Silicon anode material with spherical thorn-shaped structure and preparation method thereof

A silicon negative electrode and thorn-shaped technology, which is applied in the field of silicon negative electrode materials and its preparation, can solve the problems of silicon negative electrode materials such as deterioration of electrical properties, consumption of limited lithium sources, and increase of internal resistance of batteries, so as to improve processing performance and electrochemical performance, Improve electrical conductivity and surface stability, slow down the effect of crushing and pulverization and membrane detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

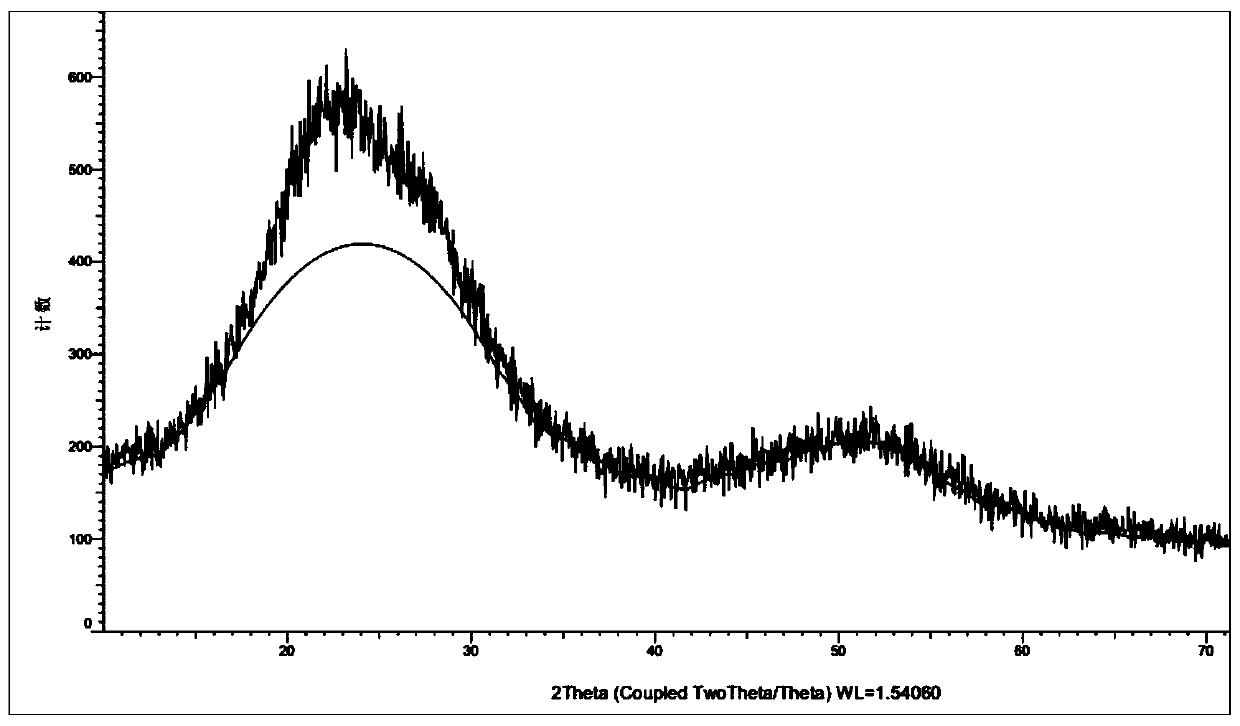

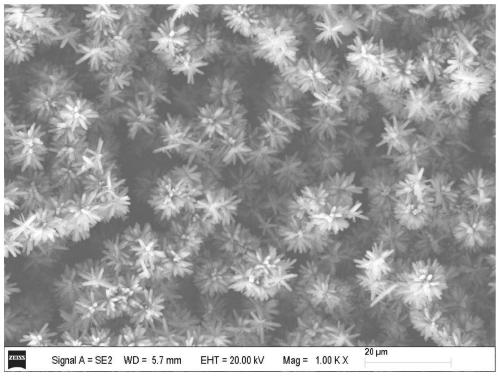

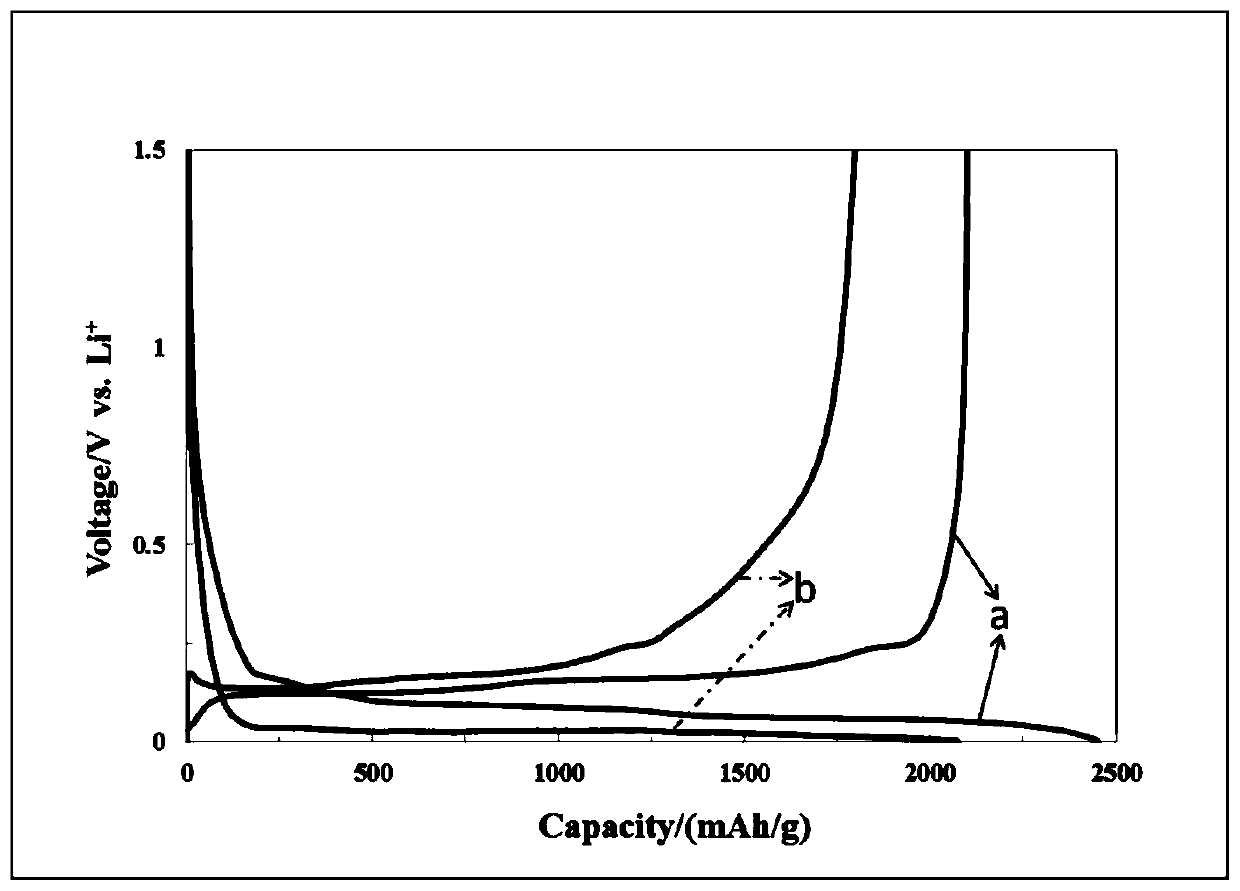

[0025] Embodiment 1: a kind of silicon negative electrode material of spherical thorn-like structure, preparation method is as follows, first weighs the tetraethyl orthosilicate of 100g, the urea of 5g, the ascorbic acid of 20g and the triton of 10g, above-mentioned raw material is joined in In 540g of glycerol solution, make a suspension with a solid content of 20%; then transfer the above suspension to a closed reactor for hydrothermal reaction, the reaction temperature is 240°C, and the reaction time is 24h; the hydrothermal reaction ends Finally, the silicon oxide compound precursor is obtained, and then the silicon oxide compound precursor obtained by the hydrothermal reaction is washed and dried; then under the protection of nitrogen, the silicon oxide compound precursor is coated with conductive carbon by vapor deposition method, and the gas carbon source is Acetylene, the carbon coating temperature is 600°C, the carbon coating time is 2 hours, and the coating carbon c...

Embodiment 2

