Patents

Literature

32results about How to "Preserve intrinsic properties" patented technology

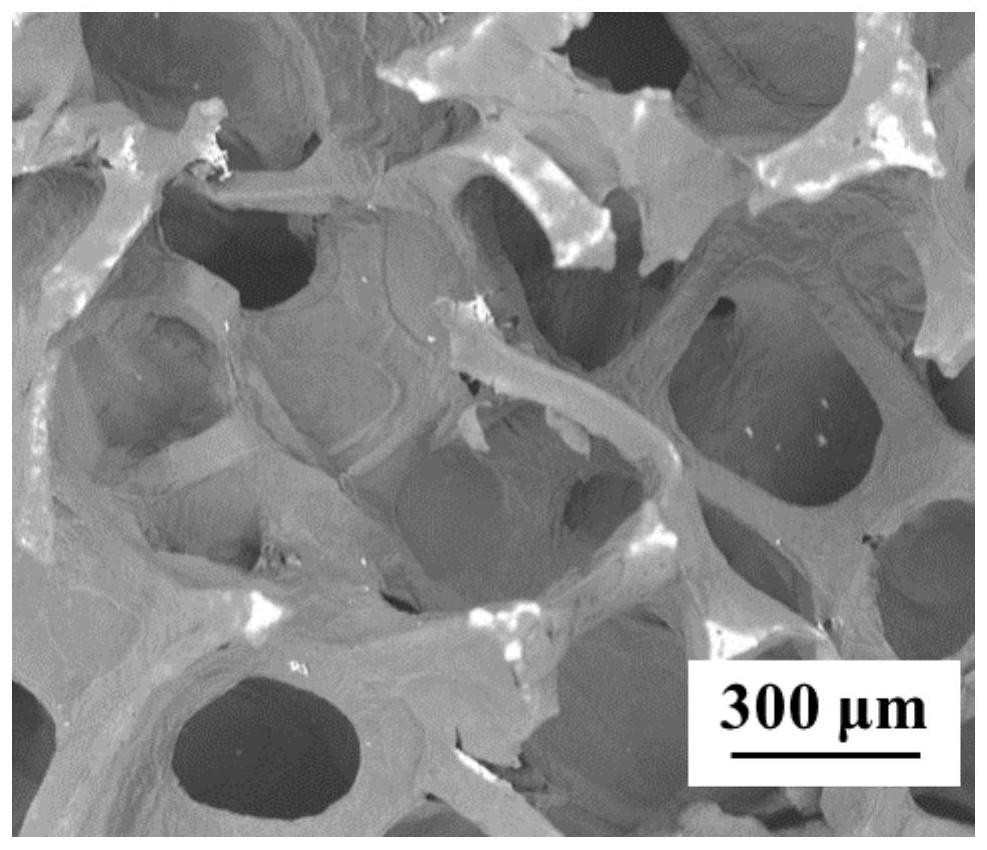

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

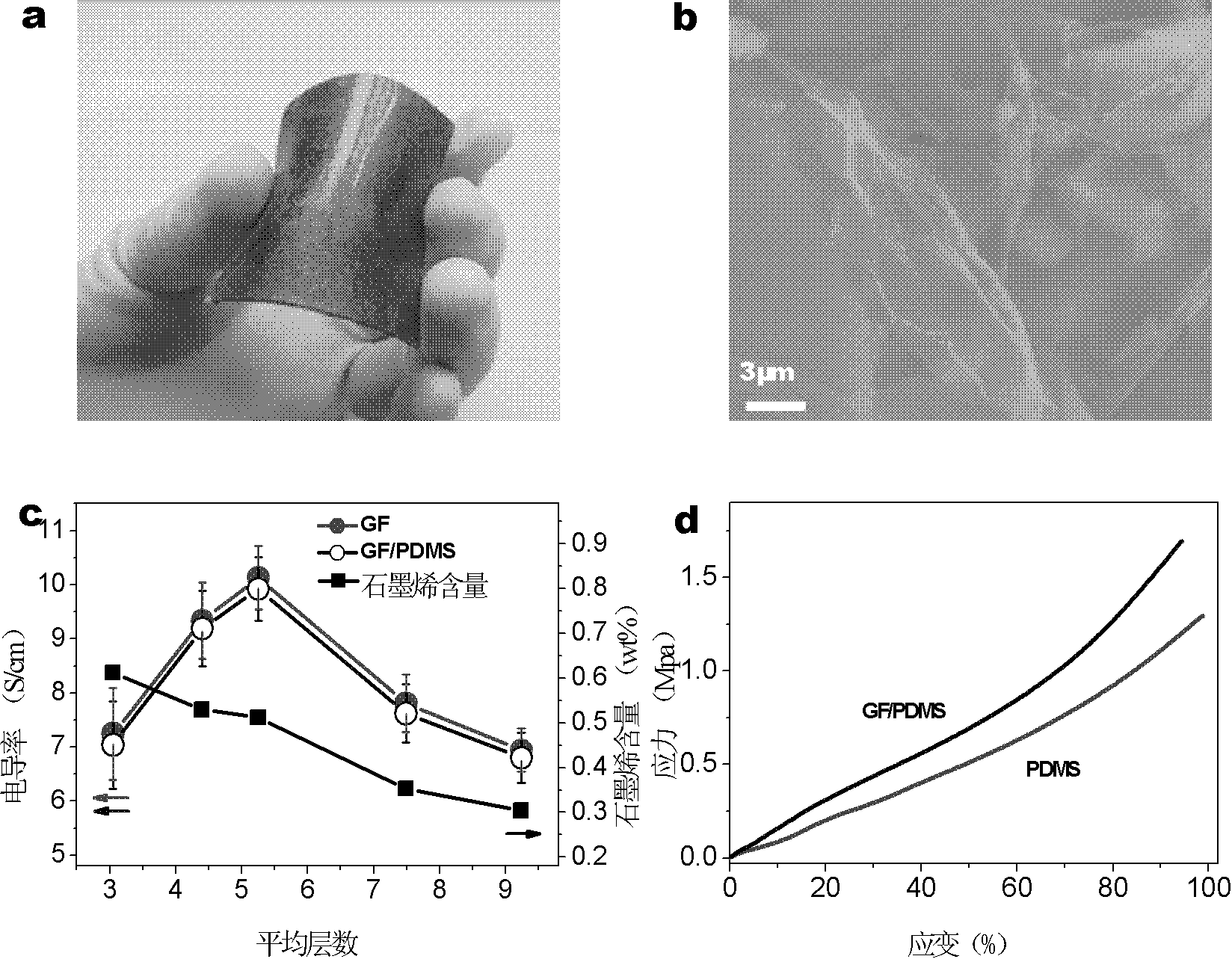

Graphene foam/polymer high-conductivity composite material preparation method and application thereof

ActiveCN102732037AImprove conductivityEasy to manufactureChemical vapor deposition coatingMaterials preparationGraphite

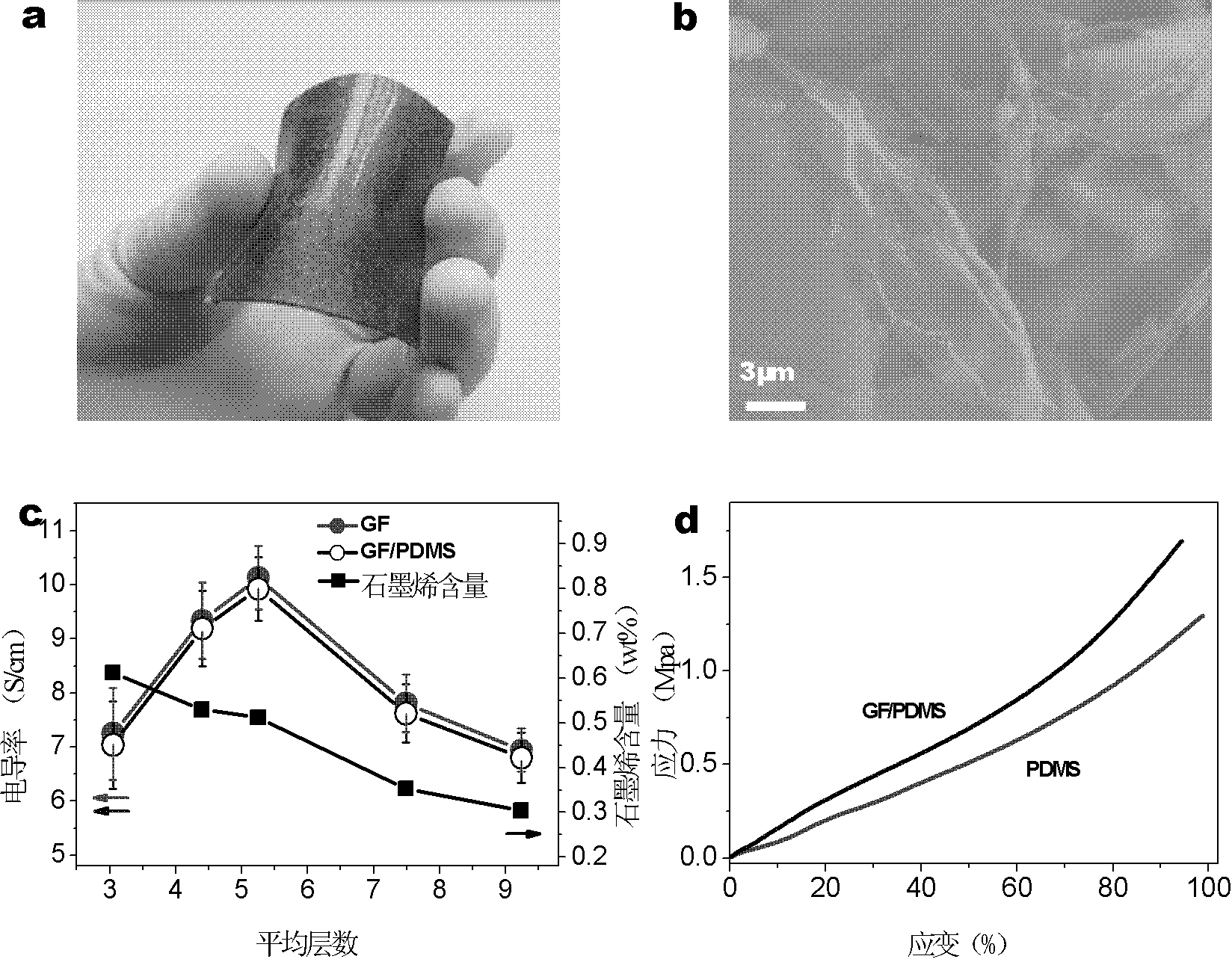

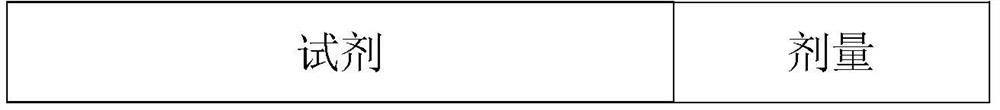

The invention relates to the graphene composite material field, and particularly to a graphene foam / polymer high-conductivity composite material, a preparation method and applications thereof. Steps of the method comprises as follows: providing a fully communicated three-dimension grapheme foam network and a precursor solution of a high-molecular polymer; mixing the graphene foam with the precursor solution of the high-molecular polymer to form a graphene foam / high-molecule polymer precursor mixture; and solidifying the precursor of the high-molecular polymer in the mixture to form a high-conductivity graphene foam composite material. The invention adopts the three-dimension graphene foam to form a fully- communicated graphite rapid transmission network by a seamless connection, which enables the graphene foam composite material to possess great conductivity and mechanical property and can be widely applied to the conductive composite materials and elasticity conductor field.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Oil tea seed cold pressing technique

InactiveCN104560371AImprove qualityExtended shelf lifeFatty-oils/fats refiningFatty-oils/fats productionActivated carbonCamellia oleifera

The invention relates to an oil tea seed cold pressing technique which comprises the following steps: selecting oil tea seed, drying, shelling, drying, crushing, carrying out cold pressing, filtering, hydrating, degumming, carrying out medium temperature drying, refrigerating to crystallize, and filling. The product quality is controlled from the raw material acquisition and raw material storage time, and the fresh seed fresh pressing and low-temperature low-pressure conditions are creatively used in the process, thereby ensuring the control on the raw oil acid number and no loss of nutrients to some extent, and enhancing the raw oil quality and the utilization value of the tea cake for byproduct deep processing. The refrigeration crystallization and activated carbon adsorption are utilized to remove the harmful substances in the oil, and the inherent characteristics and nutrients in the oil tea seed oil are effectively maintained, thereby greatly improving the oil quality. The inert gas charging process is adopted to enhance the preservation period and stability of the oil and avoid using additives, thereby ensuring to use the physical production method in the overall process.

