A method for preparing vertical arrays of carbon nanotubes covered with flexible thin layers of carbon

A carbon nanotube and carbon-covered technology, which is applied in the field of preparation of flexible thin-layer carbon-covered carbon nanotube vertical arrays, can solve the difficulty of preparing self-supporting flexible arrays, carbon nanotubes do not participate in thermal conduction, and the contact thermal resistance of the array surface is large, etc. problems, to achieve the effect of retaining intrinsic properties, excellent adhesion strength, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

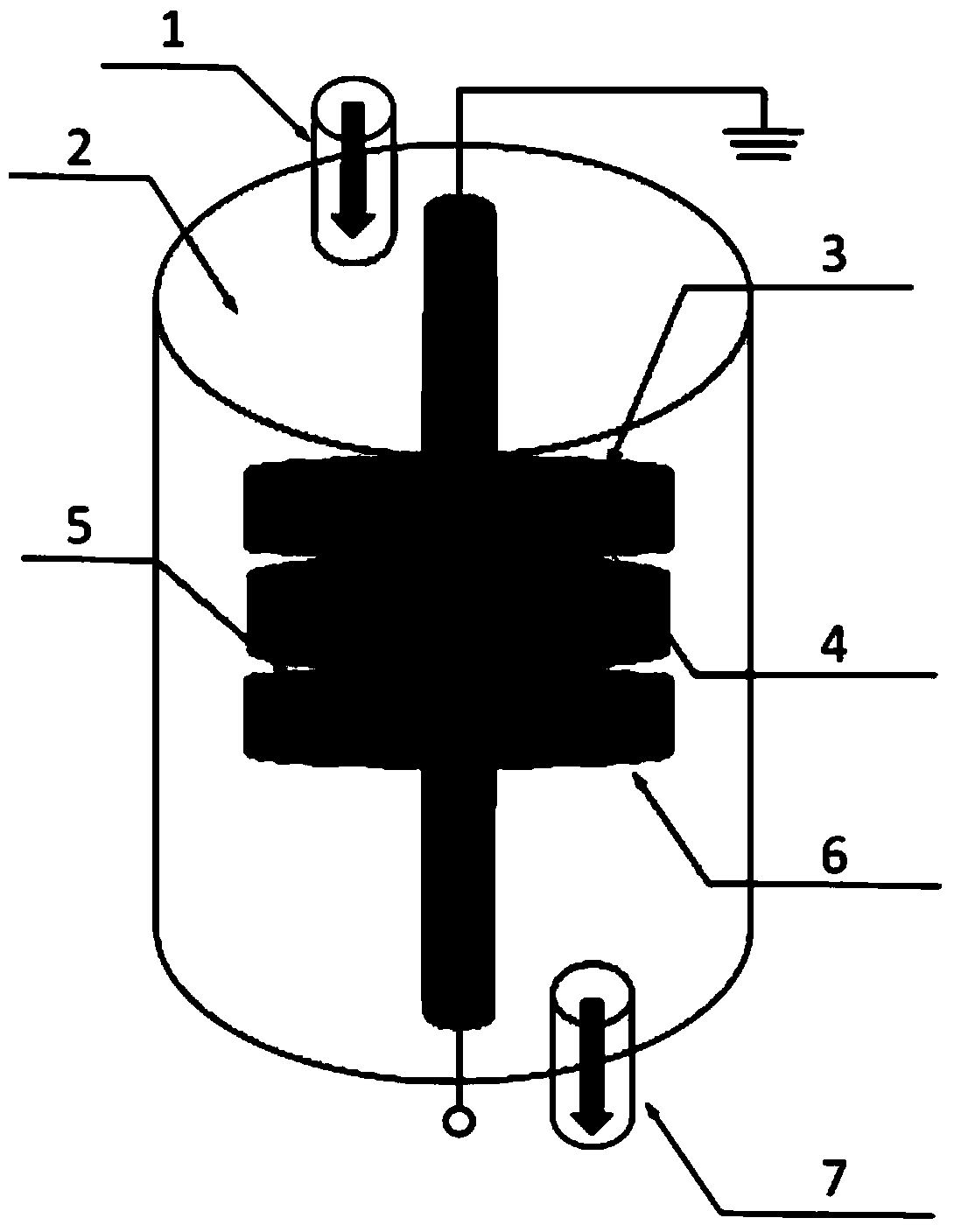

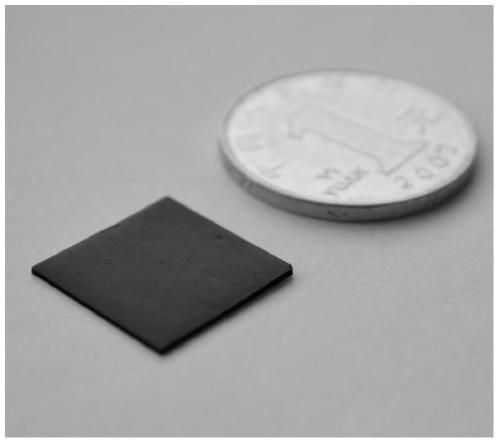

[0046] In this example, the vertical arrays of carbon nanotubes were prepared on the basis of copper foil, first loaded with Al 2 o 3 A thin layer of carbon is plasma-deposited on the surface of the copper substrate of the barrier layer and Fe nanoparticles, and then carbon nanotubes are grown by plasma-enhanced chemical vapor deposition, so as to obtain a composite structure of vertical arrays of carbon nanotubes covered by a thin layer of carbon. The thin layer of carbon on the top connects the carbon nanotubes in the vertical array and places them under a flat surface to ensure that all the carbon nanotubes in the array participate in heat transfer. The specific steps are as follows:

[0047] Place a copper foil with an area of 1.6cm×1.6cm and a thickness of 25μm on the surface of the lower heating plate 5. The surface of the copper foil has been plated with Al with a particle size of 10nm in advance using an ion sputtering device. 2 o 3 and Fe with a particle size of 1...

Embodiment 2

[0054] In this embodiment, a vertical array of carbon nanotubes is grown on a nickel sheet as a substrate, and the specific steps are as follows:

[0055] The difference from Example 1 is that the copper substrate in Example 1 is replaced by a nickel sheet, the design of the barrier layer and the design of the catalyst remain unchanged, the plasma pretreatment temperature is 500 °C under the carbon source atmosphere, and a thin layer is plasma deposited on the surface of the substrate Carbon, thin layer carbon thickness is 1nm ~ 3nm. The growth temperature of carbon nanotubes is 850° C., and other growth process parameters remain unchanged. Scanning electron microscopy and transmission electron microscopy revealed that a thin layer of carbon is still formed on the surface of the vertical array of carbon nanotubes, which can be completely torn off after compression. Utilize the test method in embodiment 1 to test that the viscous adhesion strength of this flexible carbon nanot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| bond strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com