Activation method of high-capacity lithium ion battery negative electrode material

A technology of lithium ion battery and activation method, which is applied in the field of activation of negative electrode materials of high capacity lithium ion battery, can solve the problems of low power density, inability to charge and discharge rapidly, etc., to increase power density, improve catalytic reaction active sites, The effect of improving capacity and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

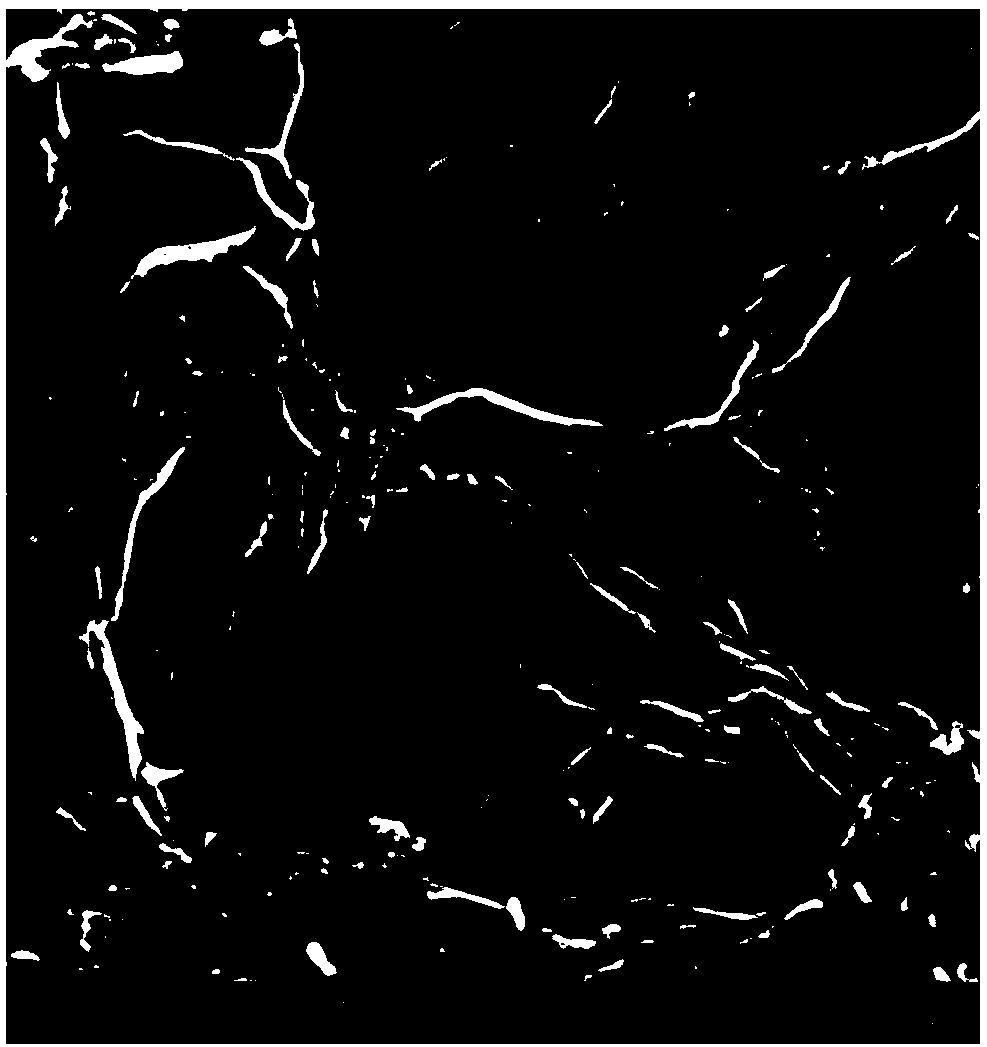

[0030] The present embodiment activates the three-dimensional graphene / foam nickel of lithium-ion battery negative electrode material according to the following steps:

[0031] 1) Ultrasonic disperse graphene oxide in water to obtain a 1 mg / mL graphene oxide aqueous solution; then form a film of graphene oxide aqueous solution at 60°C in nickel foam by drop-coating method, and obtain a three-dimensional oxide film after standing for 72 hours Graphene / nickel foam attachment material, drying;

[0032] 2) Spray the graphene oxide aqueous solution on the dried three-dimensional graphene oxide / nickel foam attachment material, and then dry it for use;

[0033] 3) Immerse the dried three-dimensional graphene oxide / nickel foam material in step 2) in 1.2 mol / L NaI aqueous solution, ultrasonic treatment time is 3h, and then stand until the activator solution is completely clarified, then take out the composite material;

[0034] 4) After drying the composite material in step 3), put it...