Owner:HUNAN QIJIA OIL

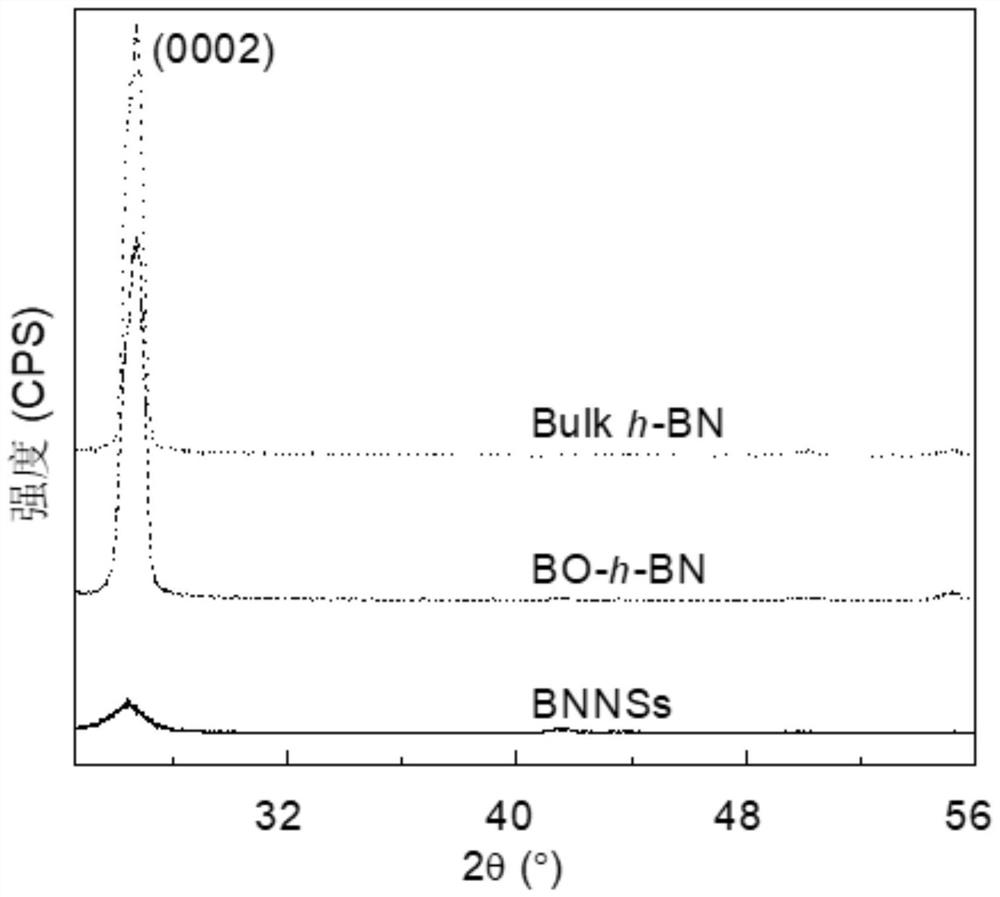

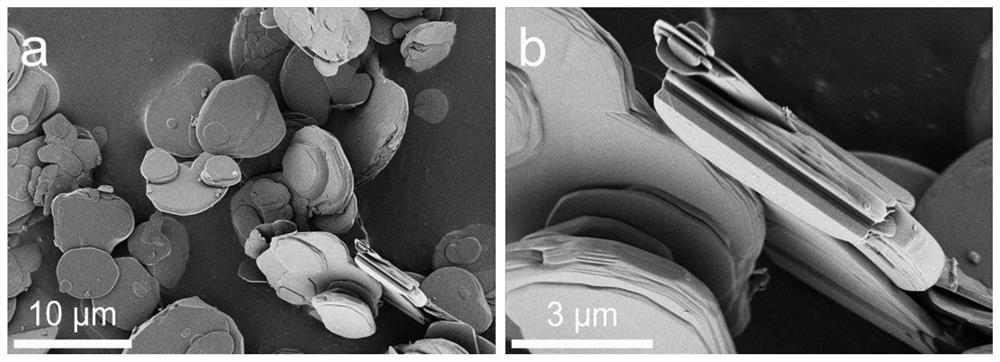

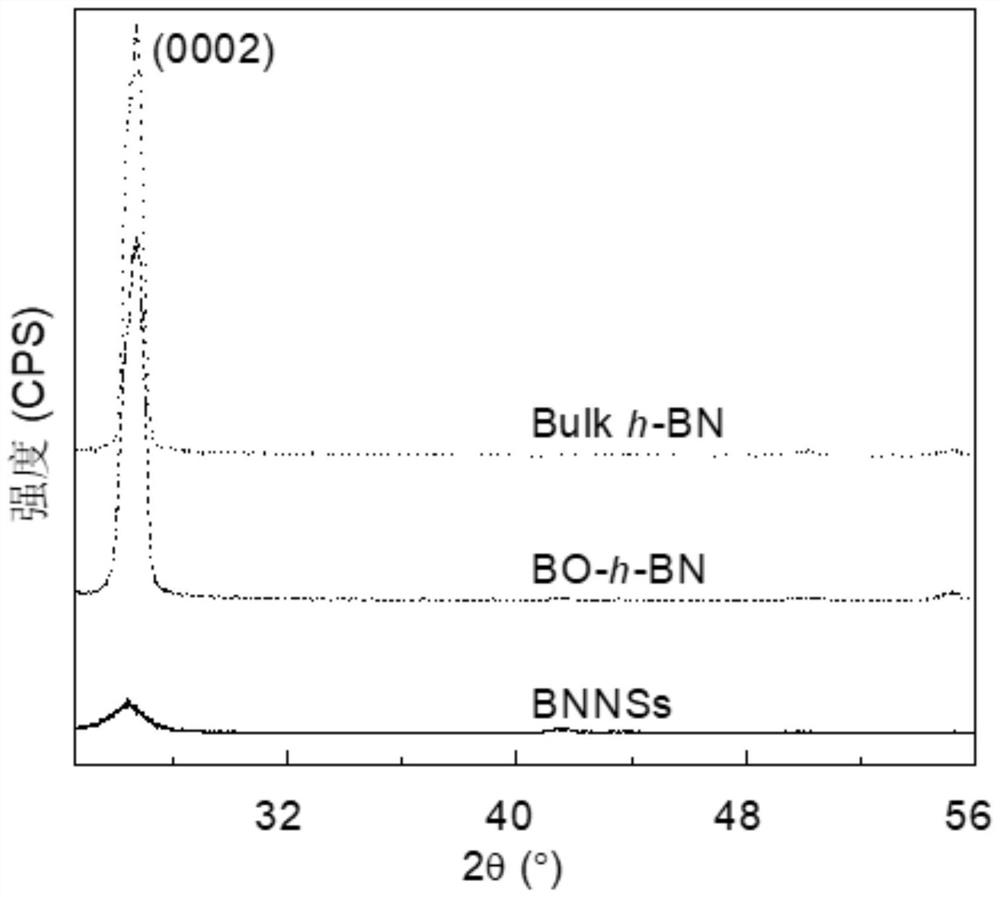

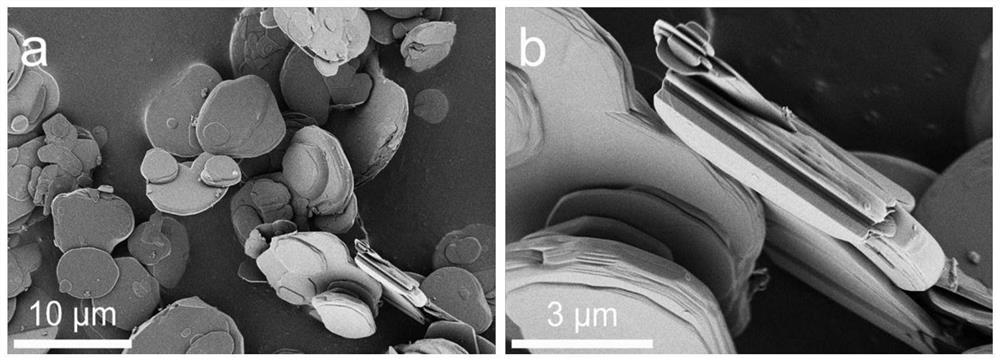

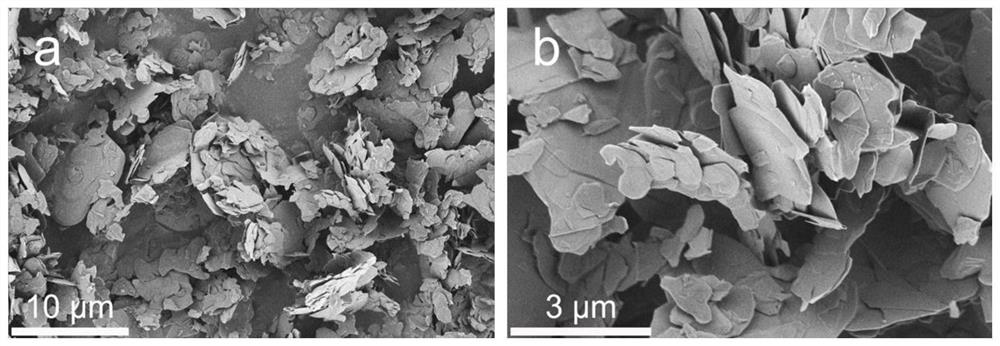

Mechanical stripping method of functionalized boron nitride nanosheet

ActiveCN111717900ADiffraction peak intensity of apparent crystal planeEfficient strippingNitrogen compoundsNanotechnologyLiquid productHexagonal boron nitride

The invention relates to a mechanical stripping method of a functionalized boron nitride nanosheet. The method adopts boric acid and commercial bulk hexagonal boron nitride as raw materials, and comprises the following three steps: uniformly mixing boric acid and commercial hexagonal boron nitride in a mortar, and carrying out high-temperature pretreatment to make the commercial bulk hexagonal boron nitride eroded by dehydrated boric acid and fixed by boron oxide in order to obtain a uniformly reacted solid mixture; roughly grinding the solid mixture obtained after the reaction, putting the ground solid mixture into a ball milling tank, and carrying out mechanical ball milling treatment; and dissolving and dispersing white powder obtained after ball milling into deionized water, and carrying out repeated washing multiple times to ensure that free boric acid is completely washed away so as to obtain a functionalized boron nitride nanosheet dispersion liquid product; or drying a productobtained by centrifugal washing to obtain a functionalized boron nitride nanosheet powder product. The method is simple to operate, harsh experimental conditions are not needed, boric acid and deionized water can be recycled, and the obtained products are high in crystallinity and functionalization degree.

Owner:HEBEI UNIV OF TECH

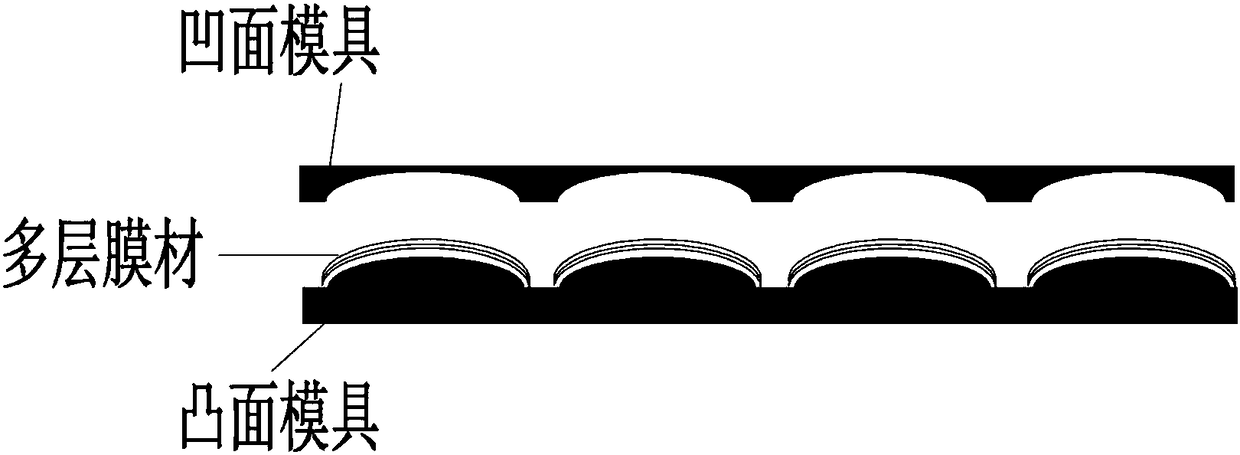

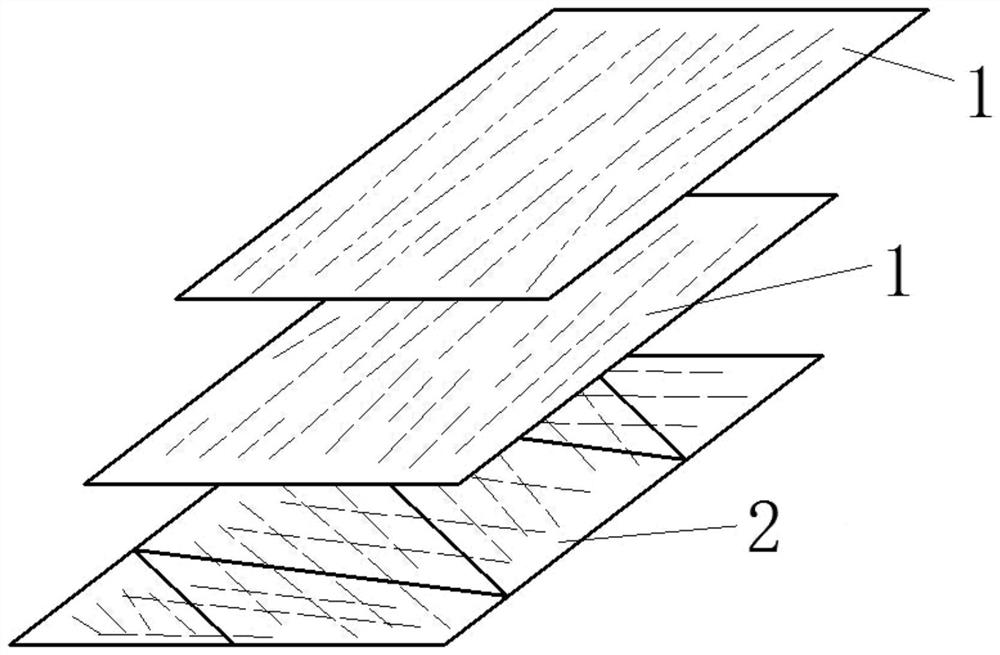

Novel composite biological tissue repairing material as well as preparation method and application thereof

PendingCN108210995APreserve intrinsic propertiesImprove tensile propertiesProsthesisSodium hyaluronateBiological tissue

The invention discloses a novel composite biological tissue repairing material which is made of multiple layers of amnia, wherein the amnia are bonded together through an adhesive; and the adhesive isa medicinal adhesive of carboxymethylcellulose, a collagen solution, sodium hyaluronate, chondroitin sulfate and alpha-cyanoacrylate. The invention further discloses a preparation method and application of the composite material. The composite material disclosed by the invention is excellent in mechanical property, high in stability and high in biocompatibility, is not rapidly degraded, can be applied to soft tissue defection repairing and tissue postoperative adhesion prevention, has the advantages of reducing risks of reducing wound infection and inflammation reactions, and has excellent clinical application prospects.

