Method for 3D printing of similar-goaf simulated building

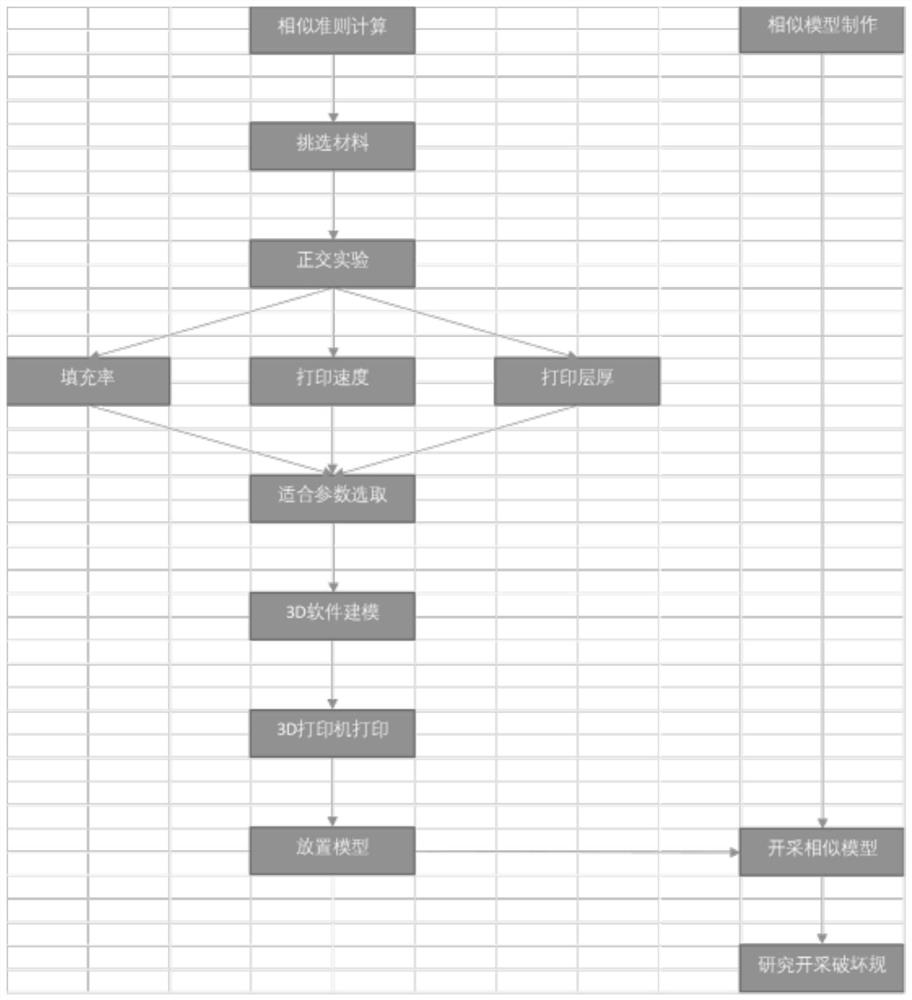

A technology similar to simulation and 3D printing, applied in 3D modeling, CAD numerical modeling, geometric CAD, etc., can solve problems such as lack, and achieve the effect of realizing structural simulation and solving deformation observation problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1 influences the mechanical property test of 3D printing specimen

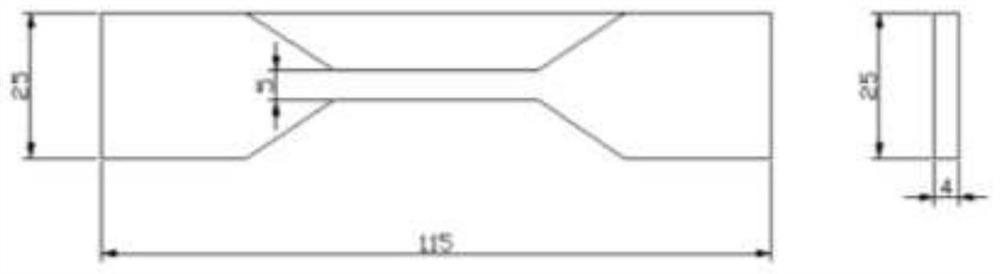

[0058] 1. Test method

[0059] Because the mechanical properties of the printed models obtained by changing the process and parameters under the same 3D printer are also different, so we can get certain rules through experiments. Therefore, under the condition of not changing the 3D printer, test the influence of different parameters on the printing model through orthogonal experiments, so as to find the most suitable parameters.

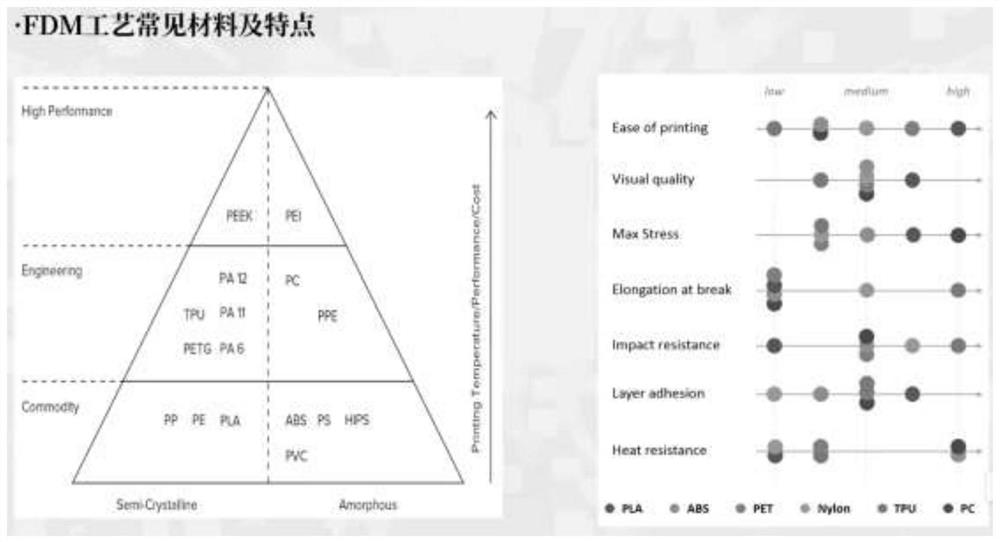

[0060] 1. Main process parameters of FDM technology

[0061] There are many control factors for the 3D model printed by FDM technology, which more or less affect the mechanical strength and processing time of the printed model. But the most important ones are controlled by the following process parameters, which are: filling rate, printing layer thickness, and printing materials.

[0062] (1) Filling rate: the actual proportion of the filling material to the tot...

Embodiment 2

[0087] Embodiment 2 Development of solid-liquid coupling similar simulation test material

[0088] 1. Design of similar simulation test scheme

[0089] 1. Similar material test selection

[0090] Based on the geological and mining conditions of Yaping Coal Mine, this experiment uses a two-dimensional solid-liquid coupling similar simulation experimental device designed by the School of Safety Engineering, North China Institute of Science and Technology, and builds a similar material model to study the rock formation damage caused by fully mechanized caving mining in Yaping Coal Mine. The law of surface movement.

[0091] According to the main mechanical property parameters of the rock strata in Yaping Coal Mine, river sand is used as aggregate, gypsum and putty powder as cement, and mica sheet as layered material to simulate rock bedding according to the previous experience in proportioning.

[0092] 2. Design and manufacture of similar models

[0093] The design of this em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com