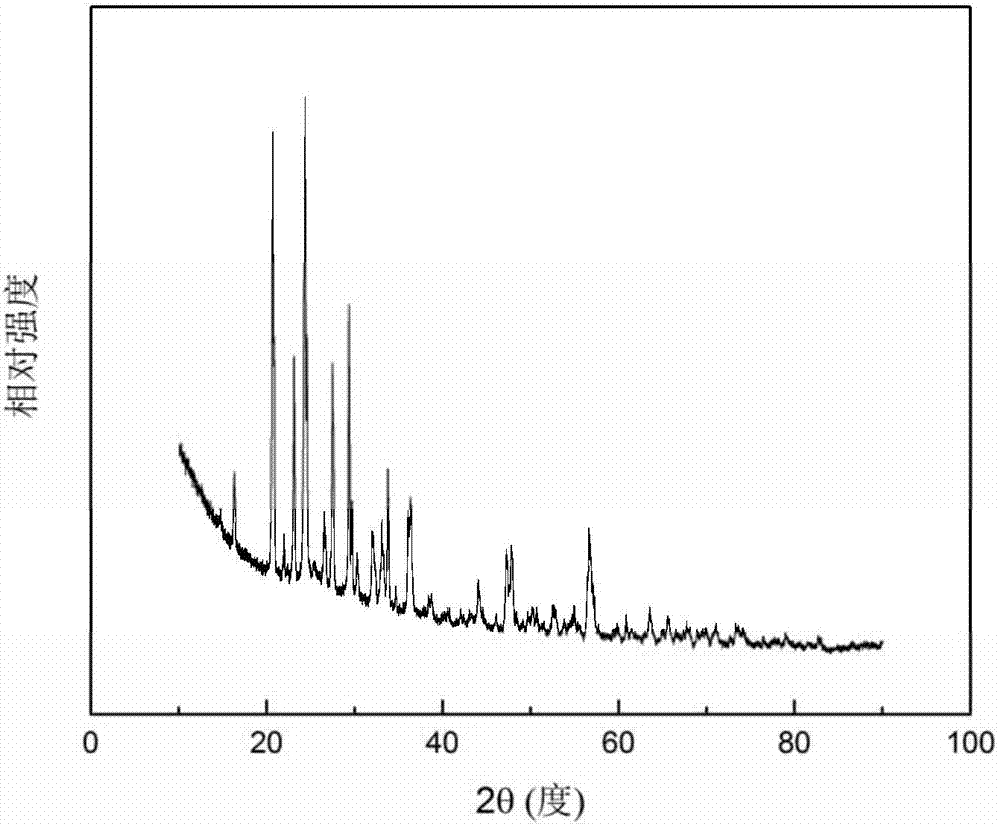

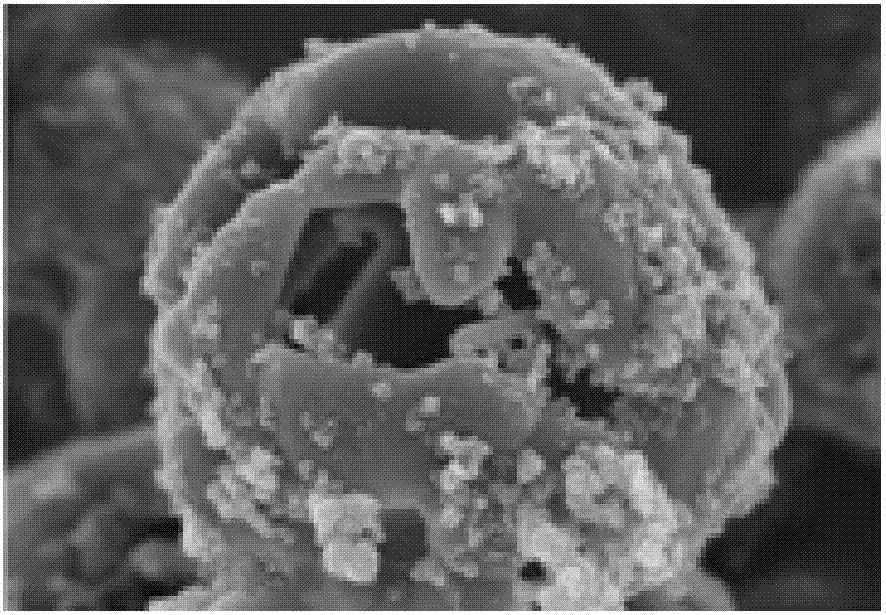

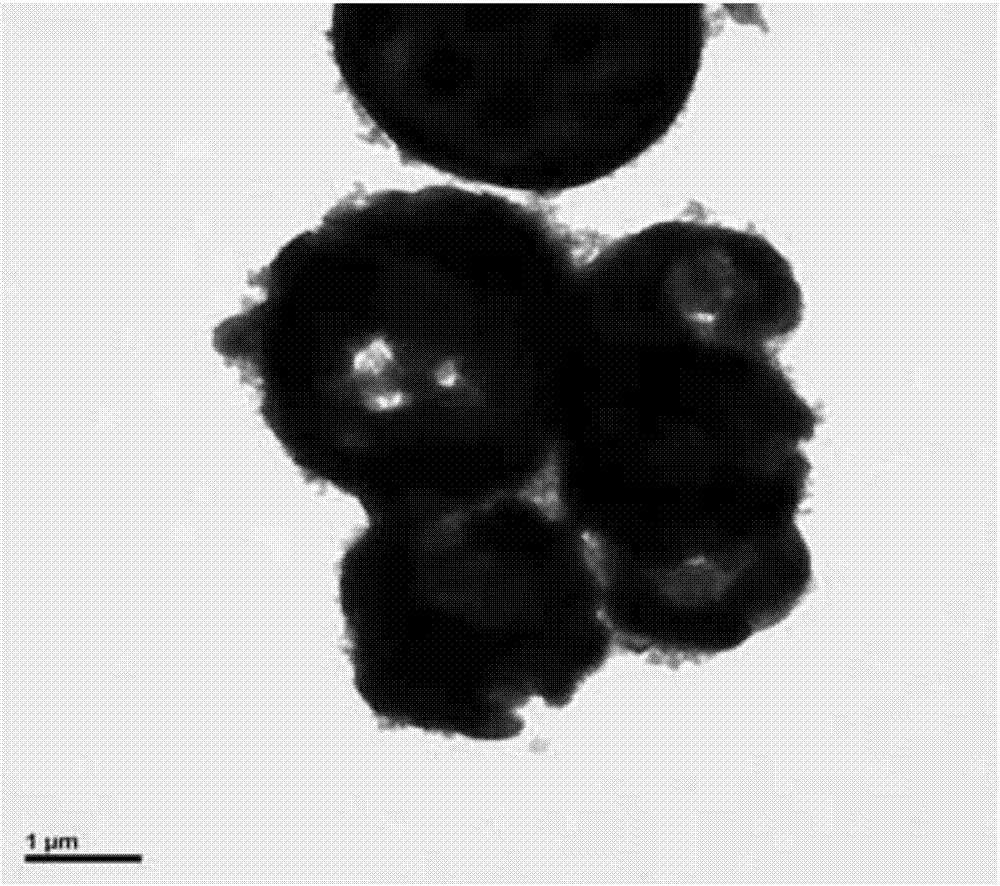

Porous hollow spherical lithium ion cell anode material of carbon-coating lithium vanadium phosphate and preparing method of anode material

A carbon-coated technology for lithium vanadium phosphate and lithium ion batteries, applied in battery electrodes, positive electrodes, secondary batteries, etc., to achieve the effects of simple method, promotion of diffusion, and full penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Dissolve 1.0555g soluble starch in 350ml deionized water, then add 3.81gLiOH·H 2 O, 5.2424gV 2 o 5 , 9.9462g NH 4 h 2 PO 4 (The concentrations of starch, lithium, vanadium and phosphorus are 0.3wt%, 0.259mol / L, 0.08mol / L, 0.24mol / L respectively), magnetically stirred at room temperature for 3 hours, and the speed is 60r / min to obtain a mixed solution ;

[0037] 2) The obtained mixed solution is spray-dried at a rate of 10mL / min in the spray drying tower, and the inlet temperature is set to 220°C to obtain a milky yellow lithium vanadium phosphate precursor;

[0038] 3) Place the acetylene black in the milky yellow lithium vanadium phosphate precursor and 8 wt% of its weight in a high-temperature tube furnace, and sinter at 800° C. for 8 hours under an inert gas. The calcination procedure is as follows: calcine at 300-450° C. for 3 hours , the heating rate is 3°C / min, calcined at 800°C for 8h, the heating rate is 3°C / min, and cooled with the furnace to obtain a ...

Embodiment 2

[0057] 1) Dissolve 1.0555g of citric acid in 350ml of deionized water, then add 3.81g of LiOH·H 2 O, 5.2424g V 2 o 5 , 9.9462g NH 4 h 2 PO 4 (The concentration of citric acid, lithium element, vanadium element and phosphorus element is 0.3wt%, 0.259mol / L, 0.08mol / L, 0.24mol / L respectively), magnetically stirred at room temperature for 3h, and the rotating speed is 60r / min to obtain a mixed liquid;

