Patents

Literature

32results about How to "Improved cycle rate performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

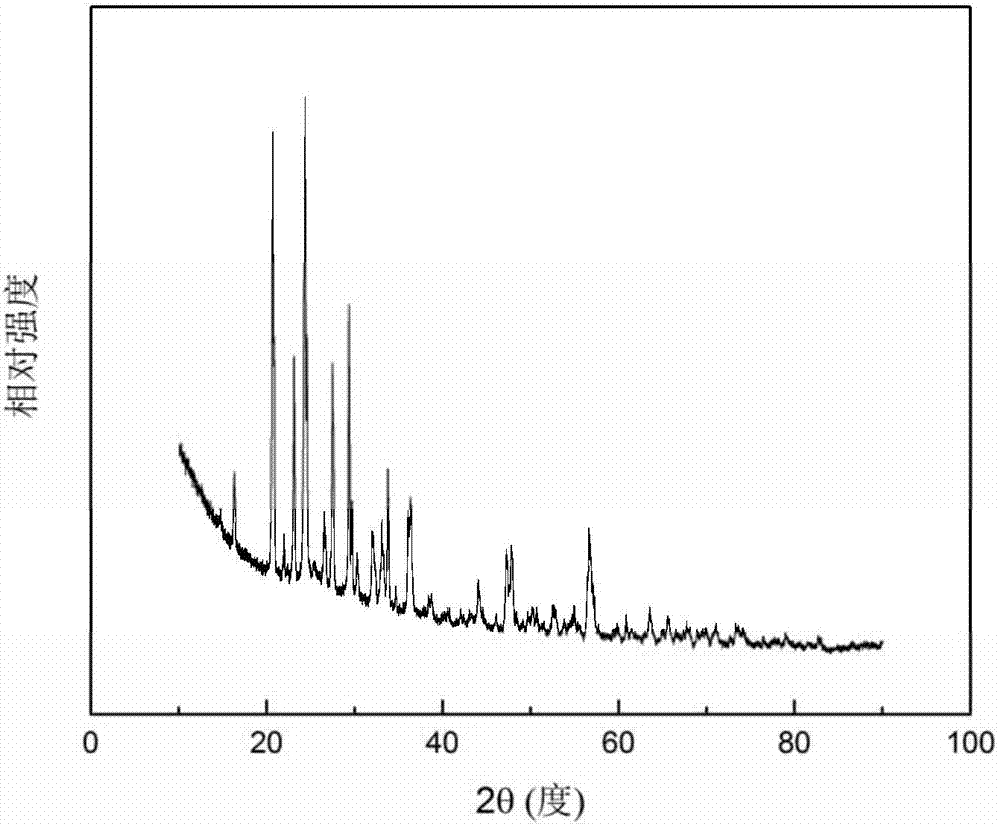

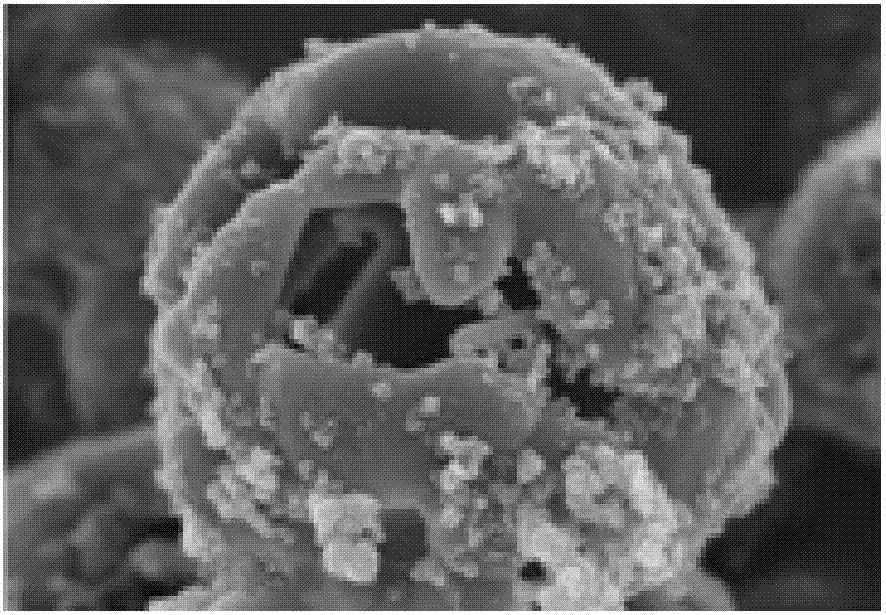

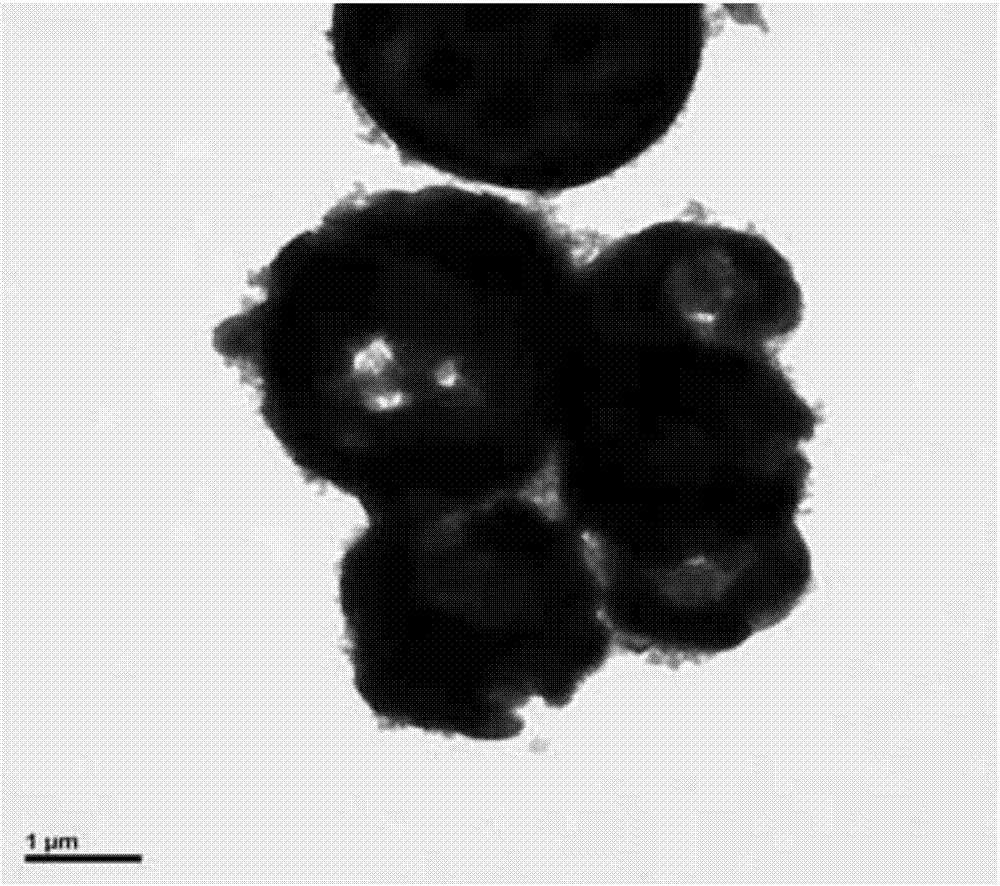

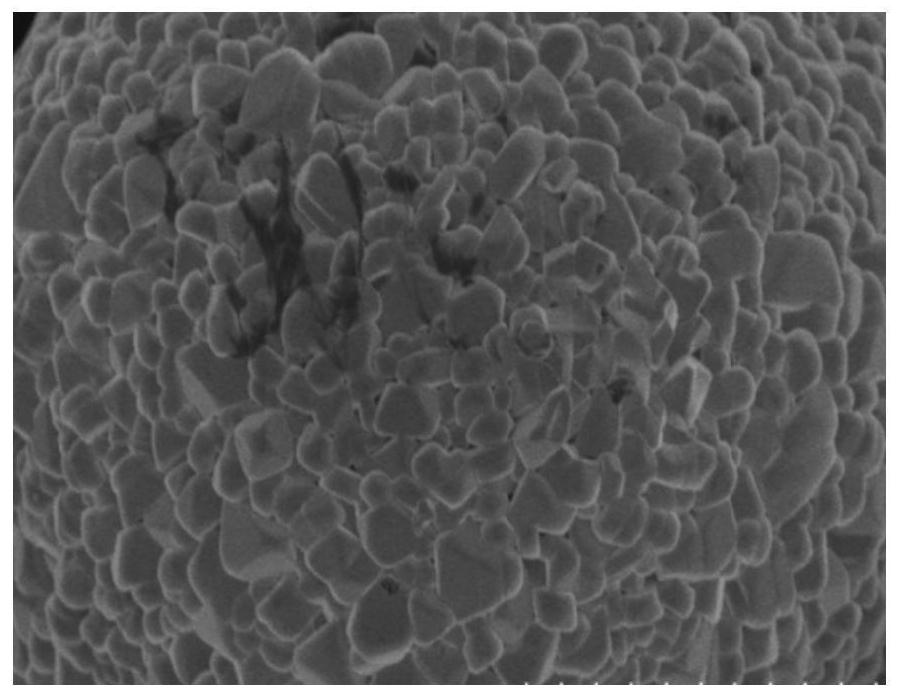

Ternary cathode material, precursor thereof, and preparation method of ternary cathode material and precursor

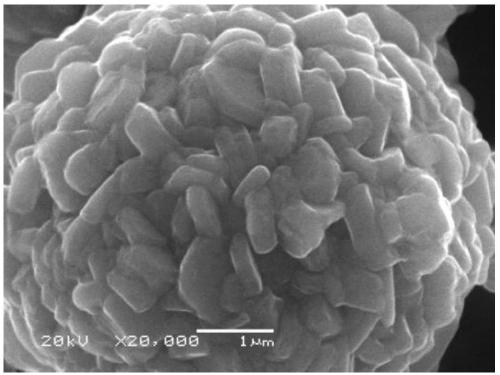

ActiveCN107585794AHigh activityShorten the diffusion pathCell electrodesSecondary cellsLayered structureSeed crystal

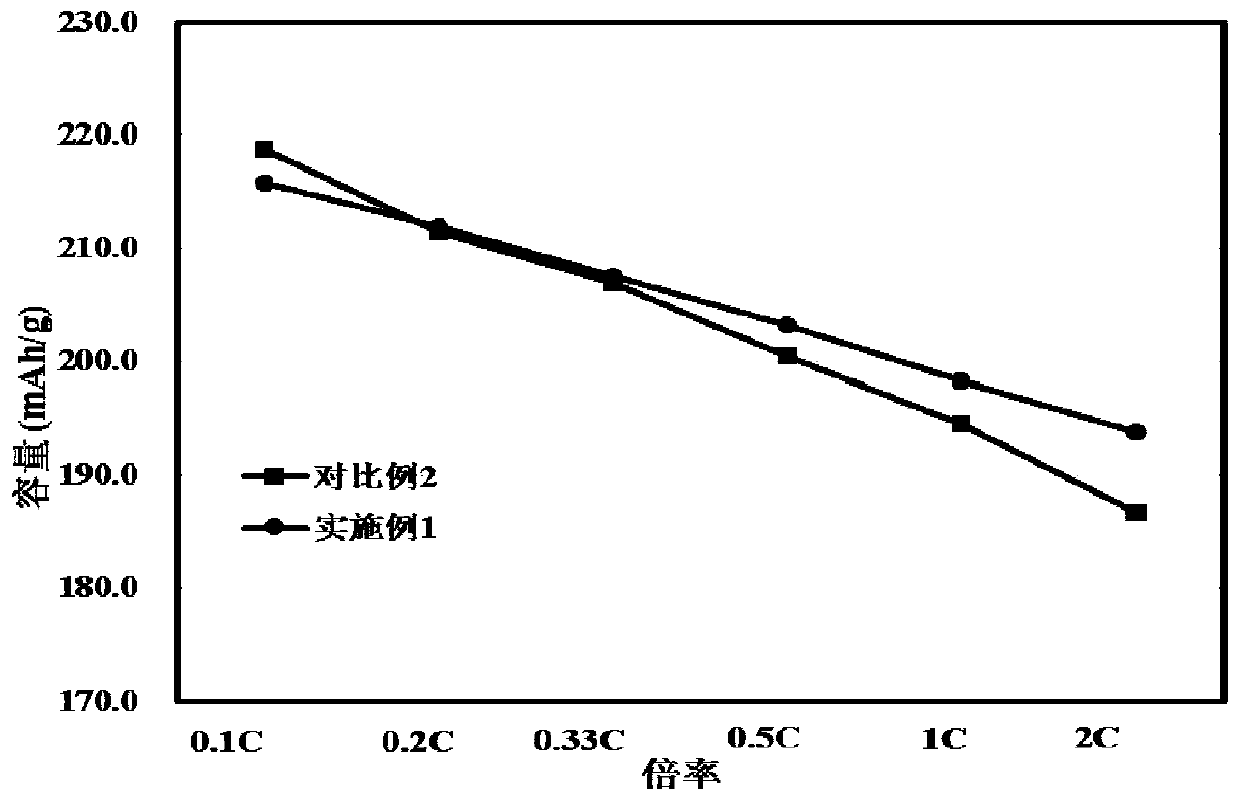

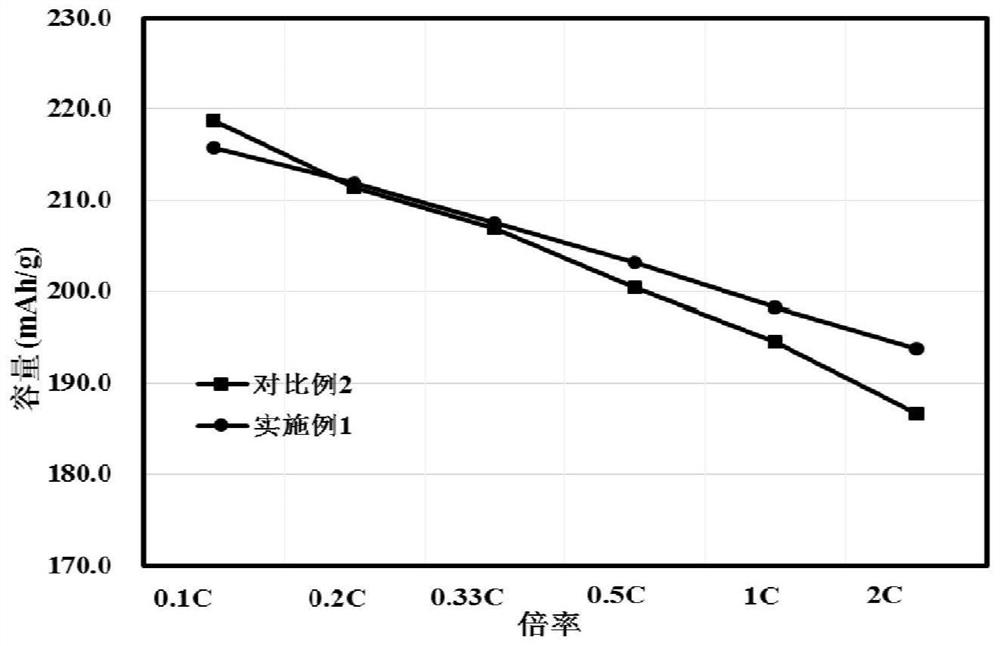

The invention provides a ternary precursor with a composite hetero-structure. The molecular formula of the ternary precursor is Ni<1-a-b>CoM(OH)2@Ni<1-x-y>Co<x>M<y>O<z>, wherein 0<a<1, 0<b<1, 0<a+b<1, 0<x<1, ,0<y<1, 0<x+y<1, 1<z<1.5, and M represents Mn or Al. The ternary precursor comprises a ternary oxide precursor and a ternary hydroxide precursor. The ternary hydroxide precursor is coated on the surface of the ternary oxide precursor. The molecular formula of the ternary oxide precursor is Ni<1-x-y>Co<x>M<y>O<z>, and the molecular formula of the ternary hydroxide precursor is Ni<1-a-b>CoM(OH)2. The invention further provides a preparation method of the ternary precursor. According to the preparation method, a spray pyrolysis method and a co-precipitation method are combined, the ternary oxide precursor obtained by spray pyrolysis is taken as the seed crystal, then a layer of ternary hydroxide precursor is coated on the surface of the ternary oxide precursor through theco-precipitation method to obtain the ternary precursor, and the ternary precursor and lithium salts are mixed and sintered to prepare the ternary cathode material. The ternary cathode material has the advantages of good layered structure, high initial efficiency, high specific capacity, and excellent circulating ratio performance.

Owner:CENT SOUTH UNIV

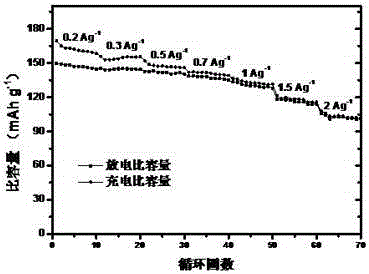

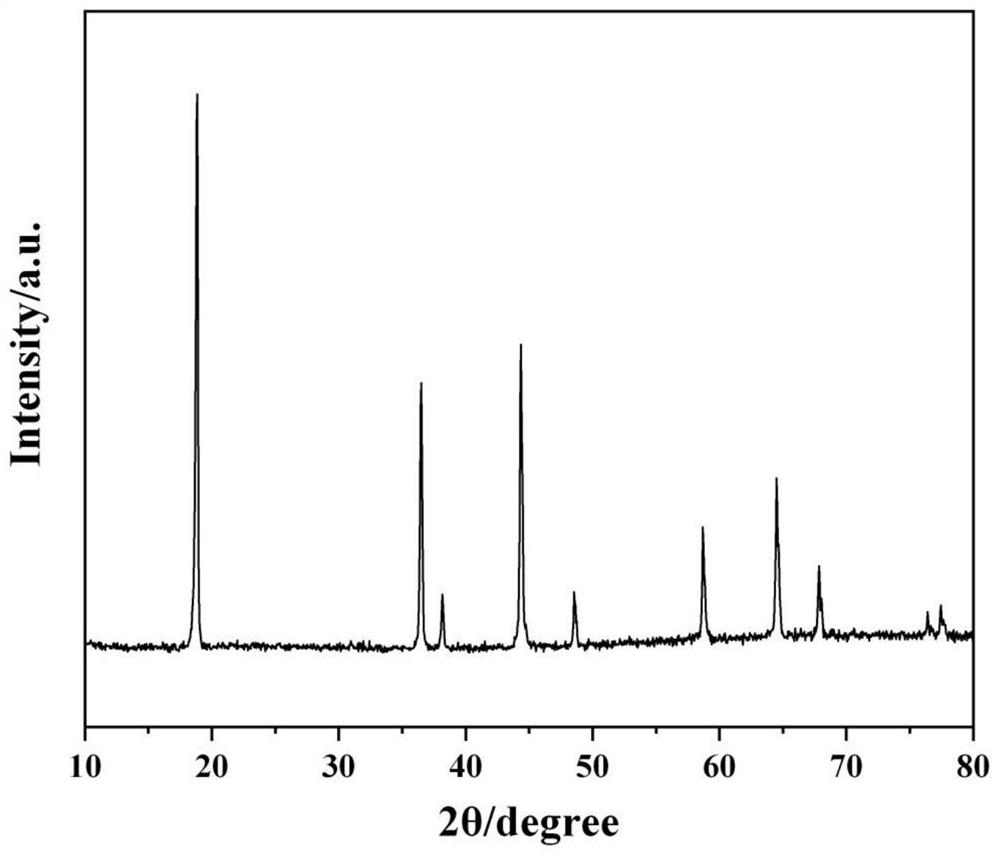

Alkaline zinc secondary battery and preparation method thereof

ActiveCN105206879ALow priceImproved cycle rate performanceCell electrodesFinal product manufactureElectrolytic agentElectrical battery

The invention discloses an alkaline zinc secondary battery and a preparation method thereof. The alkaline zinc secondary battery comprises a positive pole piece, a negative pole piece, aqueous electrolyte and a diaphragm and is characterized in that a positive pole adopts transition metal sulfide, a negative pole adopts a zinc metal piece, and the electrolyte adopts alkaline aqueous electrolyte containing zinc ions. The transition metal sulfide which is low in cost and simple to synthesize is taken as a cathode material; the assembled aqueous zinc secondary battery has the characteristics of high energy density and excellent rate performance, and requirements of the high-performance zinc secondary battery for the overall performance of the cathode material are met.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

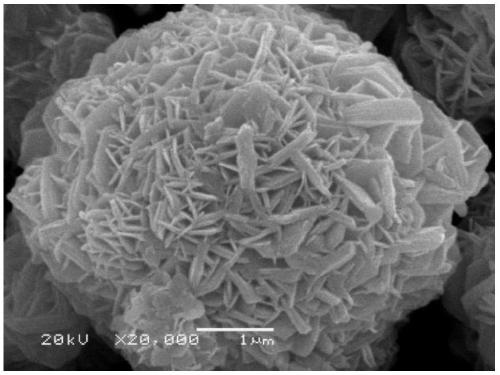

A preparation method of ternary cathode material for coated lithium ion battery

ActiveCN109037644AReduce side effectsImprove migration efficiencyCell electrodesSecondary cellsSolubilityCoprecipitation

A method for preparing ternary cathode material of coated lithium ion battery includes such steps as sequentially adding solution with different ion solubility to carry out coprecipitation reaction, adding polyacrylamide during coprecipitation reaction, pre-sintering and removing polyacrylamide to obtain porous spherical ternary material precursor; Then the precursor of porous spherical ternary material was coated with Al2O3, and sodium dodecyl benzene sulfonate was added into the coated solution. Finally, the cathode active material of lithium ion battery was obtained by sintering. A method for preparing a ternary cathode material of a coated lithium ion battery according to that present embodiment greatly improve the capacity, rate performance and cycle stability of the ternary cathode material of the lithium ion battery.

