Supported cobalt monatomic catalyst and preparation method and application thereof

A catalyst and supported technology, applied in the direction of catalyst activation/preparation, carbon-based compound preparation, chemical instruments and methods, etc., can solve the problems of restricting large-scale application, high cost and scarcity of precious metal catalysts, and achieve environmentally friendly selective oxidation , low cost, high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

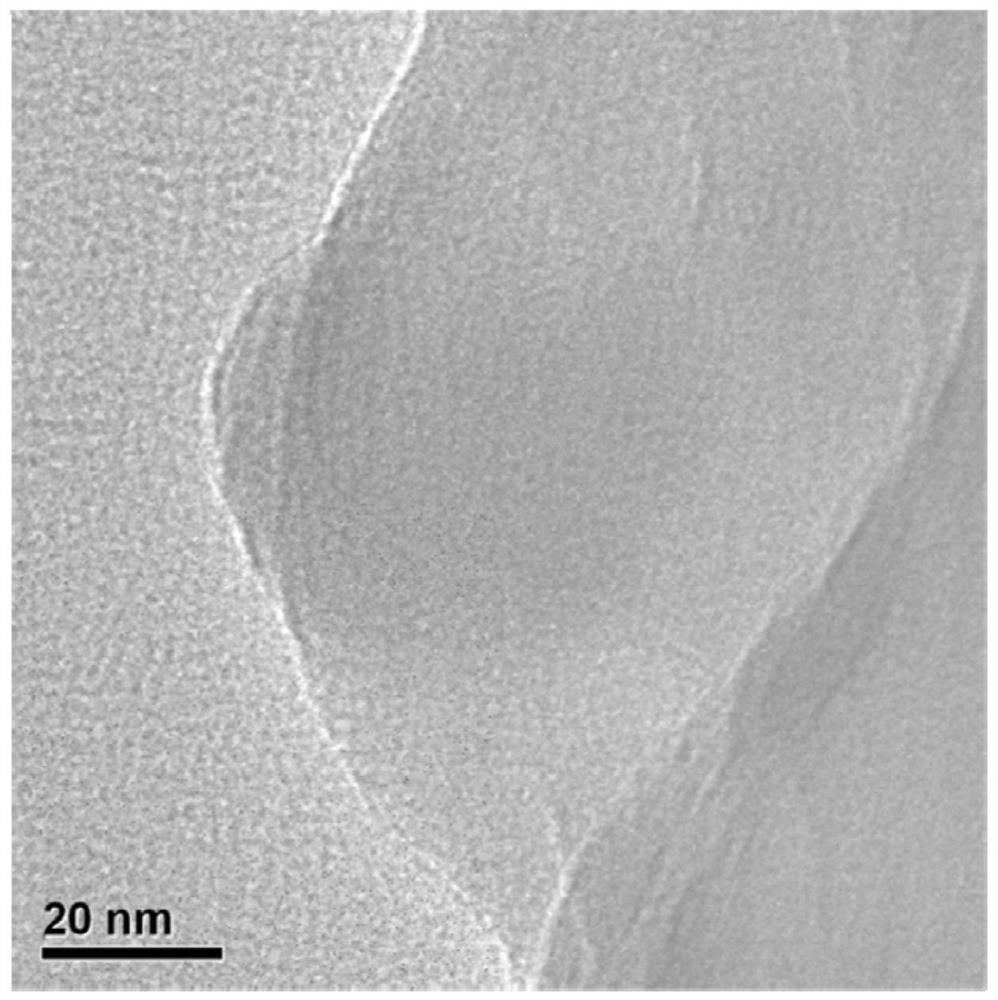

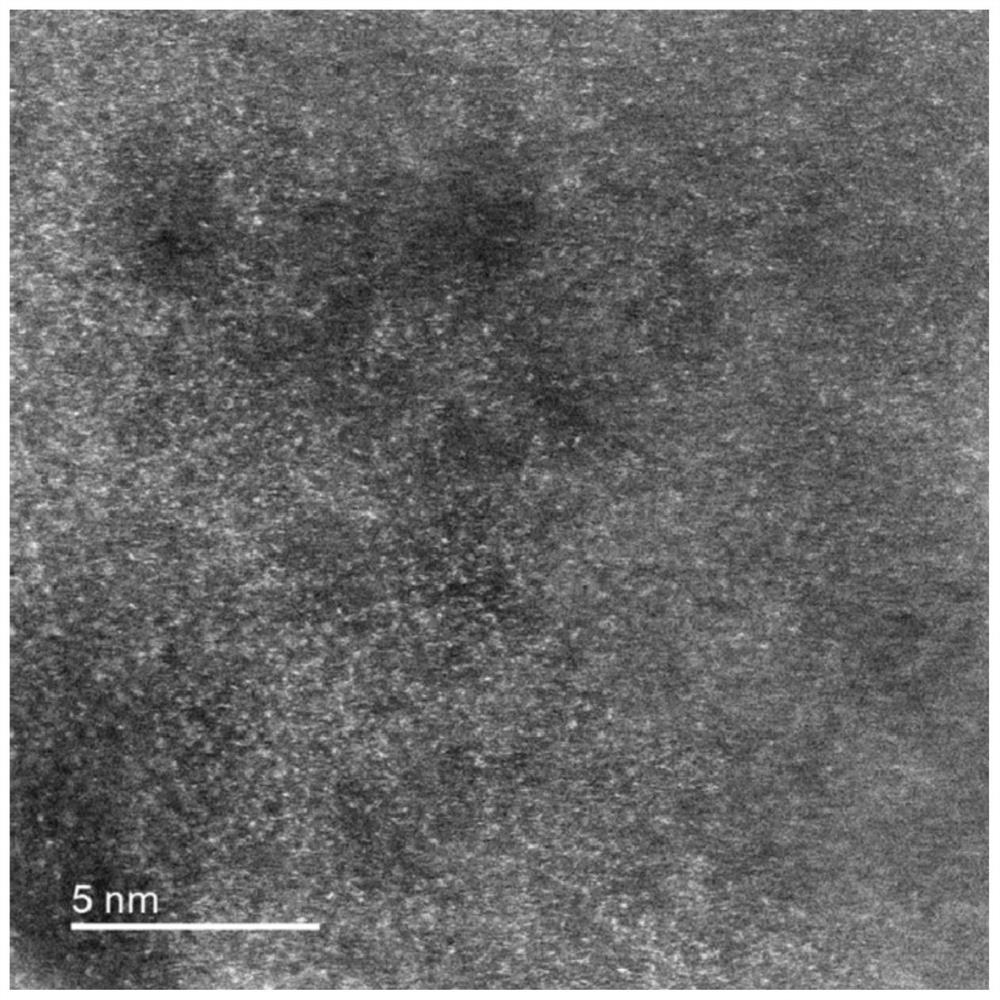

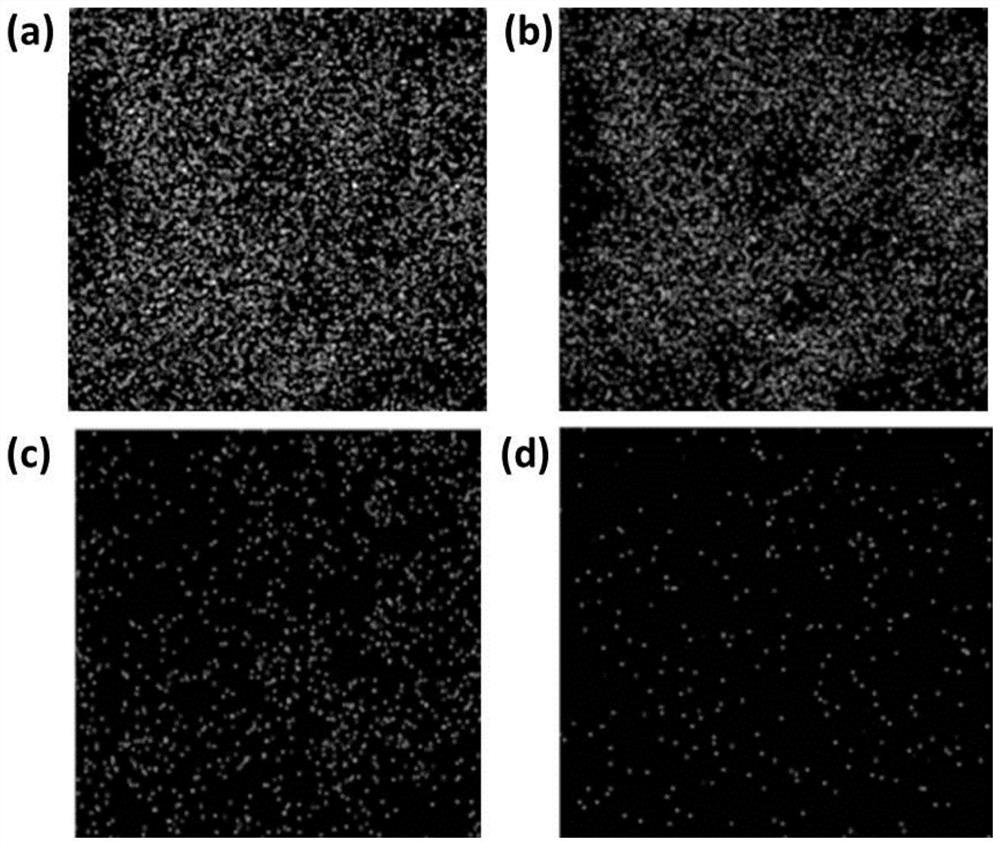

[0076] A preparation method of a supported cobalt single-atom catalyst, specifically comprising the steps of:

[0077] (1) Graphitized carbon nitride (g-C 3 N 4 ) preparation: put 10 g of urea in a crucible with a cover and transfer it to a muffle furnace, raise the temperature of the muffle furnace from room temperature to 600 °C at a rate of 5 °C / min, keep the temperature for 2 hours, and then cool it naturally. The powder was ultrasonically washed in deionized water, centrifuged, and vacuum-dried at 60°C, and the obtained solid powder was g-C 3 N 4 ;

