Patents

Literature

41results about How to "Hydrophobic and lipophilic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

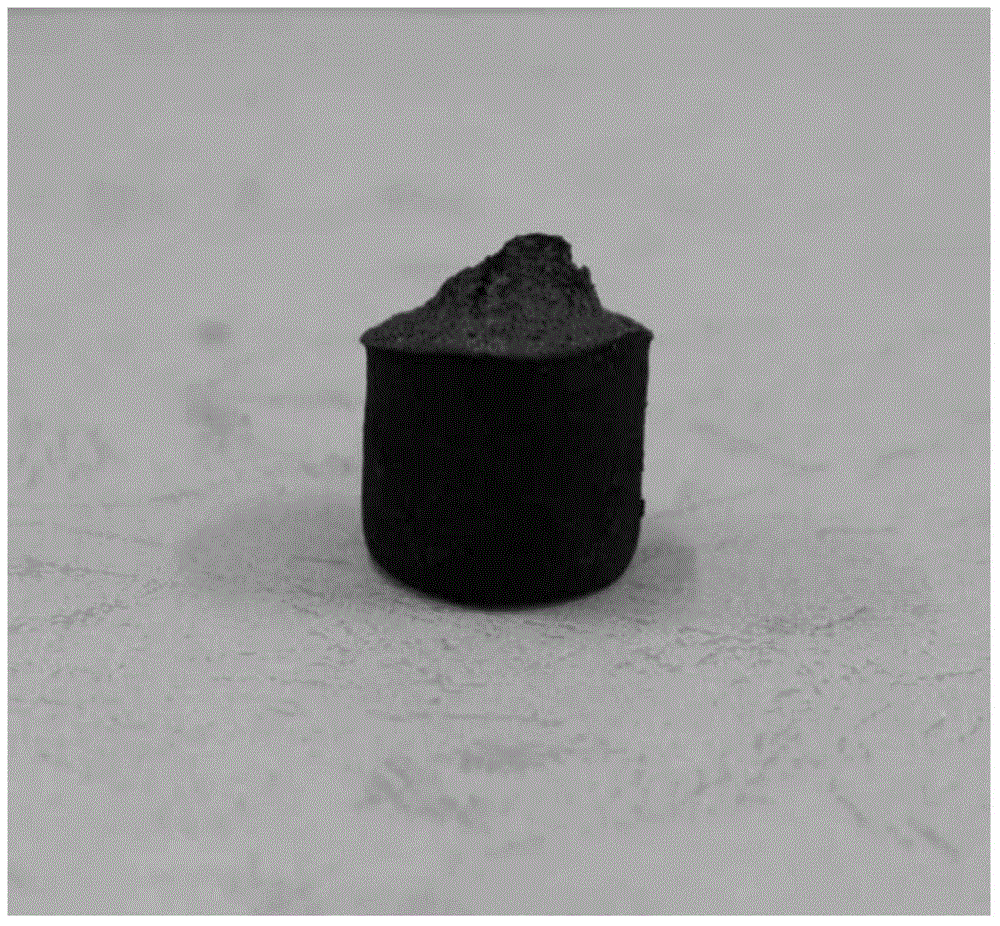

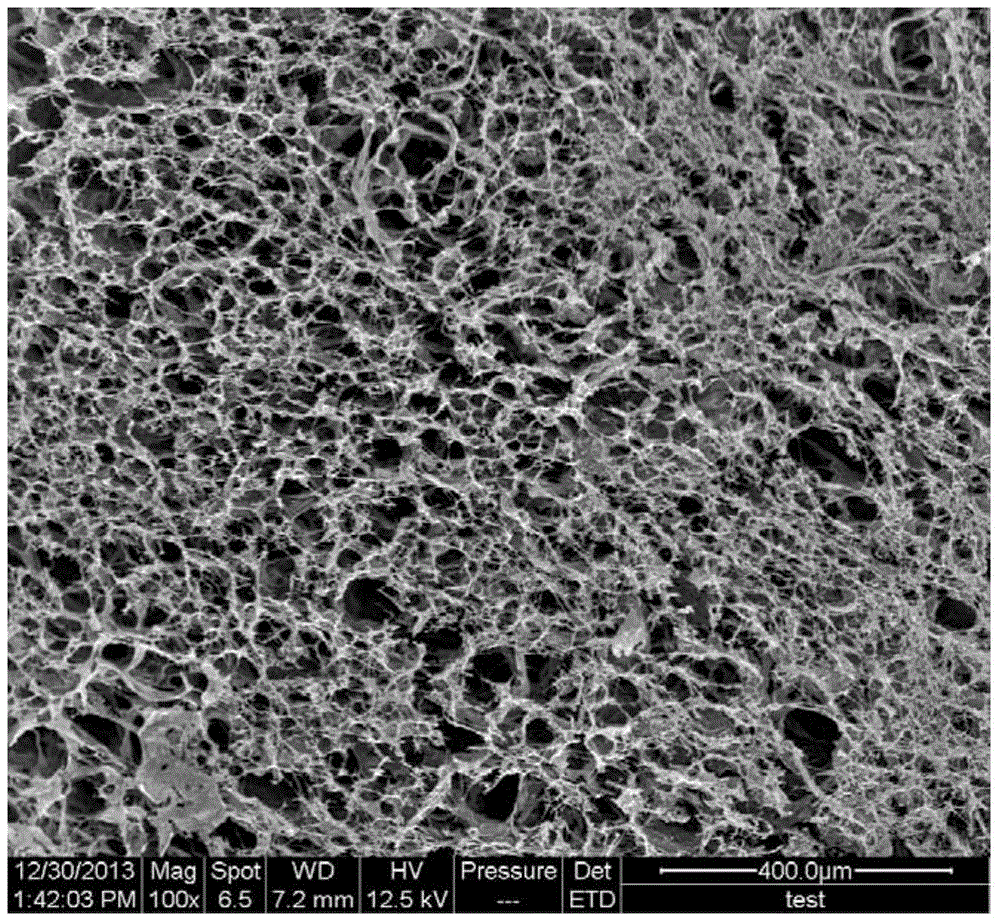

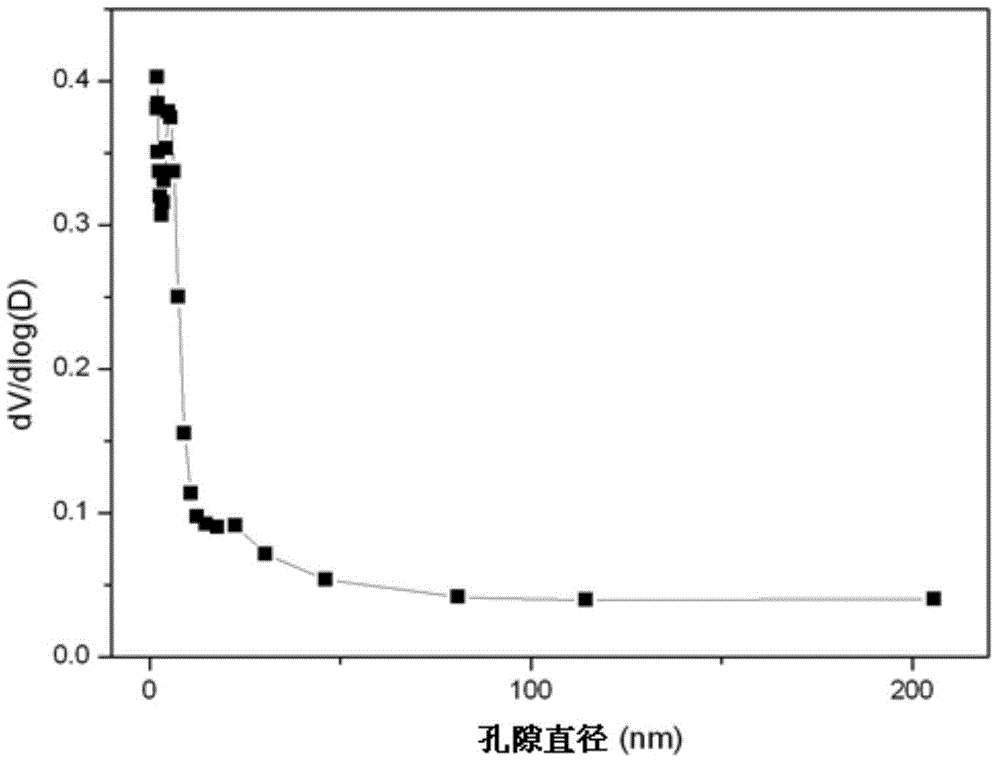

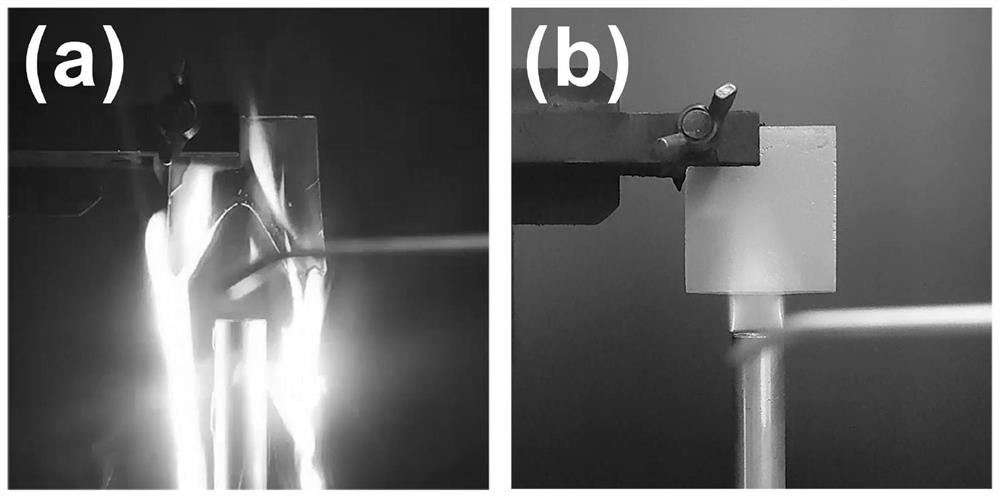

Preparation method of biomass nano cellulose carbon aerogel

The invention relates to a preparation method of a carbon aerogel, particularly a preparation method of a biomass nano cellulose carbon aerogel, and aims to solve the problems of complex preparation process and lack of raw materials in the traditional carbon aerogel. The method comprises the following steps: 1. treatment of biomass material: treating the biomass material with acidified sodium chlorite, and treating with a 1-10 wt% potassium hydroxide solution to obtain purified cellulose; 2. preparing purified cellulose water solutions with different concentrations; 3. mechanical treatment: carrying out ultrasonic treatment on the purified cellulose water solution, carrying out high-pressure homogenization treatment to obtain a nano cellulose water suspension, and standing the nano cellulose water suspension to obtain the nano cellulose aquagel by self-assembly; 4. drying the nano cellulose aquagel to prepare the nano cellulose aerogel; and 5. carrying out carbonizing treatment on the nano cellulose aerogel in a pipe furnace in an inert gas protective atmosphere to prepare the nano cellulose carbon aerogel. The method is applicable to the field of aerogel materials.

Owner:NORTHEAST FORESTRY UNIVERSITY

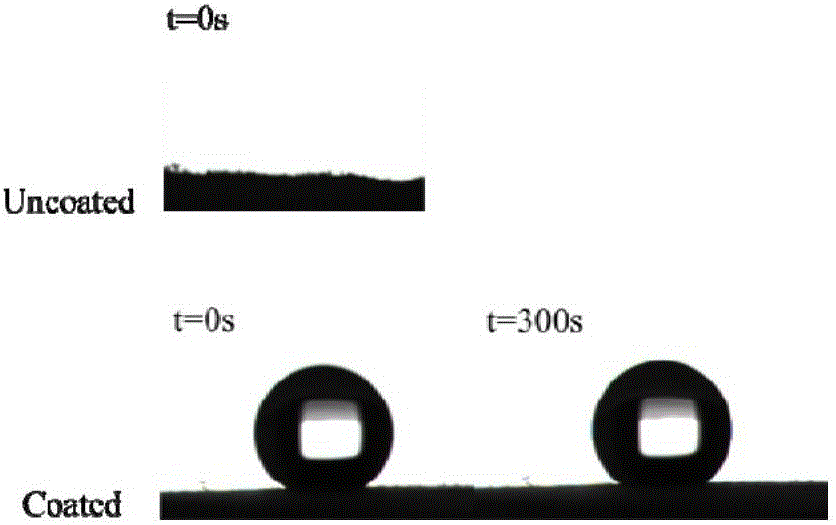

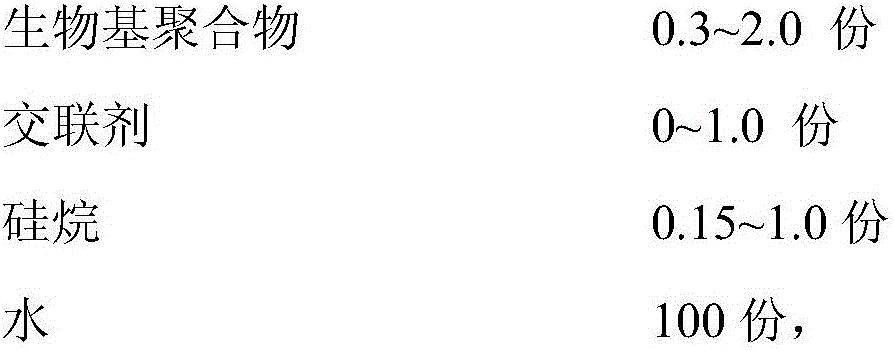

Biology base polymer aerogel oil absorption material and preparation method thereof

The invention discloses a biology base polymer aerogel oil absorption material. The oil absorption material is prepared by the following steps: at first, crosslinking biology base polymers by a crosslinking agent, to obtain a precursor liquid, then freeze-drying the precursor liquid to obtain aerogel, and finally grafting silane onto the aerogel surface to obtain the hydrophobic biology base polymer aerogel oil absorption material. The density of the oil absorption material is 3.8 to 23.1 kg / m3. The water contact angle is at least 117.8 degrees. The adsorption capacities on gasoline, paraffin oil, chloroform, and crude oil are 30.5-109.0 g / g, 33.2-131.2 g / g, 58.2-163.0 g / g, and 24.7-95.8 g / g. After 50 times of gasoline adsorption-extrusion circulation, the retention rate of adsorption capacity is 43 to 99%. The disclosed aerogel oil absorption material has the advantages of large oil absorption capacity and high oil absorption efficiency. Moreover, the oil absorption material can be repeatedly used by simply extruding the oil absorption material, while a high retention rate of adsorption capacity can be maintained. At the same time, the raw material sources are wide, the raw materials are cheap and easily available, the preparation is simple, the technology is matured, the method is environment-friendly, and the requirements of sustainable development can be met.