Owner:QINGYUAN JIAZHI NEW MATERIAL RES INST CO LTD +1

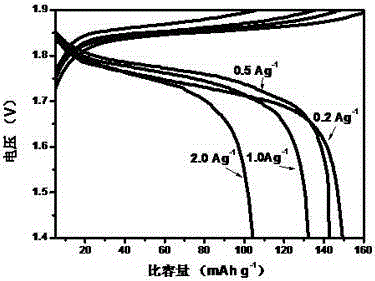

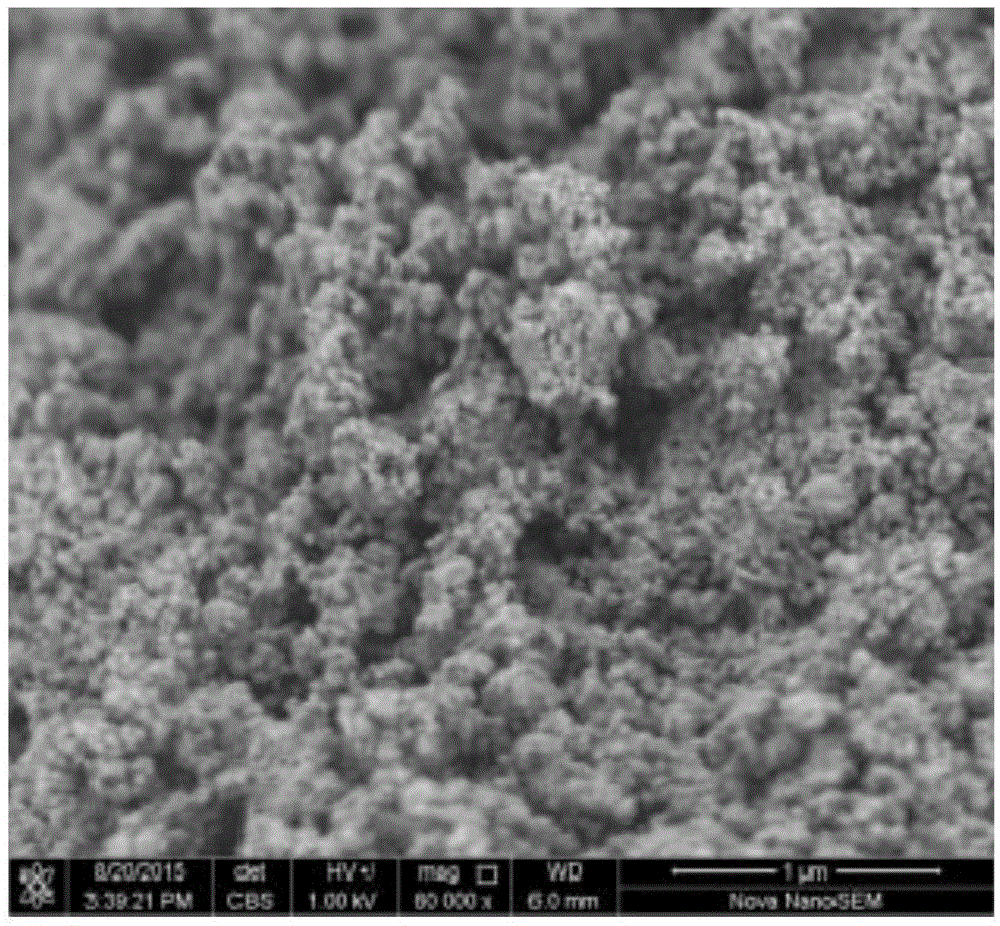

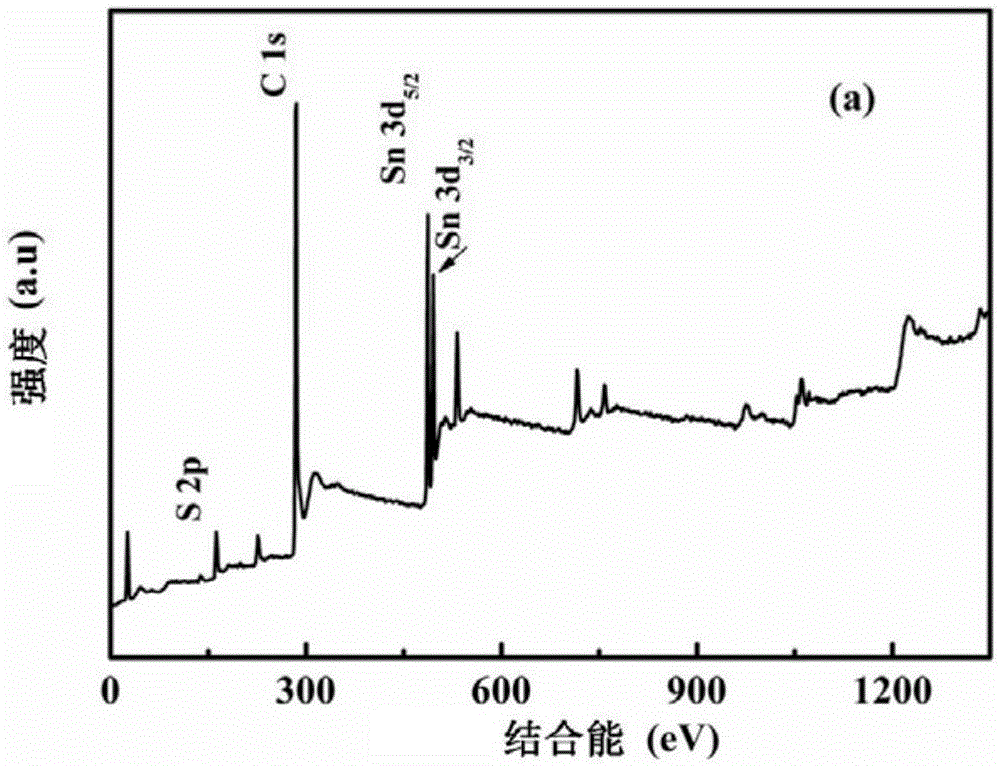

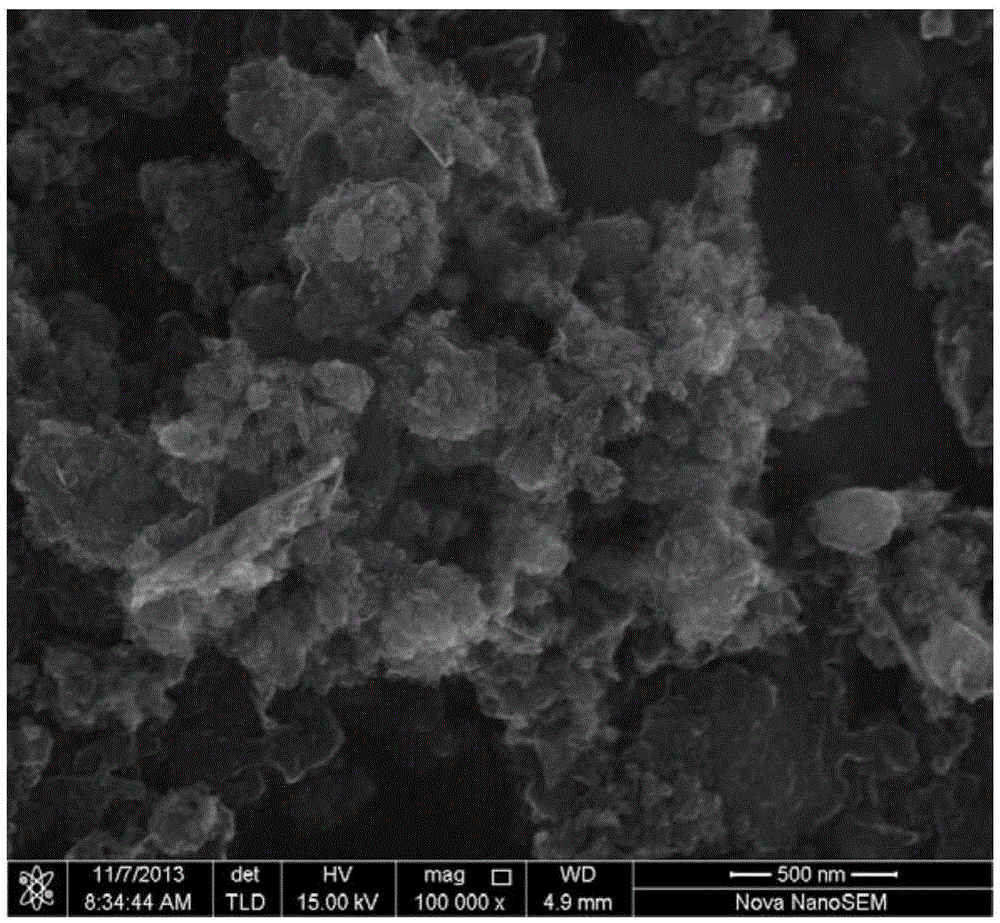

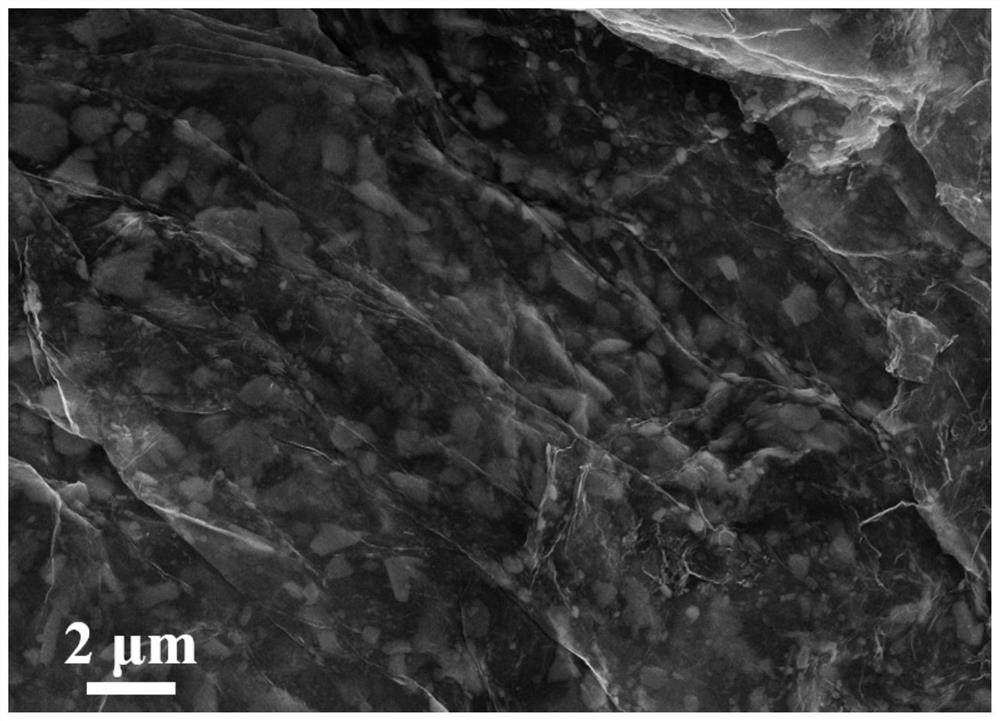

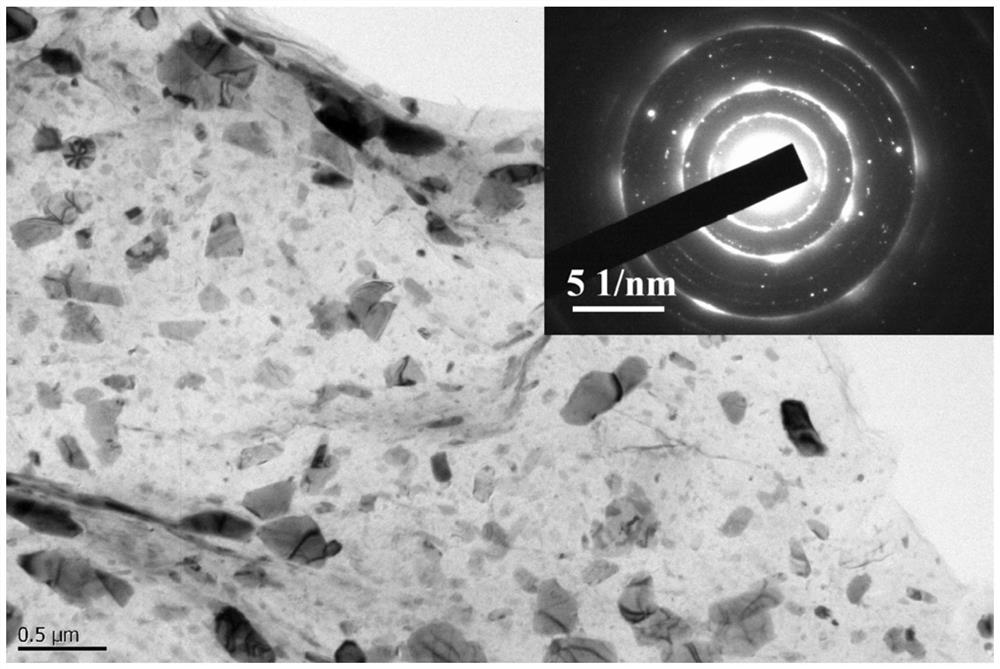

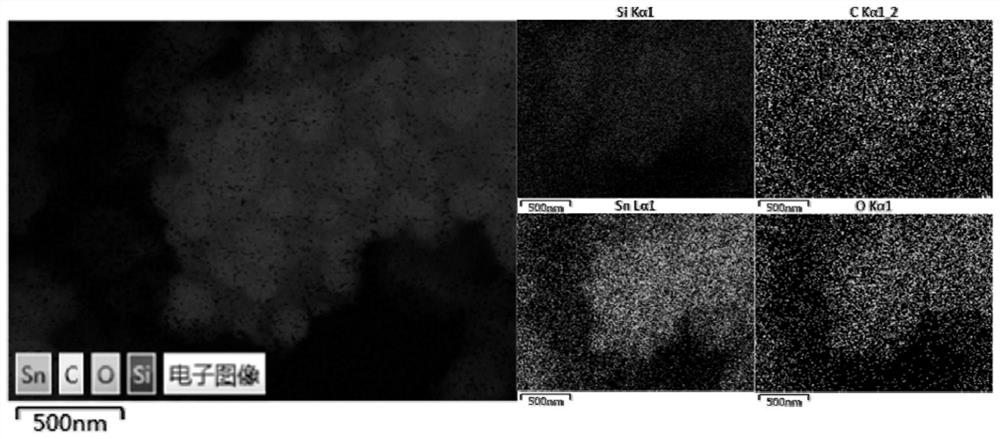

SnS2-C negative electrode nanocomposite and preparation method and application therefor

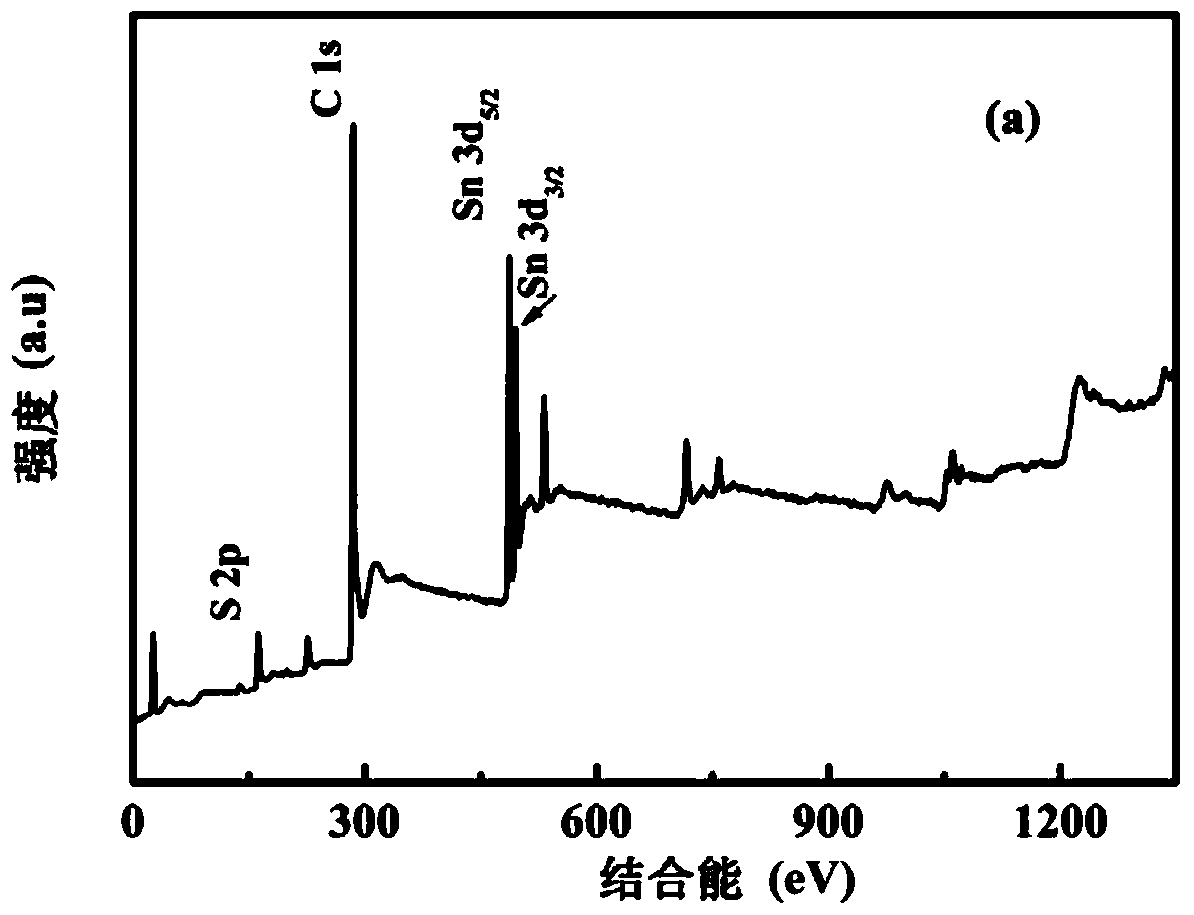

ActiveCN105406065ALarge specific surface areaImprove electrochemical performanceMaterial nanotechnologyCell electrodesMass ratioNanoparticle

The invention discloses an SnS2-C negative electrode nanocomposite and a preparation method and an application therefor. The composite negative electrode material consists of SnS2 nanoparticles and a carbon material wrapping the SnS2 nanoparticles; the grain diameter of the SnS2 nanoparticles is less than 100 nm, and the SnS2 nanoparticles are uniformly distributed in the carbon material; and the mass ratio of the SnS2 nanoparticles to the carbon material is 0.625-12.5:1. The preparation method for the SnS2-C negative electrode nanocomposite comprises the following steps: performing ball milling on stannic disulphide for the first time to obtain the SnS2 nanoparticles; adding the SnS2 nanoparticles into a glucose solution for performing ball milling for the second time to obtain a mixture; and drying the mixture and then performing thermal treatment on the dried mixture to obtain the SnS2-C nanocomposite. The SnS2-C negative electrode nanocomposite is high in circulation rate capability, high in capacity retention ratio, can be applied to the field of a lithium ion battery, and is bright in the application and industrial prospects.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

