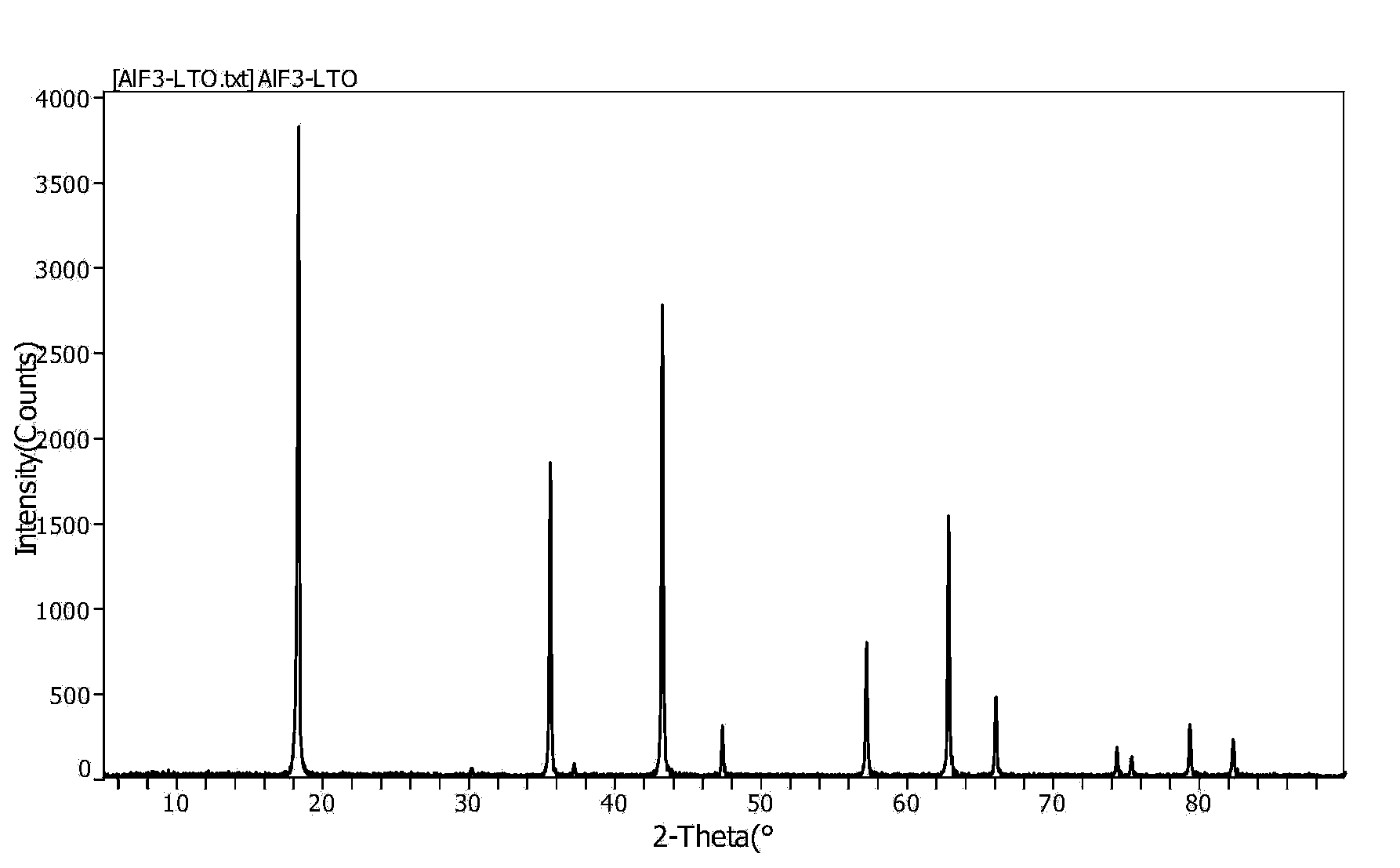

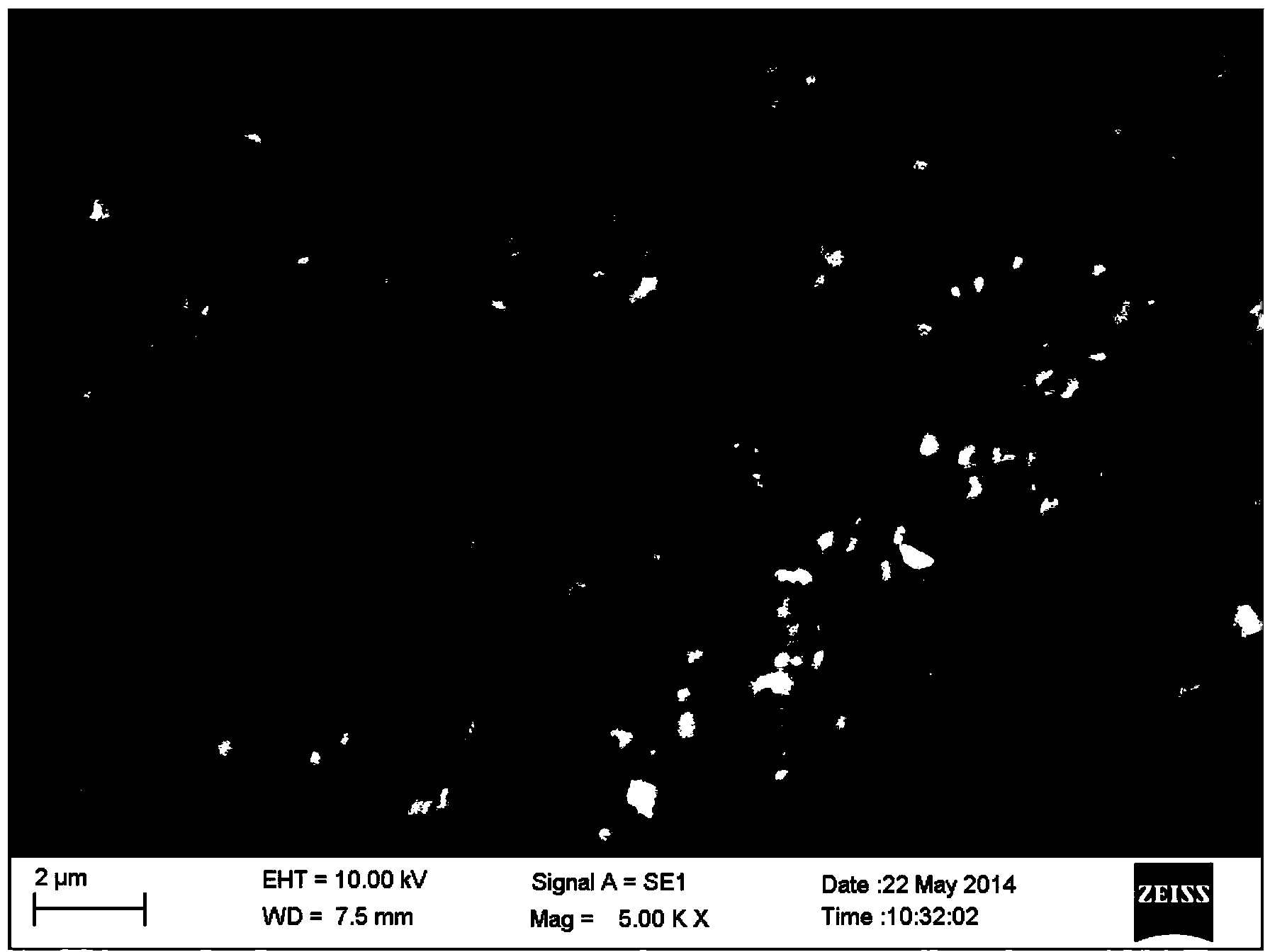

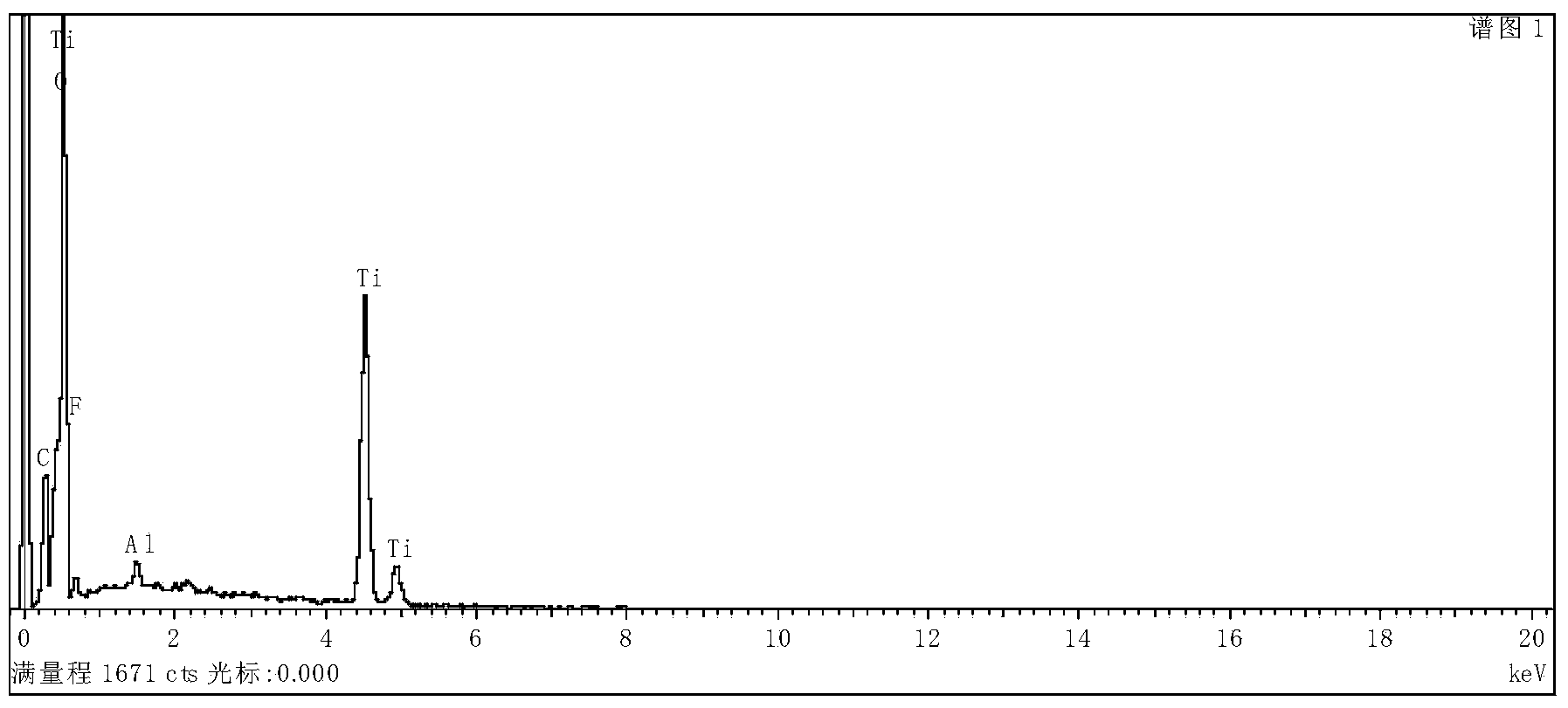

Preparation method and application of aluminum fluoride-coated carbon-coated lithium titanate nitride

A technology of lithium titanate nitride and aluminum fluoride is applied in the field of nanomaterials to achieve the effects of low equipment requirements, high gram capacity, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing aluminum fluoride-coated carbon-doped lithium titanate nitride, comprising the following steps:

[0048] Step 1) Preparation of spinel lithium titanate 1

[0049] Lithium carbonate and rutile titanium dioxide were weighed according to the Li:Ti molar ratio of 0.8:1, mixed with absolute ethanol, and ball milled in an argon atmosphere in a QM-2SP12 ball mill of Nanjing University Instrument Factory for 12 hours. The uniformly mixed sample