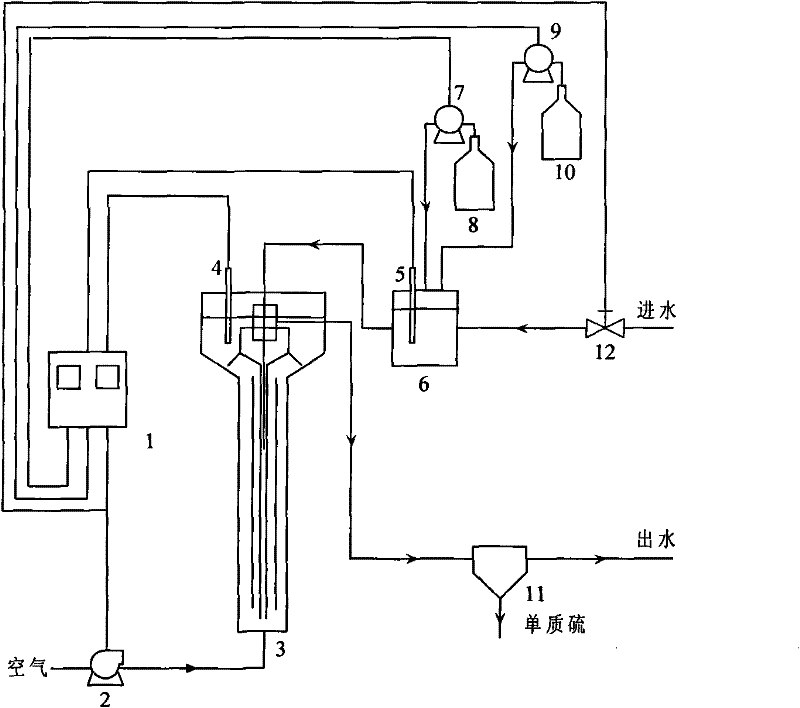

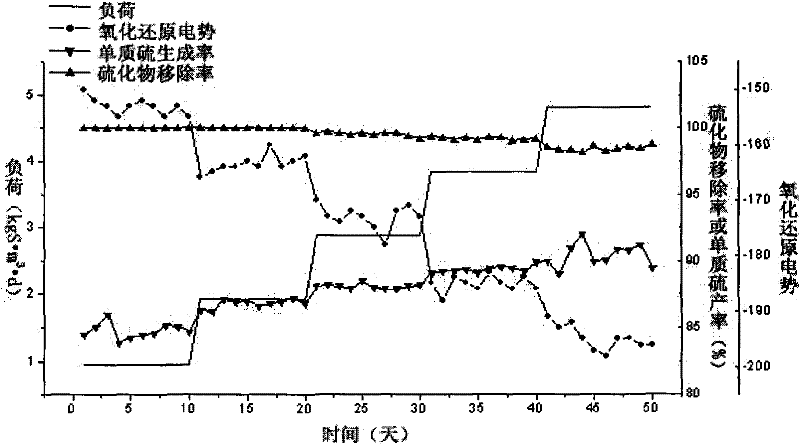

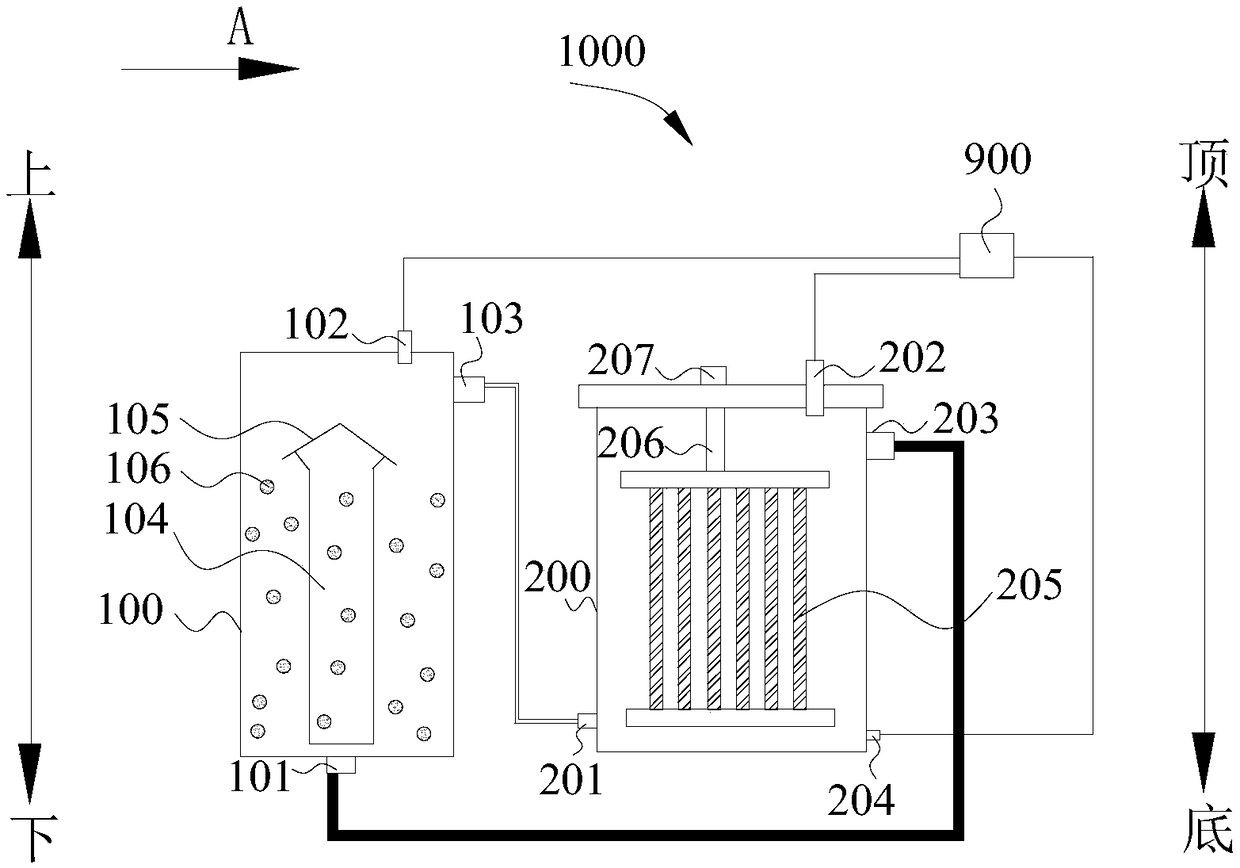

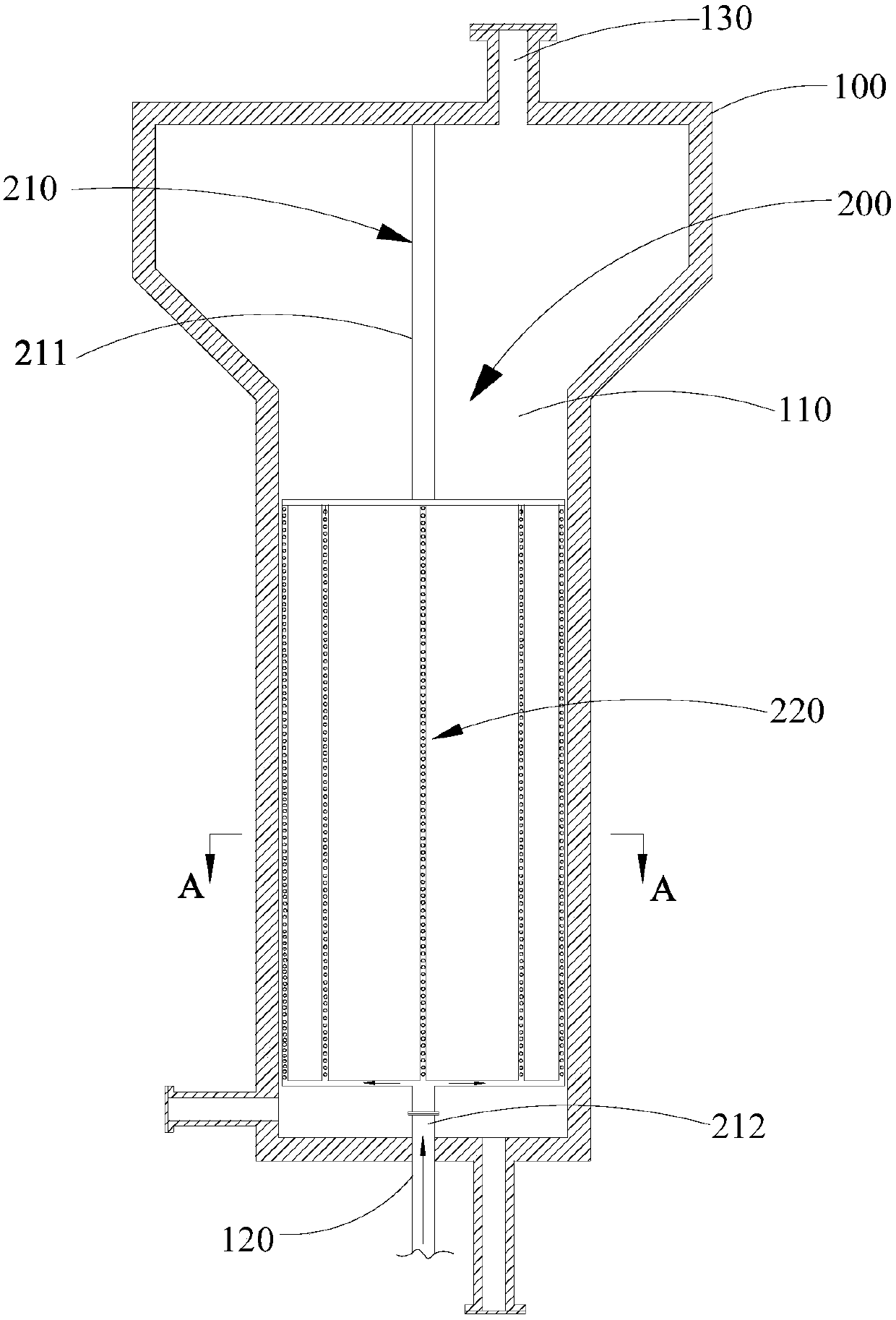

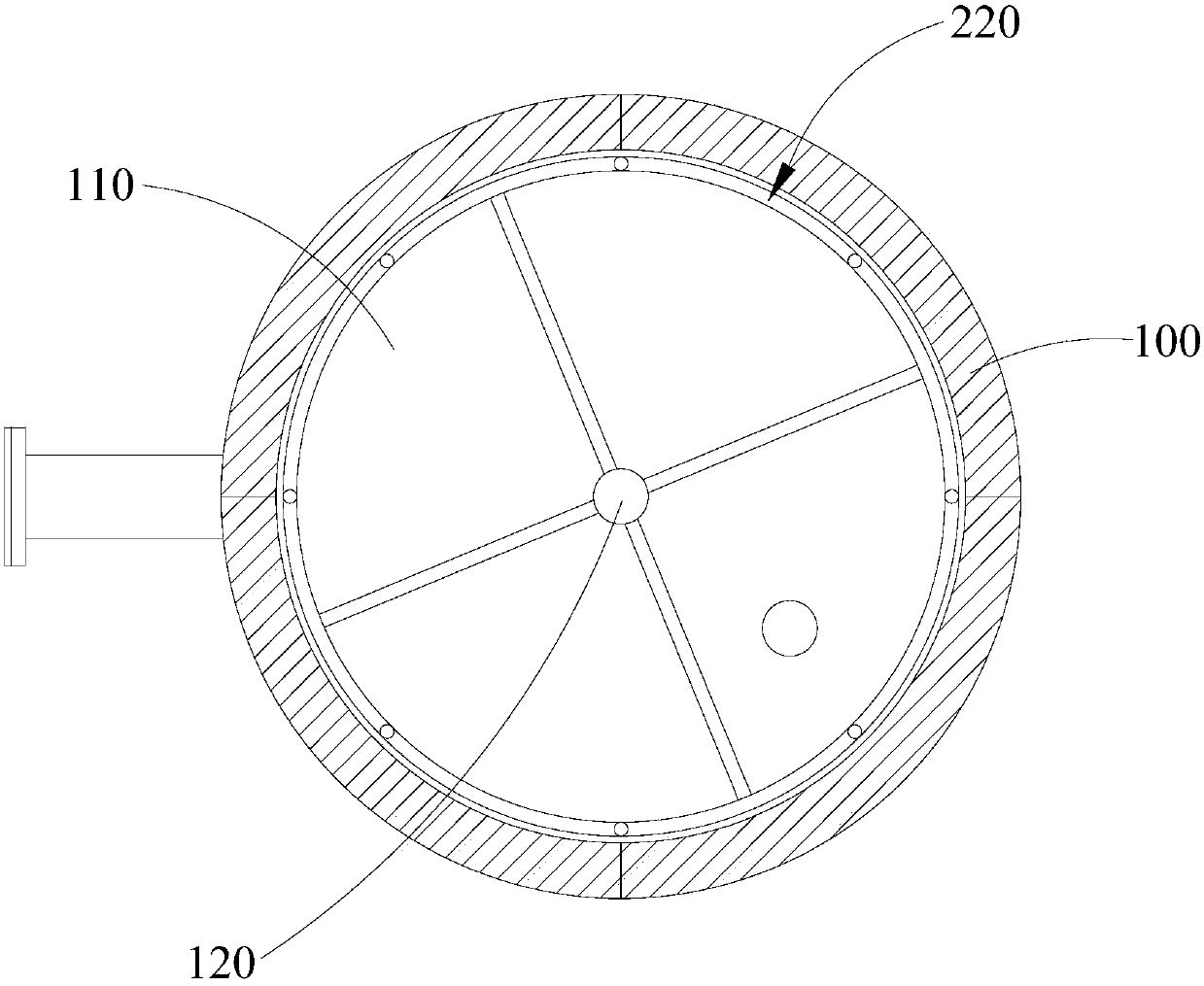

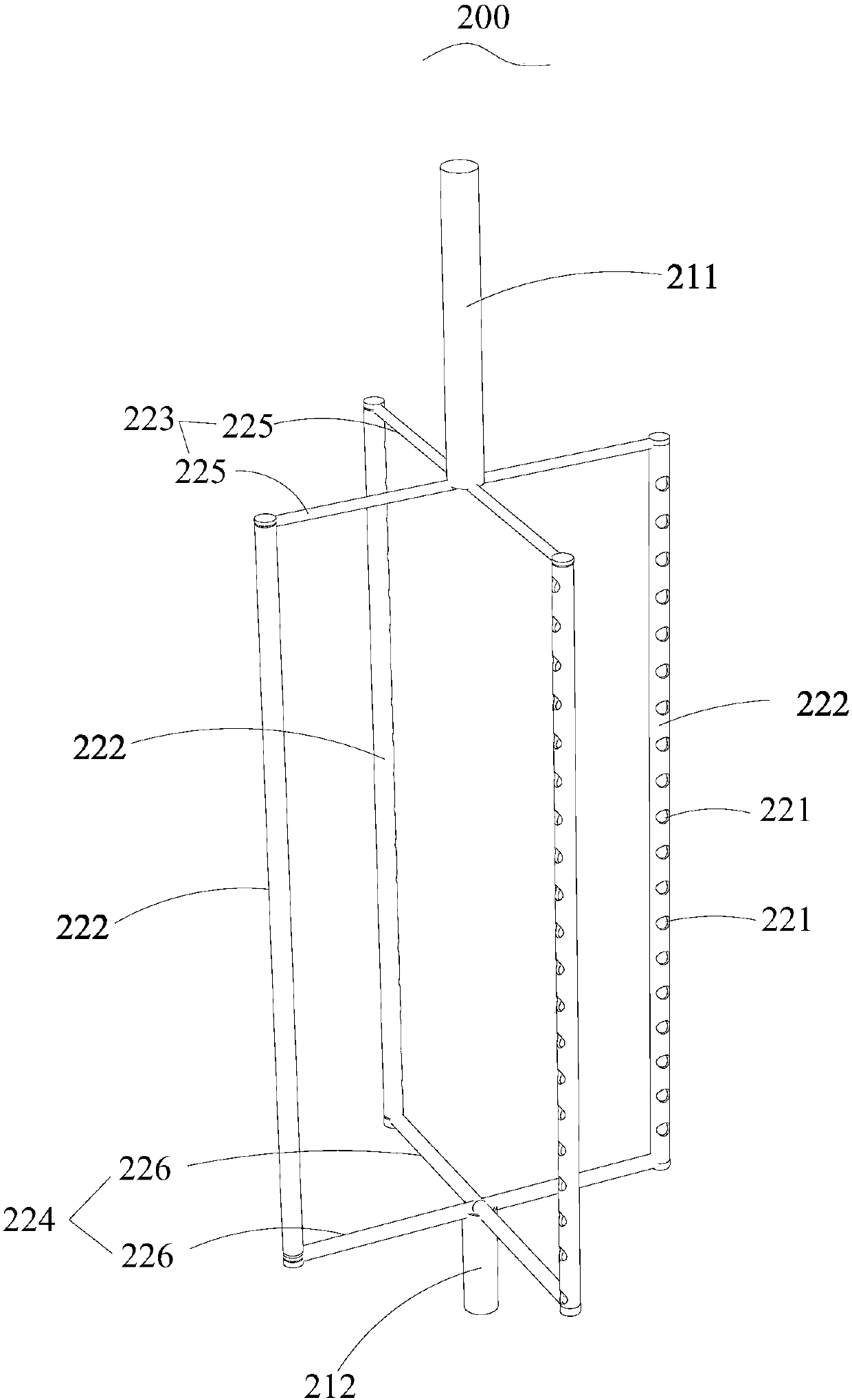

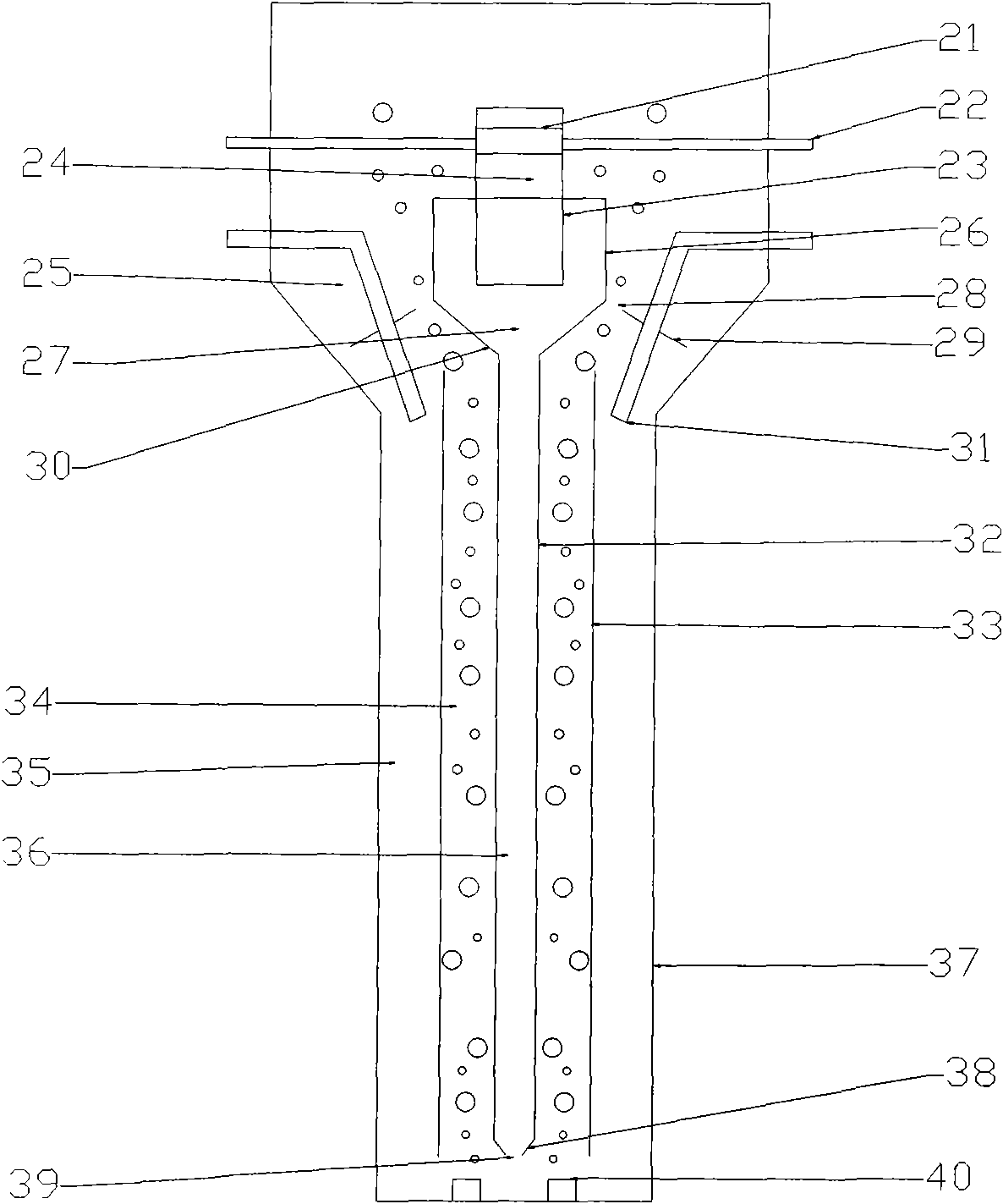

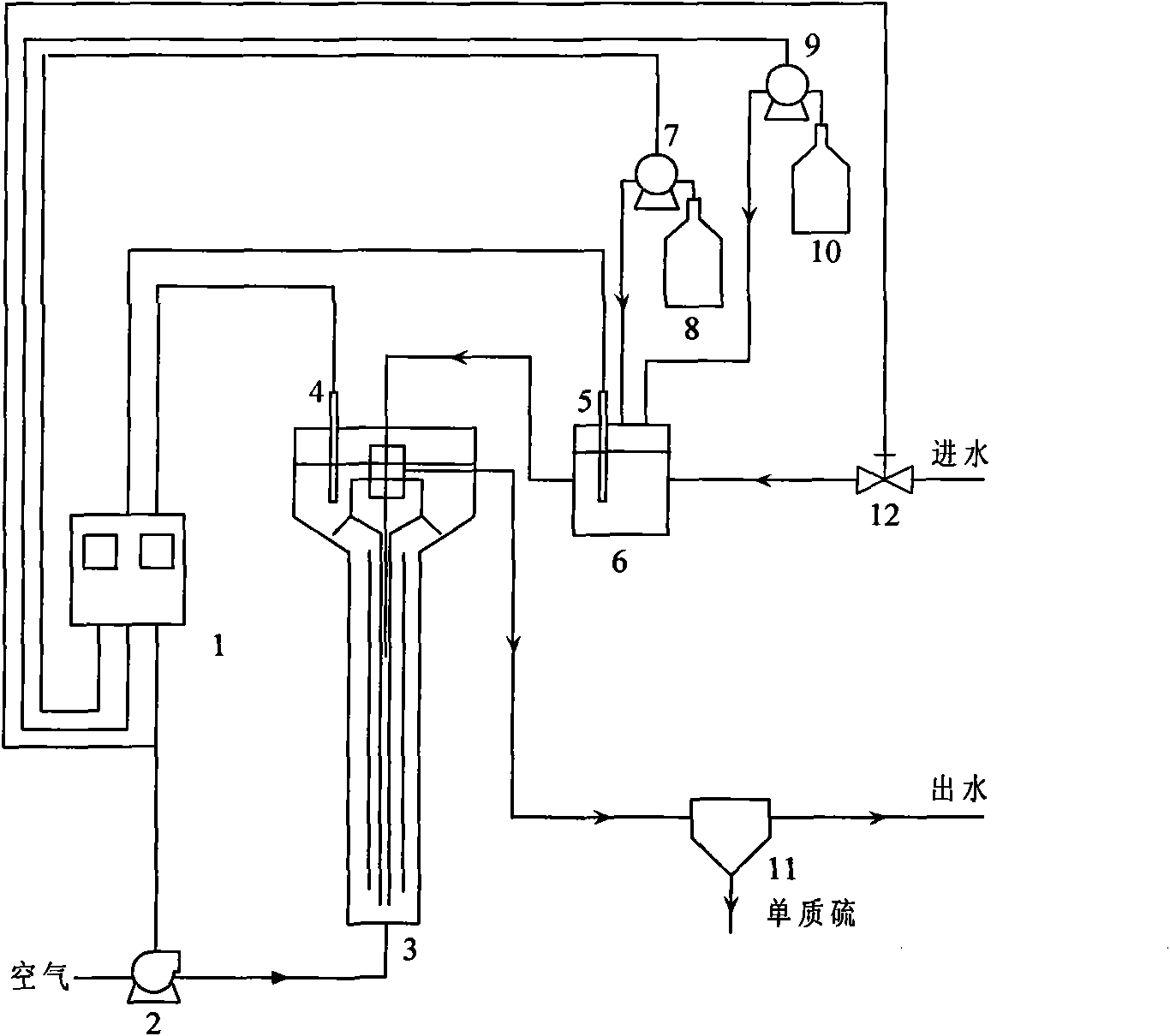

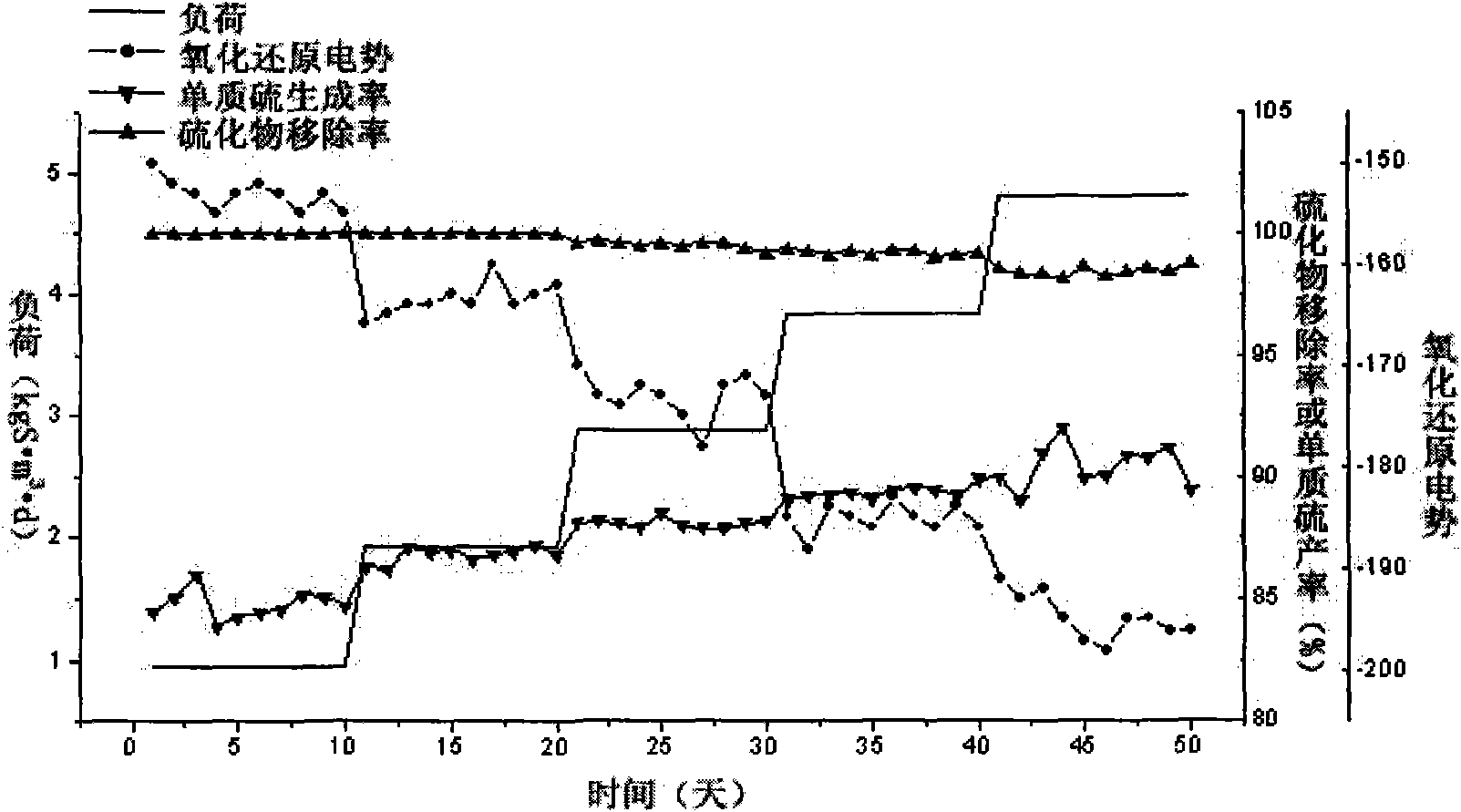

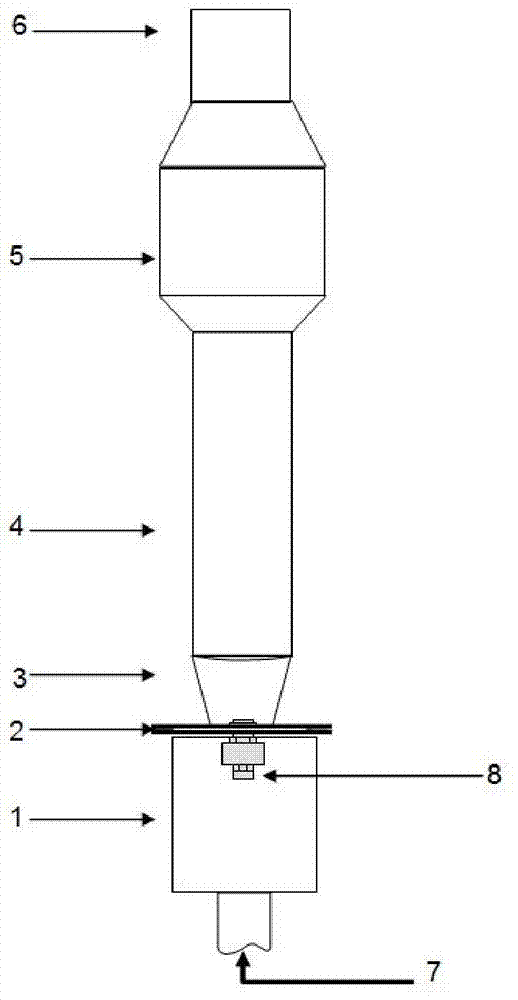

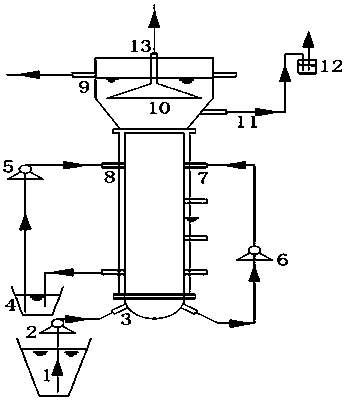

Biological desulphurization processing reactor, biological desulphurization processing system, and processing method

ActiveCN102476893ALow purityAvoid cloggingSulfur preparation/purificationMultistage water/sewage treatmentGas phaseSulfide

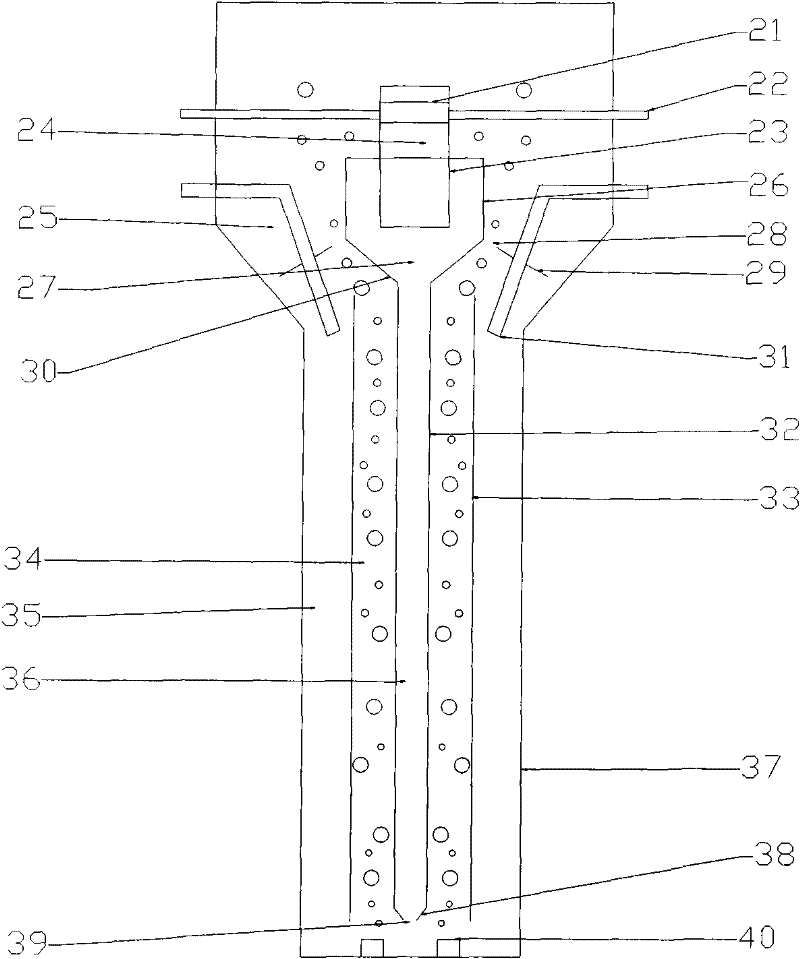

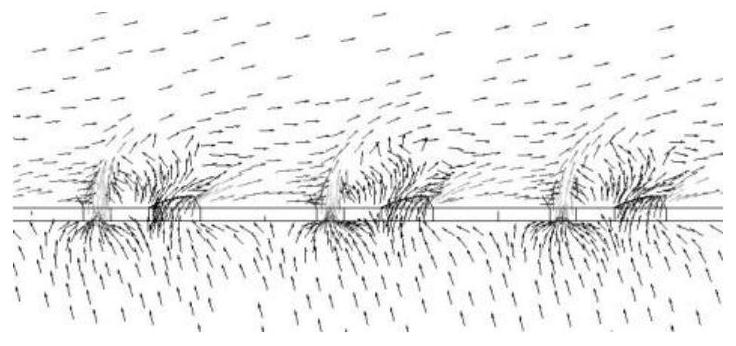

The invention provides a biological desulphurization processing reactor, a biological desulphurization processing system, and a processing method. The reactor comprises a three phase separator and a reaction zone. The reaction zone comprises an outer cylinder, a gas guiding cylinder and a lower flow guiding cylinder, such that the reaction zone is separated into an air-lift zone, an anoxic zone, and a descent zone. The three phase separator comprises an outer frustum, an inner inverted frustum, an outer sedimentation tank, an inner sedimentation tank, and an overflow groove, such that the three phase separator is separated into three sedimentation zones. Sulfide-containing wastewater is mixed with oxygen-containing water from the air-lift zone in the anoxic zone; under the effect of immobilized microorganisms, the sulfide is partially oxidized into elementary sulfur; the mixture is delivered through the three phase separator arranged above, such that the immobilized carrier is separated from a water phase and a gas phase, and sulfur particles flow out with water. According to the invention, with the structure of the reactor and the processing method, a good fluidized state is maintained, and the loss of the immobilized carrier is inhibited. The reactor, the system and the method are advantaged in high elementary sulfur production rate, good processing capacity, hydraulic load impact resistance, substrate load impact resistance, simple structure, and easy amplification.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

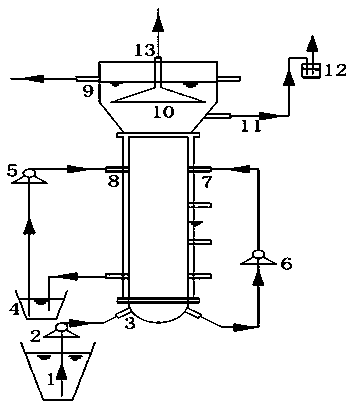

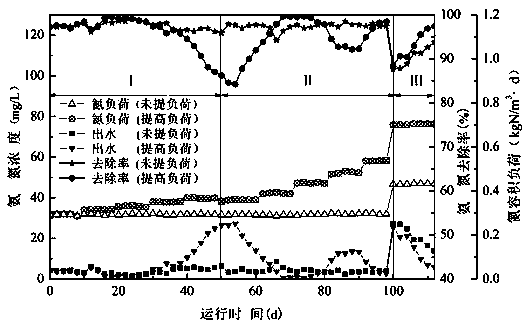

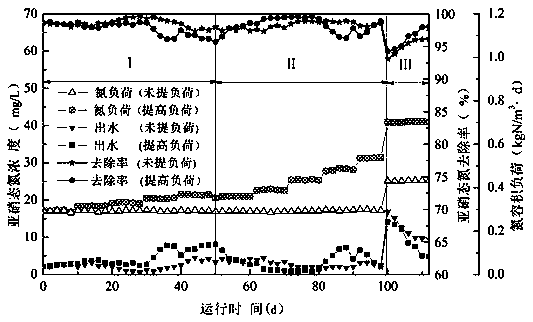

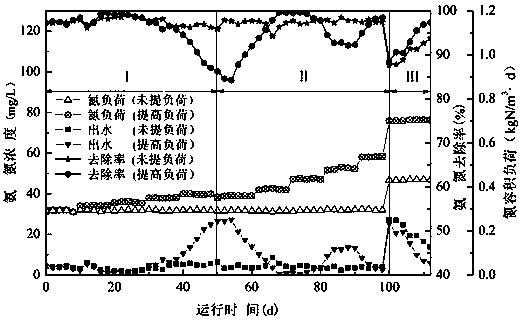

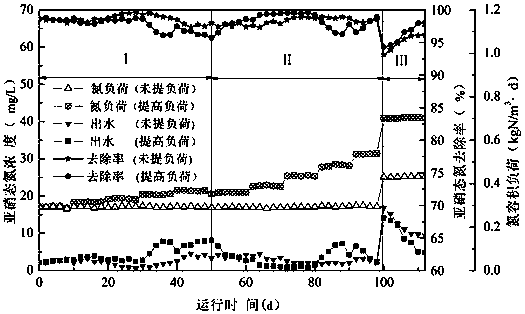

Method for increasing forming speed of anaerobic ammonia oxidation granule sludge

ActiveCN105502652AIncreased nitrogen loadingRapid enrichmentWater contaminantsTreatment with anaerobic digestion processesFecesSubstrate concentration

The invention relates to a method for increasing the forming speed of anaerobic ammonia oxidation granule sludge. The method comprises the steps that practical industrial wastewater with low C / N is taken as a culturing nutrient source of the anaerobic ammonia oxidation granule sludge, and the mass concentration ratio of NH4<+>-N to NO2<->-N of inflow water is controlled to be (1.05-1.42) to 1; a mixture of anaerobic sludge and livestock breeding faeces is taken as inoculated sludge, by means of the modes of changing the substrate concentration of the inflow water, shortening the hydraulic retention time, controlling the granule size, the granule sludge settling speed and MLVSS / MLSS of the anaerobic ammonia oxidation granule sludge and the like, a nitrogen load of anaerobic ammonia oxidation inflow water is changed, the retention and amplification problems of anaerobic ammonia oxidation bacteria can be effectively solved, and by means of granulation of anaerobic ammonia oxidation sludge, the influence of nitrogen removal efficiency dropping caused by environmental changes can be weakened to some extent.

