Patents

Literature

57results about How to "Enough buffer space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

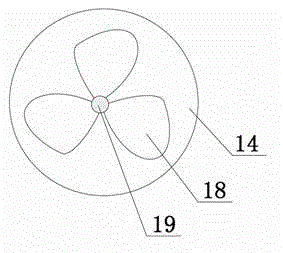

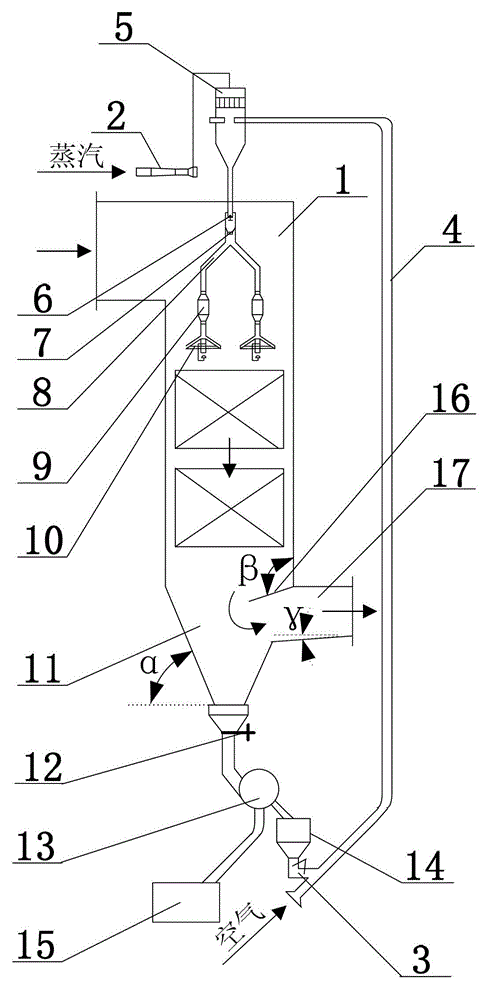

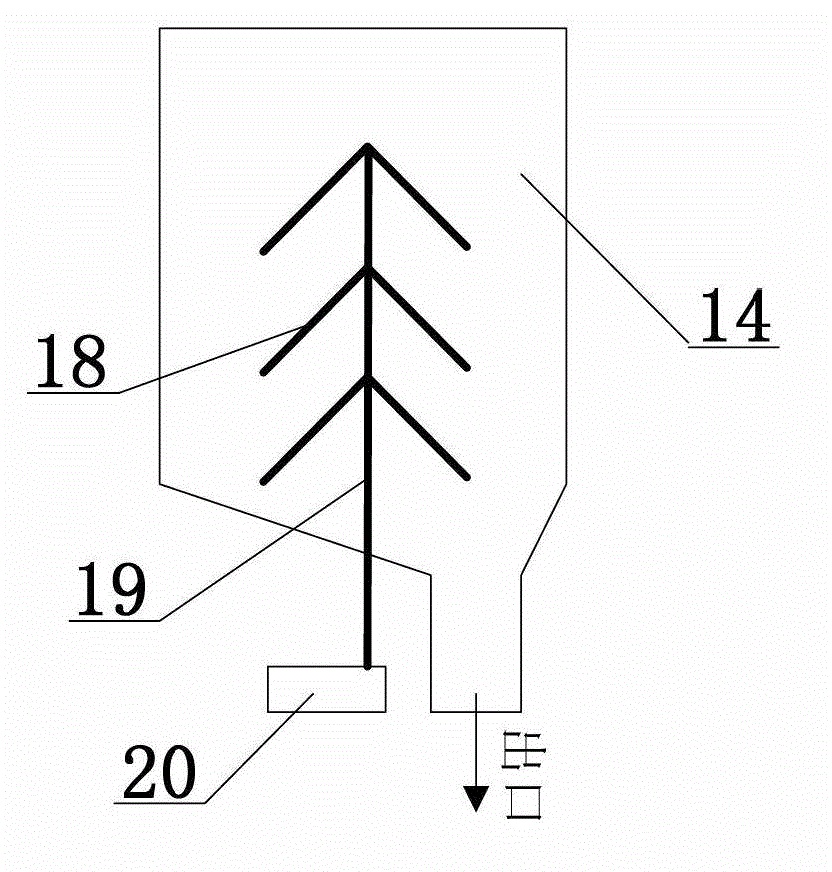

Steel ball gas removal system of pulverized coal boiler

The invention relates to a steel ball gas removal system of a pulverized coal boiler, belonging to a boiler tail flue gas removal device. The steel ball gas removal system comprises a steam ejector, a steel ball capture and spread system, a gas lock, a steel ball separation and storage system, a ball supplier and a steel ball conveying pipe, wherein a magnetic classifier and a ball storage bucket are sequentially arranged between the gas lock and the ball supplier; the magnetic classifier can used for realizing the effective separation of steel balls and ash, and the system reliability is good; the ball storage bucket is used for storing falling steel balls, and in order to prevent the steel balls from being corroded and caked, a rotating blade is arranged in the ball storage bucket; the intersection angle of the wall surface of the ash bucket and the horizontal plane is 45-60 degrees; and an adjustable baffle plate is arranged above an inlet part of a flue gas outlet pipe, and the lower part of the flue gas outlet pipe is inclined for 5-10 degrees towards the inner side of the ash bucket to prevent the steel balls from entering the flue gas outlet pipe along with gas flows. By adopting the steel ball gas removal system provided by the invention, cohesive ash deposits on a heating surface of a boiler tail flue can be effectively cleared away, and the stability and reliability of the system are good.

Owner:TSINGHUA UNIV

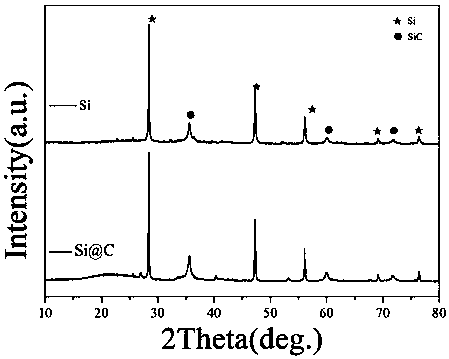

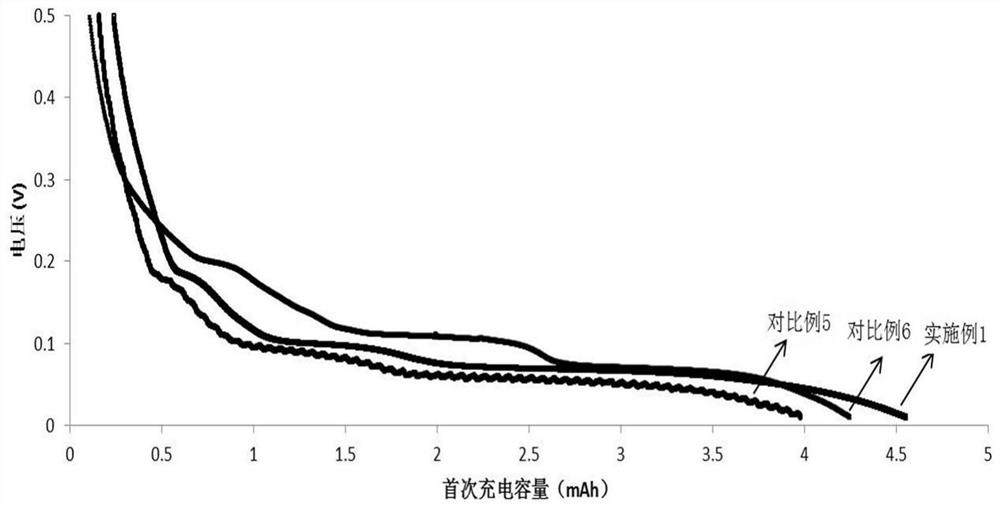

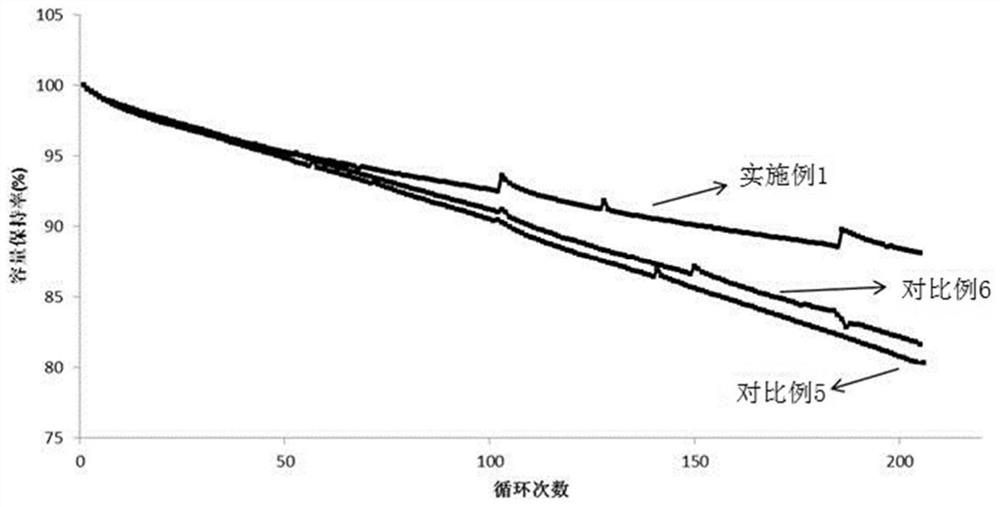

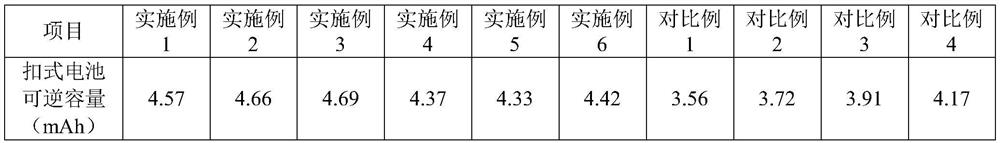

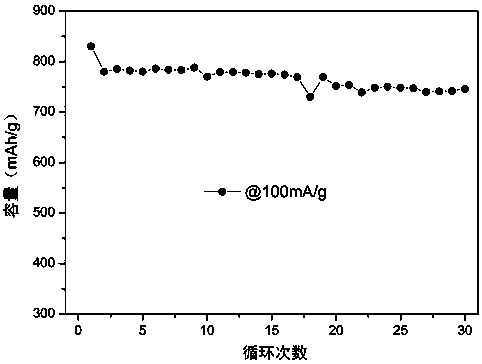

Preparation method of silicon carbon composite material and application thereof used as lithium ion battery negative electrode material

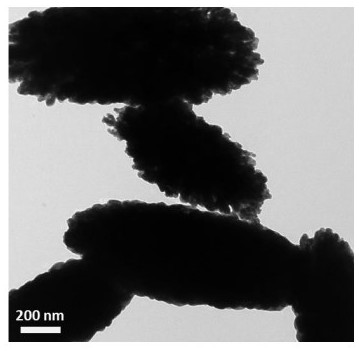

InactiveCN107768618ASimple processReduce energy consumptionCell electrodesSecondary cellsCarbon coatingMolecular sieve

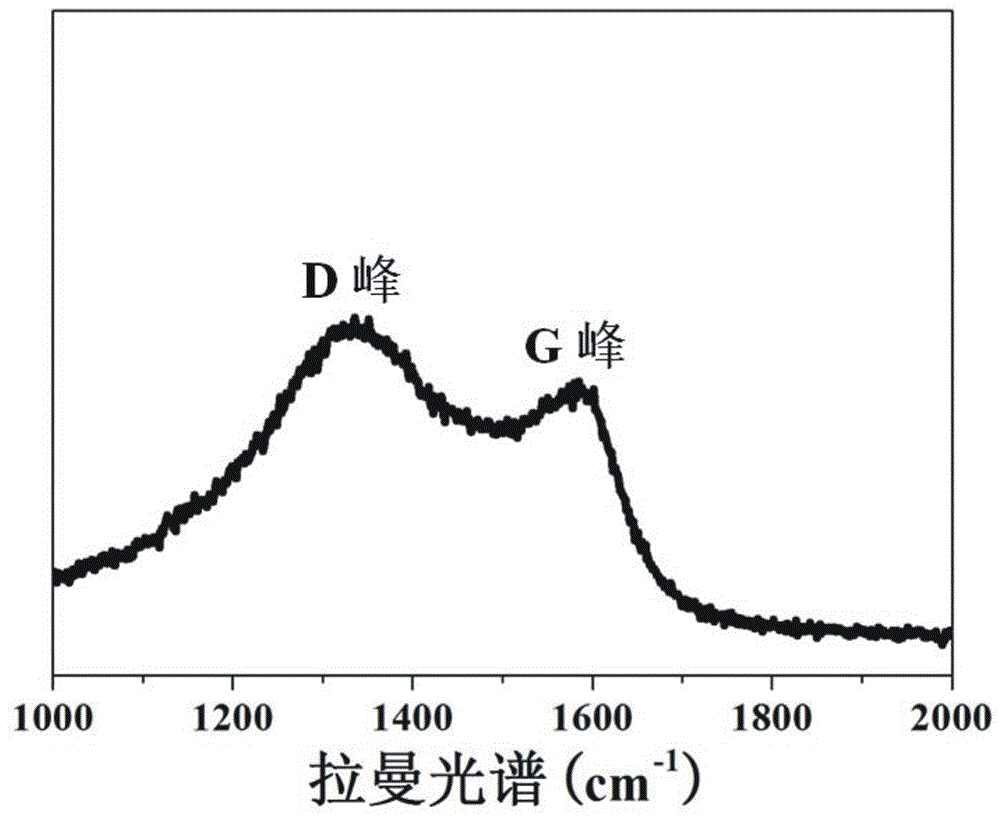

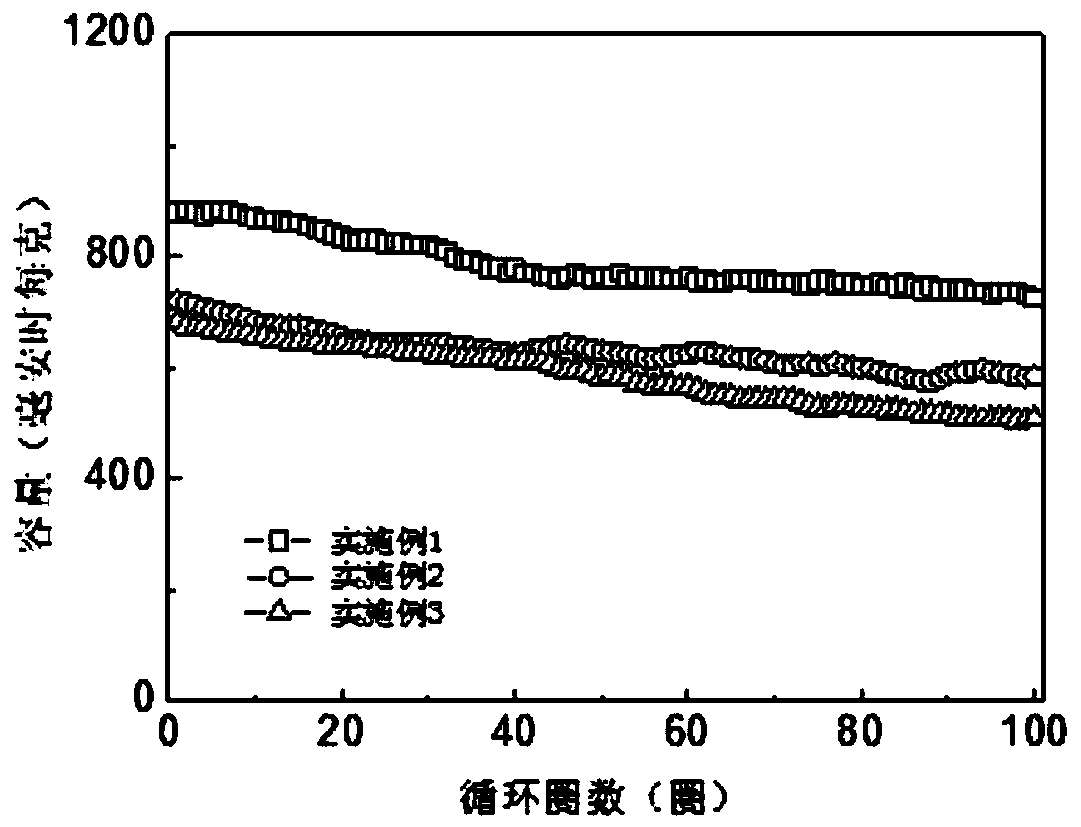

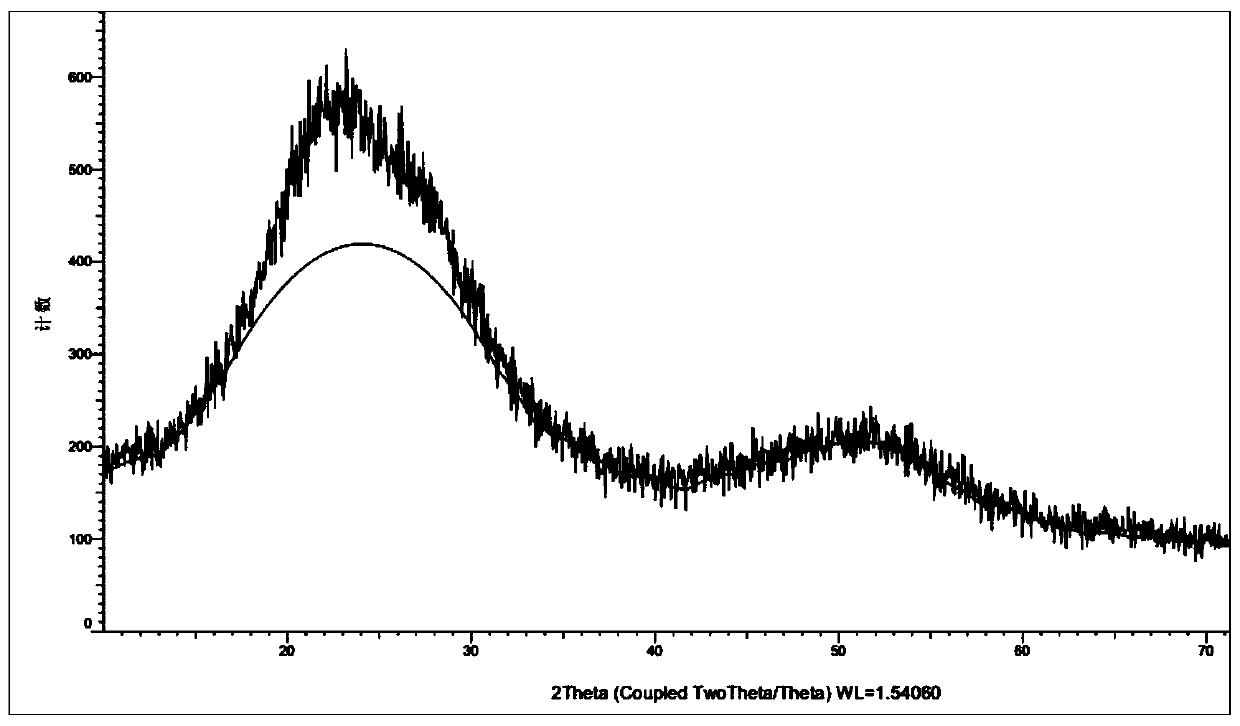

The invention discloses a preparation method of a silicon carbon composite material and application thereof used as a lithium ion battery negative electrode material. Porous elemental silicon is prepared by taking a molecular sieve and silicon dioxide aerogel as a silicon source, metal elemental powder as a reducing agent and a low-temperature molten salt as a medium and achieving reduction of metal power on silicon dioxide during thermal processing in a certain temperature, and then the silicon carbon composite material is obtained by mixing the elemental silicon and asphalt and performing high-temperature carbon coating. Due to the porous characteristic of a raw material, the prepared silicon carbon composite material has a good three-dimensional porous structure, a good buffer effect onvolume expansion of a silicon negative electrode during the circulation process is achieved, moreover, the electron conductivity of the material after carbon coating is greatly improved, and long-term circulation stability of a silicon-based negative electrode material is facilitated. The method is low in cost of the raw material and simple in process and is suitable for industrial production ona large scale.

