Steel ball gas removal system of pulverized coal boiler

A technology for steel ball ash removal and pulverized coal boilers, which is applied in the field of pulverized coal boilers. It can solve the problems of corroded steel balls, steel balls rusted into blocks, and low separation efficiency of separators, so as to remove cohesive ash, prevent steel balls from agglomerating, and separate high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

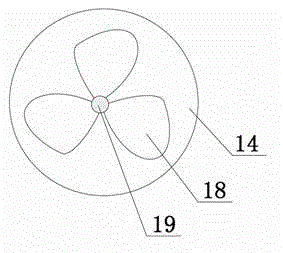

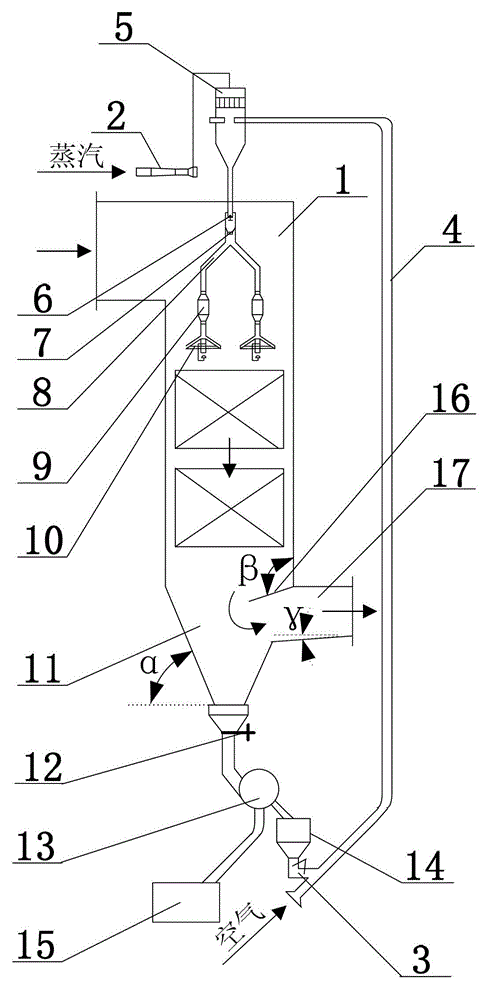

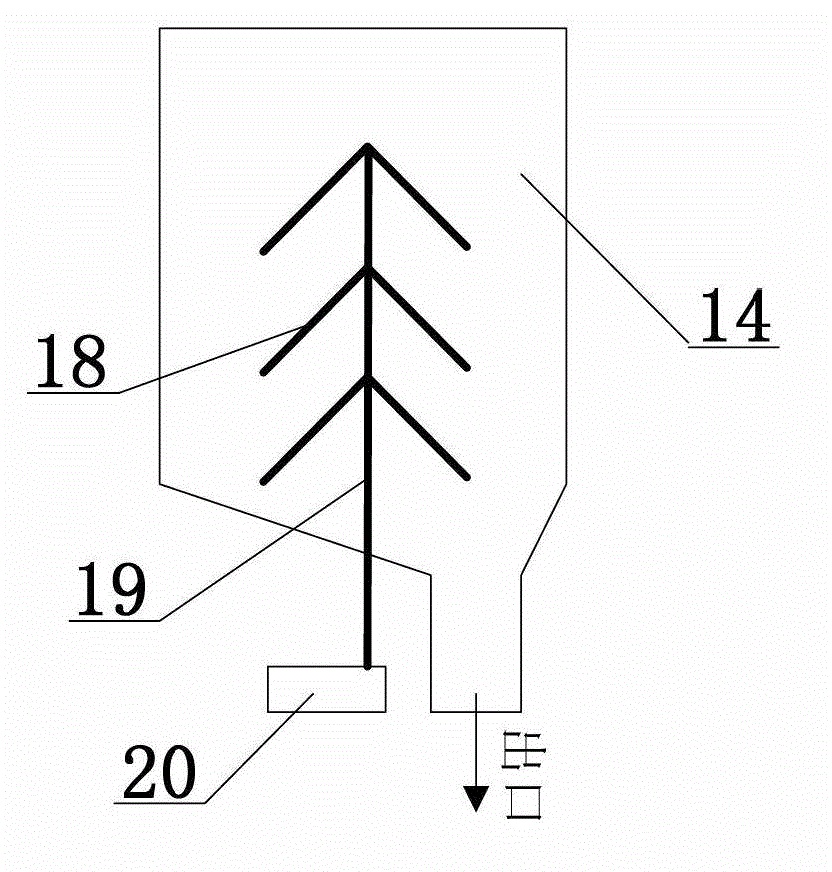

[0015] figure 1 It is a structural schematic diagram of a steel ball ash removal system for a coal-fired boiler provided by the present invention. As shown in the figure, the system includes a steam ejector 2 , a steel ball capture and spreading system, an air lock 12 , a steel ball separation and storage system, a bead feeder 3 and a steel ball delivery pipe 4 . The steel ball capture and dissemination system is arranged on the upper part of the boiler tail flue, including steel ball catcher 5, conical air locker 6, small bucket 7, distributor 8, buffer 9 and spreader 10. One end of the steel ball conveying pipe 4 is connected with the bead feeder 3 , and the other end is connected with the steel ball catcher 5 . Between the air locker 12 and the bead feeder 3, a magnetic separator 13 and a bead storage bucket 14 are sequentially arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com