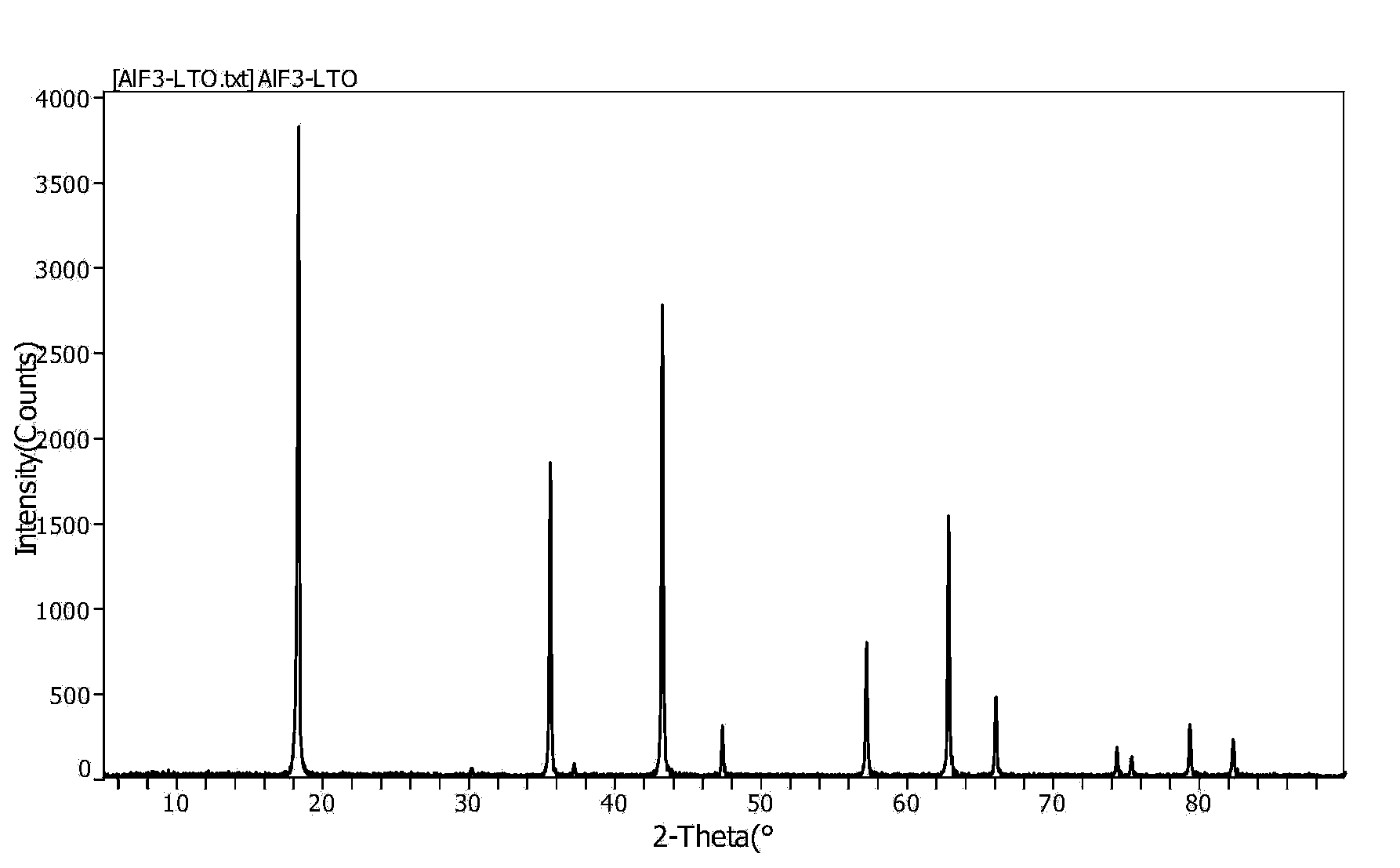

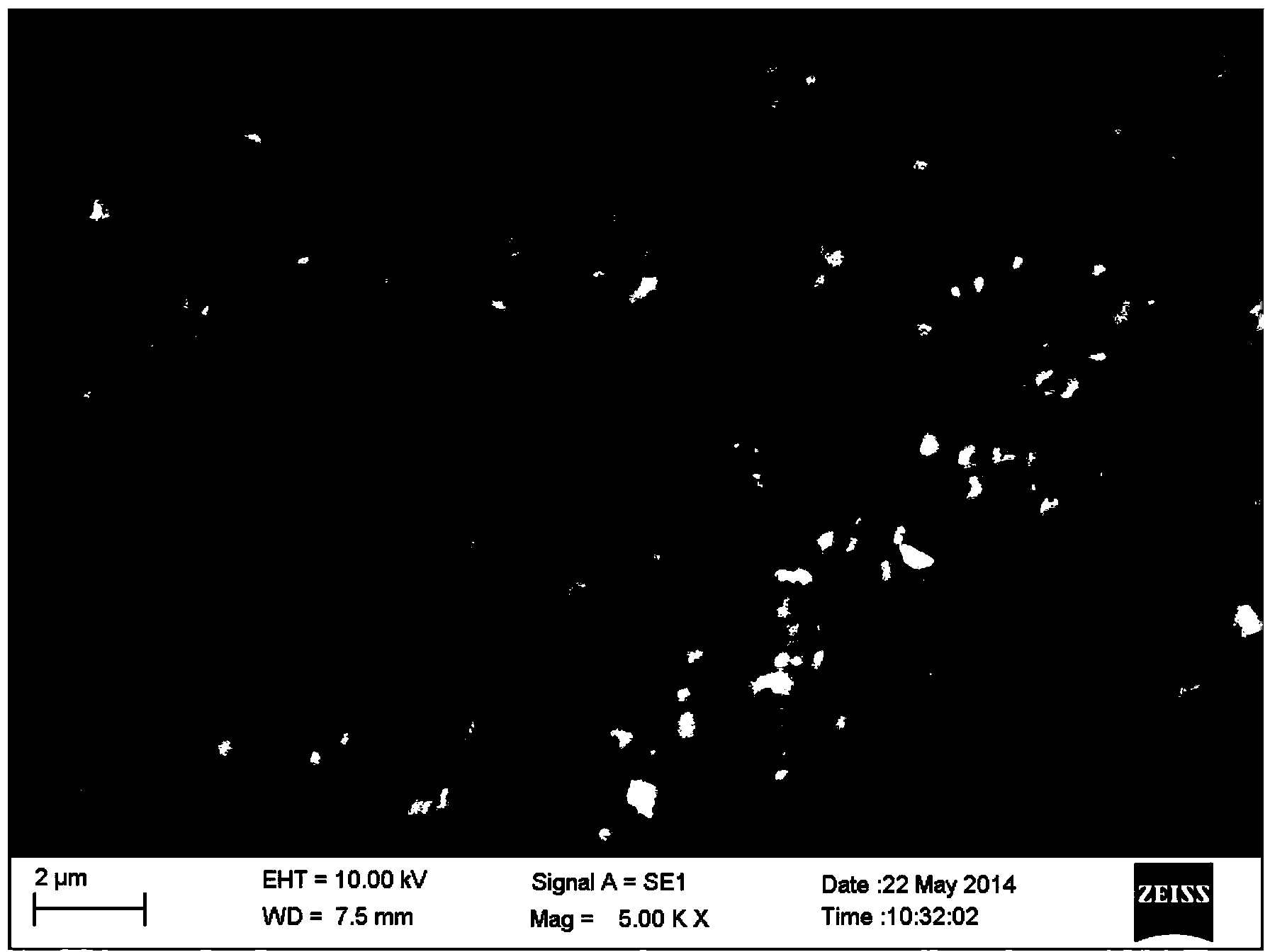

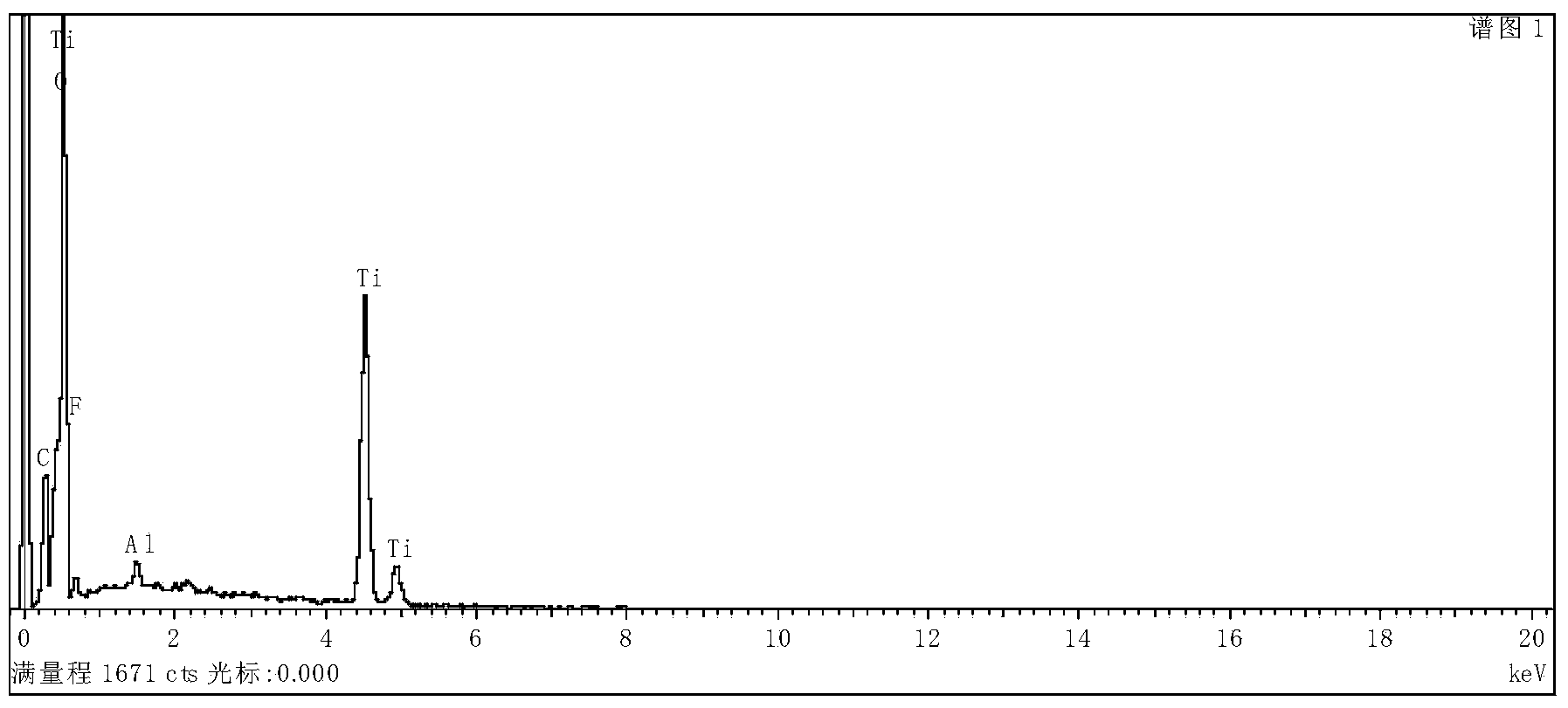

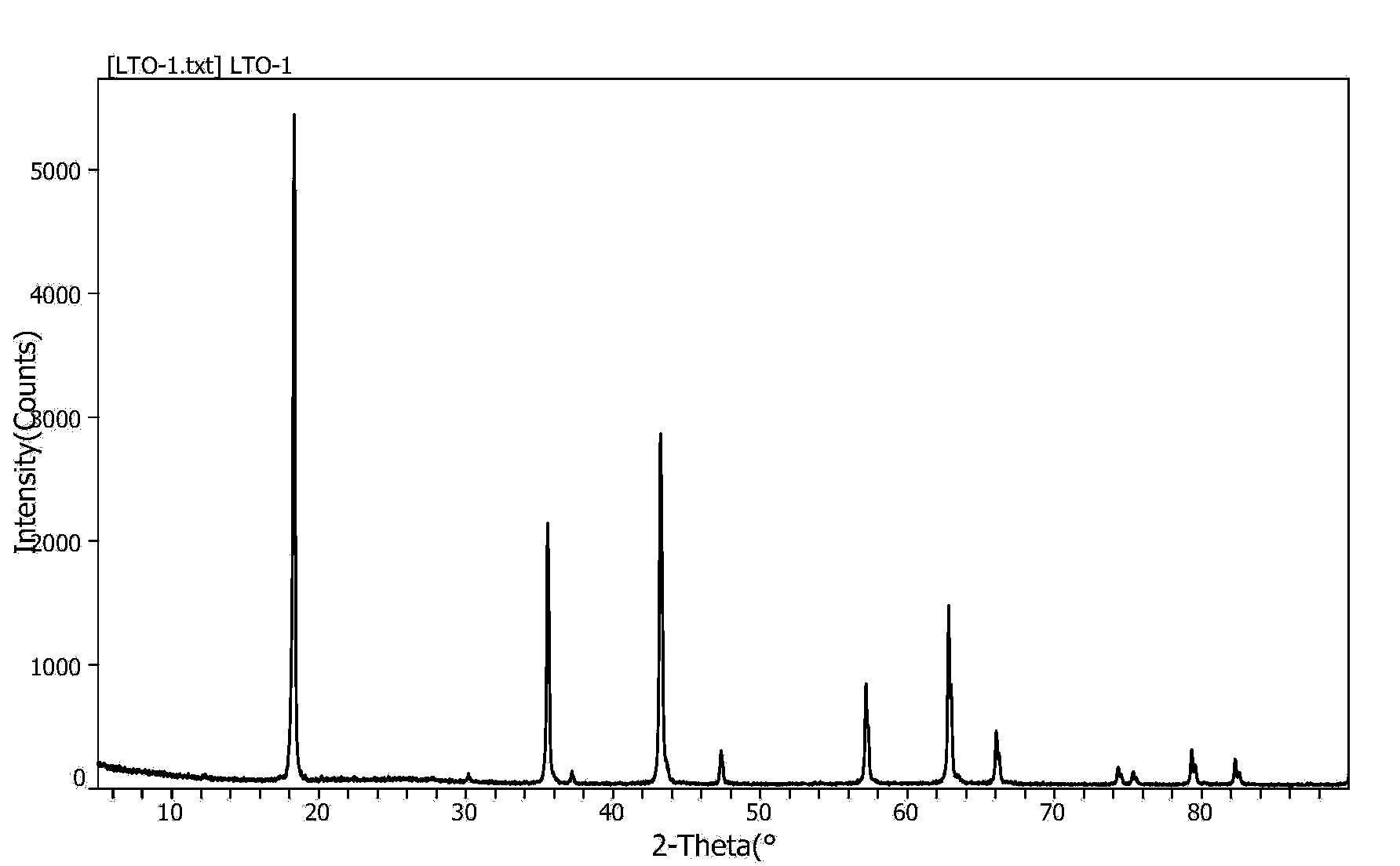

Preparation method and application of aluminum fluoride-coated carbon-coated lithium titanate nitride

InactiveCN104362324AIncrease gram capacityImproved cycle rate performanceCell electrodesSecondary cellsShielding gasCarbon coated

The invention discloses a preparation method and application of aluminum fluoride-coated carbon-coated lithium titanate nitride. The preparation method comprises the following steps: preparing lithium titanate with a spinel structure; mixing a carbon source with the lithium titanate till the mixture is uniform, and carrying out calcination in a vacuum or a shielding gas atmosphere to obtain carbon-coated lithium titanate; uniformly mixing a nitrogen source with the carbon-coated lithium titanate, and carrying out calcination in a vacuum or a shielding gas atmosphere to obtain carbon-coated lithium titanate nitride; adding aluminum salt and ammonium fluoride into a turbid liquid of the carbon-coated lithium titanate nitride, completely evaporating the mixed solution, and conducting calcination on the uniformly mixed particles in a vacuum or a shielding gas atmosphere to obtain aluminum fluoride-coated carbon-coated lithium titanate nitride. The preparation method provided by the invention has the advantages that the preparation process is simple, pollution is avoided during reactions, the product uniformity is excellent, the obtained aluminum fluoride-coated carbon-coated lithium titanate nitride is high in capacity per gram, and the industrial application prospect is wide.

Owner:西安中科新能源科技有限公司

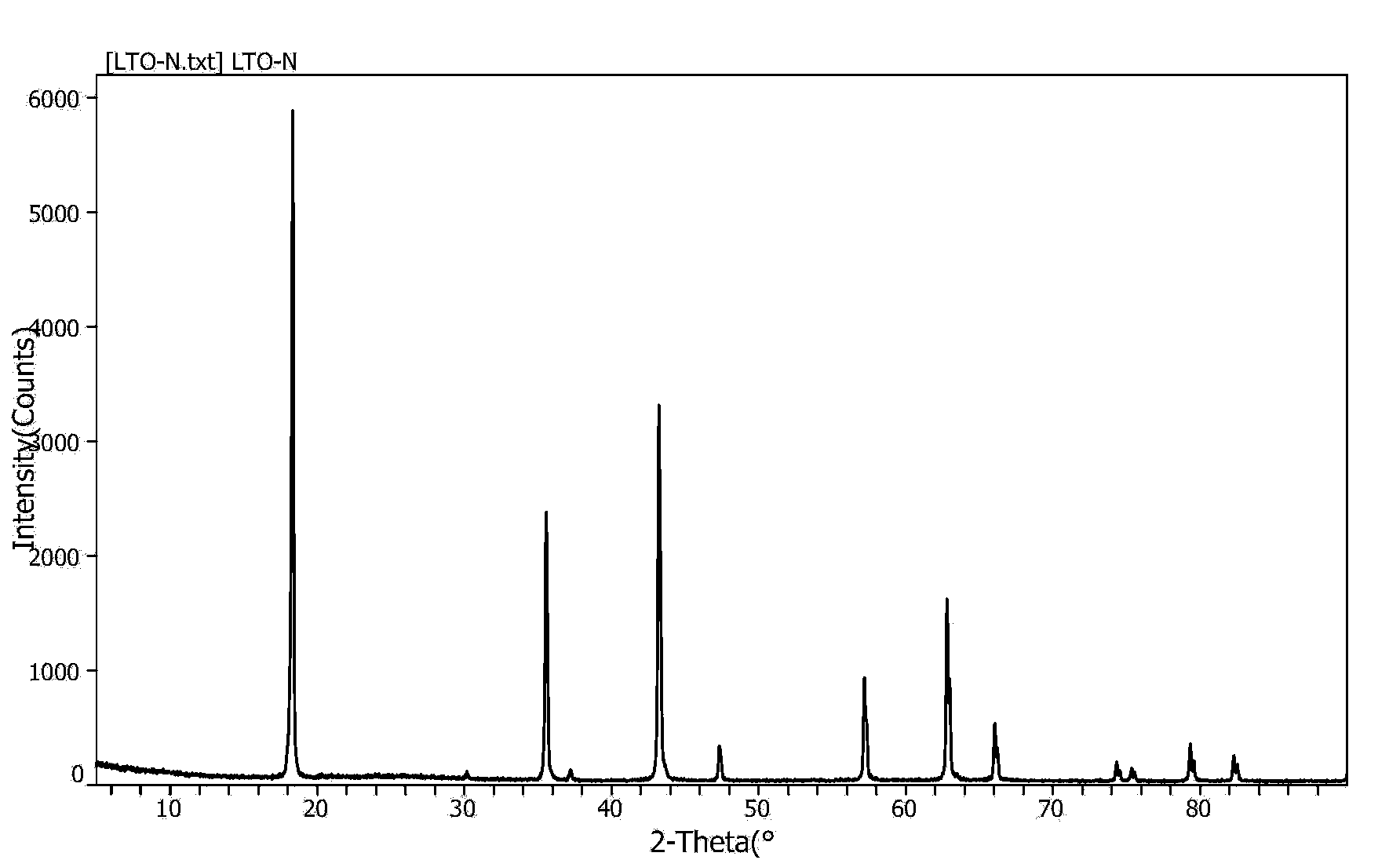

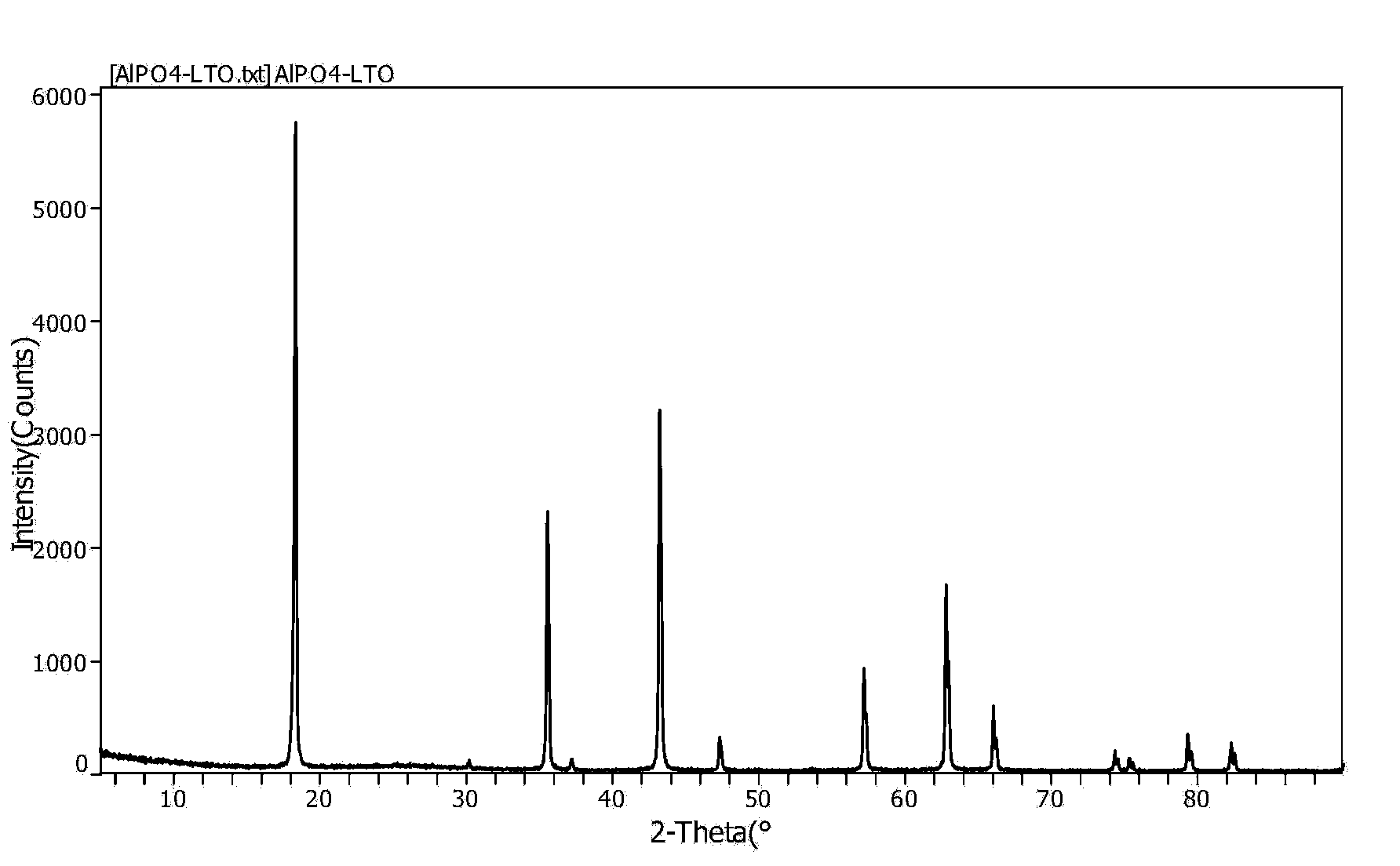

Preparation and application of aluminium-phosphate-cladded carbon-cladded Li4Ti5O12/TiN

InactiveCN104269546AIncrease gram capacityImproved cycle rate performanceCell electrodesPhosphoric acidTitanium nitride

The invention discloses preparation and application of aluminium-phosphate-cladded carbon-cladded Li4Ti5O12 / TiN. The preparation method for the aluminium-phosphate-cladded carbon-cladded Li4Ti5O12 / TiN comprises the following steps: firstly, preparing Li4Ti5O12 of a spinel structure; then uniformly mixing a carbon source and the Li4Ti5O12, and calcining the mixture in vacuum or protective gas atmosphere to obtain carbon-cladded Li4Ti5O12; then uniformly mixing a nitrogen source and the carbon-cladded Li4Ti5O12, and calcining the mixture of the nitrogen source and the carbon-cladded Li4Ti5O12 in the vacuum or protective gas atmosphere to obtain carbon-cladded Li4Ti5O12 / TiN; and adding aluminium salt and phosphate into the suspending liquid of the carbon-cladded Li4Ti5O12 / TiN, uniformly cladding the particle surfaces of carbon-doped Li4Ti5O12 / TiN with the obtained aluminium phosphate, and calcining the particles of the aluminium-phosphate-cladded carbon-doped Li4Ti5O12 / TiN in the vacuum or protective gas atmosphere to obtain the aluminium-phosphate-cladded carbon-cladded Li4Ti5O12 / TiN. The preparation process of the preparation method disclosed by the invention is simple, no pollution in reaction is achieved, the product homogeneity is good, and the prepared aluminium-phosphate-cladded carbon-cladded Li4Ti5O12 / TiN is high in gram volume, and has a good industrial application prospect.