Owner:CHENGDU QINGSHAN LIKANG PHARMA CO LTD

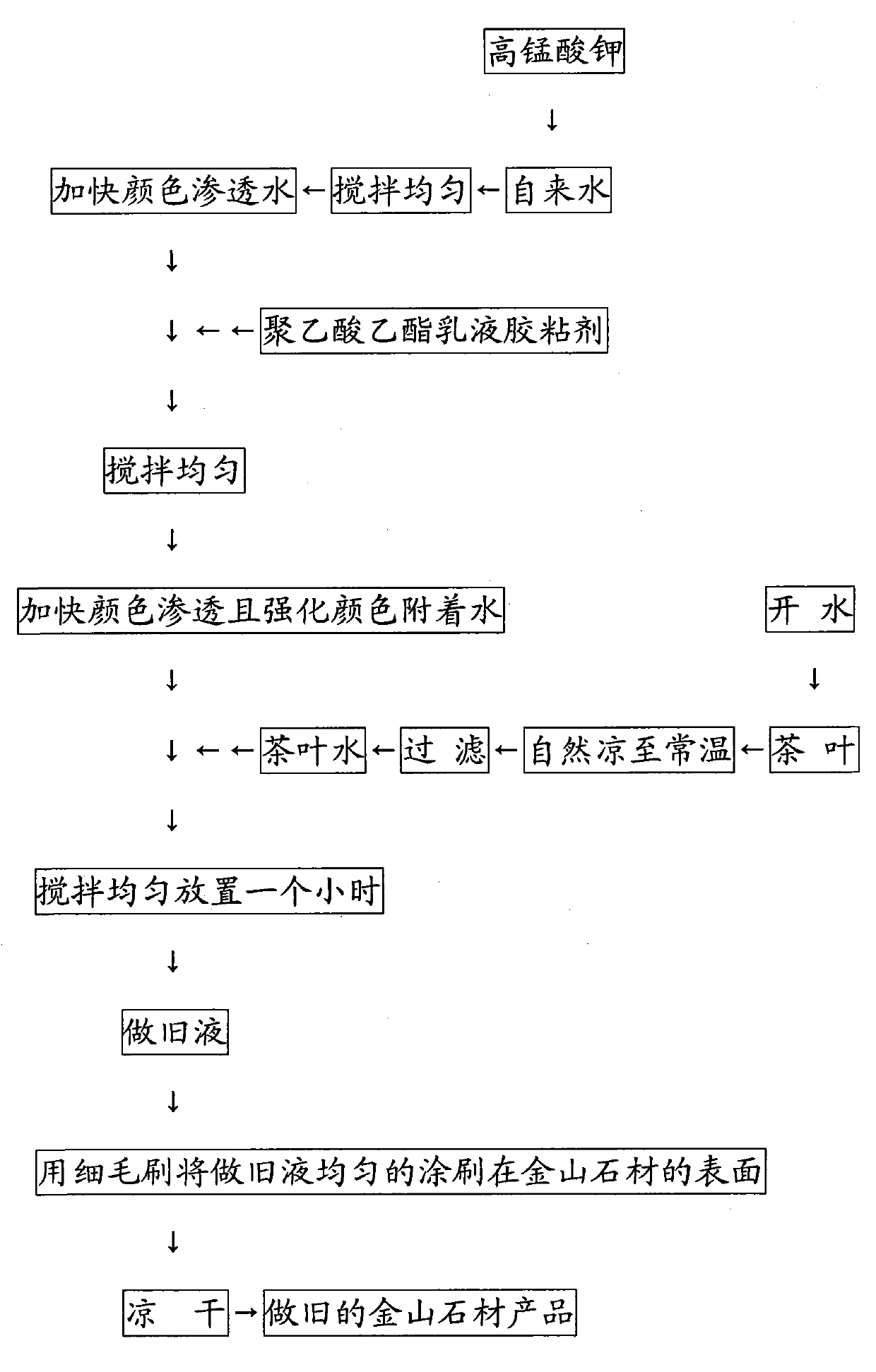

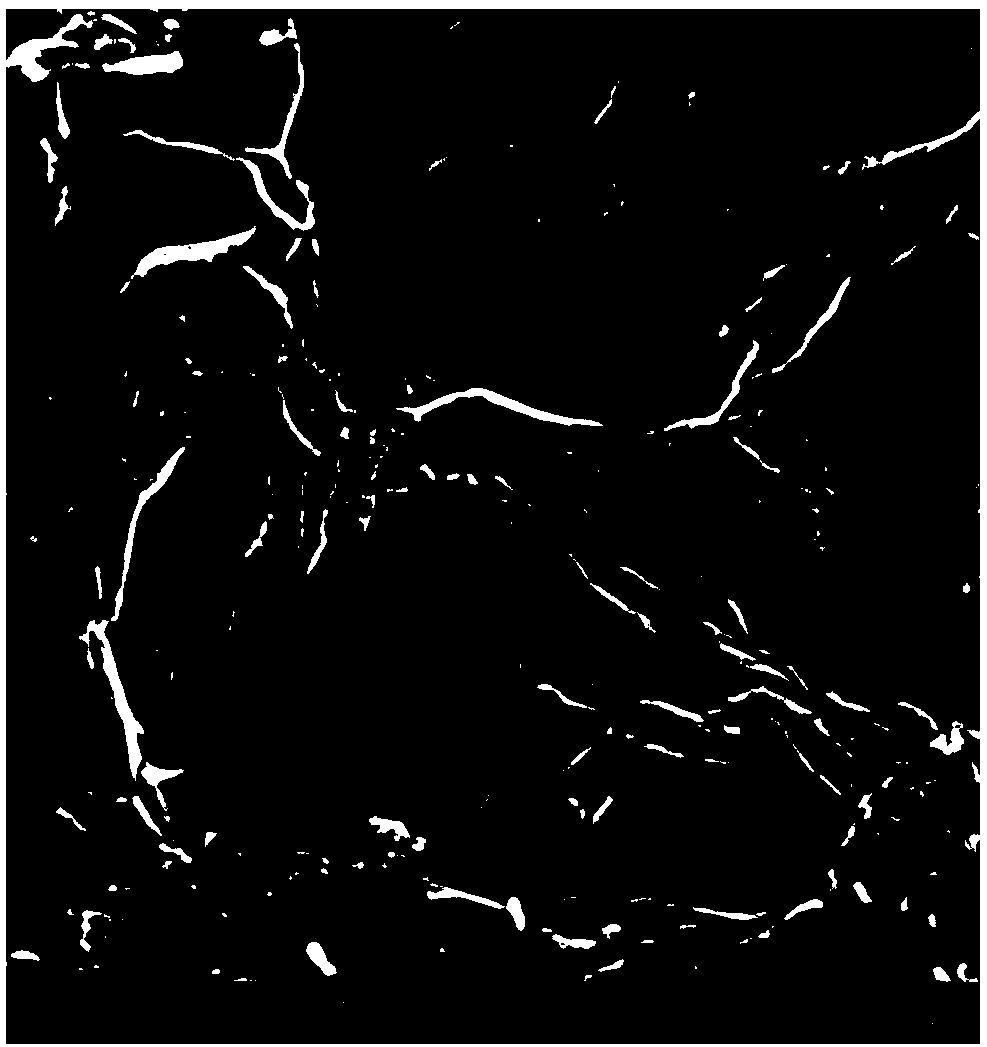

Old style forming method of Jinshan stone with decoration effect

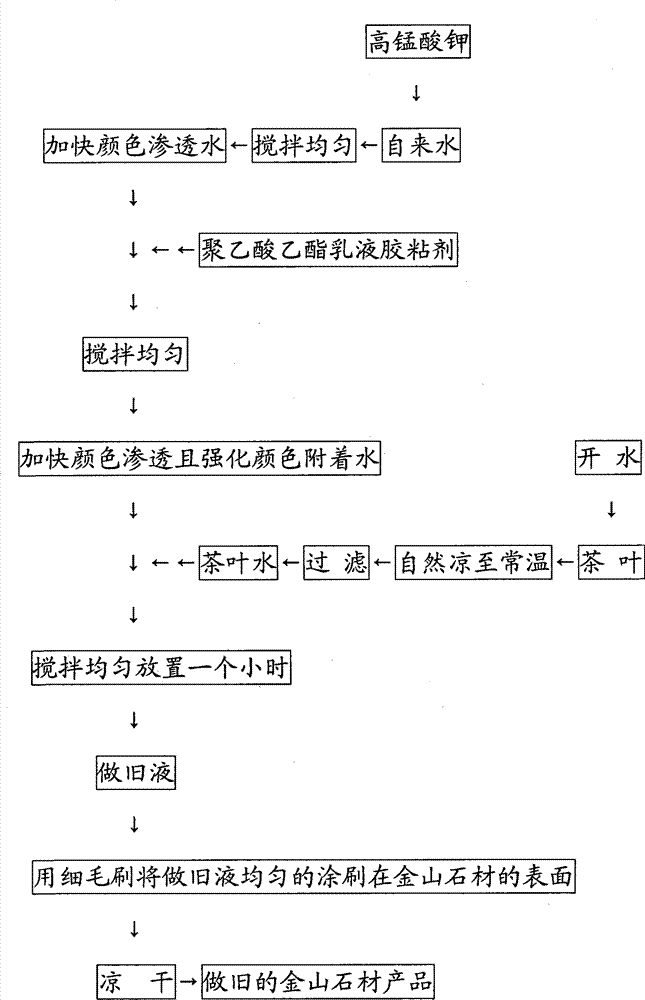

ActiveCN103387415ASimple and elegant decorative effectUnique and ingenious ideaEmulsionEthyl acetate

The invention relates to an old style forming method of Jinshan stone with a decoration effect, and relates to the technical field of building materials. According to the invention, a key technology of accelerating color penetration and strengthening color attachment is adopted, specifically, the method comprises the following steps of: brewing 100g of tea leaves by using 1L of boiled water, cooling to the room temperature, filtering by using gauze to obtain tea water for spare use; placing 5g of potassium permanganate in 25L of tap water, and uniformly stirring, thus obtaining a solution for accelerating color permeation for spare use; adding 250ML of poly ethyl acetate emulsion adhesive into the solution for accelerating color permeation, and uniformly stirring, thus obtaining a solution for accelerating color permeation and strengthening color attachment for spare use; adding the tea water into the solution for accelerating color permeation and strengthening color attachment, uniformly stirring, and placing for one hour, thus obtaining the old style forming liquid for spare use; painting the old style forming liquid on the surface of Jinshan stone by using a soft fur brush, cooling, and preparing an old-style Jinshan stone product. The Jinshan stone old style forming method is used for old forming decoration treatment on Jinshan stone, is simple, ingenious and practical, ensures that the product is plain and elegant, and ensures that the decoration effect is good.

Owner:GAUNGLIN SUZHOU CO LTD

Ordinary pressure intermittent sterilization method of production of wheat cultures of edible fungus

InactiveCN103314783APreserve intrinsic propertiesLess susceptible to pyrolysisHeatHorticultureBiotechnologyHigh pressure

The invention relates to an ordinary pressure intermittent sterilization method which can be used for achieving the complete sterilization effect in the production of wheat cultures of edible fungus. Compared with the high-pressure sterilization technology, the ordinary pressure intermittent sterilization method has the advantages that the inherent nature of the cultures is retained to enable vitamin to be affected by pyrolysis as less as possible and to reduce the nutrition effect decline of protein; the expensive high pressure equipment investment is omitted to obtain great application values, especially for small rural township enterprises.

Owner:邬金飞

Limonite purple-clay product and preparation method thereof

ActiveCN102060511APreserve intrinsic propertiesImprove breathabilityClaywaresTrace elementWork in process

The invention discloses a limonite purple-clay product, which consists of the following raw materials in percentage by weight: 30 to 50 percent of limonite, and 50 to 70 percent of purple-clay mud. The preparation method comprises the following steps: grinding the limonite and the purple clay mud into powder of between 80 and 120 meshes; mixing according to a proportion, adding water and stirringto prepare unfired pottery; sealing and packaging the unfired pottery, and aging for 10 to 15 days; preparing a blank of the required product, and drying in the shade indoors for 2 to 3 days; grinding and polishing the shady dried blank to prepare a semi-finished product; and firing the prepared semi-finished product in a kiln for 15 to 20 hours at the temperature of between 1,120 and 1,180 DEG C, and cooling to prepare the required product. In the invention, the limonite resource is sufficiently utilized, and waste is turned into wealth; and the fired limonite purple-clay product has light weight, high strength and no toxicity or radiation, the original characteristic and separated trace elements of the limonite have no changes, and the advantages of good ventilation and plasticity of the purple-clay are combined. The limonite purple-clay product can be manufactured into various nice new material tea sets, mugs and other products.

Owner:北方红杉生态科技有限公司

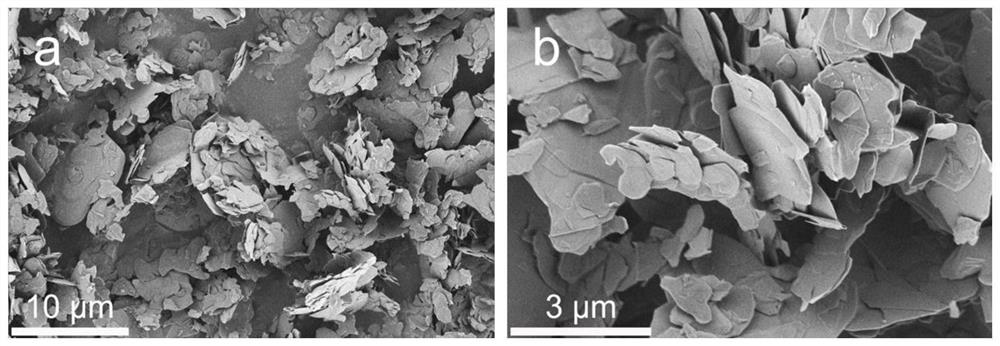

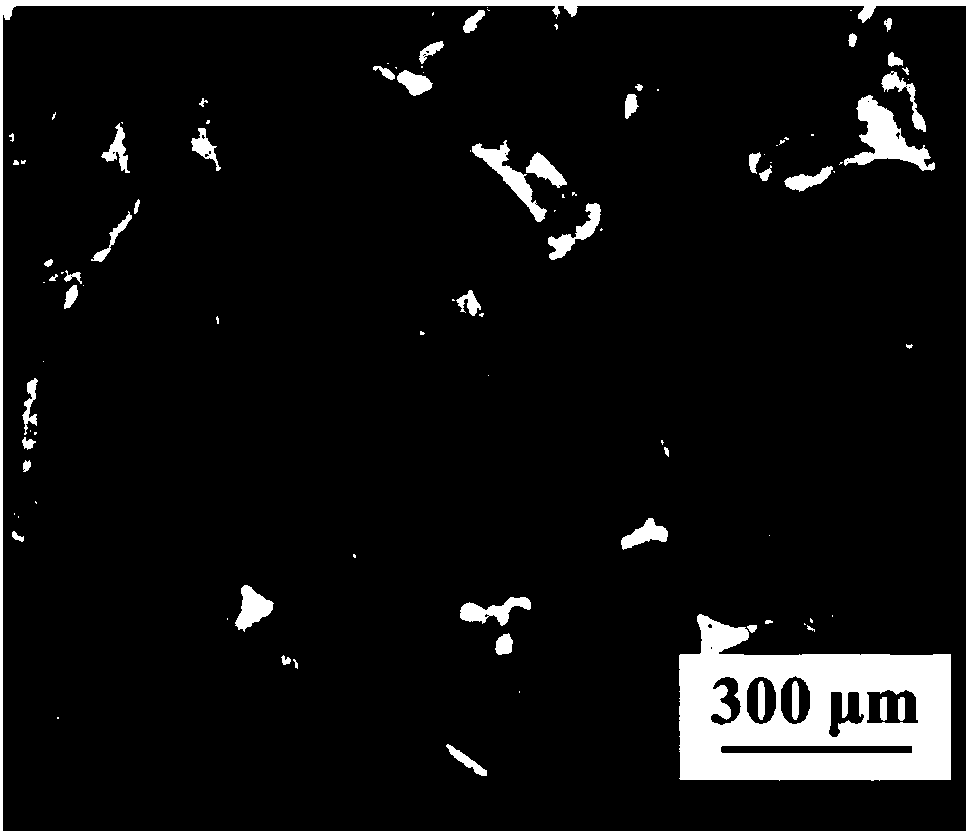

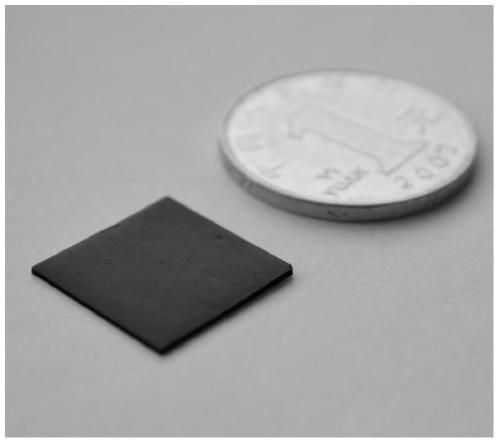

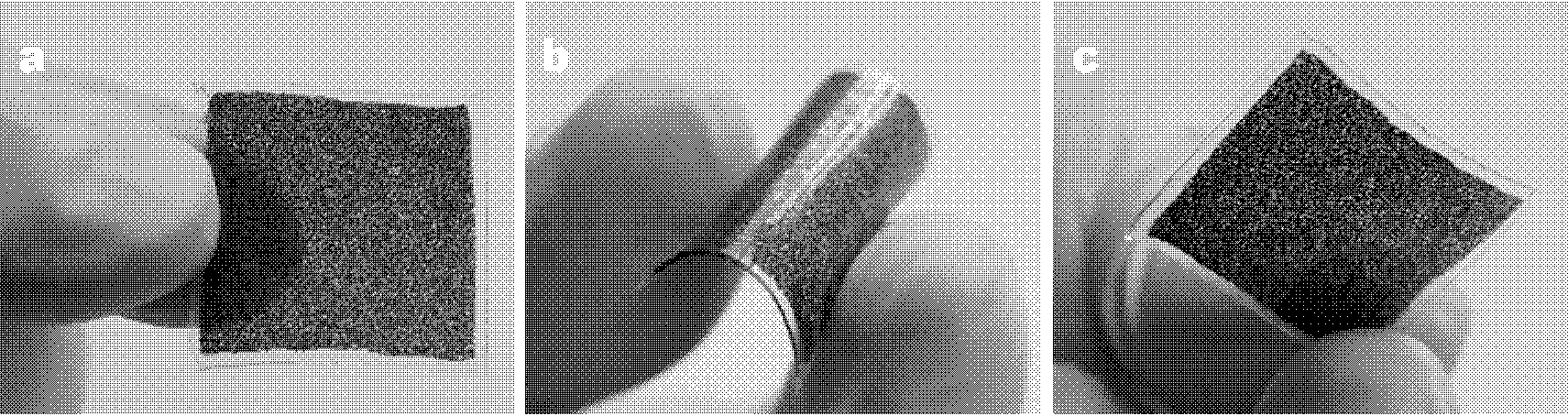

Preparation method of graphene/styrene-butadiene rubber composite with functional characteristic

