Method of processing sample and determining element content

A technology of element content and content, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of difficult preparation of standard samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

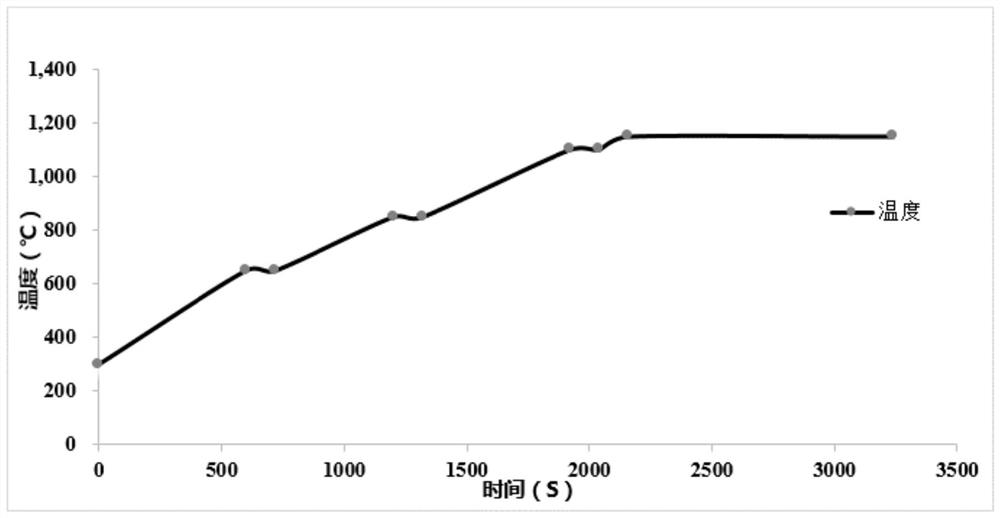

Image

Examples

preparation example Construction

[0048] 2. Preparation of samples to be tested

[0049] Step 1. (for the first time) weigh 0.40 g (accurate to 0.0001 g) of metallurgical lime to be tested, and put it into a crucible whose bottom has been paved with anhydrous lithium tetraborate. Then (for the second time) weigh 1.00 g (accurate to 0.0001 g) of anhydrous lithium tetraborate. Stir with a stirring wire to ensure that the raw material is evenly mixed with the lithium tetraborate weighed for the second time.

[0050] Step 2, adding anhydrous lithium tetraborate to cover the surface of the uniform mixture of anhydrous lithium tetraborate and metallurgical lime to be tested. The amount of anhydrous lithium tetraborate used to cover the surface is 2.00 to 3.00 grams (to the nearest 0.0001 gram).

[0051] The addition of covered lithium tetraborate is based on such considerations: in order to overcome the violent reaction of the metallurgical lime to be measured with a large amount of burning loss in the heating pro...

Embodiment

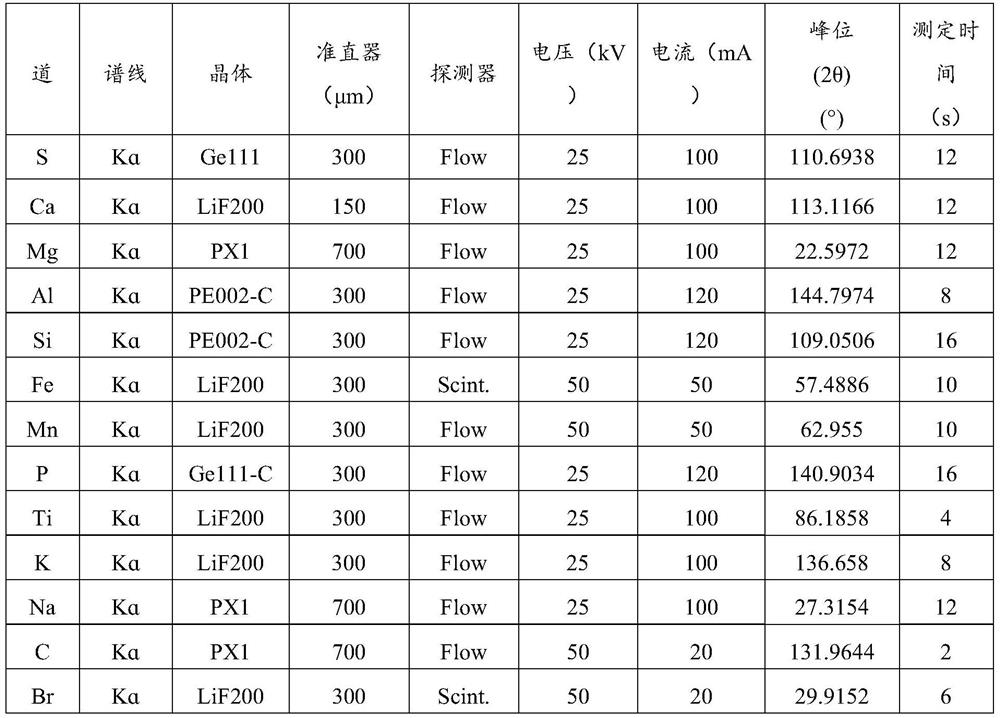

[0096] (1) Main equipment

[0097] 1.1. Main instruments and equipment

[0098] Axios type X-ray fluorescence spectrometer (end window rhodium target X-ray tube 4kW), Panalytical Instruments Company of the Netherlands; RYL-05 automatic melting furnace Luoyang Pruikangda Heat Resistance Test Equipment Co., Ltd.

[0099] (2) Reagents

[0100] Unless otherwise specified, use only approved reagents of analytical grade; use distilled water or water of equivalent purity, which should comply with the provisions of GB / T6682.

[0101] 2.1. Anhydrous lithium tetraborate, solid.

[0102] 2.2. Lithium bromide solution (1000g / L)

[0103] Slowly add 100g of lithium bromide into a 250mL beaker filled with about 40mL of distilled water, stir while adding the reagent, stir with a glass rod for 2-3min, then dilute the reagent solution to about 90mL, continue stirring until the reagent is completely dissolved, cool to room temperature, release To 100mL, stored in the reagent bottle for later...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com