Owner:上海生迈缘生物科技有限公司

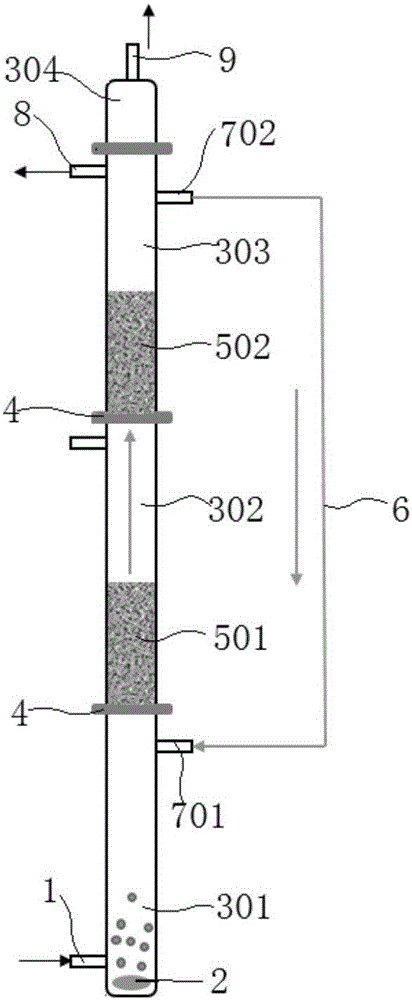

Integrated fluidized bed device for gradient ozone catalyzing and application of integrated fluidized bed device

PendingCN106630110AEasy to handleGuaranteed treatment effectWater treatment compoundsWater contaminantsRefluxFluidized bed

The invention discloses an integrated fluidized bed device for gradient ozone catalyzing and application of the integrated fluidized bed device. The integrated fluidized bed device comprises a primary reactor, a secondary reactor, a tertiary reactor and a quaternary reactor from bottom to top, a water inlet and an ozone aerating apparatus are arranged at the bottom of the primary reactor, a recycling water inlet is arranged on an upper portion of the primary reactor, a catalyzer layer and a second catalyzer layer are respectively arranged in the secondary reactor and the tertiary reactor, a water outlet and a recycling water outlet are arranged on an upper portion of the tertiary reactor, the recycling water inlet is connected with the recycling water outlet through a reflux pump and a circulating tube, and an upper cut angle is reserved between the recycling water inlet and a main reactor body. The integrated fluidized bed device for gradient ozone catalyzing has the advantages that a usage rate and a catalytic oxidation efficiency of ozone are increased, a catalytic oxidation reaction is more efficient and more thorough, a compact reaction mechanism is adopted to enable the reaction to be finished in one device, and small floor area is occupied.

Owner:NANJING UNIV +1

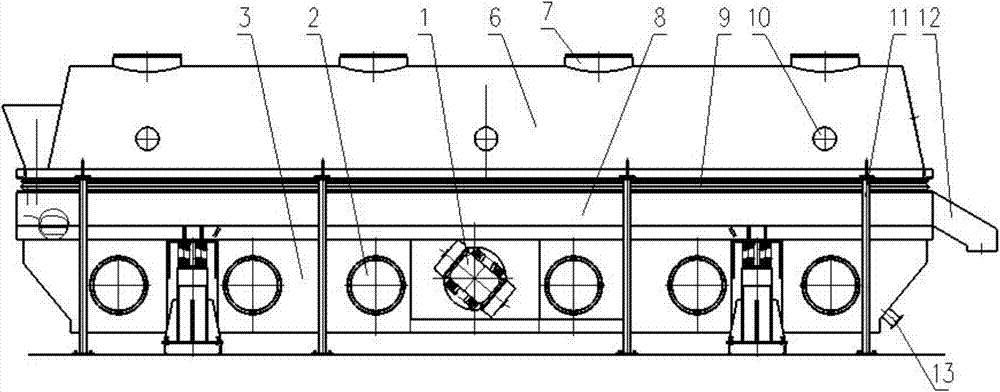

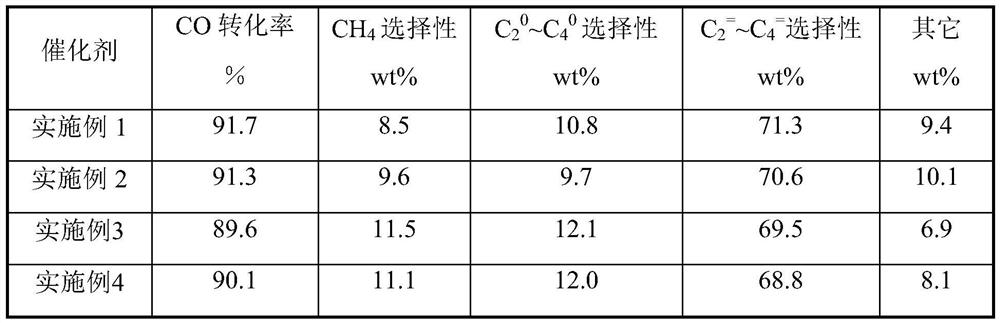

White granulated sugar vibrated fluidized bed

InactiveCN103571975AHigh strengthFluidized state is goodSugar dryingDrying solid materials with heatSeashellVibratory fluidized bed

The invention discloses a white granulated sugar vibrated fluidized bed. The white granulated sugar vibrated fluidized bed comprises a main machine box, a vibration motor and a macroporous plate and a seashell-type pore plate, wherein the main machine box is of a hollow structure with a ventilation cavity, and a vibration bed is arranged at the upper part of the main machine box; the vibration motor is used for driving the vibration bed to vibrate in an upper and down slant direction, and the slant direction is the white granulated sugar advancing direction; the macroporous plate is arranged on the vibration bed and vibrates along with the vibration bed under the driving of the vibration bed, and multiple straight-through holes are formed in the macroporous plate and are communicated with the ventilation cavity; the seashell-type pore plate is arranged on the macroporous plate, multiple seashell-shaped raised seashell through holes are formed in the seashell-type pore plate and are two groups of seashell-shaped through holes which are arranged in a staggering manner, and the opening directions of the seashell-shaped through holes are vertical to each other; white granulated sugar to be fluidized is fed into the seashell-type pore plate. Materials in the white granulated sugar vibrated fluidized bed are at good mixing and boiling state under the effect of wind power, and as vertical surfaces are not provided with openings, the materials are unlikely to block the openings and leak below the bed.