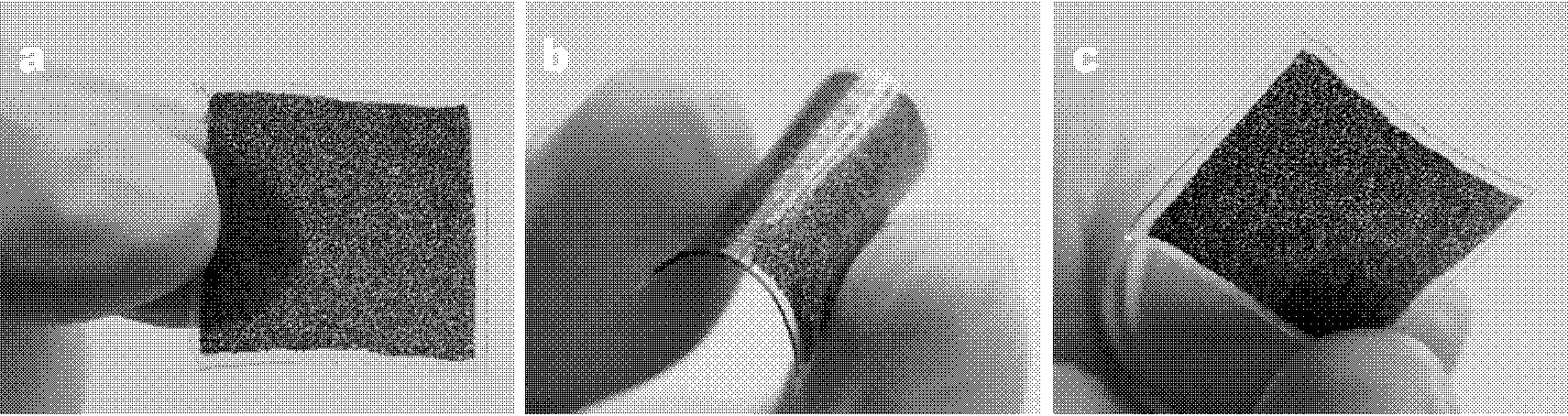

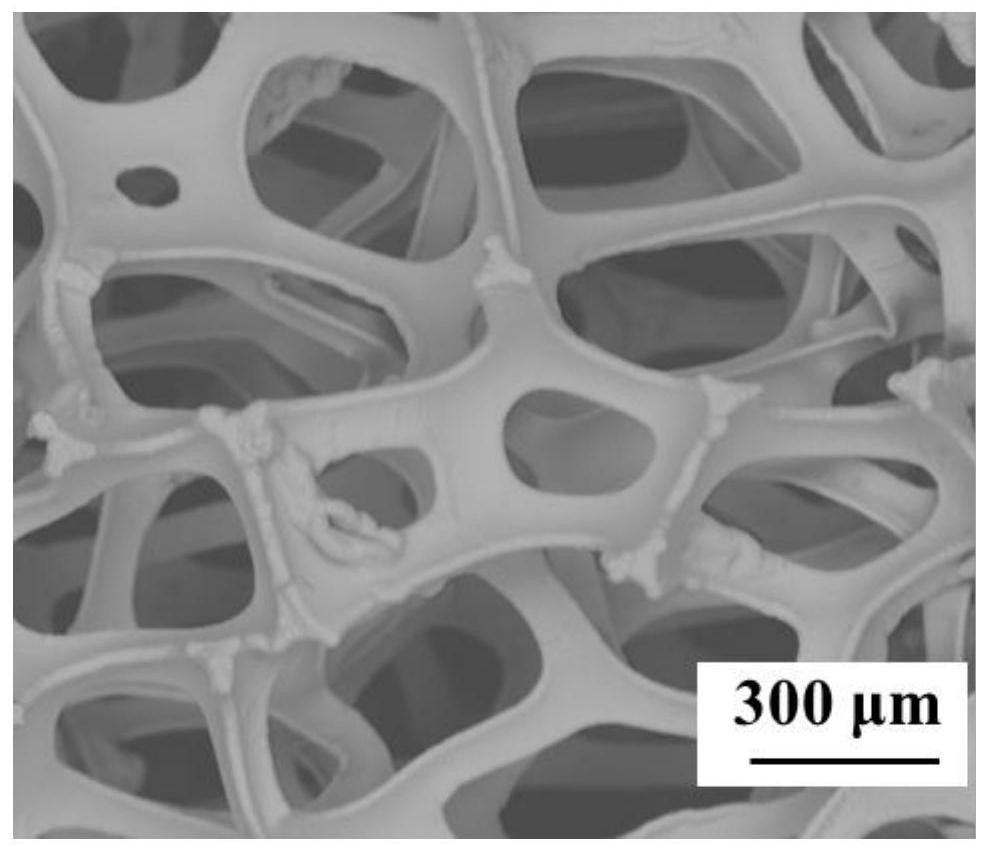

ActiveCN108192170AGood dispersionGood electrical conductivityRubber insulatorsCvd grapheneButadiene-styrene rubber

The invention relates to a preparation method of a graphene / styrene-butadiene rubber composite with a functional characteristic and aims at compounding directionally-arranged graphene nanosheets intostyrene-butadiene rubber so as to provide excellent conductivity, wear resistance and the like. The material provided by the invention is of a double-layer structure, one layer is a functional layer mainly formed by directional arrangement of the graphene nanosheets, and the other layer is an elastic insulation layer mainly made of the styrene-butadiene rubber. The preparation method comprises thesteps: (1) carrying out ultrasonic treatment on the graphene nanosheets in a polyvinylpyrrolidone (PVP) solution to obtain a graphene dispersion solution; (2) adding the graphene dispersion solutioninto styrene-butadiene latex to carry out ultrasonic treatment or mechanical stirring; and (3) pouring the mixed solution obtained in the step (2) into a die, and carrying out solidification at a certain temperature to obtain a final composite. The composite is low in graphene nanosheet addition amount, excellent in conductivity and wear resistance in a direction parallel to the directional arrangement direction of the graphene nanosheets, good in insulation property in a direction vertical to the arrangement direction of the graphene nanosheets, soft and foldable and can be used in the fieldsuch as electrostatic protection and electromagnetic wave shielding.

Owner:SICHUAN UNIV

Coating of polysilicon reduction furnace, preparation method of coating, polysilicon reduction furnace and uses of polysilicon reduction furnace

ActiveCN111334788AHigh bonding strengthReduce oxidation rateSiliconTransportation and packagingMetallurgyBonding strength

The invention provides a coating of a polysilicon reduction furnace, a preparation method of the coating, the polysilicon reduction furnace and uses of the polysilicon reduction furnace, and relates to the field of polysilicon technical equipment in production. The preparation method of the coating of the polysilicon reduction furnace comprises the steps of spraying first particles on the surface,in contact with materials, of the polysilicon reduction furnace by virtue of first cold gas dynamic spraying to form a base layer, and spraying second particles on the surface, away from the polysilicon reduction furnace, of the base layer by virtue of second cold gas dynamic spraying to form a surface layer. The speed of the first particles of the first cold gas dynamic spraying and the speed ofthe second particles of the second cold gas dynamic spraying are both supersonic speed, and the speed of the first particles is greater than the speed of the second particles. The base layer and thesurface layer are suitable for reflecting infrared radiation. The spraying speed of the first particles forming the base layer is higher, so that the bonding strength of the base layer and the surfaceof the polysilicon reduction furnace is higher. The spraying speed of the second particles forming the surface layer is lower so as to facilitate the reduction of the spraying cost of the coating.

Owner:ASIA SILICON QINGHAI +1

Activation method of high-capacity lithium ion battery negative electrode material

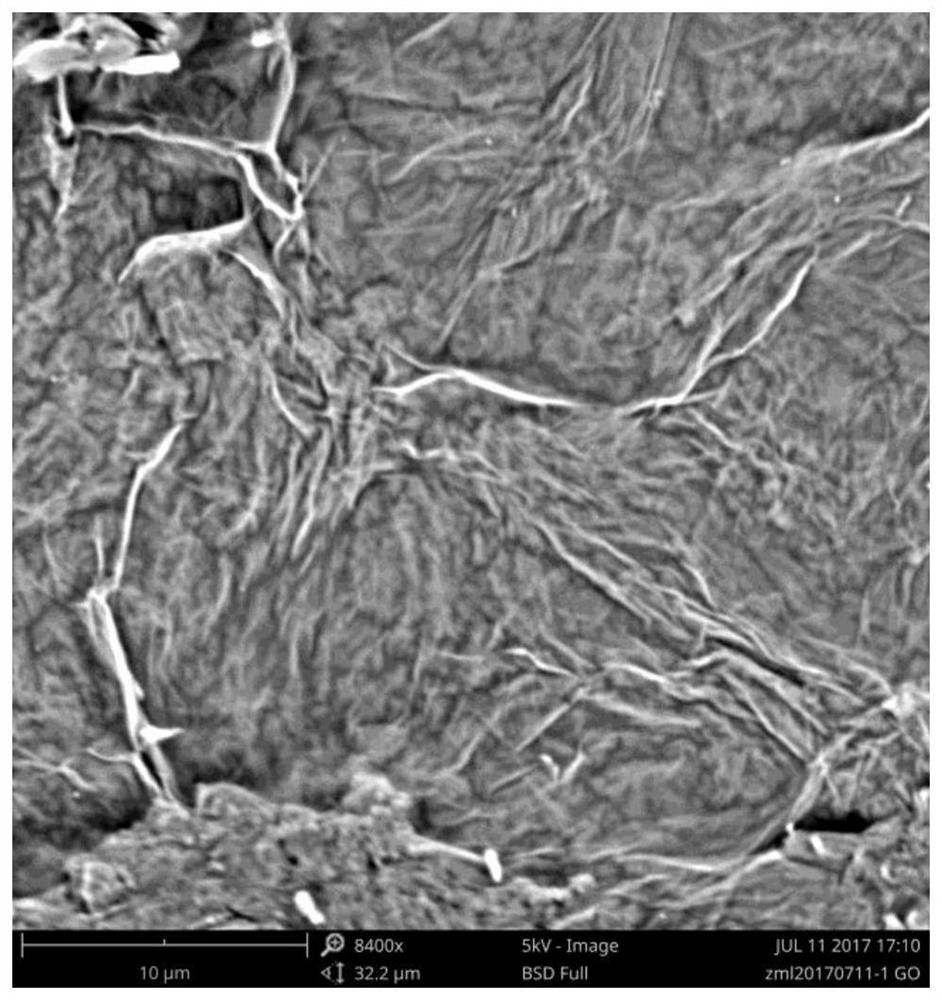

ActiveCN108063252APreserve intrinsic propertiesEvenly distributedCell electrodesSecondary cellsActivation methodCycle rate

The invention provides an activation method of a high-capacity lithium ion battery negative electrode material. The activation method comprises the following steps of 1) performing film formation on agraphene oxide aqueous solution in a porous template by a drop-coating method, and allowing to stand; 2) spraying the graphene oxide aqueous solution onto the dried three-dimensional graphene oxide / template attachment material, and drying for use; 3) impregnating the material in an aqueous solution dissolved with an activation agent, and allowing to stand after ultrasonic processing; and 4) placing the product in a tubular furnace for oxygen-free sintering after drying, cooling the sintered product to a room temperature, washing the product with deionized water until washing water is neutral,and drying, thereby obtaining the activated graphene / template negative electrode material. By the activation method, the inherent characteristic of a two-dimensional graphene sheet is maintained, meanwhile, graphene and the porous template are more uniformly distributed, the active sites of graphene phase-template phase-electrolyte phase catalytic reaction are remarkably improved, and the power density and the cycle rate performance are remarkably improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY CO LTD CO LTD