Owner:SICHUAN UNIV

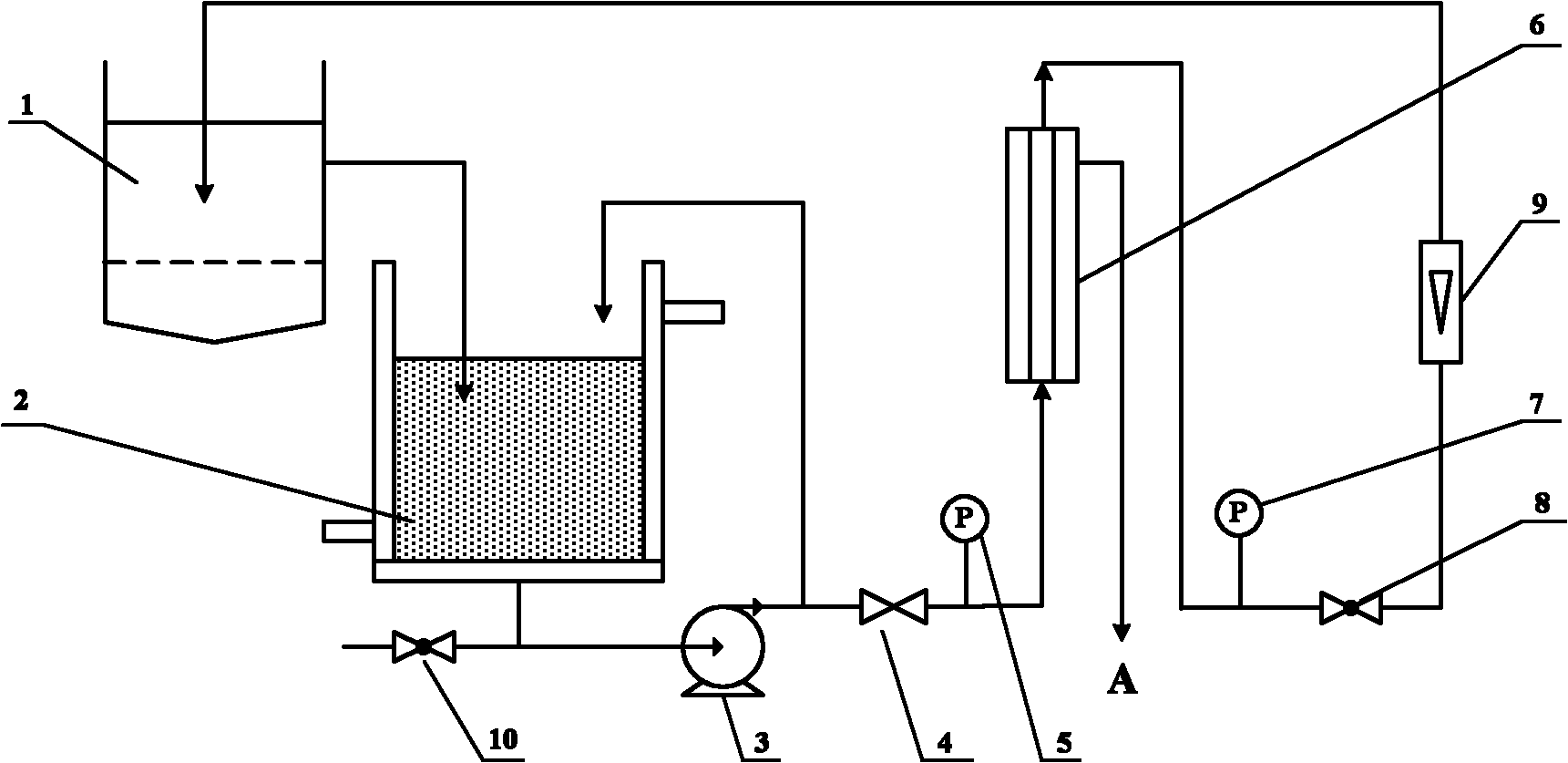

Method for deacidification of alkylation reaction product

ActiveCN102021016AReduce dosageReduce productionRefining by dialysisCross-flow filtrationElectrostatic precipitation

The invention relates to a method for deacidification of an alkylation reaction product. In the method, after being subject to gravity settling, mixed emulsified liquid of the alkylation reaction product (hydrocarbon oil) and sulfuric acid passes through a component with hydrophobic modified ceramic membrane at a membrane surface speed of 0.01-5m / s for separation, and the deacidification of oil is achieved in a cross current filtration mode under the operation pressure of 0.01-0.3MPa and at the operation temperature of 0-40 DEG C. Under the push of pressure, the oil passes through the ceramic membrane, acid in the oil is trapped, and the acid content in the obtained oil is lower than 100ppm, thereby greatly reducing alkaline usage and waste water generation amount in an acid-base refine system of an alkylation technology and reducing the use of electrostatic precipitation; and the ceramic membrane surface is subject to hydrophobic modification, thus the contact angle of water droplet on the membrane surface is 70 degrees-16 degrees. The method is suitable for removal of polar liquid in various oils, has the advantages of simple process, low energy consumption, high separation precision, no environment pollution and high economic and practical value, and is easy to achieve industrial application.

Owner:NANJING UNIV OF TECH

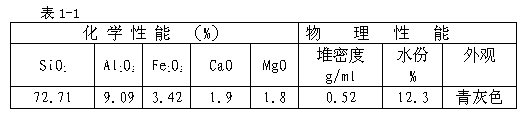

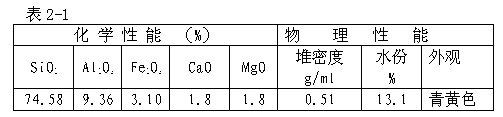

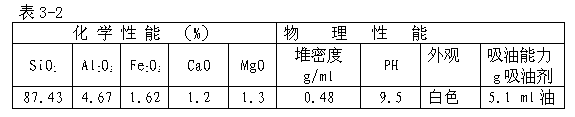

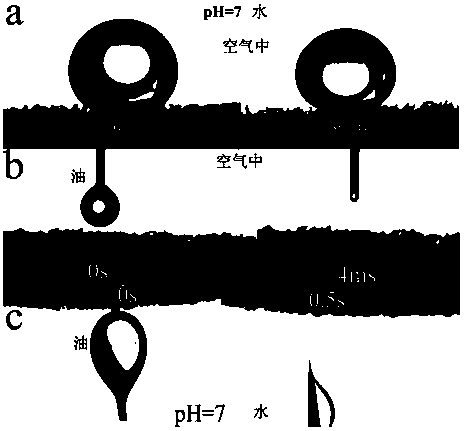

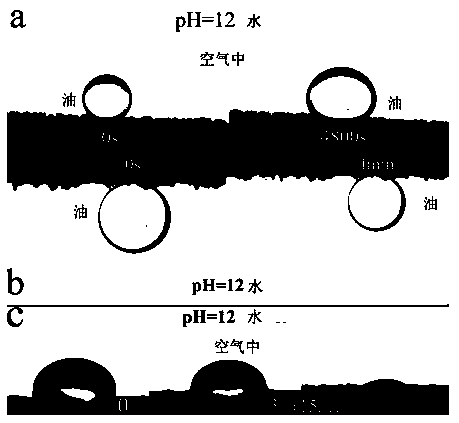

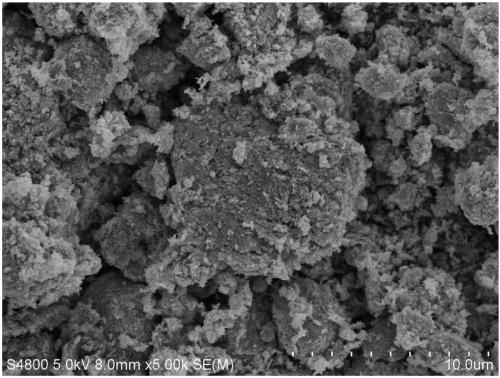

Oil absorbent prepared from low grade diatomite and preparation method thereof

InactiveCN103252209AGood compatibilityGood dispersionFatty/oily/floating substances removal devicesOther chemical processesVolumetric Mass DensityPollution

The invention relates to a preparation method of an oil absorbent, in particular to a method for preparing the oil absorbent from low grade diatomite. The preparation method comprises the following 9 steps of: low grade diatomite raw material selection, crushing, acidification treatment, washing, drying, adding of the assistant (3%-5%) Na2Cl (industrial salt) and mixing, roasting at 750-850DEG C, breaking winnowing, and adding of the silane coupling agent KH-550 (gamma-aminopropyl triethoxysilane, Nanjing Union silicon Chemical Co., LTD. 5%-7%) to conduct modification treatment, thus obtaining the particle and powder diatomite oil absorbent. The oil absorbent has simple and easy preparation method, wide raw material sources and low cost, solves the current solid waste pollution problem of low grade diatomite, opens up a new way for low grade diatomite application, and realizes recycling of waste materials. The oil absorbent has good selectivity, strong absorptivity up to 500% of its own weight, rapid oil absorption speed, small oil absorbent stacking density, a melting point of 1450DEG C, and a high use temperature, and can float on the water surface before and after oil absorption, thus being convenient for recovery and post-treatment.

