Preparation method of novel all-solid-state lithium ion battery

A lithium-ion battery, all-solid-state technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of high hardness, limited application, and fragility of oxide solid electrolyte particles, and is suitable for large-scale production and increased The effect of exerting gram capacity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

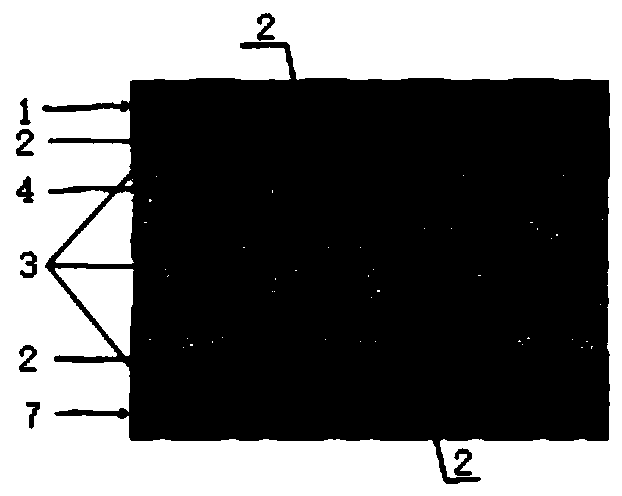

[0041] A preparation method of a novel all-solid-state lithium-ion battery, comprising the following steps:

[0042] Step 1: The positive electrode active material 1, the conductive agent 2 and the binder solid electrolyte Li 3 OX 3 is mixed and dispersed uniformly as a positive electrode ingredient;

[0043] Step 2: Negative electrode active material 7, conductive agent 2 and binder solid electrolyte Li 3 OX 3 is mixed and dispersed evenly as the negative electrode ingredient;

[0044] Step 3: Combine the main body solid electrolyte 4 with the binder solid electrolyte Li 3 OX 3 is mixed and dispersed uniformly as a solid electrolyte layer ingredient;

[0045] Step 4: Coating the positive electrode ingredients on the positive electrode current collector, coating the negative electrode ingredients on the negative electrode current collector, stacking the negative electrode current collector, negative electrode ingredients, solid electrolyte layer ingredients, positive electr...

specific Embodiment approach 2

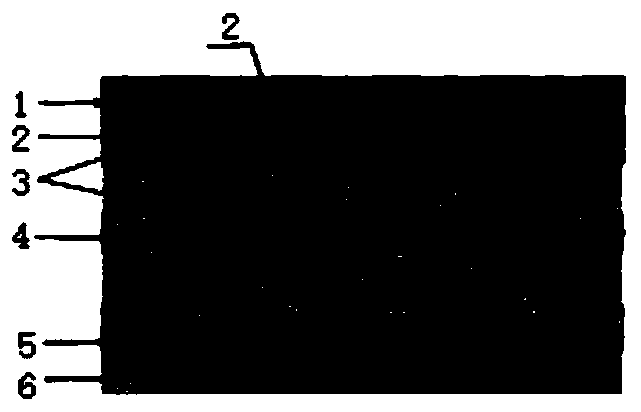

[0054] A preparation method of a novel all-solid-state lithium-ion battery, comprising the following steps:

[0055] Step 1: The positive electrode active material 1, the conductive agent 2 and the binder solid electrolyte Li 3 OX 3 is mixed and dispersed uniformly as a positive electrode ingredient;

[0056] Step 2: Combine the main body solid electrolyte 4 with the binder solid electrolyte Li 3 OX 3 is mixed and dispersed uniformly as a solid electrolyte layer ingredient;

[0057] Step 3: Coating the positive electrode ingredients on the positive electrode current collector, stacking the positive electrode current collector, positive electrode ingredients and solid electrolyte layer ingredients in sequence to form a stack, and then applying pressure to the stack at a temperature of 282-400 ° C Sintering for 0.5h-48h to form a combination of positive electrode sheet and solid electrolyte layer;

[0058] Step 4: Coating the molten metal lithium-based material 6 on the solid...