Owner:广西幸丰科技有限责任公司

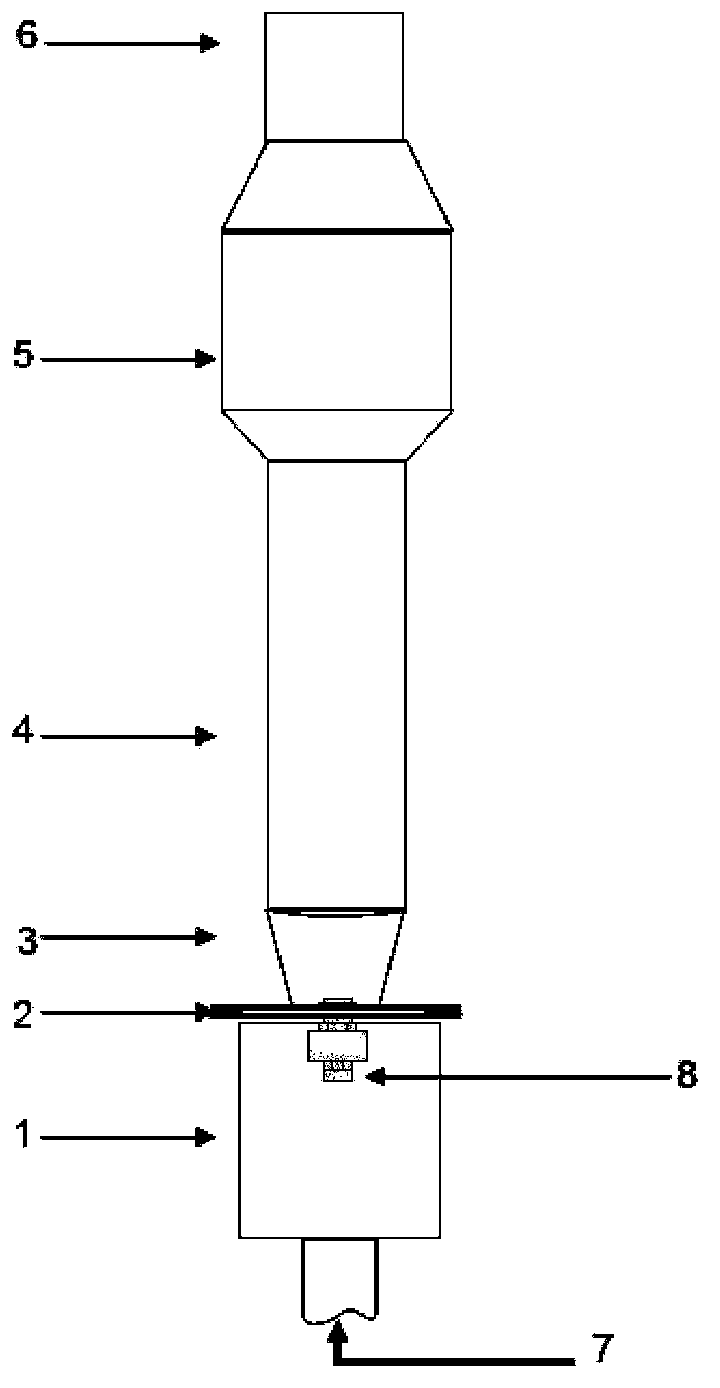

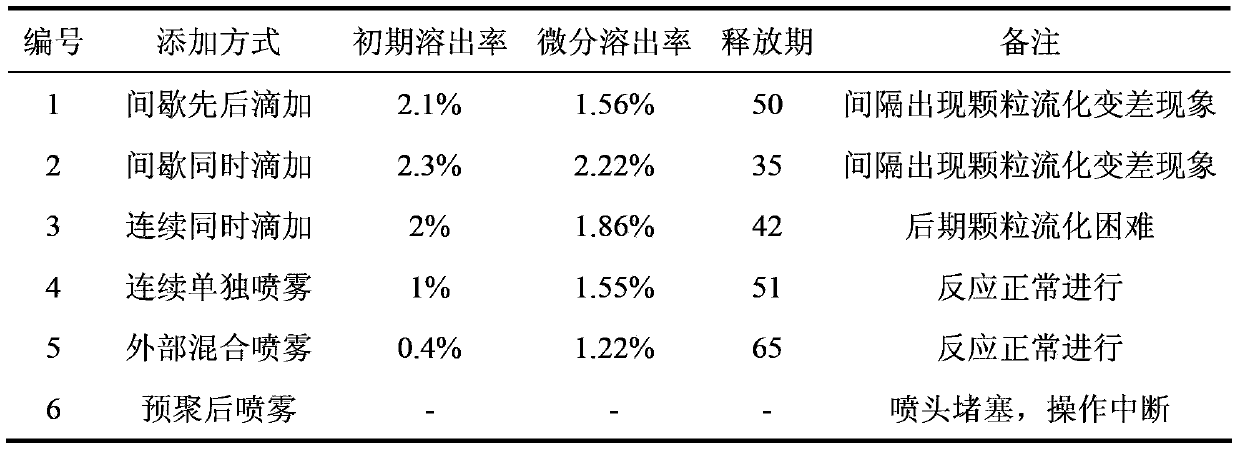

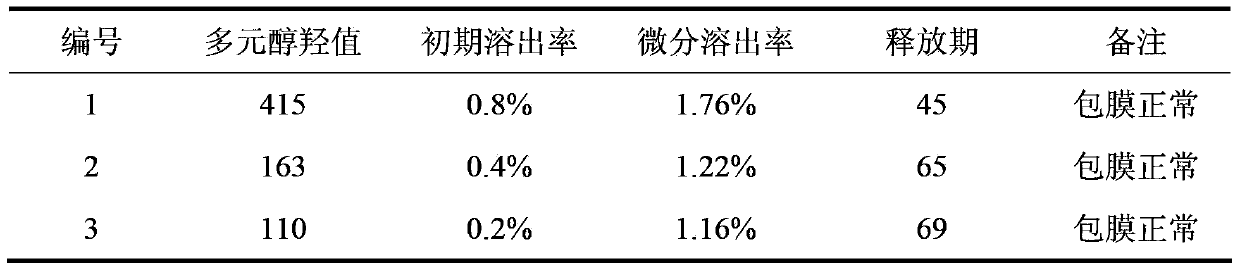

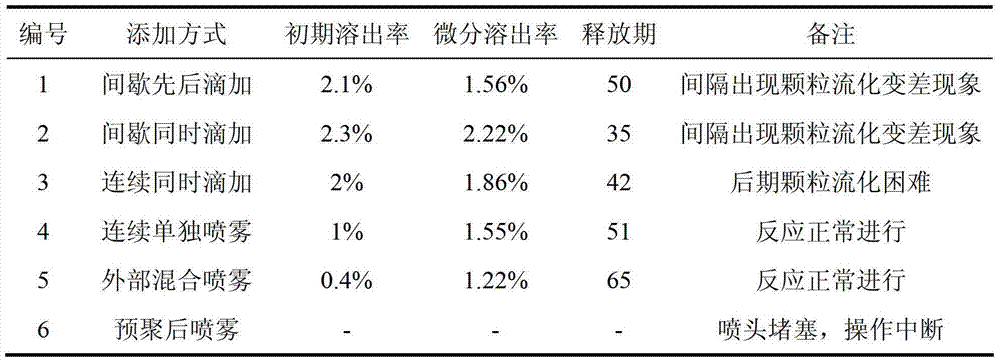

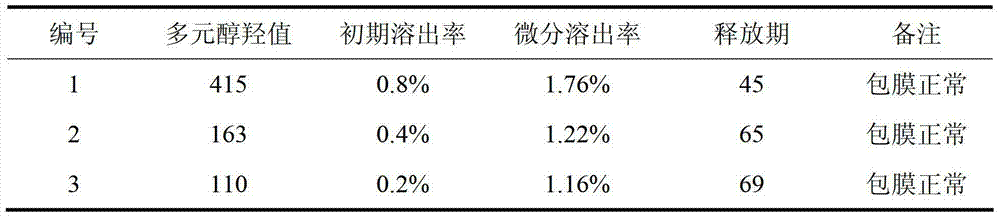

Production method for polyurethane enveloped controlled release fertilizer

The invention relates to a production method for polyurethane enveloped controlled release fertilizer. The production method comprises the following steps: preheating granulated fertilizer in a fluidized bed in a fluidizing state; atomizing liquid paraffin, and pretreating the surface of the granulated fertilizer; mixing polyatomic alcohol and isocyanate in a nozzle, atomizing the mixture fast, and spraying the mixture onto the surface of the granulated fertilizer; controlling material adding speeds to ensure that polyurethane reaction can be fulfilled fast; adding liquid paraffin and carrying out surface anti-sticking treatment after the filling of reaction materials. According to the invention, the fluidized bed is adopted as enveloping equipment, polyatomic alcohol and isocyanate are used for spraying and enveloping after being premixed, and the adding speeds are regulated in a matched manner, so that the whole enveloping reaction process is fast and continuous. The production method can improve the polyurethane enveloping efficiency to a relatively large extent, and ensure relatively stable and reliable quality of the enveloped fertilizer due to continuous reaction.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