Owner:北京博雅合众环保科技有限公司

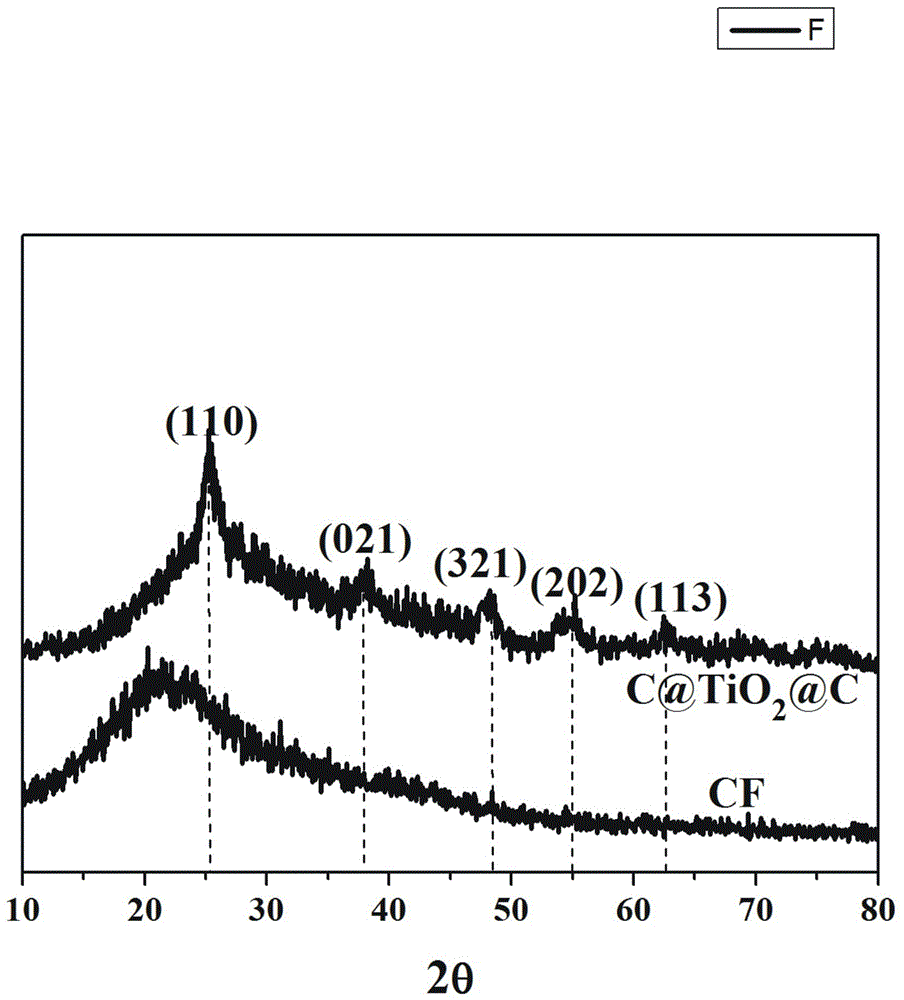

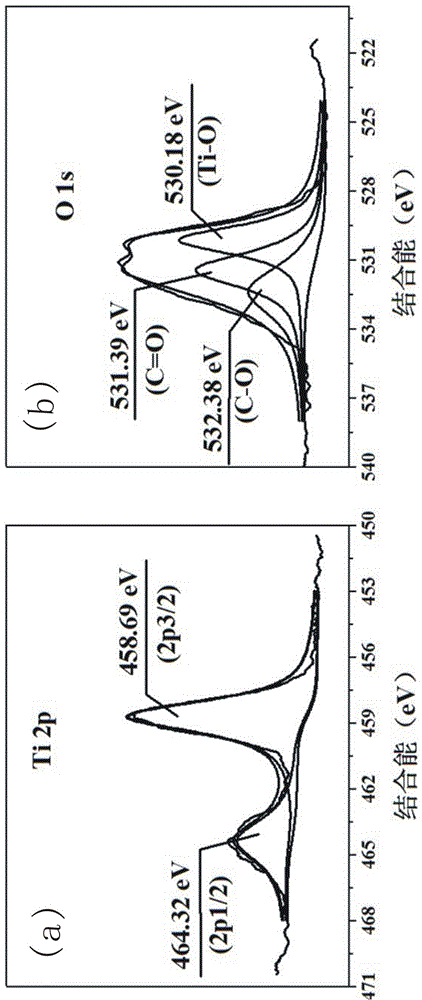

Lithium battery negative electrode material and preparation method thereof

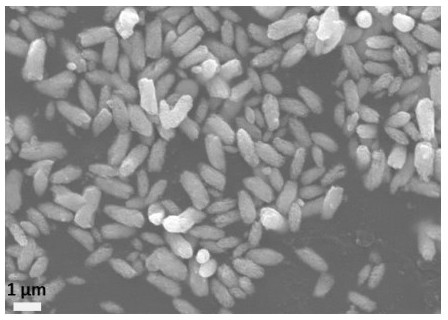

ActiveCN106159243AImprove ductilityImprove cycle stabilityMaterial nanotechnologyCell electrodesCarbon coatingCarbonization

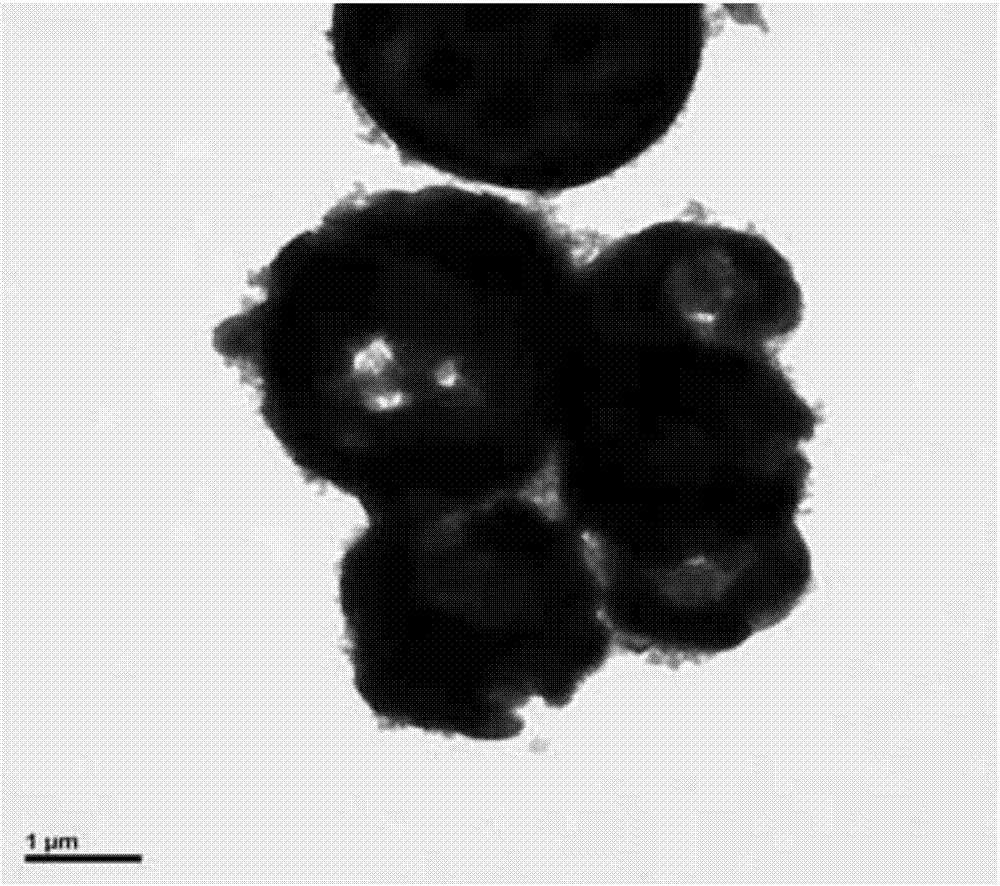

The invention provides a method for preparing a lithium battery negative electrode material with collagenous fiber and plant polyphenol as a biological template and a carbon source. The preparation method comprises the following steps that 1, collagenous fiber and transition metal ions react to prepare collagenous fiber loaded transition metal ions; 2, plant polyphenol is utilized for carrying out surface coating modification on the collagenous fiber loaded transition metal ions; 3, high-temperature carbonization treatment is carried out. The prepared material is black powder in appearance, and is a nanometer fiber bundle with the diameter larger than or equal to 1 micrometer composed of carbon-transition metal oxide-carbon nanofiber with the diameter of 10-150 nm. When used as the lithium battery negative electrode material, the carbon coating layer and the carbon nanofiber skeleton of composite nanofiber can form a conductive network, the transition metal oxide can be prevented from being smashed in charging-discharging circulation, the circulation stability can be improved, the excellent conductivity can be provided, and the excellent rate capability is given for the electrode material.

Owner:SICHUAN UNIV

Material for lithium-sulfur battery positive electrode and preparation method thereof

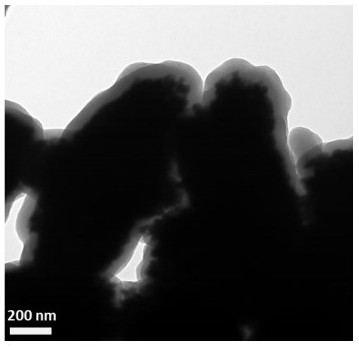

PendingCN111477874AGood electrical conductivityGood Coulombic efficiency and cycle stabilityMaterial nanotechnologyCarbon compoundsHigh conductivityLithium–sulfur battery

The invention belongs to the technical field of lithium-sulfur batteries, and particularly relates to a material for a lithium-sulfur battery positive electrode and a preparation method of the material. The material is a self-supporting mesoporous vanadium nitride nanowire / carbon nanotube composite material with a three-dimensional network structure. According to the material, the vanadium nitridenanowire with the mesoporous structure is connected with the carbon nanotube to form the self-supporting three-dimensional network structure; the material has high conductivity, ultrahigh specific surface area and excellent mechanical properties; and the method is simple, effective and easy to operate.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

High speed digital image/ video signal analysis and treatment option secondary development board based on video and audio embedded type development platform

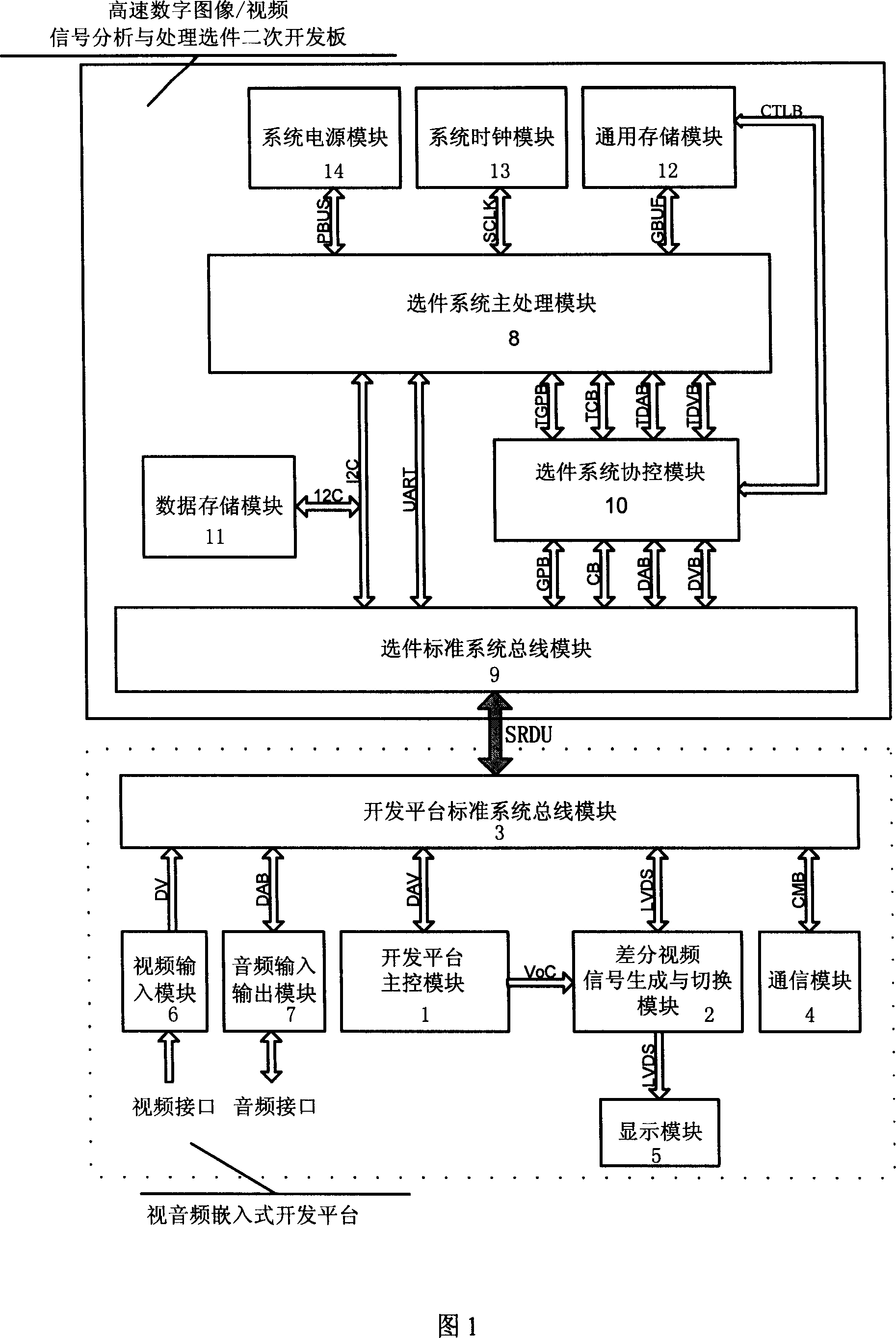

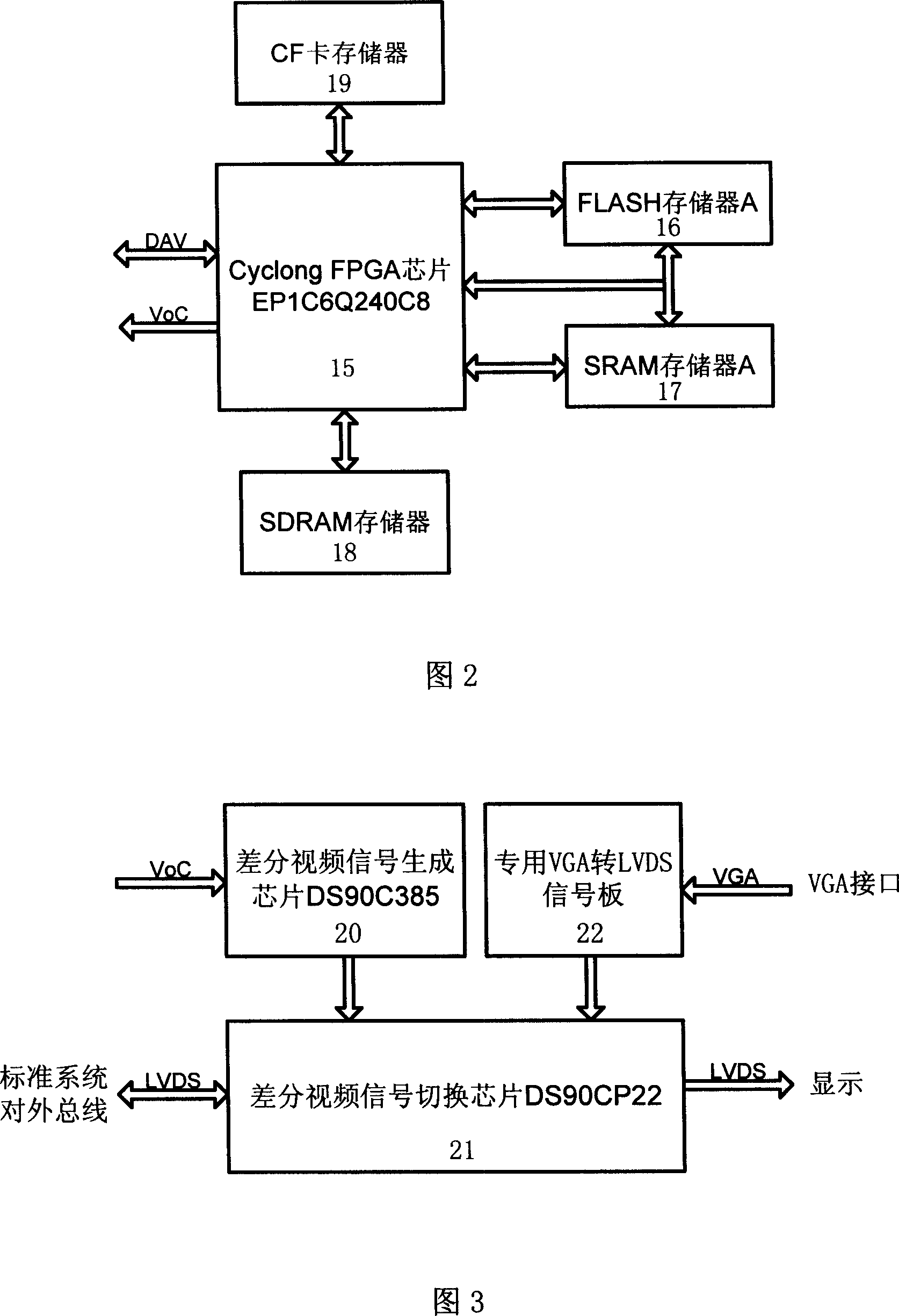

InactiveCN101105784AGuaranteed clarityPerfect Display ChannelTelevision system detailsColor television detailsReal time analysisTreatment options

The invention relates to a secondary development board of high-speed digital picture / video signal analysis and handling option based on audio and video embedded development platform. The invention comprises a video and audio embedded development platform, the development platform standard system bus module thereof is connected with a secondary development board of the high-speed digital picture / video signal analysis and handling option through a SRDU interface. The invention can realize functions of catching, storing, and transmitting real-time video data conforming to various video standards, real-time analysis of picture / video information, picture / image decoding and encoding, special effect of pictures, etc.

Owner:SHANGHAI UNIV +1

Novel high-performance lithium-sulfur battery positive electrode material and preparation method thereof

ActiveCN111342009AImprove conductivityFast transferCell electrodesGrapheneElectrical batteryLithium–sulfur battery

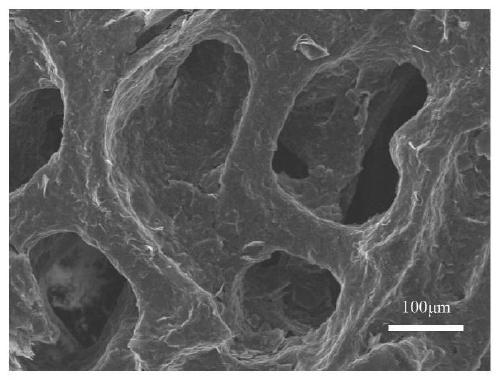

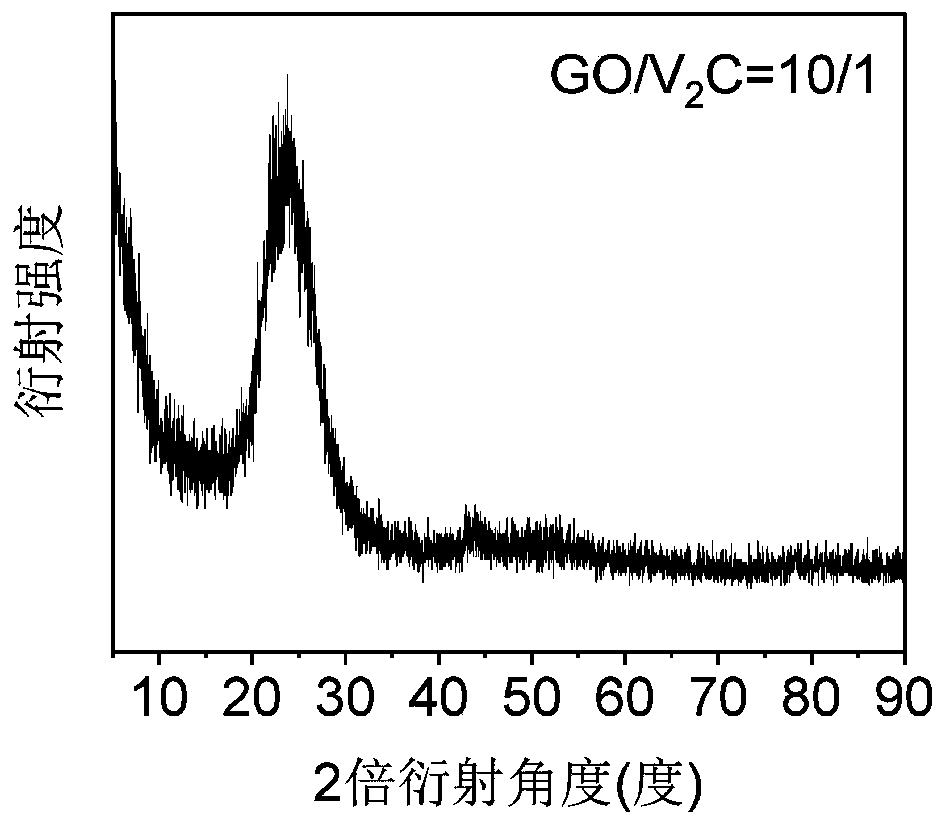

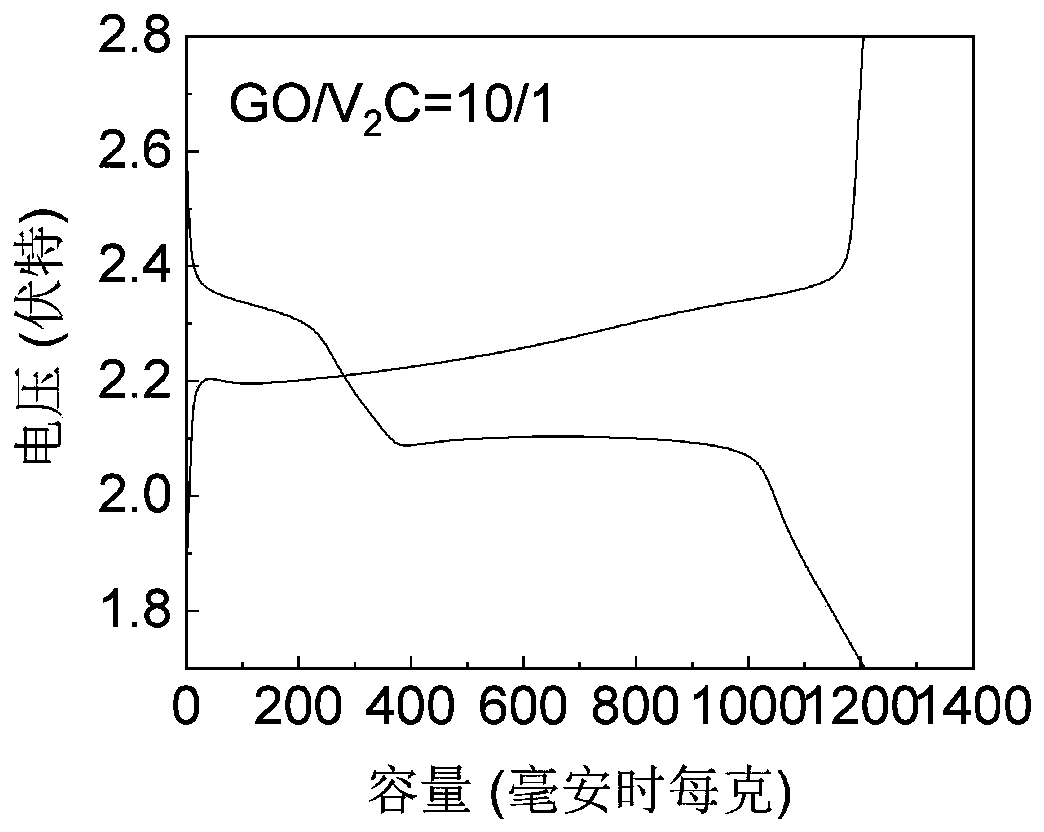

The invention belongs to the technical field of lithium-sulfur batteries, and particularly relates to a novel high-performance lithium-sulfur battery positive electrode material and a preparation method thereof. The positive electrode material is a composite material of graphene with a three-dimensional foam structure and V2C Mxene. The positive electrode material is a graphene and V2C Mxene composite material with a three-dimensional foam structure, and graphene has good conductivity; the V2C Mxene has the characteristics of excellent adsorbability and electrochemical energy storage; meanwhile, the three-dimensional foam structure limits soluble polysulfide, increases active sites and forms a rapid ion channel, and the electrochemical performance of the lithium-sulfur battery is promotedthrough the combined action of the three components. The preparation method is simple, effective and easy to implement.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