Owner:任象玉

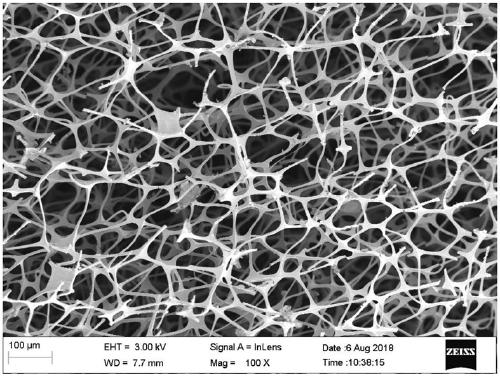

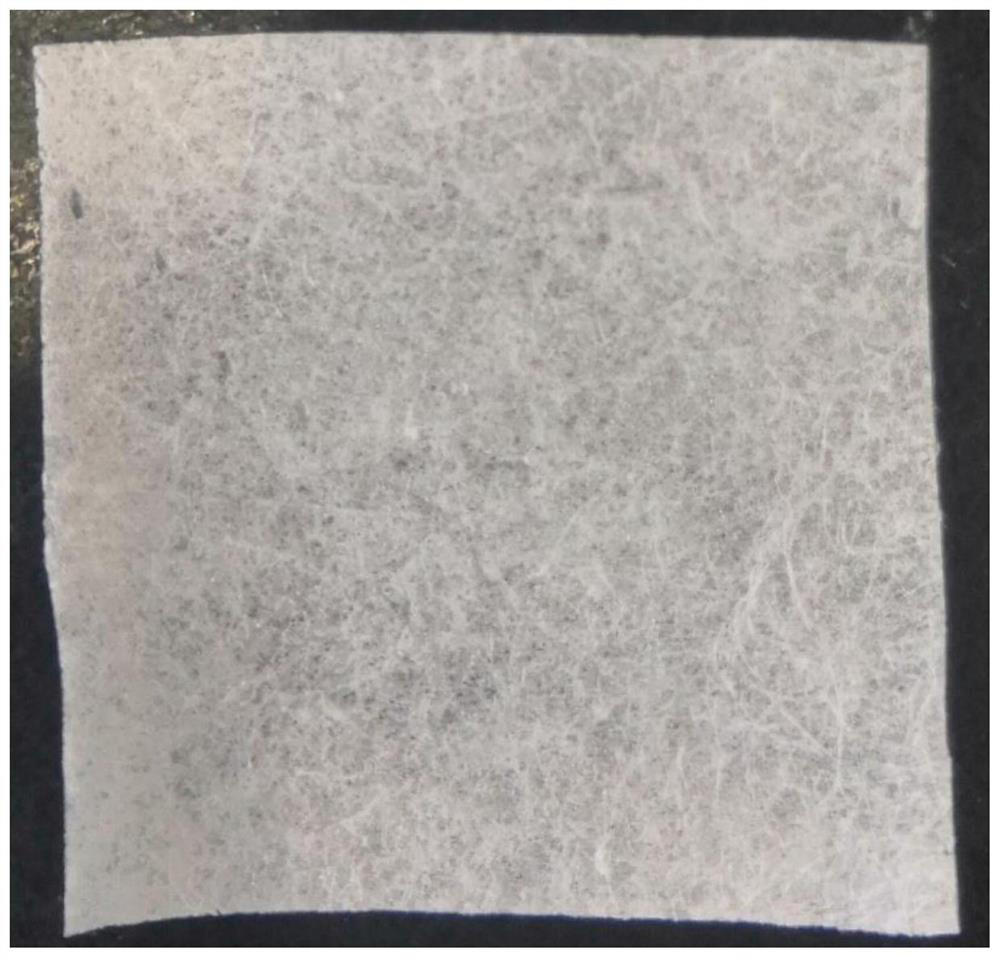

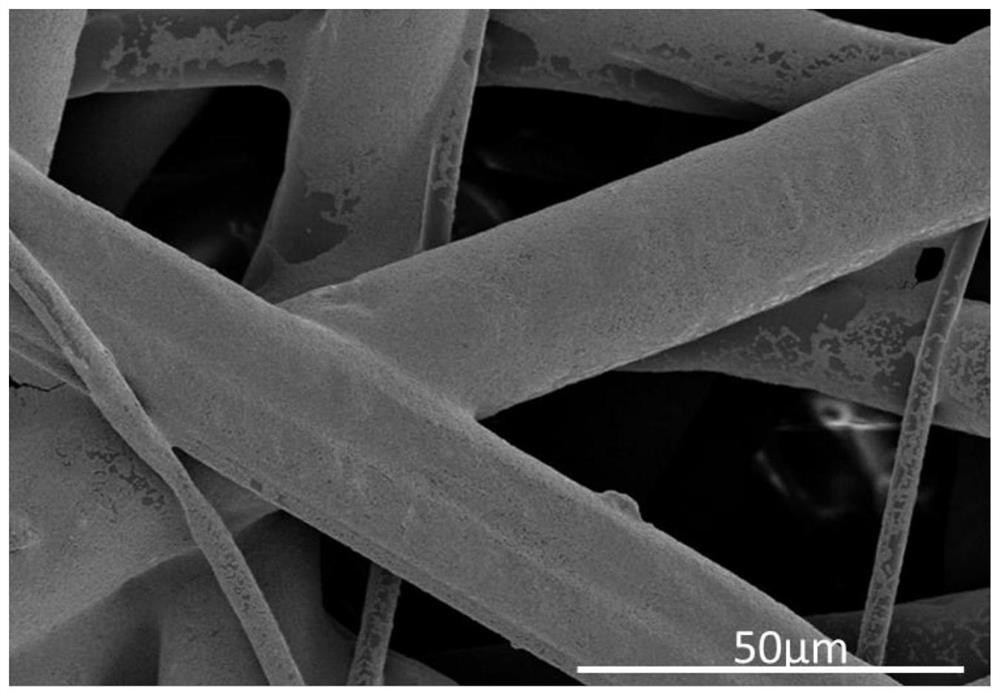

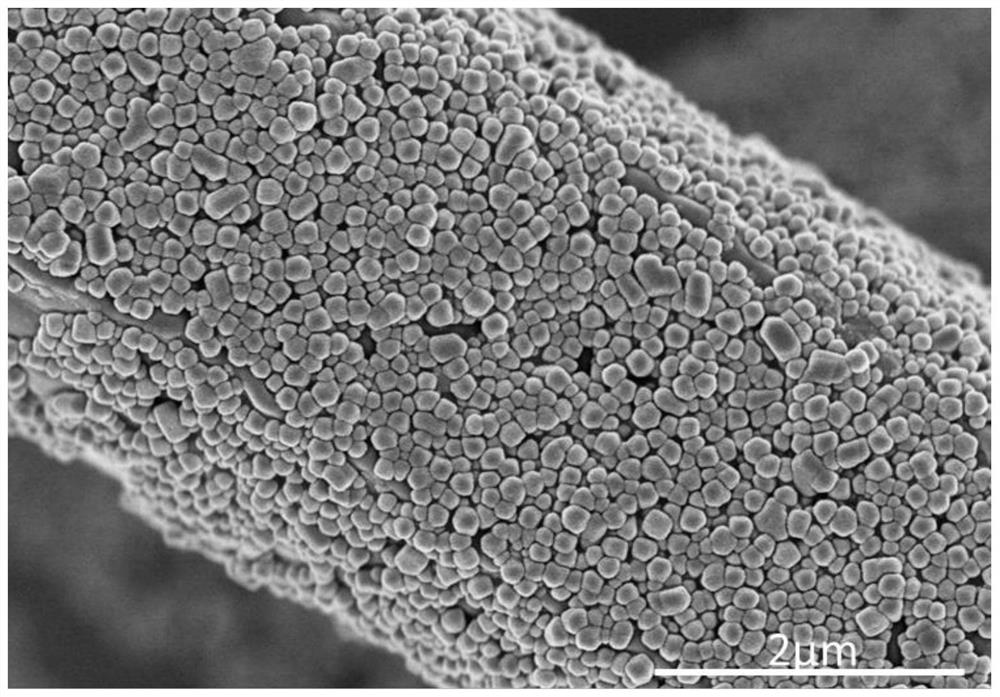

ZIF-8/nonwoven fabric composite material and preparation method thereof

ActiveCN110777537AEvenly distributedHas a multi-level pore structureLiquid repellent fibresNon-woven fabricsNonwoven fabricLipophilicity

The invention discloses a ZIF-8 / nonwoven fabric composite material and a preparation method thereof. The preparation method includes following steps: preparing a ZIF-8 primary solution; putting nonwoven fabric into the ZIF-8 primary solution; drying to obtain the ZIF-8 / nonwoven fabric composite material. ZIF-8 particles are deposited on the surface of the nonwoven fabric in situ by soaking the nonwoven fabric into the ZIF-8 primary solution and standing for aging and uniformly distributed on the surface of the nonwoven fabric, and the ZIF-8 / nonwoven fabric composite material with a multistagehole structure is obtained by adopting the ZIF-8 particles to fill the nonwoven cloth; the composite material has good adsorption performance and excellent hydrophobicity and lipophilicity. Methods ofin-situ deposition and low-temperature drying are adopted, so that the preparation method is simple in process, low in cost and energy consumption and suitable for popularization and implementation.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

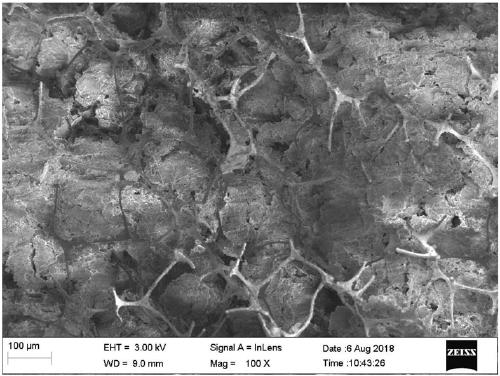

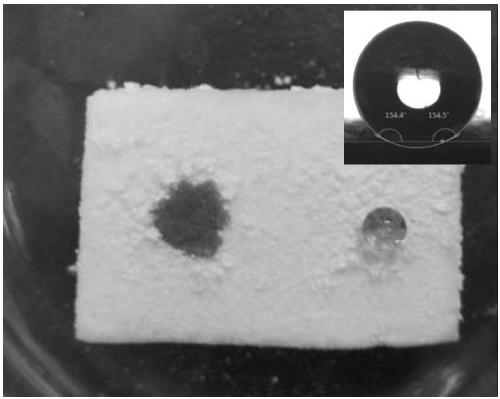

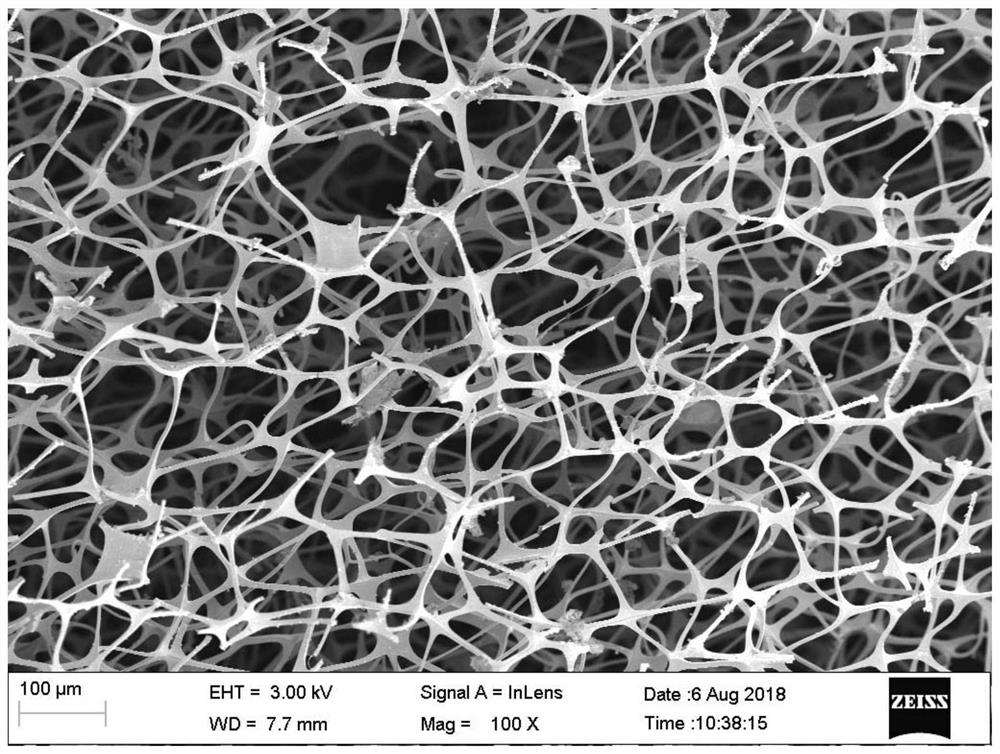

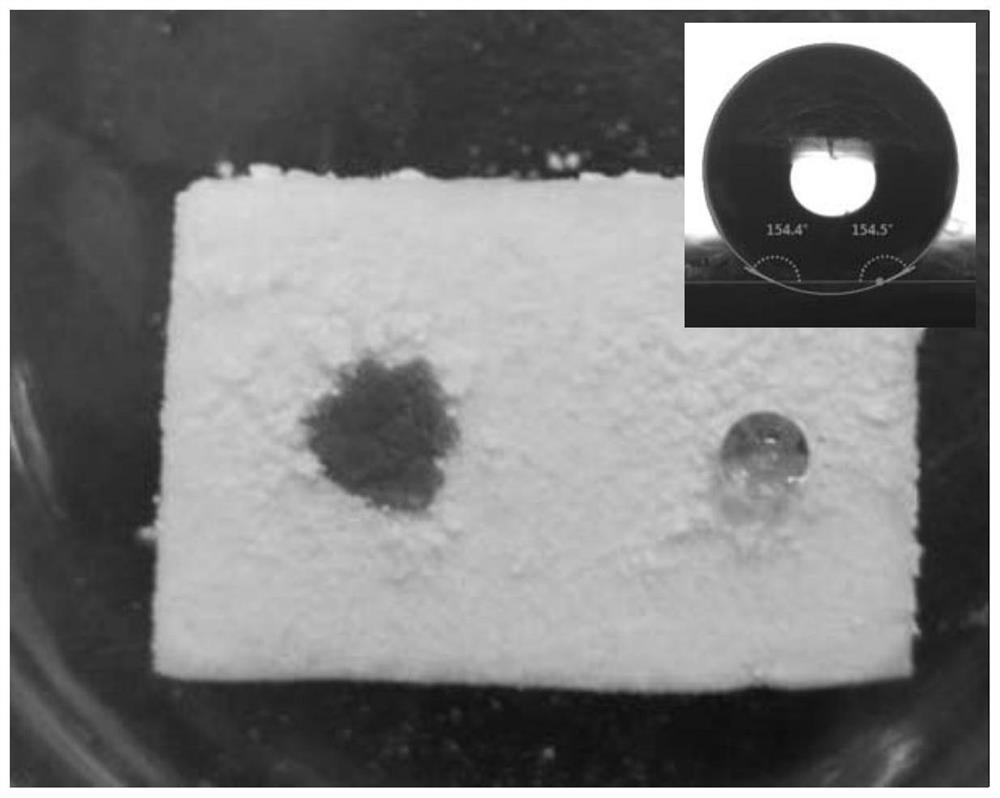

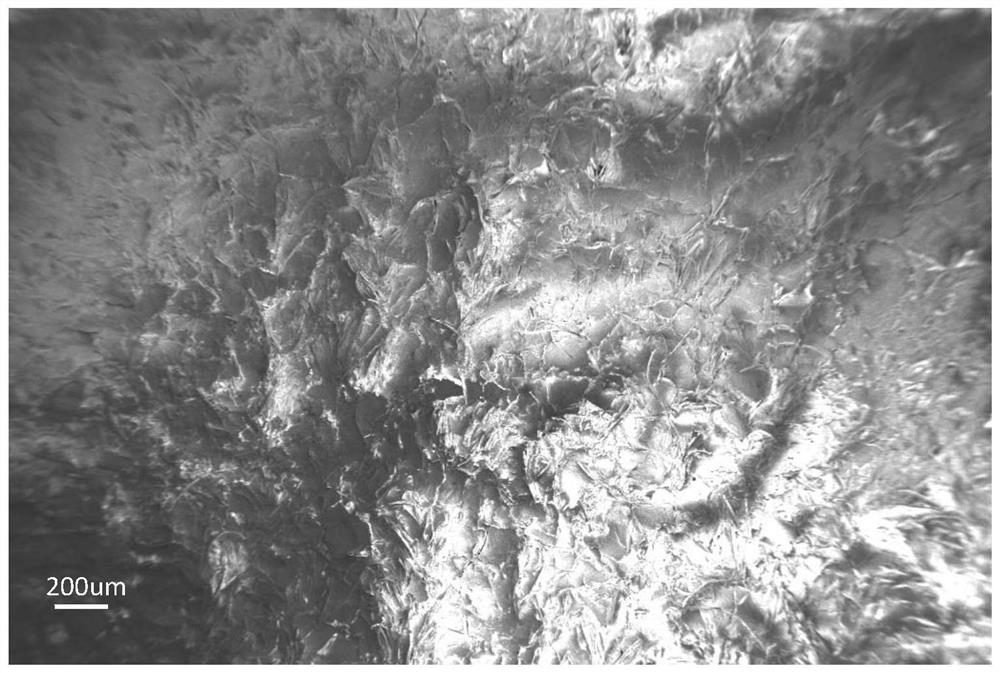

Super-hydrophobic sponge, and preparation method and application thereof

ActiveCN109608689ALow priceHydrophobic and lipophilicOther chemical processesLiquid separationAlcoholOil water

The invention discloses a super-hydrophobic sponge, and a preparation method and application thereof. The preparation method comprises the following steps: putting prepared polydivinylbenzene into absolute ethyl alcohol, carrying out ultrasonic stirring to prepare a polydivinylbenzene suspension, soaking a cleaned and dried sponge into the polydivinylbenzene suspension for 3 minutes, and then putting the soaked sponge into a drying oven for drying to obtain the super-hydrophobic sponge. Compared with other processes, the preparation method disclosed by the invention is simple and feasible in preparation process and mild in environment, and has no complex equipment instrument requirements. The contact angle can reach 154.4 degrees, superhydrophobicity and superoleophilicity are exhibited, an oil-water mixture can be effectively separated, and a good adsorption effect on volatile organic compounds is also achieved. The super-hydrophobic sponge provided by the invention can be widely applied to the fields of water pollution control, atmospheric pollution control and the like.