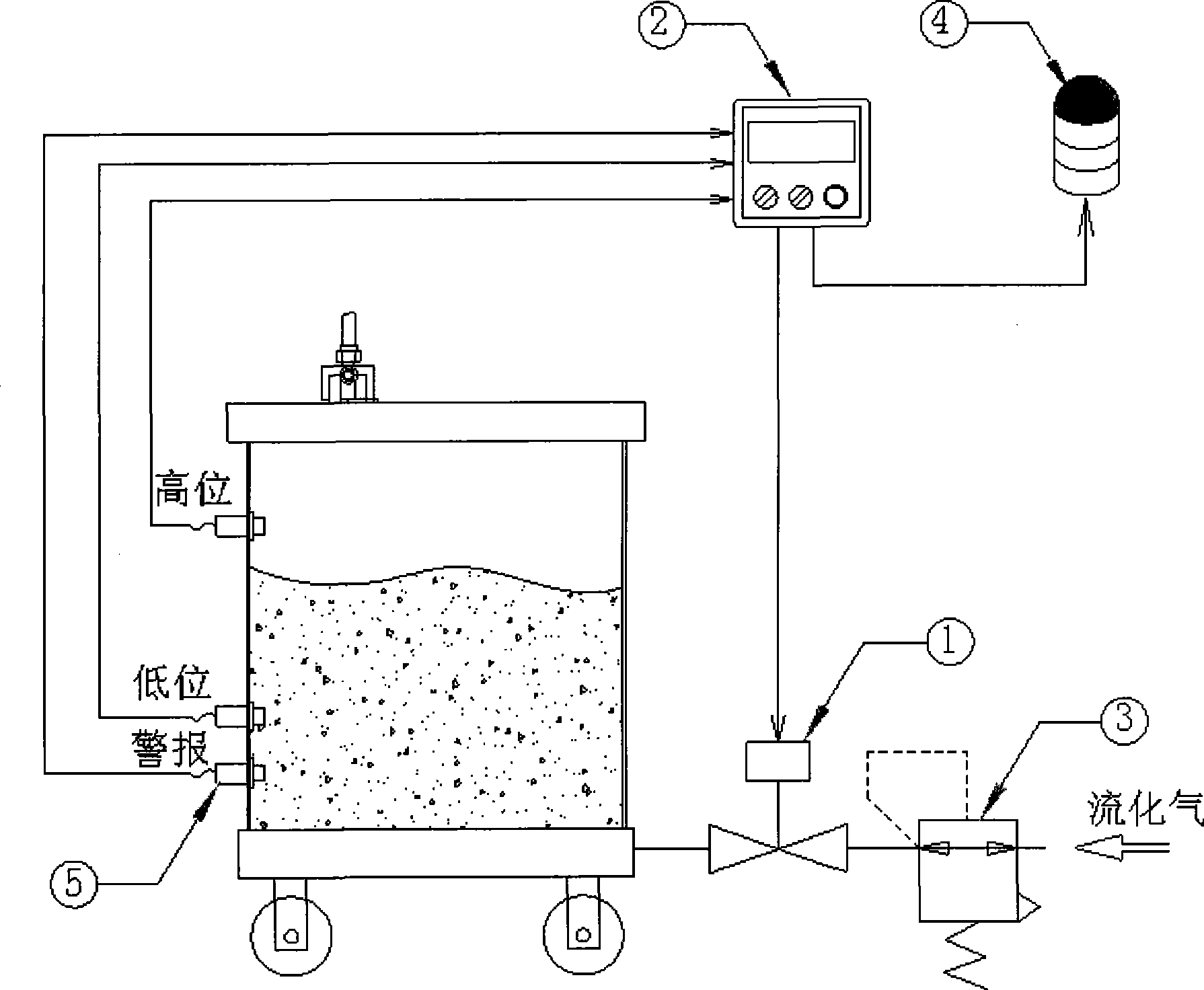

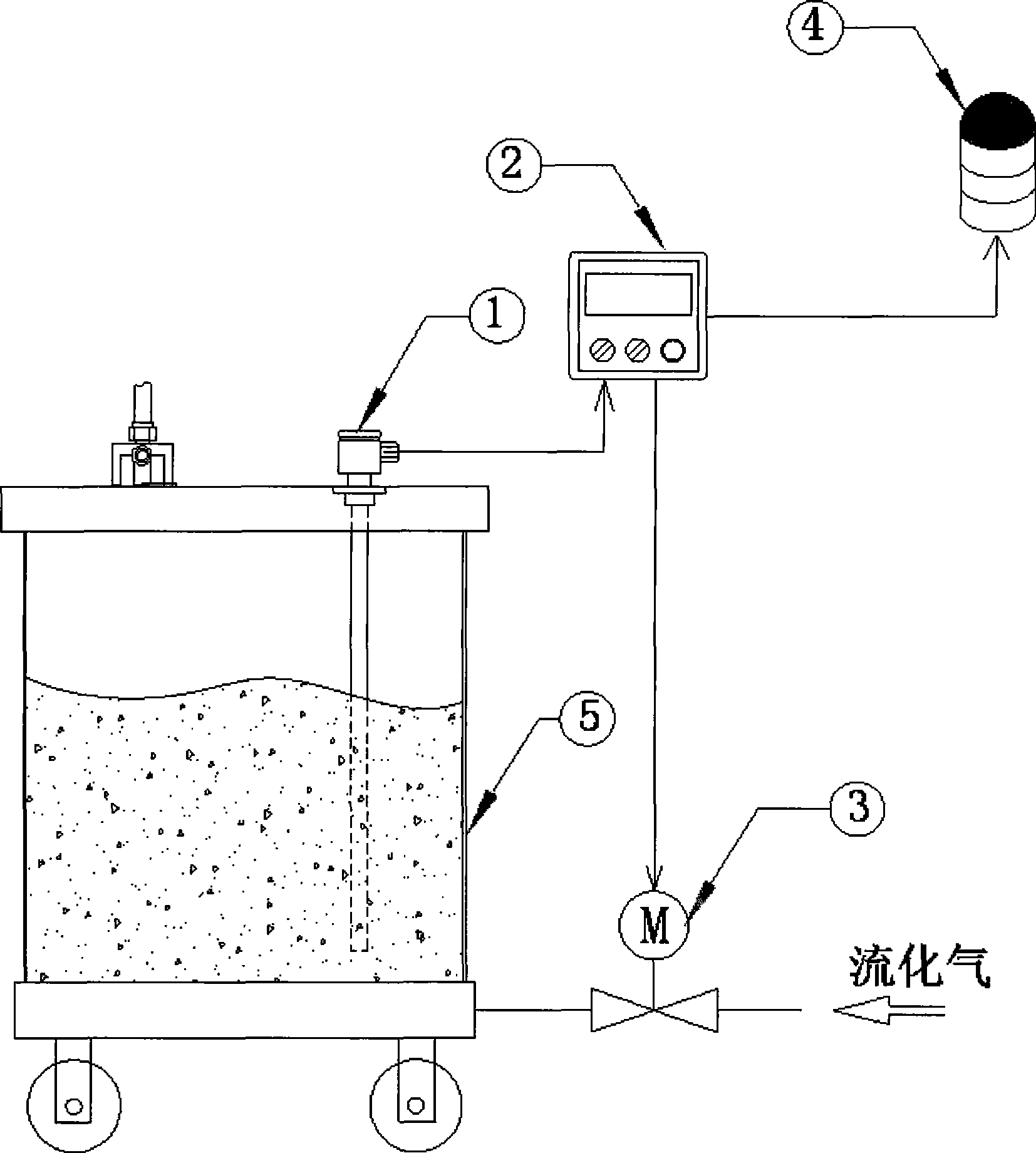

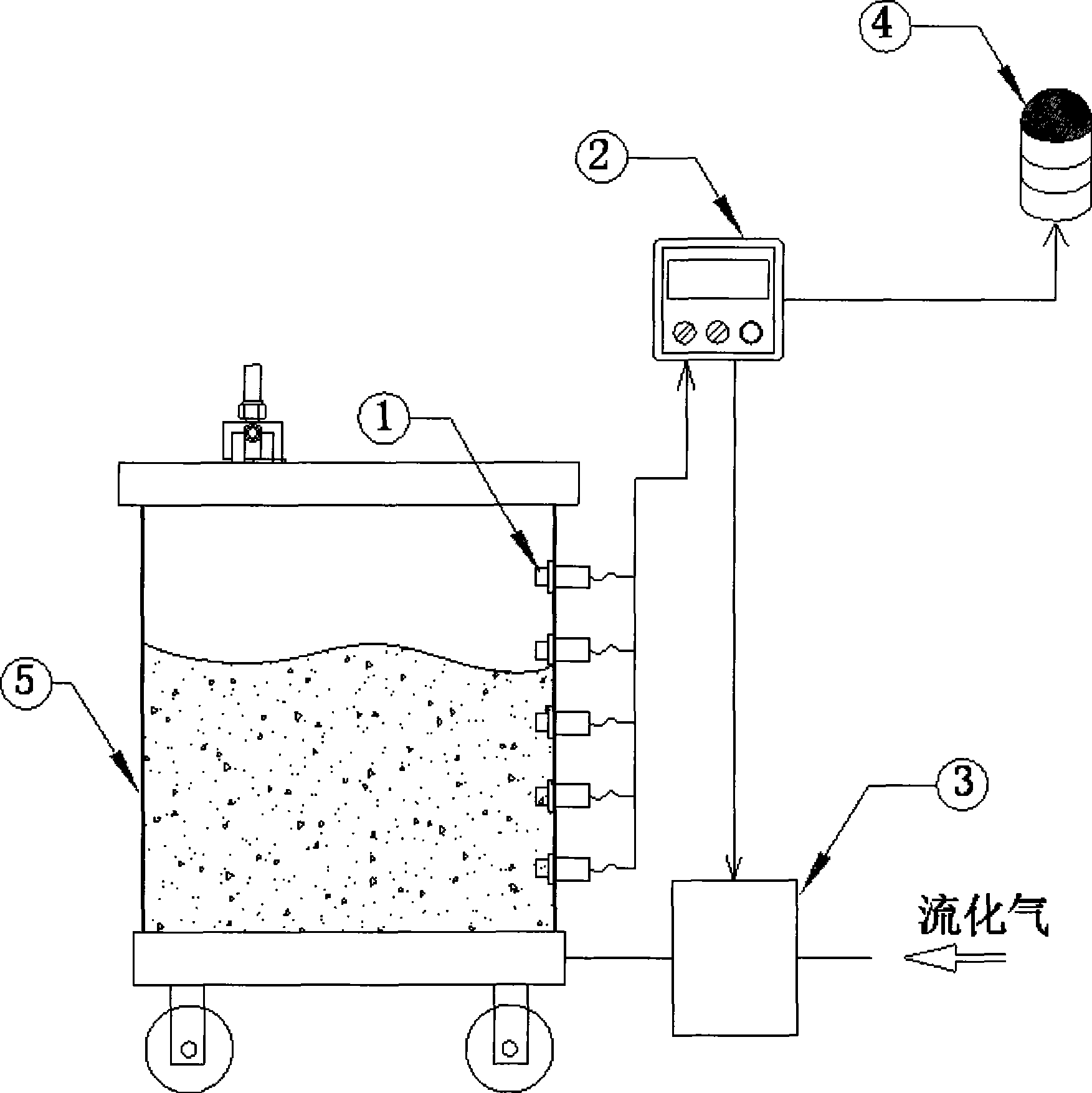

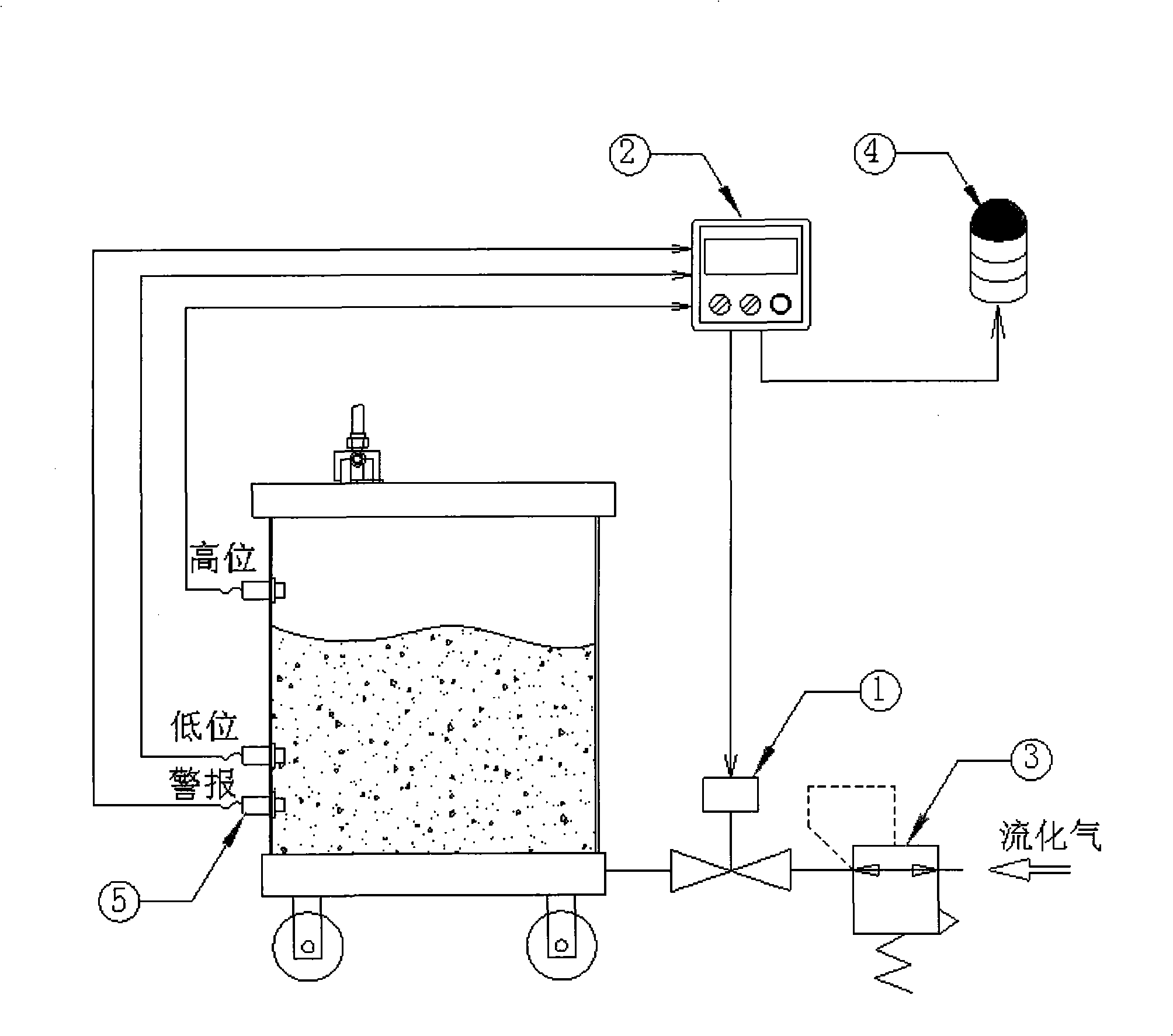

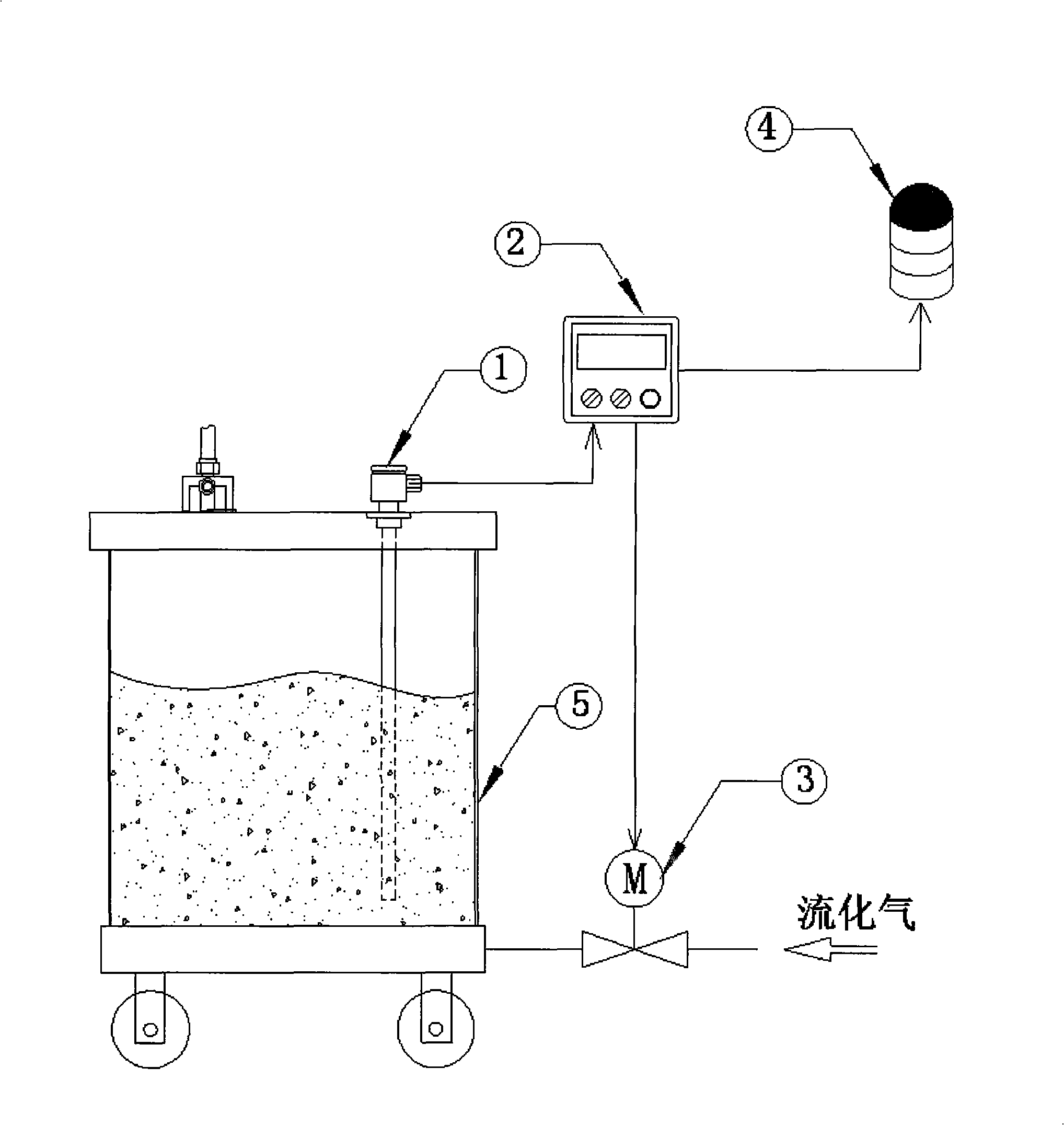

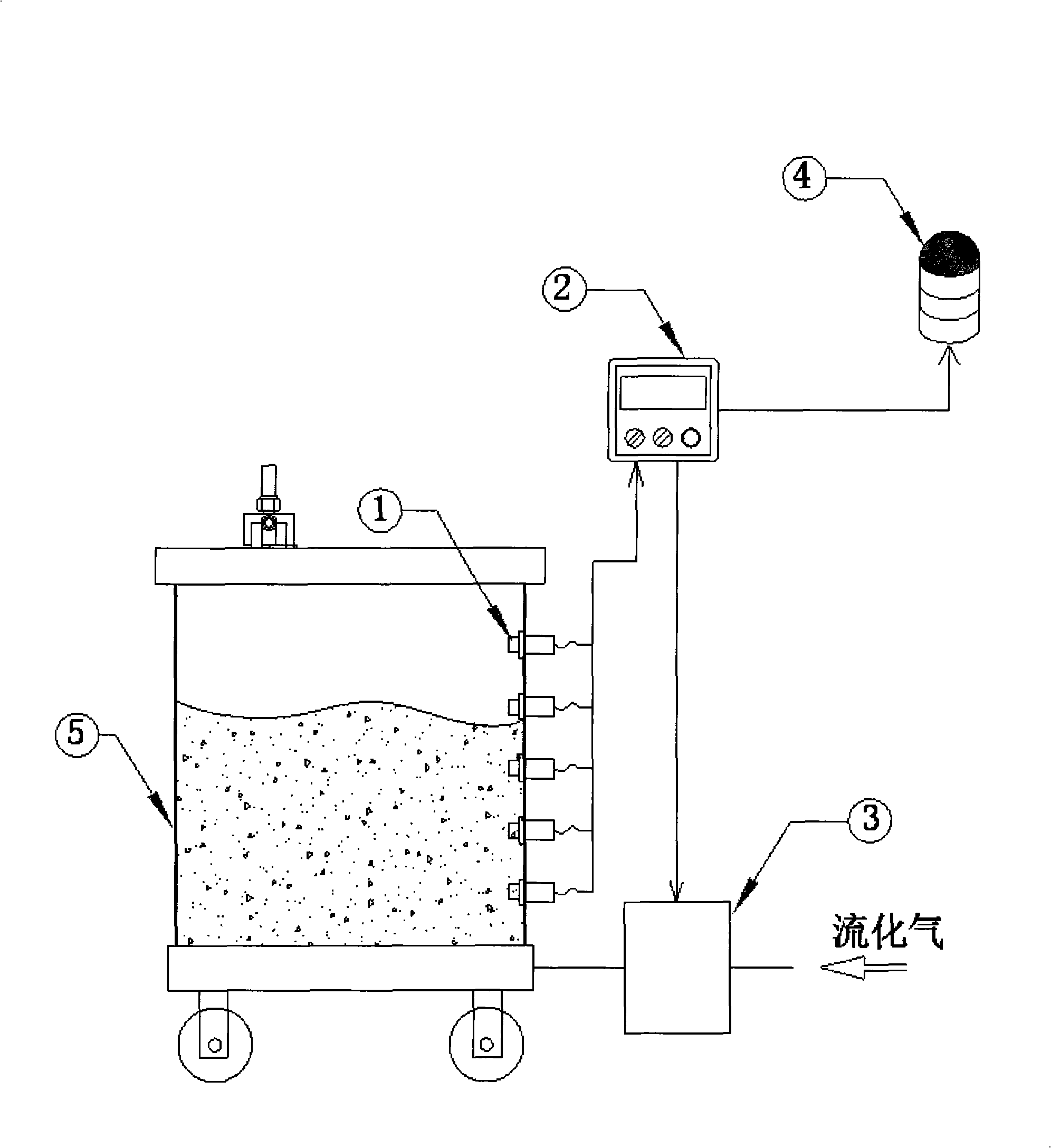

Self-regulating powder-feeding device by fluidizing gas

InactiveCN101439322AFluidized state is goodAlarm is accurateLiquid supply arrangementsLower limitElectricity

The invention provides a fluidizing gas automatic regulating powder feeding device which comprises a powder bucket, a valve for controlling the input pressure and flow rate of fluidizing gas, a sensor used for monitoring the powder level in the powder bucket, a controller for controlling the actions of the valve according to the data of the sensor and alarm equipment; wherein, the sensor is electrically connected with the controller which is electrically connected with the valve and the alarm equipment. The controller controls the flow rate and the pressure of the fluidizing gas input by the valve according to the information of the height of the powder level obtained by the sensor, and dynamically regulates the height of the powder level in the powder bucket. When height of the powder level exceeds the upper limit or the lower limit preset by the controller, the controller drives the alarm equipment to give the alarm, so that the powder feeding device is avoided being damaged. According to the invention, full-automatic regulation of powder feeding can be realized, thus saving manpower and materials, reducing the consumption quantity of the fluidizing gas; in addition, the best fluidizing effect can be provided under the conditions of different powder levels.

Owner:YU TUNG ZHONGSHAN ENG

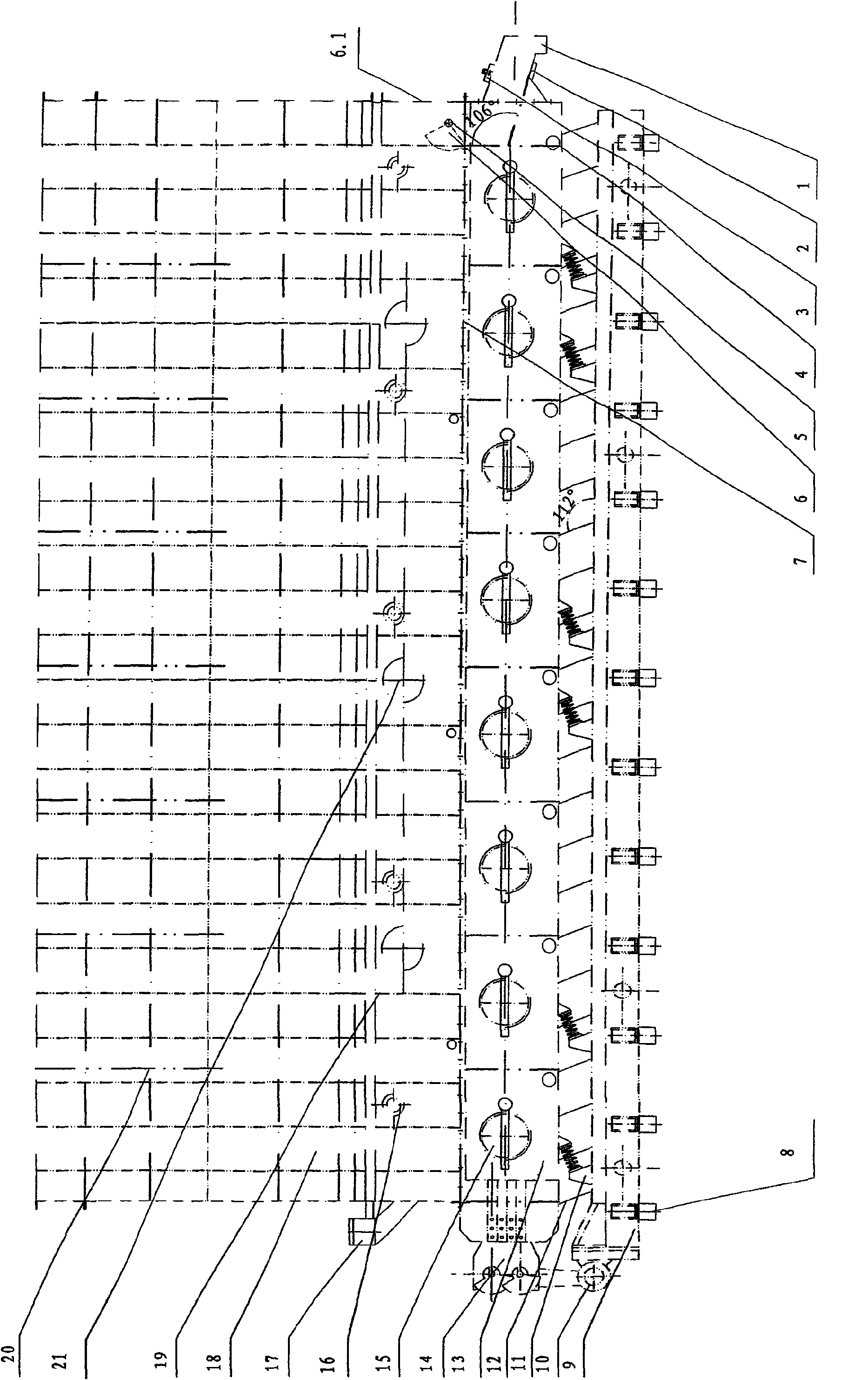

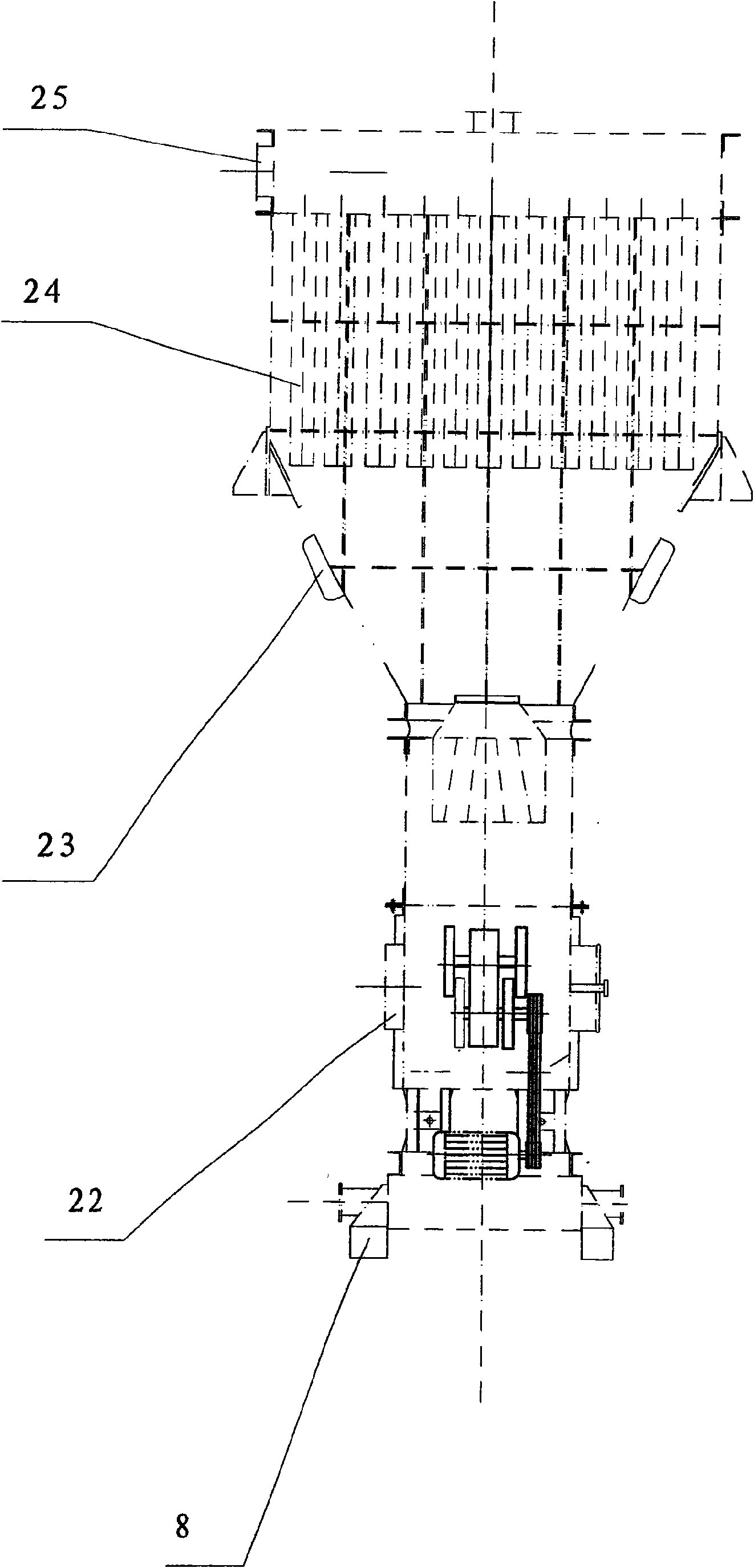

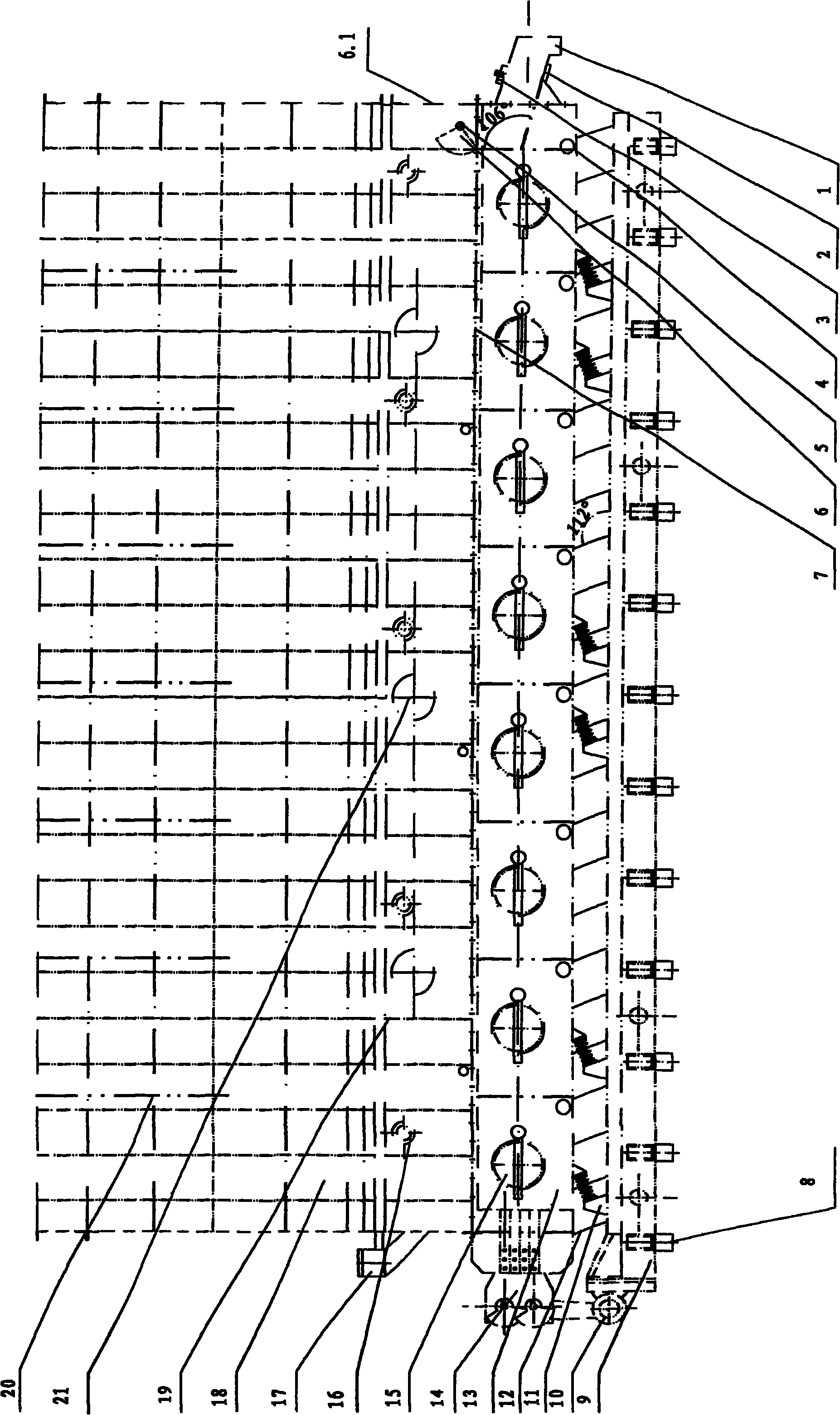

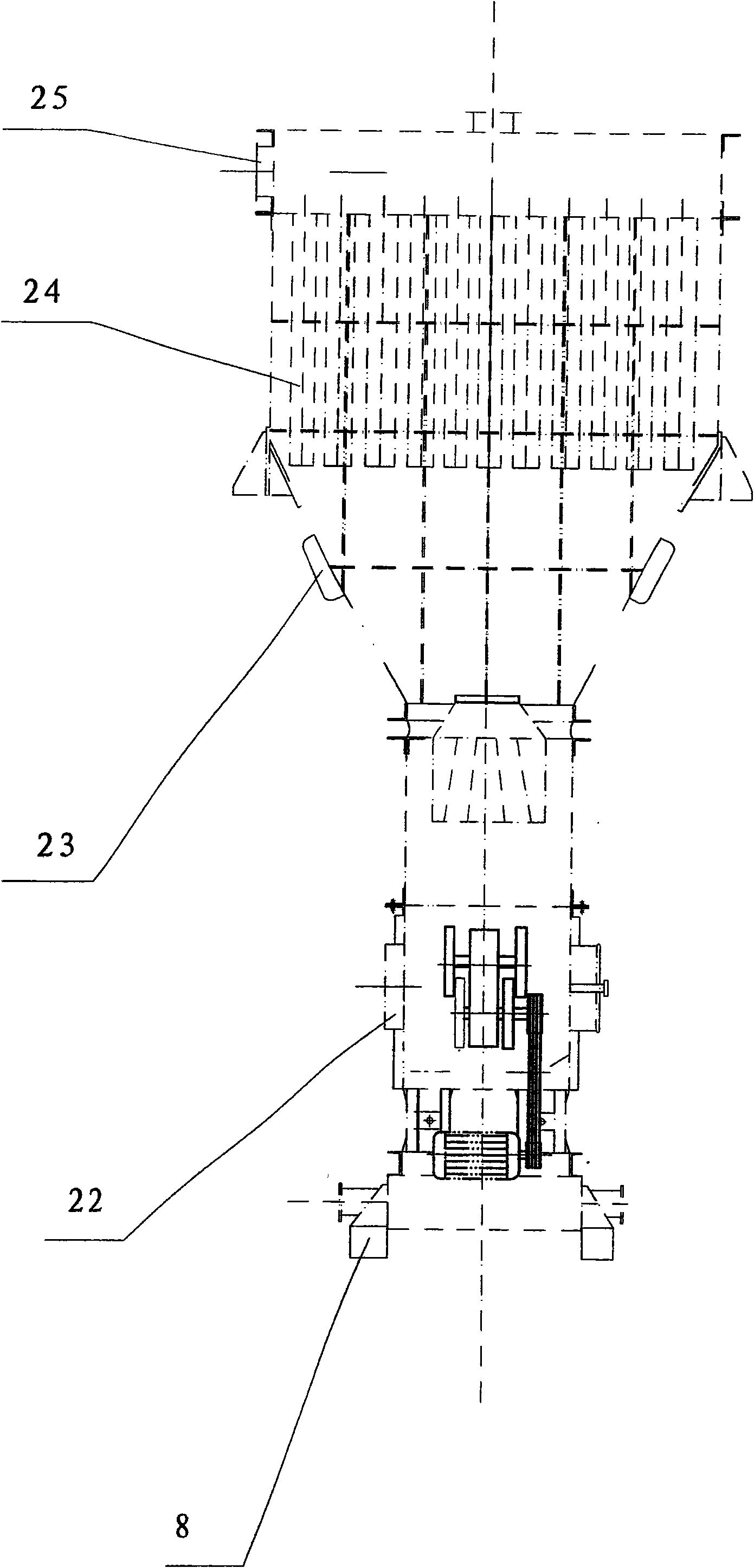

Three-plasmid whole sealing environmentally friendly vibration fluidized bed dryer