was placed in a vacuum oven at 80°C, heated and dried for 5 hours, and then cooled to room temperature under vacuum. Put the sample in the high-temperature atmosphere electric furnace of Shanghai Jiugong Electric Co., Ltd., evacuate it, pass 99.9% nitrogen protective gas, then raise the temperature to 500°C at a speed of 5°C / min, and keep it at this temperature for 1 hour, and then continue to The temperature was raised to 850° C. at a rate of 2° C. / min, and kept at this temperature for 1 hour. After natural cooli...

Embodiment 2

[0059] The preparation method of the aluminum phosphate-coated carbon-coated lithium titanate nitride comprises the following steps:

[0060] Step 1), 2) 3) and 4) the reaction environment and conditions are the same as in Example 2, the difference is that in step 3), the nitrogen source is ionic liquid 1-ethyl-3-methylimidazole dinitrile amine salt (C 8 h 11 N 5 ).

[0061] The product of step 3) is gray carbon-coated lithium titanate nitride powder. The carbon coating contains pyrolytic carbon 3 and carbon nitride 4 (CN X ) compounds. Among them, carbon nitride (CN X ) compounds are highly conductive.

Embodiment 3

[0063] The preparation method of the aluminum phosphate-coated carbon-coated lithium titanate nitride comprises the following steps:

[0064] Step 1), 2) 3) and 4) reaction environment and condition are the same as embodiment 2, difference is, in step 3), nitrogen source is ionic liquid 1-butyl-3-methyl-pyridine dinitrile amine Salt (C 12 h 16 N 4 ).

[0065] The product of step 3) is gray carbon-coated lithium titanate nitride powder. The carbon coating contains pyrolytic carbon and carbon nitride (CN X ) compounds. Among them, carbon nitride (CN X ) compounds are highly conductive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com