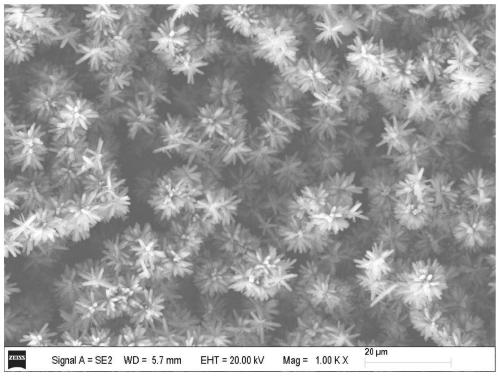

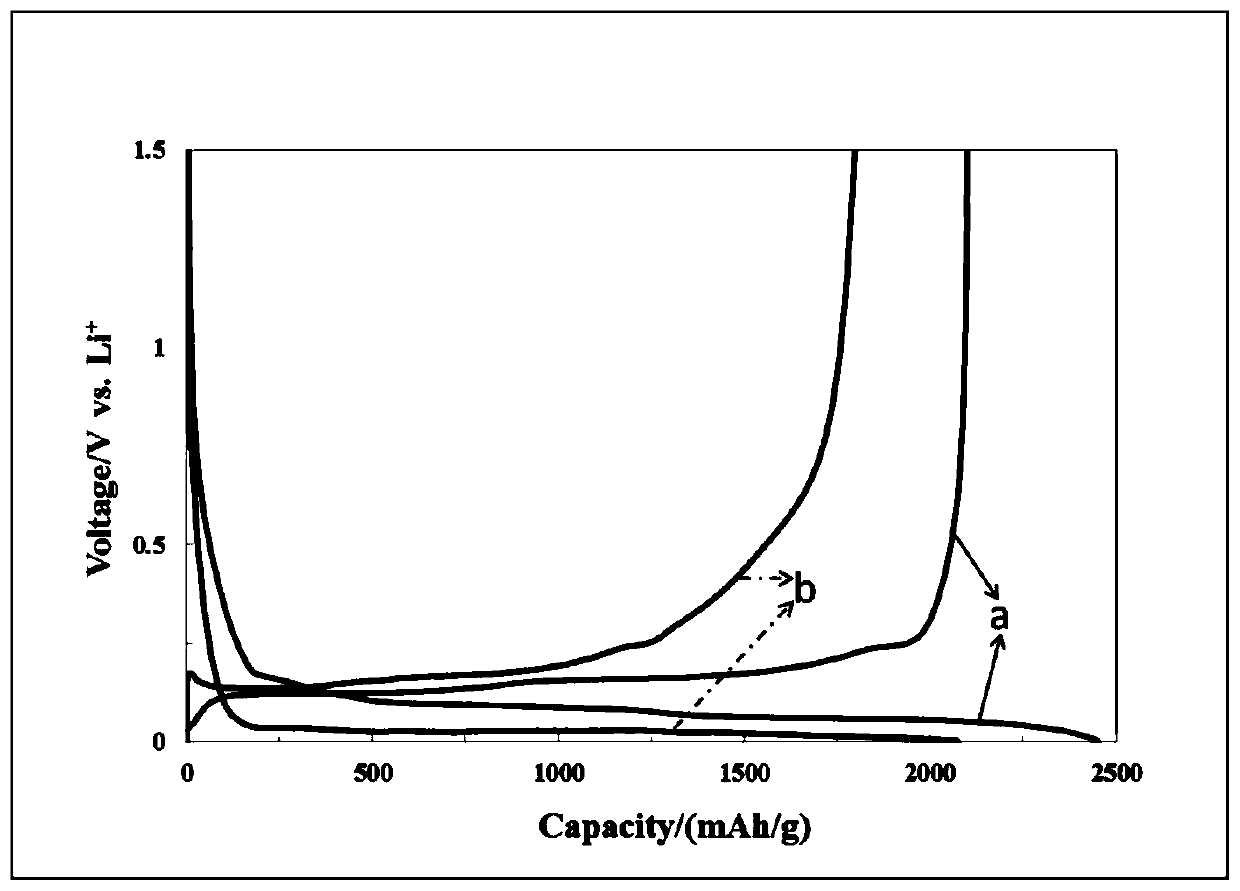

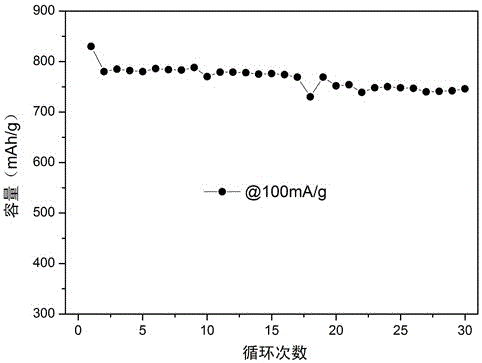

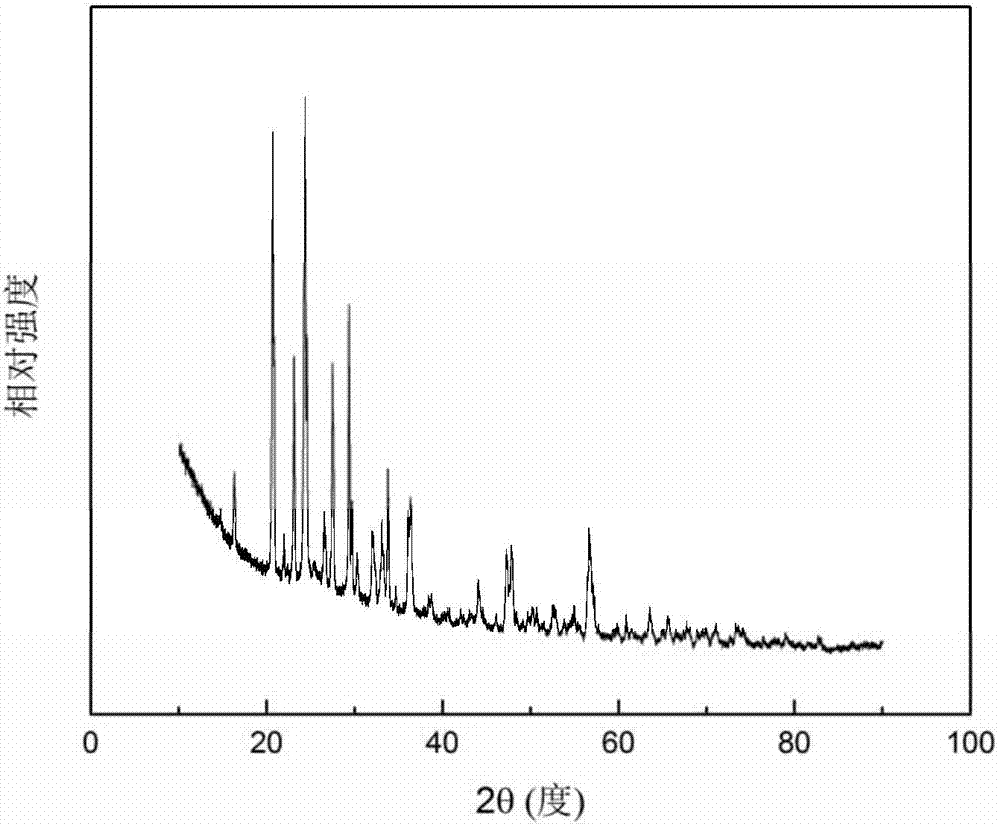

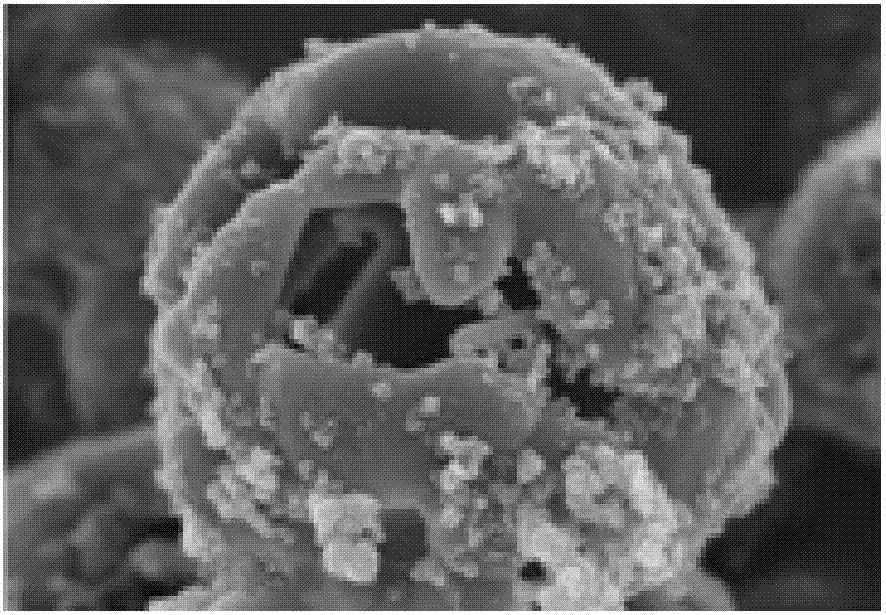

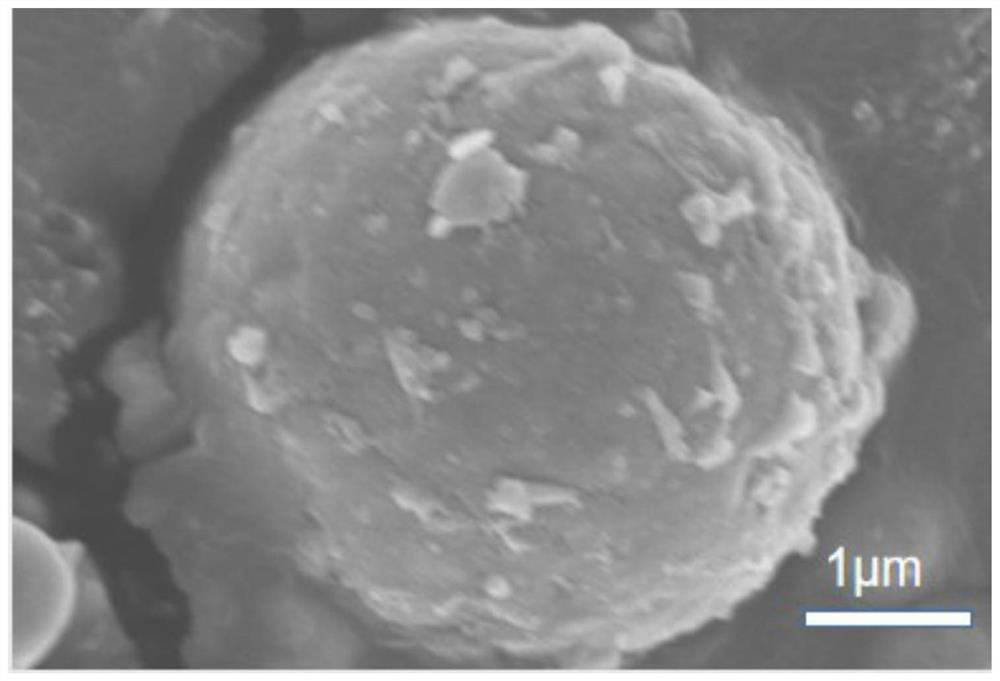

Silicon anode material with spherical thorn-shaped structure and preparation method thereof

ActiveCN109942001AGood three-dimensional gapImprove conductivityMaterial nanotechnologyCell electrodesCarbon coatingSilicon oxygen

The invention belongs to the technical field of lithium ion battery electrode materials and preparation thereof and discloses a silicon anode material with a spherical thorn-shaped structure and a preparation method thereof, and belongs to the technical field of lithium ion battery electrode materials and preparation thereof. A silicon source compound, a hydrolyzing agent, a reducing agent and a surfactant are added into an inert solvent, the suspension liquid is transferred to a closed reaction kettle, and a silicon-oxygen material precursor is prepared through a hydrothermal method; then conductive carbon coating is conducted on a silicon oxide compound by adopting a vapor deposition method under the protection of nitrogen, and finally cooling is executed to obtain the silicon anode material with the spherical thorn-shaped structure, wherein the chemical formula of the siliconanode material is SiOx / C, and x is greater than 0 but is smaller than 1. The gram capacity of the first reversible discharge of the silicon anode material prepared by the preparation method is 2101 mAh / g and the first efficiency is 86% under the current of 0.1C, the capacity retention rate is 100% after 100charge-discharge cycles under the current of 0.5C, and the silicon anode material has excellent electrochemical performance.

Owner:CAMEL GRP WUHAN OPTICS VALLEY R&D CENT CO LTD

Preparation method of lithium battery anode material

InactiveCN106521705AAvoid cumbersomenessImprove cycle stabilitySecondary cellsNegative electrodesFiberPolymer science

The invention relates to a preparation method of a lithium battery anode material. A SnO2@ / C composite material which contains fibers and adopts a hollow structure can be prepared with the method, SnO2 has enough buffering space in the charging and discharging process due to the fibers adopting the hollow structure, a C outer layer can serve as a network framework of SnO2, efflorescence of the material is reduced, the conductivity of the material is improved, the one-step method for preparation of SnO2@ / SiO2@ / C composite fibers is not as complicated as a traditional method in which fibers are coated after being prepared, and the SnO2@C nanofibers prepared with the method have good cyclic stability.

Owner:JILIN NORMAL UNIV

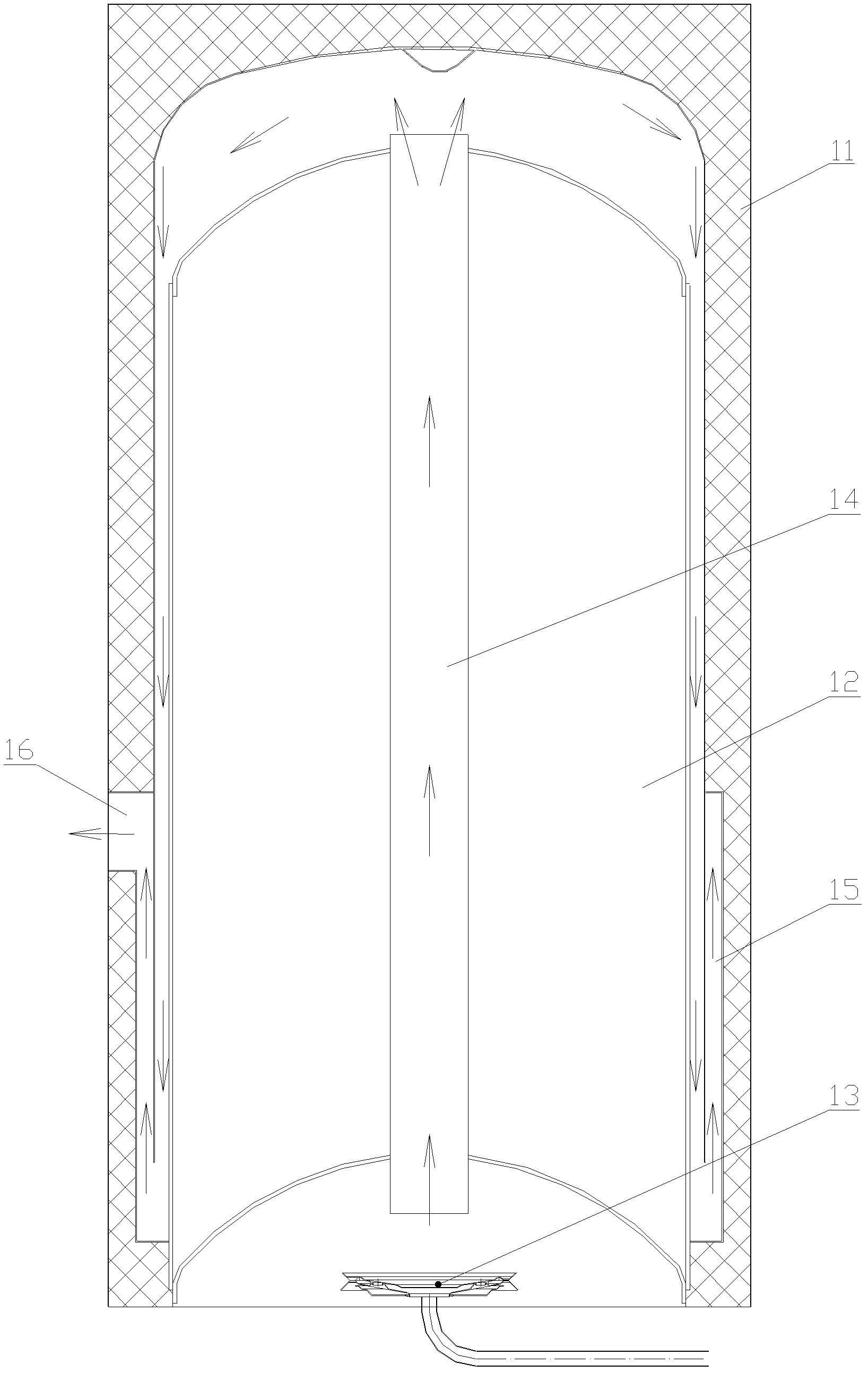

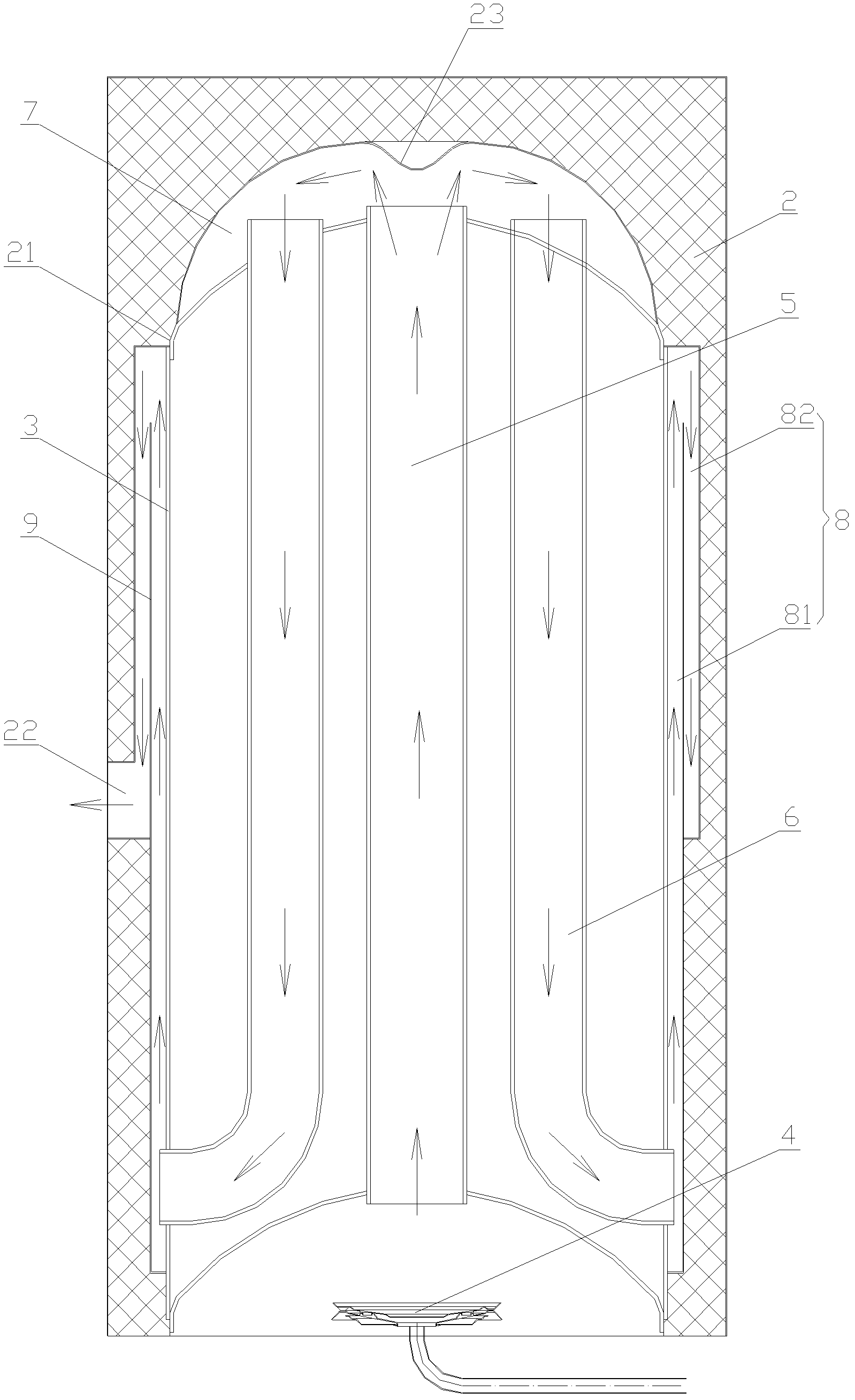

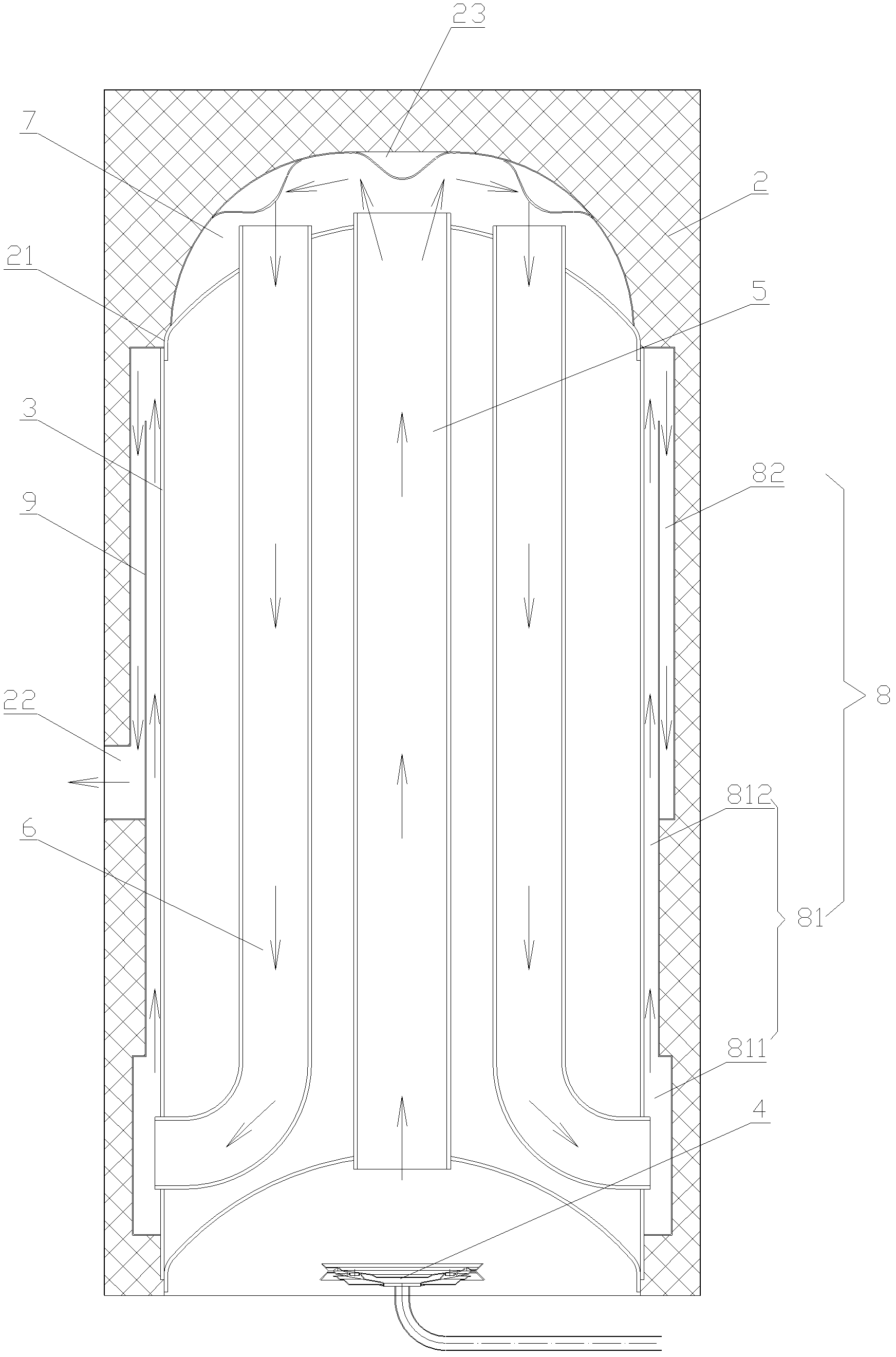

Volume type gas water heater

InactiveCN102305469AEasy to moveImprove reliabilityRecuperative heat exchangersWater heatersCombustorEngineering

The invention discloses a volume type gas water heater, which comprises a shell, a water tank, a burner arranged at the bottom of the water tank, a first heat exchange channel which passes through the top and the bottom of the water tank, and a second heat exchange channel which passes through the top and the side face of the water tank, wherein a sealing boss is arranged on the circumferential inner wall of the shell; the sealing boss presses against the periphery of the water tank, so that the periphery of the water tank is divided into a top heat exchange cavity and a side face heat exchange cavity; the second heat exchange channel is communicated with the top heat exchange cavity and the side face heat exchange cavity; and high temperature gas is subjected to three heat exchange processes in the first heat exchange channel, the second heat exchange channel and the side face heat exchange cavity sequentially before flowing out of the shell. Compared with the prior art that the high temperature gas only exchanges heat in the first heat exchange channel and the side face heat exchange cavity, the water heater has the advantages that the heat exchange channel for the high temperature gas is extended; therefore, the heat exchange time for the gas and water in the water tank is prolonged, the heat exchange is more sufficient and the heating efficiency of the water heater is improved.