InactiveCN101598484ASmooth vibrationConstant amplitudeDrying solid materials with heatHearth type furnacesVibratory fluidized bedEnvironmentally friendly

The invention relates to a three-plasmid whole sealing environmentally friendly vibration fluidized bed dryer which is suitable for drying powder material of regular shape such as Laroflex MP with granularity ranging from 50mu m to 5000mu m. The drier comprises a foundation (9), a lower housing (13), a fluidized bed body (6), an upper housing (18) and a bag type dust collector (24); wherein the lower housing (13) is supported on the foundation (9) by a slantly arranged plate spring (12), a case type vibration exciter (14) is arranged at the front end of the lower housing (13), the fluidized bed body (6) is arranged above the lower housing (13) and internally provided with a hood-shaped fluidized bed plate (7), the upper housing (18) is arranged above the fluidized bed body (6) and internally provided with a plurality of groups of bag type dust collectors (24). An air-reserve tank (24.6) is arranged outside the upper housing (18), a plurality of air branch pipes (24.3) are internally arranged in the air-reserve tank (24.6), wherein each air branch pipe (24.3) is provided with a pulse solenoid valve (24.5), the bottom part thereof is provided with an air source hole (24.7). The drier of the invention features low energy consumption, high production efficiency, good operation stability and good uniformity of products.

Owner:江阴丰力生化工程装备有限公司

Black Locust particle/polyvinyl formal composite filler and preparation method thereof

InactiveCN103274519AGood biocompatibilityImprove film formationSustainable biological treatmentBiological water/sewage treatmentPolymer sciencePolyvinyl alcohol

The invention relates to a Black Locust particle / polyvinyl formal composite filler and a preparation method thereof, and belongs to the environmental engineering material field. The composite filler is obtained through compounding polyvinyl formal (PVFM) foam tissues as a matrix with a disperse phase; and the disperse phase comprises Black Locust particles having particle sizes of 60-120 meshes, and the Black Locust particles are obtained through peeling natural Black Locust particle branches, boiling in an alkali, and crushing. The preparation method of the composite filler comprises the following steps: dissolving polyvinyl alcohol in water, adding a surfactant and the Black Locust particles at 40-80DEG C, uniformly stirring, adding an acid for adjusting the pH value to 1-3, adding formaldehyde or paraformaldehyde, and carrying out high speed stirring while reacting for foaming the obtained system until the volume is not expanded; and dumping the obtained system to a foam die, and carrying out heat insulation curing at 50-65DEG C for 10-24h. The composite filler provided by the invention has the advantages of high biocompatibility, superior film hanging performance, and maintenance of many excellent characteristics of the PVFM, such as low density, high specific surface area, high poriness, good elasticity, wear resistance, corrosion resistance and the like.

Owner:ZHENGZHOU UNIV

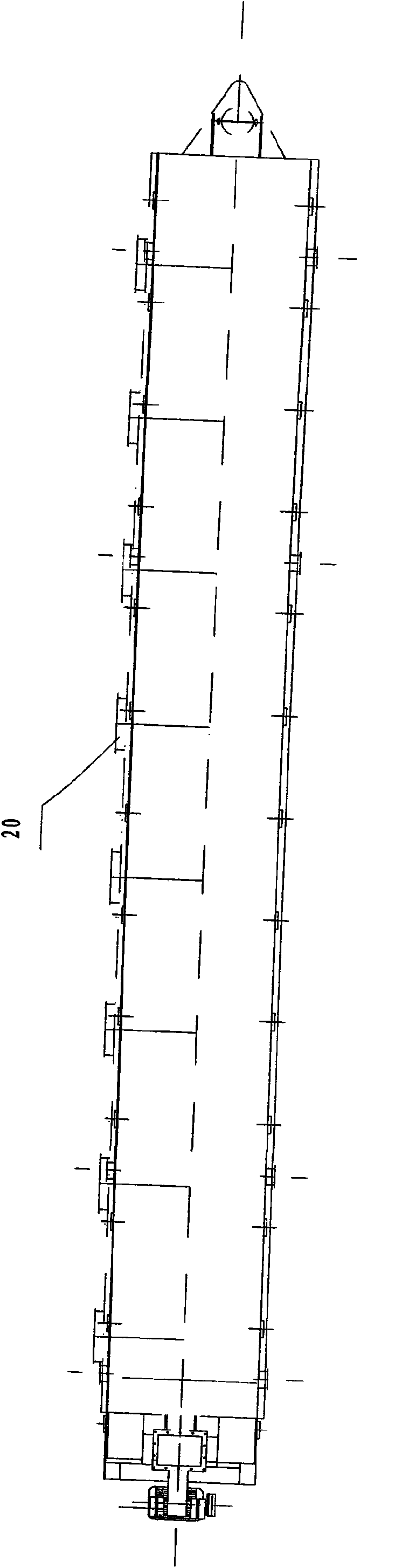

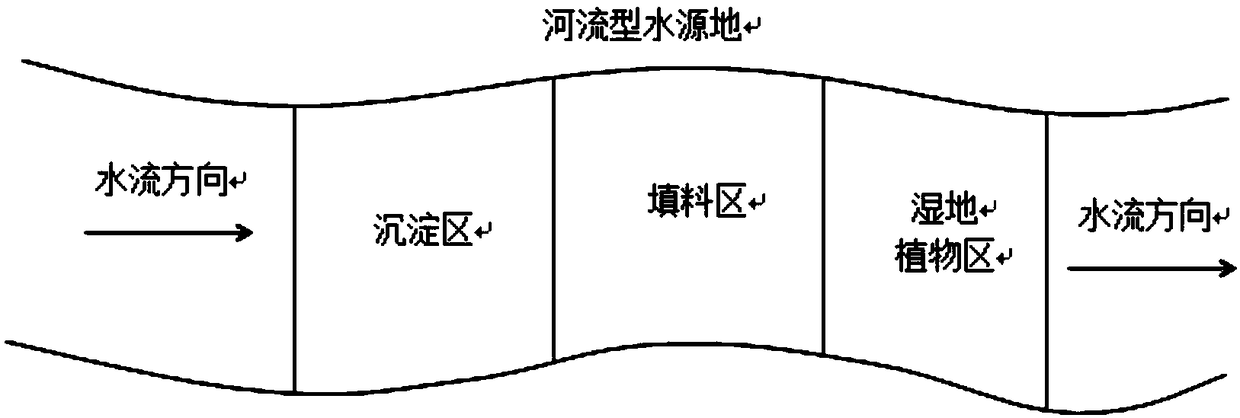

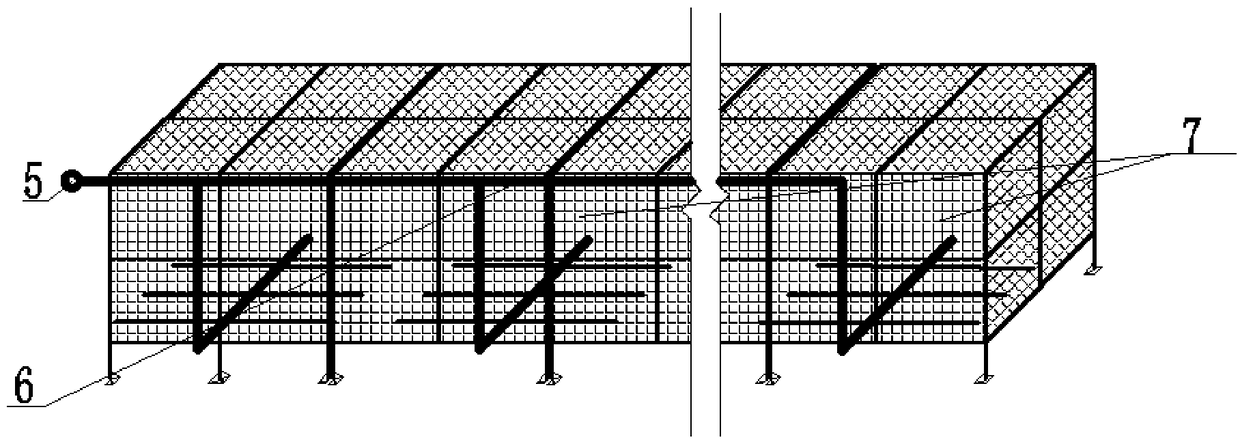

Biological pretreatment system and method applicable to river type source water

PendingCN109437484AReduce pollution loadFluidized state is goodTreatment using aerobic processesWater contaminantsWater treatmentSedimentation

The invention discloses a biological pretreatment system and method applicable to river type source water and the method belongs to the technical field of water treatment. The biological pretreatmentmethod applicable to river type source water does not require new construction of structures, does not occupy land and is an in-situ pretreatment method. Source water flows into a filler zone after natural sedimentation and makes full contact with filler for reaction under the dual action of natural flow state and microporous aeration of water, the biodegradability of the water is improved, the concentration of ammonia nitrogen and COD in the water can be effectively reduced, finally, the water flows into a wetland plant area, and pollutants in the source water are further reduced under the actions of assimilation, absorption and conversion of plants-organisms. The method has the advantages of low capital construction investment, implement simplicity, stable operation, significant effectsand the like.

Owner:NANJING UNIV YANCHENG ENVIRONMENTAL PROTECTION TECH & ENG RES INST +1

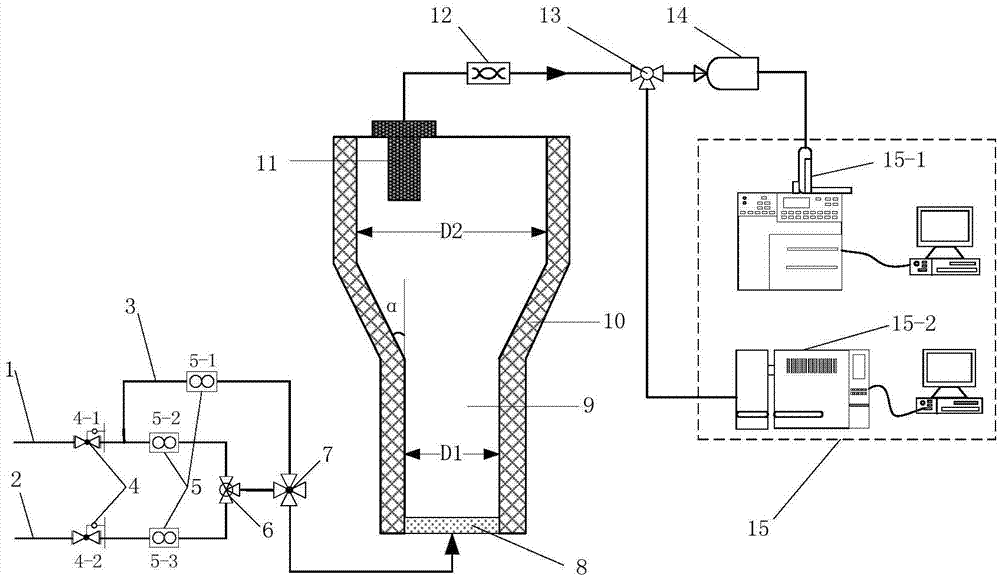

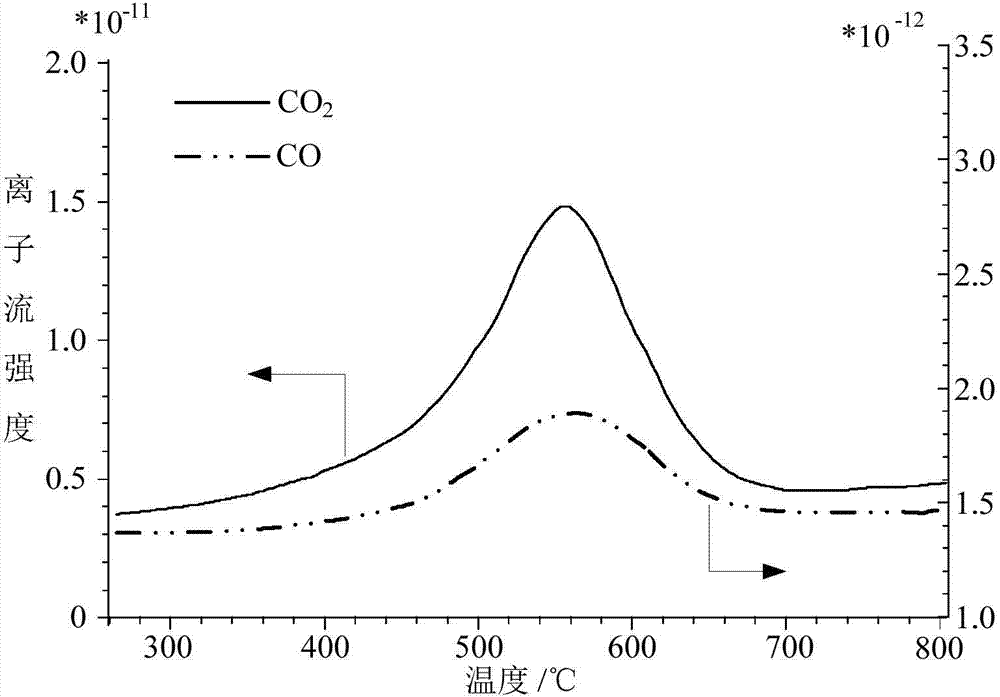

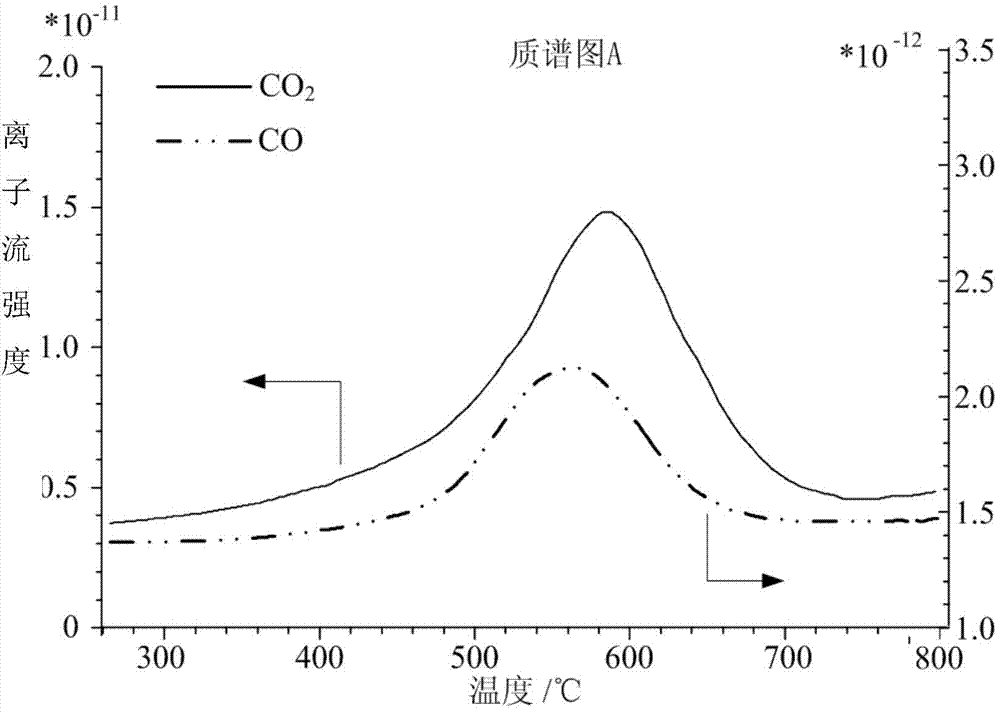

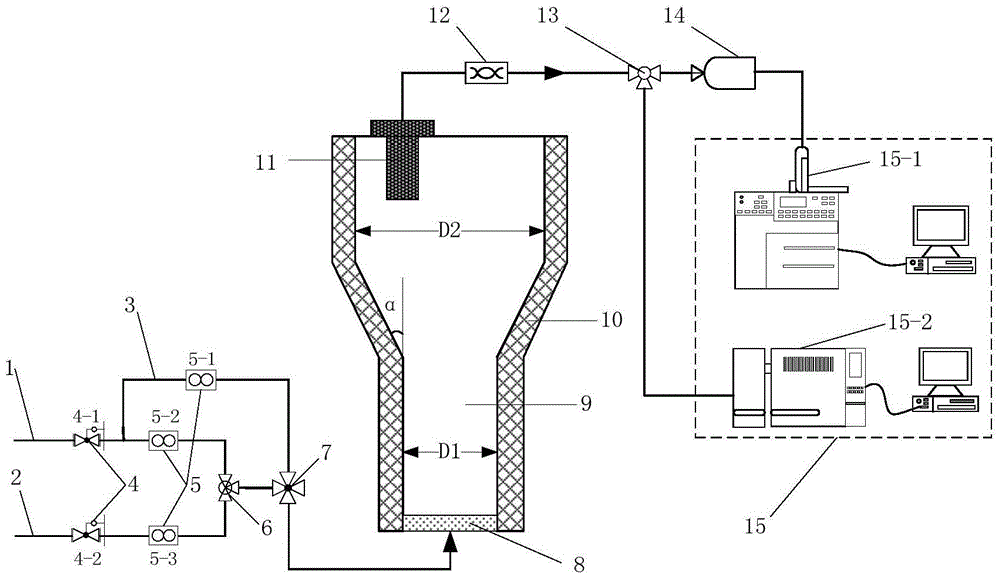

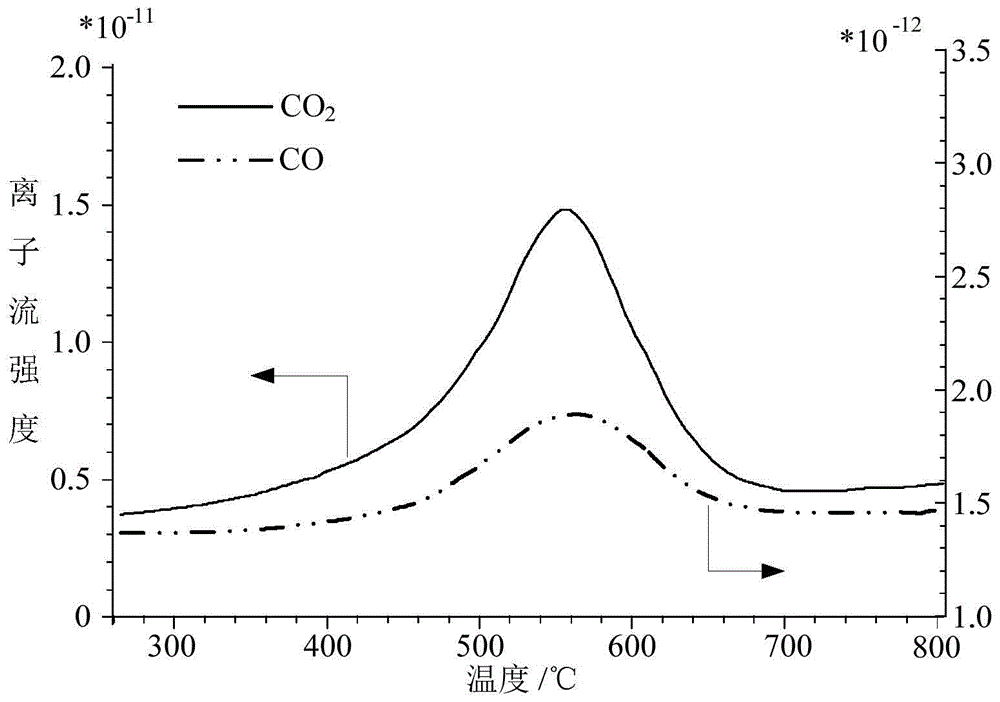

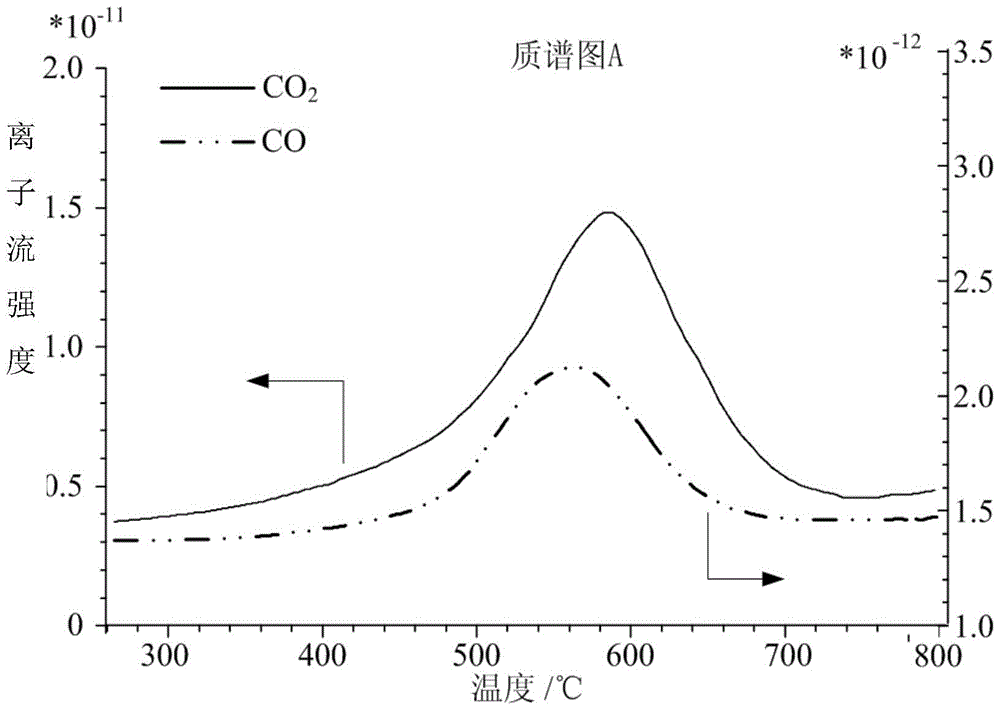

Catalytic cracking reactivator test simulation method and device

ActiveCN104845661AFluidized state is goodFully contactedCatalytic crackingCatalyst regeneration/reactivationProduct gasOperant conditioning