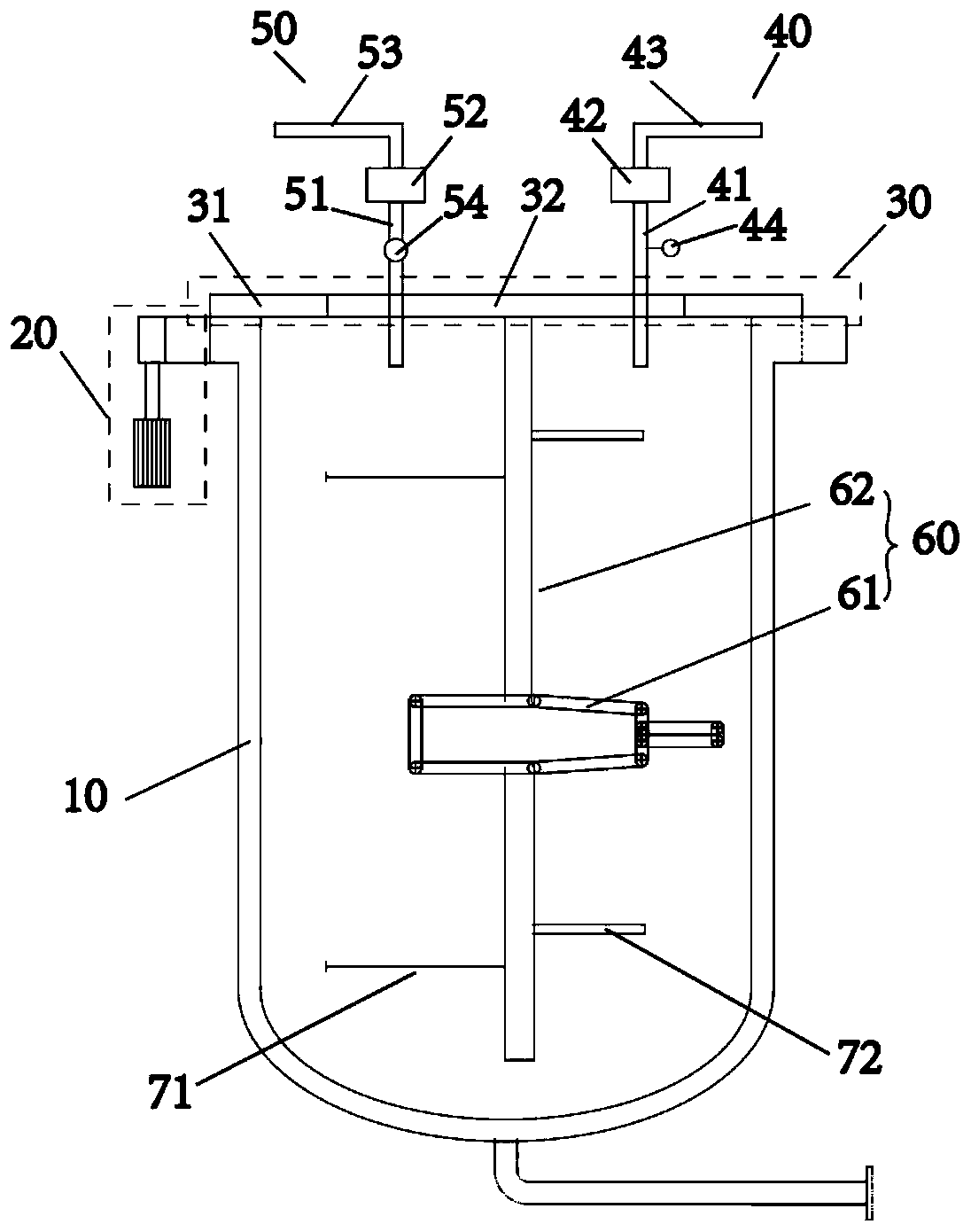

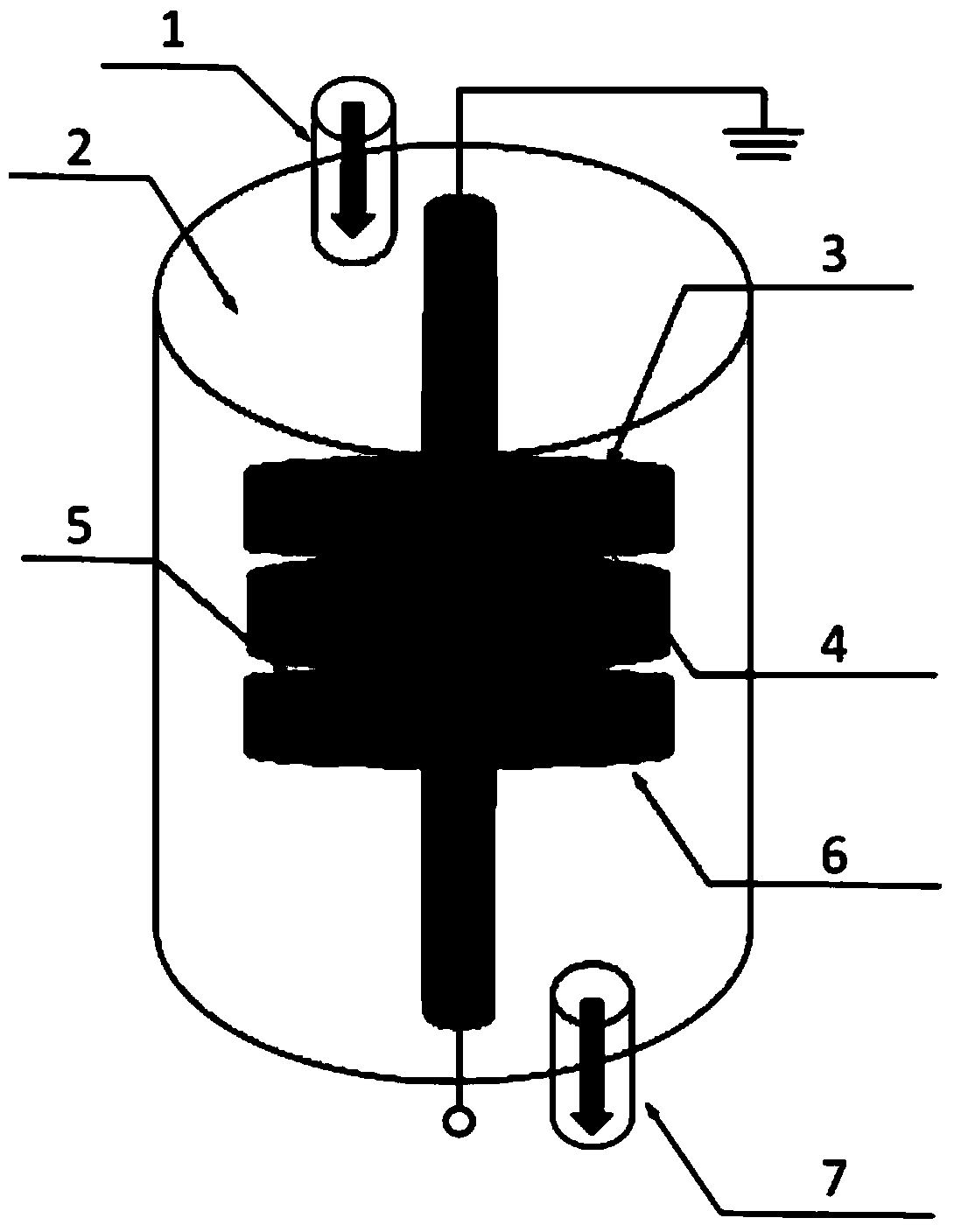

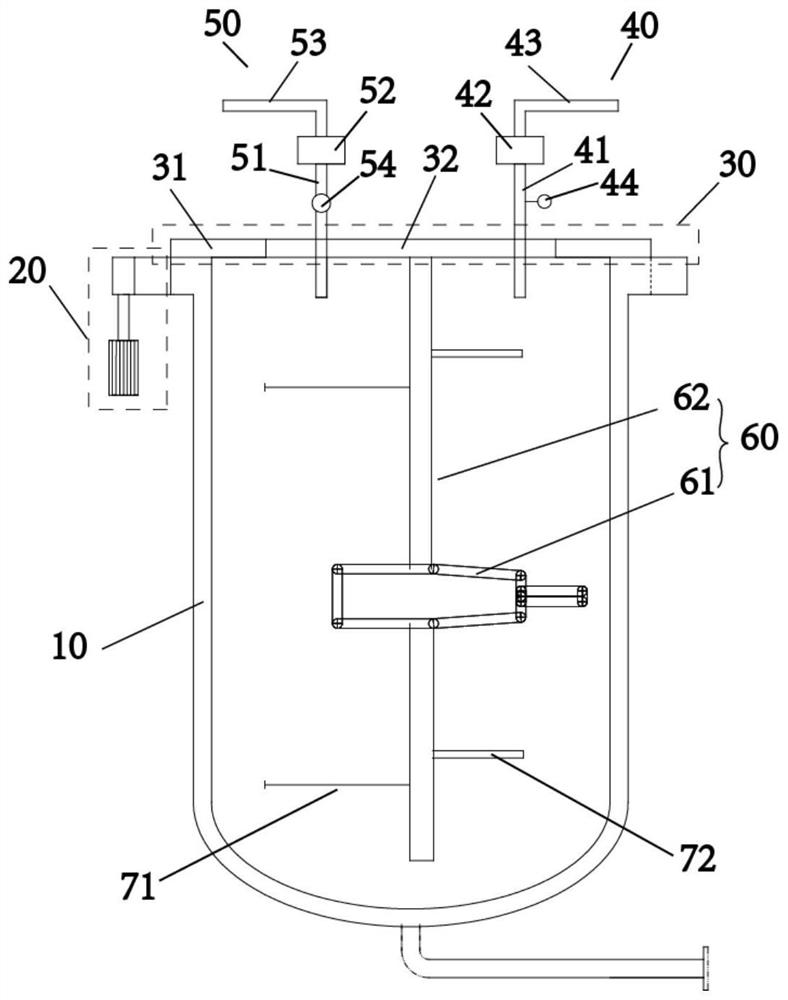

Reduction furnace bell jar inner wall spraying device and spraying method and reduction furnace

ActiveCN111468344APreserve intrinsic propertiesPrevent oxidationSpraying apparatusPretreated surfacesPumping vacuumPolycrystalline silicon

The invention provides a reduction furnace bell jar inner wall spraying device and spraying method and a reduction furnace, and relates to the technical field of polycrystalline silicon equipment. Thespraying device comprises a bell jar, a rotating part, a sealing part, a vacuumizing part, an exhaust part and a cold gas power spraying part; and after a closed space is formed in the bell jar through a sealing part, the interior of the bell jar is in a high-temperature protective gas atmosphere through the vacuumizing part, the cold gas power spraying part and the exhaust part, then the cold gas power spraying part is adopted to spray powder to the inner wall of the bell jar to form a coating on the inner wall of the bell jar, the interior of the bell jar is in the high-temperature protective gas atmosphere before spraying, oxidation of the coating in the spraying process can be avoided, and the intrinsic performance of a coating material can be reserved to the maximum extent; and meanwhile, the inner wall of the bell jar is preheated by using high-temperature protective gas, so that the coating with high bonding strength is obtained under a relatively low spraying condition. The invention further provides the reduction furnace bell jar inner wall spraying method.

Owner:ASIA SILICON QINGHAI +1

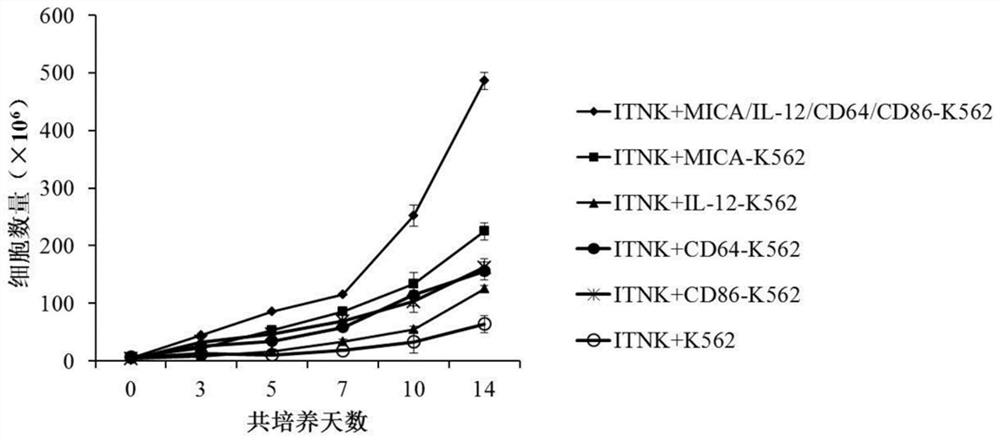

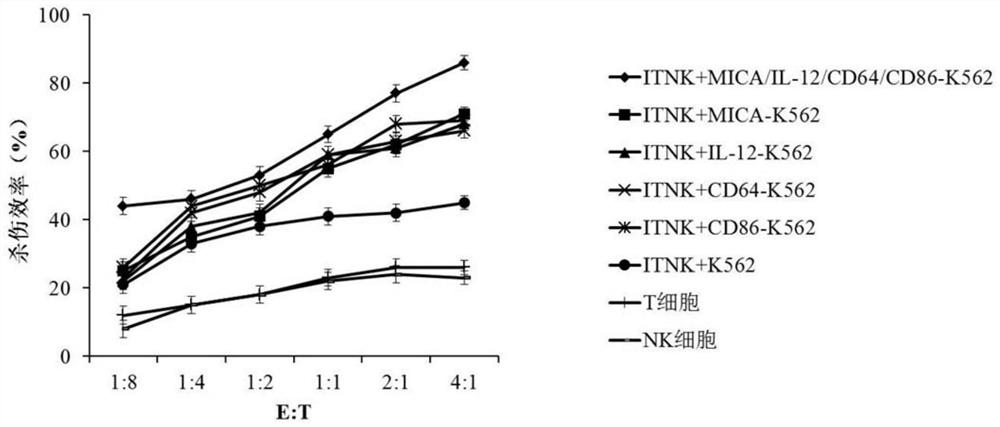

Engineered cell for activating NK-like cell, and preparation method and application of engineered cell

PendingCN112626028AImprove proliferative abilityImprove tumor killing abilityMicroorganism based processesMammal material medical ingredientsCD86Cell Membrane Proteins

The invention provides an engineered cell for activating a NK-like cell, and a preparation method and application of the engineered cell. The engineered cell is a mammalian cell for expressing membrane proteins MICA, IL-21, CD64 and CD86. The engineered cell disclosed by the invention expresses and activates the membrane protein of the NK-like cell; the amplification capacity of the NK-like cell and the toxicity of tumour cells are improved; and a strategy for standardizing in-vitro amplification of the NK-like cell is provided.

Owner:广东昭泰细胞生物科技有限公司

Limonite purple-clay product and preparation method thereof

ActiveCN102060511BPreserve intrinsic propertiesImprove breathabilityClaywaresPhysical chemistryMaterials science

The invention discloses a limonite purple-clay product, which consists of the following raw materials in percentage by weight: 30 to 50 percent of limonite, and 50 to 70 percent of purple-clay mud. The preparation method comprises the following steps: grinding the limonite and the purple clay mud into powder of between 80 and 120 meshes; mixing according to a proportion, adding water and stirringto prepare unfired pottery; sealing and packaging the unfired pottery, and aging for 10 to 15 days; preparing a blank of the required product, and drying in the shade indoors for 2 to 3 days; grinding and polishing the shady dried blank to prepare a semi-finished product; and firing the prepared semi-finished product in a kiln for 15 to 20 hours at the temperature of between 1,120 and 1,180 DEG C, and cooling to prepare the required product. In the invention, the limonite resource is sufficiently utilized, and waste is turned into wealth; and the fired limonite purple-clay product has light weight, high strength and no toxicity or radiation, the original characteristic and separated trace elements of the limonite have no changes, and the advantages of good ventilation and plasticity of the purple-clay are combined. The limonite purple-clay product can be manufactured into various nice new material tea sets, mugs and other products.

Owner:北方红杉生态科技有限公司

A kind of activation method of high-capacity lithium-ion battery negative electrode material

ActiveCN108063252BPreserve intrinsic propertiesEvenly distributedCell electrodesGrapheneElectrolytic agentTube furnace

The invention provides an activation method of a high-capacity lithium ion battery negative electrode material. The activation method comprises the following steps of 1) performing film formation on agraphene oxide aqueous solution in a porous template by a drop-coating method, and allowing to stand; 2) spraying the graphene oxide aqueous solution onto the dried three-dimensional graphene oxide / template attachment material, and drying for use; 3) impregnating the material in an aqueous solution dissolved with an activation agent, and allowing to stand after ultrasonic processing; and 4) placing the product in a tubular furnace for oxygen-free sintering after drying, cooling the sintered product to a room temperature, washing the product with deionized water until washing water is neutral,and drying, thereby obtaining the activated graphene / template negative electrode material. By the activation method, the inherent characteristic of a two-dimensional graphene sheet is maintained, meanwhile, graphene and the porous template are more uniformly distributed, the active sites of graphene phase-template phase-electrolyte phase catalytic reaction are remarkably improved, and the power density and the cycle rate performance are remarkably improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY CO LTD CO LTD

Old style forming method of Jinshan stone with decoration effect

The invention relates to an old style forming method of Jinshan stone with a decoration effect, and relates to the technical field of building materials. According to the invention, a key technology of accelerating color penetration and strengthening color attachment is adopted, specifically, the method comprises the following steps of: brewing 100g of tea leaves by using 1L of boiled water, cooling to the room temperature, filtering by using gauze to obtain tea water for spare use; placing 5g of potassium permanganate in 25L of tap water, and uniformly stirring, thus obtaining a solution for accelerating color permeation for spare use; adding 250ML of poly ethyl acetate emulsion adhesive into the solution for accelerating color permeation, and uniformly stirring, thus obtaining a solution for accelerating color permeation and strengthening color attachment for spare use; adding the tea water into the solution for accelerating color permeation and strengthening color attachment, uniformly stirring, and placing for one hour, thus obtaining the old style forming liquid for spare use; painting the old style forming liquid on the surface of Jinshan stone by using a soft fur brush, cooling, and preparing an old-style Jinshan stone product. The Jinshan stone old style forming method is used for old forming decoration treatment on Jinshan stone, is simple, ingenious and practical, ensures that the product is plain and elegant, and ensures that the decoration effect is good.

Owner:GAUNGLIN SUZHOU CO LTD

Light flexible graphene/polymer foam electromagnetic shielding material, preparation method and application thereof