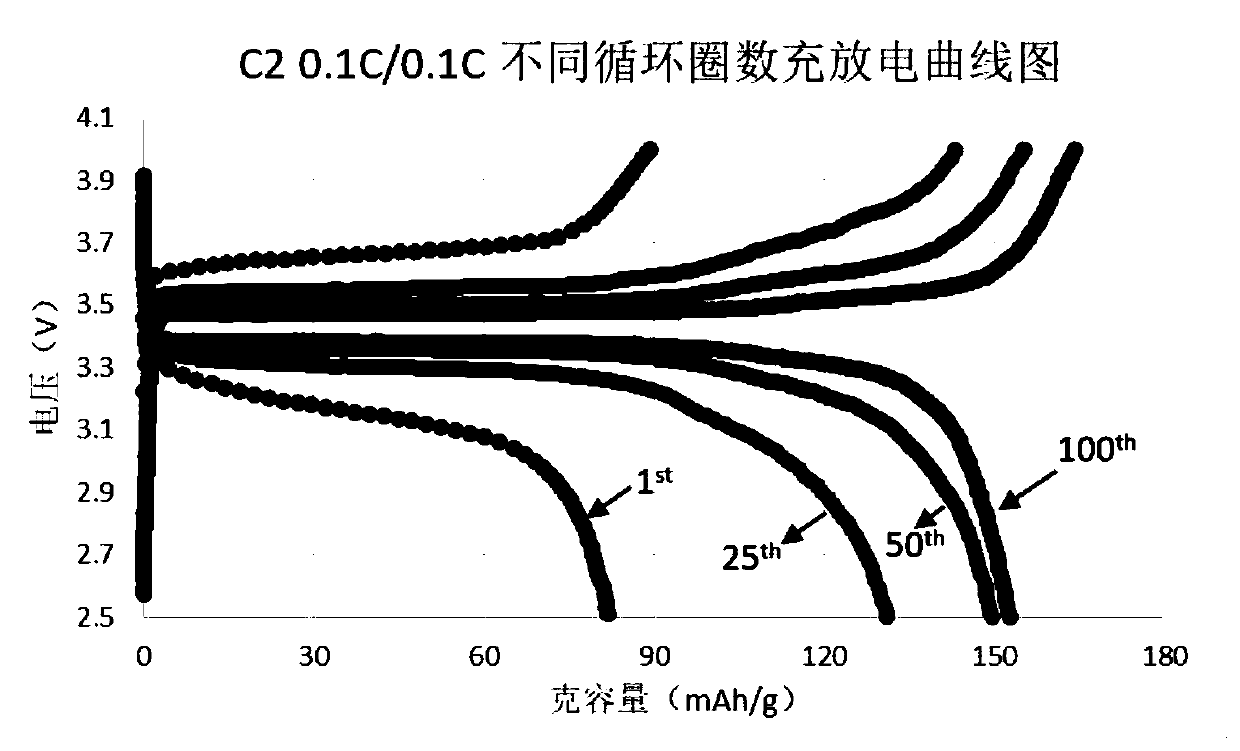

Embodiment 1

[0066] (1) Preparation of positive electrode ingredient P1

[0067] The positive electrode active material LiFePO 4 , conductive carbon black and binder solid electrolyte Li 3 OCl is mixed, and put into a ball mill or a stirring tank for ball milling or stirring to obtain a uniformly dispersed positive electrode ingredient P1. In the positive electrode ingredient P1, the solid component contains 85wt% LiFePO 4 , 10wt% binder solid electrolyte Li 3 OCl and 5 wt% conductive carbon black.

[0068] (2) Preparation of negative electrode ingredient N1

[0069] Graphite, conductive carbon black and solid electrolyte Li 3 OCl is mixed, and put into a ball mill or a stirring tank for ball milling or stirring to obtain a uniformly dispersed negative electrode ingredient N1. In the negative electrode ingredient N1, the solid component includes 85wt% graphite and 10wt% solid electrolyte Li 3 OCl and 5 wt% conductive carbon black.

[0070] (3) Preparation of solid electrolyte layer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com