Owner:西安中科新能源科技有限公司

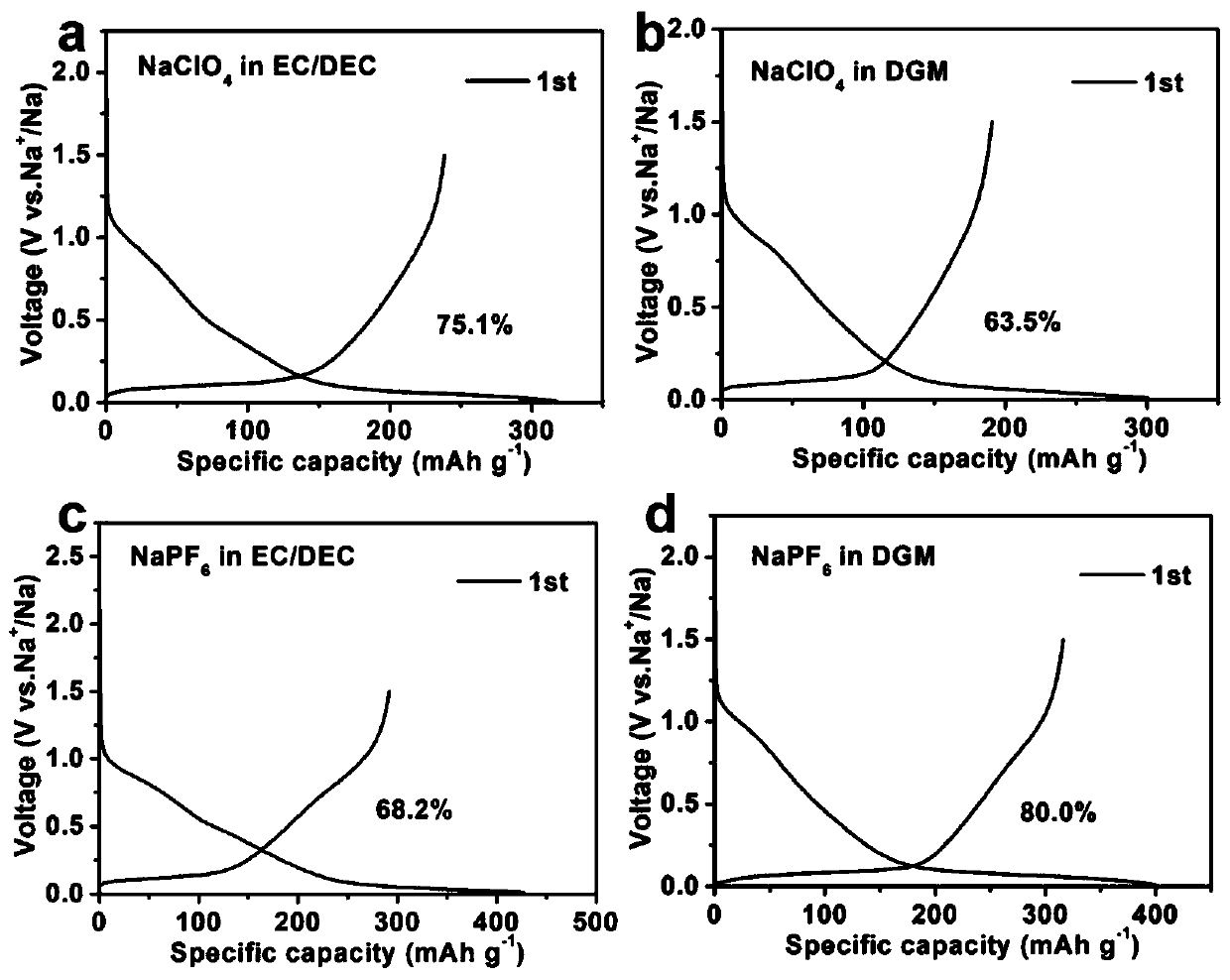

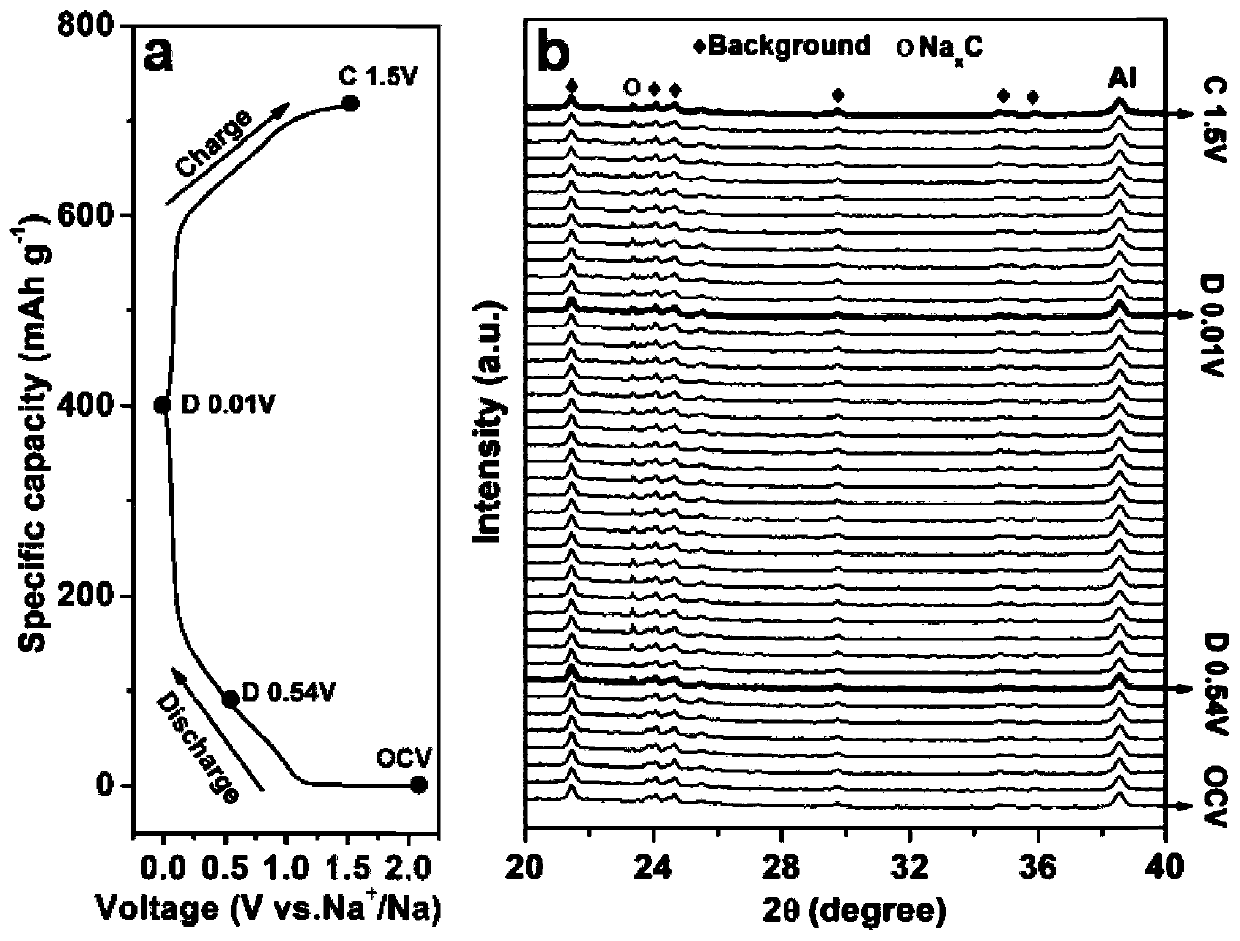

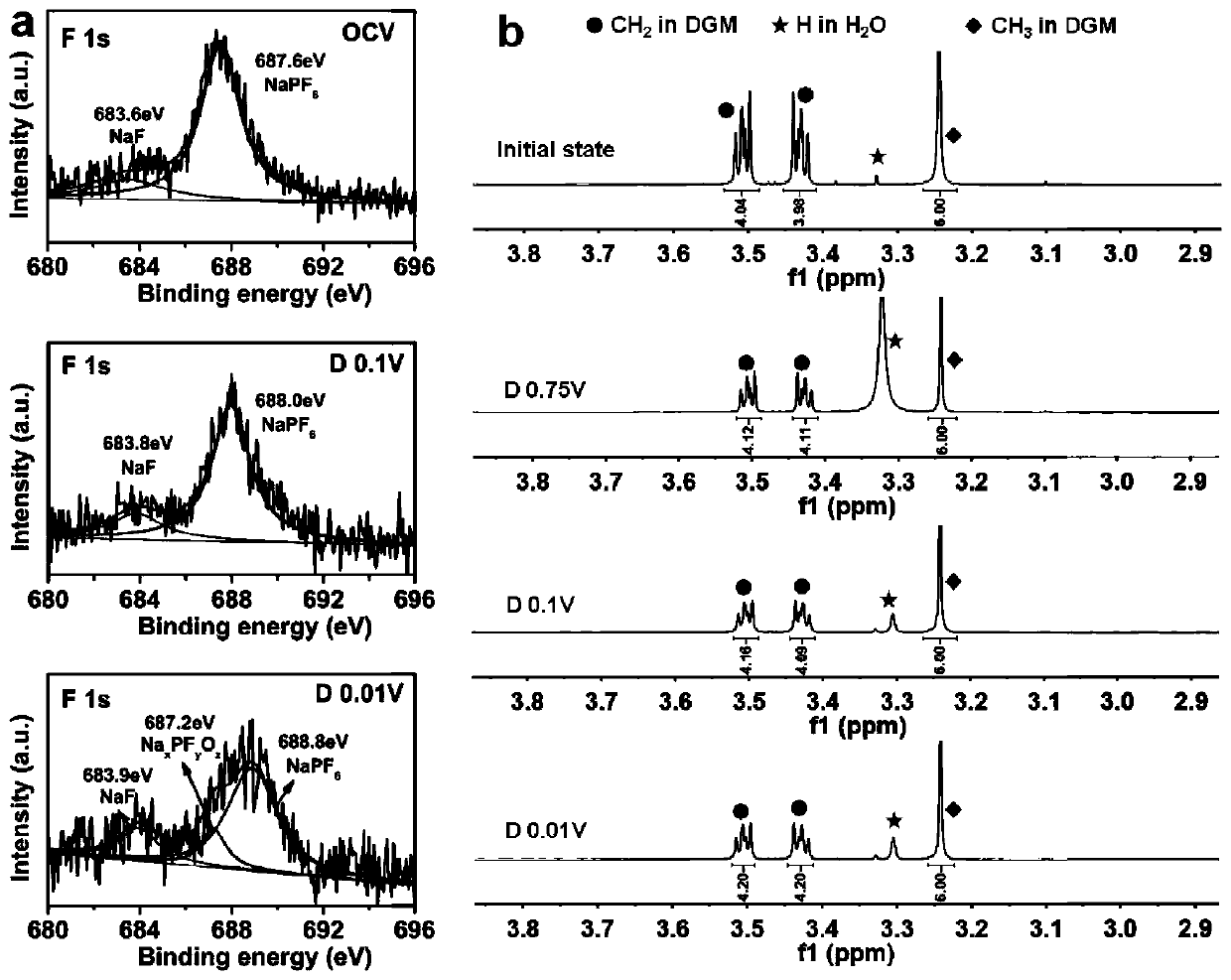

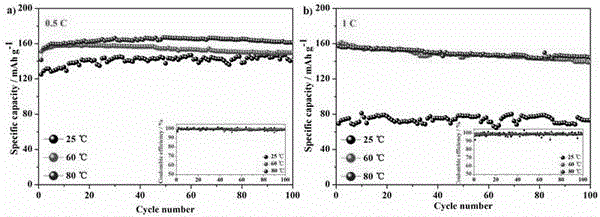

Application method of hard carbon negative electrode material in sodium-ion battery

InactiveCN111600021AEasy transferImpede passingFinal product manufactureElectrode collector coatingElectrolytic agentElectrical battery

The invention relates to an application method of a hard carbon negative electrode material in a sodium ion battery. According to the invention, commercial hard carbon is selected as a negative electrode material of a sodium-ion battery, NaPF6-DGM is used as an electrolytic solution, Celgard 2325 is used as a diaphragm, and the formed sodium ion battery has low polarization voltage and excellent cycle rate performance in the aspect of electrochemical property, has high first effect and coulombic efficiency, takes high capacity and long service life into consideration, and still has the capacity of 224.4 mAh g<-1> after being circulated 3500 circles under the current density of 1 A g<-1>.

Owner:SHANDONG UNIV

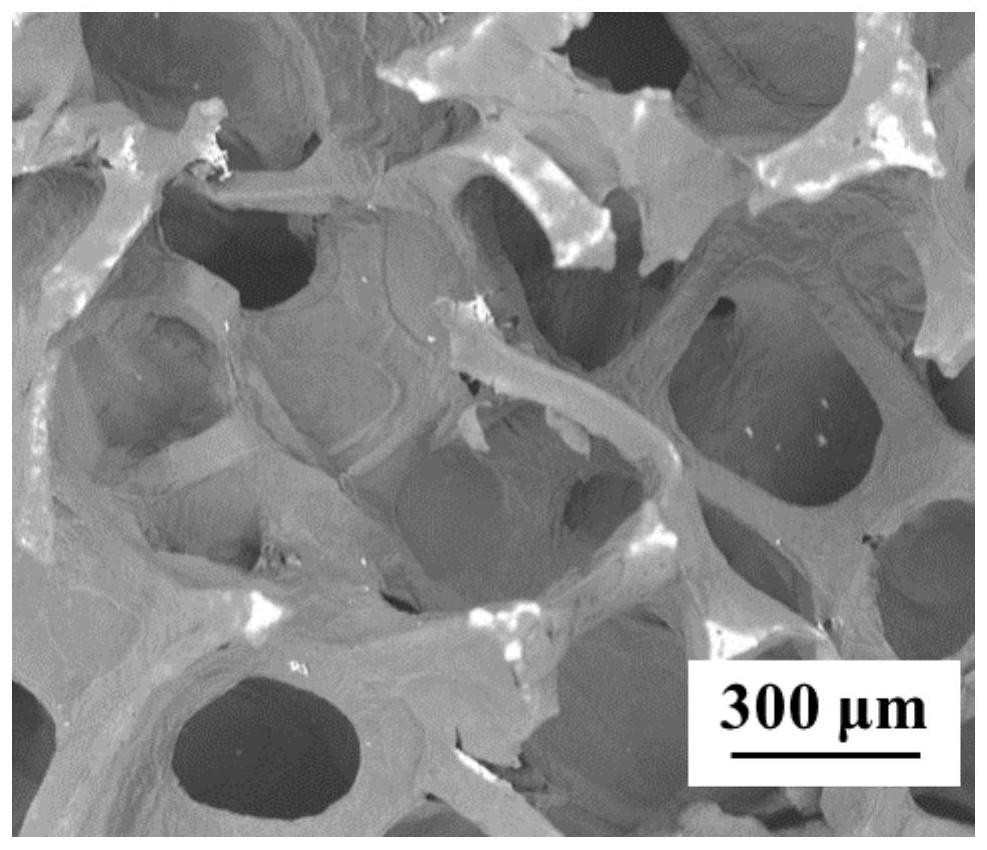

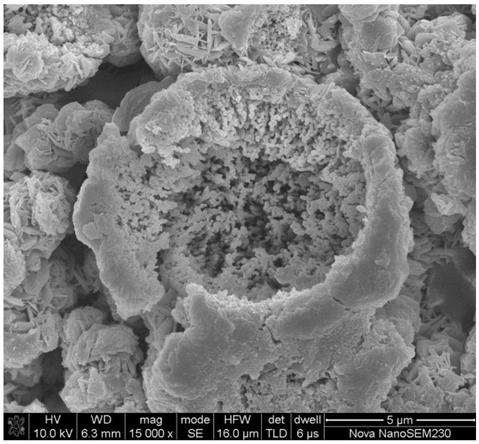

Porous hollow spherical lithium ion cell anode material of carbon-coating lithium vanadium phosphate and preparing method of anode material

InactiveCN107331855AIncreased breathability inside and outIncrease microporositySecondary cellsPositive electrodesLithium vanadium phosphate batteryPhysical chemistry

The invention discloses a porous hollow spherical lithium ion cell anode material of carbon-coating lithium vanadium phosphate and a preparing method of the anode material. The preparing method of the anode material comprises the steps of taking a binder, a lithium source, a vanadium source and a phosphorous source into water, stirring and dissolving the materials, and conducting spraying drying on the obtained mixed solution to obtain a precursor; mixing the obtained precursor with a carbon source, conducting calcination under a protective atmosphere condition to obtain the anode material, wherein the concentration of the binder in water is 0.3-0.5 wt%, the concentration of the lithium element of the lithium source in water is 0.1-1 mol / L, the concentration of the vanadium element of the vanadium source in water is 0.06-0.6 mol / L, the concentration of the phosphorous element of the phosphorous source in water is 0.09-0.9 mol / L, and the additive amount of the carbon source is 4-20 wt% that of the precursor. The anode material prepared through the method is in a porous hollow spherical shape, and has a high specific area, and the circulation factor performance of the obtained product can be effectively improved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