The invention discloses a catalytic cracking reactivator test simulation method. The method includes mixing a gas 1 and a gas 2 online to enter a reactor; allowing the catalyst in a reaction tube to be in a fluidizing state through the mixed gas; allowing the mixed gas to react with the catalyst; performing gas-solid separation on the reacted gas; metering and / or analyzing the separated gas. The fluidizing principle is utilized, on the set operation condition, the catalyst can be maintained in a fine fluidizing state in the reaction tube, the reactivating process for catalytic cracking of the catalyst to reactivate in the industrial state can be simulated effectively, and the important significance is provided for predicting and indicating the actual industry process.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

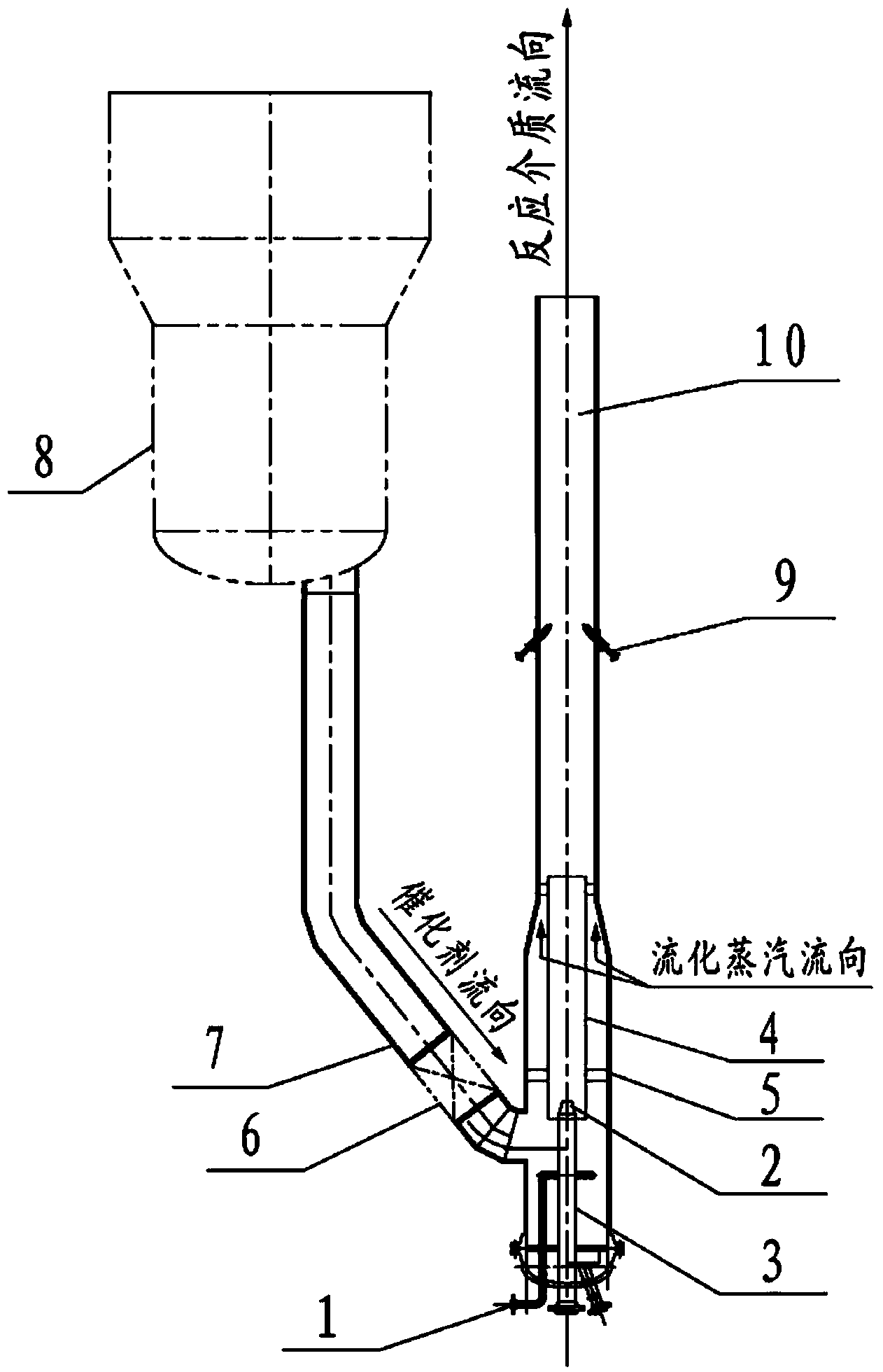

Lift pipe reactor pre-lifting device and process flow thereof

InactiveCN103849424AEnough buffer spaceSmall pressure fluctuationsCatalytic crackingChemical/physical processesSpray nozzleEngineering

The invention relates to a lift pipe reactor pre-lifting device and a process flow thereof. The lift pie reactor pre-lifting device comprises a fluidized vapor ring, a pre-lifting vapor nozzle, a pre-lifting vapor pipe, an expansion section, a single-action slide valve and a regeneration inclined pipe. An inner conveyor pipe is arranged in the expansion section, the lower part of the inner conveyor pipe is connected with the upper part of the pre-lifting vapor pipe, and the inner diameter of the pre-lifting device is twice as large as the inner diameter of the upper part of a lift pipe reactor. By adopting the method in which the inner conveyor pipe is increased, the inner diameter of the pre-lifting device is increased and therefore the structure of the expansion section is changed, the catalyst entering the expansion section has a sufficient buffering space, so that the blanking pressure fluctuation of the regeneration inclined pipe is reduced, the bias current generated by an S-shaped movement orbit can be eliminated, the pre-lifting vapor pipe can avoid the regeneration inclined pipe, the direct impact of the pre-lifting vapor on a blanking port of the regeneration inclined pipe can be avoided, the circulating capacity of the catalyst of a settlement regenerator can be increased, the catalyst in the lift pipe can be uniformly distributed, and the yield of a target product can be improved.

Owner:LUOYANG ZHIBANG PETROCHEM EQUIP

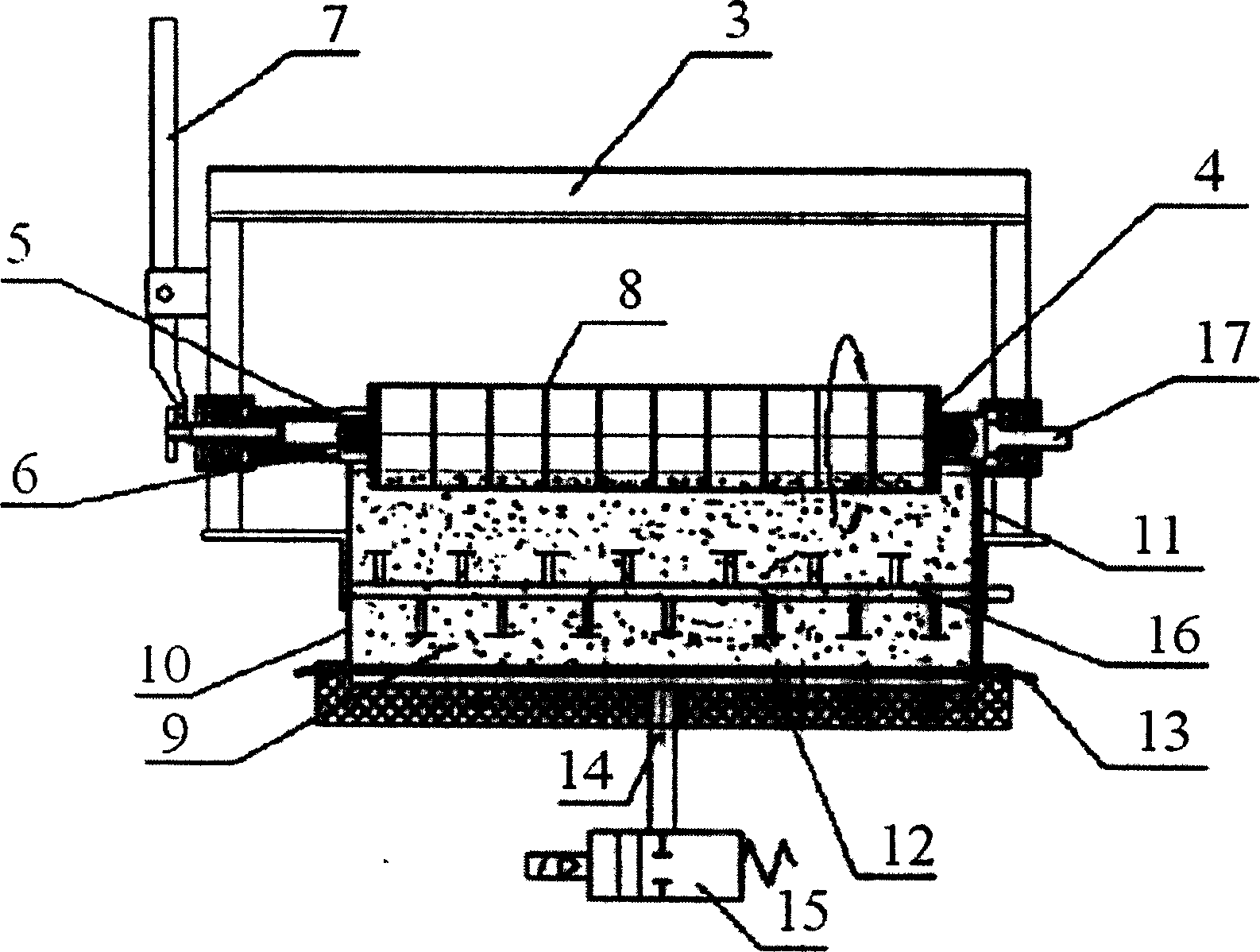

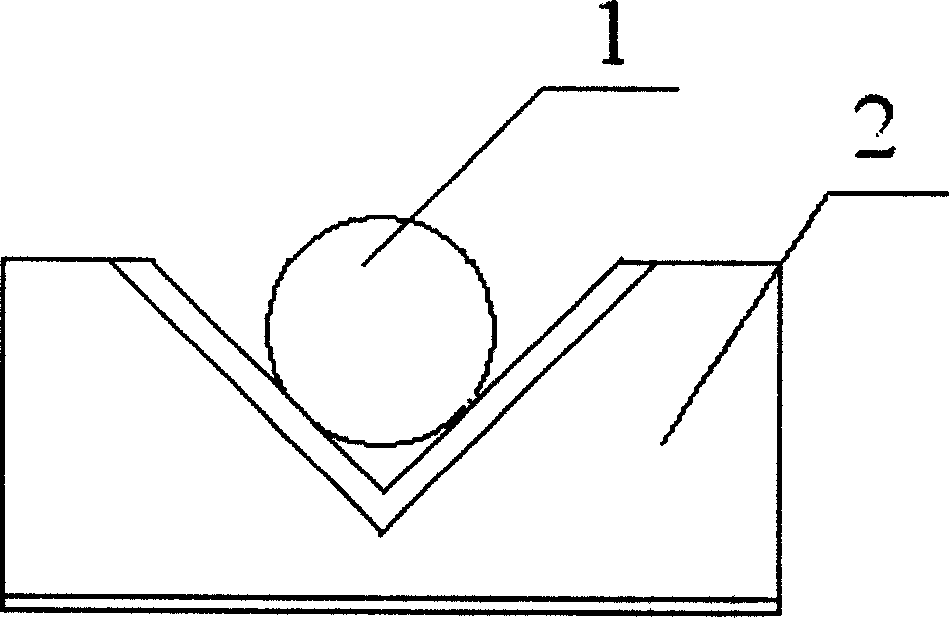

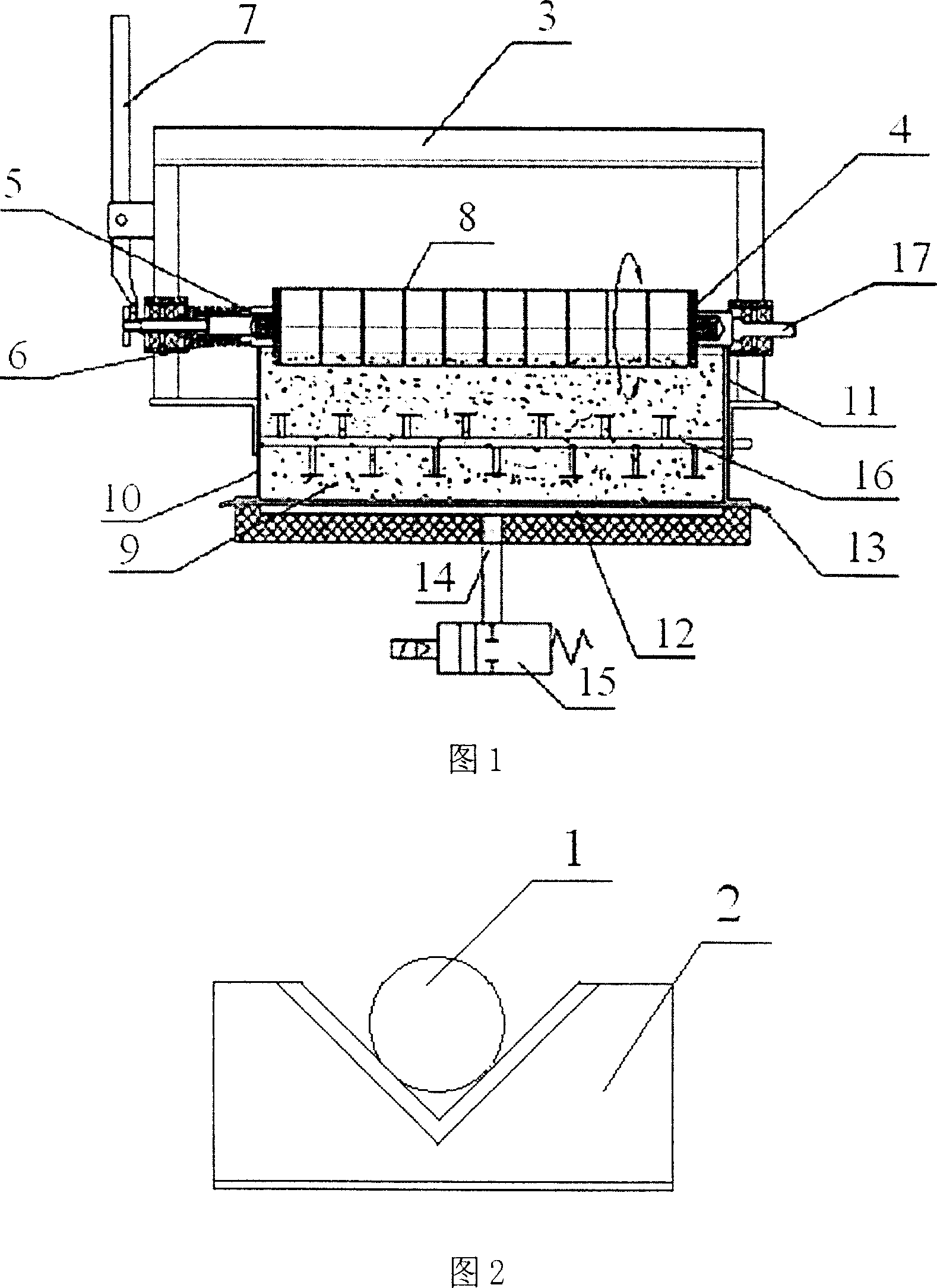

Zinc-oxide resistor-piece side insulation package device and packing method

InactiveCN1677578AFluidized state is goodEnvelope/housing resistor manufactureResistor housing/enclosing/embeddingEpoxyFluidized bed

The packaging set comprises fluid bed and clamping apparatus on the fluid bed. The fluid bed includes upper box, lower box and distribution plate between the upper and lower box. Air in nozzle connected to air current control valve is on the lower box. The said clamping apparatus includes two pieces of grip holders. One holder is connected to rotating shaft. Located between two holders, V shaped mould is in use for placing resistance pieces of zinc oxide. Isolation layers are setup between two resistance pieces. The fluid bed loosens epoxy-insulating powder, keeps it in good condition, and preheats temperature of sidewall of resistance pieces above melting point of epoxy insulating powder. Heat deposition method is adopted for carrying out encapsulation. After thermofixation, excellent insulation protection layer is formed on side faces of resistance pieces of zinc oxide.

Owner:XI AN JIAOTONG UNIV

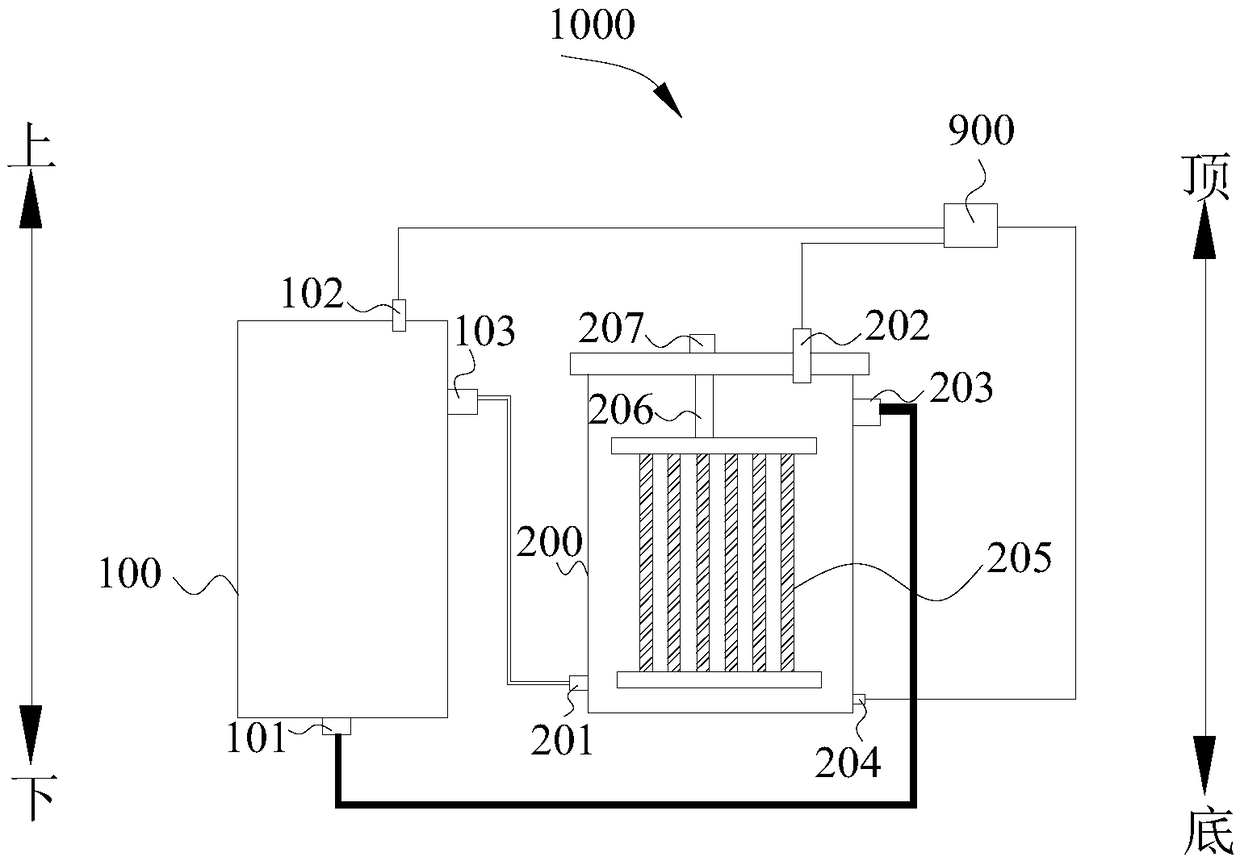

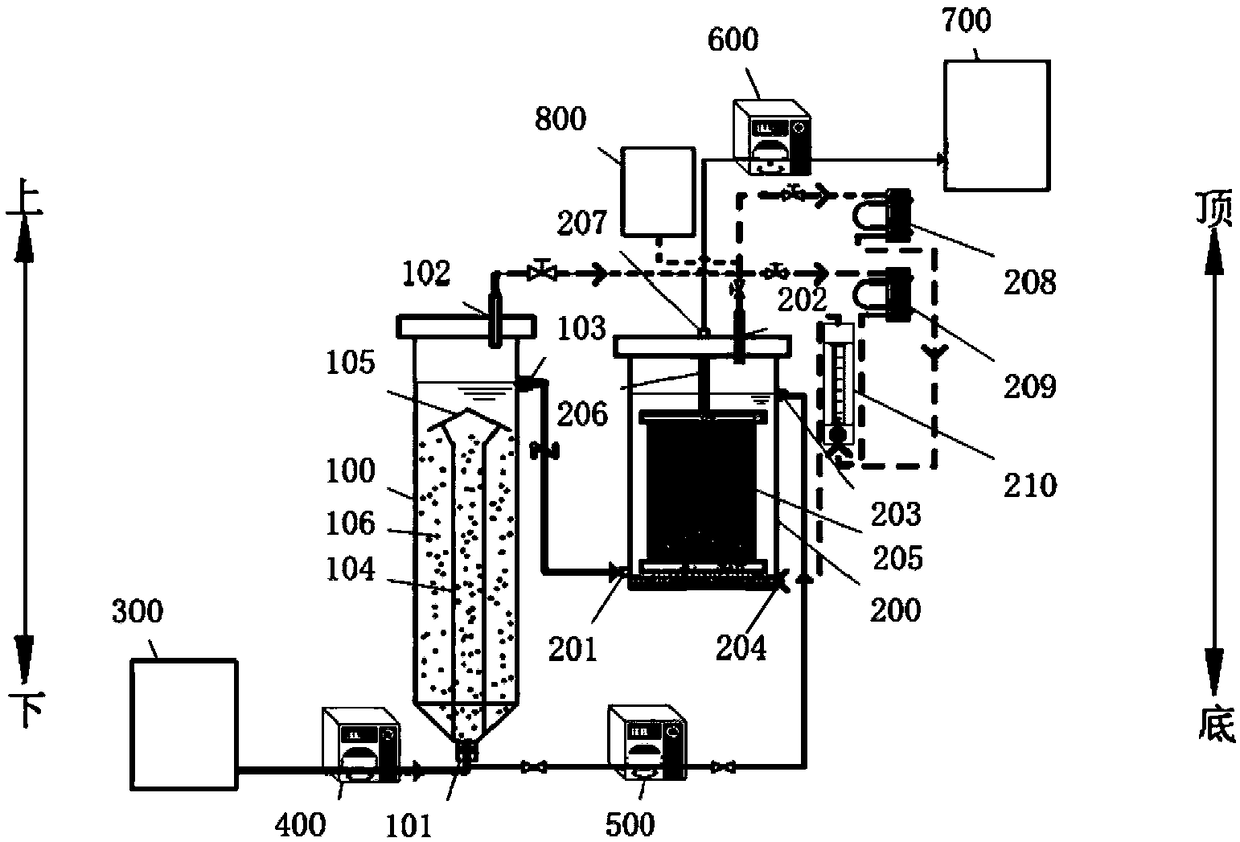

Sewage treatment device and sewage treatment method

PendingCN109052815AFluidized state is goodSave running costSpecific water treatment objectivesWater/sewage treatment bu osmosis/dialysisFluidized bedOperating energy

