Method for preparing graphene through full liquid water phase physical stripping

A technology of physical exfoliation and liquid water, applied in the direction of graphene, nano-carbon, etc., can solve the problems of low production efficiency, low efficiency, and low production cost, and achieve the effects of reduced production cost, simple preparation process, and complete lattice structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

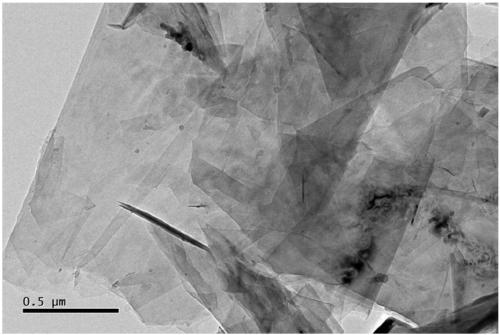

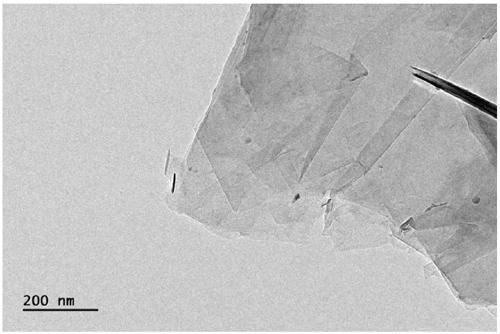

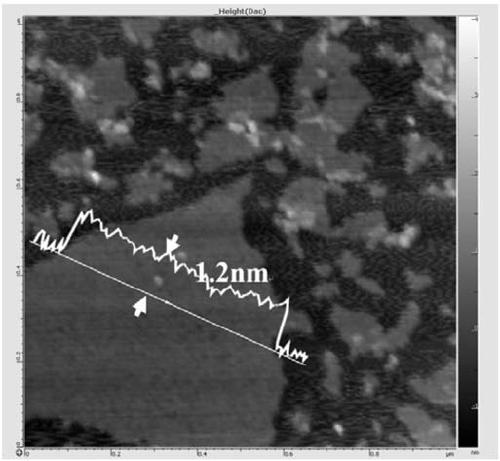

Image

Examples

Embodiment 1

[0038] A method for preparing graphene by physical exfoliation of all liquid water phases, comprising the following steps:

[0039] 1) Add 100g of high-purity and high-carbon-content expanded graphite into 800ml of ultra-pure water and soak for 20 hours for wetting and soaking treatment;

[0040] 2) Put the expanded graphite after wetting and soaking treatment in step 1) into a sand mill equipped with a small amount of zirconium beads and stir for 2h, the rotating speed is 1500rad / min, then put into the colloid mill for 4h, the power of the colloid mill is Be 1.1KW, obtain expanded graphite soaking liquid;

[0041] 3) Put the expanded graphite soaking solution in step 2) into a high-pressure homogenizer, carry out high-pressure homogenization treatment at a pressure of 80Mpa for 2 hours, then use a high-shear emulsification pump for 3 hours, and then use an ultra-high pressure critical device at pressure Treat for 3h under 150Mpa to obtain a graphene dispersion;

[0042] 4) ...

Embodiment 2

[0046] A method for preparing graphene by physical exfoliation of all liquid water phases, comprising the following steps:

[0047] 1) Add 100g of high-purity and high-carbon-content expanded graphite into 1000ml of ultra-pure water and soak for 18 hours for wetting and soaking treatment;

[0048]2) Put the expanded graphite after wetting and soaking treatment in step 1) into a sand mill equipped with a small amount of zirconium beads and stir for 1.5h, the rotating speed is 2000rad / min, and then put into the colloid mill for 3h, the power of the colloid mill is The power is 1.1KW, and the expanded graphite soaking solution is obtained;

[0049] 3) Put the expanded graphite soaking solution in step 2) into a high-pressure homogenizer, perform high-pressure homogenization treatment at a pressure of 80Mpa for 1.5 hours, then use a high-shear emulsification pump for 2.5 hours, and then use an ultra-high pressure critical device Treating for 5h at a pressure of 150Mpa to obtain a...

Embodiment 3

[0052] A method for preparing graphene by physical exfoliation of all liquid water phases, comprising the following steps:

[0053] 1) Add 100g of high-purity and high-carbon-content expanded graphite into 1000ml of ultra-pure water and soak for 20 hours for wetting and soaking treatment;

[0054] 2) Put the expanded graphite after wetting and soaking treatment in step 1) into a sand mill equipped with a small amount of zirconium beads and stir for 3h, the rotating speed is 1200rad / min, then put into the colloid mill for 4h, the power of the colloid mill is Be 1.1KW, obtain expanded graphite soaking liquid;

[0055] 3) Put the expanded graphite soaking solution in step 2) into a high-pressure homogenizer, carry out a high-pressure homogenization process at a pressure of 80Mpa for 2.5 hours, then use a high-shear emulsification pump for 3 hours, and then use an ultra-high pressure critical device to Pressure is 150Mpa under processing 3h, obtains graphene dispersion liquid;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com