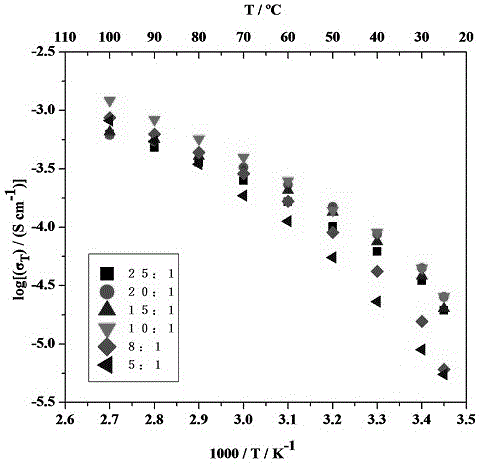

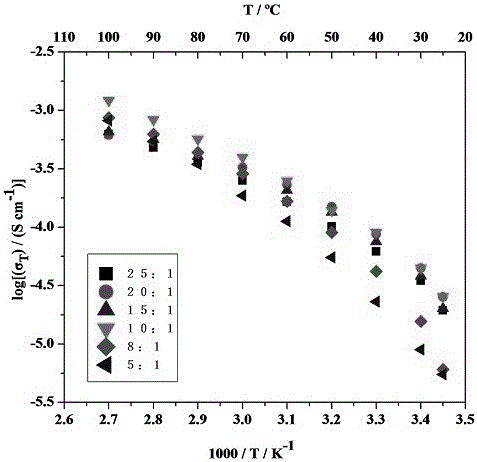

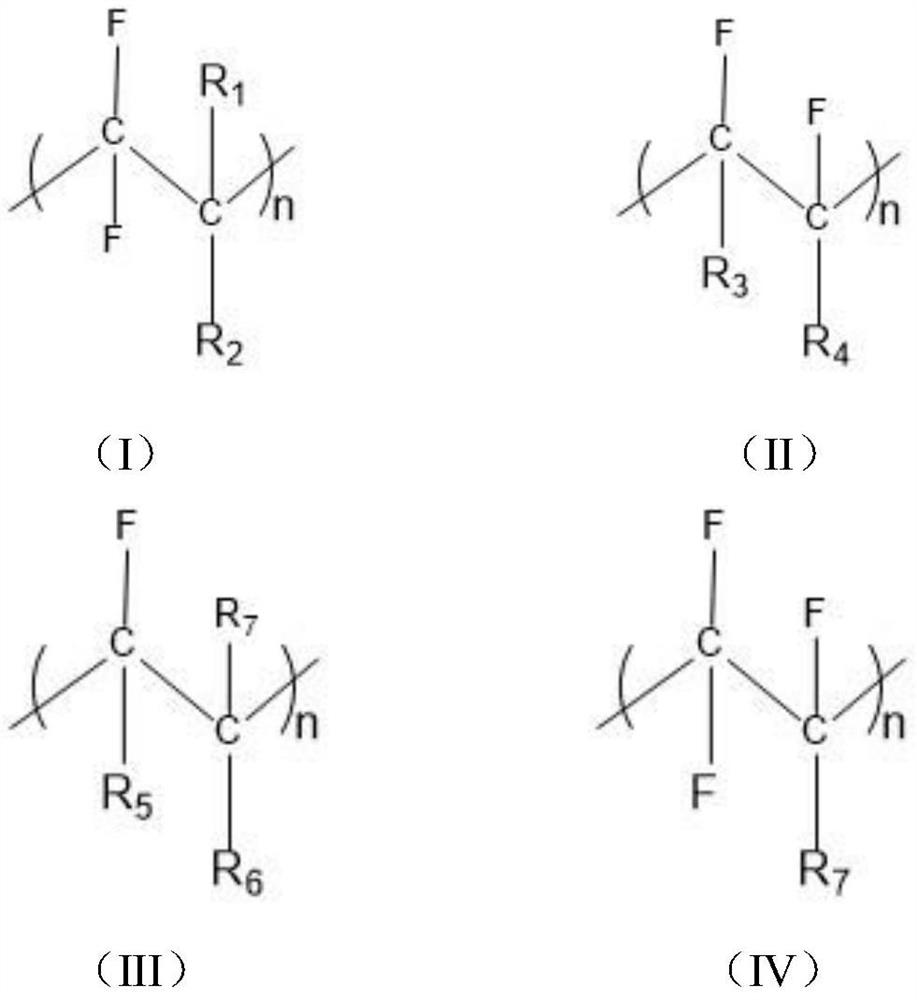

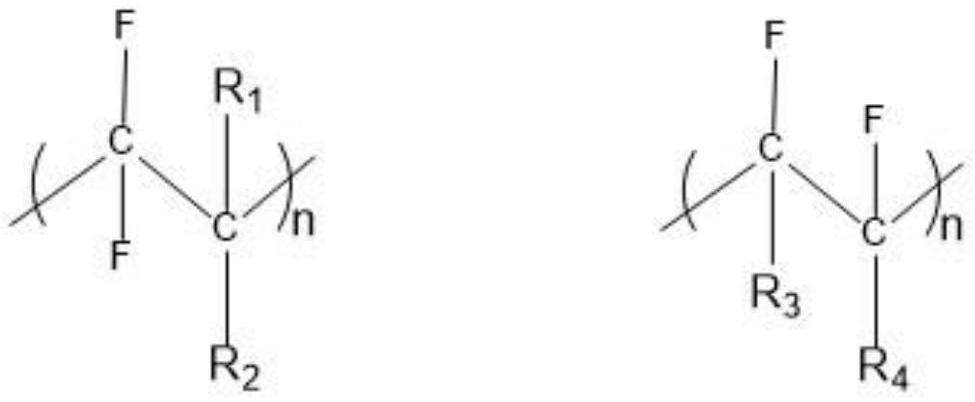

Quasi-solid polymer electrolyte for lithium ion secondary battery and preparation method

The invention provides a quasi-solid polymer electrolyte for a lithium ion secondary battery and a preparation method. The electrolyte has a fixed shape and is in a quasi-solid mode with certain fluidity, and a polymer membrane is a copolymer formed by PEGMEM (poly (ethylene glycol)methyl ether methacrylate) monomers and SMA (stearyl methacrylate) monomers and doped with organic lithium salt. The PEGMEM-co-SMA amorphous solid prepared through a polymerization reaction is doped with the organic lithium salt to obtain a mixture, and the mixture is dissolved in an organic solution, is dropped on a diaphragm material and is subjected to vacuum drying by an evaporation solvent to obtain the polymer electrolyte. According to the PEGMEM-co-SMA copolymer, crystallization of ethylene oxide (EO) segments in the PEGMEM monomers is effectively inhibited, the electrical conductivity of the all-solid-state polymer electrolyte is improved, further, the polymer appearance is in a high-adhesion amorphous state, the polymer can be sufficiently contacted with a positive pole and a negative pole and has high interface stability and electrochemical performance, and accordingly, the circulating rate performance of the battery is improved.

Owner:CENT SOUTH UNIV +1

Modified lithium nickel cobalt aluminate cathode material and preparation method and application thereof

ActiveCN111180690AImproved cycle rate performanceLow surface residual LiCell electrodesSecondary cells servicing/maintenanceMetallurgyPhysical chemistry

The invention relates to the technical field of lithium ion batteries, and discloses a modified lithium nickel cobalt aluminate cathode material and a preparation method and application thereof. The cathode material has a composition as shown in a general formula I which is described in the specification, li1+[alpha]NixCoyAlzMdGePf2, wherein 0<=[alpha]<=0.1, 0.80<=x<=0.99, 0.01<=y<=0.20, 0.01<=z<=0.06, 0<=d<=0.005, 0<=e<=0.004, 0<=f<=0.04, and M is selected from at least one of Ca, Sr, Ba, Zr, Y, Ce, Mg, Ti and Mn, G is selected from at least one of Ca, Sr, Ba, Zr, Y, La, Ce, Mg, Ti, B and W,P is selected from at least one of Ni, Co, Al, Nb, W and Mn, and d, e and f are not zero at the same time. The cathode material has the high cycle rate performance and low surface residual Li, and thebattery prepared from the cathode material has good cycle stability, thermal stability and safety performance.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD +1

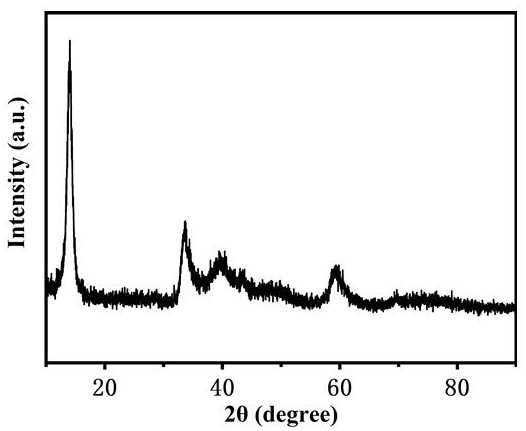

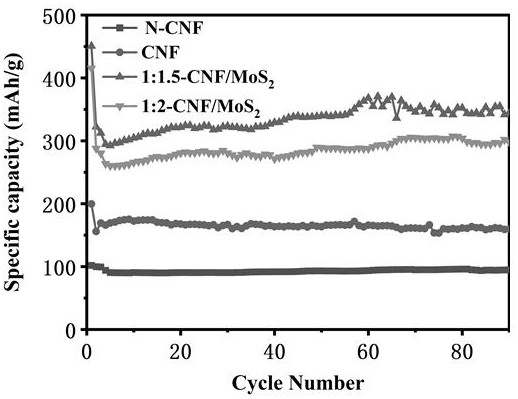

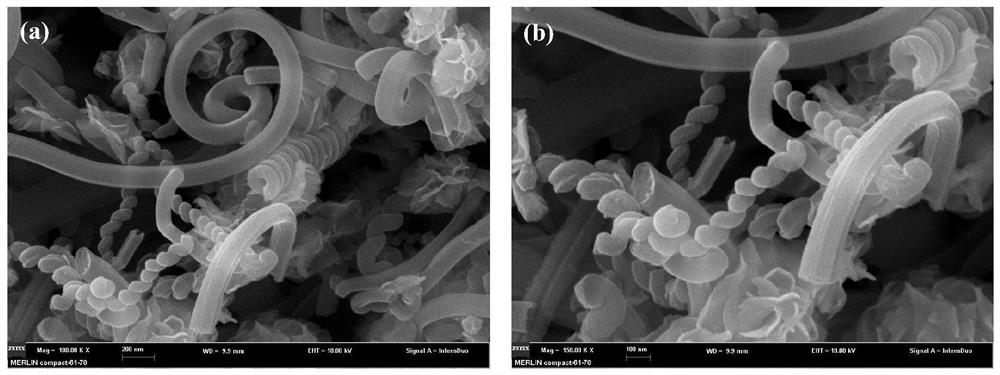

Sodium ion battery negative electrode material and preparation method thereof

ActiveCN113622055AReduce energy consumptionLow costMaterial nanotechnologyCarbon fibresFiberCarbon fibers

The invention discloses a sodium ion battery negative electrode material and a preparation method thereof. The preparation method comprises the steps that spiral nanometer carbon fibers are prepared at low temperature through a chemical vapor deposition method, then the spiral nanometer carbon fibers are carbonized and acidified in sequence, finally, a molybdenum source, a sulfur source and the acidified spiral nanometer carbon fibers are mixed, and then the mixture is put into a reaction kettle for hydrothermal reaction, and then is subjected to centrifuging, freeze-drying and annealing to obtain the sodium ion battery negative electrode material. The sodium ion battery negative electrode material prepared by the method has good conductivity and cycling stability.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

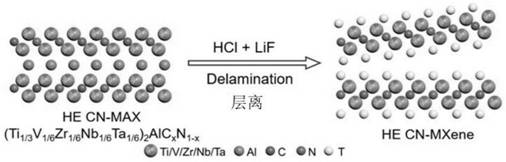

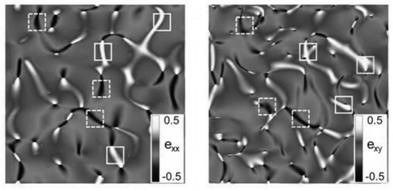

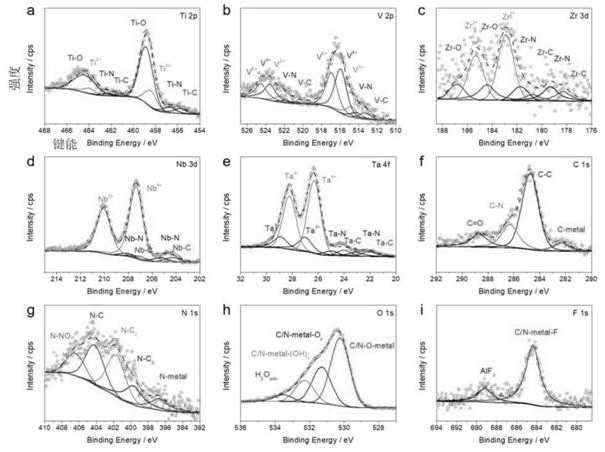

Nitrogen-containing high-entropy MXene with sulfur catalysis function, diaphragm composite material and battery

ActiveCN113968741AImprove adsorption capacityAvoid lostPositive electrodesLi-accumulatorsLithium–sulfur batteryPhysical chemistry

The invention discloses a nitrogen-containing high-entropy MXene used for a battery and having a sulfur catalysis function. The battery is a lithium-sulfur battery. The chemical formula of the nitrogen-containing high-entropy MXene is shown as M'X, wherein M' is selected from at least five metal elements in IIIB, IVB, VB, VIB, VIIB, VIII, IB and IIB groups, and X is C and N elements. The nitrogen-containing high-entropy MXene shows good adsorption and catalysis capability on LiPSs under the action of mechanical strain and five or more metal-N bonds, shows high Li2S deposition capacity, is applied to a lithium-sulfur battery, and realizes high rate performance and relatively long cycle life in the Li-S battery.

Owner:BEIHANG UNIV

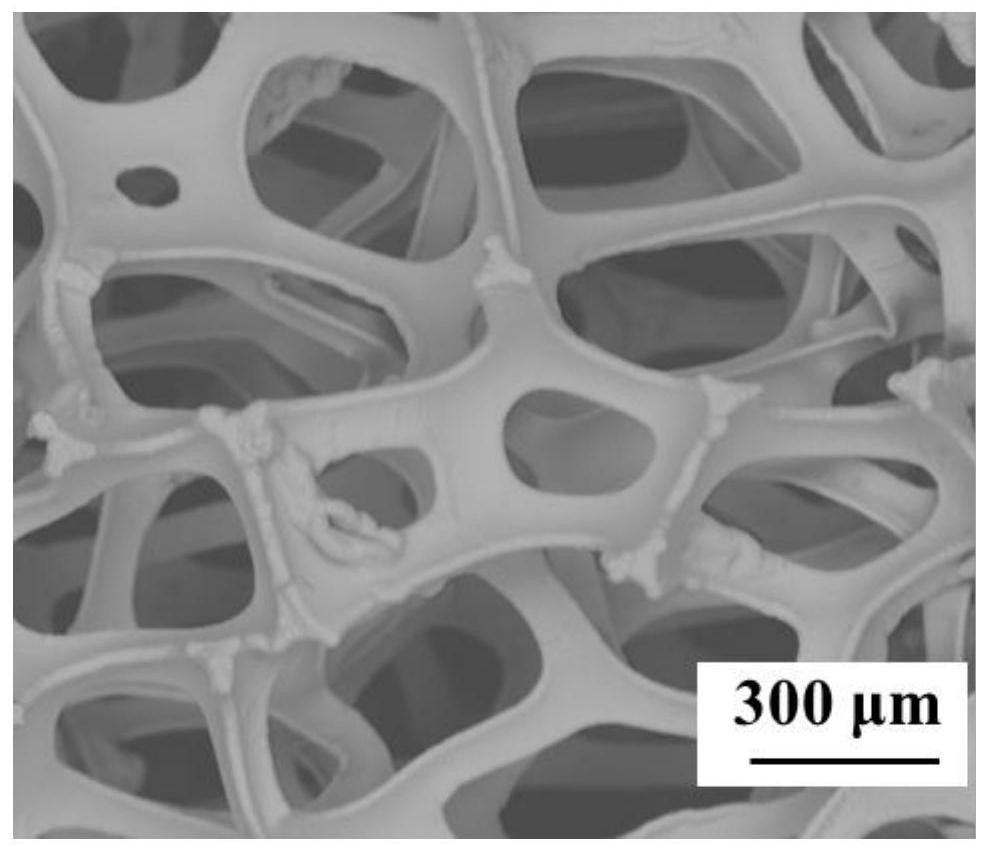

Activation method of high-capacity lithium ion battery negative electrode material

ActiveCN108063252APreserve intrinsic propertiesEvenly distributedCell electrodesSecondary cellsActivation methodCycle rate

The invention provides an activation method of a high-capacity lithium ion battery negative electrode material. The activation method comprises the following steps of 1) performing film formation on agraphene oxide aqueous solution in a porous template by a drop-coating method, and allowing to stand; 2) spraying the graphene oxide aqueous solution onto the dried three-dimensional graphene oxide / template attachment material, and drying for use; 3) impregnating the material in an aqueous solution dissolved with an activation agent, and allowing to stand after ultrasonic processing; and 4) placing the product in a tubular furnace for oxygen-free sintering after drying, cooling the sintered product to a room temperature, washing the product with deionized water until washing water is neutral,and drying, thereby obtaining the activated graphene / template negative electrode material. By the activation method, the inherent characteristic of a two-dimensional graphene sheet is maintained, meanwhile, graphene and the porous template are more uniformly distributed, the active sites of graphene phase-template phase-electrolyte phase catalytic reaction are remarkably improved, and the power density and the cycle rate performance are remarkably improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY CO LTD CO LTD

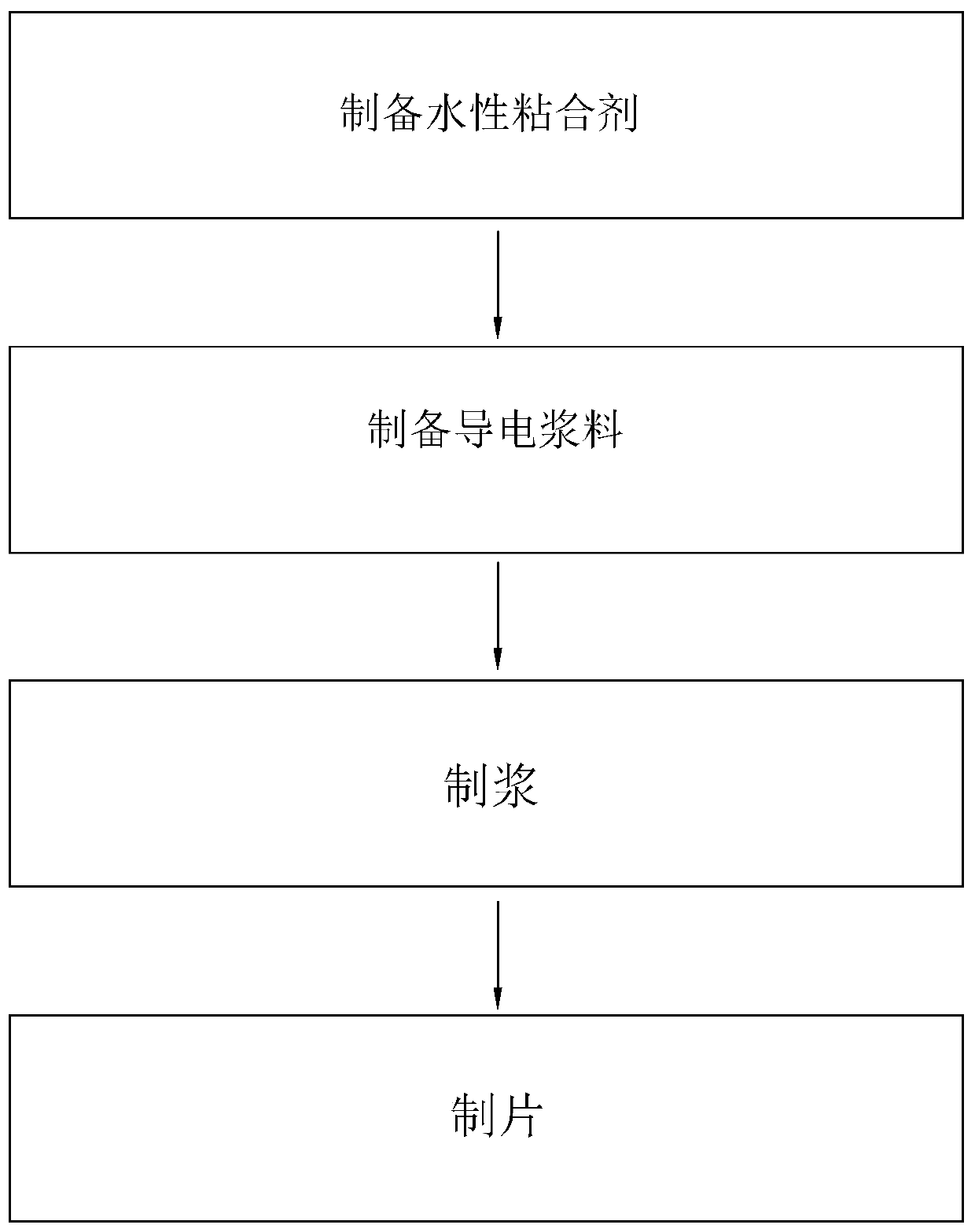

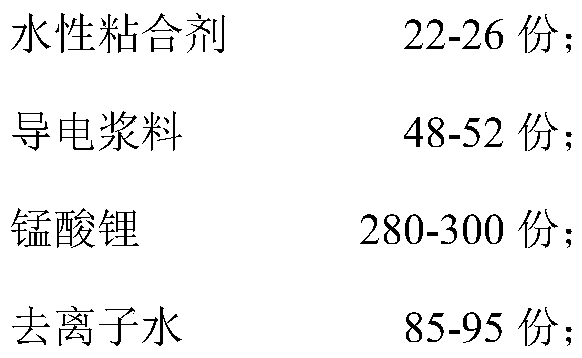

Lithium manganate battery positive electrode piece and preparation method thereof

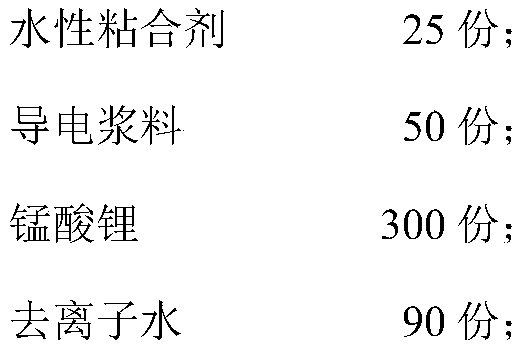

The invention discloses a lithium manganate battery positive electrode piece and a preparation method thereof, and belongs to the technical field of lithium manganate batteries. The positive electrodepiece comprises the following raw materials by weight: 22-26 parts of an aqueous binder; 48-52 parts of conductive paste; 280-300 parts of lithium manganate; 85-95 parts of deionized water; the water-based adhesive is prepared from the following raw materials in parts by weight: 16-18 parts of carboxymethyl chitosan; 5-6 parts of polyethylene glycol; and 1-2 parts of a cross-linking agent. Carboxymethyl chitosan serving as a water-based binder has the advantages of good water solubility, no pollution, low price and the like, and also has good cycle rate performance when being compared with aPVDF system. Polyethylene glycol has good water solubility, excellent lubricity, dispersibility and adhesion, and strong toughness, and can be blended with carboxymethyl chitosan to improve the flexibility of the grade sheet. The chemical crosslinking of the cross-linking agent and carboxymethyl chitosan can improve the adhesive property and mechanical stability of the electrode piece, thereby improving the performance of the battery.

