All-solid-state battery with low interface resistance and preparation method of all-solid-state battery

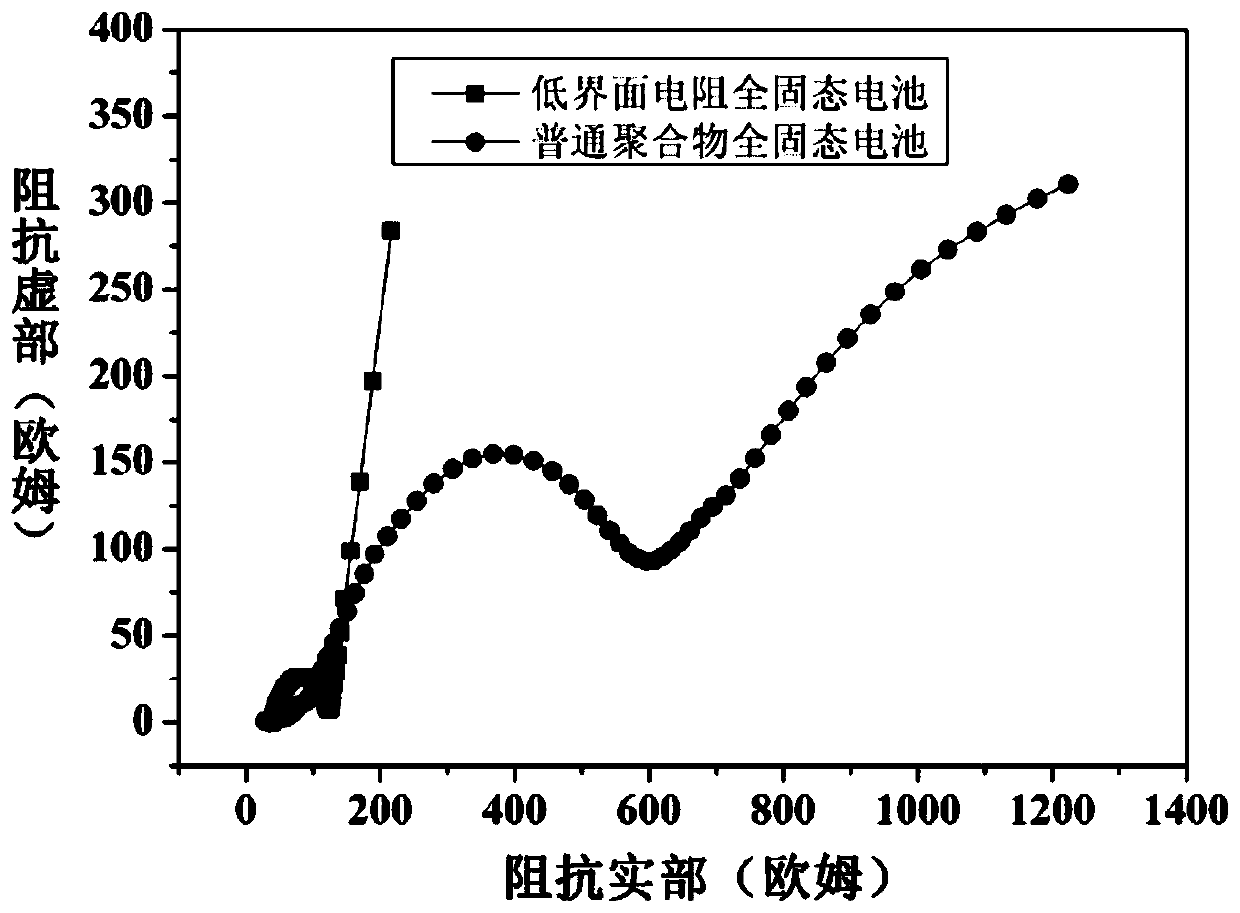

An all-solid-state battery and interface resistance technology, applied in the power supply field, can solve the problems of increased interface impedance, easy interface separation, side reactions, etc., and achieve the effects of reducing interface stress and interface resistance, improving cycle stability, and buffering volume expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