[0058] 2) The obtained mixed solution is spray-dried at a rate of 10mL / min in the spray drying tower, and the inlet temperature is set to 220°C to obtain a milky yellow lithium vanadium phosphate precursor;

[0059] 3) Place the acetylene black in the obtained milky yellow lithium vanadium phosphate precursor and 4 wt% of its weight in a high-temperature tube furnace, and sinter at 800° C. for 8 hours under an inert gas. The calcination procedure is as follows: calcine at 300° C. for 3 hours, heat up The rate is 3°C / min, calcined at 800°C for 8 hours, the heating rate is 3°C / ...

Embodiment 3

[0064] 1) Dissolve 1.75g glucose in 350ml deionized water, then add 2.8868g Li 2 CO 3 , 3.719gV 2 o 3 , 6.1g H 3 PO 3 (Concentrations of glucose, lithium, vanadium, and phosphorus are 0.5wt%, 0.1mol / L, 0.07mol / L, and 0.2mol / L, respectively), magnetically stirred at room temperature for 3 hours, and the speed was 70r / min to obtain a mixed solution ;

[0065] 2) The obtained mixed solution is spray-dried at a rate of 15mL / min in a spray-drying tower, and the inlet temperature is set to 220°C to obtain a milky yellow lithium vanadium phosphate precursor;

[0066] 3) Place the obtained milky yellow lithium vanadium phosphate precursor and CMC equivalent to 12 wt% of its weight in a high-temperature tube furnace, and sinter at 800° C. for 8 hours under an inert gas. The calcination procedure is as follows: calcine at 300-450° C. for 3 hours, The heating rate is 3°C / min, calcined at 800°C for 8 hours, the heating rate is 3°C / min, and cooled with the furnace to obtain a black...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com