Owner:深圳中华自行车(集团)股份有限公司

High-voltage electrolyte for lithium ion battery and preparation method of high-voltage electrolyte

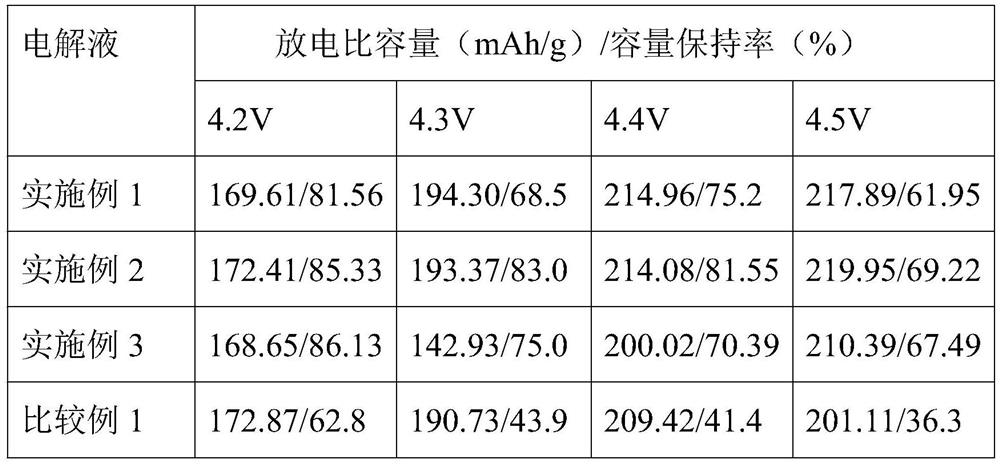

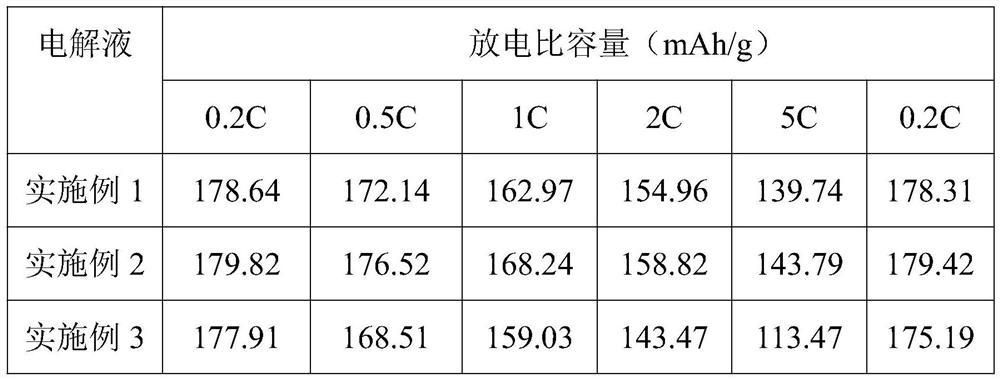

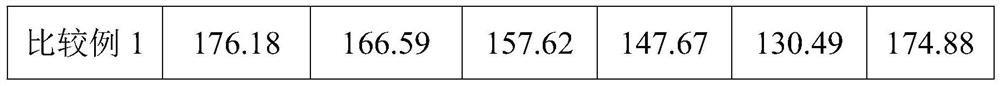

ActiveCN113193231AStrong high pressure resistanceGood capacity retentionFinal product manufactureSecondary cellsElectrolytic agentOrganosolv

The invention relates to a high-voltage electrolyte for a lithium ion battery and a preparation method of the high-voltage electrolyte, and belongs to the technical field of lithium ion batteries. The high-voltage electrolyte is composed of a ternary organic solvent, an electrolyte and an additive, and the additive comprises thiophene-2, 5-diyl dimethyl phosphonic acid tetramethyl ester (TTD). The high-temperature electrolyte is relatively low in cost of required raw materials, simple to prepare and excellent in high-pressure performance, and when the high-temperature electrolyte is applied to the lithium ion battery taking a high-nickel material (NCM811) as a positive electrode, the electrochemical performance, especially the cycle rate performance, of the battery is obviously improved.

Owner:JIANGXI UNIV OF SCI & TECH

Lithium ion battery, anode material and preparation method thereof

InactiveCN109802115AImprove discharge capacityImproved cycle rate performanceCell electrodesSecondary cellsWrinkle skinGraphite

The invention relates to the field of lithium ion batteries and discloses a lithium ion battery, an anode material and a preparation method thereof. The method comprises preparing graphene oxide, anddispersing the graphene oxide in a first solvent to form a first suspension; separating graphene oxide powder from the first suspension, wherein the surface of the graphene oxide powder has three-dimensional wrinkles; mixing and dispersing the graphene oxide powder and graphite powder in a second solvent to form a second suspension; spray-drying the second suspension to obtain a dried solid powder; baking the solid powder under an inert atmosphere, and then cooling the solid powder so as to obtain the lithium ion battery anode material.

Owner:江西星盈科技有限公司

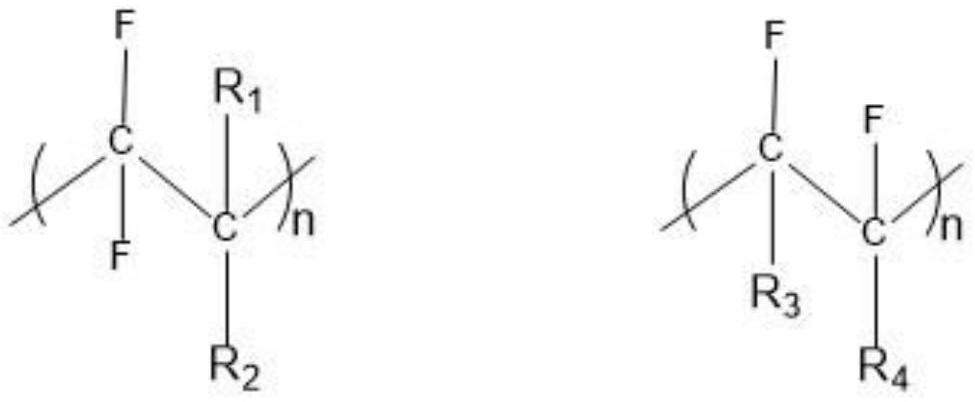

Composite binder for lithium ion battery, positive electrode slurry for lithium ion battery, and lithium ion battery

ActiveCN106099114BImprove cycle performanceGood compatibilityCell electrodesSecondary cellsAdhesivePole piece

The invention relates to a composite binder for a lithium ion battery, a positive pole slurry of the lithium ion battery and the lithium ion battery and belongs to the technical field of lithium ion batteries. The composite binder for the lithium ion battery is prepared from, by weight, 94-98 parts of adhesive and 1-3 parts of ethylene carbonate. The composite binder for the lithium ion battery contains the adhesive, is also added with the ethylene carbonate and is adopted to prepare a pole piece, the compatibility of the binder and electrolyte in the pole piece can be improved, change of an electrode material layer on the pole piece can be avoided in the charge and discharge process of the lithium ion battery, the stability of the electrode material layer is improved, and further the cycle performance of the lithium ion battery is improved.

Owner:LUOYANG LIRONG NEW ENERGY TECH

Quasi-solid polymer electrolyte for lithium ion secondary battery and preparation method thereof

The invention provides a quasi-solid polymer electrolyte for a lithium ion secondary battery and a preparation method. The electrolyte has a fixed shape and is in a quasi-solid mode with certain fluidity, and a polymer membrane is a copolymer formed by PEGMEM (poly (ethylene glycol)methyl ether methacrylate) monomers and SMA (stearyl methacrylate) monomers and doped with organic lithium salt. The PEGMEM-co-SMA amorphous solid prepared through a polymerization reaction is doped with the organic lithium salt to obtain a mixture, and the mixture is dissolved in an organic solution, is dropped on a diaphragm material and is subjected to vacuum drying by an evaporation solvent to obtain the polymer electrolyte. According to the PEGMEM-co-SMA copolymer, crystallization of ethylene oxide (EO) segments in the PEGMEM monomers is effectively inhibited, the electrical conductivity of the all-solid-state polymer electrolyte is improved, further, the polymer appearance is in a high-adhesion amorphous state, the polymer can be sufficiently contacted with a positive pole and a negative pole and has high interface stability and electrochemical performance, and accordingly, the circulating rate performance of the battery is improved.

Owner:CENT SOUTH UNIV +1

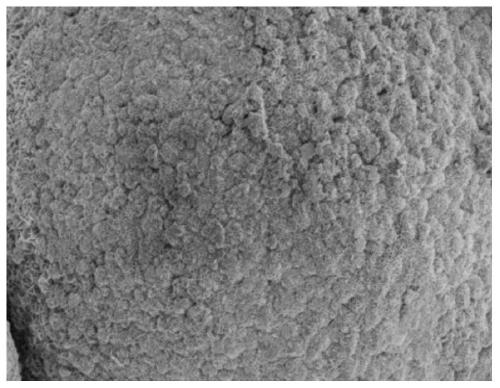

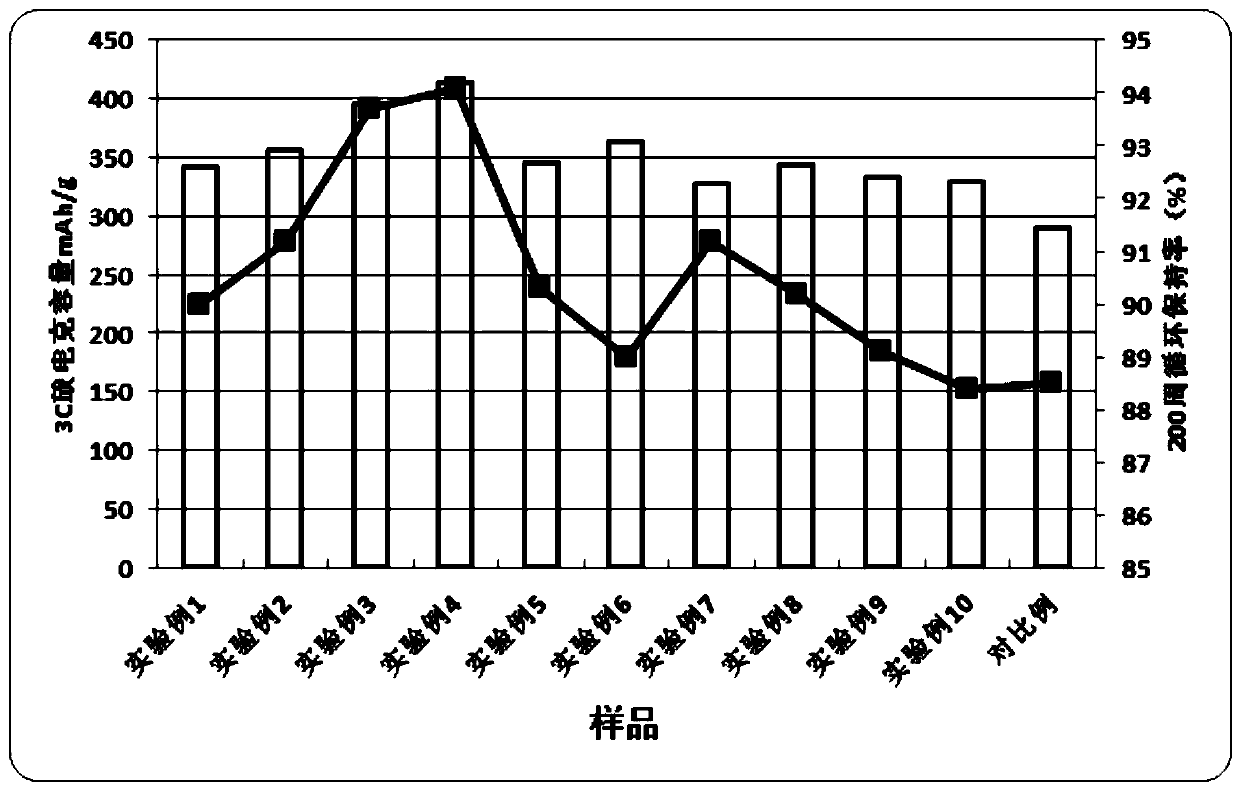

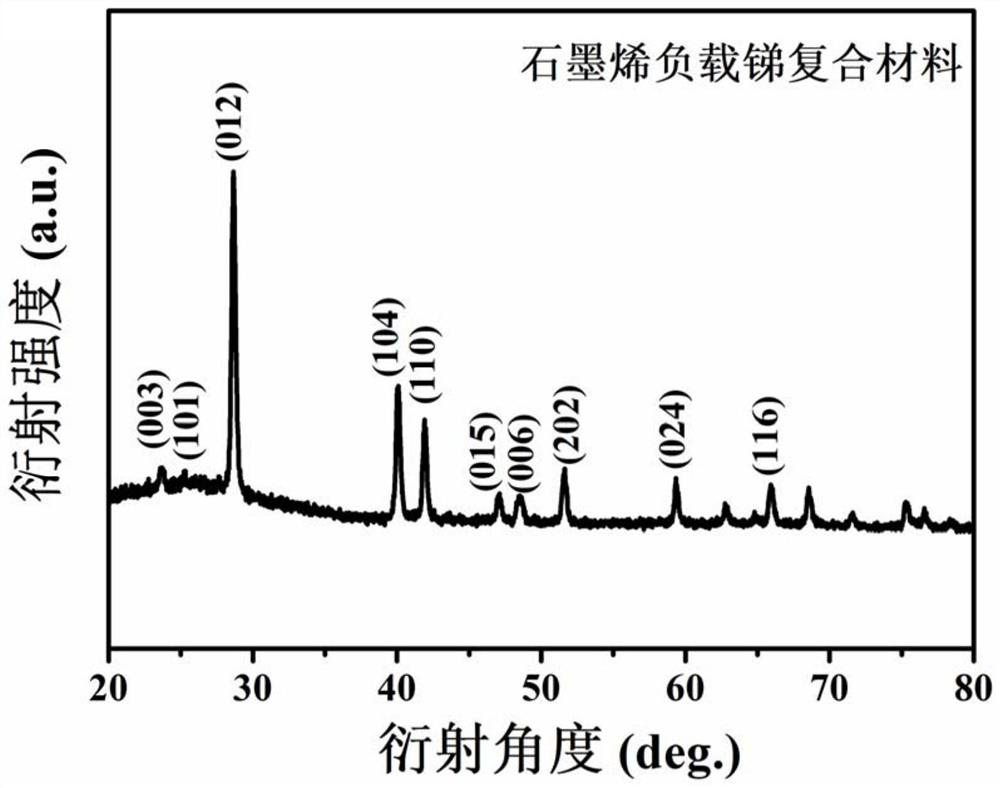

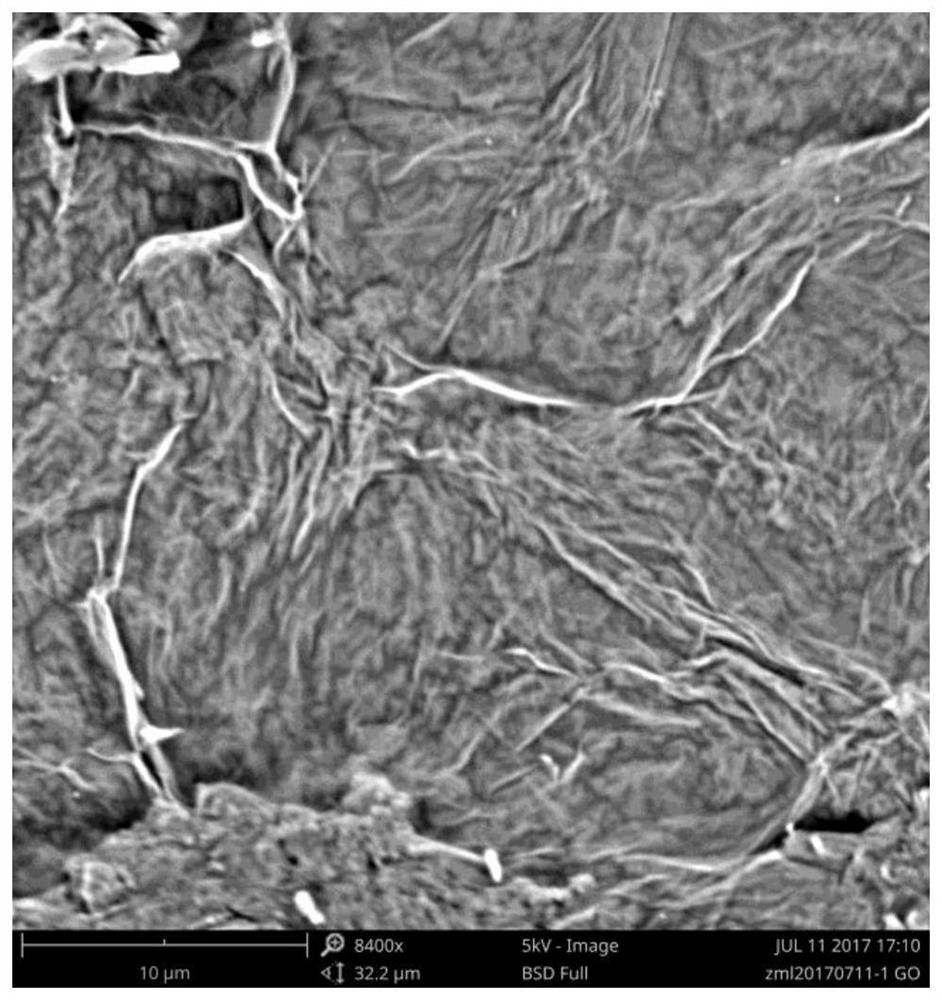

A kind of sodium ion battery anode material and preparation method thereof of reduced graphene oxide loaded with antimony

ActiveCN109473663BImproved cycle rate performanceSimple methodCell electrodesHigh current densityElectrical battery

The invention discloses a sodium ion battery anode material for reducing graphene oxide and supporting antimony and a preparation method thereof, and relates to the technical field of electrochemical energy storage. The invention uses antimony trichloride, ammonia water and flake graphite as raw materials, uses chemical oxidation method and exfoliation method to prepare graphene oxide, improves liquid phase synthesis method to load antimony precursor particles on the graphene oxide sheet layer, and finally conducts thermal reduction treatment The anode material of sodium ion battery supported by reduced graphene oxide with antimony is obtained. The sodium ion battery negative electrode material of the reduced graphene oxide supported antimony of the present invention has excellent cycle rate performance; at 2A g ‑1 After 100 cycles at high current density, Sb‑rGO still maintains 140mAh g ‑1 The above capacity is maintained, and the coulombic efficiency is maintained at more than 97%; the preparation method provided by the present invention does not need to add surfactants and reducing agents, the method is simple, the cost is low, and it is suitable for large-scale preparation.