Owner:CHONGQING SANWENNUAN ELECTRIC

Porous hollow spherical lithium ion cell anode material of carbon-coating lithium vanadium phosphate and preparing method of anode material

InactiveCN107331855AIncreased breathability inside and outIncrease microporositySecondary cellsPositive electrodesLithium vanadium phosphate batteryPhysical chemistry

The invention discloses a porous hollow spherical lithium ion cell anode material of carbon-coating lithium vanadium phosphate and a preparing method of the anode material. The preparing method of the anode material comprises the steps of taking a binder, a lithium source, a vanadium source and a phosphorous source into water, stirring and dissolving the materials, and conducting spraying drying on the obtained mixed solution to obtain a precursor; mixing the obtained precursor with a carbon source, conducting calcination under a protective atmosphere condition to obtain the anode material, wherein the concentration of the binder in water is 0.3-0.5 wt%, the concentration of the lithium element of the lithium source in water is 0.1-1 mol / L, the concentration of the vanadium element of the vanadium source in water is 0.06-0.6 mol / L, the concentration of the phosphorous element of the phosphorous source in water is 0.09-0.9 mol / L, and the additive amount of the carbon source is 4-20 wt% that of the precursor. The anode material prepared through the method is in a porous hollow spherical shape, and has a high specific area, and the circulation factor performance of the obtained product can be effectively improved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

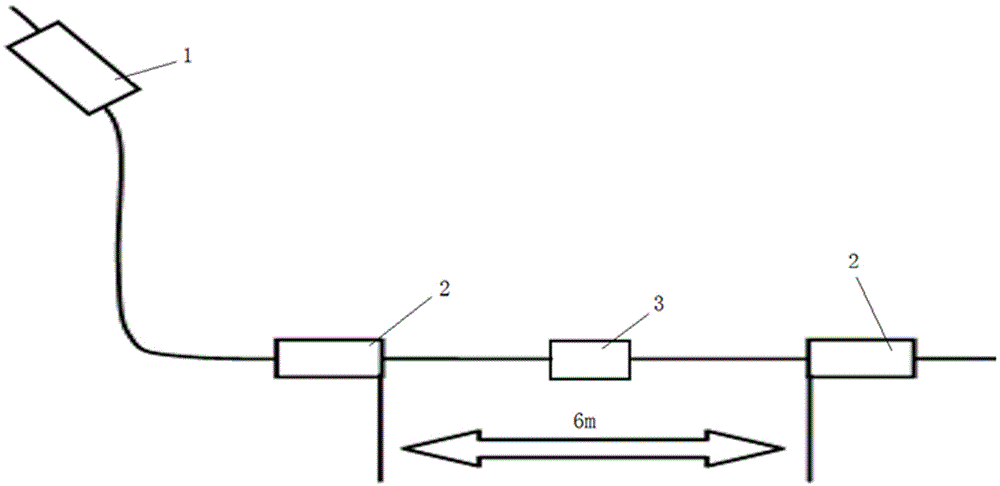

Full-dry type access optical cable

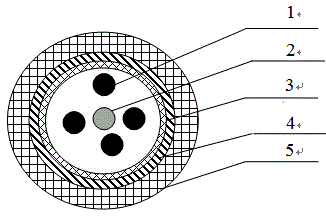

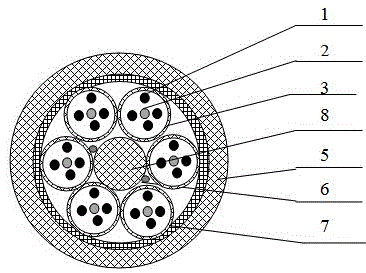

InactiveCN105652400AFacilitate divergent continuationConvenient laying and constructionFibre mechanical structuresDirect to homeWater block

The invention relates to a full-dry type access optical cable which comprises an outer sheath and a sleeve. The full-dry type access optical cable is characterized in that tight tube optical fibers and a water blocking piece are laid in the sleeve, and a nonmetal reinforcing piece is arranged outside the sleeve. The full-dry type access optical cable has the advantages that the structure arrangement is simple and reasonable, the mechanical performance is good, the bending performance is high, and the full-dry type access optical cable can be conveniently laid in a corridor; the full-dry type full-medium structure is adopted, the optical cable without factice can be beneficial to divergence continuation, and construction laying, operation and use of the optical cable are facilitated; the loose tube structure of the tight tube optical fibers is adopted, enough buffer space is provided for the tight tube optical fibers, the performance of the cable is improved, divergent optical fibers are effectively protected, access construction is facilitated, and the FTTH direct-to-home requirement is met.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

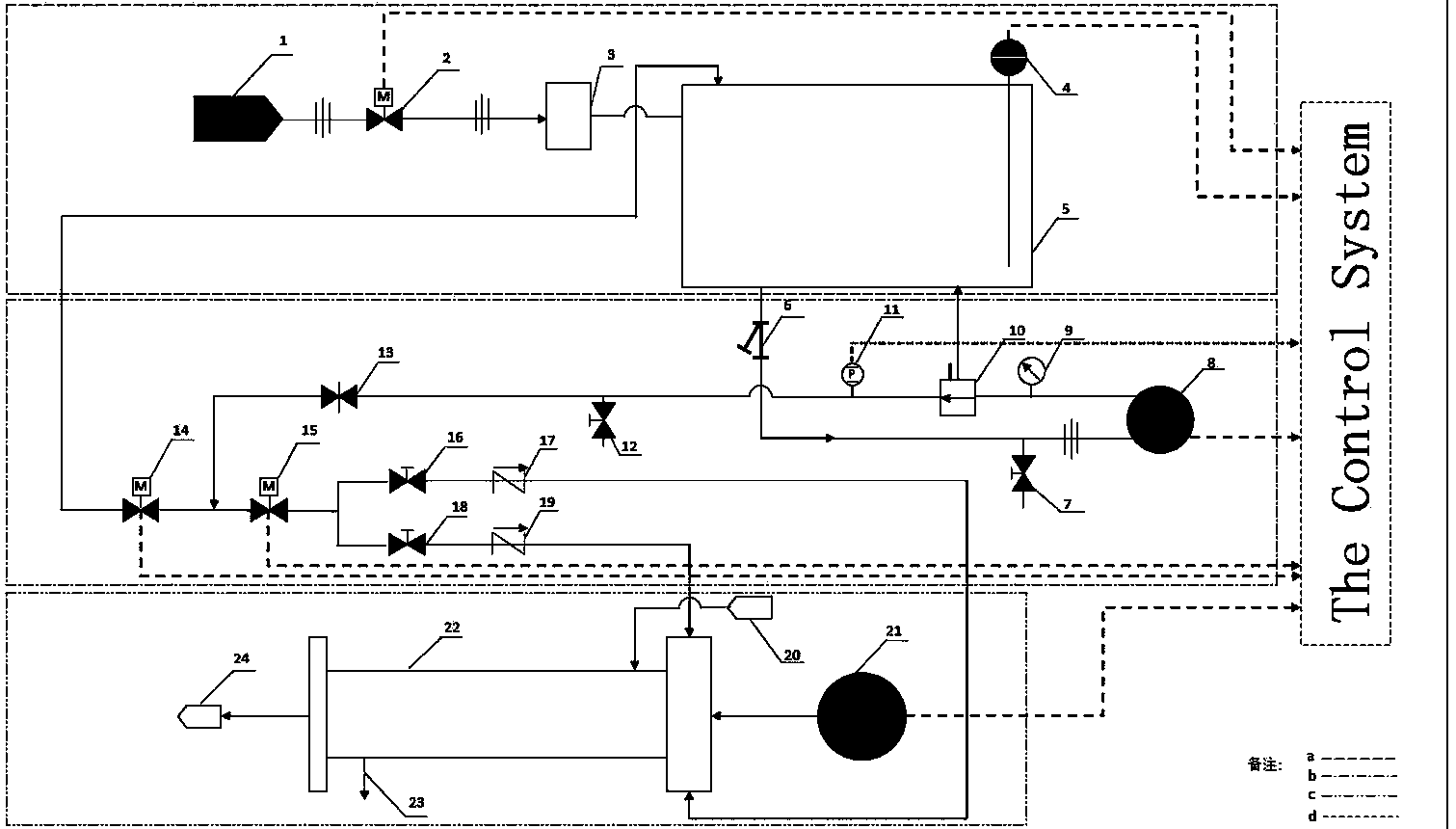

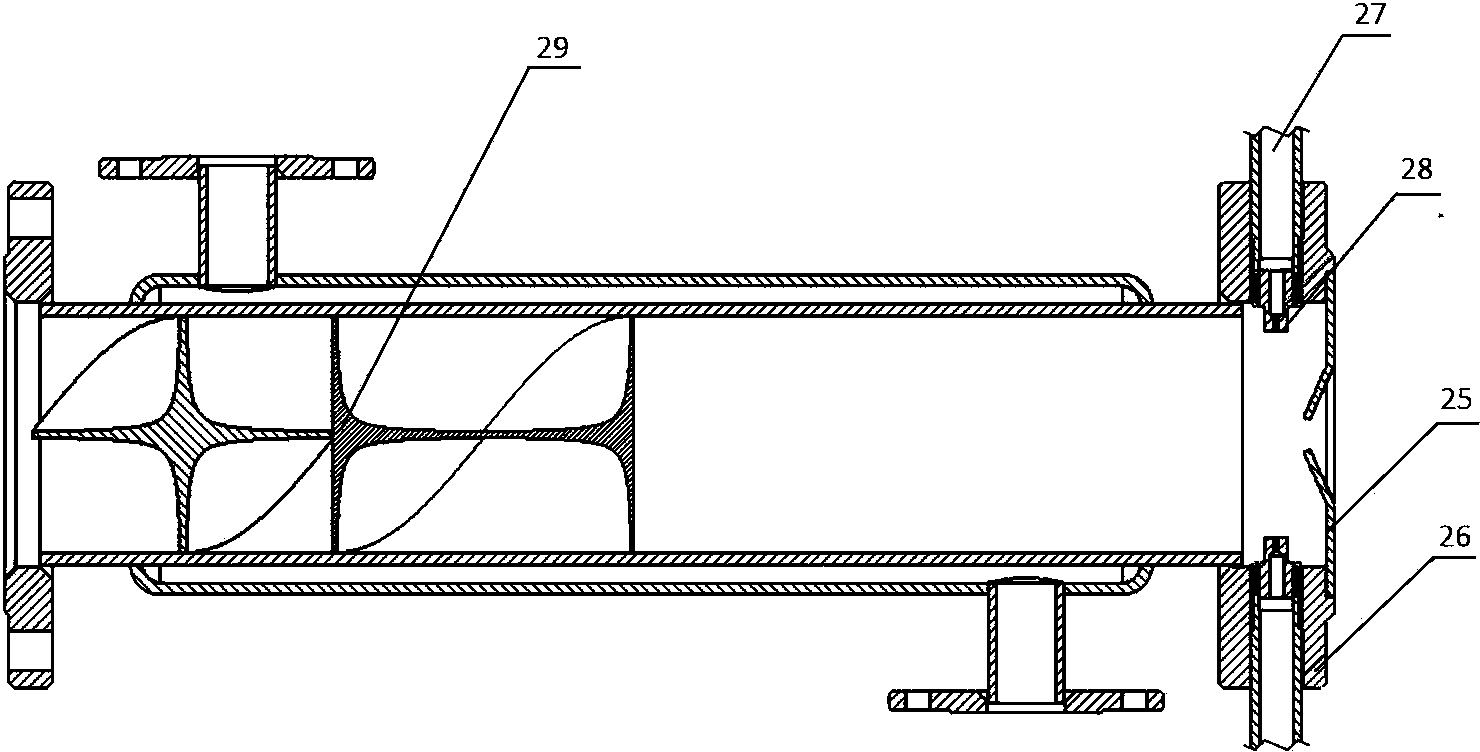

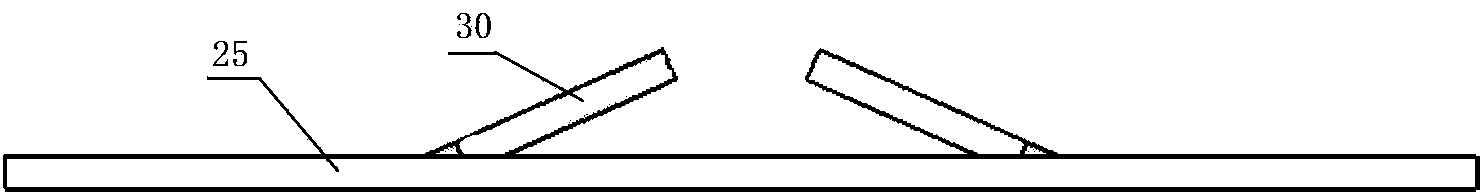

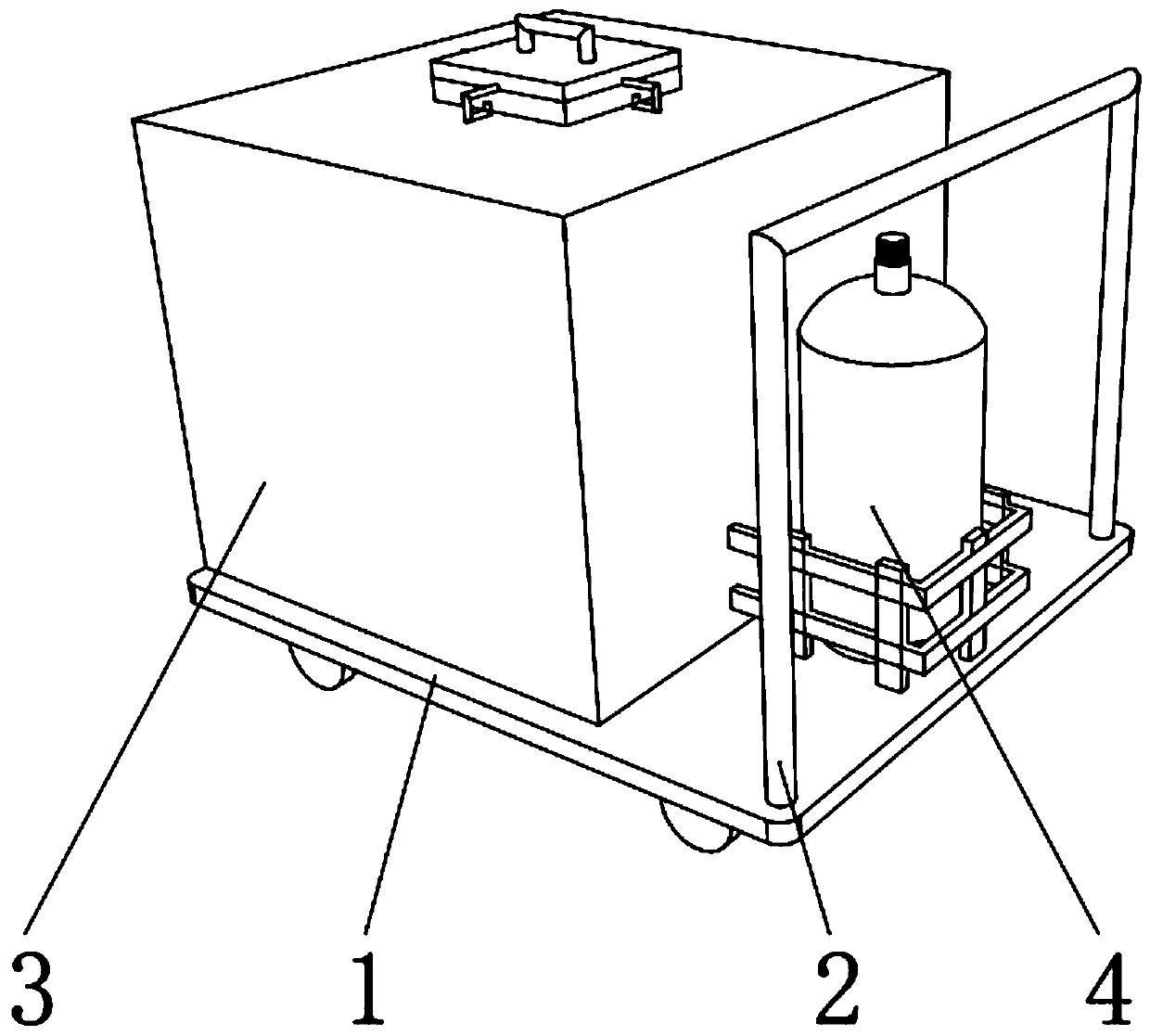

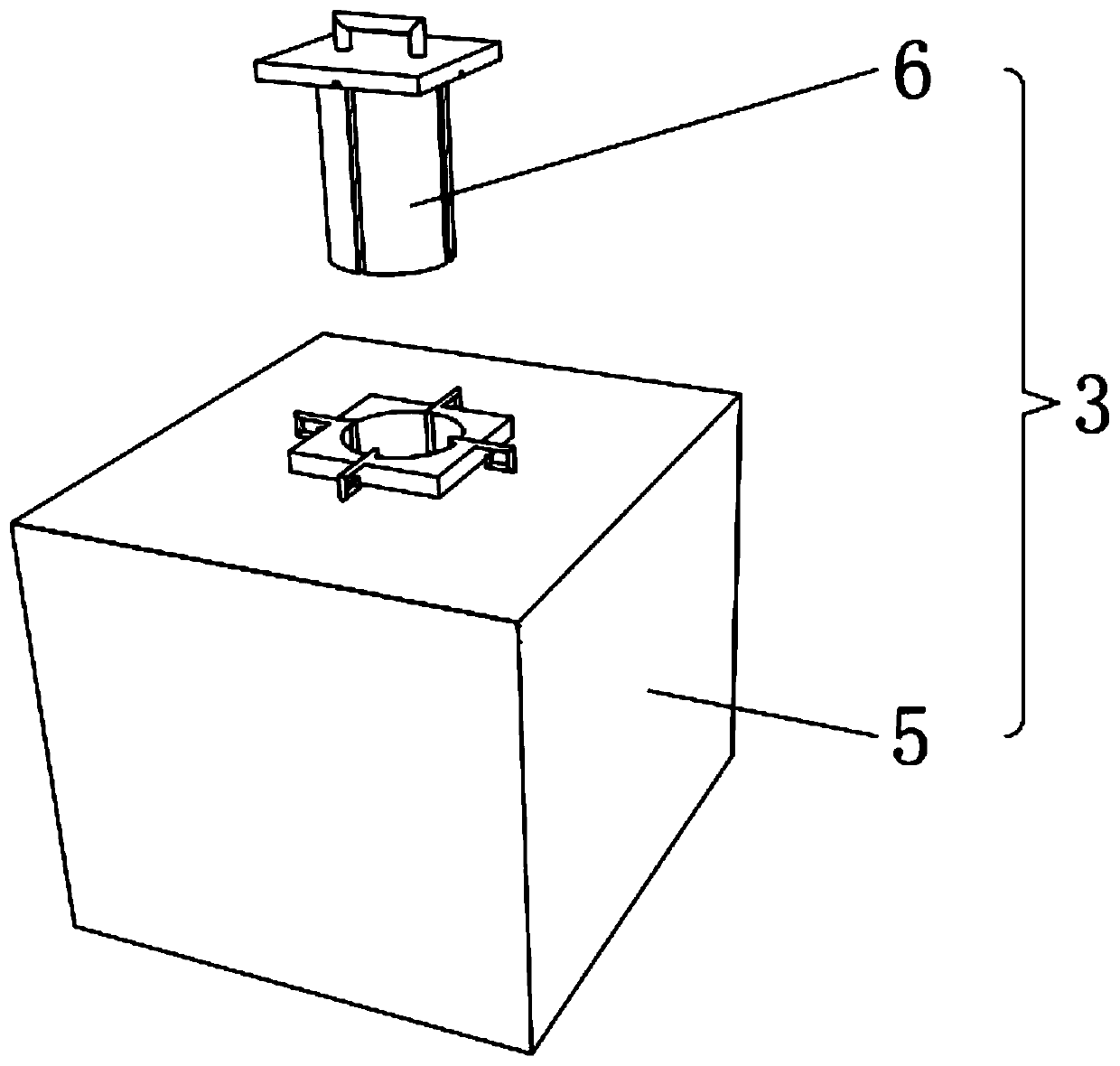

Asphalt warm-mixing foaming system

ActiveCN104032651ARealize automatic adjustmentWater level automatic adjustmentClimate change adaptationRoads maintainenceHelical bladeElectric equipment

The invention discloses an asphalt warm-mixing foaming system which is used for solving the problem of mixing hot asphalt for high class highways. The system mainly consists of a water storing device, a water feed device, an asphalt foaming device and an electric equipment control device, wherein the water storing device is connected with the water feed device which is connected with the asphalt foaming device; the electric equipment control device is connected with the water storing device, the water feed device and the foaming device; an asphalt foaming pipe in the asphalt foaming device is in a two-layer sleeve structure, wherein an outer casing pipe is a heat transfer oil heating casing pipe, and an inner core pipe is a foam asphalt generating core pipe; splitter plates are arranged at an asphalt inlet part, and fixed helical blades which are orthometric are arranged at the inner part of a pipe cavity of the foam asphalt generating core pipe; water spray nozzles for foaming are symmetrically arranged. Through the adoption of the foaming system, the hot asphalt and water are combined to enable the asphalt to generate foams, so that the stickiness of the asphalt is reduced, the temperature and the time for mixing the asphalt with aggregates are reduced and shortened, and the problems of energy dissipation and low construction efficiency are solved; at the same time, the environmental pollution degree and the production cost are reduced, and the construction is facilitated. The system disclosed by the invention has the advantages of simple and practical structure, easy manufacture, simple control, accurate computation, strong compatibility and the like.

Owner:河南亚龙智能装备有限公司

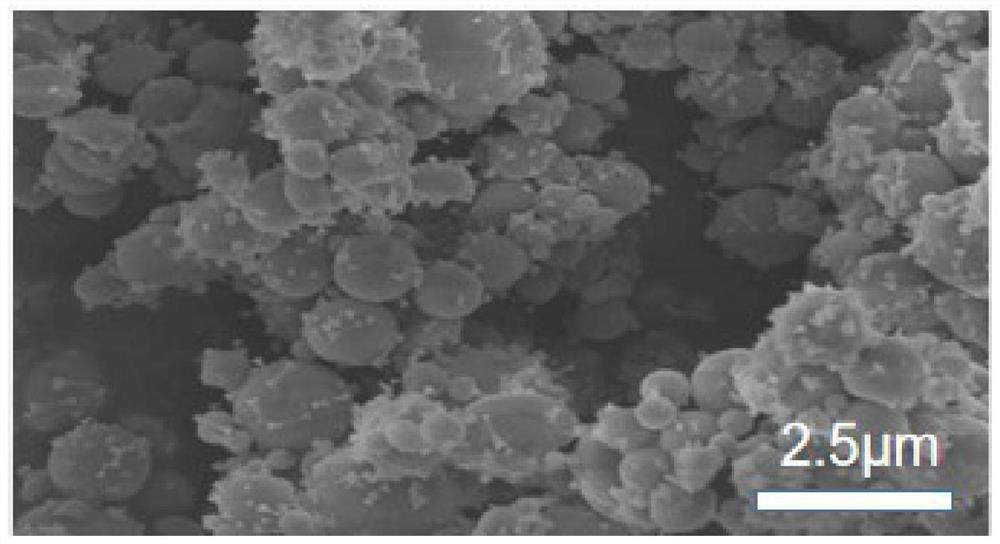

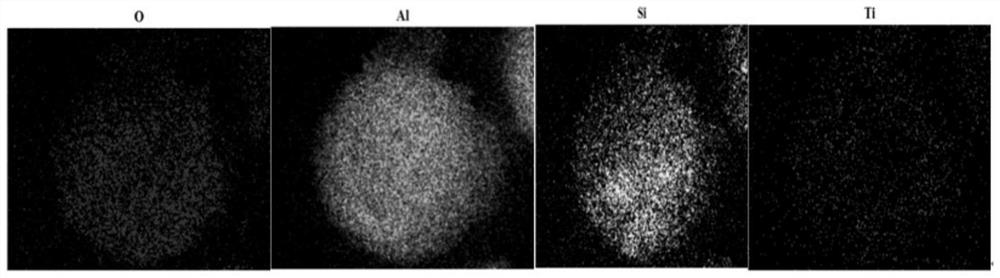

Porous silicon/titanium dioxide/graphene composite material as well as preparation method and application thereof

ActiveCN113346060ASmall volume changePrevent disengagement failureSecondary cellsGrapheneTitanium oxideBattery cell

The invention relates to the technical field of batteries, in particular to a porous silicon / titanium dioxide / graphene composite material and a preparation method and application thereof. The invention discloses a porous silicon / titanium dioxide / graphene composite material. The porous silicon / titanium dioxide / graphene composite material comprises a titanium dioxide coated porous silicon composite material and reduced graphene oxide for supporting the titanium dioxide coated porous silicon composite material; the reduced graphite oxide is doped with a strong electronegative element. The composite material has the high lithium storage characteristic of a silicon material and the high cycle stability of a carbon material, and has the characteristics of high specific capacity, good cycle stability, excellent rate capability and safety performance, and the preparation raw materials are low in price.

