Carbon-series micro-nano graded cross-scale fiber reinforced cement mortar and preparation method thereof

A fiber-reinforced cement, cross-scale technology, applied in the field of carbon-based micro-nano graded cross-scale fiber-reinforced cement mortar and its preparation, can solve the problems of difficult uniform dispersion, easy peeling, pull-out damage, etc., and achieve the goal of improving mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

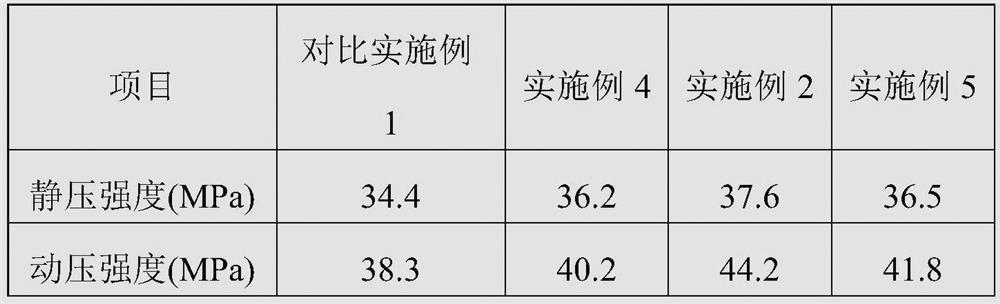

Examples

Embodiment 1

[0031] A carbon-based micro-nano graded cross-scale fiber-reinforced cement mortar is made of the following substances in corresponding parts by weight:

[0032] 1 part of micro-nano graded cross-scale fiber, 700 parts of cement, 1200 parts of sand, 7 parts of water reducer, 1 part of defoamer, 3 parts of dispersant, 220 parts of water.

[0033] The preparation method of the micro-nano hierarchical cross-scale fiber includes the following steps:

[0034] (1) carbon fiber desizing treatment;

[0035] Based on the Soxhlet extraction method, use acetone to extract the carbon fiber tow, remove the sizing agent on its surface, take out the carbon fiber after 48 hours, then put it into absolute ethanol and wash it three times, then put it into deionized water and wash it three times, and finally put it in Dry in a constant temperature drying oven for later use.

[0036] (2) Preparation of carbon nanotube dispersion;

[0037] The carbon nanotubes and cetyltrimethylammonium bromide...

Embodiment 2

[0050] A carbon-based micro-nano graded cross-scale fiber-reinforced cement mortar is made of the following substances in corresponding parts by weight:

[0051] 2.64 parts of micro-nano graded cross-scale fibers, 766 parts of cement, 1280 parts of sand, 7.66 parts of water reducer, 1.53 parts of defoamer, 3.06 parts of dispersant, and 230 parts of water.

[0052] The preparation method of the micro-nano hierarchical cross-scale fiber includes the following steps:

[0053] (1) carbon fiber desizing treatment;

[0054] Based on the Soxhlet extraction method, use acetone to extract the carbon fiber tow, remove the sizing agent on its surface, take out the carbon fiber after 48 hours, then put it into absolute ethanol and wash it three times, then put it into deionized water and wash it three times, and finally put it in Dry in a constant temperature drying oven for later use.

[0055] (2) Preparation of carbon nanotube dispersion;

[0056] Mix carbon nanotubes and hexadecyltrim...

Embodiment 3

[0069] A carbon-based micro-nano graded cross-scale fiber-reinforced cement mortar is made of the following substances in corresponding parts by weight:

[0070] 4 parts of micro-nano graded cross-scale fiber, 800 parts of cement, 1300 parts of sand, 8 parts of water reducer, 2 parts of defoamer, 4 parts of dispersant, 240 parts of water.

[0071] The preparation method of the micro-nano hierarchical cross-scale fiber includes the following steps:

[0072] (1) carbon fiber desizing treatment;

[0073] Based on the Soxhlet extraction method, use acetone to extract the carbon fiber tow, remove the sizing agent on its surface, take out the carbon fiber after 48 hours, then put it into absolute ethanol and wash it three times, then put it into deionized water and wash it three times, and finally put it in Dry in a constant temperature drying oven for later use.

[0074] (2) Preparation of carbon nanotube dispersion;

[0075] The carbon nanotubes and cetyltrimethylammonium bromi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile modulus | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Monofilament diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com