Owner:SOUTH CHINA UNIV OF TECH

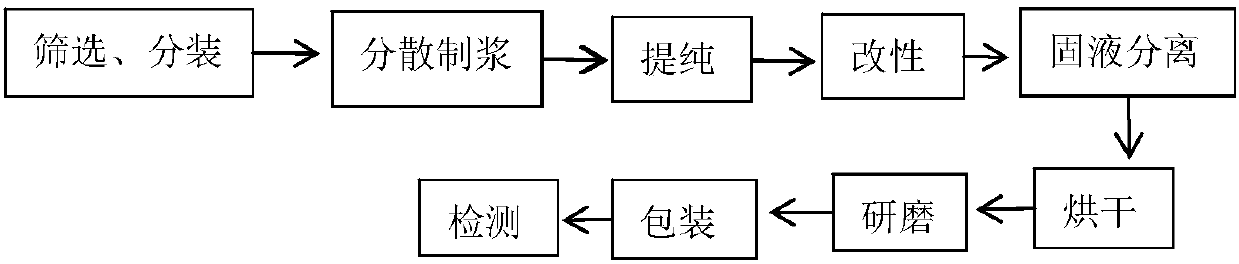

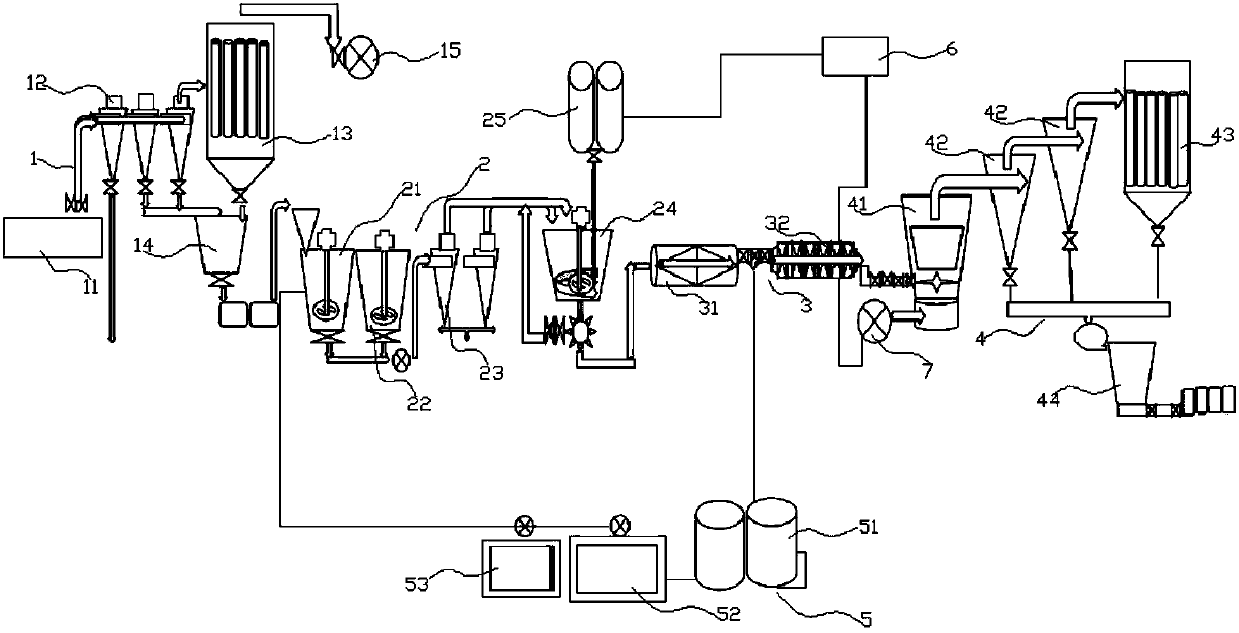

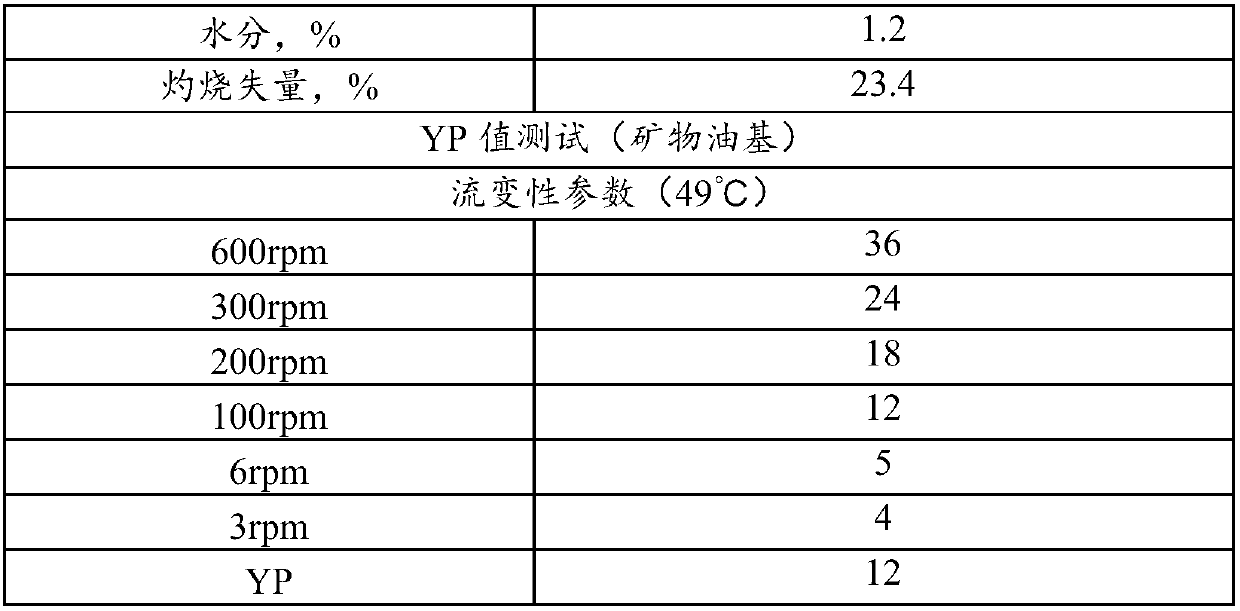

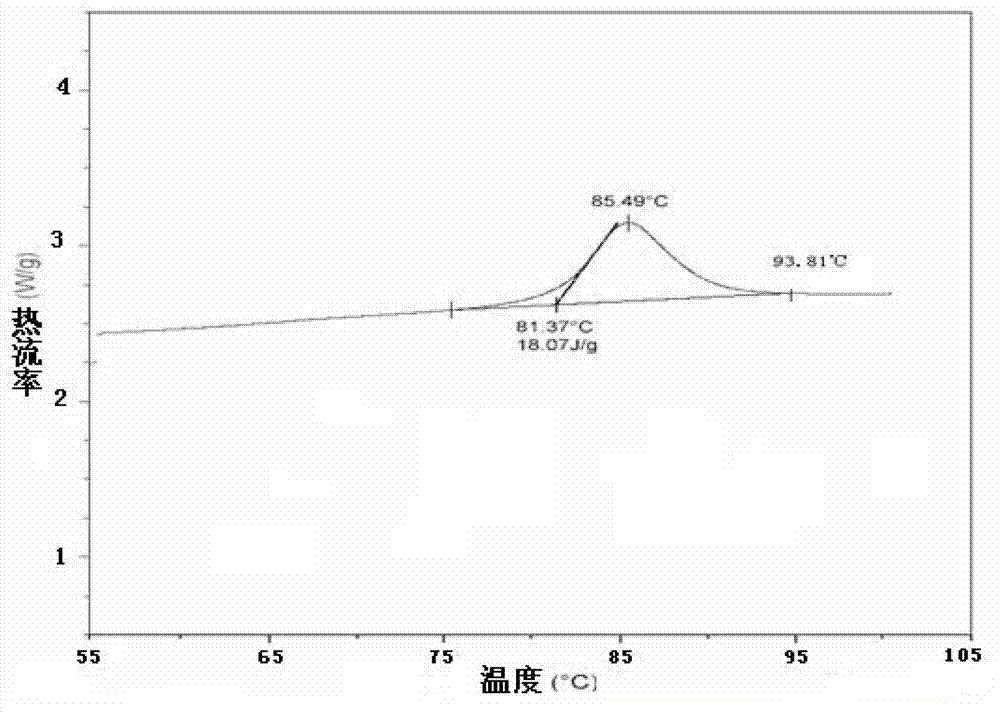

Production method of modified montmorillonite powder and system thereof

The invention discloses a production method of modified montmorillonite powder and a system thereof, and belongs to the technical field of modified montmorillonite powder. The production method disclosed by the invention sequentially comprises the steps of dispersion slurrying, sodium modification, standing for settlement, centrifuging, shear stirring, modification, solid-liquid separation, drying, grinding and packaging and the like; the modified montmorillonite powder with uniform form and stable performance is prepared; the technology is simple, and the energy consumption is reduced. The production system disclosed by the invention comprises a natural soil treatment device, a purifying and modifying device, a separating and drying device, a grinding and packaging device and a wastewatertreatment device, wherein the natural soil treatment device, the purifying and modifying device, the separating and drying device and the grinding and packaging device are communicated in turn; the wastewater treatment device is communicated with the separating and drying device and the purifying and modifying device through a pipeline respectively, so as to form a wastewater circulating loop. The production system has the advantages of compact and reasonable structure, strong industrial operability and good using effect.

Owner:联技精细材料(珠海)有限公司

Method for extracting taro starch and application of taro starch

InactiveCN103242457AHigh purityThe effect of deproteinization is obviousFreeze thawingAnhydrous ethanol