Owner:GUANGDONG UNIV OF TECH

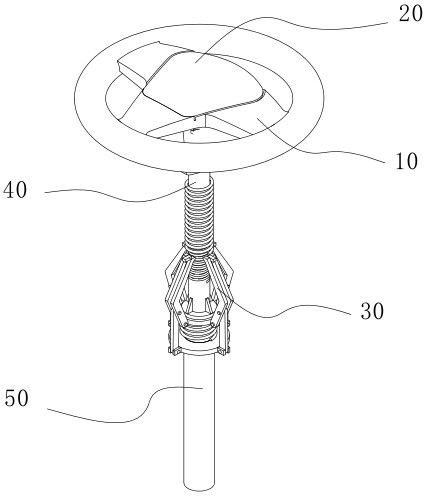

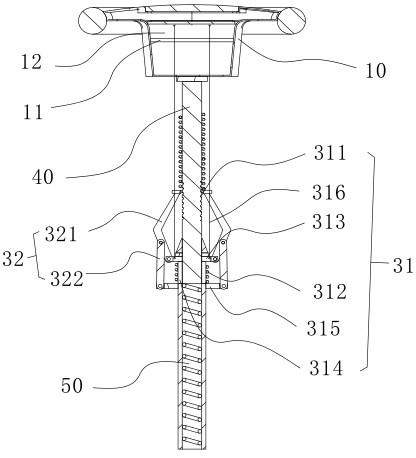

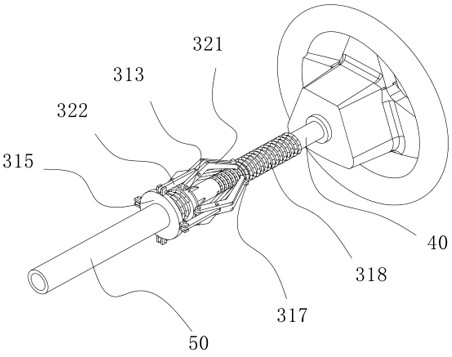

Protective automobile steering wheel structure for buffering human chest impact

ActiveCN113788062AEnough buffer timeEnough buffer spacePedestrian/occupant safety arrangementHand wheelsSteering wheelAirbag

The invention provides a protective automobile steering wheel structure for buffering human chest impact, the structure comprises a steering wheel, an air bag cover plate is fixed on the surface of one side of the steering wheel, a steering wheel shaft is fixed on the surface of the other side of the steering wheel, and a buffering propelling device and a rotating shaft sleeve sequentially sleeve outside the steering wheel shaft from top to bottom; a supporting plate is fixed into the steering wheel, and a safety air bag is fixed to the upper surface of the supporting plate. The buffering propelling device comprises a buffering mechanism arranged outside the steering wheel shaft and a locking mechanism connected with the executing end of the buffering mechanism, and the locking mechanism comprises a supporting disc fixed to the outer surface of the rotating shaft sleeve, an electromagnet fixed to the upper surface of the supporting disc, and a lifting disc arranged at the top end of the electromagnet, and the lifting disc is connected with the safety air bag through a steel wire rope. When the driver rushes to the safety air bag, sufficient buffer space can be provided by adjusting the position between the safety air bag and the position of the driver.

Owner:深圳市炫客汽车电子有限公司

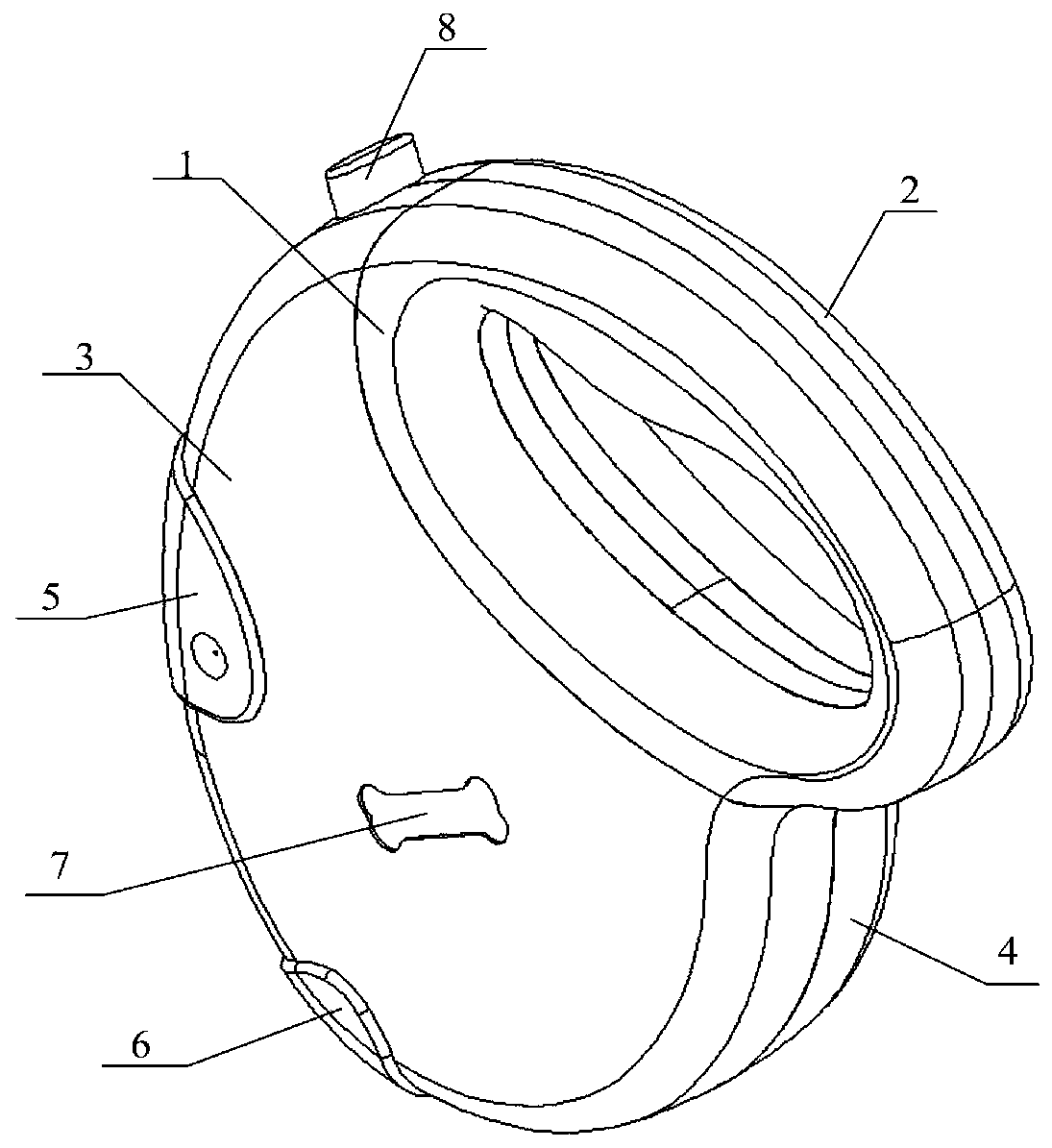

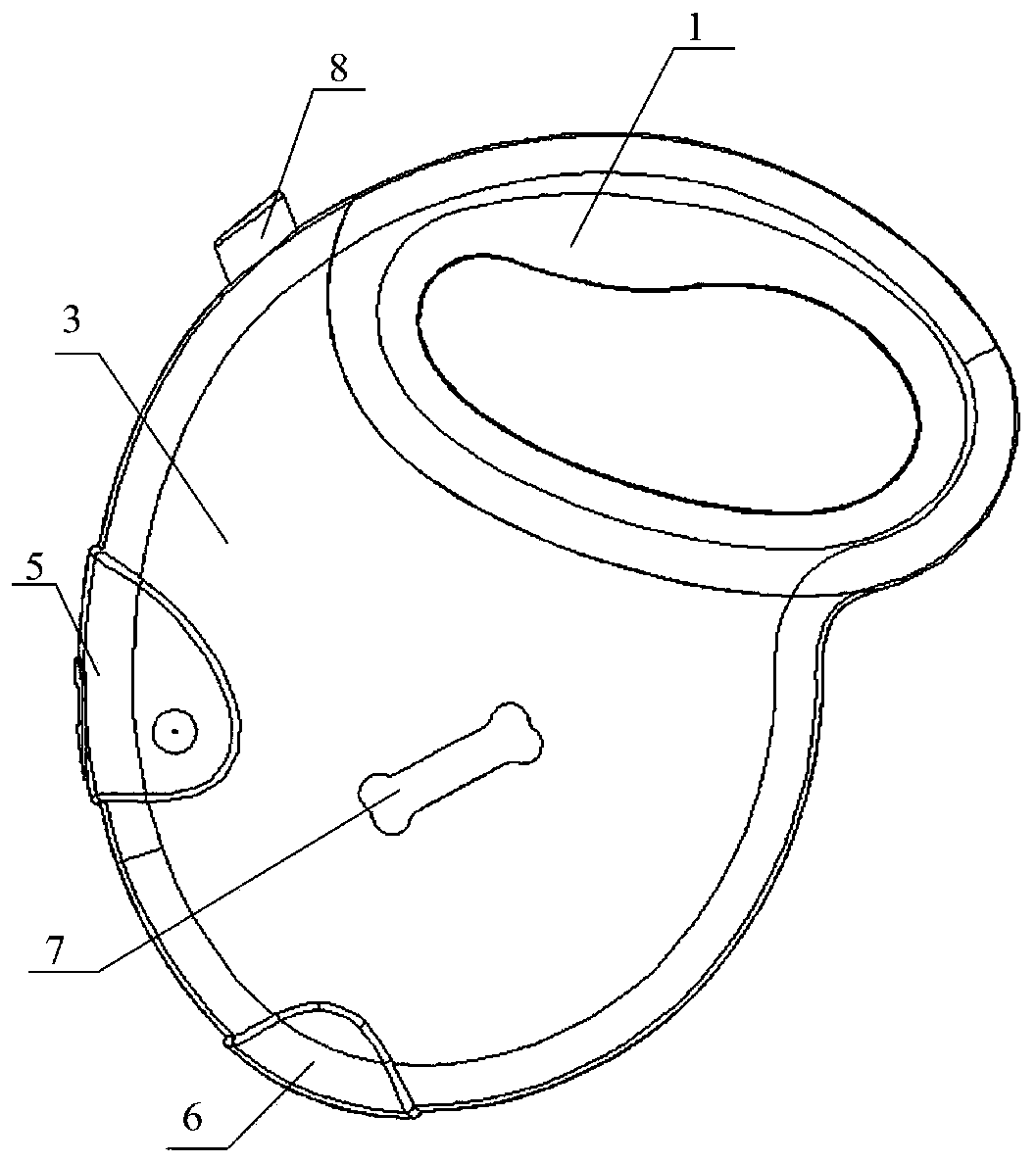

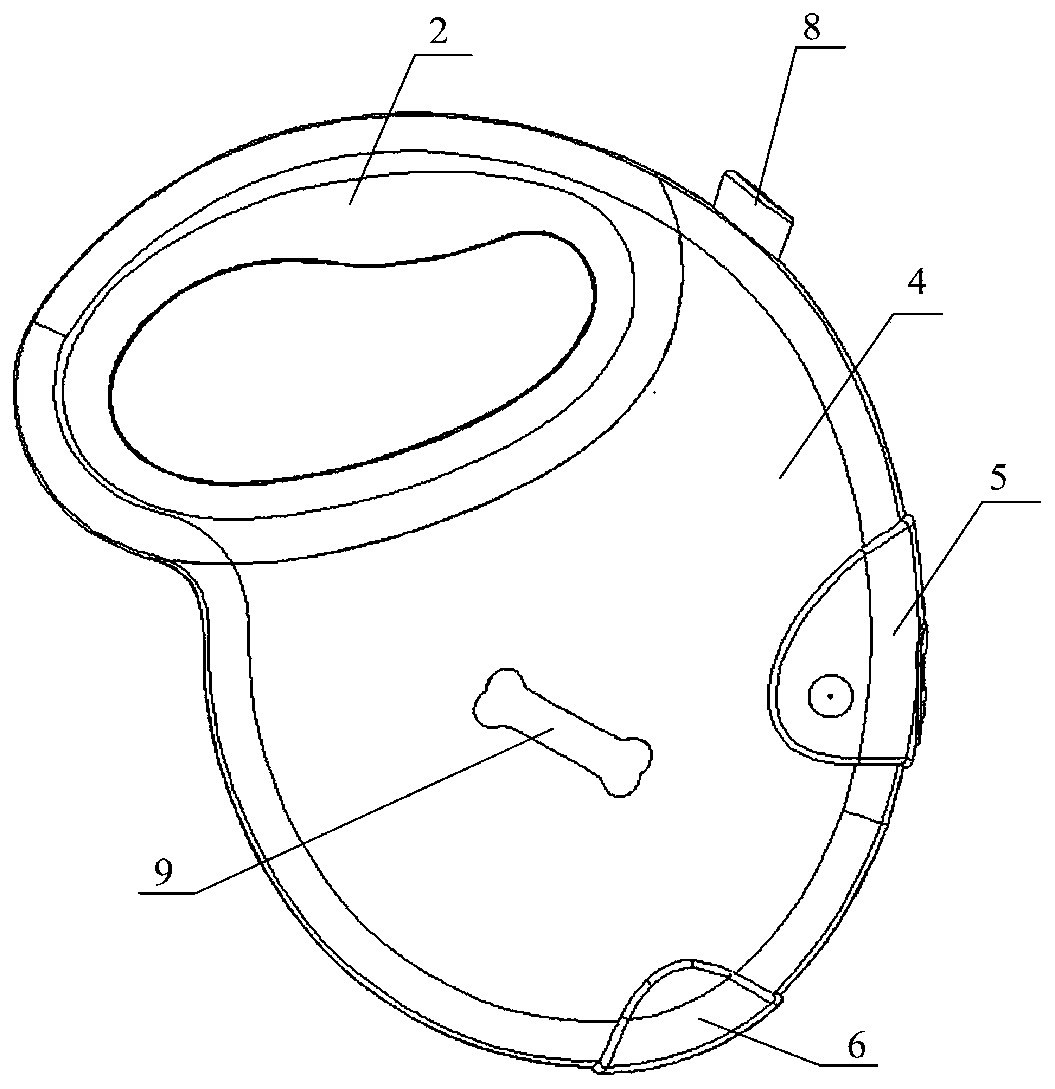

Pet pulling device

PendingCN110278883AAvoid pets rushing out suddenlyAvoid traction rope not stuck running ropeTaming and training devicesEngineeringBreakage probability

The invention discloses a pet pulling device, and relates to the field of pulling devices. The pet pulling device comprises a first upper shell, a first lower shell, a second upper shell, a second lower shell, a button assembly, a rotary fixing assembly and a pull rope inlet and outlet mechanism, wherein the first lower shell and the first upper shell are integrated, the second lower shell and the second upper shell are integrated, the first upper shell and the second upper shell are relatively fixed, the first lower shell and the second lower shell are relatively fixed, the button assembly and the rotary fixing assembly are installed in the first lower shell and the second lower shell, and the pull rope inlet and outlet mechanism is installed on the side face of the first lower shell and the side face of the second lower shell. By means of the pet pulling device, damage conditions can be effectively reduced, the rope breakage probability is reduced, the use quality is improved for a user, and the service life is prolonged.

Owner:SHENZHEN ZHONGBANG GLOBAL IND CO LTD

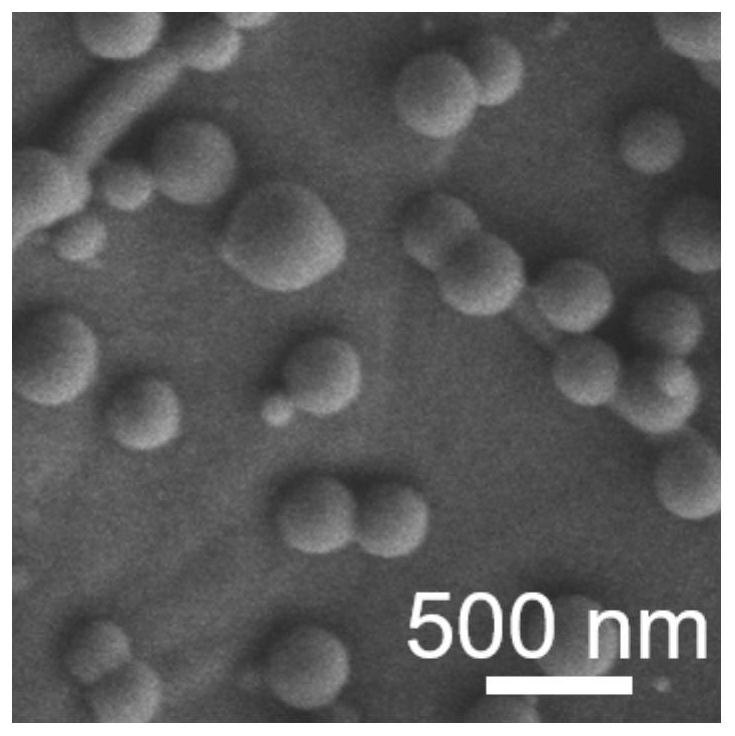

Monoatomic dispersed in-situ growth nitrogen atom-doped carbon nanosphere graphene foam, preparation method and application

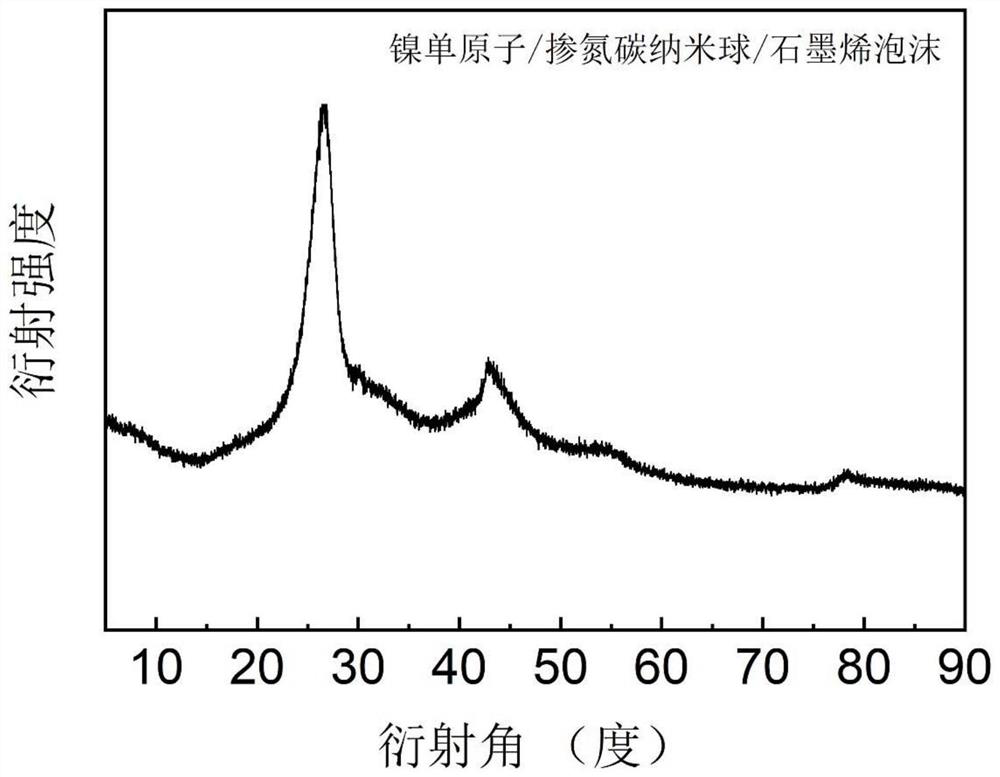

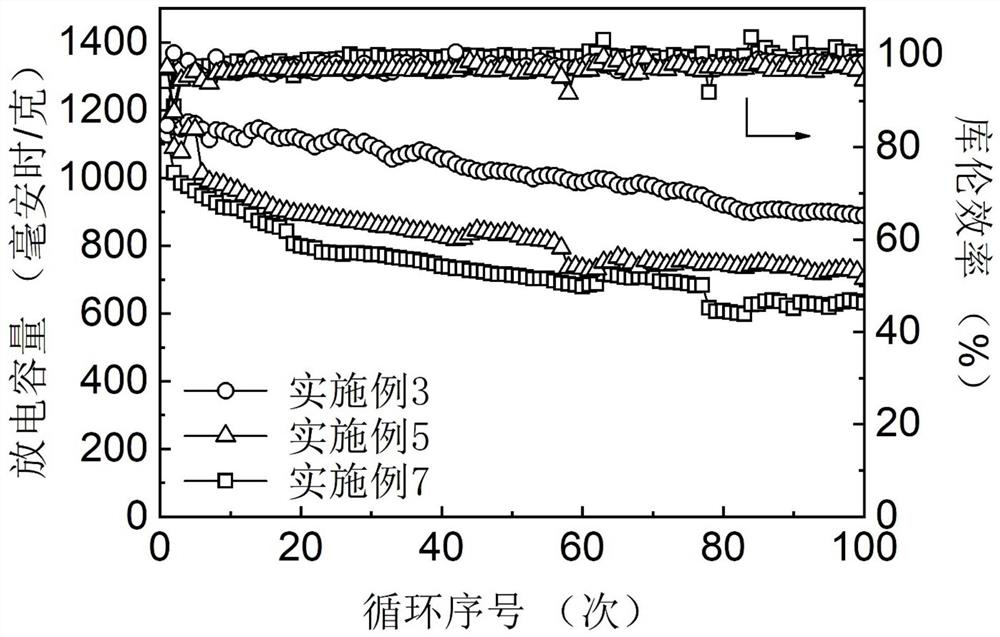

PendingCN113104840ASolve the adsorption problemIncrease profitCell electrodesGrapheneLithium–sulfur batteryNew energy

The invention relates to the technical field of new energy materials, in particular to a monoatomic dispersed in-situ growth nitrogen atom-doped carbon nanosphere graphene foam, a preparation method and application, wherein carbon nanospheres grow in situ on graphene foam, and the carbon nanospheres are doped with nitrogen atoms and metal single atoms. The preparation method comprises the following steps: preparing graphene foam on the surface of a foam metal template by adopting a vapor deposition method, then growing nitrogen-containing organic nanospheres on the surface of the graphene foam in situ, calcining, and removing the foam template in sequence to obtain the graphene foam doped with nitrogen atoms and metal monatomic carbon nanospheres through in-situ growth. When the obtained composite material is applied to the lithium-sulfur battery, the utilization rate of active substances can be greatly improved, and the overall electrochemical performance is excellent.

