Method for preparing diamond coatings by using SiC precursor method

A diamond coating and precursor technology, which is applied in the coating process and coating of metal materials, can solve the problems of low diamond coating preparation efficiency and poor adhesion performance, and achieve low cost, good consistency and compactness, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

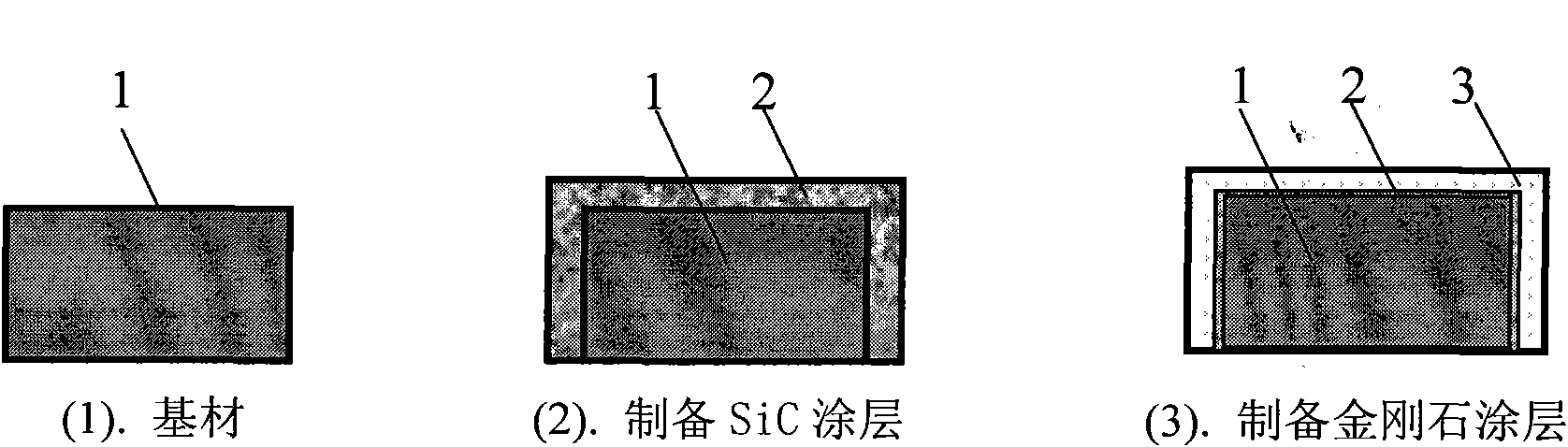

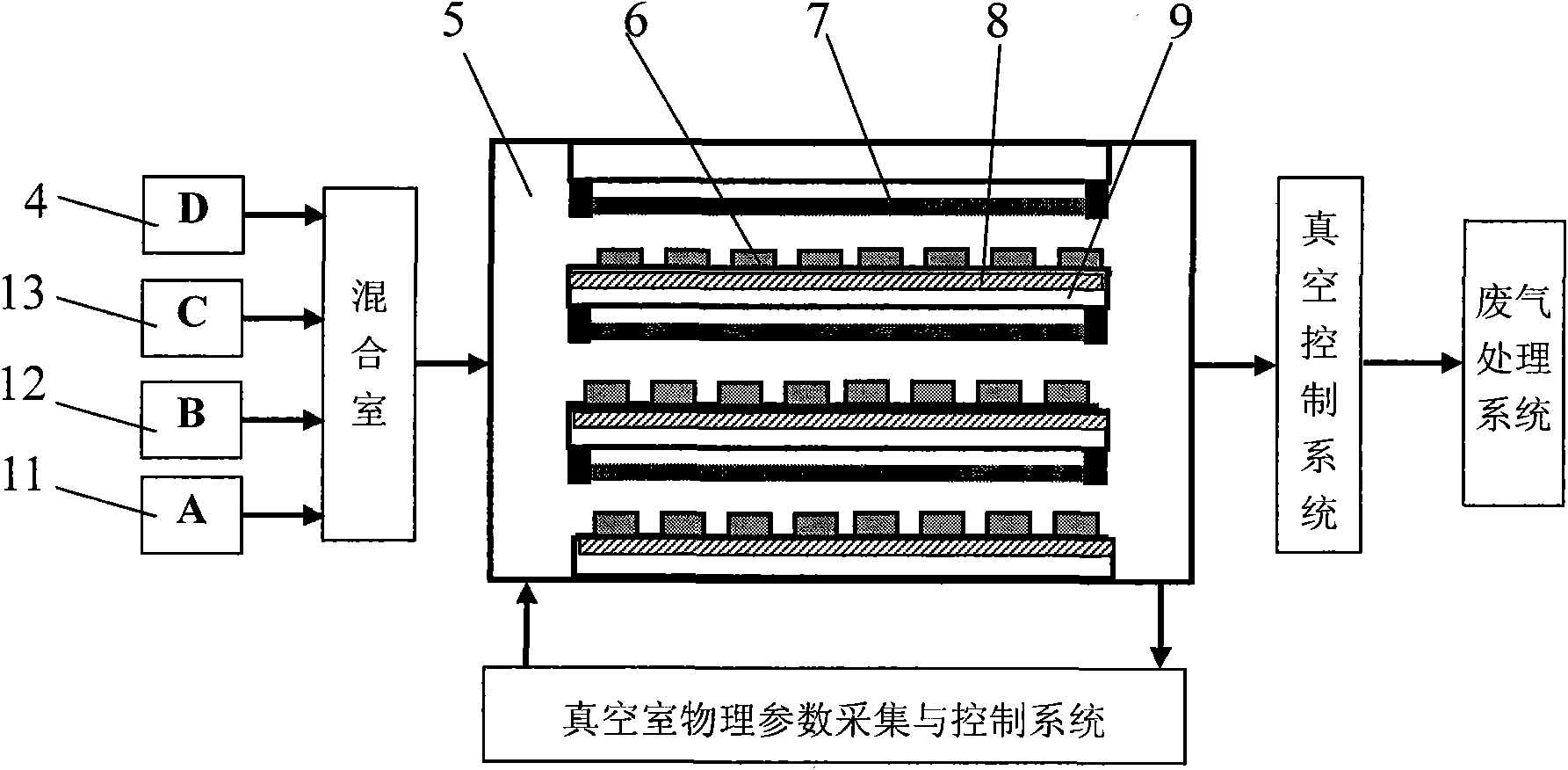

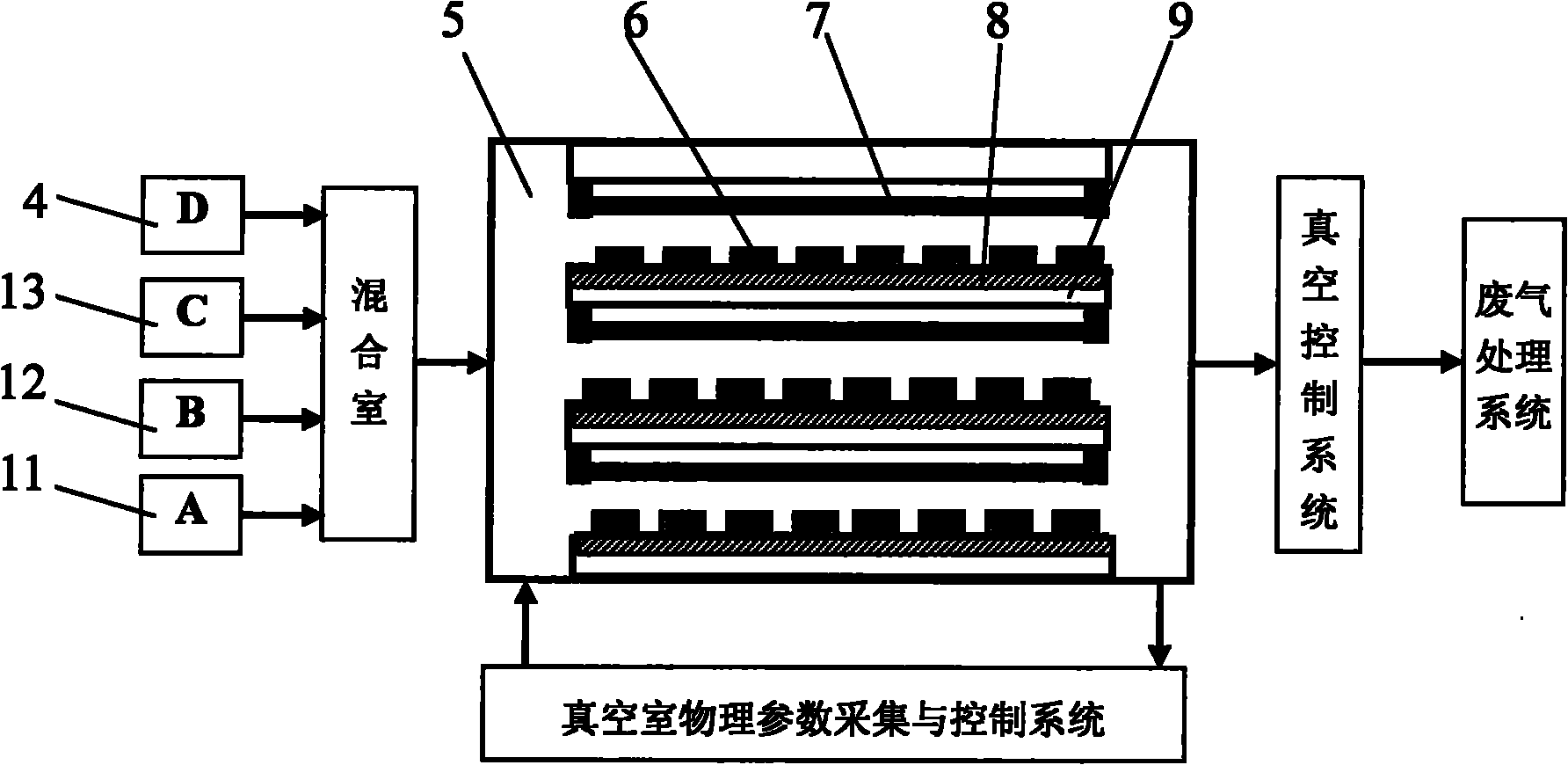

[0024] figure 1 , 2 shown.

[0025] A preparation method of SiC precursor method diamond coating, it comprises the following steps:

[0026] ①Substrate treatment: Select one of high-speed steel, hard alloy, cermet or ceramic as the substrate, and use emery grinding or sandblasting to treat the surface of the substrate so that the surface roughness is 0.01≤Ra≤0.63 microns, Then decontaminate and clean the surface of the substrate, and finally dry the surface of the substrate with clean compressed air and put it in an oven for drying;