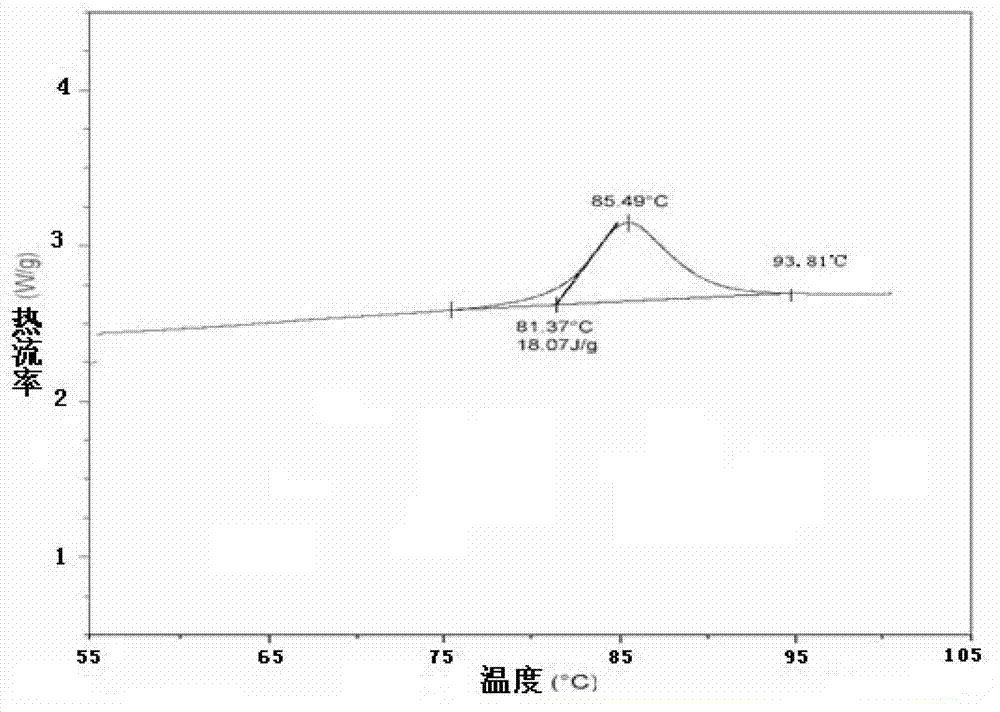

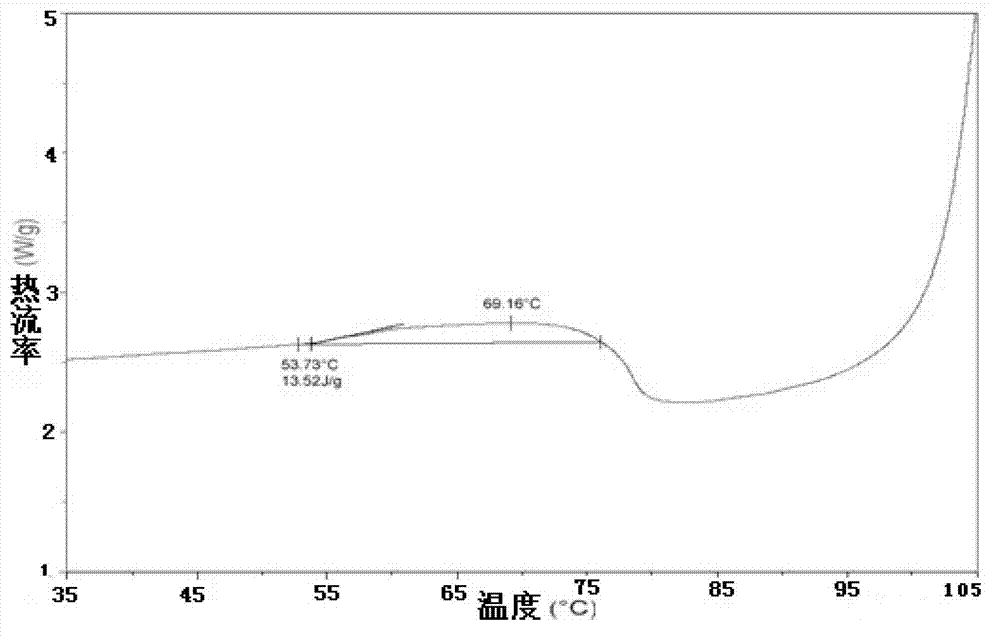

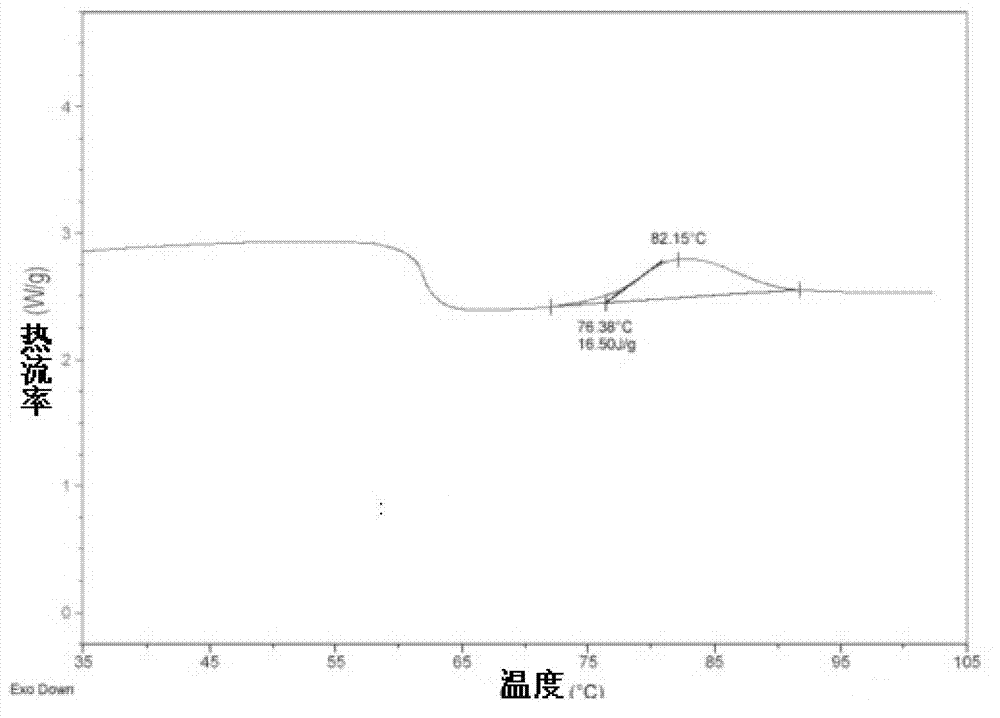

The invention discloses a method for extracting taro starch and a method for preparing modified taro starch from the taro starch. The method for extracting the taro starch is characterized by specifically comprising the steps of peeling and cleaning taros, slicing the taros, soaking the sliced taros in an ammonia water solution for 2-4 min, taking out the sliced taros, crushing the sliced taros, continuously soaking the crushed taros in the ammonia water solution for 2-4 h, sieving, centrifuging filtrate for 15 min at the speed of 3,000 r / s, washing the precipitate obtained through centrifuging by using water, repeatedly centrifuging the precipitate for 15 min at the speed of 3,000 r / s, baking the precipitate which is finally obtained through centrifuging in a baking oven at the temperature of 40-50 DEG C so as to obtain coarse dry starch, crushing the coarse dry starch, degreasing the crushed coarse dry starch for 20-24 h by using methanol with the volume percent of 85%, degreasing the crushed coarse dry starch for 6-8 h by using anhydrous ethanol, baking the crushed coarse dry starch in the baking oven at the temperature of 40-50 DEG C, and crushing, thereby obtaining the taro starch. The methods have the advantages that the deproteinizing and degreasing effects are good, impurities in finished products are few, and the prepared modified taro starch is low in gelatinization temperature, high in viscosity, high in transparency, good in freeze-thaw stability and strong in ageing resistance.

Owner:NINGBO UNIV

Inorganic filling material modified high-molecular absorbent, and preparation method thereof

InactiveCN105037638AHigh oil absorption rateImprove thermal stabilityOther chemical processesButyl methacrylateChemistry

The invention discloses an inorganic filling material modified high-molecular absorbent. The inorganic filling material modified high-molecular absorbent is prepared from, by weight, 3 to 4 parts of bentonite, 2 to 3 parts of calcium carbonate, 1 to 2 parts of hexadecyl trimethyl ammonium bromide, 0.3 to 0.5 parts of liquid paraffin, 0.2 to 0.3 part of titanate coupling agent TC-F, 23 to 25 parts of butyl methacrylate, 22 to 24 parts of tetradecyl acrylate, 4 to 5 parts of tetradecyl acrylate, 21 to 23 parts of ethyl acetate, 1 to 1.2 parts of azodiisobutyronitrile, 0.15 to 0.2 part of ethylene glycol dimethacrylate, 0.9 to 1.2 parts of p-methylstyrene, 1.8 to 2.5 parts of divinyl benzene, 1 to 2 parts of nano aluminium hydroxide, 0.05 to 0.07 part of silane coupling agent kh450, 1 to 1.2 parts of di(isooctyl) phosphate, 0.5 to 0.6 part of silicone oil, and an appropriate amount of distilled water. The inorganic filling material modified high-molecular absorbent is wide in application range, rapid in absorption speed, and convenient and efficient for application.