Owner:BEIHANG UNIV

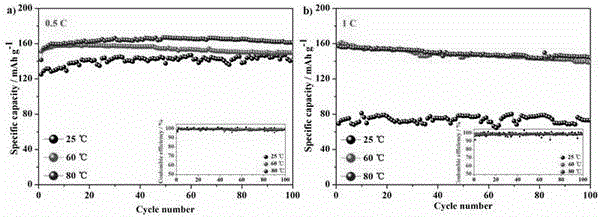

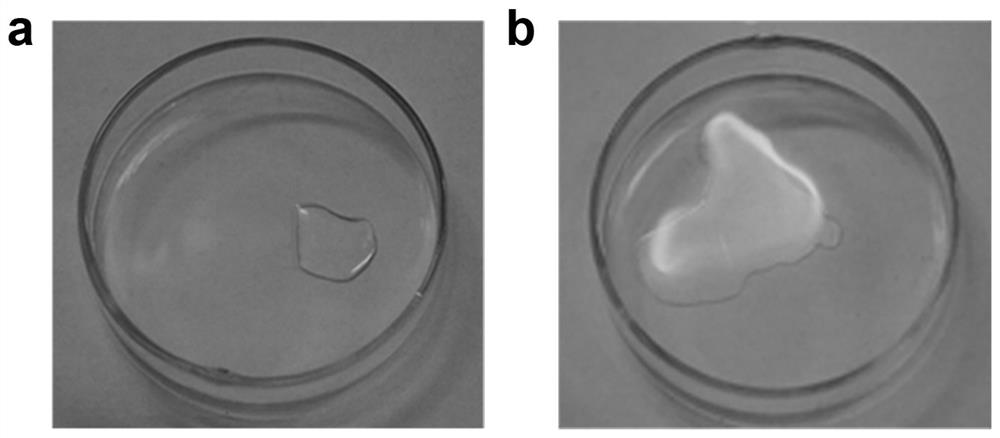

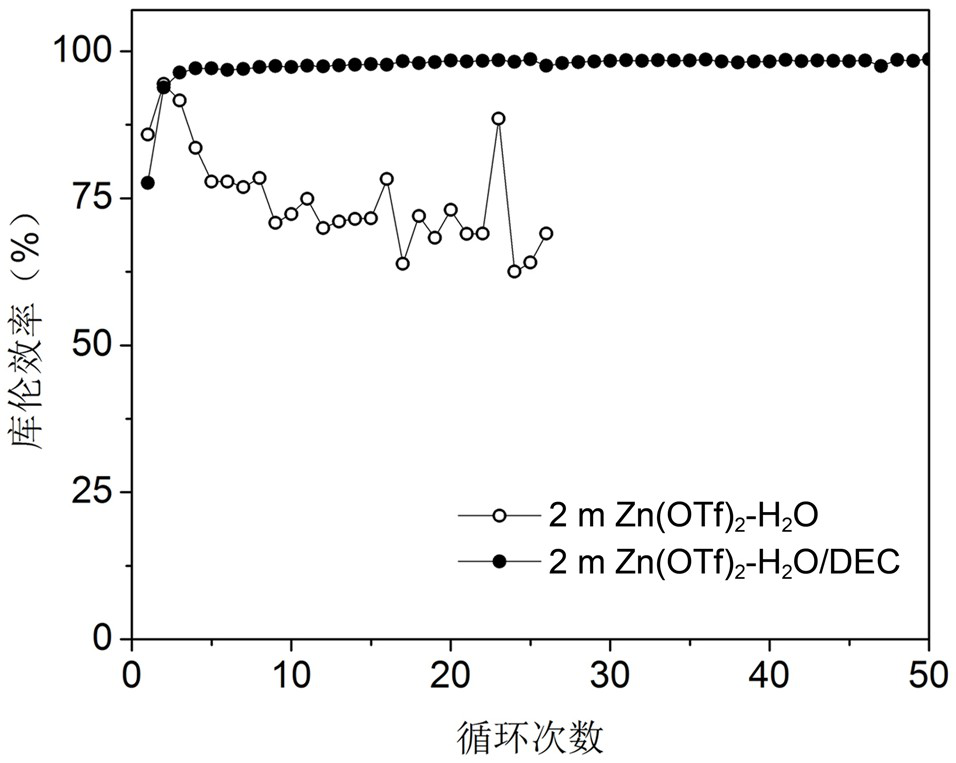

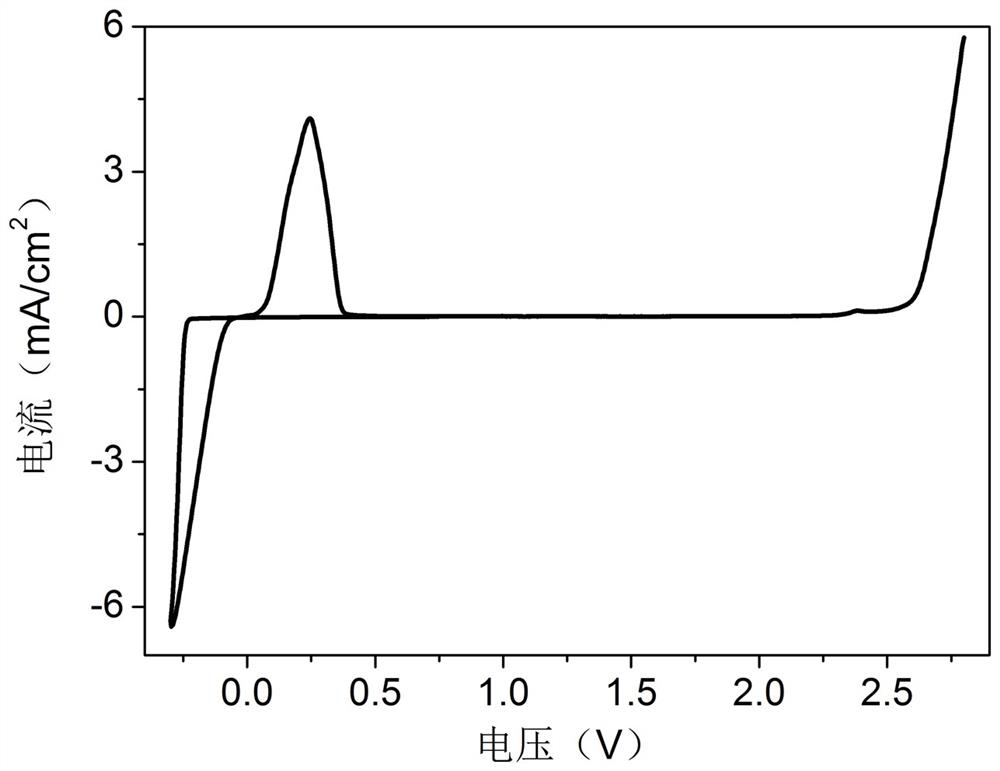

A kind of electrolyte solution for rechargeable zinc ion battery, its preparation method and rechargeable zinc ion battery

ActiveCN111509306BUniform depositionAvoid corrosionSecondary cellsAqueous electrolytesElectrolytic agentElectrical battery

The invention provides an electrolyte for a rechargeable zinc ion battery, a preparation method thereof and a rechargeable zinc ion battery. The electrolyte uses water and an organic carbonate solvent as the electrolyte solvent, and a zinc salt as the electrolyte salt, wherein The carbonate solvent volume is 30%~70% of the solvent volume, and the zinc salt concentration is 1~4 mol / kg. The electrolyte of the invention has high electrical conductivity, good safety and good electrochemical stability, and has strong interaction between anions and cations in the electrolyte, carbonate molecules and water molecules, effectively inhibits the activity of water molecules, and improves the voltage window. , to improve the Coulombic efficiency of Zn deposition / precipitation. The electrolyte has good compatibility with the zinc anode, and effectively solves the problems of dendrite growth, hydrogen evolution, corrosion, etc. faced by the zinc anode in traditional aqueous electrolytes. Using it in a rechargeable zinc-ion battery system can significantly improve the battery's cycle stability. The battery system has high safety, low cost, good electrochemical performance, meets the needs of large-scale energy storage, and has good application prospects.

Owner:HEBEI UNIVERSITY

A kind of activation method of high-capacity lithium-ion battery negative electrode material

ActiveCN108063252BPreserve intrinsic propertiesEvenly distributedCell electrodesGrapheneElectrolytic agentTube furnace

The invention provides an activation method of a high-capacity lithium ion battery negative electrode material. The activation method comprises the following steps of 1) performing film formation on agraphene oxide aqueous solution in a porous template by a drop-coating method, and allowing to stand; 2) spraying the graphene oxide aqueous solution onto the dried three-dimensional graphene oxide / template attachment material, and drying for use; 3) impregnating the material in an aqueous solution dissolved with an activation agent, and allowing to stand after ultrasonic processing; and 4) placing the product in a tubular furnace for oxygen-free sintering after drying, cooling the sintered product to a room temperature, washing the product with deionized water until washing water is neutral,and drying, thereby obtaining the activated graphene / template negative electrode material. By the activation method, the inherent characteristic of a two-dimensional graphene sheet is maintained, meanwhile, graphene and the porous template are more uniformly distributed, the active sites of graphene phase-template phase-electrolyte phase catalytic reaction are remarkably improved, and the power density and the cycle rate performance are remarkably improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY CO LTD CO LTD

Binder for lithium ion battery and preparation method of binder

ActiveCN112768693AImprove stabilityReduce expansionCell electrodesSecondary cellsElectrolytic agentCarbon nanotube

The invention discloses a binder for a lithium ion battery and a preparation method of the binder. The binder comprises polyvinyl fluoride, carboxymethyl cellulose gel and modified sodium polyacrylate; the carboxymethyl cellulose gel is modified by graphene oxide; and the sodium polyacrylate is modified by carbon nanotubes and sodium dodecyl benzene sulfonate. The binder prepared by the invention has relatively good conductivity and stability; the expansion rate of the binder is very small after the binder is soaked in an electrolyte; the reduction rate of the bonding strength of the binder is small; meanwhile, the assembled battery has relatively good cycle rate capability and cycle life; and the binder can improve the performance of the lithium ion battery on the whole.

Owner:乌海瑞森新能源材料有限公司

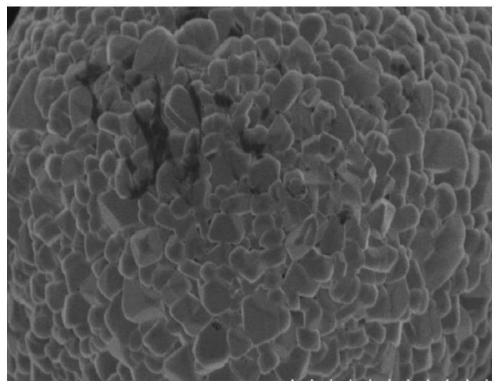

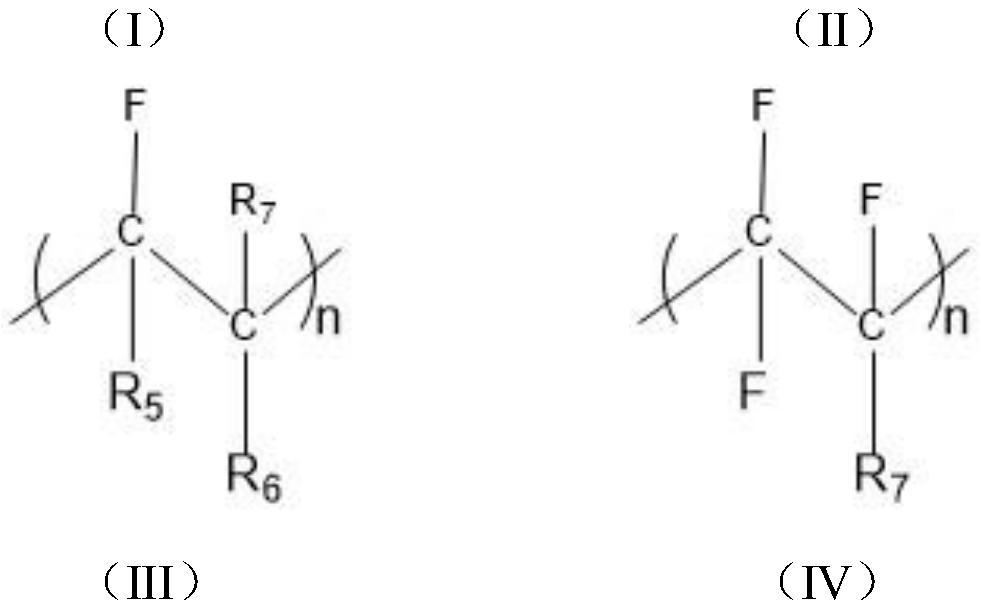

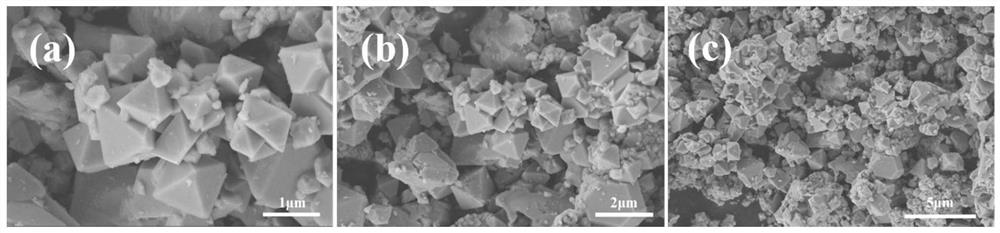

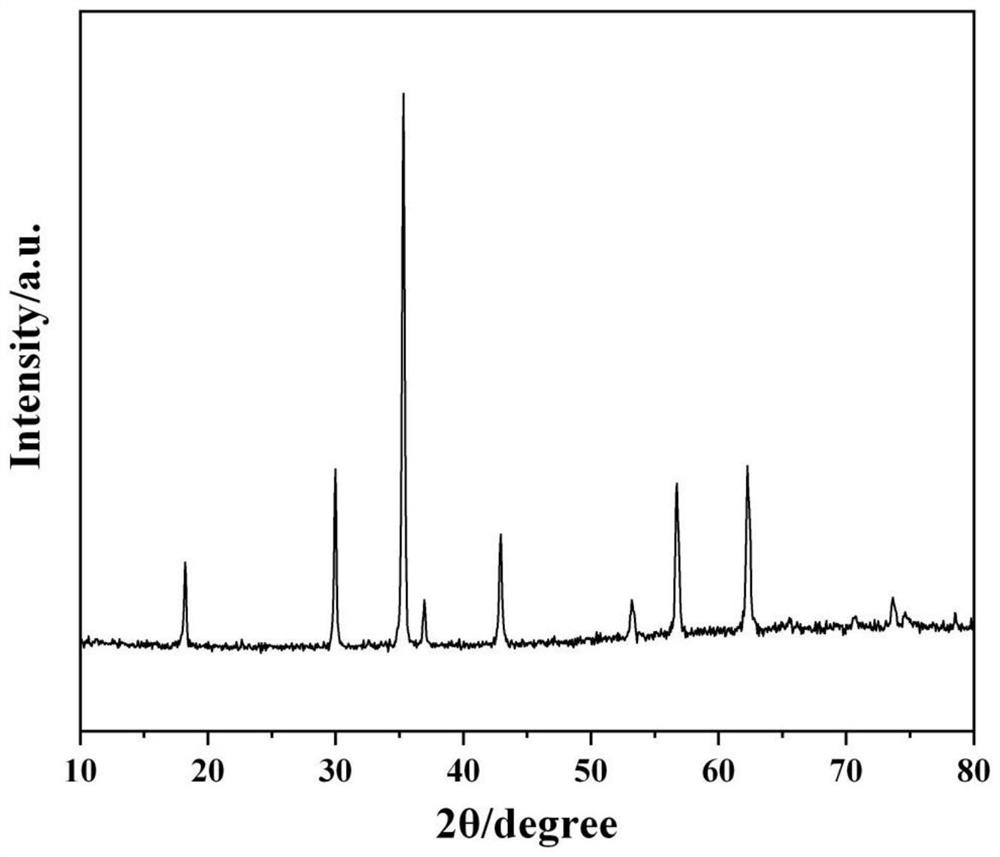

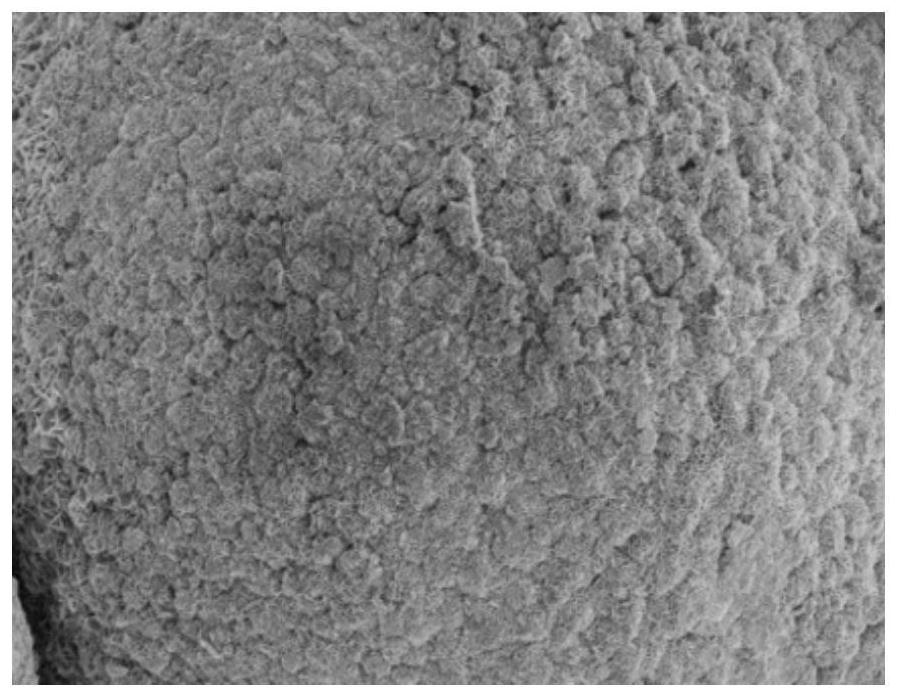

A preparation method of lithium nickel manganese oxide material with submicron octahedral structure

ActiveCN110217833BClear and uniform{111} There are many crystal facesPositive electrodesNickel compoundsOXALIC ACID DIHYDRATEOctahedron

The invention discloses a preparation method of a submicron regular octahedral structure nickel manganate material. The manganese source, the nickel source and the lithium source are accurately weighed according to the stoichiometric ratio; the manganese source and the nickel source obtained by weighing are mixed and mixed together Carry out ball milling; dry the mixture of manganese source and nickel source obtained by ball milling into powder; weigh a certain amount of oxalic acid, and mix the above-mentioned oxalic acid, the weighed lithium source and the mixture of manganese source and nickel source dried into powder by ball milling ; Add a certain amount of PEG to the mixture obtained above, stir to obtain a black-gray colloidal mixture, and preheat the black-gray colloidal mixture; first heat the mixture obtained by preheating at 300 ° C for 1 to 5 h, and then The temperature is raised to 800° C. for 1 to 5 hours, and then annealed to room temperature to obtain a submicron regular octahedral structure lithium nickel manganate material. The present invention utilizes a low-cost high-temperature solid-phase method combined with a polymer-assisted method to obtain a submicron regular octahedral structure lithium nickel manganate material, which greatly improves the cost performance.

Owner:DALIAN UNIV OF TECH

Modified nickel cobalt lithium aluminate positive electrode material and its preparation method and application

ActiveCN111180690BImproved cycle rate performanceLow surface residual LiCell electrodesSecondary cells servicing/maintenanceMetallurgyElectrical battery

The invention relates to the technical field of lithium ion batteries, and discloses a modified nickel-cobalt lithium aluminate cathode material, a preparation method and application thereof. The positive electrode material has a composition shown in general formula I: Li 1+α Ni x co y Al z m d G e P f o 2 Formula I, wherein, 0≤α≤0.1, 0.80≤x≤0.99, 0.01≤y≤0.20, 0.01≤z≤0.06, 0≤d≤0.005, 0≤e≤0.004, 0≤f≤0.04, M is selected from At least one of Ca, Sr, Ba, Zr, Y, Ce, Mg, Ti and Mn; G is selected from at least one of Ca, Sr, Ba, Zr, Y, La, Ce, Mg, Ti, B and W One; P is at least one selected from Ni, Co, Al, Nb, W and Mn; wherein, d, e and f are not 0 at the same time. The positive electrode material has high cycle rate performance and low surface residual Li, and the battery made from it has good cycle stability, thermal stability and safety performance.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD +1

sns2-c nanocomposite negative electrode material and its preparation method and application

ActiveCN105406065BImprove conductivityImproved cycle rate performanceMaterial nanotechnologyCell electrodesMass ratioNanoparticle

The invention discloses an SnS2-C negative electrode nanocomposite and a preparation method and an application therefor. The composite negative electrode material consists of SnS2 nanoparticles and a carbon material wrapping the SnS2 nanoparticles; the grain diameter of the SnS2 nanoparticles is less than 100 nm, and the SnS2 nanoparticles are uniformly distributed in the carbon material; and the mass ratio of the SnS2 nanoparticles to the carbon material is 0.625-12.5:1. The preparation method for the SnS2-C negative electrode nanocomposite comprises the following steps: performing ball milling on stannic disulphide for the first time to obtain the SnS2 nanoparticles; adding the SnS2 nanoparticles into a glucose solution for performing ball milling for the second time to obtain a mixture; and drying the mixture and then performing thermal treatment on the dried mixture to obtain the SnS2-C nanocomposite. The SnS2-C negative electrode nanocomposite is high in circulation rate capability, high in capacity retention ratio, can be applied to the field of a lithium ion battery, and is bright in the application and industrial prospects.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

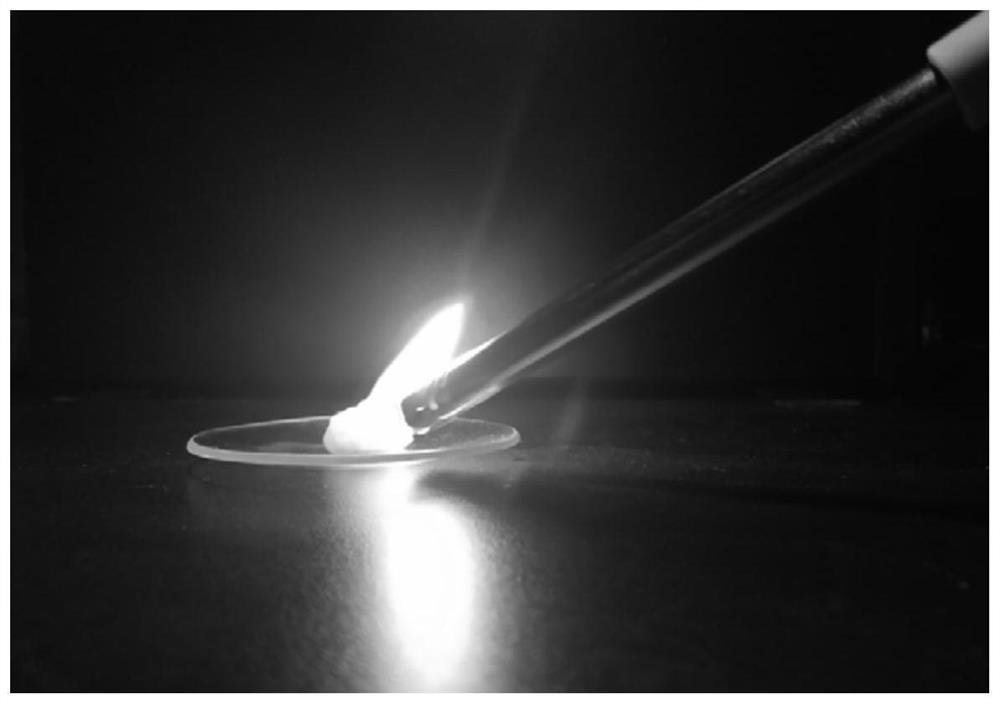

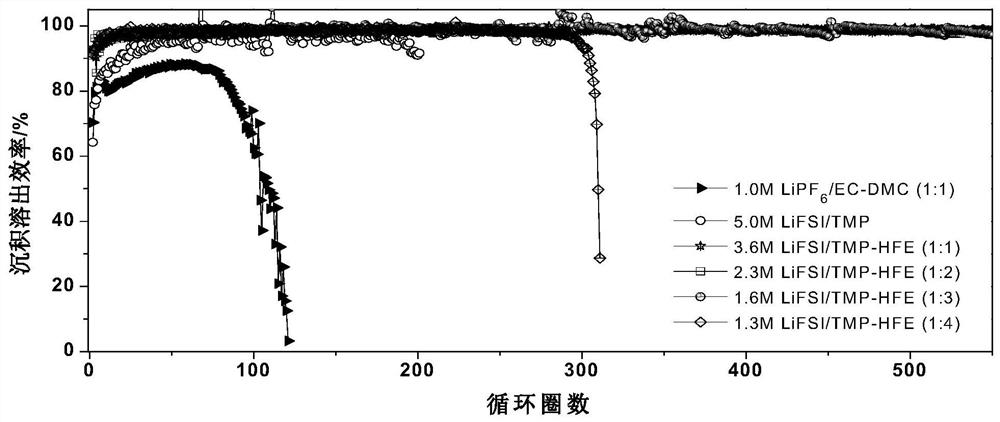

A kind of intrinsically safe electrolyte for secondary lithium-sulfur battery and preparation method thereof

ActiveCN109599592BImprove electrochemical performanceImprove securityLi-accumulatorsOrganic electrolytesElectrolytic agentOrganic solvent

The present invention relates to an intrinsically safe electrolyte for a secondary lithium-sulfur battery and a preparation method thereof. The electrolyte comprises a lithium salt and an organic solvent, and the organic solvent is a phosphate solvent or a phosphate solvent and a hydrofluoroether. A mixed solvent composed of a similar solvent; lithium salt is added to the organic solvent, and the electrolyte is uniformly stirred to form an electrolyte, that is, an intrinsically safe electrolyte for a secondary lithium-sulfur battery is prepared. Compared with the prior art, the lithium-sulfur battery after using the electrolyte can realize safe cycling, which is embodied in the uniform lithium deposition morphology, no obvious dendrites and complete flame retardancy. On this basis, the electrochemical performance is significantly improved. , which is more advantageous than other sulfur materials and lithium metal batteries.