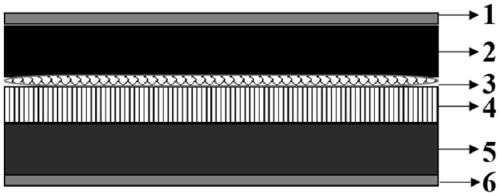

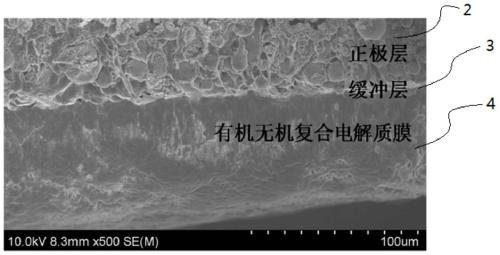

[0050] The invention innovatively combines the preparation method of solid-state thin-film battery with the preparation method of polymer solid-state battery, and arranges a soft buffer layer and an organic-inorganic composite electrolyte membrane between the positive electrode and the negative electrode, and realizes the membrane structure of different components through integrated molding The seamless interconnection greatly alleviates the problem of high interface resistance existing in all-solid-state batteries, and obtains all-solid-state batteries with low interface resistance.

[0051] Concrete preparation method of the present invention is as follows:

[0052] Step 1: Prepare the positive electrode slurry, first dissolve the binder in the NMP solution, then add the conductive agent, after dispersion, add the active material and lithium salt to the glue solution according to the mass ratio for dispersion and stirring, and obtain the positive electrode slurry;

[0053] S...

Embodiment 1

[0064] Step 1: Prepare positive electrode slurry. First, the binder polyvinylidene fluoride (PVDF) is dissolved in the NMP solution, then the conductive agent Super P is added, and after dispersion, the active material lithium iron phosphate (LiFePO 4 ) and lithium salt LiClO 4 According to the mass ratio (PVDF:SuperP:LiFePO 4 :LiClO 4 =10:10:77:3) added to the glue solution for dispersion and stirring to obtain positive electrode slurry;

[0065] Step 2: Use a coating machine to coat the positive electrode slurry on the aluminum foil, the coating thickness is 150-300 μm, the drying temperature of the coating machine is 120 ° C, and the pole piece after winding is dried in a vacuum oven at 100 ° C After 24 hours, the dried electrode sheet is rolled and punched to obtain the positive electrode sheet;

[0066] Step 3: mixing polyethylene oxide, LiTFSI, ethylene carbonate and ionic liquid in acetonitrile as a solvent to obtain a uniform polymer slurry;

[0067] Step 4: unifo...

Embodiment 2

[0076] Step 1: Prepare positive electrode slurry. First, the binder polyvinylidene fluoride (PVDF) is dissolved in the NMP solution, then the conductive agent Super P is added, and after dispersion, the active material nickel-cobalt-manganese ternary material (LiNi 0.5 co 0.2 mn 0.3 o 2 ) and lithium salt LiClO 4 According to the mass ratio (PVDF:SuperP:LiNi 0.5 co 0.2 mn 0.3 o 2 :LiClO 4 =10:10:77:3) added to the glue solution for dispersion and stirring to obtain positive electrode slurry;

[0077] Step 2: Use a coating machine to coat the positive electrode slurry on the aluminum foil, the coating thickness is 150-300 μm, the drying temperature of the coating machine is 120 ° C, and the pole piece after winding is dried in a vacuum oven at 100 ° C After 24 hours, the dried electrode sheet is rolled and punched to obtain the positive electrode sheet;

[0078] Step 3: mixing polyethylene oxide, LiTFSI, ethylene carbonate and ionic liquid in acetonitrile as a solvent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com