[0027] ② Preparation of SiC coating: use one of the methods of physical vapor deposition, chemical vapor deposition or thermal spraying to deposit a SiC coating with uniform thickness and dense structure on the surface of the pretreated substrate, and the thickness of the SiC coating is controlled at 5-50 μm ;

[0028] ③SiC coating treatment: use corundum to sandblast the surface of SiC coating, the pressure of sandblasting compressed air is ...

Embodiment 2

[0039] The difference between this embodiment and the first embodiment is that SiC is directly used as the substrate, which can save the substrate treatment and SiC deposition in the first embodiment, and can directly start from the third step until the desired coating is obtained.

Embodiment 3

[0041] Use YG6 cemented carbide turning tool as the substrate, use 240# emery paper to polish the surface of the substrate, and use an aqueous solution of sodium phosphate (30g / L) + OP emulsifier (2g / L) to polish the surface of the substrate at 70°C Ultrasonic decontamination for 5 minutes, using deionized water to ultrasonically clean the surface of the decontaminated YG6 cemented carbide turning tool for 3 times, drying the surface moisture with clean compressed air, and then putting it in an oven at 120°C for baking 30 minutes. A SiC coating with a thickness of 8 μm was deposited on the surface of the treated YG6 cemented carbide turning tool by chemical vapor deposition. The surface of the SiC coating is sandblasted with 180 mesh corundum, the pressure of the sandblasting compressed air is 0.2Mpa, the surface roughness of the SiC coating after sandblasting is Ra2 、H 2 is the conversion agent, and the gas flow ratio of the conversion agent is Cl 2 :H 2 =1:98 (also can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com