Owner:SHANGHAI JIAOTONG UNIV

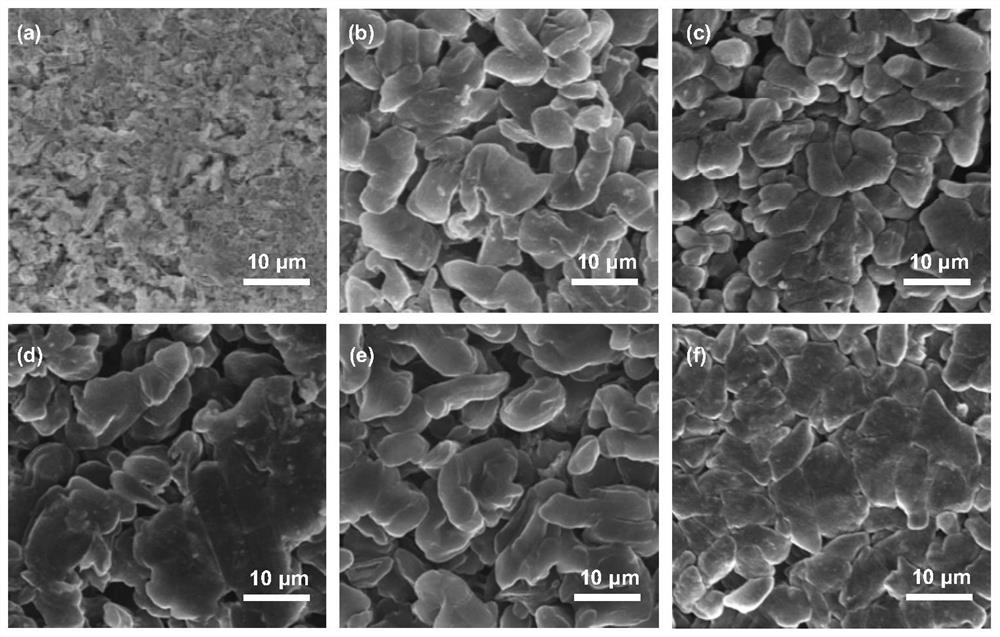

Ternary cathode material and preparation method of the material and its precursor

ActiveCN107585794BImproved cycle rate performanceHigh tap densityCell electrodesSecondary cellsSpray pyrolysisSeed crystal

The invention provides a ternary precursor with a composite hetero-structure. The molecular formula of the ternary precursor is Ni<1-a-b>CoM(OH)2@Ni<1-x-y>Co<x>M<y>O<z>, wherein 0<a<1, 0<b<1, 0<a+b<1, 0<x<1, ,0<y<1, 0<x+y<1, 1<z<1.5, and M represents Mn or Al. The ternary precursor comprises a ternary oxide precursor and a ternary hydroxide precursor. The ternary hydroxide precursor is coated on the surface of the ternary oxide precursor. The molecular formula of the ternary oxide precursor is Ni<1-x-y>Co<x>M<y>O<z>, and the molecular formula of the ternary hydroxide precursor is Ni<1-a-b>CoM(OH)2. The invention further provides a preparation method of the ternary precursor. According to the preparation method, a spray pyrolysis method and a co-precipitation method are combined, the ternary oxide precursor obtained by spray pyrolysis is taken as the seed crystal, then a layer of ternary hydroxide precursor is coated on the surface of the ternary oxide precursor through theco-precipitation method to obtain the ternary precursor, and the ternary precursor and lithium salts are mixed and sintered to prepare the ternary cathode material. The ternary cathode material has the advantages of good layered structure, high initial efficiency, high specific capacity, and excellent circulating ratio performance.

Owner:CENT SOUTH UNIV

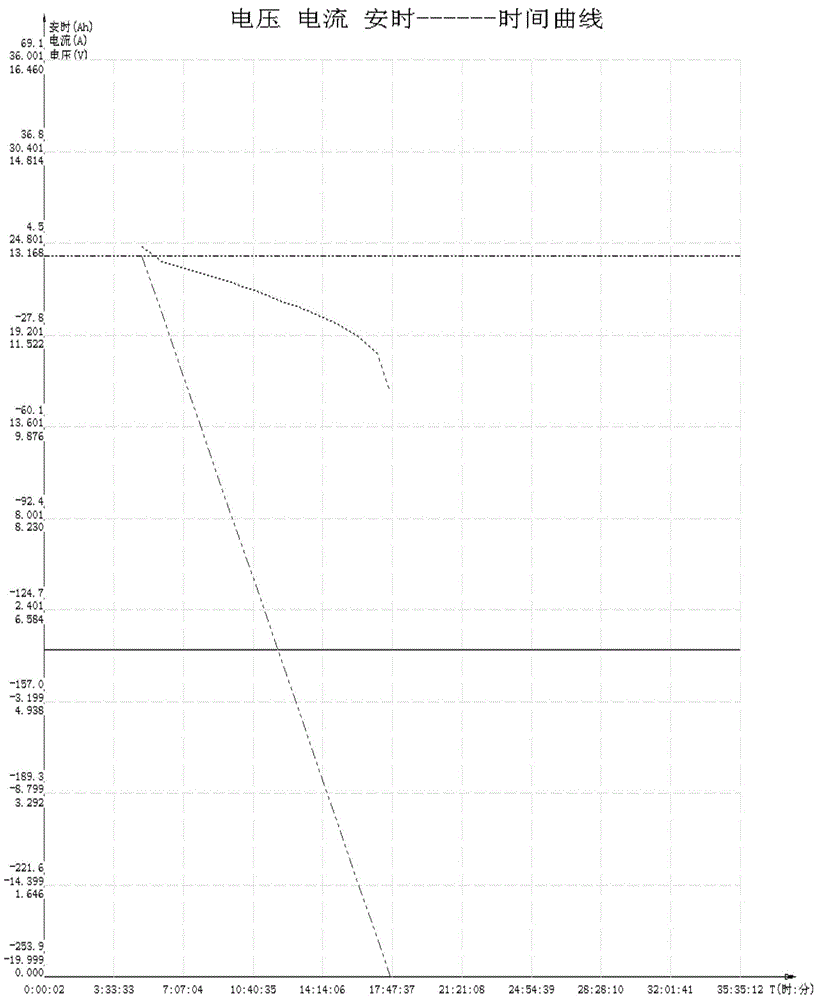

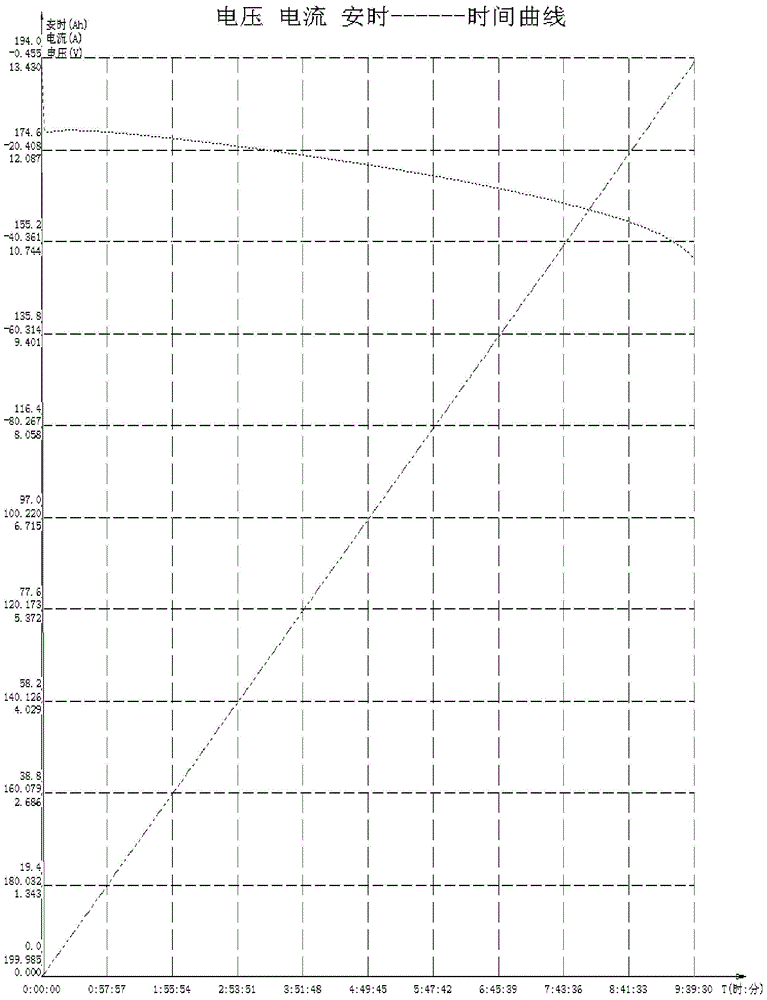

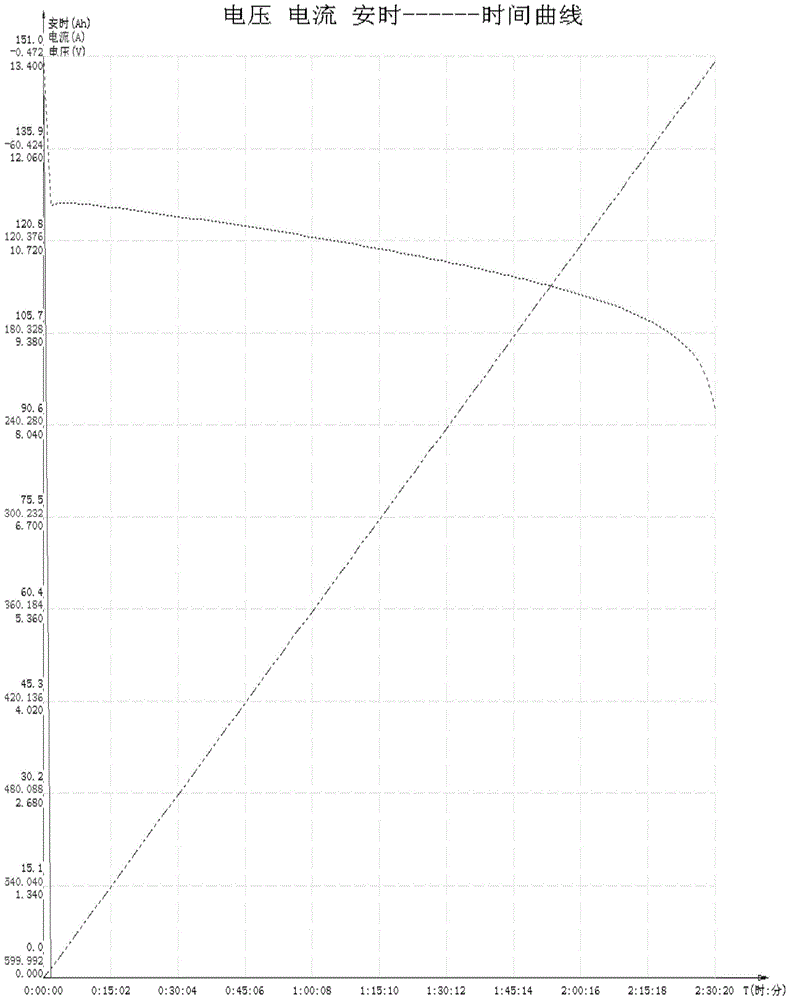

A kind of magnesium-based composite material and its application in lead-acid storage battery and the method for using this material to prepare lead-acid storage battery

ActiveCN104466120BIncrease capacityImproved cycle rate performanceLead-acid accumulator electrodesMagnesium matrix compositeProcess conditions

The invention discloses a magnesium-based composite material and application of the material in a lead acid storage battery as well as a method for preparing the lead acid storage battery by utilizing the material. The preparation method of the magnesium-based lead acid storage battery with ultra-low temperature, long service life and high capacity comprises the following steps: preparing a magnesium alloy at first; preparing the magnesium-based composite material; mixing the prepared magnesium-based composite material with positive and negative electrode materials of the lead acid battery to prepare paste; preparing an un-formed magnesium-based lead acid storage battery according to the preparation method and the process condition of the standard lead acid storage battery; and preparing the magnesium-based lead acid storage battery according to a certain formation condition. The prepared magnesium-based lead acid storage battery has the characteristics of ultra-low temperature, high capacity, high magnification and long cycle life, and has a good industrial application prospect; the performance of the magnesium-based lead acid storage battery is obviously superior to that of the traditional lead acid storage battery.

Owner:李宏斌

A kind of binder for lithium ion battery and preparation method thereof

ActiveCN112768693BImprove stabilityReduce expansionCell electrodesSecondary cellsElectrolytic agentCellulose

The invention discloses a binder for lithium-ion batteries and a preparation method thereof, comprising that the binder includes polyfluoroethylene, carboxymethyl cellulose gel, and modified sodium polyacrylate; wherein, carboxymethyl The base cellulose gel was modified by graphene oxide, and sodium polyacrylate was modified by carbon nanotubes and sodium dodecylbenzenesulfonate. The adhesive prepared by the present invention has good electrical conductivity and stability, and its expansion rate is very small after soaking in the electrolyte, and the rate of decrease in bond strength is small, and the assembled battery has better cycle rate performance and Cycle life, the binder can improve the performance of lithium-ion batteries as a whole.

Owner:乌海瑞森新能源材料有限公司

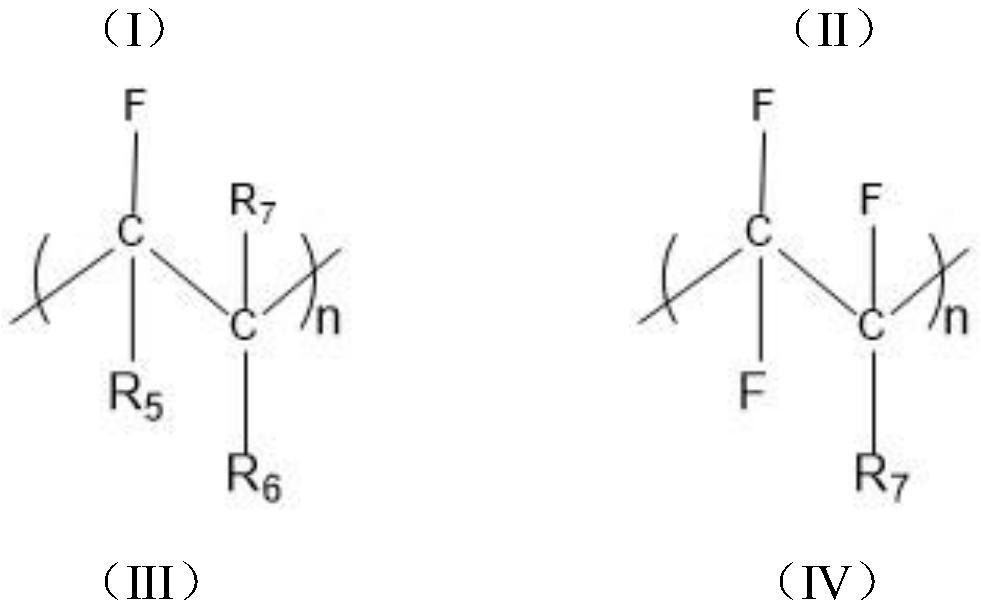

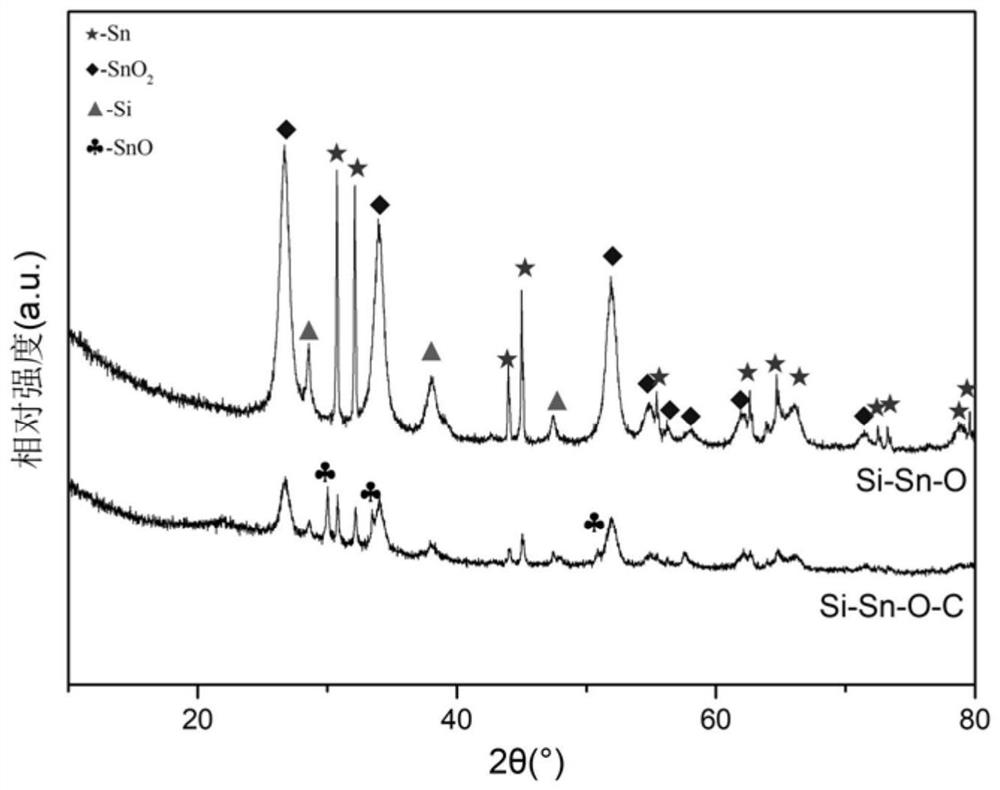

Silicon-tin-oxygen-carbon compound electrode material and preparation method and application thereof

PendingCN114447335AImprove cycle stabilityImproved cycle rate performanceMaterial nanotechnologyNegative electrodesCarbon compositesHigh energy

The invention discloses a silicon-tin-oxygen-carbon composite electrode material and a preparation method and application thereof, the material comprises silicon particles, tin and tin oxide particles and an amorphous carbon layer, and the molar ratio of the silicon particles to the tin and tin oxide particles is (1-2): 1; wherein the tin particles are coated with the silicon particles, the tin oxide particles and the amorphous carbon layer. Compared with the prior art, the silicon-tin-oxygen-carbon composite electrode material has the following advantages: (1) the silicon-tin-oxygen-carbon composite electrode material overcomes the defect of volume expansion of a silicon electrode material, and ensures the high energy density and reversible capacity of the material; (2) the electrode material is good in cycling stability and excellent in cycling rate performance, and can be produced on a large scale; and (3) the silicon-based material provides a new direction for the treatment of the solar waste silicon plate, and the whole process is free of acid pickling and environment-friendly.

Owner:无锡新锂耀辉能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com