[0078] (2) Composites of cobalt and graphitized carbon nitride (Co 1 / C 3 N 4 ) preparation: the g-C that 160mg step (1) obtains 3 N 4 Mix with 50mL deionized water, ultrasonically disperse evenly and transfer to 80°C oil bath; mix 3mg cobalt nitrate with 1.5mL deionized water to make a solution, and mix it with g-C 3 N 4 The aqueous dispersion was mixed, stirred and reacted in an oil bath at 80°C for 18h; after the...

Embodiment 2

[0085] A preparation method of a supported cobalt single-atom catalyst, specifically comprising the steps of:

[0086] (1) Graphitized carbon nitride (g-C 3 N 4 ) preparation: put 10 g of urea in a crucible with a cover and transfer it to a muffle furnace, raise the temperature of the muffle furnace from room temperature to 450 °C at a rate of 2 °C / min, keep the temperature for 4 hours, and then cool it naturally. The powder was ultrasonically washed in deionized water, centrifuged, and vacuum-dried at 80°C, and the obtained solid powder was g-C 3 N 4 ;

[0087] (2) Composites of cobalt and graphitized carbon nitride (Co 1 / C 3 N 4 ) preparation: the g-C that 50mg step (1) obtains 3 N 4 Mix with 100mL deionized water, ultrasonically disperse evenly and transfer to an oil bath at 100°C; mix 2.5mg cobalt acetate with 30mL deionized water to make a solution, and mix it with g-C 3 N 4 The water dispersion was mixed, stirred and reacted in an oil bath at 100 °C for 10 h; ...

Embodiment 3

[0090] A preparation method of a supported cobalt single-atom catalyst, specifically comprising the steps of:

[0091] (1) Graphitized carbon nitride (g-C 3 N 4 ) preparation: put 10g of urea in a crucible with a cover and transfer it to a muffle furnace, raise the temperature of the muffle furnace from room temperature to 650°C at a rate of 10°C / min, keep the temperature constant for 2.5h and then cool it naturally. The powder was ultrasonically washed in deionized water, centrifuged, and vacuum-dried at 50°C, and the obtained solid powder was g-C 3 N 4 ;

[0092] (2) Composites of cobalt and graphitized carbon nitride (Co 1 / C 3 N 4 ) preparation: the g-C that 500mg step (1) obtains 3 N 4 Mix with 100mL deionized water, ultrasonically disperse evenly and transfer to 60°C oil bath; mix 5mg cobalt chloride with 5mL deionized water to make a solution, and mix it with g-C 3 N 4 The aqueous dispersion was mixed, stirred and reacted in an oil bath at 60°C for 24h; after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com