The invention discloses a sewage treatment device and a sewage treatment method. The sewage treatment device provided by the invention specifically comprises: an anaerobic fluidized bed having a firsthousing, the lower part of the first housing having a first water inlet port, the upper part of the first housing having a first water outlet port and a first gas outlet; a membrane filtration processing unit having a second housing, the lower part of the second housing having a second water inlet port and an aeration port, the upper part of the second housing having a second water outlet port and a second gas outlet, the second water inlet port being connected to the first water outlet port, a filter membrane component being arranged in the second housing, a water outlet port being arrangedat the top part of the filter membrane component, the water outlet port being connected to the second water outlet port, a return port being arranged at the side wall of the second housing, the returnport being arranged between the filter membrane component and the top part of the second housing, and the return port being communicated with the first water inlet port; and a biogas circulation unitrespectively connected to the first gas outlet and the second gas outlet, the unit being able to continuously supply gas to the aeration port. The sewage treatment device can reduce membrane pollution and reduce operating energy consumption.

Owner:TSINGHUA UNIV

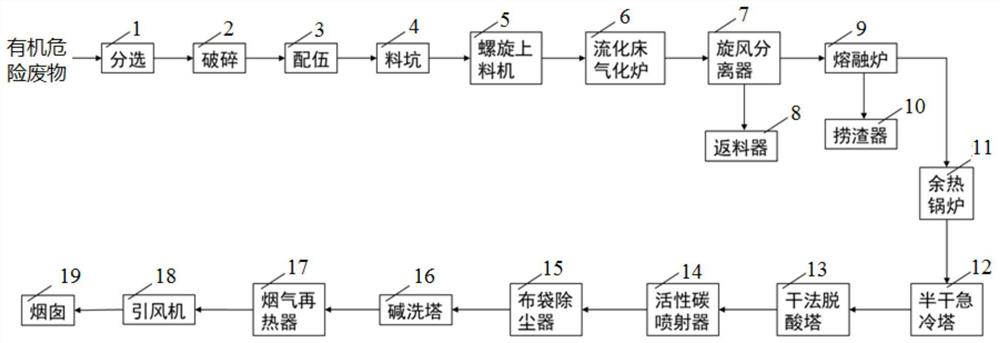

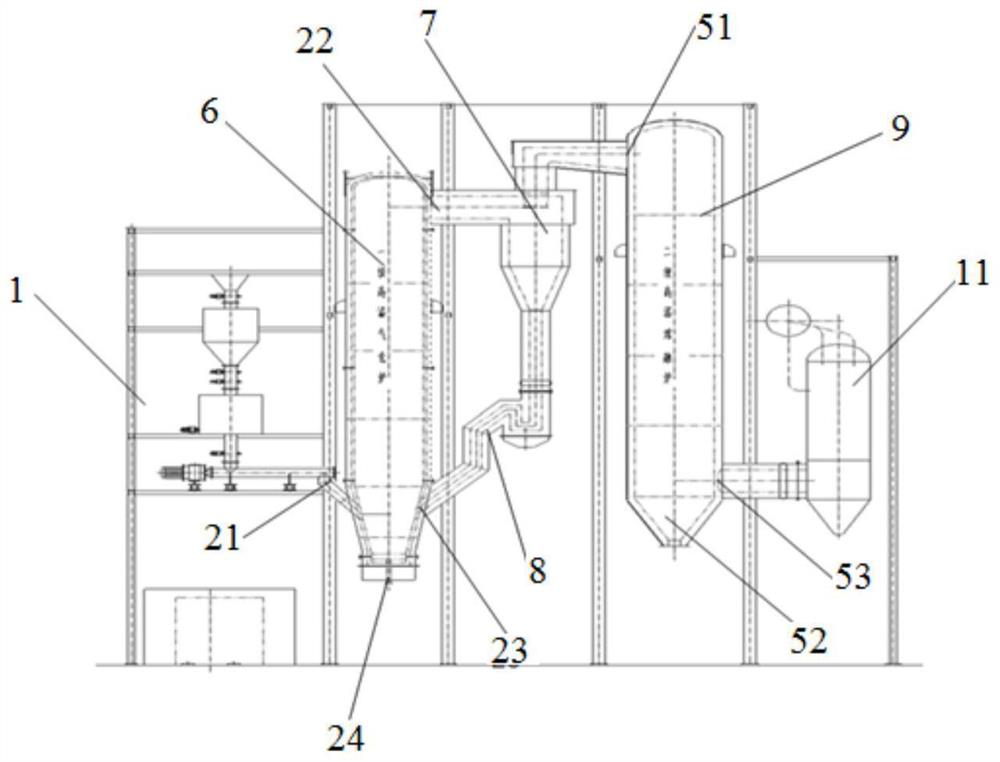

Organic hazardous waste gasification melting treatment system and method

PendingCN114110606AFluidized state is goodLess coking problemsIndirect carbon-dioxide mitigationIncinerator apparatusCarbonizationMolten slag

The invention discloses an organic hazardous waste gasification and melting treatment system and method.The gasification and melting treatment system comprises a material matching and feeding system used for matching and conveying materials; the circulating fluidized bed gasification melting system comprises a circulating fluidized bed gasification furnace, a cyclone separator, a return feeder, a melting furnace and a slag dredger which are connected in sequence, the circulating fluidized bed gasification furnace is connected with the spiral feeding machine of the feeding system, and organic hazardous waste is subjected to pyrolysis gasification to obtain pyrolysis gas, carbonized coarse particles and carbonized fine particles; the cyclone separator separates the pyrolysis gas, the carbonized fine particles and the carbonized coarse particles, the carbonized coarse particles are returned to the circulating fluidized bed gasification furnace through the return feeder, and the pyrolysis gas and the carbonized fine particles enter the melting furnace; the melting furnace is used for carrying out oxygen-enriched combustion on the pyrolysis gas and melting the carbonized fine particles at a high temperature, and molten slag forms a glass body in a slag salvaging device; the waste heat boiler is used for recovering sensible heat of flue gas discharged by the melting furnace; and the flue gas purification system is used for purifying flue gas generated after sensible heat is recovered by the waste heat boiler.

Owner:中广核环保产业有限公司

Nickel catalytic packing for Fenton reactors

InactiveCN109107576AFluidized state is goodReduce resistanceWater treatment compoundsWater contaminantsEconomic benefitsWastewater

The invention relates to a nickel catalytic packing for Fenton reactors, which belongs to the technical field of wastewater treatment. The nickel catalytic packing for Fenton reactors consists of a carrier and a catalyst loaded on the surface of the carrier, the carrier is natural volcanic rock, which has high mechanical strength and large specific surface area, and can ensure that the packing hasa good fluidized state when in use, and the attached catalyst layer on the surface of the natural volcanic rock is nickel oxide, which has strong catalytic capacity; when the packing is loaded into aFenton tower to treat wastewater, the addition amount of agentia can be greatly reduced, the treatment cost is low, moreover, reaction is rapid, the effluent effect is good, and economic benefit is obvious.

Owner:江苏滨元环境科技有限公司

A catalytic cracking regenerator experimental simulation method and device

ActiveCN104845661BFluidized state is goodFully contactedCatalytic crackingCatalyst regeneration/reactivationGas solidOperant conditioning

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Zinc-oxide resistor-piece side insulation package device and packing method

InactiveCN1319080CFluidized state is goodEnvelope/housing resistor manufactureResistor housing/enclosing/embeddingEpoxyHeat deposition

The packaging set comprises fluid bed and clamping apparatus on the fluid bed. The fluid bed includes upper box, lower box and distribution plate between the upper and lower box. Air in nozzle connected to air current control valve is on the lower box. The said clamping apparatus includes two pieces of grip holders. One holder is connected to rotating shaft. Located between two holders, V shaped mould is in use for placing resistance pieces of zinc oxide. Isolation layers are setup between two resistance pieces. The fluid bed loosens epoxy-insulating powder, keeps it in good condition, and preheats temperature of sidewall of resistance pieces above melting point of epoxy insulating powder. Heat deposition method is adopted for carrying out encapsulation. After thermofixation, excellent insulation protection layer is formed on side faces of resistance pieces of zinc oxide.

Owner:XI AN JIAOTONG UNIV

Self-regulating powder-feeding device by fluidizing gas

InactiveCN101439322BReduce dosageFluidized state is goodLiquid supply arrangementsLower limitElectricity