Owner:ANHUI CHENGFANG NEW MATERIAL TECH

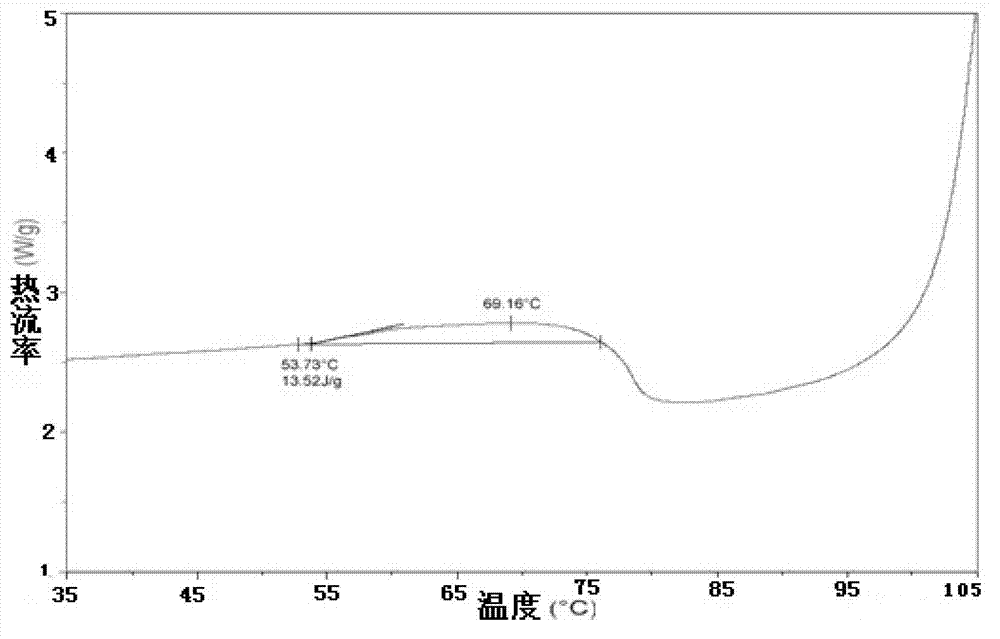

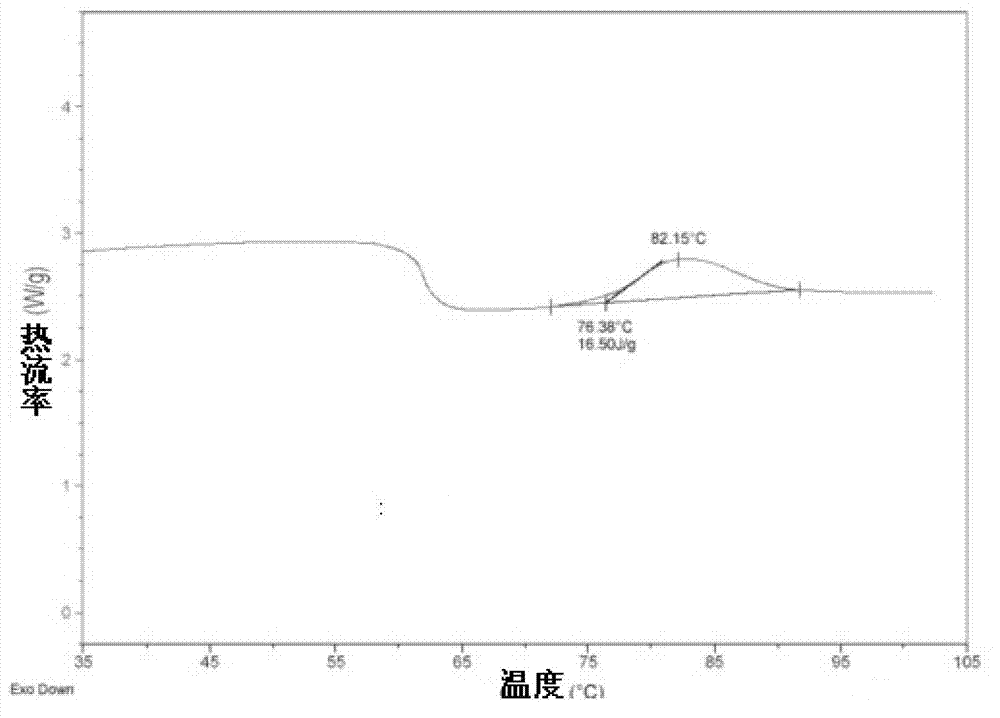

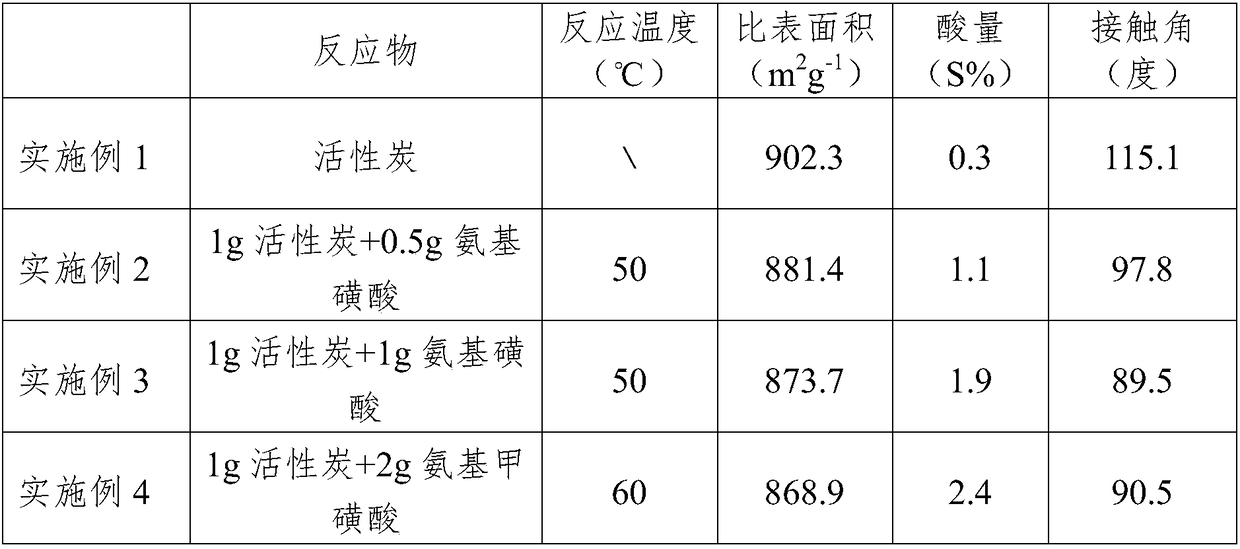

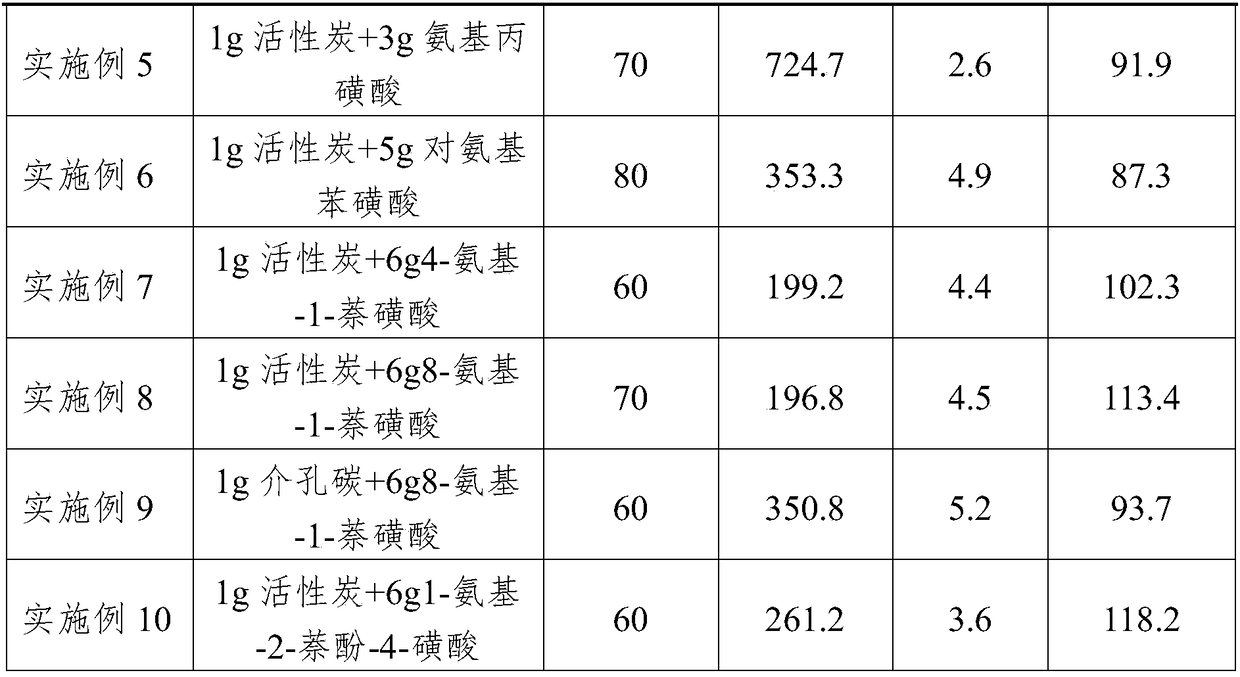

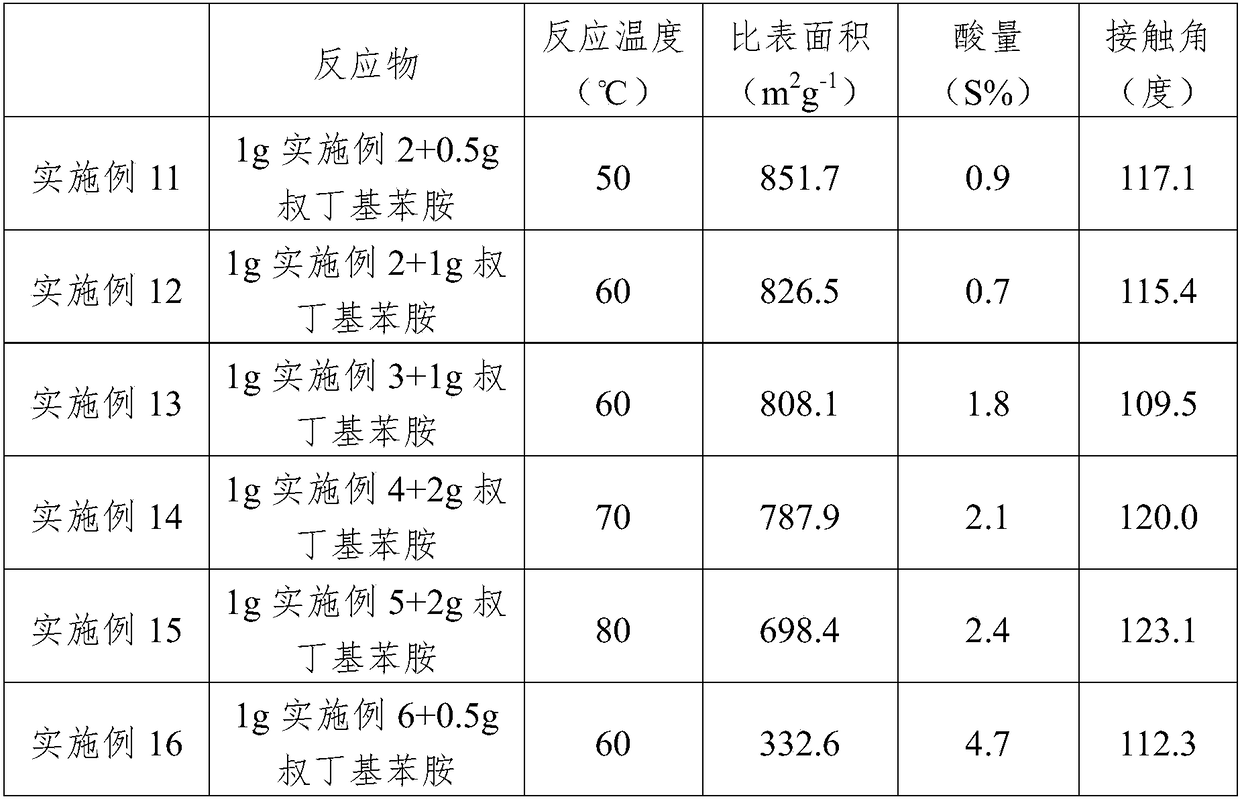

Preparation method of hydrophobic strongly acidic carbon material

ActiveCN108435209AIncrease the areaHydrophobic and lipophilicOrganic-compounds/hydrides/coordination-complexes catalystsPorous carbonSulfamic acid

The invention relates to a preparation method of a hydrophobic strongly acidic carbon material, and belongs to the technical field of catalytic materials. The method comprises the following steps: (1)enabling a porous carbon material and an sulfamic acid compound to be subjected to diazotization in an acidic solvent in the presence of an oxidant, grafting sulfonic acid groups, and generating a strongly acidic carbon material; (2) enabling the strong acidic carbon material prepared in step (1) and tert-butylaniline or n-butylamine to be subjected to diazotization in an acidic solvent in the presence of an oxidant, grafting hydrophobic functional groups, and generating the hydrophobic strongly acidic carbon material. The catalyst prepared with the method has ultrahigh hydrophobicity, higheracid density and better stability; preparation steps are simple, the cheap and available porous carbon material is adopted as a support, equipment requirements are low, industrialization is facilitated, and the material can be used for multiple catalytic reactions and has wide application prospect.

Owner:NANCHANG UNIV

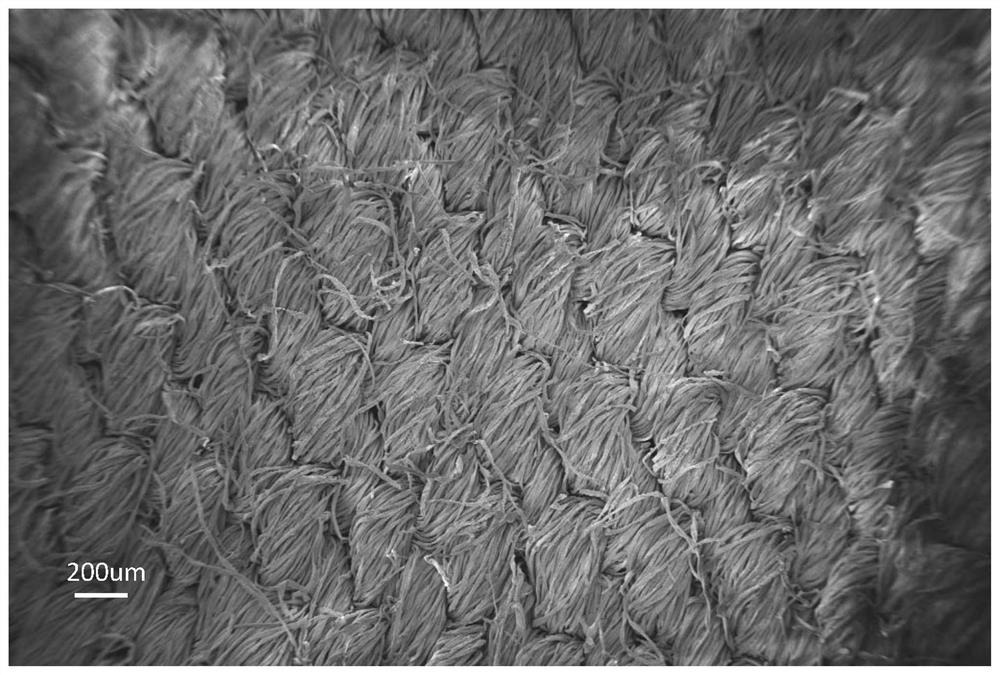

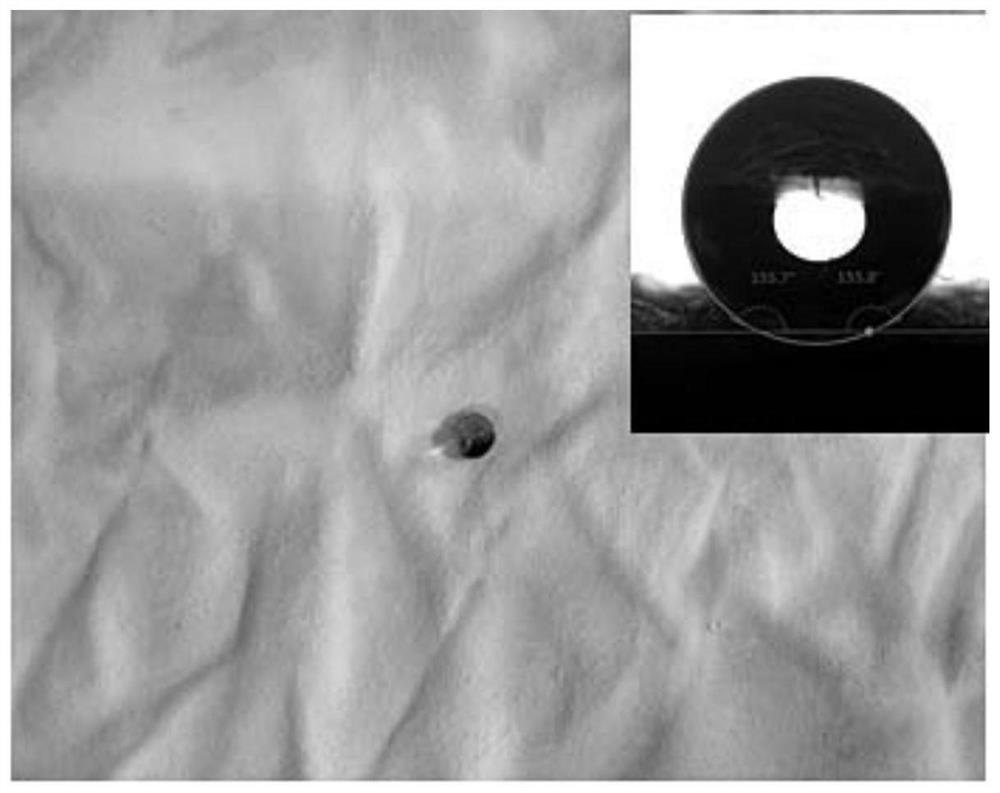

Super-hydrophobicity textile cloth and preparation method and application thereof

ActiveCN109629232AHigh mechanical strengthLow priceLiquid repellent fibresLiquid separationOrganic solventOil water

The invention discloses super-hydrophobicity textile cloth and a preparation method and application thereof. The method comprises the steps that under the effect of an initiator azodiisobutyronitrile,divinyl benzene in an organic solvent is subjected to the polymerization reaction on textile cloth, polydivinylbenzene is generated, and the super-hydrophobicity textile cloth is formed. The contactangle of the textile cloth can reach 155.7 degrees, the super-hydrophobicity characteristic and the super-oleophylic characteristic are shown, and an oil-water mixture can be separated effectively andselectively. The super-hydrophobicity textile cloth can be prepared through a hydrothermal method, and is stable in structural performance, good in reproducibility and capable of being widely appliedto the fields of water pollution control, adsorption of volatile organic compounds and the like.

Owner:SOUTH CHINA UNIV OF TECH

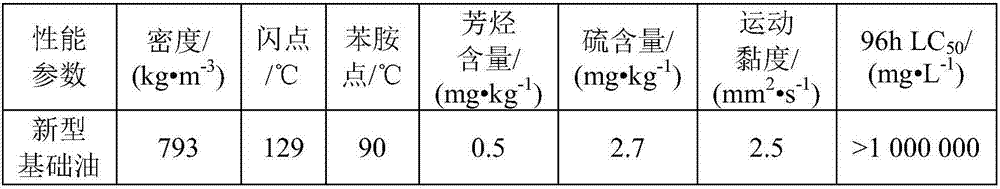

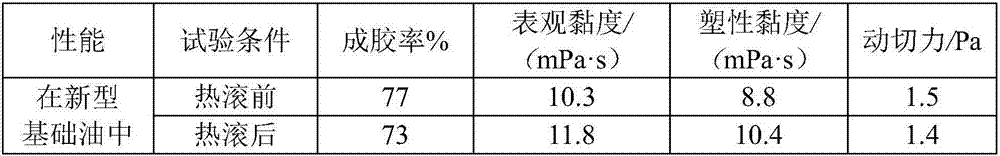

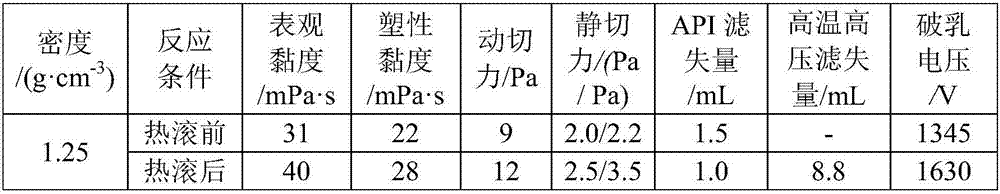

Oil-based drilling fluid and preparation method thereof

The invention provides oil-based drilling fluid and a preparation method thereof. The oil-based drilling fluid comprises the following components in percentage by weight: 10-30 percent of a CaCl2 solution, 2.0-4 percent of modified organic soil, 1.0-2.0 percent of a main emulsifying agent, 1.0-2.0 percent of an auxiliary emulsifying agent, 1.0-2.0 percent of a modified rubber plugging agent, 1.0-2.0 percent of a resin type filtrate reducer, 1.0-2.0 percent of a sulfonated asphalt type filtrate reducer, 1.0-2.0 percent of a wetting agent, 1.0-1.5 percent of an alkalinity regulator, a weighing agent and the balance of base oil, wherein the mass fraction of the CaCl2 solution is 20-25 percent, and a solvent is water; the weighing agent is used for regulating the density of the oil-based drilling fluid to 0.95-2.00 g / cm<3>; the base oil comprises raw material oil after desulfurization and dearomatization treatment.