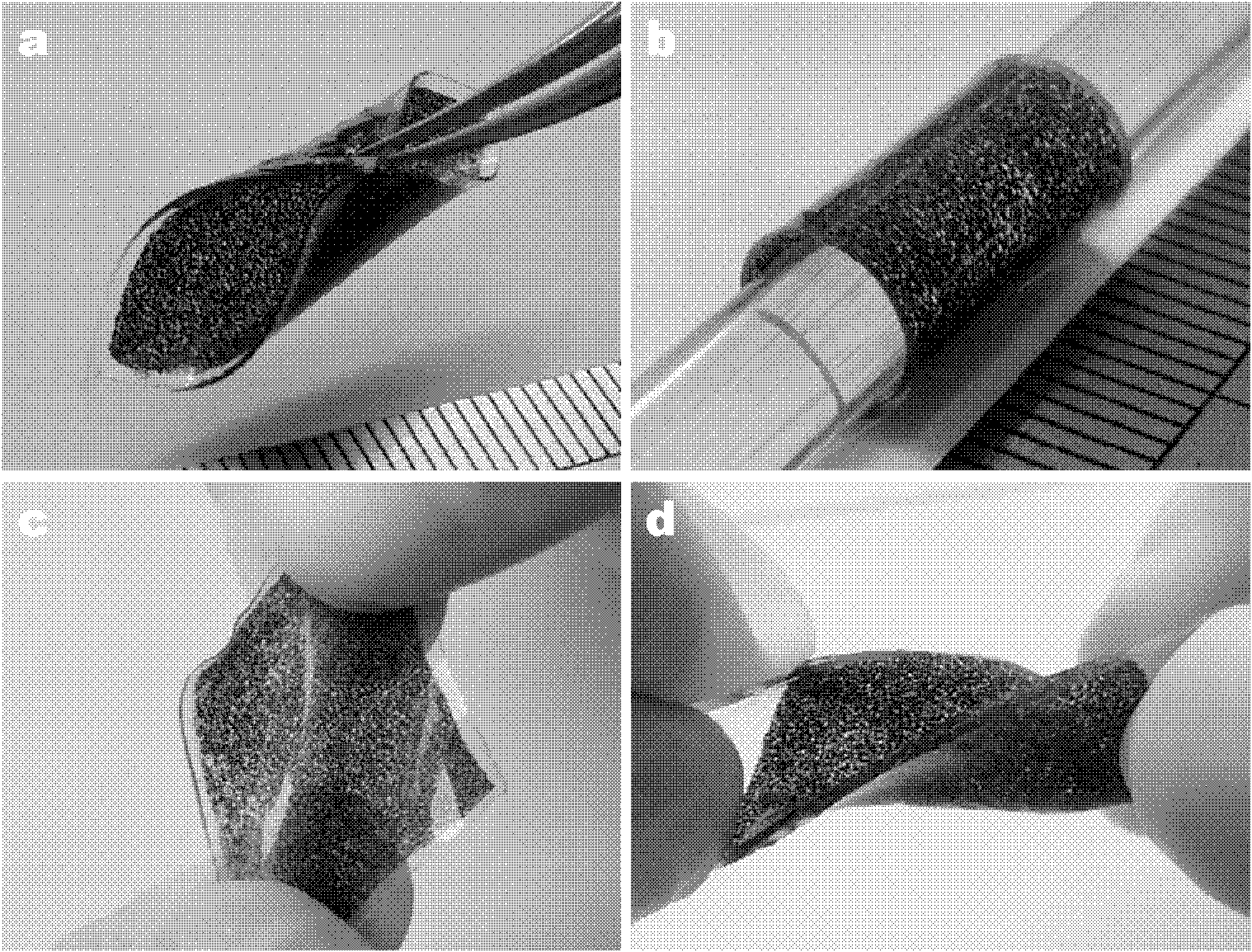

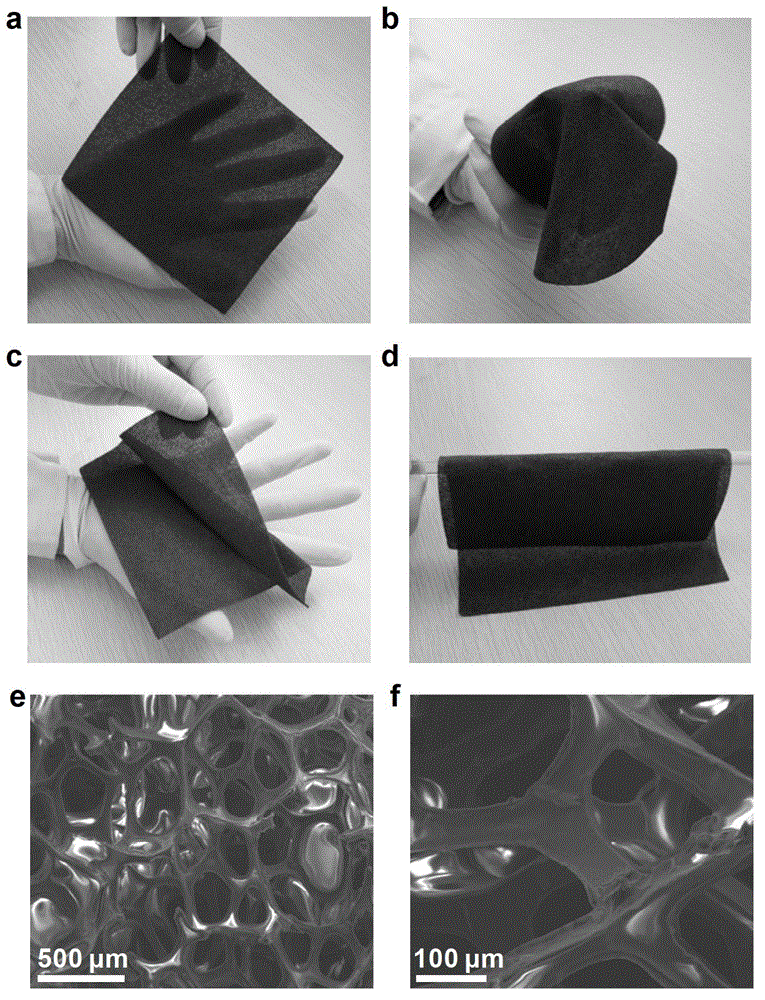

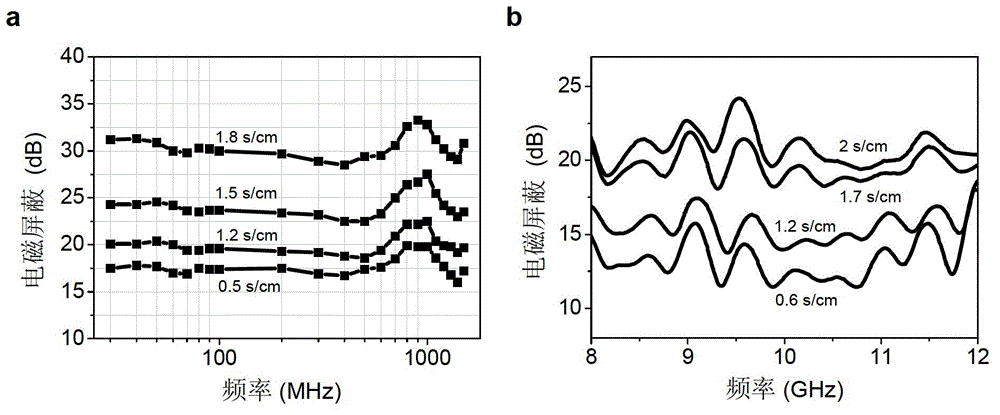

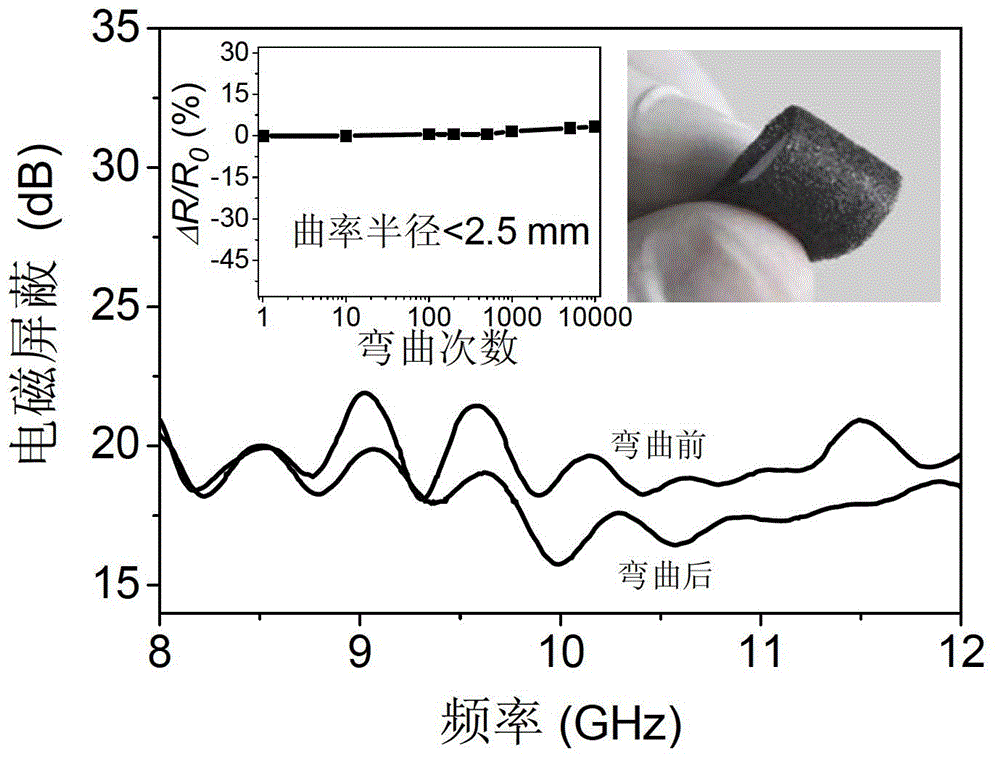

ActiveCN103030974BEasy to manufacturePreserve intrinsic propertiesElectromagnetic shieldingCvd graphene

The invention relates to the field of graphene-based foam composites, in particular to a light flexible graphene / polymer foam electromagnetic shielding material, and a preparation method and an application thereof. The preparation method comprises the steps that three-dimensional full-communicated metal foam grown with graphene and a high molecular polymer precursor are adopted; a graphene / metal foam complex is mixed with the high molecular polymer precursor to ensure that the surface of the graphene / metal foam complex is coated with a layer of high molecular polymer precursor; the high molecular polymer precursor in a mixture is cured and then dissolved to remove a porous metal base; and then the light flexible graphene / polymer foam electromagnetic shielding material is obtained. The graphene / polymer foam composite has very low density and good flexibility, and graphene in the graphene / polymer foam composite forms a full-communicated network in a seamless connection manner, so that the composite has excellent conductivity and electromagnetic shielding property, and can be widely applied to the fields of aerospaces, portable electronic devices and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

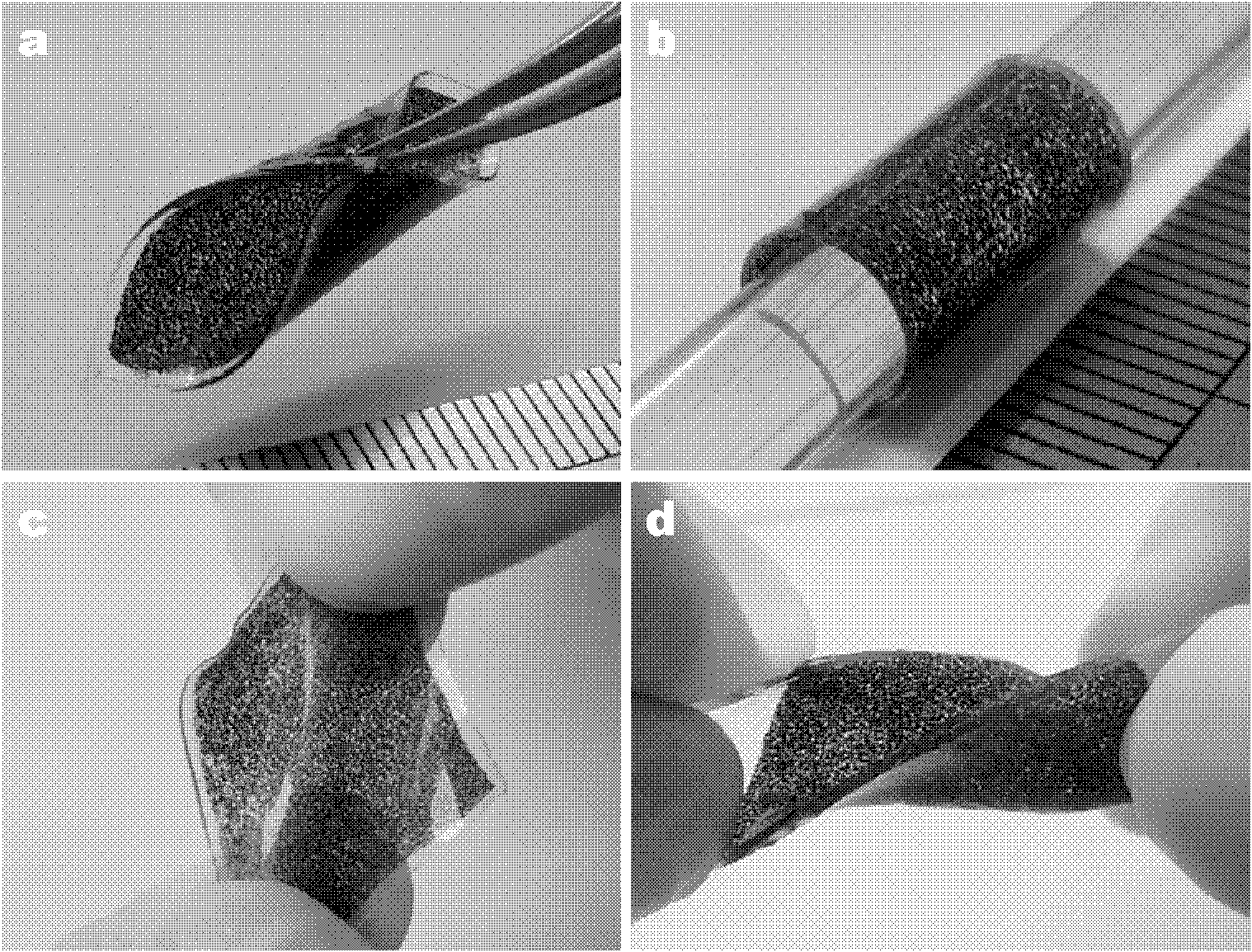

A method for preparing vertical arrays of carbon nanotubes covered with flexible thin layers of carbon

ActiveCN107572504BSolve preparation difficultiesImprove thermal conductivityCarbon nanotubesPlasma depositionChemical vapor deposition

The invention specifically relates to a preparation method for a flexible vertically-aligned carbon nanotube array covered with thin-layer carbon, belonging to the field of preparation of flexible vertically-aligned carbon nanotube arrays. The preparation method comprises the following steps: depositing a thin layer of carbon on the surface of a substrate through plasma deposition; then growing carbon nanotubes by using a plasma-enhanced chemical vapor deposition method so as to obtain a composite structure of a vertically-aligned carbon nanotube array covered with the thin-layer carbon, wherein the thin-layer carbon located at the top allows the carbon nanotubes in the vertically-aligned array to be interconnected so as to guarantee that all the carbon nanotubes in the array participate in heat transfer; simply pressing the vertically-aligned array and peeling the vertically-aligned array from the substrate so as to obtain the self-supported flexible vertically-aligned carbon nanotubearray. The prepared self-supported flexible vertically-aligned carbon nanotube array has excellent thermal conductivity, good bendability and strong adhesion, and has good application prospects in the fields of flexible thermal interface materials and flexible energy storage materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

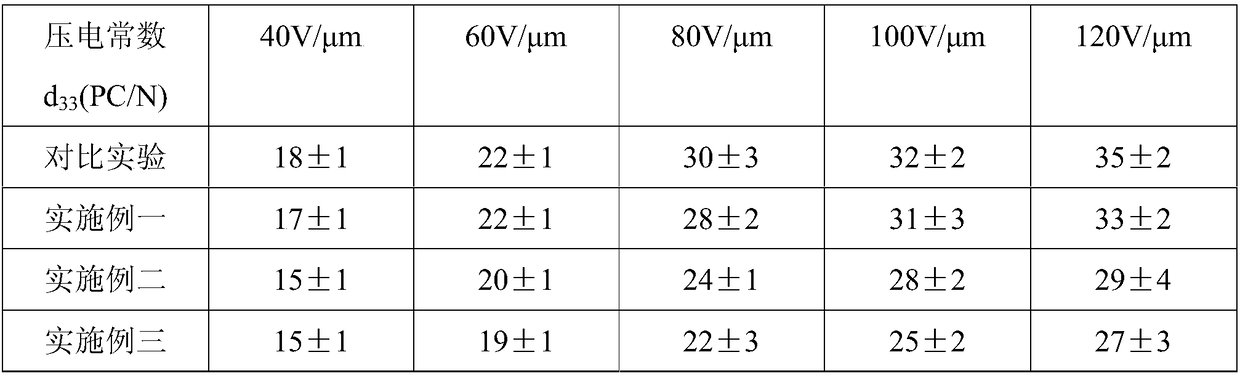

Nano hybrid P(VDF-TrFE)(polyvinylidene fluoride copolymer) composite film as well as preparation method and application thereof

InactiveCN108822449AImproves strength and modulusImprove performanceAtomic oxygenPolyvinylidene fluoride

The invention discloses a nano hybrid P(VDF-TrFE)(polyvinylidene fluoride copolymer) composite film as well as a preparation method and an application thereof and belongs to the technical field of high-compatibility, AO (atomic oxygen) scouring resistant, high-hydrophobicity and piezoelectric high-polymer hybrid composites to solve the technical problem that existing polyvinylidene fluoride is easily corroded by AO. The nano hybrid P(VDF-TrFE) composite film contains, in percentage by mass, 92%-98% of P(VDF-TrFE) and 2%-8% of polyhedral oligomeric silsesquioxane. The method comprises steps asfollows: 1) P(VDF-TrFE) and polyhedral oligomeric silsesquioxane are dissolved in an organic solvent; 2) a pre-prepared solution is prepared; 3) the pre-prepared solution is drained and poured into aculture dish, left to stand and dried. The method is simple and easy to implement, the piezoelectric property of a substrate is kept, the modulus and the hardness of an original substrate material canbe notably improved, the hydrophobic property and the AO corrosion resistance are enhanced, the properites of the composite are relatively comprehensively improved, and requirements of part of special fields can be better met.