Embodiment 2

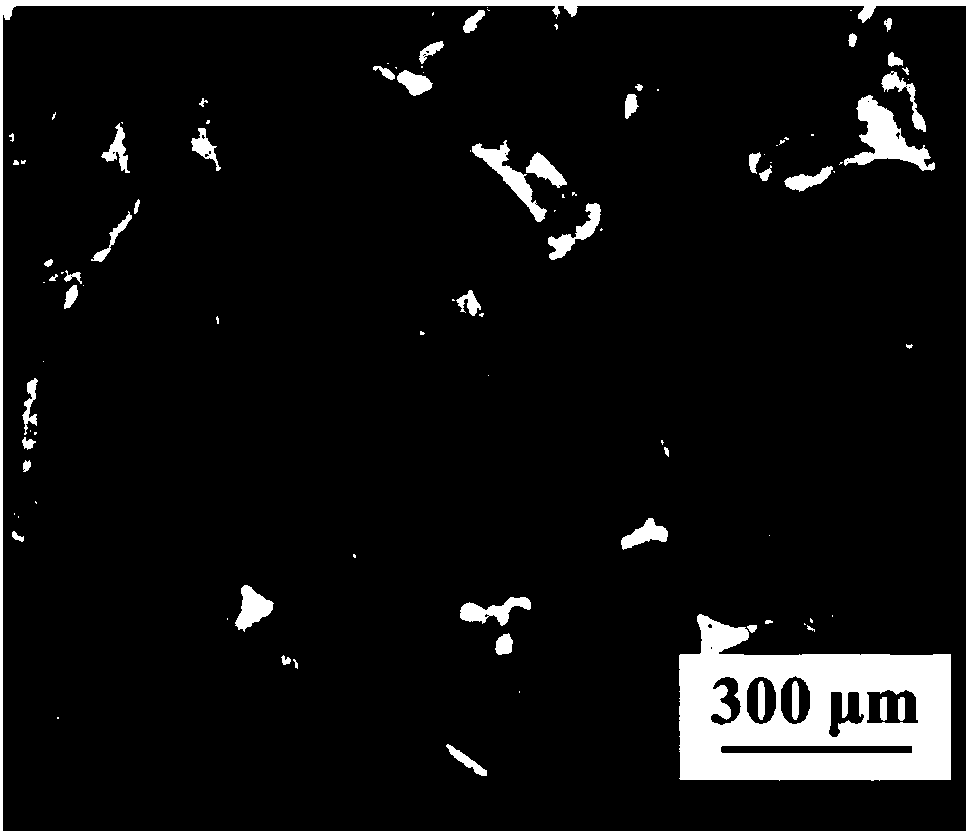

[0039] The present embodiment activates the three-dimensional graphene / copper foam of lithium-ion battery negative electrode material according to the following steps:

[0040] 1) Ultrasonically disperse graphene oxide in water to obtain a 2 mg / mL graphene oxide aqueous solution; then form a film of graphene oxide aqueous solution at 90 ° C in foamed copper by drop-coating method, and obtain a three-dimensional oxide after standing for 16 hours Graphene / copper foam attachment material, drying;

[0041] 2) Spray the graphene oxide aqueous solution on the dried three-dimensional graphene oxide / copper foam attachment material, and then dry it for use;

[0042] 3) Immerse the dried three-dimensional graphene oxide / copper foam attachment material in step 2) in 1.5 mol / L KI aqueous solution, ultrasonic treatment time is 5h, and then stand until the activator solution is completely clarified, then take out the composite material;

[0043] 4) After the composite material in step 3) i...

Embodiment 3

[0046] The present embodiment activates the three-dimensional graphene / foam nickel of lithium-ion battery negative electrode material according to the following steps:

[0047]1) Ultrasonic disperse graphene oxide in water to obtain a 4 mg / mL graphene oxide aqueous solution; then form a film of graphene oxide aqueous solution at 70°C in nickel foam by drop-coating method, and obtain a three-dimensional film after standing for 32 hours Graphene oxide / nickel foam attachment material, drying;

[0048] 2) Spray the graphene oxide aqueous solution on the dried three-dimensional graphene oxide / nickel foam attachment material, and then dry it for use;

[0049] 3) Immerse the dried three-dimensional graphene oxide / nickel foam attachment material in step 2) in 1.8 mol / L NaBr aqueous solution, ultrasonic treatment time is 4h, and then stand until the activator solution is completely clarified, then take out the composite material;

[0050] 4) After drying the composite material in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com