Owner:PETROCHINA CO LTD

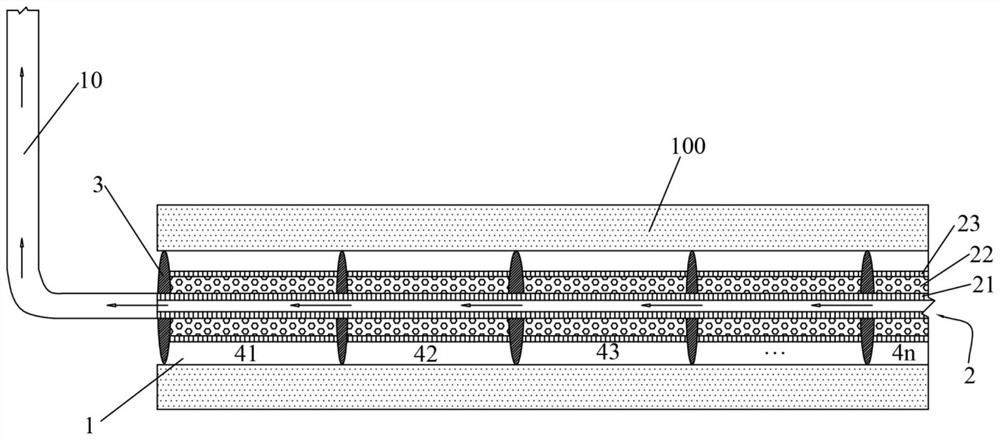

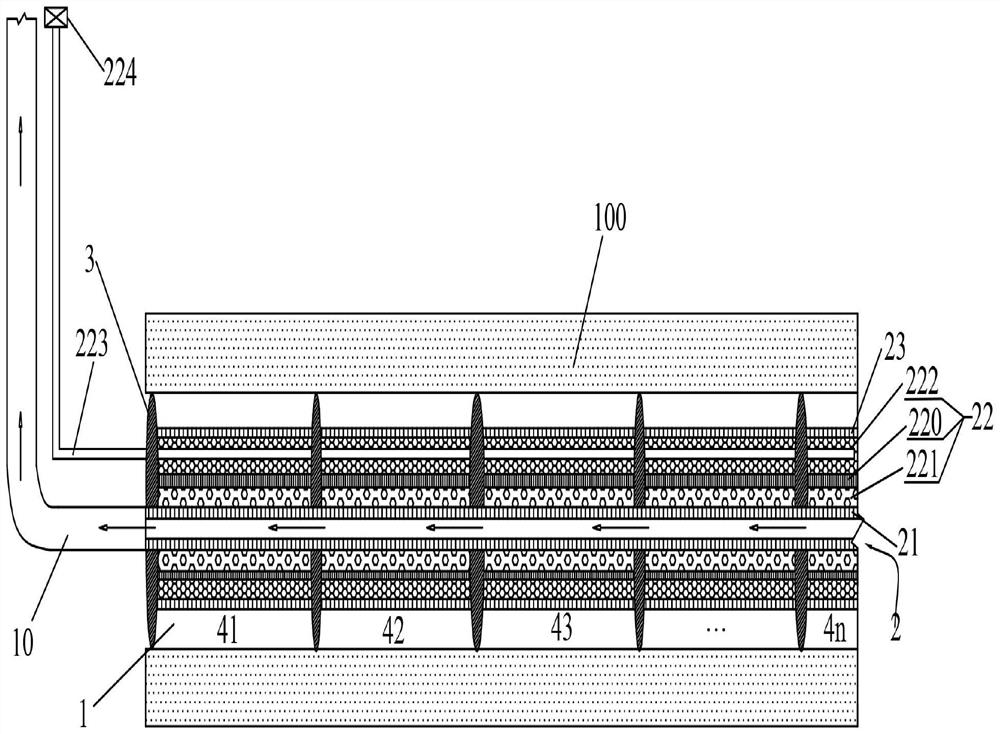

Horizontal well sand prevention and water control pipe string and oil production increasing method

ActiveCN112302580ASpeed up entryReduce post-processing costsFluid removalSealing/packingSocial benefitsHorizontal wells

The invention discloses a horizontal well sand prevention and water control pipe string and an oil production increasing method. The pipe string comprises a sand prevention pipe assembly and a plurality of packers; the sand prevention pipe assembly comprises an inner pipe, a supporting particle layer and an outer pipe; and a hydrophobic oleophylic laminating propping agent is arranged in the supporting particle layer. The method comprises the steps that a water plugging experimental section is selected from a horizontal part of a horizontal well and a reservoir around the horizontal part; thesand prevention pipe assembly is prepared; the sand prevention pipe assembly is installed, and a plurality of packing sections are arranged; and oil in the reservoir is gradually conveyed out, and theoutput of water is controlled. According to the horizontal well sand prevention and water control pipe string and the oil production increasing method, after an oil layer discharges water, an instrument or a tool does not need to be lowered to independently find and control water, the oil layer can be effectively prevented from producing water and allowing oil to pass through the hydrophobic oleophylic laminating propping agent, the productivity is not affected, manual intervention is not needed, and operation procedures are reduced. The method not only can prevent sand, but also can controlwater and convey oil; and the method is simple and effective and has remarkable economic benefits and social benefits.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

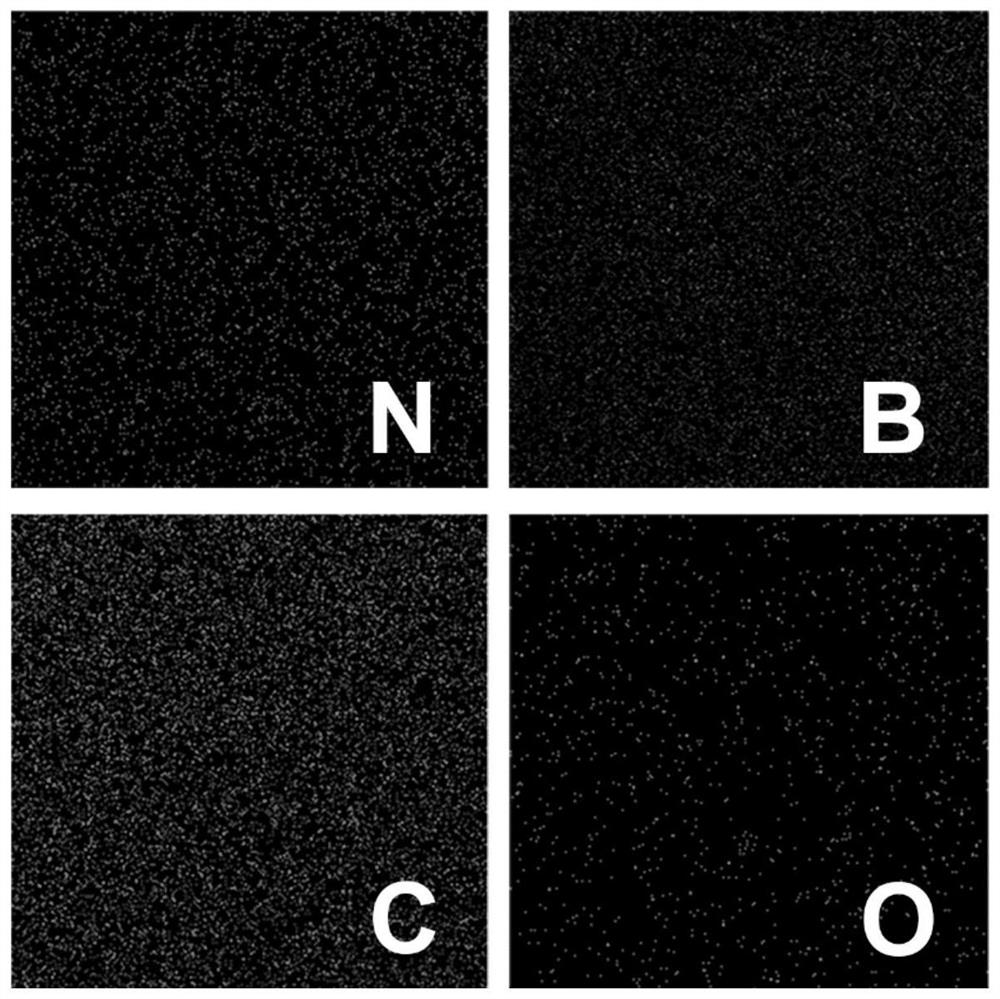

High-thermal-conductivity flame-retardant polyolefin-based composite material and preparation method thereof

ActiveCN112225986AAchieve a strong bondRealize surface hydrophobic modificationThermal dilatationPolyolefin

The invention discloses a high-thermal-conductivity flame-retardant polyolefin-based composite material and a preparation method thereof. The preparation method comprises the following steps: treatinggraphene oxide and boron nitride, and performing combining to form an intermediate; adding a modifier into the intermediate to obtain a modified filler; and compounding the modified filler with polyolefin to form a network structure, synchronously performing in-situ reduction in the process to obtain a powdery composite material, and then performing melting and hot pressing to obtain the high-thermal-conductivity flame-retardant polyolefin-based composite material. The high-thermal-conductivity flame-retardant polyolefin-based composite material prepared by the invention has the advantages that the thermal conductivity can reach 58W / (m.K), the flame-retardant property reaches V0 level, the thermal expansion coefficient is low, the mechanical strength is good, the composite material can bewidely applied to the fields of thermal conductivity and heat dissipation of electronic equipment, and the method is high in preparation efficiency, low in cost and easy for large-scale industrial preparation.

Owner:LANZHOU UNIVERSITY

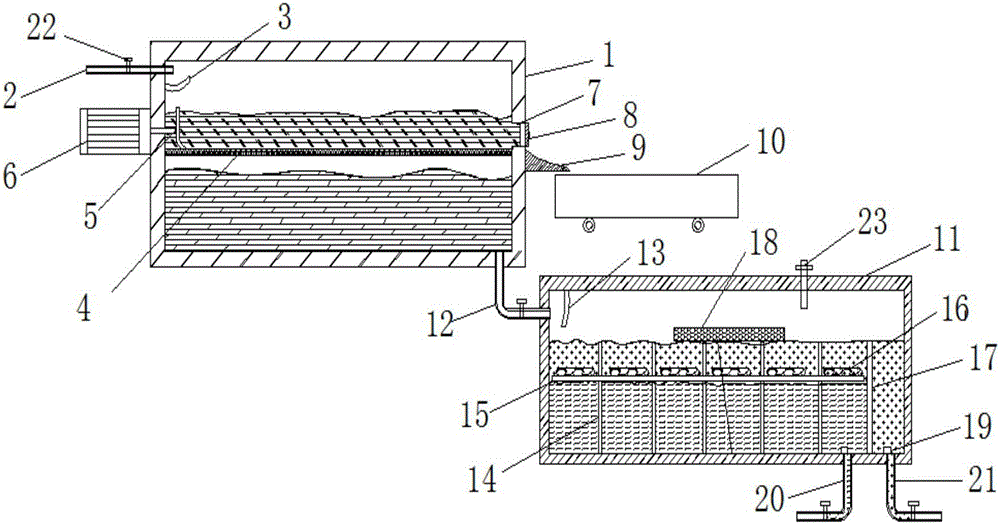

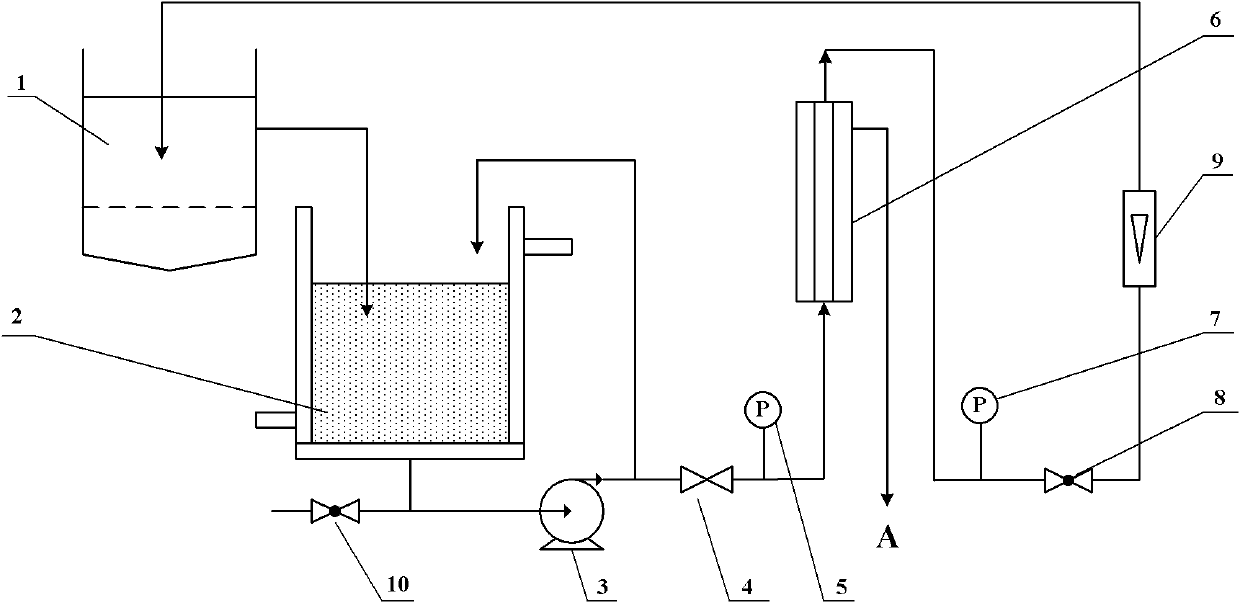

Printing and dyeing sewage and waste material treatment system

InactiveCN106380012AEasy to separateHydrophobic and lipophilicFatty/oily/floating substances removal devicesTreatment involving filtrationHydraulic cylinderSewage

The invention provides a printing and dyeing sewage and waste material treatment system. The printing and dyeing sewage and waste material treatment system comprises a depositing device and an oil-water separator, wherein a sewage and waste material feeding hole is formed in the upper left end of the depositing device; a buffering plate is arranged on an inner wall of the depositing device located just below the feeding hole; a filter screen is horizontally arranged in the middle position of the depositing device. According to the printing and dyeing sewage and waste material treatment system, the filter screen is utilized firstly, and solid-phase waste materials and liquid-phase sewage are separated in the depositing device; in a separation process, the deposited waste materials are pushed out of a discharging hole by a material push plate above the filter screen at fixed time under the driving of a hydraulic cylinder; the waste materials fall into a waste material recycling device through a material guide plate, and the filtered sewage passes through a sewage outlet in the bottom of the depositing device and flows into the oil-water separator through a sewage pipe.

