Preparation method of water-soluble vinylon fiber spunlace nonwoven fabric

A water-soluble vinylon, non-woven technology, used in non-woven fabrics, textiles and papermaking, etc., to achieve good moisture absorption and air permeability, dry heat resistance, and good chemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

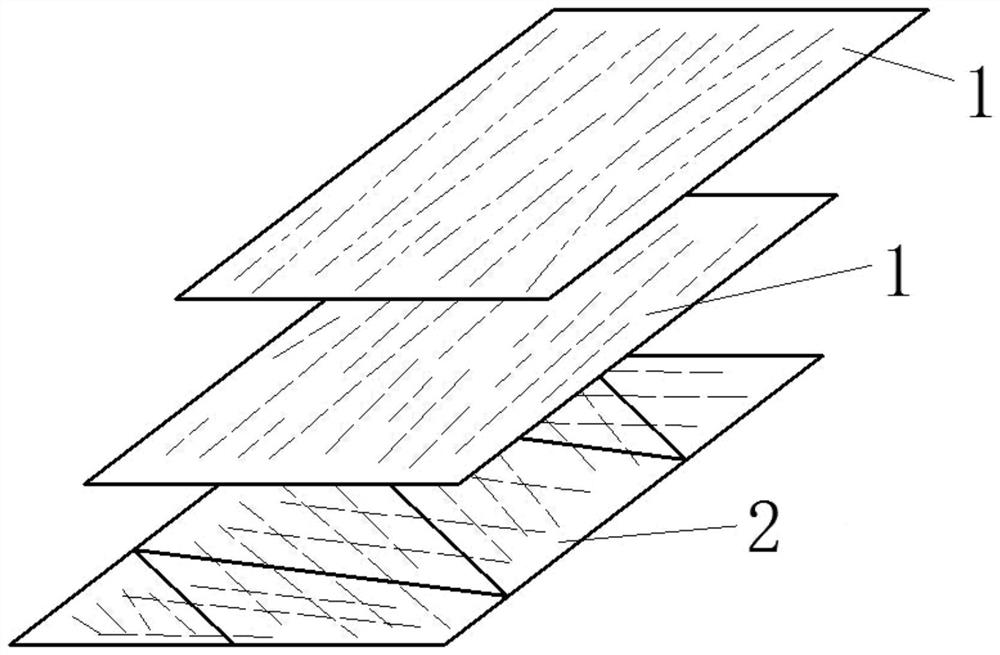

[0034] The invention discloses a method for preparing water-soluble vinylon fiber spunlace nonwoven fabric, which is made by adopting 100% water-soluble vinylon fiber through a combination of semi-crossing and parallel laying, and adopting a spunlace reinforcement technology. The fiber web after the first carding machine is then formed into a four-layer cross-laid fiber web by the action of the cross-lapper, which has the functions of anti-friction and anti-fluffing. The fibers passing through the second carding machine are laid in parallel to obtain a flat fiber web. The fiber webs from the two carding machines are overlapped and superimposed, and are reinforced by a hydroentanglement machine to form six layers of four functional layers on the top and two protective layers on the bottom. Composite structure. Then it is dried by a drying machine, and then the water-soluble vinylon nonwoven material of the required specification is made through winding, slitting and other proce...

Embodiment 1

[0052] A kind of manufacture method of above-mentioned vinylon spunlaced nonwoven fabric 4, with reference to attached figure 1 , including the following steps:

[0053] (1) Prepare the fiber web of cross-lapping: adopt 100% water-soluble vinylon fiber, the average length of vinylon fiber is 38mm, the average fineness is 1.67dtex, the grammage of the fiber web of gained is 25.3g / m 2 , the fiber raw materials are sequentially opened by the W1051A cotton opener, carded by the AUTEFA carding machine and laid by the AUTEFA 500889 cross-lapper to obtain a 4-layer fiber web. The output fiber web is sent to the drafting machine for drafting. The process parameters : Pneumatic box pressure 650Pa, feeding speed of carding machine 0.3m / min, cylinder speed 1000m / min, work roll speed 80m / min, stripping roller speed 140m / min, doffer speed 80m / min, condensing roller speed 50m / min min, the net speed is 55m / min, the web width is 3.2m, the number of web layers is 2, the unevenness of the outp...

Embodiment 2

[0058] A kind of manufacture method of above-mentioned vinylon spunlaced nonwoven fabric 4, with reference to attached figure 1 , including the following steps:

[0059] (1) Prepare the fiber web of cross-lapping: adopt 100% water-soluble vinylon fiber, the average length of vinylon fiber is 38mm, the average fineness is 1.67dtex, the grammage of the fiber web of gained is 25.3g / m 2 , the fiber raw materials are sequentially opened by the W1051A cotton opener, carded by the AUTEFA carding machine and laid by the AUTEFA 500889 cross-lapper to obtain a 4-layer fiber web. The output fiber web is sent to the drafting machine for drafting. The process parameters : Pneumatic box pressure 500Pa, feeding speed of carding machine 0.2m / min, cylinder speed 800m / min, work roll speed 100m / min, stripping roller speed 180m / min, doffer speed 60m / min, condensing roller speed 30m / min min, the net speed is 40m / min, the web width is 3.4m, the number of web layers is 2, the unevenness of the outp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com