Production and processing technology of raw potato whole powder

A technology for raw potato whole flour and processing technology, which is applied in the fields of food science, food drying, application, etc., can solve the problems of difficult storage and transportation, prone to browning, limited processing capacity, etc. Suitable for long-term storage, wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

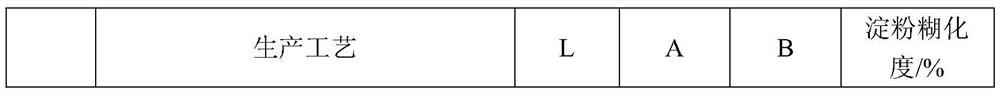

Image

Examples

Embodiment 1

[0027] A production and processing technology of raw potato powder, comprising the steps of:

[0028] (1) Raw material pretreatment: according to the taste and taste requirements of the product, select potatoes of the corresponding variety as raw materials, select potatoes with no green skin, insect damage and uniform size, prohibit the use of germinated and green-skinned potatoes, wash and peel the formed potatoes, Potatoes are cleaned and peeled in a potato brush peeler, and the peeled thickness is 0.2mm;

[0029] (2) Cleaning: washing and cleaning the peeled potatoes obtained in step (1), removing impurities, and removing residual soil, broken buds and part of the skin on the surface of the potatoes;

[0030] (3) crushing: the potatoes in the step (2) are crushed into potato pulp through a kneading machine or a filing machine, and the concentration of the potato pulp is 15%;

[0031] (4) Homogenization: the potato pulp in step (3) is processed by a homogenizer to obtain po...

Embodiment 2

[0045] A production and processing technology of raw potato powder, comprising the steps of:

[0046] (1) Raw material pretreatment: according to the taste and taste requirements of the product, select potatoes of the corresponding variety as raw materials, select potatoes with no green skin, insect damage and uniform size, prohibit the use of germinated and green-skinned potatoes, wash and peel the formed potatoes, Potatoes are cleaned and peeled in a potato brush peeler, and the peeled thickness is 0.9mm;

[0047] (2) Cleaning: washing and cleaning the peeled potatoes obtained in step (1), removing impurities, and removing residual soil, broken buds and part of the skin on the surface of the potatoes;

[0048] (3) crushing: the potatoes in the step (2) are crushed into potato pulp through a kneading machine or a filing machine, and the concentration of the potato pulp is 18%;

[0049] (4) Homogenization: the potato slurry in step (3) is processed by a homogenizer to obtain ...

Embodiment 3

[0064] A production and processing technology of raw potato powder, comprising the steps of:

[0065] (1) Raw material pretreatment: according to the taste and taste requirements of the product, select potatoes of the corresponding variety as raw materials, select potatoes with no green skin, insect damage and uniform size, prohibit the use of germinated and green-skinned potatoes, wash and peel the formed potatoes, Potatoes are cleaned and peeled in a potato brush peeler, and the peeled thickness is 0.5mm;

[0066] (2) Cleaning: washing and cleaning the peeled potatoes obtained in step (1), removing impurities, and removing residual soil, broken buds and part of the skin on the surface of the potatoes;

[0067] (3) crushing: the potatoes in the step (2) are broken into potato pulp through a kneading machine or a filing machine, and the concentration of the potato pulp is 17%;

[0068] (4) Homogenization: the potato slurry in step (3) is processed by a homogenizer to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com