Owner:HEBEI UNIV OF TECH +1

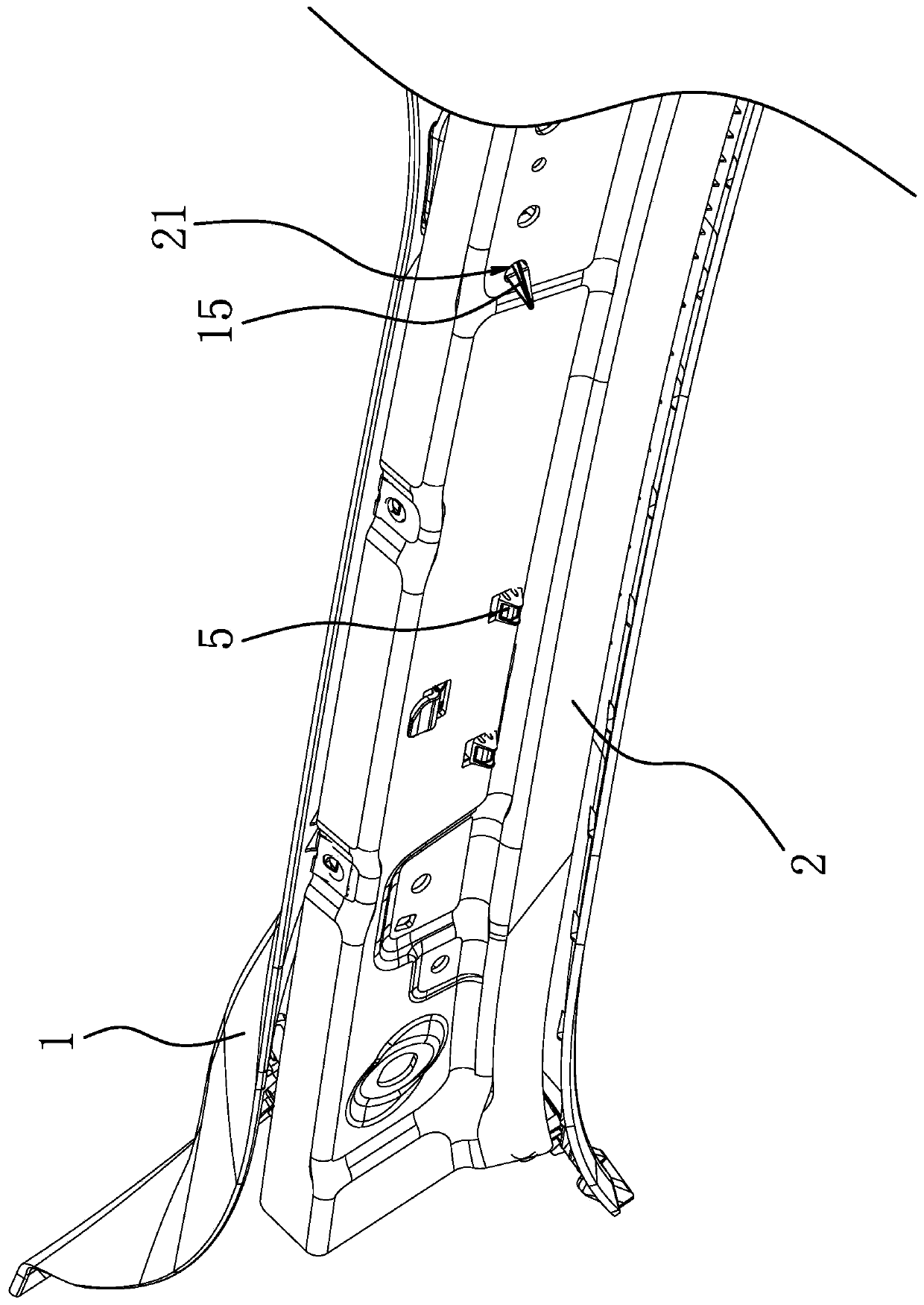

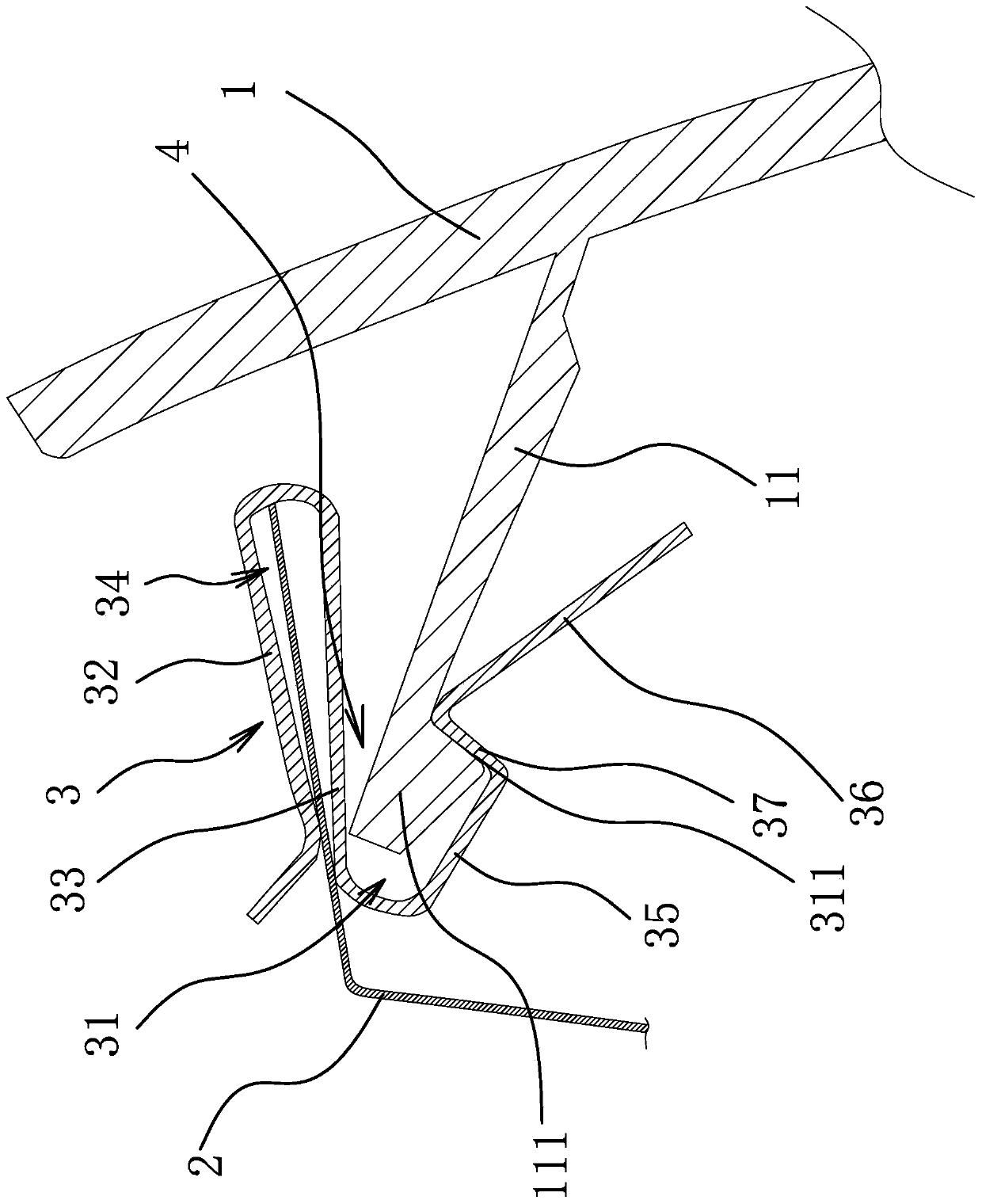

Mounting structure of A-pillar trim and automobile body metal plate

ActiveCN111301309AInhibit sheddingAvoid breakingSuperstructure subunitsSuperstructure connectionsStructural engineeringMechanical engineering

The invention provides a mounting structure of an A-pillar trim and an automobile body metal plate, and belongs to the technical field of automobiles. The problem that when an air curtain of an existing A-pillar trim is exploded, the A-pillar trim is prone to falling off or deforming is solved. The mounting structure of the A-pillar trim and the automobile body metal plate comprises a connecting assembly capable of positioning the A-pillar trim on the automobile body metal plate, the mounting structure comprises a buckle connected with the automobile body metal plate and a limiting block arranged on one side of the A-pillar trim, a clamping groove is formed in the buckle, the limiting block can be embedded into the clamping groove and is connected with the buckle in a clamped mode, a gap allowing the limiting block to move is formed between the limiting block and the groove wall of the clamping groove, and when the A-pillar trim panel moves towards the automobile body metal plate afterbeing not positioned with the automobile body metal plate, the A-pillar trim panel can drive the limiting block to move towards the gap. The mounting structure of the A-pillar trim and the automobilebody metal plate is small in required space, and the stability of connection between the A-pillar trim and the automobile body metal plate can be improved.

Owner:GEELY AUTOMOBILE INST NINGBO CO LTD +1

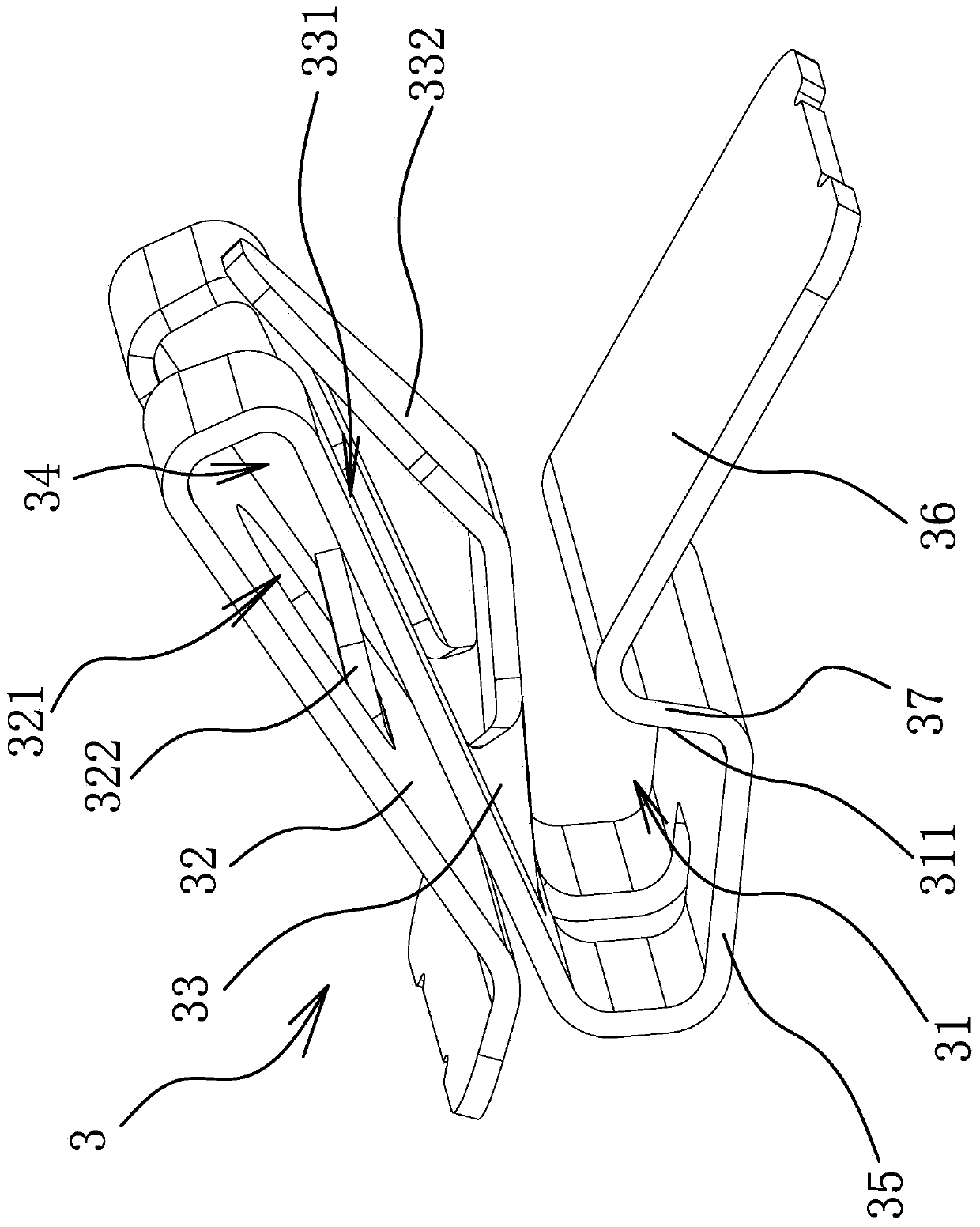

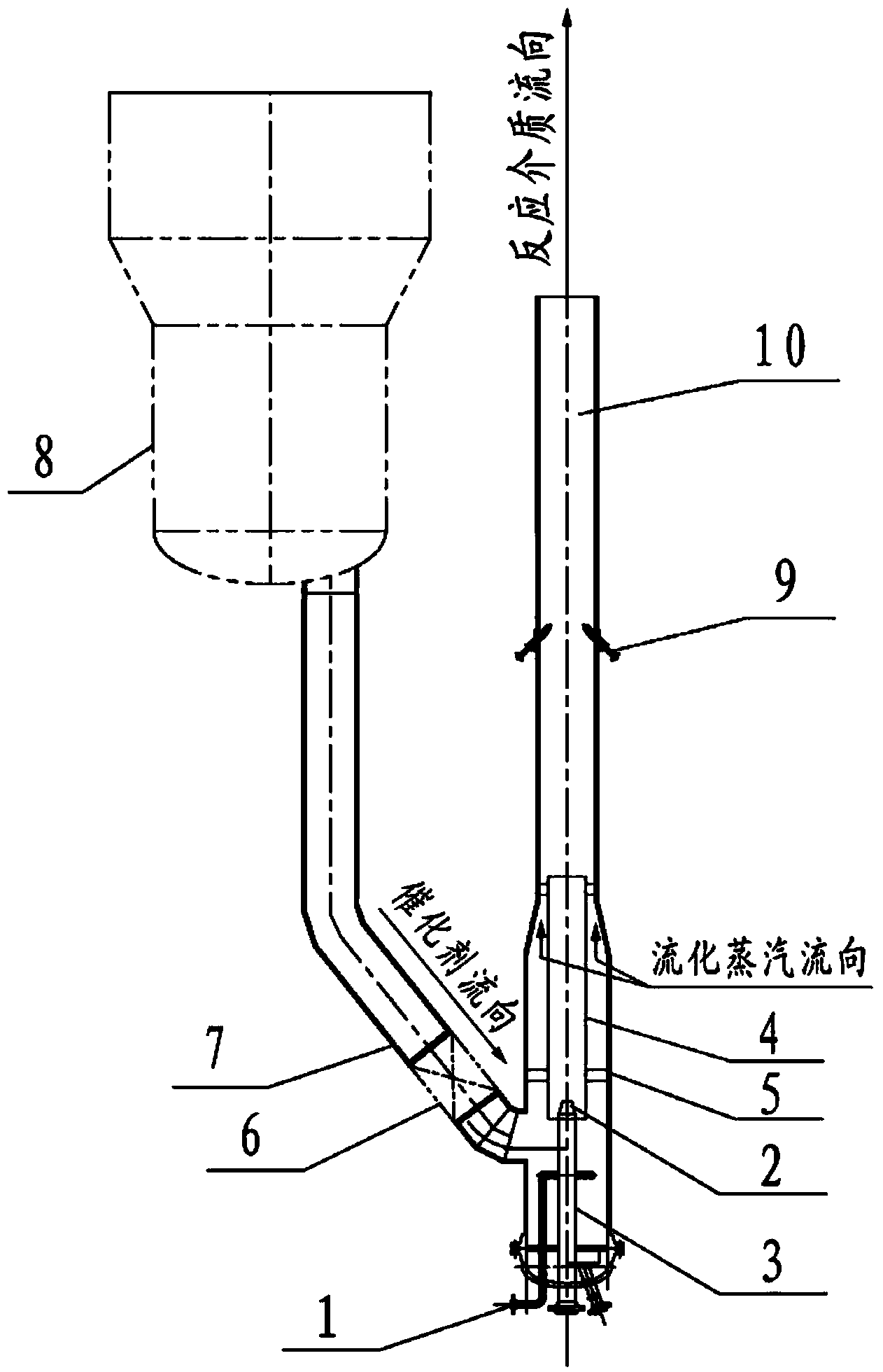

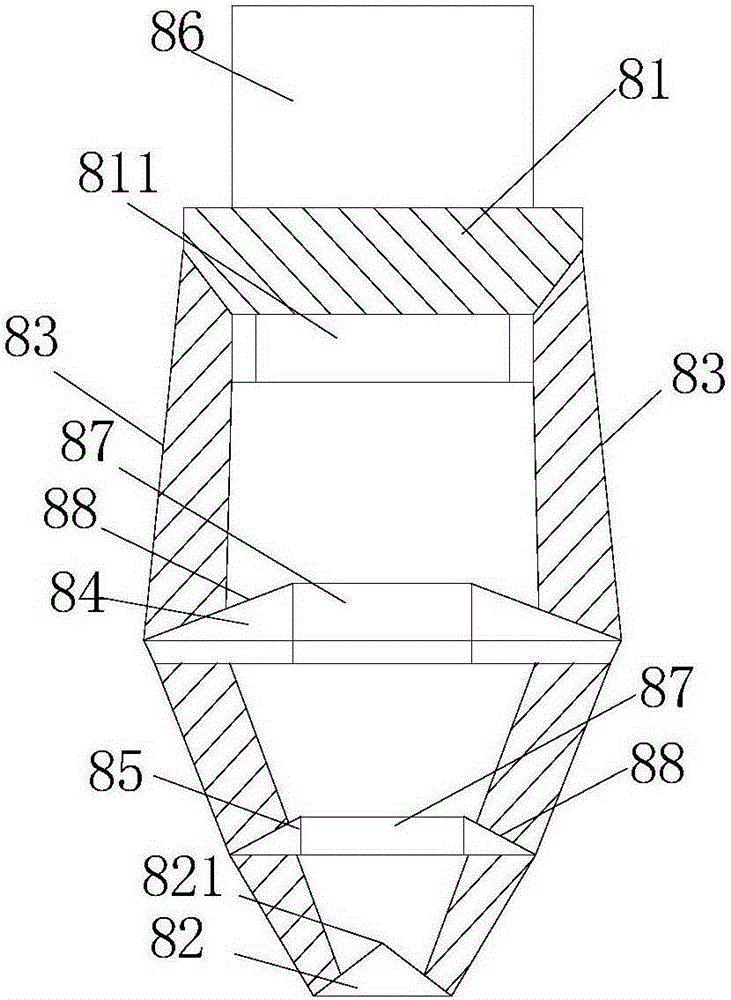

Lift pipe reactor pre-lifting device and process flow thereof

InactiveCN103849424AEnough buffer spaceSmall pressure fluctuationsCatalytic crackingChemical/physical processesSpray nozzleEngineering

The invention relates to a lift pipe reactor pre-lifting device and a process flow thereof. The lift pie reactor pre-lifting device comprises a fluidized vapor ring, a pre-lifting vapor nozzle, a pre-lifting vapor pipe, an expansion section, a single-action slide valve and a regeneration inclined pipe. An inner conveyor pipe is arranged in the expansion section, the lower part of the inner conveyor pipe is connected with the upper part of the pre-lifting vapor pipe, and the inner diameter of the pre-lifting device is twice as large as the inner diameter of the upper part of a lift pipe reactor. By adopting the method in which the inner conveyor pipe is increased, the inner diameter of the pre-lifting device is increased and therefore the structure of the expansion section is changed, the catalyst entering the expansion section has a sufficient buffering space, so that the blanking pressure fluctuation of the regeneration inclined pipe is reduced, the bias current generated by an S-shaped movement orbit can be eliminated, the pre-lifting vapor pipe can avoid the regeneration inclined pipe, the direct impact of the pre-lifting vapor on a blanking port of the regeneration inclined pipe can be avoided, the circulating capacity of the catalyst of a settlement regenerator can be increased, the catalyst in the lift pipe can be uniformly distributed, and the yield of a target product can be improved.

Owner:LUOYANG ZHIBANG PETROCHEM EQUIP

Porous carbon material added into silicon-based negative electrode, silicon-based negative electrode and lithium ion battery

ActiveCN113353911AImprove cycle performanceImprove cycle lifeSecondary cellsNegative electrodesPorous carbonPhysical chemistry

The invention relates to the technical field of lithium ion batteries, and aims to provide a porous carbon material added into a silicon-based negative electrode in view of the problem that the cost is high when a high-grade porous structure graphite material is prepared and applied to a silicon-based negative electrode at present. The invention discloses a porous carbon material added into a silicon-based negative electrode, which is prepared by taking a biomass material as a raw material through high-temperature oxygen isolation hardening, particle size refining, low-temperature oxygen isolation pre-carbonization, mixed alkali calcination, cleaning and drying. The invention provides the porous carbon material which can be added into a lithium ion battery silicon-carbon negative plate. The porous carbon material is prepared from a cheap biomass raw material through a specific process. A rich microporous structure is obtained, an enough buffer space is provided for volume expansion of the silicon material through the microporous structure of porous carbon, and the cycle performance of the lithium ion battery is improved.