Owner:HARBIN INST OF TECH

Graphene foam/polymer high-conductivity composite material preparation method and application thereof

ActiveCN102732037BImprove conductivityEasy to manufactureChemical vapor deposition coatingGraphiteGraphene

The invention relates to the graphene composite material field, and particularly to a graphene foam / polymer high-conductivity composite material, a preparation method and applications thereof. Steps of the method comprises as follows: providing a fully communicated three-dimension grapheme foam network and a precursor solution of a high-molecular polymer; mixing the graphene foam with the precursor solution of the high-molecular polymer to form a graphene foam / high-molecule polymer precursor mixture; and solidifying the precursor of the high-molecular polymer in the mixture to form a high-conductivity graphene foam composite material. The invention adopts the three-dimension graphene foam to form a fully- communicated graphite rapid transmission network by a seamless connection, which enables the graphene foam composite material to possess great conductivity and mechanical property and can be widely applied to the conductive composite materials and elasticity conductor field.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

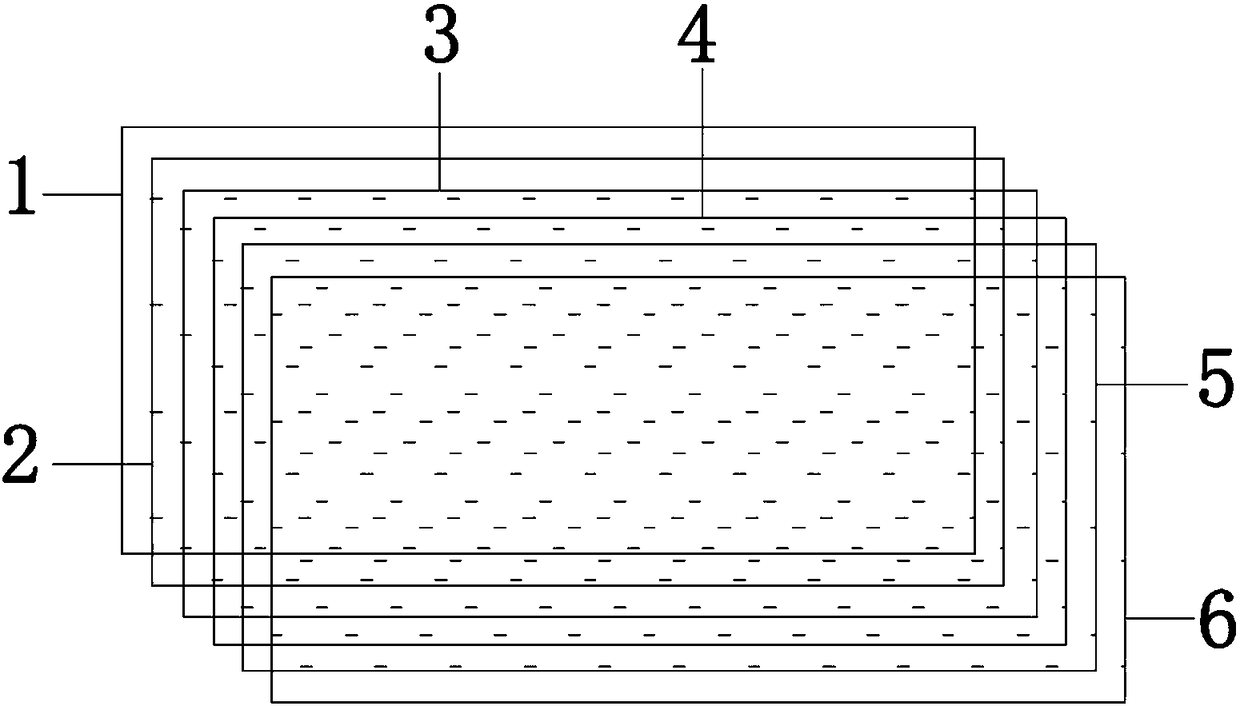

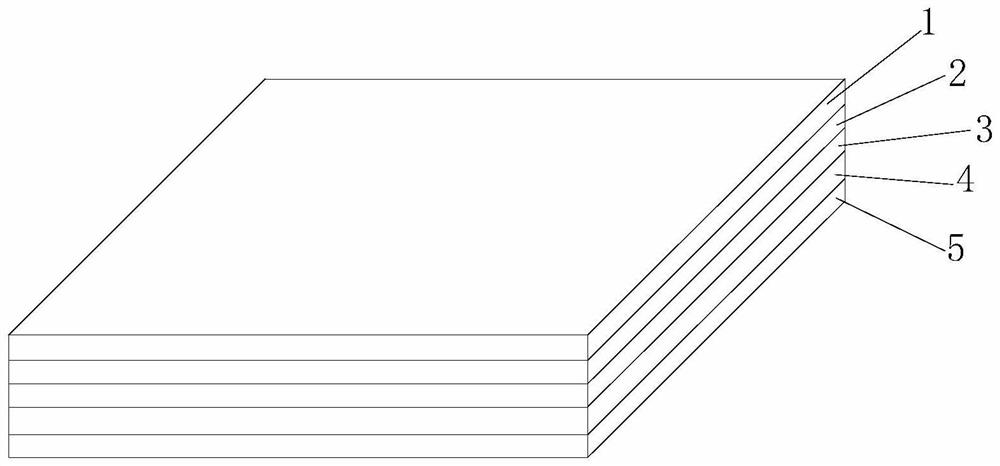

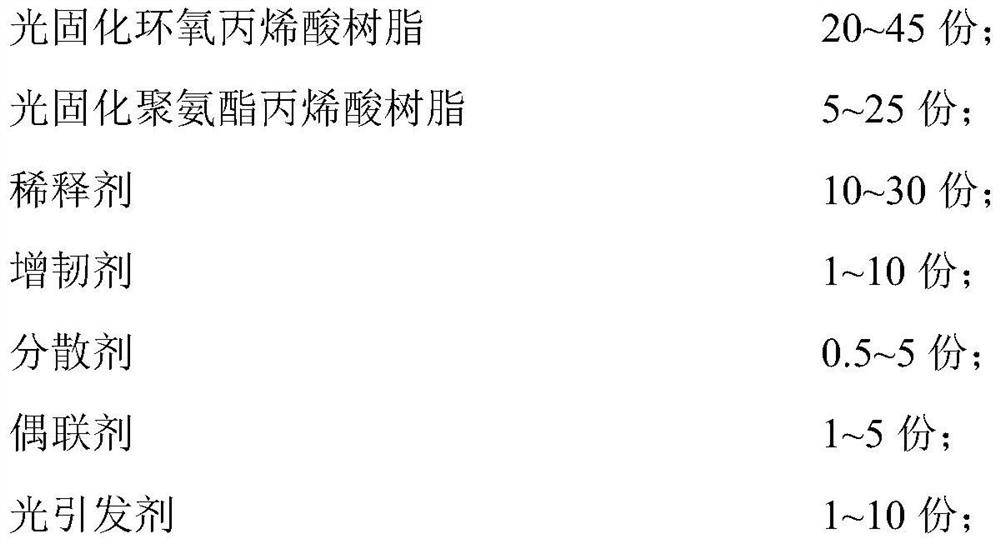

Anti-corrosion flexible epoxy composite coiled material as well as preparation method and application thereof

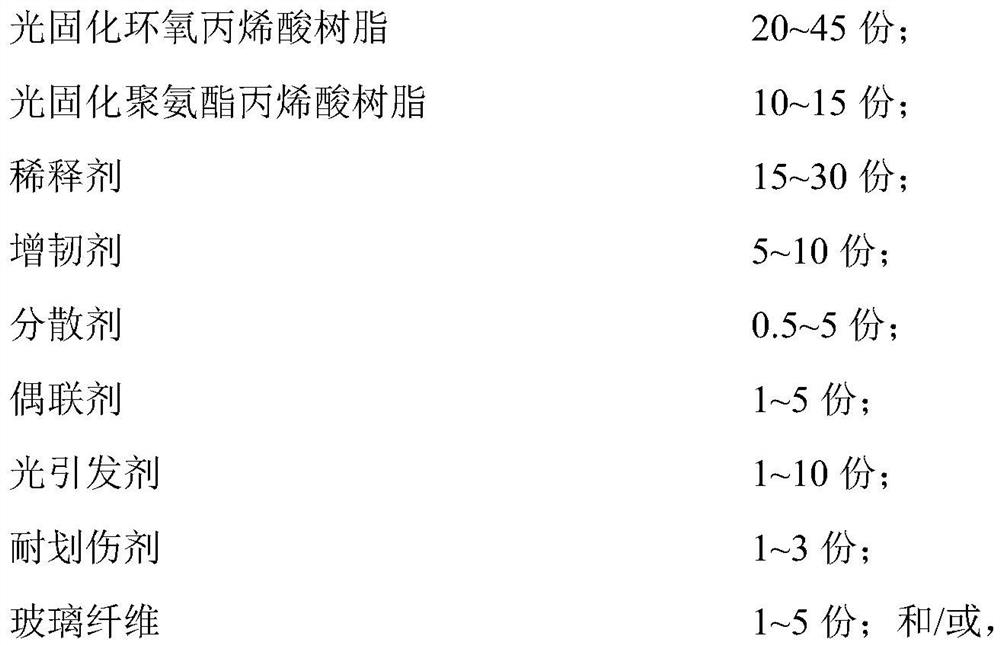

PendingCN114806092AGood flexibilityReduce process energy consumptionCovering/liningsLamination ancillary operationsWeather resistanceLong chain

The invention relates to an anti-corrosion flexible epoxy composite coiled material as well as a preparation method and application thereof, and the flexible epoxy composite coiled material comprises a first resin layer, a first reinforcing layer, a second resin layer, a second reinforcing layer and a third resin layer which are sequentially stacked, the first resin layer, the second resin layer and the third resin layer are respectively compounded by light-cured epoxy acrylic resin and light-cured polyurethane acrylic resin as main raw materials, and the light-cured epoxy acrylic resin is selected from aliphatic flexible long-chain modified epoxy acrylic resin; and the light-cured polyurethane acrylic resin is selected from aliphatic polyurethane acrylic resin with polyfunctionality. The three resin layers not only retain the inherent characteristics of epoxy resin, but also increase the advantages of acrylic resin and polyurethane resin, and meanwhile, the film layer is toughened from the molecular level to form a cross-linked network composite film layer structure reinforced in an elastomer; the composite resin system has weather resistance, flexibility and good mechanical strength at the same time.

Owner:JIANGSU CANLON BUILDING MATERIALS

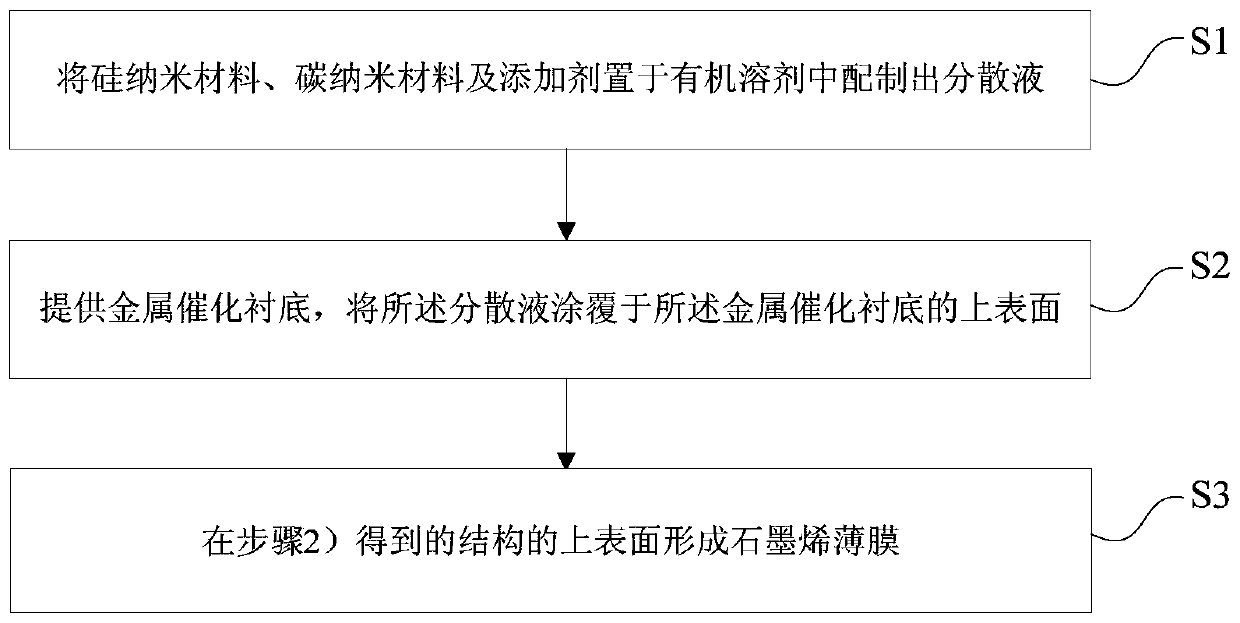

Lithium-ion battery anode material structure, lithium-ion battery and preparation method thereof

ActiveCN107394138BImprove electrochemical stabilityImprove electrochemical performanceMaterial nanotechnologyCell electrodesPhysical chemistryGraphite

The invention provides a lithium ion battery anode material structure, a lithium ion battery and a preparation method of the lithium ion battery anode material structure. The preparation method comprises the steps of: (1), putting a silicon nano-material, a carbon nano-material and an additive in an organic solvent to prepare dispersion liquid; (2), providing a metal catalytic substrate, and coating the dispersion liquid on the upper surface of the metal catalytic substrate; and (3), forming a graphene film on the upper surface of the structure obtained in the step (2). According to the battery anode material structure provided by the invention, the inherent characteristics of the silicon anode material and graphene are reserved; furthermore, the synergistic effect between the silicon anode material and graphene can be played; simultaneously, effective contact between a silicon nano-material / carbon nano-material composite film and a metal catalytic substrate current collector can be realized; high-efficiency lithium storage capability can be provided; furthermore, great volume change of the silicon nano-material in a charging and discharging process can be relieved; and generation of the internal stress of the anode material can be effectively inhibited and improved, so that pulverization of the anode material can be avoided.

Owner:SHANGHAI PYLON TECH CO LTD

Preparation method of water-soluble vinylon fiber spunlace nonwoven fabric

ActiveCN110468502BGood moisture absorption and air permeabilityHigh strengthNon-woven fabricsVinyl fibersPollutant emissions

The invention discloses a preparation method of a water-soluble vinylon fiber spunlace nonwoven fabric, which comprises the following steps: using 100% water-soluble vinylon fiber to prepare a cross-laid fiber web protection layer; using 100% water-soluble vinylon fiber to prepare a parallel-laid fiber web Mesh functional layer; spunlace compounding; drying; slitting and packaging, slitting and winding on the slitting machine according to the required specifications. The invention has the characteristics of good moisture absorption and air permeability, high strength, good chemical stability and fast water-soluble degradation. The invention does not produce any harmful pollutants during the production process, and the product can be degraded quickly in boiling water. It is fully in line with the current trend of green and environmental protection.

Owner:SHANDONG PROVINCE WINSON NON WOVEN MATERIALS

Reduction furnace bell inner wall spraying device, spraying method and reduction furnace

ActiveCN111468344BHigh bonding strengthPrevent oxidationSpraying apparatusPretreated surfacesMetallurgyBell jar

The invention provides a reduction furnace bell inner wall spraying device, a spraying method and a reduction furnace, and relates to the technical field of polysilicon equipment. The spraying device includes a bell jar, a rotating part, a sealing part, a vacuum pumping part, an exhaust part and a cold gas power spraying part, and after the sealing part is used to form a closed space inside the bell jar, the vacuum pumping part, the cold gas power spraying part and the The exhaust part makes the inside of the bell jar under the high-temperature protective gas atmosphere, and then uses the cold gas power spraying part to spray powder on the inner wall of the bell jar to form a coating on the inner wall of the bell jar, wherein the inside of the bell jar is kept under high temperature protection before spraying In the atmosphere of inert gas, the oxidation of the coating can be avoided during the spraying process, and the intrinsic properties of the coating material can be preserved to the greatest extent. Coating with high bond strength. The invention also provides a method for spraying the inner wall of the bell jar of the reduction furnace.

