A kind of intrinsically safe electrolyte for secondary lithium-sulfur battery and preparation method thereof

A lithium-sulfur battery and electrolyte technology, which is applied in the field of intrinsically safe electrolyte for secondary lithium-sulfur battery and its preparation, can solve the problem that the rate performance of high-viscosity battery of electrolyte cannot be exerted, and high-efficiency lithium metal deposition and dissolution cannot be realized. , low coulombic efficiency deposition and dendrite morphology, etc., to achieve the effect of improving safety performance and electrochemical performance, safety performance and electrochemical performance improvement, and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of the positive electrode of the lithium-sulfur secondary battery includes the following steps: uniformly dispersing the sulfur-containing material, the binder and the conductive agent in water in a mass ratio of 60-80:2-20:4-40, and then coating them on the collector On the fluid, the positive electrode of the lithium-sulfur secondary battery is obtained by pressing after drying.

[0051] The sulfur-containing material is elemental sulfur S 8 , Lithium polysulfide 2 S n (where 1≤n≤8), sulfur-based composites, organosulfur compounds or carbon-sulfur polymers (C 2 S x ) n (where x is 2-20, and n≥2); wherein the sulfur-based composite material is a mixture of elemental sulfur and polyacrylonitrile in a mass ratio of 4-16:1, heated to 250-400°C under nitrogen protection and kept for 1- 16 hours to get.

[0052] The molecular weight of the polyacrylonitrile is 10,000-1,000,000.

[0053] The conductive agent is acetylene black or conductive grap...

Embodiment 1

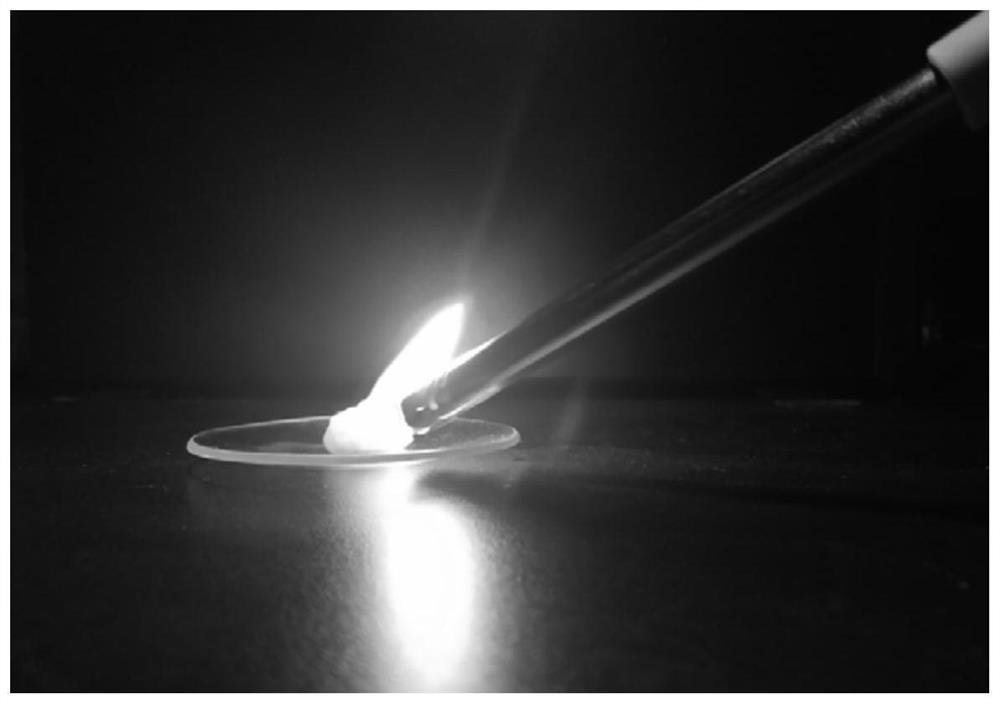

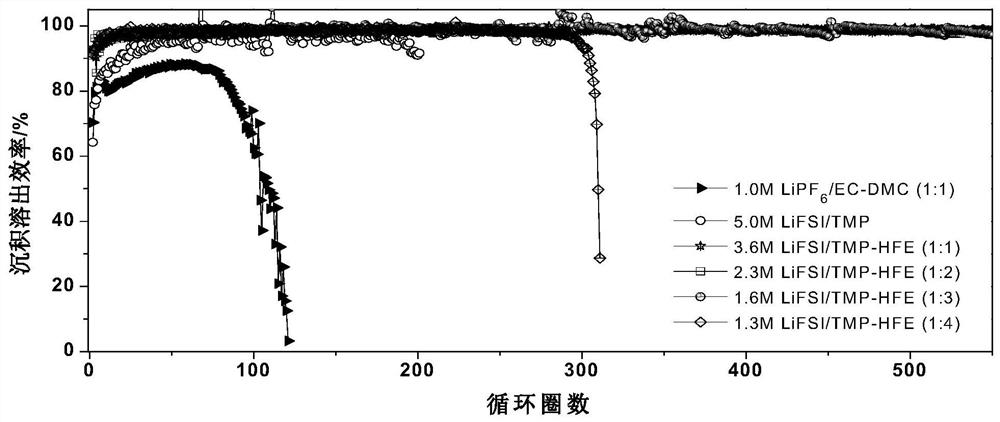

[0059] Mix trimethyl phosphate and hydrofluoroether HFE458 (1,1,2,2-tetrafluoroethyl-2,2,3,3-tetrafluoropropyl ether) uniformly in a glove box according to a certain volume ratio, stir well , the volume ratio of the two solvents is 1:4, so as to obtain a mixed solvent. figure 1 , the solvent does not burn on a flame.

Embodiment 2

[0061] In the glove box, uniformly mix triethyl phosphate and methyl nonafluorobutyl ether (MFE) according to a certain volume ratio, stir evenly, and the volume ratio of the two solvents is 1:0.5 to obtain a mixed solvent, into which LiODFB is added , dubbed 0.5M salt solution, the flame retardant properties are still maintained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com