Method and device for carboxylation modification of carbon nano-material by ozone and use thereof

A technology of carbon nanomaterials and nanomaterials, which is applied in the field of oxidation modification of nanomaterials, can solve the problems of long processing time and difficulty in regulating the proportion of oxygen-containing functional groups, and achieve the advantages of simple operation, important industrial value and application prospects, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

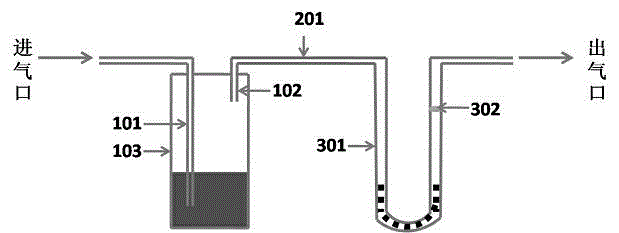

[0027] In this example, see figure 1 and figure 2 , a device for carboxylation and modification of carbon nanomaterials using ozone, mainly including a reaction chamber device, a bubbling device is arranged before the reaction chamber device, an exhaust gas treatment device is arranged after the reaction chamber device, and the bubbling device adopts a sealed solvent Bottle 103, the bottle stopper of solvent bottle 103 is fixedly provided with air inlet pipe 101 and air outlet pipe 102, has good airtightness between the bottle body of solvent bottle 103 and the bottle stopper, puts solvent in solvent bottle 103, one end of air inlet pipe 101 Reaching below the liquid level of the solvent in the solvent bottle 103, the other end of the inlet pipe 101 communicates with the gas supply pipe of the reaction gas. The reaction chamber device 301 adopts a vertically placed "U" shaped reaction tube, and the "U" shaped reaction tube The "U"-shaped inner cavity forms a reaction chamber...

Embodiment 2

[0035] This embodiment is basically the same as Embodiment 1, especially in that:

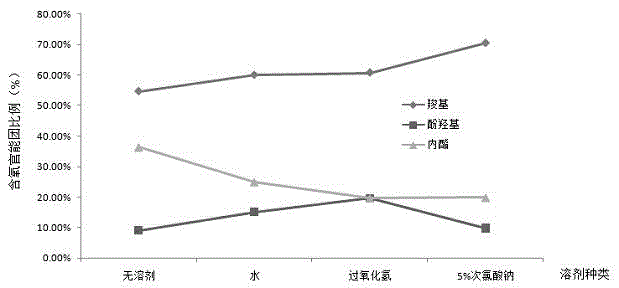

[0036] A kind of method that utilizes ozone to carry out carboxylation modification to carbon nanometer material, use the reaction device identical with embodiment one, operation steps are as follows:

[0037] a. This step is identical with embodiment one;

[0038] B. adopt solvent bottle 103 as bubbling device, first open solvent bottle 103, the hydrogen peroxide of 60ml is injected in the solvent bottle 103 as solvent, then close the bottle stopper, the inlet pipe 101 is communicated with the ozone output pipe of ozone generator , turn on the ozone generator, control the ozone generator to prepare ozone with a volume percentage concentration of 3.6%, pass the ozone / oxygen mixed gas through the hydrogen peroxide in the solvent bottle 103, and make the ozone / oxygen mixed gas carry out solvent bubbling reaction;

[0039] c. This step is the same as the first embodiment.

Embodiment 3

[0041] This embodiment is basically the same as the previous embodiment, and the special features are:

[0042] A kind of method that utilizes ozone to carry out carboxylation modification to carbon nanometer material, use the reaction device identical with embodiment one, operation steps are as follows:

[0043] a. This step is identical with embodiment one;

[0044] B. adopt solvent bottle 103 as bubbling device, at first open solvent bottle 103, the mass concentration of 60ml is that the sodium hypochlorite solution of 5% is injected in solvent bottle 103 as solvent, closes bottle stopper again, air inlet pipe 101 and ozone generator The ozone output pipe is communicated, open the ozone generator, control the ozone generator to prepare the ozone with a volume percentage concentration of 3.6%, pass the ozone / oxygen mixed gas through the sodium hypochlorite solution in the solvent bottle 103, and make the ozone / oxygen mixed gas carry out the solvent drum Bubble reaction;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com