Owner:WANXIANG 123 CO LTD

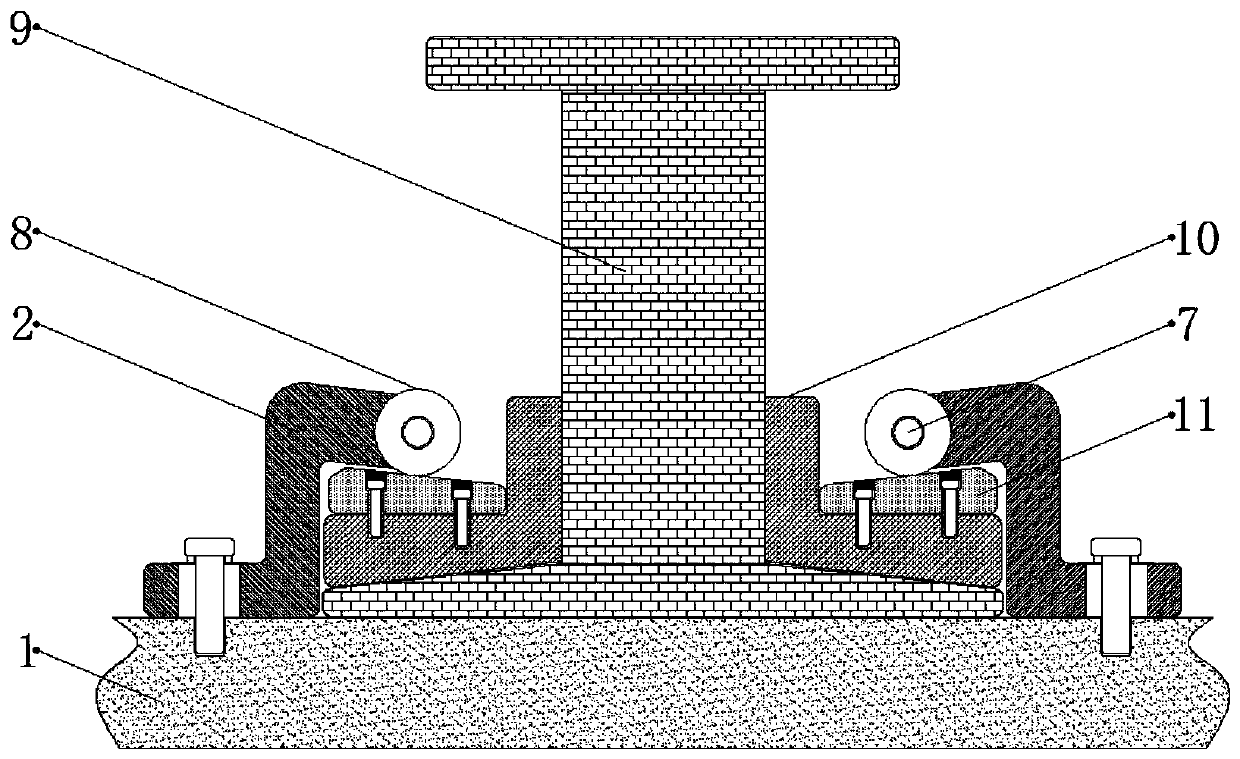

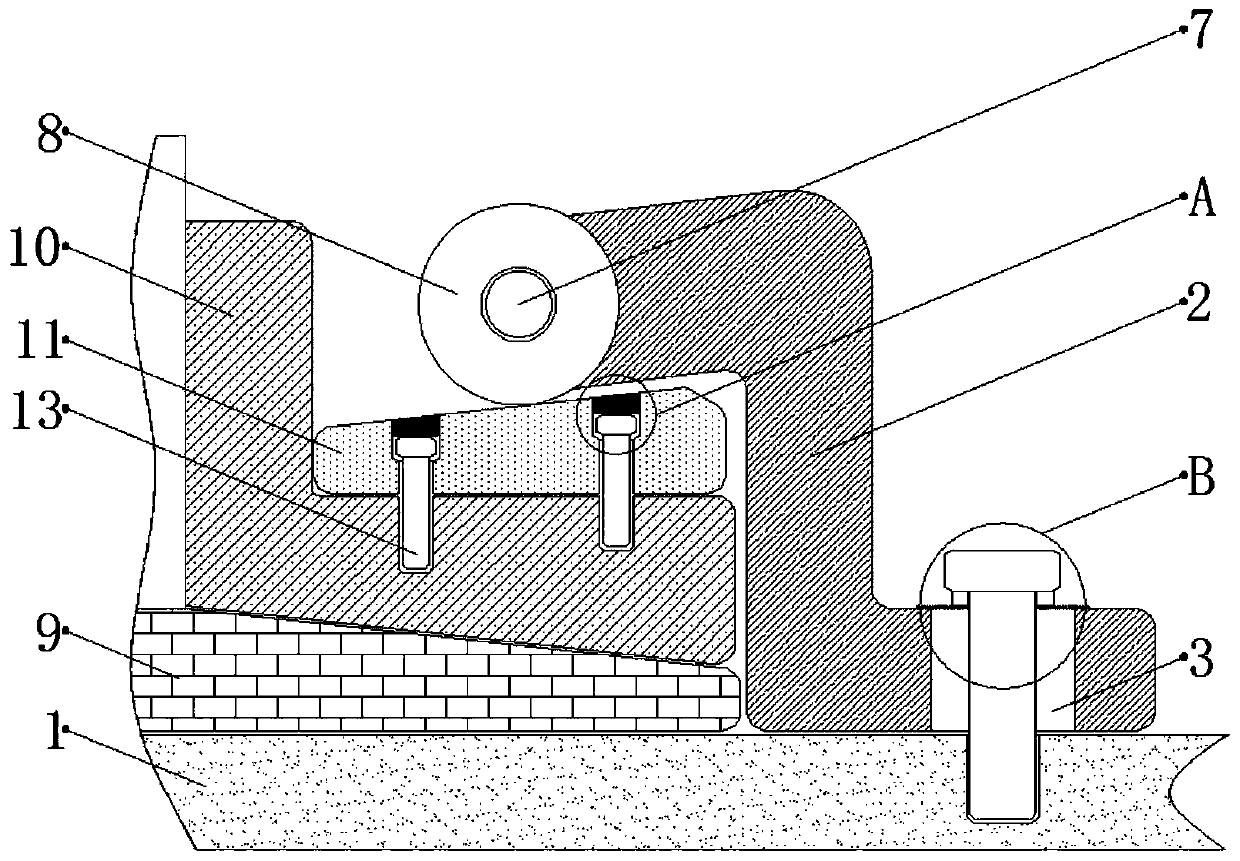

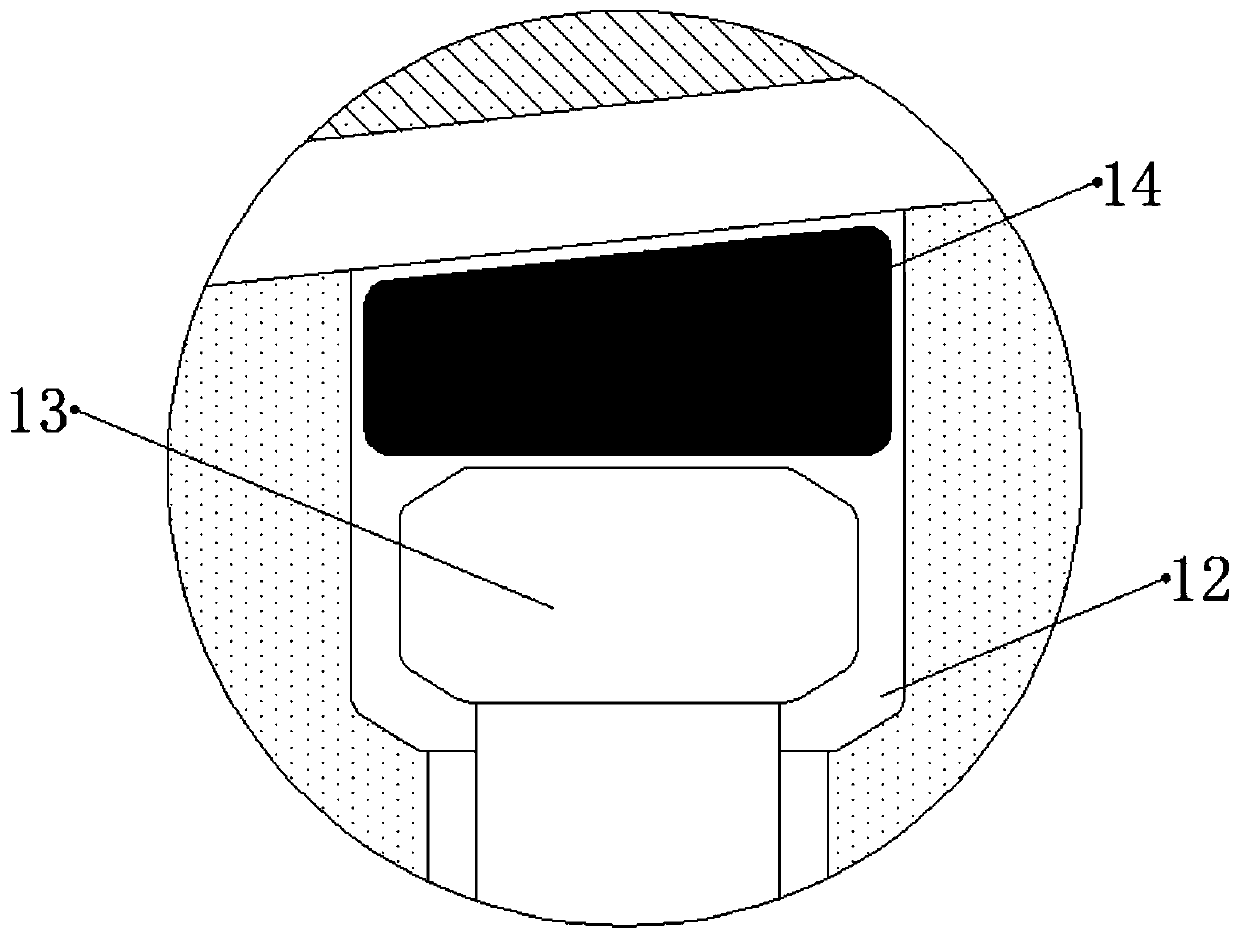

Automatic adjusting device for thermal expansion and cold contraction of railway fastener

ActiveCN111235975AImprove securityImprove the ability to adapt to the environmentRail fastenersFastenerEngineering

The invention relates to the technical field of rail transit, and discloses an automatic adjusting device for thermal expansion and cold contraction of the railway fastener. The device comprises a sleeper body, the sleeper body is built by concrete, two clamping plates are placed at the top of the sleeper body, the clamping plates are in a Z shape and are fixed to the sleeper body through fixing bolts, fixing holes are formed in the tops of the clamping plates, and teeth are arranged at the bottom of a base plate and openings of the fixing holes. The utility model discloses a railway fastenerthermal expansion and cold contraction automatic adjusting device. A connecting plate and a mounting block are mounted between a clamping plate and a rail; rail when heated to expand, the mounting block is pushed by the movable connecting plate to move obliquely upwards; when the installation blocks slide along the rolling wheels and the rail contracts, the connecting plates move obliquely downwards, so that the distance between the clamping plates and the installation blocks is increased during expansion, expansion space is provided for the rail, the distance between the clamping plates and the installation blocks is reduced during contraction, the rail is kept in a clamped state all the time, and the safety of the rail is improved.

Owner:芜湖市金友精密机械有限责任公司

Preparation method of ultrahigh-rate potassium ion battery bismuth-based composite negative electrode material

ActiveCN114784256ANovel and stable structureStable structureSecondary cellsNegative electrodesPotassium ionsAmmonium metavanadate

The invention discloses a preparation method of an ultrahigh-rate potassium ion battery bismuth-based composite negative electrode material, and belongs to the technical field of potassium ion batteries. The preparation method of the composite negative electrode material comprises the following steps: (1) dropwise adding an ammonium metavanadate solution into a bismuth source solution, uniformly stirring to obtain a yellow solution, and carrying out hydrothermal reaction to obtain a BiVO4 precursor; and (2) ultrasonically dispersing the BiVO4 precursor in a buffer solution, adding dopamine hydrochloride, stirring and reacting to obtain a polydopamine-coated BiVO4 composite material, and calcining in an inert atmosphere to obtain the ultrahigh-rate bismuth-based composite negative electrode material for the potassium ion battery. The synthesis method is simple, the material morphology structure is novel and stable, the utilization rate of active substances is high, the electrode material structure is stable, the number of active sites is large, and the rate and cycling stability of the potassium ion battery are remarkably improved.

Owner:JINAN UNIVERSITY

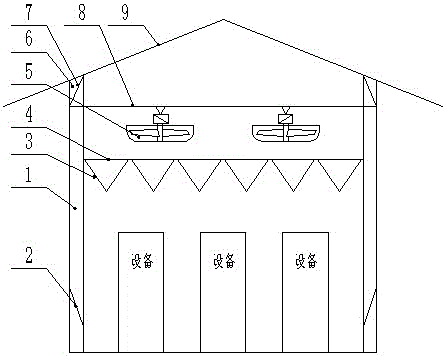

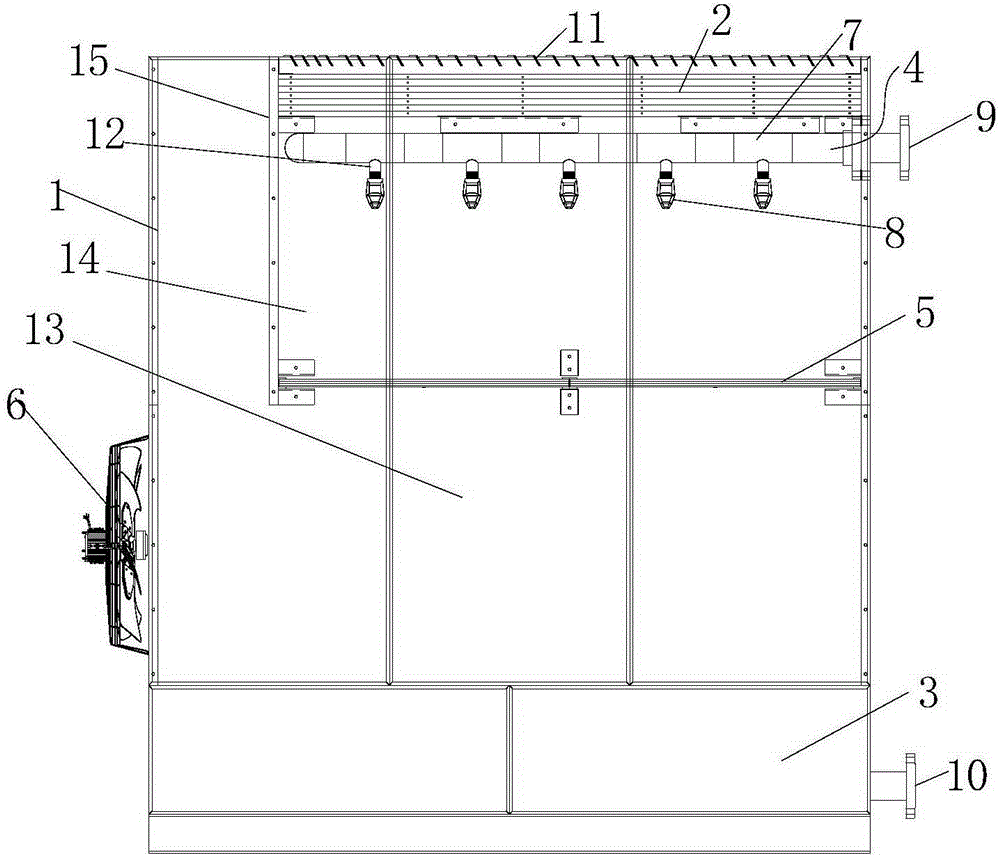

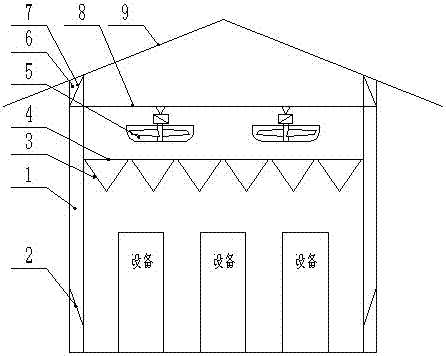

Equipment room structure of base station

InactiveCN106223666ASimple structure setupAddress negative issuesLighting and heating apparatusSpace heating and ventilation detailsBase stationFixed Beam

The invention specifically relates to an equipment room structure of a base station. The equipment room structure is simple and has good ventilation and dust removal effects. According to the technical scheme, the equipment room structure comprises a four-surface wall body, wherein a plurality of filter screens are arranged at the lower part of the wall body, a plurality of guide plates are arranged at the upper part in an equipment room, and each guide plate is formed by two plates forming an included angle; the guide plates are arranged at the upper part of the equipment room through a crossbeam bridged on the wall body; one or more fixed beams are further arranged above the crossbeam, and one or more venting fans are arranged on each fixed beam; and a plurality of vent holes are uniformly formed in the wall body from the fixed beams to the roof, and top filter nets are mounted in the vent holes.

Owner:郭志清

Cable construction device

InactiveCN106786184AReduce wearEnough buffer spaceApparatus for laying cablesEngineeringMechanical engineering

The invention discloses a cable construction device. The cable construction device comprises a conveyor, at least two power-driven guide wheels and a roller assembly, wherein the at least two power-driven guide wheels are connected with the conveyor, the roller assembly is alternatively arranged between adjacent power-driven guide wheels, and a cable passes through the roller assembly, is in close contact with surfaces of the power-driven guide wheels and is transmitted by the conveyor. By the cable construction device, the distance between the power-driven guide wheels is reasonably set, an enough buffer space is generated during cable laying, and the abrasion of an outer surface of the cable is reduced.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

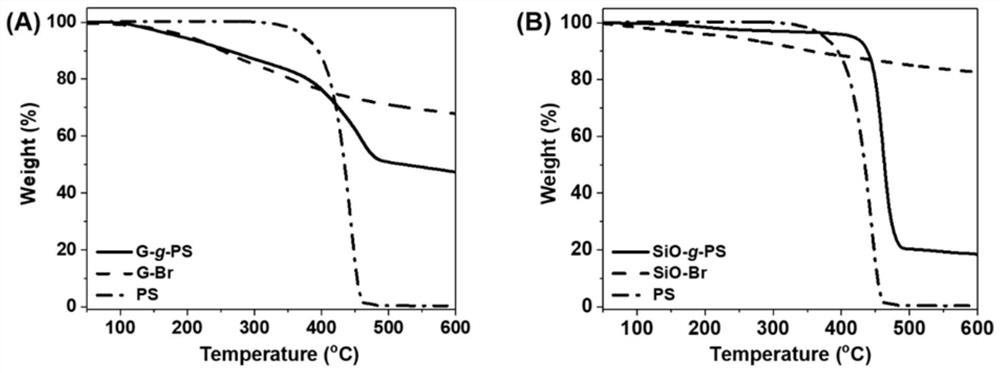

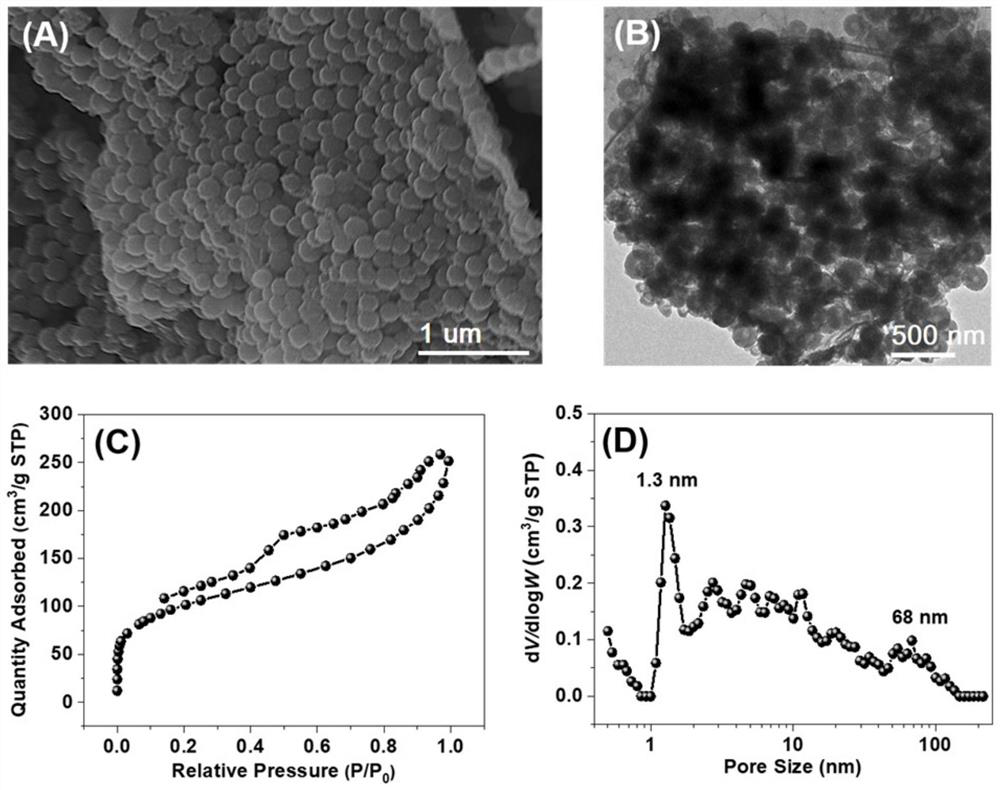

Advanced porous polymer nanosheet, preparation method and application thereof

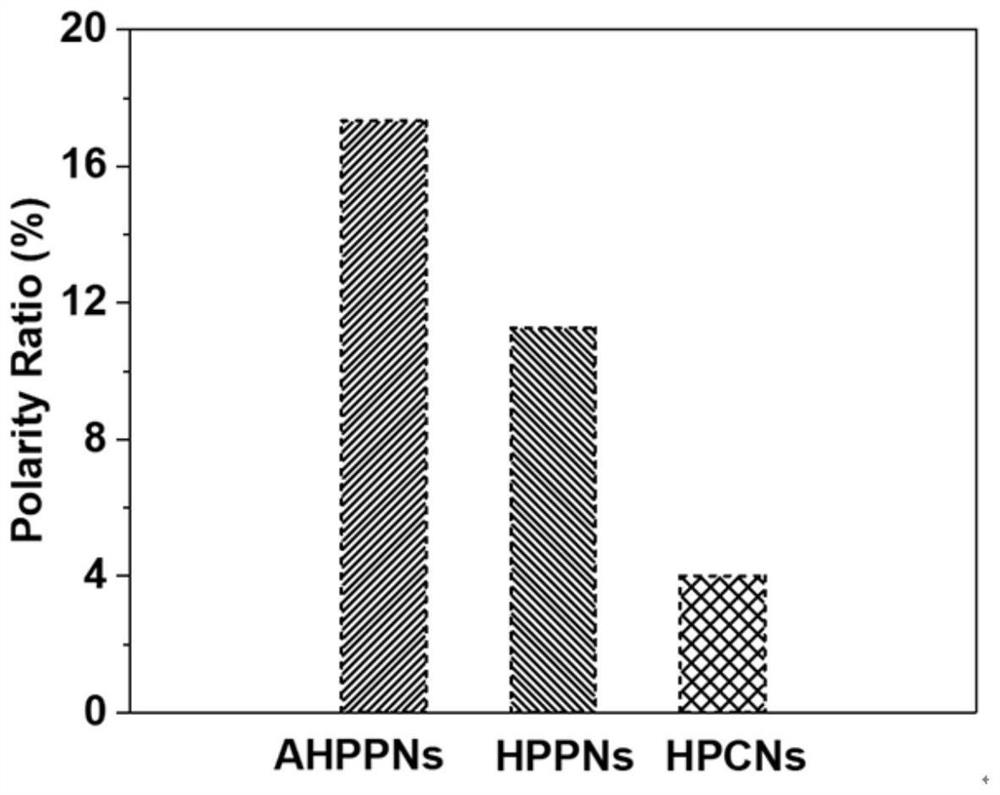

ActiveCN113036208AHigh sulfur contentEnough buffer spaceMaterial nanotechnologyCell electrodesLithium sulfurSilicon oxide

The invention discloses an advanced porous polymer nanosheet, a preparation method and application thereof. According to the invention, a zero-dimensional silicon dioxide molecular brush and a two-dimensional graphene molecular brush are prepared on the surfaces of zero-dimensional silicon dioxide and two-dimensional graphene by utilizing a polymer surface grafting technology, a co-assembly reaction is induced through cross-linking of the zero-dimensional silicon dioxide molecular brush and the two-dimensional graphene molecular brush, and then silicon dioxide is etched to obtain the porous polymer nanosheet, wherein a large number of polymer nanospheres with hierarchical pore structures are uniformly distributed on the surface of the prepared nanosheet, so that enough buffer space can be provided for volume change in conversion of sulfur active substances in the charging and discharging process of the lithium-sulfur battery, and graphene serving as a conductive trunk of the nanosheet can promote rapid transfer of charges so as to improve the conductivity of the electrode; the cross-linking induced co-assembly strategy can generate a large number of strong polar groups in the porous polymer skeleton, and can effectively inhibit the diffusion and loss of polysulfide; and the nanosheet shows excellent multiplying power and cycle performance when being used for a positive electrode material of a lithium-sulfur battery.