[0026] Embodiment 2: a silicon negative electrode material with a spherical thorn-like structure, the preparation method is as follows, first weigh 100g of silicone, 15g of ammonia, 10g of reduced hydrazine and 20g of oleic acid, and add the above-mentioned raw materials to 217.5g of di In the methyl formamide solution, a suspension with a solid content of 40% was prepared; then the above suspension was transferred to a closed reactor for hydrothermal reaction, the reaction temperature was 180°C, and the reaction time was 18h; then the hydrothermal reaction The obtained silicon oxide compound precursor was washed and dried; then, under the protection of nitrogen, the silicon oxide compound was coated with conductive carbon by vapor phase deposition method, the gas carbon source was methane, the carbon coating temperature was 500°C, and the carbon coating time was 6h. The amount of coated carbon is 4%; finally cooled to obtain a silicon negative electrode material with a spheric...

Embodiment 3

[0027] Embodiment 3: a silicon negative electrode material with a spherical thorn-like structure, the preparation method is as follows, first weigh 100g of silicic acid, 10g of hydrochloric acid, 15g of sodium borohydride and 5g of stearic acid, and add the above-mentioned raw materials to 303g of A suspension with a solid content of 30% was prepared in an ethylene glycol solution; then the above suspension was transferred to a closed reactor for hydrothermal reaction, the reaction temperature was 360 ° C, and the reaction time was 10 h; then the hydrothermal reaction was obtained The silicon oxide compound precursor was washed and dried; then under the protection of nitrogen, the silicon oxide compound was coated with conductive carbon by vapor phase deposition. The carbon content is 6%; the silicon negative electrode material with a spherical thorn-like structure is finally cooled, which is a spherical thorn-shaped particle formed by the agglomeration of silicon-oxygen nanoro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com