Owner:YU TUNG ZHONGSHAN ENG

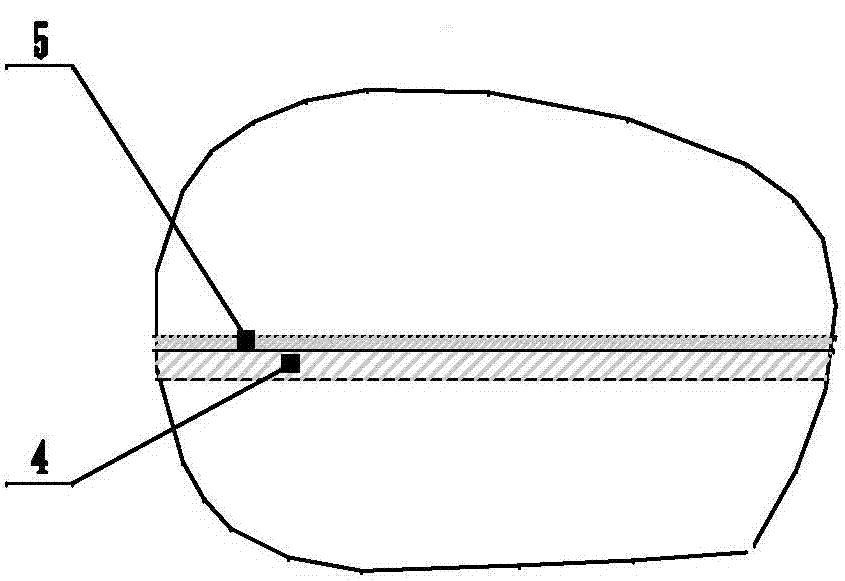

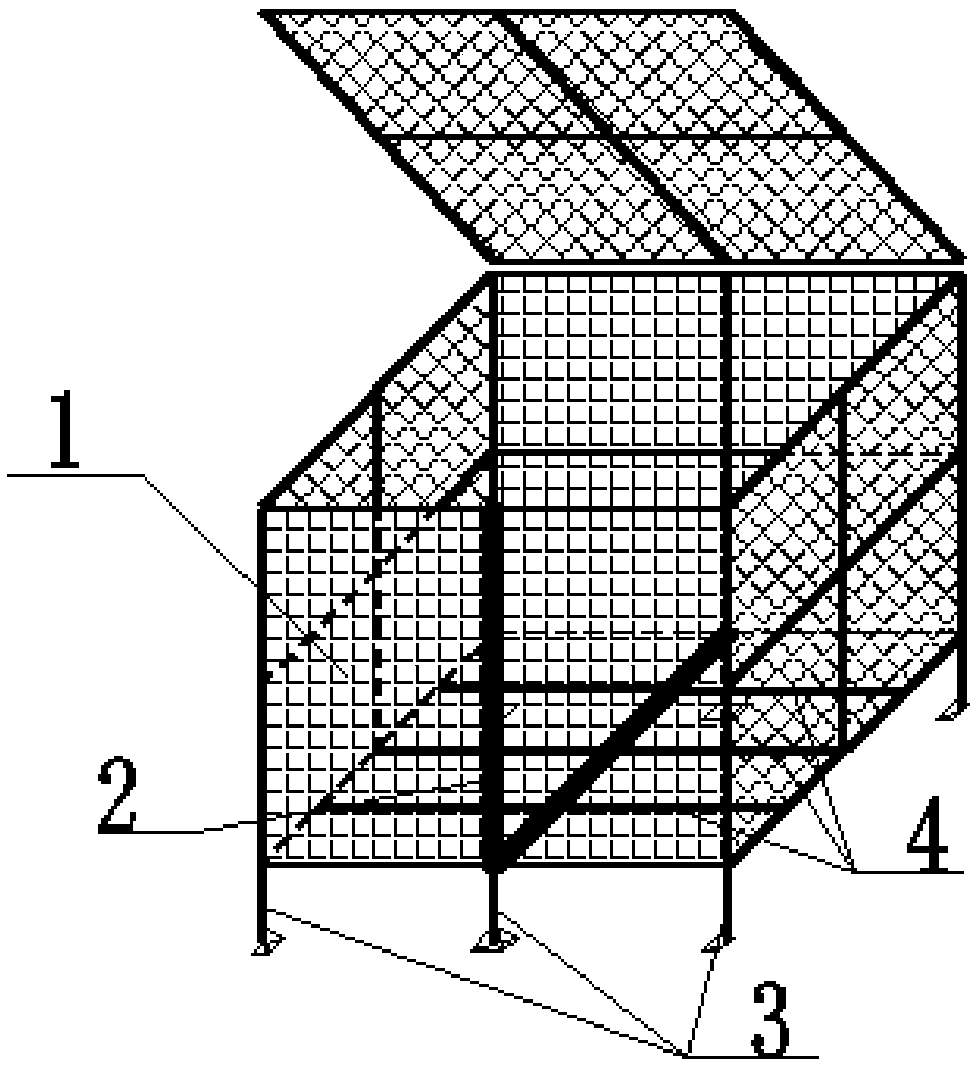

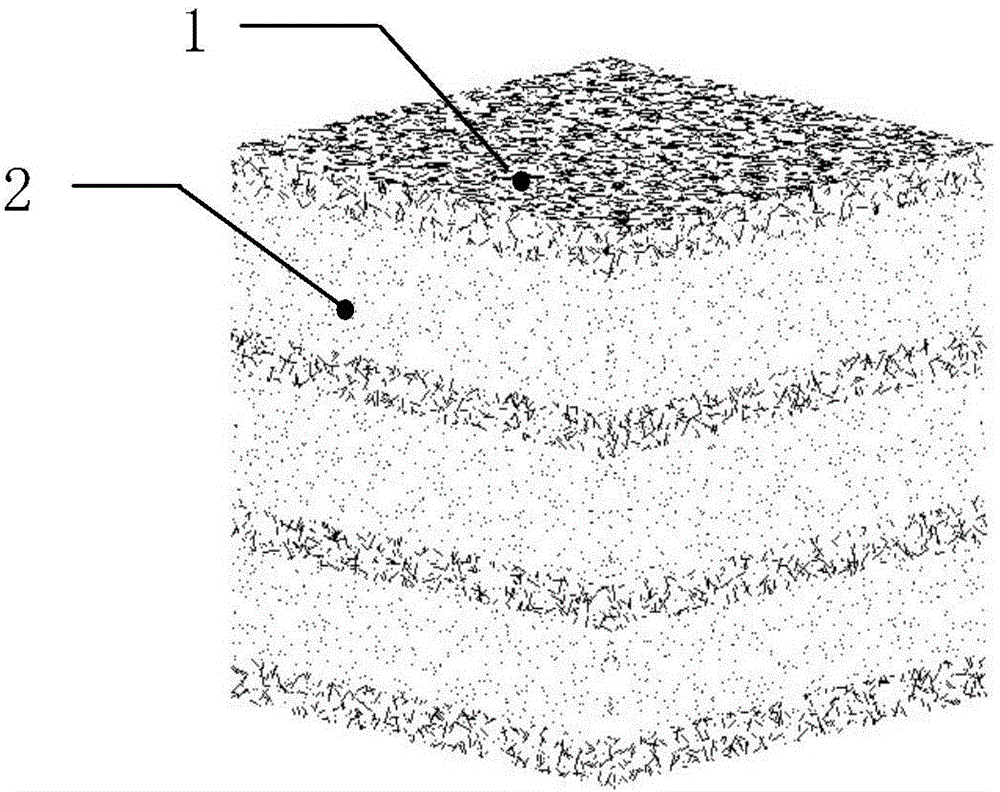

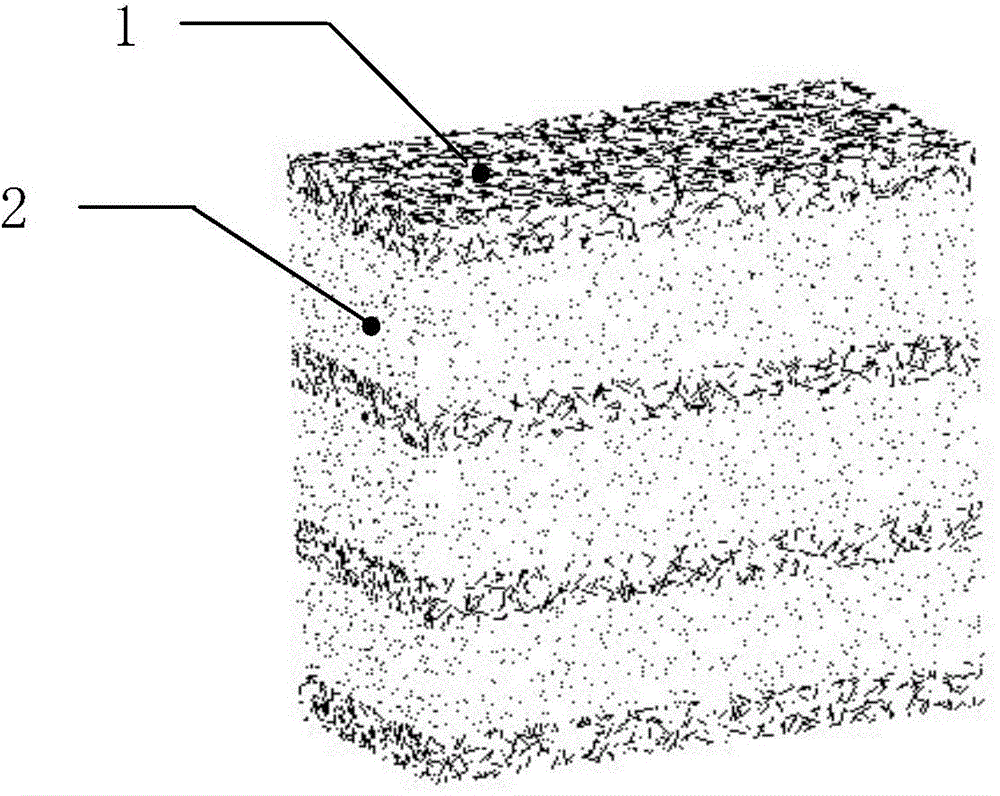

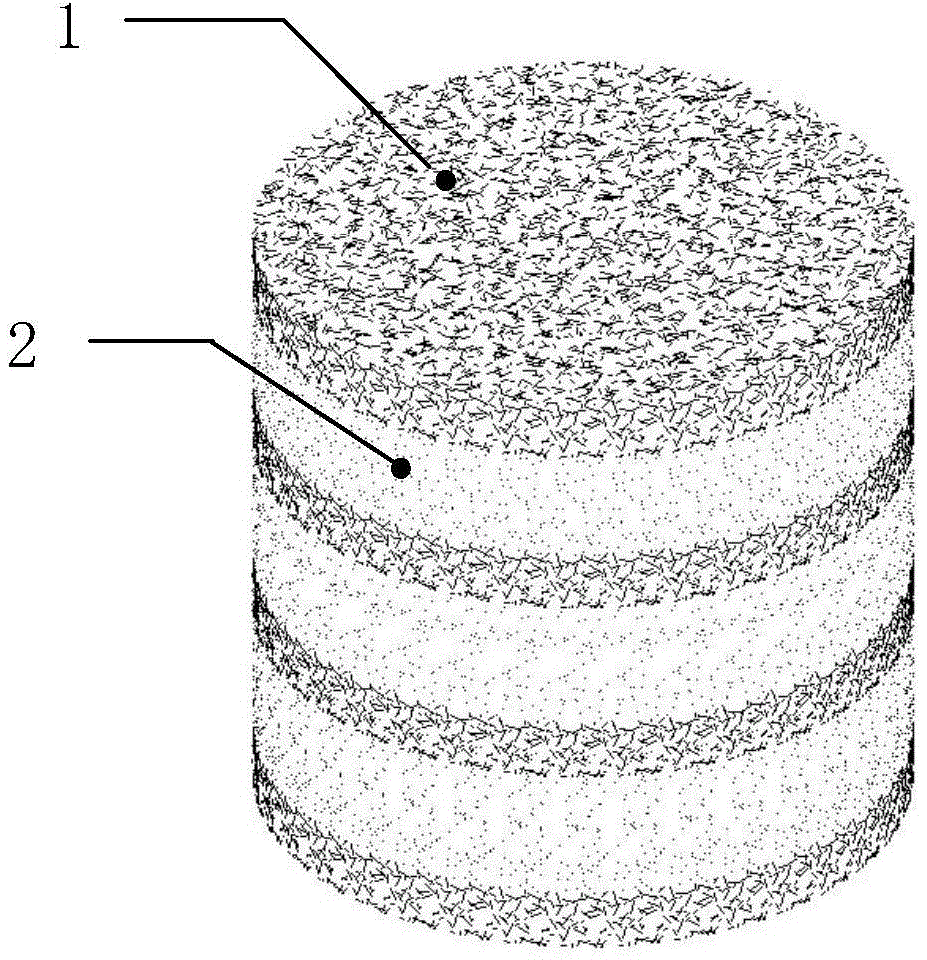

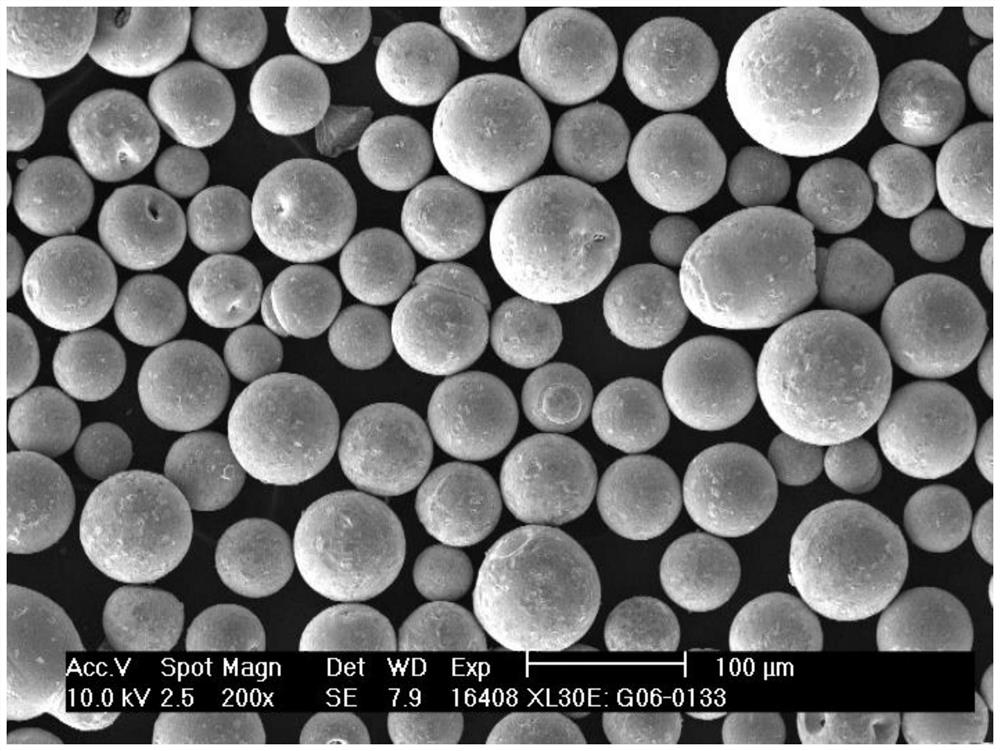

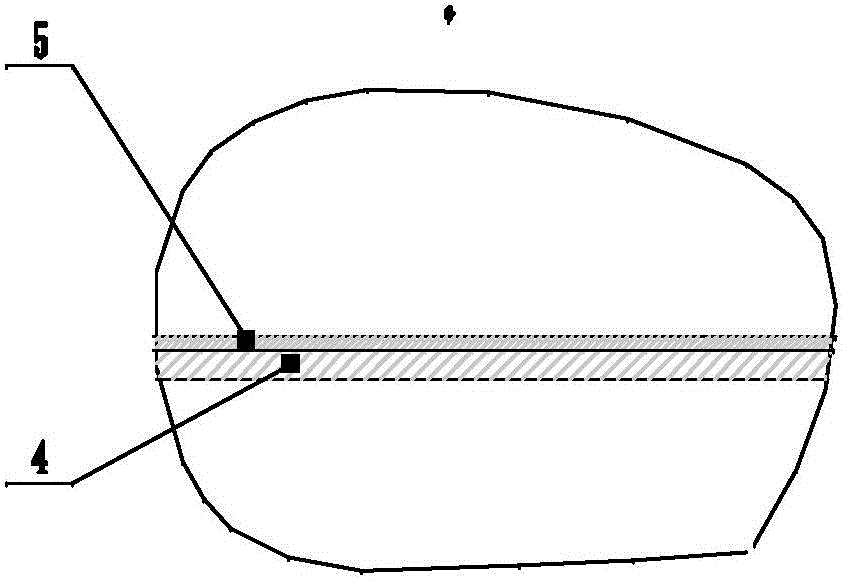

Anaerobic ammonia oxidizing bacteria sandwich-type multilayer immobilized bioactive filler, and preparation and application thereof

ActiveCN103951053AFluidized state is goodReduce mutual frictionTreatment with anaerobic digestion processesLayered structureChemistry

The invention discloses an anaerobic ammonia oxidizing bacteria sandwich-type multilayer immobilized bioactive filler, and preparation and an application thereof, and belongs to the technical field of water treatment. The bioactive filler is composed of two parts: embedding bodies and non-woven carriers; the embedding bodies and the non-woven carriers are in alternative arrangement; fiber yarns of the non-woven carriers and the embedding bodies are combined into a stable organic whole; an embedding liquid formed by mixing an anaerobic ammonia oxidizing bacteria suspension and a polyvinyl alcohol solution evenly coats the non-woven carriers, multiple layers of carriers are overlaid together, after boric acid secondary cross-linking immobilization, the embedding liquid is cured to form the embedding bodies, then a layered filler having a sandwich-like structure is prepared, and then the granular bioactive filler is prepared through cutting the layered filler. A sandwich-like layered structure formed by the non-woven fabrics and the embedding bodies improves the stability of the bioactive filler, the problem of poor stability of a filler prepared by a conventional anaerobic ammonia oxidizing bacteria immobilization method is solved, the concentration of anaerobic ammonia oxidizing bacteria on the filler is high, the treatment efficiency is high, and the bioactive filler has a good application prospect.

Owner:湖南汨罗循环经济产业园区科技创新服务中心

Three-plasmid whole sealing environmentally friendly vibration fluidized bed dryer

InactiveCN101598484BStable fluidizationStable deliveryDrying solid materials with heatHearth type furnacesSolenoid valveGranularity

The invention relates to a three-plasmid whole sealing environmentally friendly vibration fluidized bed dryer which is suitable for drying powder material of regular shape such as Laroflex MP with granularity ranging from 50mu m to 5000mu m. The drier comprises a foundation (9), a lower housing (13), a fluidized bed body (6), an upper housing (18) and a bag type dust collector (24); wherein the lower housing (13) is supported on the foundation (9) by a slantly arranged plate spring (12), a case type vibration exciter (14) is arranged at the front end of the lower housing (13), the fluidized bed body (6) is arranged above the lower housing (13) and internally provided with a hood-shaped fluidized bed plate (7), the upper housing (18) is arranged above the fluidized bed body (6) and internally provided with a plurality of groups of bag type dust collectors (24). An air-reserve tank (24.6) is arranged outside the upper housing (18), a plurality of air branch pipes (24.3) are internally arranged in the air-reserve tank (24.6), wherein each air branch pipe (24.3) is provided with a pulse solenoid valve (24.5), the bottom part thereof is provided with an air source hole (24.7). The drier of the invention features low energy consumption, high production efficiency, good operation stability and good uniformity of products.

Owner:江阴丰力生化工程装备有限公司

Self-cleaning fluidized bed reactor for carbon nanotube production

ActiveCN105854740BFluidized state is goodSmall effective volumeCarbon nanotubesChemical/physical processesFluidized bedCarbon nanotube

Owner:SHENZHEN SSZK NEW MATERIALS CO LTD

Biological desulphurization processing reactor, biological desulphurization processing system, and processing method

ActiveCN102476893BLow purityAvoid cloggingSulfur preparation/purificationMultistage water/sewage treatmentProduction rateParticle flow

The invention provides a biological desulphurization processing reactor, a biological desulphurization processing system, and a processing method. The reactor comprises a three phase separator and a reaction zone. The reaction zone comprises an outer cylinder, a gas guiding cylinder and a lower flow guiding cylinder, such that the reaction zone is separated into an air-lift zone, an anoxic zone, and a descent zone. The three phase separator comprises an outer frustum, an inner inverted frustum, an outer sedimentation tank, an inner sedimentation tank, and an overflow groove, such that the three phase separator is separated into three sedimentation zones. Sulfide-containing wastewater is mixed with oxygen-containing water from the air-lift zone in the anoxic zone; under the effect of immobilized microorganisms, the sulfide is partially oxidized into elementary sulfur; the mixture is delivered through the three phase separator arranged above, such that the immobilized carrier is separated from a water phase and a gas phase, and sulfur particles flow out with water. According to the invention, with the structure of the reactor and the processing method, a good fluidized state is maintained, and the loss of the immobilized carrier is inhibited. The reactor, the system and the method are advantaged in high elementary sulfur production rate, good processing capacity, hydraulic load impact resistance, substrate load impact resistance, simple structure, and easy amplification.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

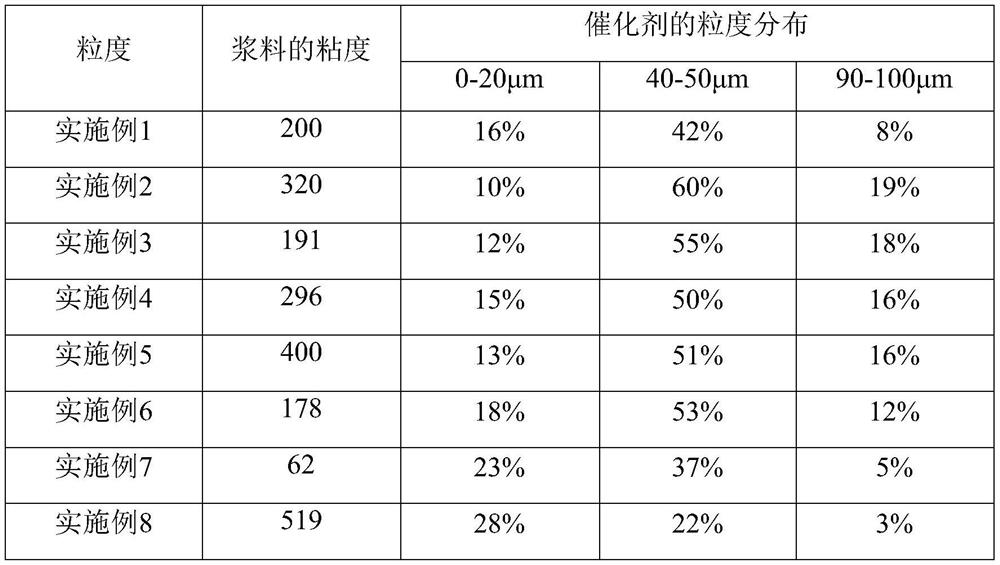

Catalyst for preparing low-carbon olefin from synthesis gas as well as preparation method and application thereof

ActiveCN112705216AImprove particle size distributionFluidized state is goodHydrocarbon from carbon oxidesHeterogenous catalyst chemical elementsPtru catalystFluidized bed

The invention discloses a catalyst for preparing low-carbon olefin from synthesis gas as well as a preparation method and an application of the catalyst. The catalyst provided by the invention has good particle size distribution, has a good fluidized state when a reaction is carried out in a fluidized bed reactor, and is excellent in performance and relatively high in CO conversion rate and low-carbon olefin selectivity. By using the catalyst provided by the invention, a synthesis reaction for preparing olefin from synthesis gas is carried out under the conditions that the reaction temperature is 200-600 DEG C, the reaction pressure is 0.5-10MPa, the catalyst load is 100-8000mL.h<-1>. g<-1> and the raw material ratio (molar) H2 / CO is (0.1-5.0): 1, the CO conversion rate can reach 91.7%, the selectivity of low-carbon olefin in a reaction product can reach 71.3%, and better technical effects can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

White granulated sugar vibrated fluidized bed

InactiveCN103571975BFluidized state is goodGood vibration reduction effectSugar dryingDrying solid materials with heatEngineeringSugar

The invention discloses a white granulated sugar vibrated fluidized bed. The white granulated sugar vibrated fluidized bed comprises a main machine box, a vibration motor and a macroporous plate and a seashell-type pore plate, wherein the main machine box is of a hollow structure with a ventilation cavity, and a vibration bed is arranged at the upper part of the main machine box; the vibration motor is used for driving the vibration bed to vibrate in an upper and down slant direction, and the slant direction is the white granulated sugar advancing direction; the macroporous plate is arranged on the vibration bed and vibrates along with the vibration bed under the driving of the vibration bed, and multiple straight-through holes are formed in the macroporous plate and are communicated with the ventilation cavity; the seashell-type pore plate is arranged on the macroporous plate, multiple seashell-shaped raised seashell through holes are formed in the seashell-type pore plate and are two groups of seashell-shaped through holes which are arranged in a staggering manner, and the opening directions of the seashell-shaped through holes are vertical to each other; white granulated sugar to be fluidized is fed into the seashell-type pore plate. Materials in the white granulated sugar vibrated fluidized bed are at good mixing and boiling state under the effect of wind power, and as vertical surfaces are not provided with openings, the materials are unlikely to block the openings and leak below the bed.

Owner:广西幸丰科技有限责任公司

Production method for polyurethane enveloped controlled release fertilizer

The invention relates to a production method for polyurethane enveloped controlled release fertilizer. The production method comprises the following steps: preheating granulated fertilizer in a fluidized bed in a fluidizing state; atomizing liquid paraffin, and pretreating the surface of the granulated fertilizer; mixing polyatomic alcohol and isocyanate in a nozzle, atomizing the mixture fast, and spraying the mixture onto the surface of the granulated fertilizer; controlling material adding speeds to ensure that polyurethane reaction can be fulfilled fast; adding liquid paraffin and carrying out surface anti-sticking treatment after the filling of reaction materials. According to the invention, the fluidized bed is adopted as enveloping equipment, polyatomic alcohol and isocyanate are used for spraying and enveloping after being premixed, and the adding speeds are regulated in a matched manner, so that the whole enveloping reaction process is fast and continuous. The production method can improve the polyurethane enveloping efficiency to a relatively large extent, and ensure relatively stable and reliable quality of the enveloped fertilizer due to continuous reaction.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

A method for increasing the formation rate of anaerobic ammonium oxidation granular sludge

ActiveCN105502652BIncreased nitrogen loadingRapid enrichmentWater contaminantsTreatment with anaerobic digestion processesSubstrate concentrationNutrient

The invention relates to a method for increasing the forming speed of anaerobic ammonia oxidation granule sludge. The method comprises the steps that practical industrial wastewater with low C / N is taken as a culturing nutrient source of the anaerobic ammonia oxidation granule sludge, and the mass concentration ratio of NH4<+>-N to NO2<->-N of inflow water is controlled to be (1.05-1.42) to 1; a mixture of anaerobic sludge and livestock breeding faeces is taken as inoculated sludge, by means of the modes of changing the substrate concentration of the inflow water, shortening the hydraulic retention time, controlling the granule size, the granule sludge settling speed and MLVSS / MLSS of the anaerobic ammonia oxidation granule sludge and the like, a nitrogen load of anaerobic ammonia oxidation inflow water is changed, the retention and amplification problems of anaerobic ammonia oxidation bacteria can be effectively solved, and by means of granulation of anaerobic ammonia oxidation sludge, the influence of nitrogen removal efficiency dropping caused by environmental changes can be weakened to some extent.

Owner:上海生迈缘生物科技有限公司

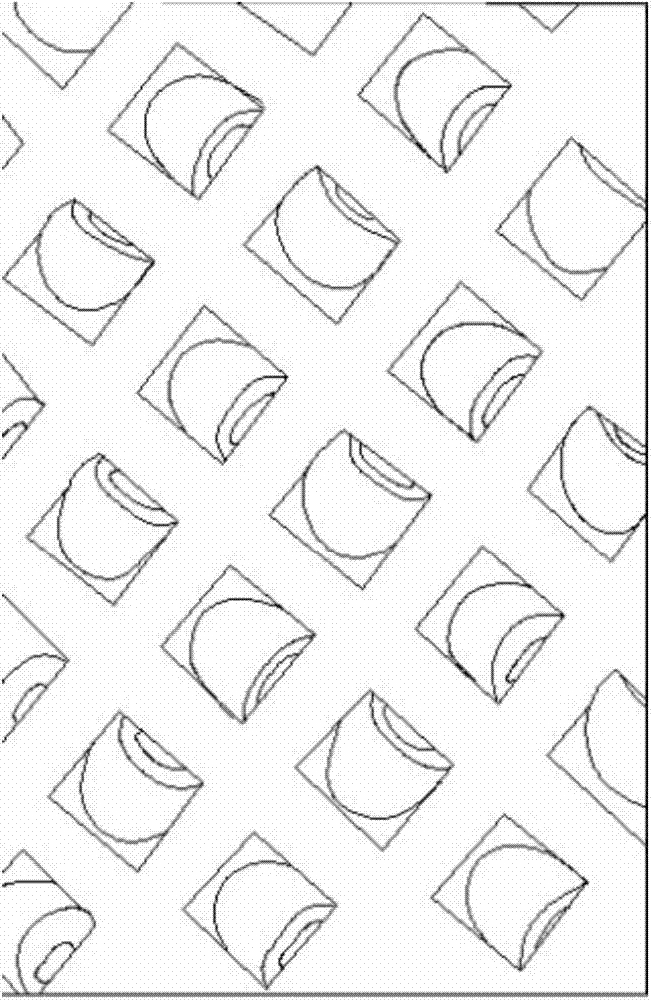

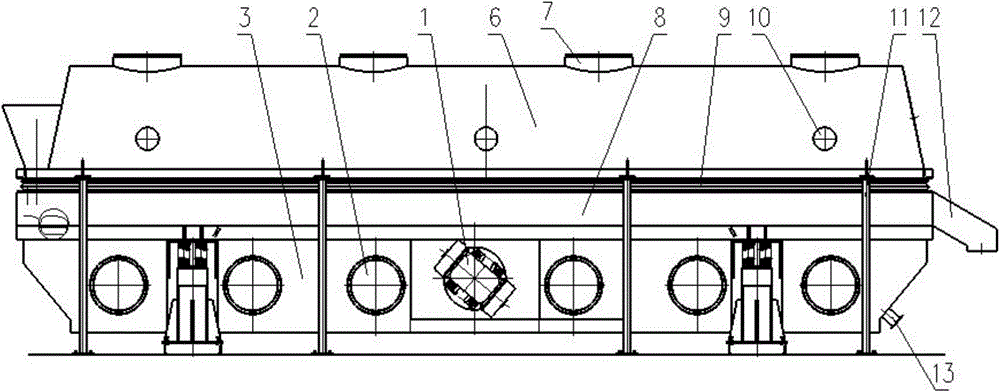

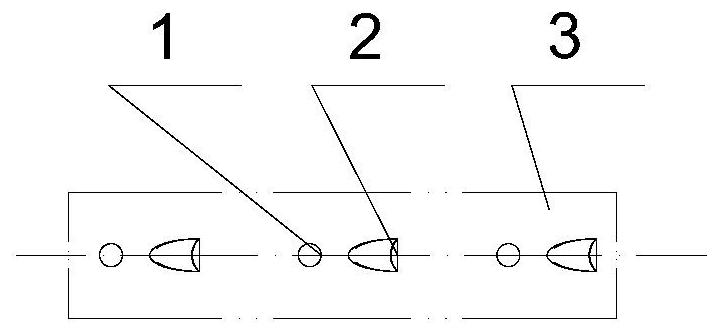

A gas distribution plate for vibrating fluidized bed

ActiveCN111282520BThe structural orientation is obviousReduce the chance of collisionChemical/physical processesGas phaseEngineering

The invention relates to a gas distribution plate for a vibrating fluidized bed. Including straight holes, ellipsoidal surface guide holes with chamfered angles and plate body; ellipsoidal curved surface guide holes with chamfered angles and straight holes are arranged alternately on the plate body. Each ellipsoid curved surface guide hole with a chamfered angle is provided with a straight hole on the opposite side of the hole opening direction; the distance from the straight hole to the opposite side of the hole opening direction from the same ellipsoid curved surface guide hole with a chamfered angle is less than the distance to the straight hole on the side of the hole opening direction . The straight holes are arranged in a triangular and rectangular way, and the arrangement of the guide holes on the ellipsoid surface with chamfered corners follows the arrangement of the straight holes. The use of this gas distribution plate makes the gas distribution more uniform; it can not only guide but also make the particles produce a good fluidized state, and can continue stably; reduce the force and probability of particles colliding with the distribution plate; the opening structure is not easy to block , damage, can reduce the number of dead zones in the bed; strengthen the disturbance of the gas phase near the surface of the gas distribution plate, so that the particles can fully contact with the hot air; the structure is simple and easy to manufacture.

Owner:TIANJIN UNIV

A kind of biological carrier used in the anaerobic and anoxic section of sewage treatment and its preparation method and application

ActiveCN106854014BImprove hydrophilicityImprove wear resistanceWater contaminantsTreatment with anaerobic digestion processesNitrifying bacteriaStearic acid

The present invention relates to a biological carrier used in anaerobic and anoxic stages of sewage treatment. The biological carrier comprises high density polyethylene, calcium carbonate, stearic acid or stearate, carbonate, polyhydroxy fatty acid amide, trace elements, biological enzymes, an antioxidant, an ultraviolet absorber and a peroxide additive. The invention further provides a preparation method of the biological carrier. The carrier can realize a good fluidized state, has good hydrophilicity and a fast film forming speed, and can massively enrich hydrolyzed bacteria, denitrifying bacteria and anaerobic ammonium oxide bacteria, has high strength, high wear resistance and high extrusion resistance, can adapt to mechanical stirring in the anaerobic and anoxic stages, and has the advantages of good anti-aging and anti-ultraviolet radiation performances, strong biofilm adsorptivity, firmness in the formed film, and extremely high promotion values.

Owner:THUNIP HLDG +1

A kind of solid molasses powder and its preparation method, application and storage method

ActiveCN105713996BFlexible adjustment of spray speedContinuous productionSugar productsFood processingMedicineProcess engineering

The present invention provides a solid molasses powder and a preparation method and a storage method thereof, and the method comprises pretreatment, fluidization granulation, cooling, grading, and, optionally, packaging, storage and other steps. The present invention also provides the solid molasses powder prepared by the method and corresponding use thereof.

Owner:COFCO GROUP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com