Owner:SUN YAT SEN UNIV

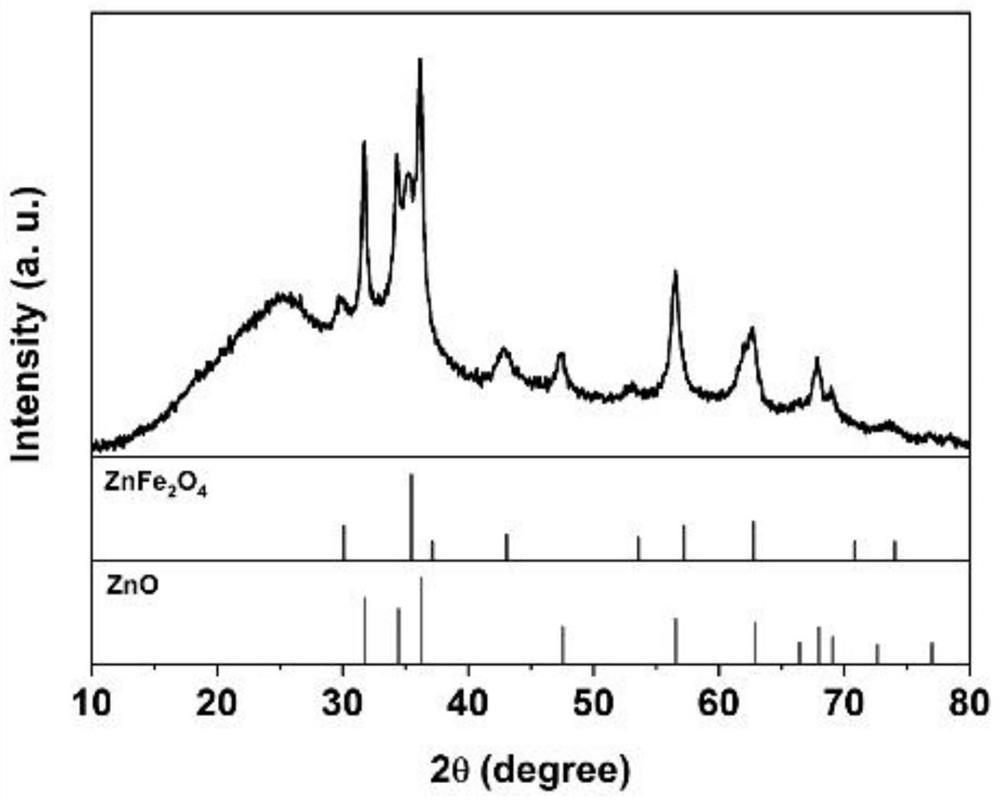

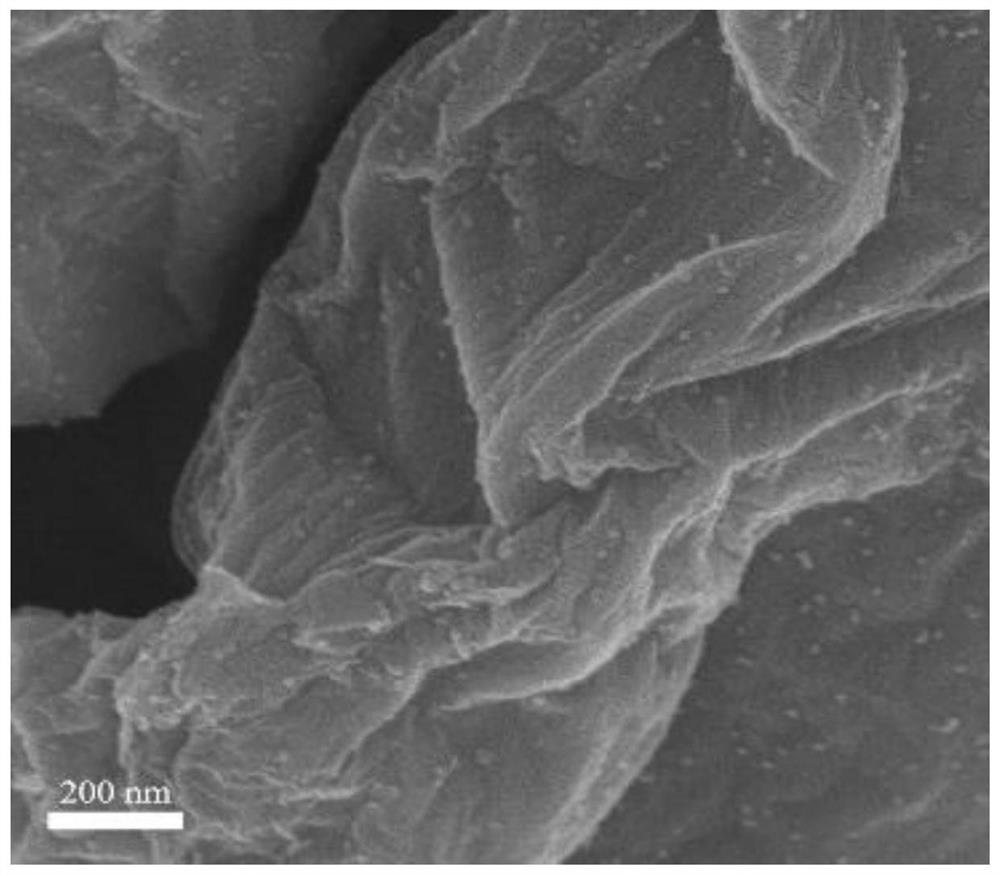

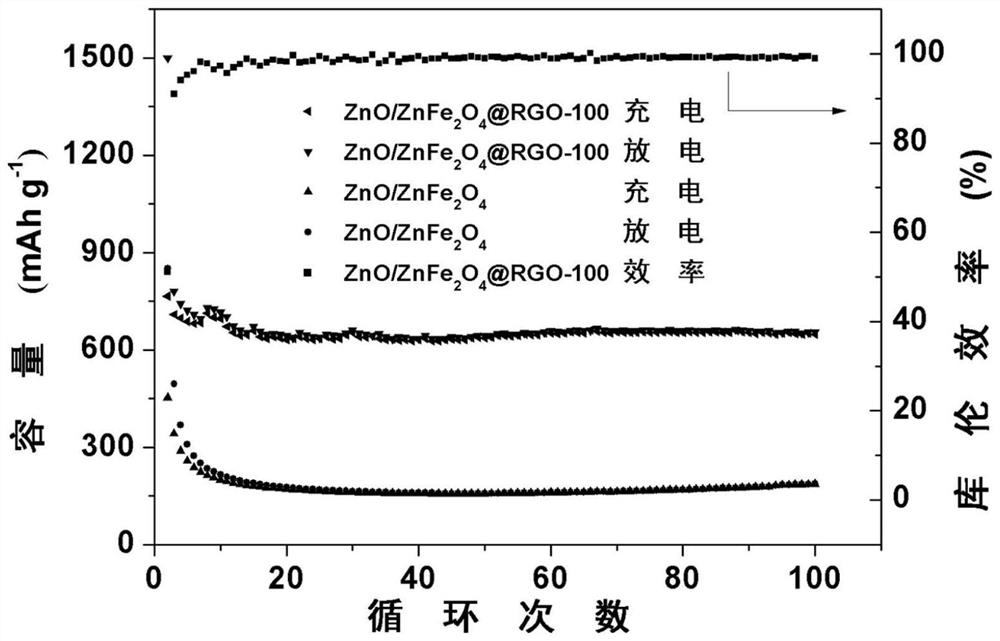

Graphene-zinc-based oxide composite material, preparation method thereof and application of graphene-zinc-based oxide composite material in lithium ion battery negative electrode material

PendingCN112803016AEnough buffer spaceImprove cycle performanceMaterial nanotechnologyZinc oxides/hydroxidesElectro conductivityLithium ion intercalation

The invention provides a graphene-zinc-based oxide composite material, a preparation method thereof and application of the graphene-zinc-based oxide composite material in a lithium ion battery negative electrode material, and relates to the technical field of lithium ion batteries. The graphene-zinc-based oxide composite material provided by the invention comprises reduced graphene oxide and ZnO-ZnFe2O4 nanoparticles grown on the surface of the reduced graphene oxide, wherein the distance between every two adjacent ZnO-ZnFe2O4 nano particles is 2 to 92 nm. According to the invention, ZnO-ZnFe2O4 nanoparticles are dispersed on the surface of reduced graphene oxide, and gaps among the ZnO-ZnFe2O4 nanoparticles provide enough buffer space for volume expansion caused by intercalation and deintercalation of lithium ions, so that the material has better cycle performance and rate capability; and the reduced graphene oxide also greatly improves the conductivity of the material.

Owner:赣州市力道新能源有限公司 +1

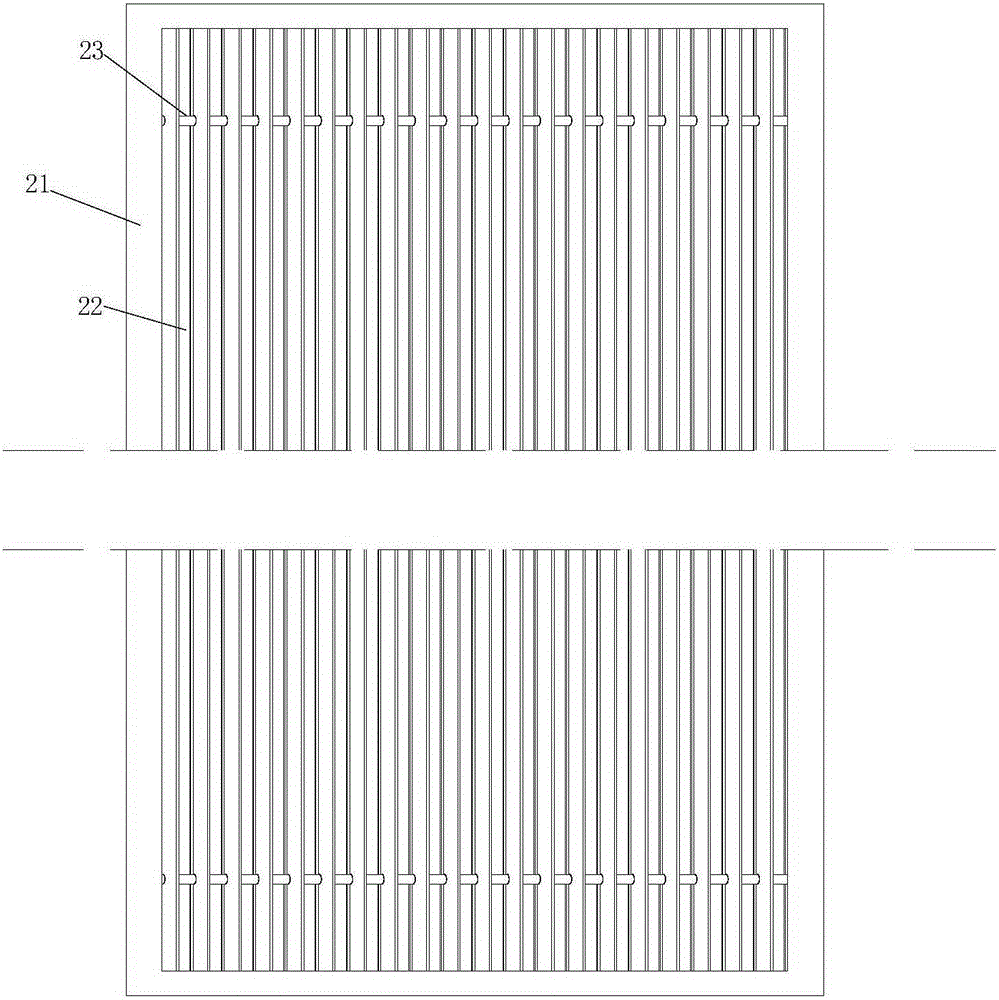

Condensing tower

The invention relates to a condensing tower. The condensing tower comprises a shell with an inner cavity, a draught fan, a partition plate arranged in the shell, a water tank, a water spraying system, a honeycomb net device and a defroster. One end of the partition plate is fixedly connected with the upper end of the shell, and the lower end of the partition plate is fixedly connected with one end of the honeycomb net device. The other end of the honeycomb net device is connected with the side wall of the shell. The inner cavity of the shell is divided into a first cavity and a second cavity through the partition plate and the honeycomb net device. The upper end of the first cavity is of a closed structure. The upper end of the second cavity is of a shutter structure. The water tank is arranged in the first cavity and located at the lower end of the first cavity. The defroster and the water spraying system are arranged in the second cavity and connected with the shell and the partition plate respectively. The defroster is located above the water spraying system. The draught fan is arranged on the side face of the outer side of the shell and located above the water tank and below the honeycomb net device. The draught fan is communicated with the first cavity. The condensing tower has the beneficial effects of being low in water bleaching rate, good in heat exchange effect, capable of saving water, convenient to hoist, and the like.

Owner:江苏河海新能源技术发展有限公司

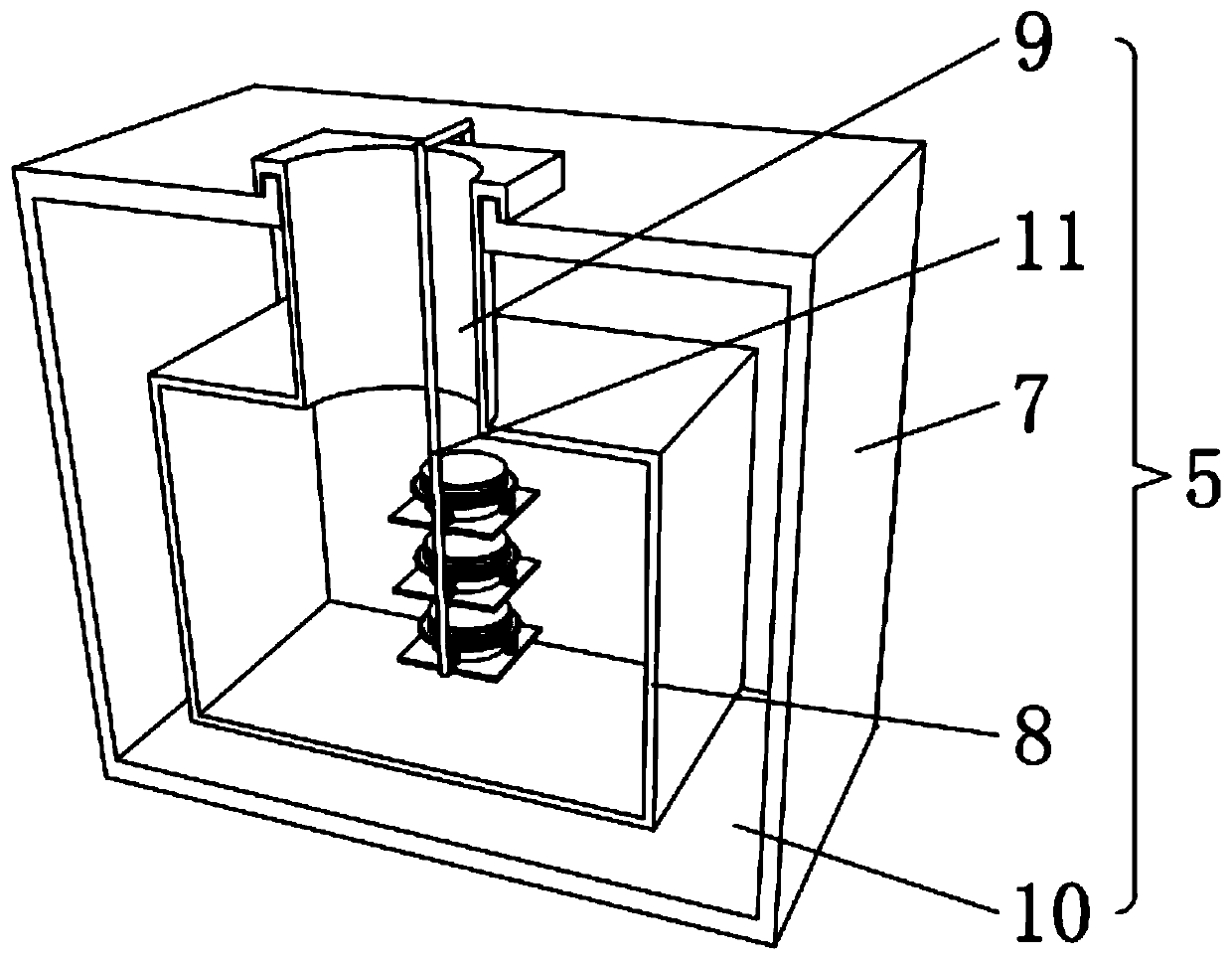

Sampling storage device for medical oncology

InactiveCN111409937AImprove seismic performanceMitigation of Contact Collision StrengthClosure with auxillary devicesDead animal preservationStructural engineeringElectrical and Electronics engineering

The invention discloses a sampling storage device for medical oncology, and relates to the technical field of medical equipment. The sampling storage device comprises a bottom plate, wherein a pull rod is fixedly connected to the right side of the top of the bottom plate, a storage mechanism is fixedly connected to the top of the bottom plate, a standby liquid nitrogen tank is arranged on the right side of the storage mechanism and located at the top of the bottom plate, the storage mechanism comprises a storage box, a cover plug is clamped to the top of the storage box, the storage box comprises a shell, an inner container is embedded in the shell, the top of the inner container extends to the outside of the shell through a neck pipe and is fixedly connected with the top of the shell, a vacuum cavity is formed between the inner container and the shell, four cryopreservation frames are arranged in the inner container, each cryopreservation frame comprises a lifting rod, three buffer assemblies are fixedly connected to the outer side of the bottom of the outer wall of the lifting rod, and cryopreservation boxes are embedded in the tops of the buffer assemblies. According to the sampling storage device for the medical oncology, the shock resistance of the cryopreservation boxes is improved by arranging the buffer assemblies.

Owner:THE FIRST AFFILIATED HOSPITAL OF WANNAN MEDICAL COLLEGE YIJISHAN HOSPITAL OF WANNAN MEDICAL COLLEGE

A kind of preparation method of lithium battery negative electrode material

InactiveCN106521705BReduce chalkingImprove conductivitySecondary cellsNegative electrodesFiberPolymer science

The invention relates to a preparation method of a lithium battery anode material. A SnO2@ / C composite material which contains fibers and adopts a hollow structure can be prepared with the method, SnO2 has enough buffering space in the charging and discharging process due to the fibers adopting the hollow structure, a C outer layer can serve as a network framework of SnO2, efflorescence of the material is reduced, the conductivity of the material is improved, the one-step method for preparation of SnO2@ / SiO2@ / C composite fibers is not as complicated as a traditional method in which fibers are coated after being prepared, and the SnO2@C nanofibers prepared with the method have good cyclic stability.

Owner:JILIN NORMAL UNIV

A base station equipment room structure

InactiveCN106223666BStrong thermoregulation abilityIncrease headroomLighting and heating apparatusSpace heating and ventilation detailsFixed BeamWaste management

The invention specifically relates to an equipment room structure of a base station. The equipment room structure is simple and has good ventilation and dust removal effects. According to the technical scheme, the equipment room structure comprises a four-surface wall body, wherein a plurality of filter screens are arranged at the lower part of the wall body, a plurality of guide plates are arranged at the upper part in an equipment room, and each guide plate is formed by two plates forming an included angle; the guide plates are arranged at the upper part of the equipment room through a crossbeam bridged on the wall body; one or more fixed beams are further arranged above the crossbeam, and one or more venting fans are arranged on each fixed beam; and a plurality of vent holes are uniformly formed in the wall body from the fixed beams to the roof, and top filter nets are mounted in the vent holes.

Owner:郭志清

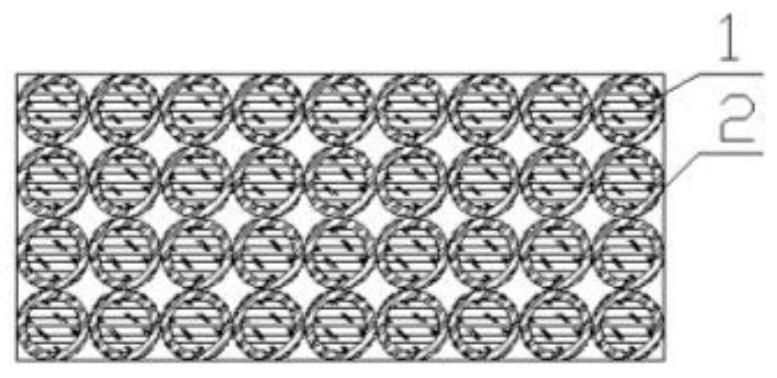

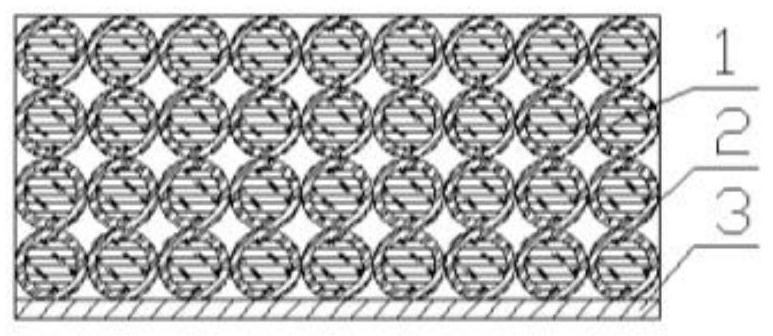

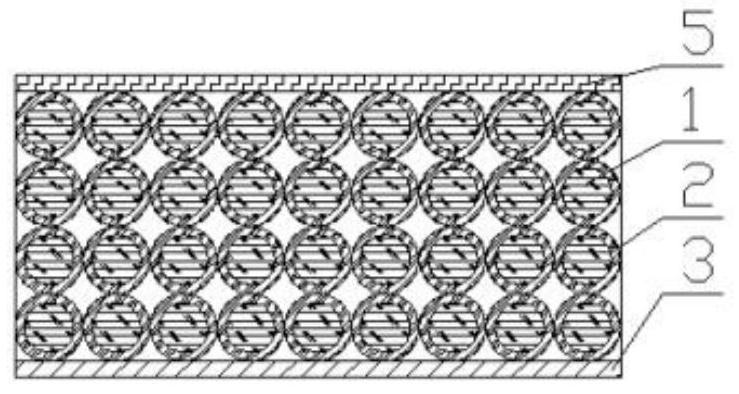

Molecular sieve spacing bar, manufacturing method and equipment

PendingCN113006652AImprove moisture absorptionAdd support functionDoors/windowsMolecular sieveAdhesive

The invention belongs to the technical field of glass deep processing, and discloses a molecular sieve spacing bar, a manufacturing method and equipment. A molecular sieve in the molecular sieve spacing bar is bonded into a strip-shaped object through an adhesive; the outer surface of the molecular sieve is wrapped with a layer of adhesive, and the spacing bar which takes the molecular sieve as a supporting framework and has a certain porosity is formed through mutual bonding of the adhesive; and the spacing bar is directly bonded on glass in an online manufacturing and online placing mode to form a spacing frame. According to the molecular sieve spacing bar, the moisture absorption function is added to the spacing bar, the supporting function is added to the molecular sieve, the molecular sieve and the spacing bar are combined into a whole, the existing molecular sieve filling process is omitted, and therefore the production cost is reduced; various additives can be added into the spacing bar, and various functional strips can be compounded, so that the performance of the spacing bar is improved; and the cost of the spacing bar is not higher than that of an existing lowest aluminum alloy strip, and the performance of the spacing bar is not lower than that of an existing highest-end TPS strip and TSS strip.

Owner:温州前瞻玻璃科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com