Owner:ASIA SILICON QINGHAI +1

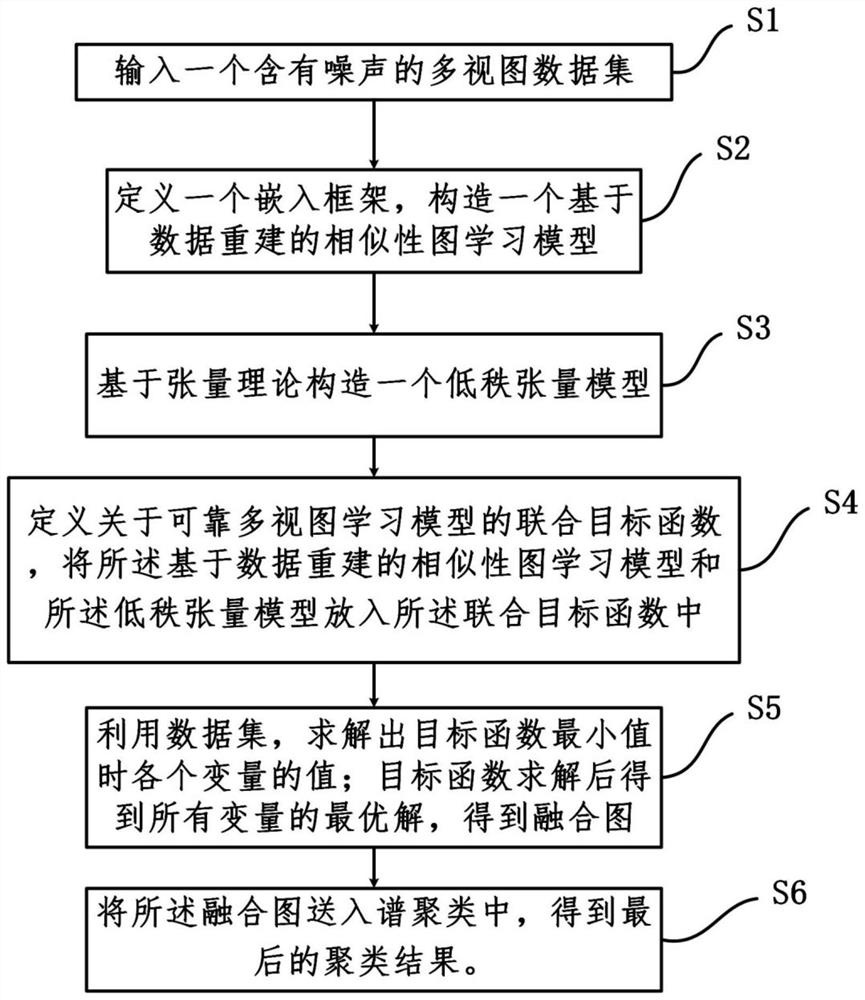

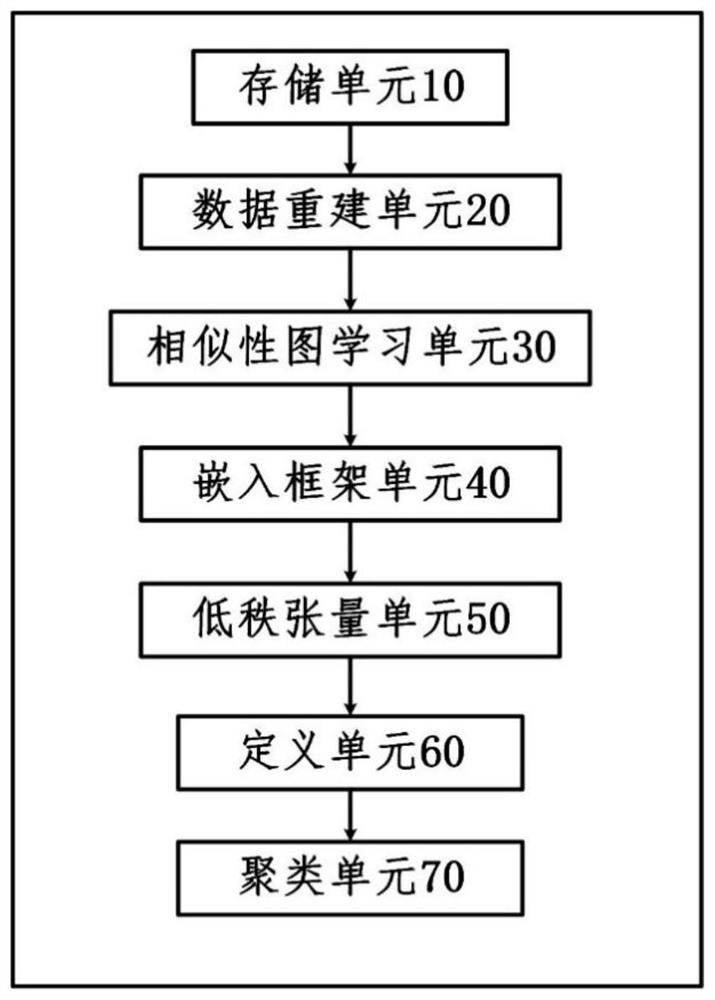

Reliable multi-view learning method and device based on data reconstruction

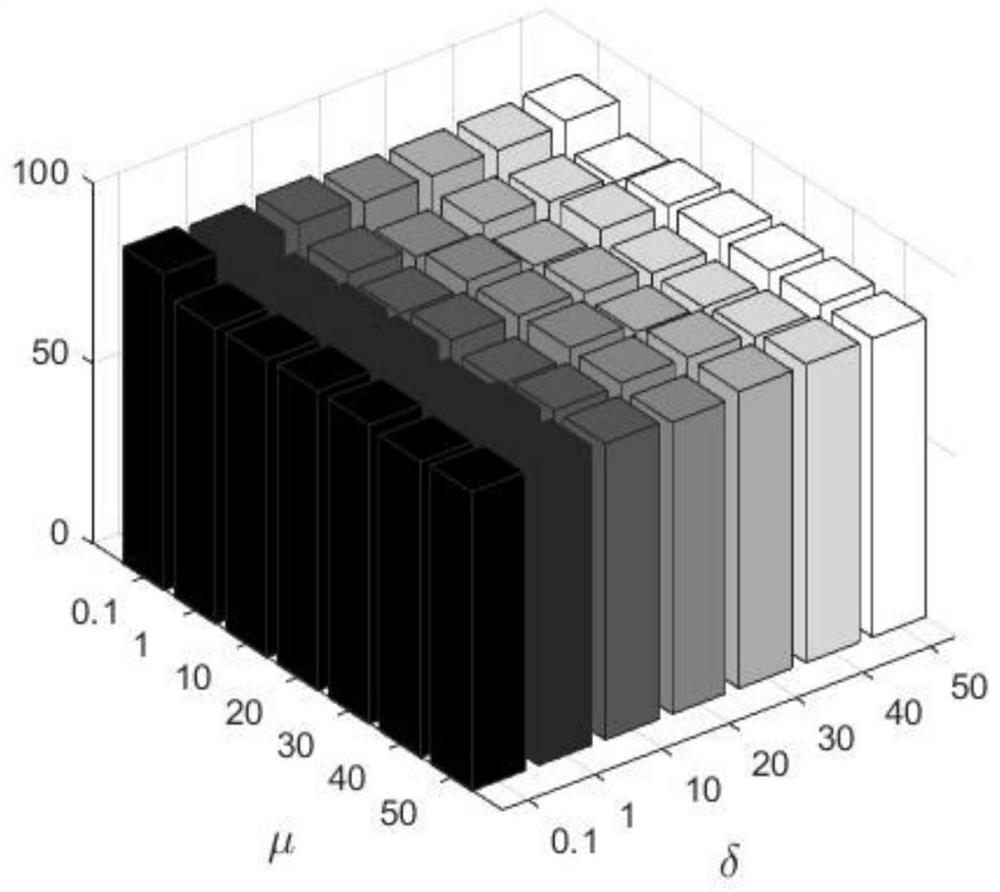

ActiveCN113312838AQuality improvementPreserve intrinsic propertiesCharacter and pattern recognitionDesign optimisation/simulationData reconstructionSelf adaptive

The embodiment of the invention provides a reliable multi-view learning method and device based on data reconstruction, and belongs to the technical field of image clustering. Low-rank self-representation is introduced to construct a data reconstruction model so as to make up for the damage of noise to the real structure of data; in order to better explore the two-dimensional similarity between different views, a low-rank tensor is adopted to capture the high-order correlation between similarity images; a combined embedded framework is developed, a data reconstruction model, similarity graph learning and a low-rank tensor model are put into the framework, and the adaptability and robustness of the method are promoted; in addition, an effective numerical function solving method is designed to obtain an optimal value of a variable coupled in a target function; compared with an existing excellent method, the invention is higher in accuracy and more stable in performance.

Owner:HARBIN UNIV OF SCI & TECH

A kind of preparation method of graphene/styrene-butadiene rubber composite material with multifunctional properties

ActiveCN108192170BGood dispersionImprove conductivityRubber insulatorsInsulation layerButadiene-styrene rubber

Owner:SICHUAN UNIV

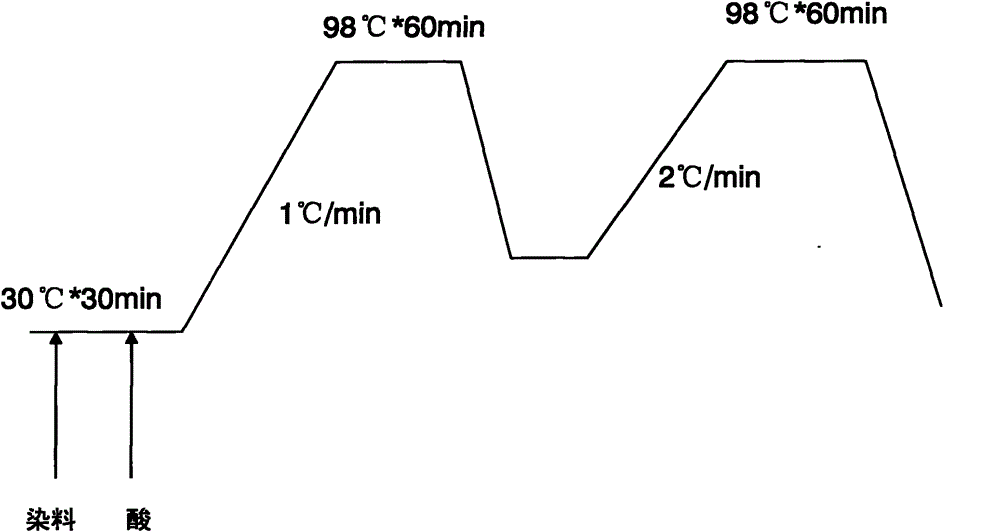

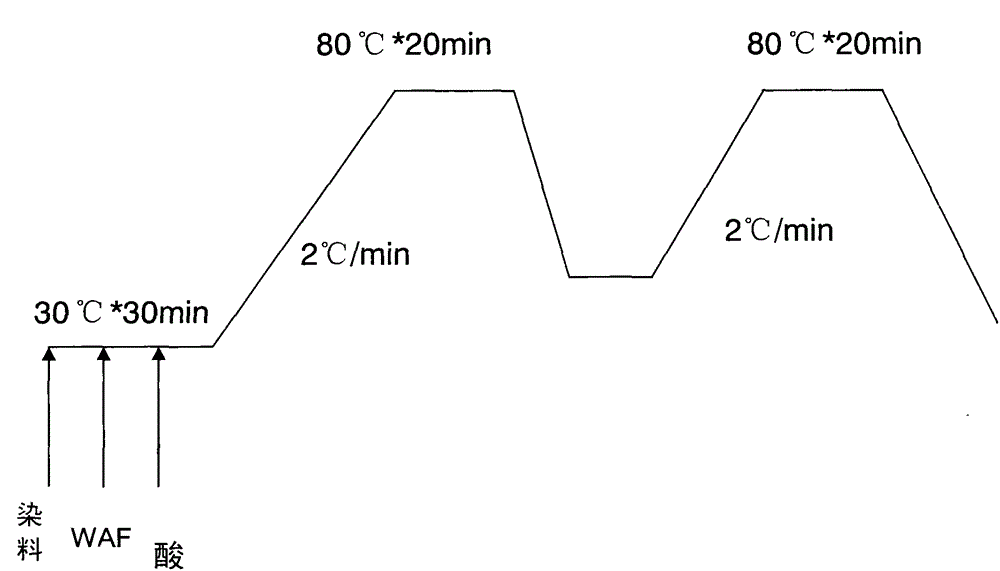

Method for dyeing wool quickly at low temperature

Owner:SHANDONG RUYI WOOLEN GARMENT GRP CO LTD

Production and processing technology of raw potato whole powder

PendingCN113080403AKeep the color and fragrancePreserve Inherent NutrientsFood homogenisationFood ingredientsBrowningPotato starch

The invention provides a production and processing technology of raw potato whole powder. The production and processing technology comprises the following steps: pretreating raw materials; cleaning; crushing; homogenizing; performing centrifugation; carrying out light-phase sand removal; concentrating a light phase; premixing; drying; crushing a finished product; and packaging the finished product to obtain the potato whole flour, injecting inert gas into a buffer tank, and maintaining the positive pressure environment in the tank. Compared with the traditional potato whole flour (cooked whole flour), the potato starch is prevented from being gelatinized in the processing process, the inherent characteristics of the original starch are reserved, the browning of the potato whole flour in the processing process is inhibited, the color, aroma and taste and inherent nutrients of potatoes are maintained, the potato whole powder is suitable for long-term storage, and the production and processing technology is wide in application field, is especially suitable for processing staple food products, is beneficial to promoting the industrialization of staple food of potatoes, and ensures the national food safety.

Owner:河南谷物淀粉工程研究院有限公司

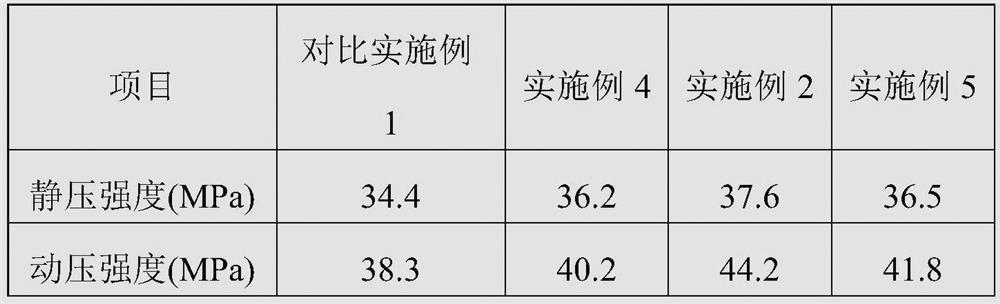

Carbon-series micro-nano graded cross-scale fiber reinforced cement mortar and preparation method thereof

InactiveCN113045254AImprove mechanical propertiesSignificant multiscale featuresCement mortarWater reducer

The invention discloses a carbon-series micro-nano graded cross-scale fiber reinforced cement mortar, and belongs to the technical field of cement mortar preparation. The cement mortar is prepared from the following substances by weight: 1-4 parts of micro-nano graded cross-scale fiber, 700-800 parts of cement, 1200-1300 parts of sand, 7-8 parts of a water reducer, 1-2 parts of an antifoaming agent, 3-4 parts of a dispersant, and 220-240 parts of water. The carbon-series micro-nano graded cross-scale fiber reinforced cement mortar prepared by the invention has more excellent mechanical and electrical properties.

Owner:AIR FORCE UNIV PLA

A kind of preparation method of collagen regenerated cellulose fiber

ActiveCN103789857BFluffy and softPreserve intrinsic propertiesArtificial filaments from viscoseCellulose fiberCollagen fiber

The invention provides a preparation method of collagen regenerated cellulose fiber. The preparation method comprises the following steps: preparing viscose spinning dope; adding collagen solution into the viscose spinning dope, wherein the adding quantity of the collagen accounts for 4-15% of the mass of the methylcellulose of the viscose spinning dope; evenly mixing to obtain protein viscose mixed liquid; adding an initiator into the mixed liquid, wherein the adding quantity of the initiator accounts for 2.3-5% of the mass of the collagen; after that, stirring at the temperature of 19-25 DEG C for 2-8h to obtain spinning solution; filtering and defoaming the spinning solution, and then carrying out wet spinning. After the preparation method is adopted, the collagen is successfully grafted into the regenerated cellulose fiber, and the collagen regenerated cellulose fiber can be spun; the grafting efficiency and the grafting rate of the method are high; the obtained collagen fiber has silk-like gloss and is fluffy and soft in hand feeling.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

A mechanical exfoliation method of functionalized boron nitride nanosheets

ActiveCN111717900BDiffraction peak intensity of apparent crystal planeEfficient strippingNitrogen compoundsNanotechnologyHexagonal boron nitridePhysical chemistry

The invention is a mechanical stripping method of functionalized boron nitride nanosheets. The method adopts boric acid and commercial hexagonal boron nitride as raw materials, and synthesizes them through the following three steps: taking boric acid and commercial hexagonal boron nitride in a mortar After uniform mixing, high-temperature pretreatment is carried out, so that the commercial block hexagonal boron nitride is corroded by dehydration boric acid and fixed by boron oxygen, and a uniformly reacted solid mixture is obtained; the solid mixture obtained after the reaction is roughly ground and placed in a ball mill tank In the process, mechanical ball milling is carried out; the white powder obtained after ball milling is dissolved and dispersed in deionized water, and washed repeatedly to ensure that the free boric acid is completely washed away, and the functionalized boron nitride nanosheet dispersion product is obtained; or The product obtained by centrifugal washing is dried to obtain a functionalized boron nitride nanosheet powder product. The method is simple to operate, does not require harsh experimental conditions, boric acid and deionized water can be recycled, and the obtained product has high crystallinity and functionalization degree.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com