Owner:张家港市双盈印染有限公司

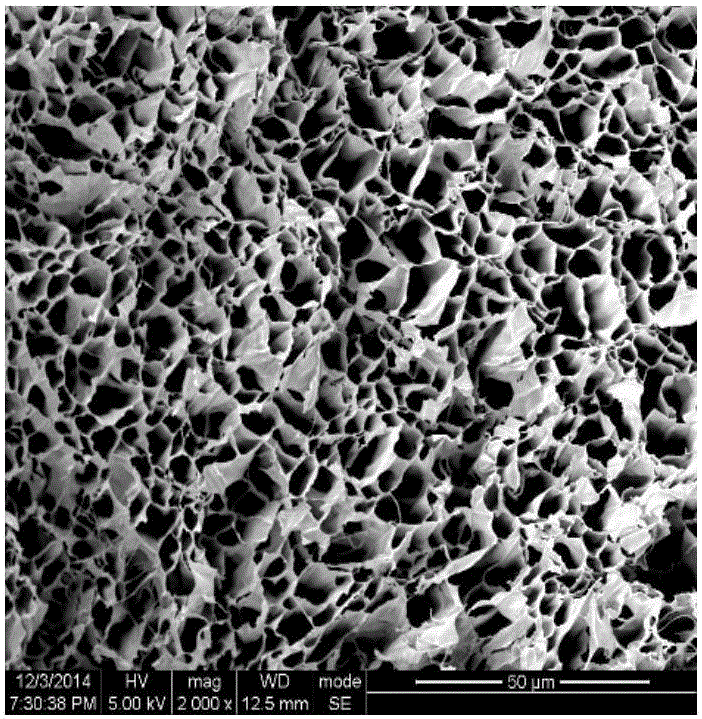

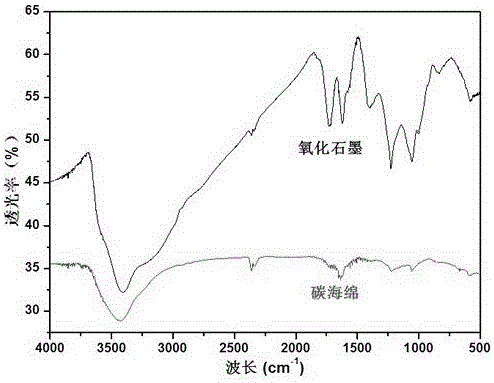

Carbon sponge material and preparation method and application thereof

InactiveCN106732412AHydrophobic and lipophilicAdjust the shape arbitrarilyOther chemical processesWater contaminantsFreeze-dryingAqueous solution

The invention discloses a carbon sponge material and a preparation method and an application thereof, and belongs to the synthetic technical field of oil absorption materials. The key points of the technical scheme of the invention are as follows: firstly, using an improved Hummers method to prepare graphite oxide with graphite powder as a raw material, preparing a graphite oxide aqueous solution with a mass concentration of 2-10 mg / mL by using the prepared graphite oxide, adding carboxymethylcellulose accounting for 0.5-3% of the mass of the graphite oxide aqueous solution, performing hydrothermal reaction at 120 DEG C for 8h in a hydrothermal reactor to obtain plasticity carbon sponge, and performing dialysis treatment and freeze drying to obtain a macroscopic bulk carbon sponge material, wherein the carbon sponge material can be applied to treatment of oily wastewater. The macroscopic bulk carbon sponge material with large adsorption capacity and easy regeneration property is synthesized, and a method for obtaining a recyclable adsorption material by a simpler preparation process is provided.

Owner:HENAN NORMAL UNIV

Method for deacidification of alkylation reaction product

ActiveCN102021016BReduce energy consumptionGood chemical stabilityRefining by dialysisCross-flow filtrationPollution

The invention relates to a method for deacidification of an alkylation reaction product. In the method, after being subject to gravity settling, mixed emulsified liquid of the alkylation reaction product (hydrocarbon oil) and sulfuric acid passes through a component with hydrophobic modified ceramic membrane at a membrane surface speed of 0.01-5m / s for separation, and the deacidification of oil is achieved in a cross current filtration mode under the operation pressure of 0.01-0.3MPa and at the operation temperature of 0-40 DEG C. Under the push of pressure, the oil passes through the ceramic membrane, acid in the oil is trapped, and the acid content in the obtained oil is lower than 100ppm, thereby greatly reducing alkaline usage and waste water generation amount in an acid-base refine system of an alkylation technology and reducing the use of electrostatic precipitation; and the ceramic membrane surface is subject to hydrophobic modification, thus the contact angle of water droplet on the membrane surface is 70 degrees-16 degrees. The method is suitable for removal of polar liquid in various oils, has the advantages of simple process, low energy consumption, high separation precision, no environment pollution and high economic and practical value, and is easy to achieve industrial application.

Owner:NANJING TECH UNIV

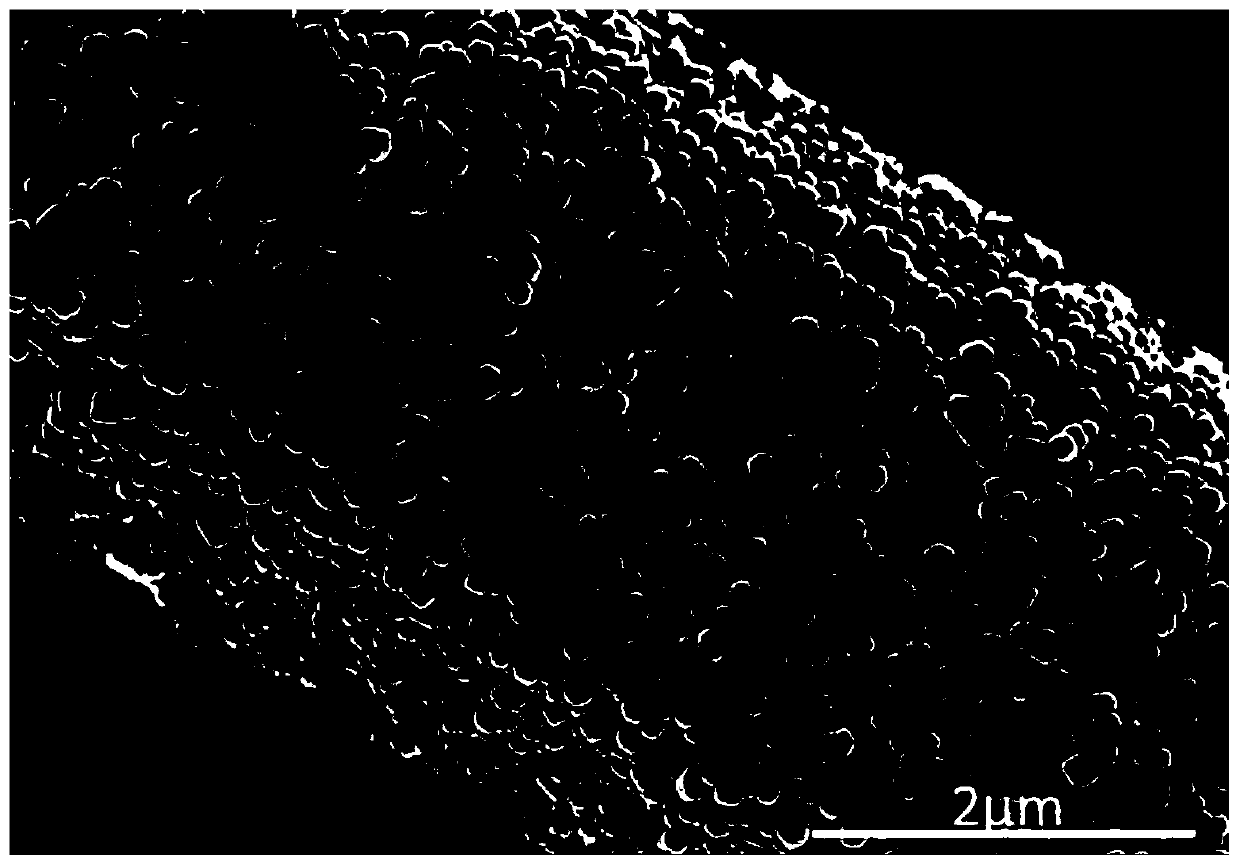

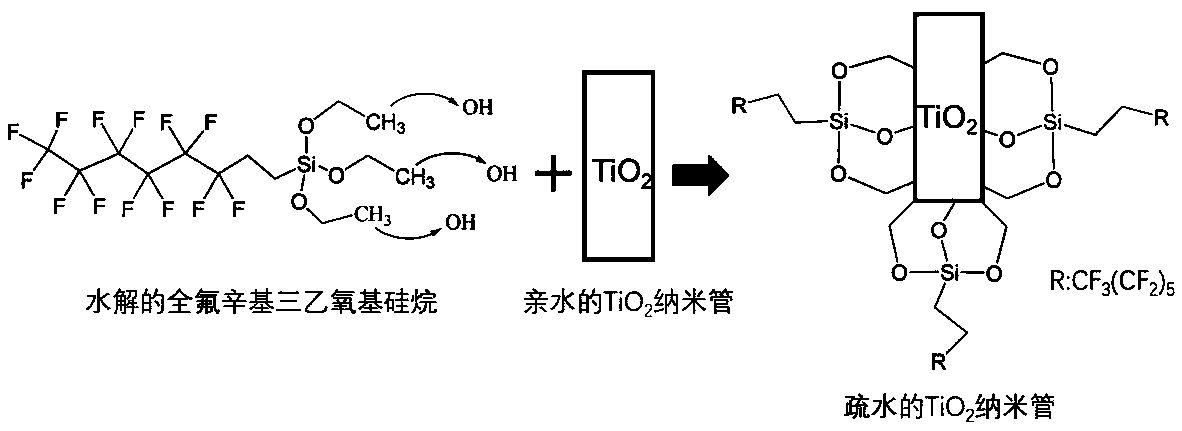

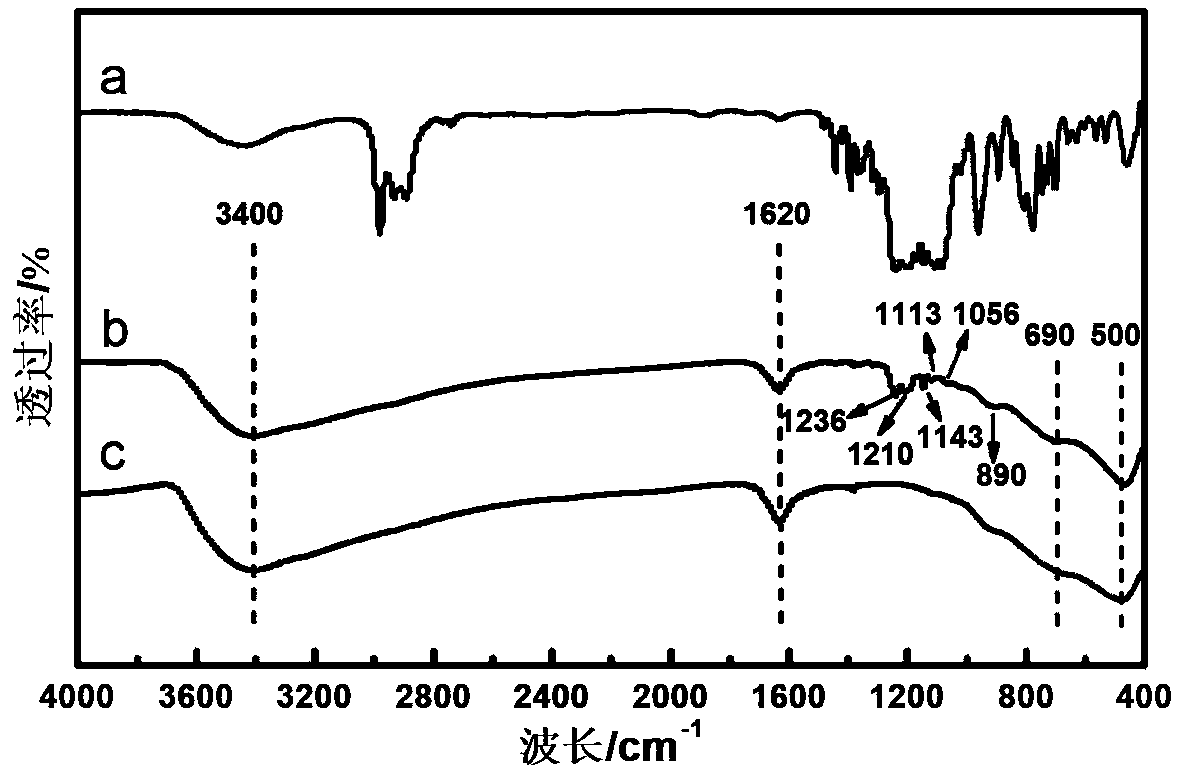

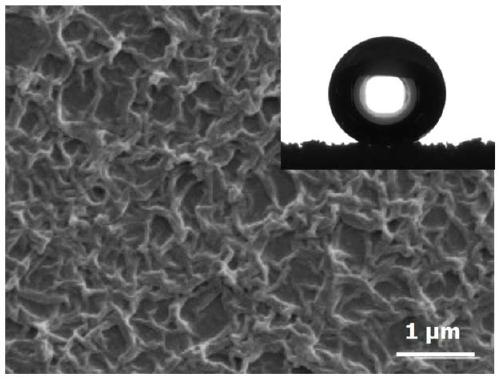

Preparation method of silane modified superhydrophobic TiO2 nanotube material

InactiveCN109183391AHydrophobic and lipophilicSimple preparation processBiochemical fibre treatmentLight resistant fibresTio2 nanotubeSilanes

The invention provides a preparation method of a silane modified superhydrophobic TiO2 nanotube material, wherein the preparation method comprises the following steps: (1) taking TiO2 nanoparticles, dissolving in a NaOH solution, carrying out ultrasonic treatment, carrying out light-shielding mechanical stirring, then putting the solution into a hydrothermal reaction kettle, and carrying out a reaction; swashing the reaction product with distilled water to the pH of 7, then pickling until the pH of a supernatant is 1, then swashing with distilled water to the pH of 7, drying, preparing TiO2 nanotubes, and carrying out light-shielding preservation; and (2) taking the TiO2 nanotubes, adding to an ethanol solution of silane, and carrying out ultrasonic oscillation; and adding distilled water,carrying out hydrolysis reaction, and thus obtaining the hydrophobic TiO2 nanotube material. The modified TiO2 nanotubes have hydrophobic and oleophylic properties, are suitable for cellulose fiber fabrics, and have great application value in superhydrophobic fields such as self-cleaning, corrosion resistance, mildew resistance, ultraviolet resistance and oil-water separation fields.

Owner:NANTONG UNIVERSITY

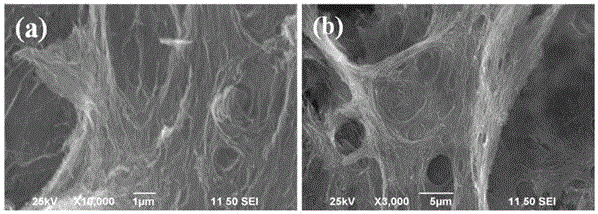

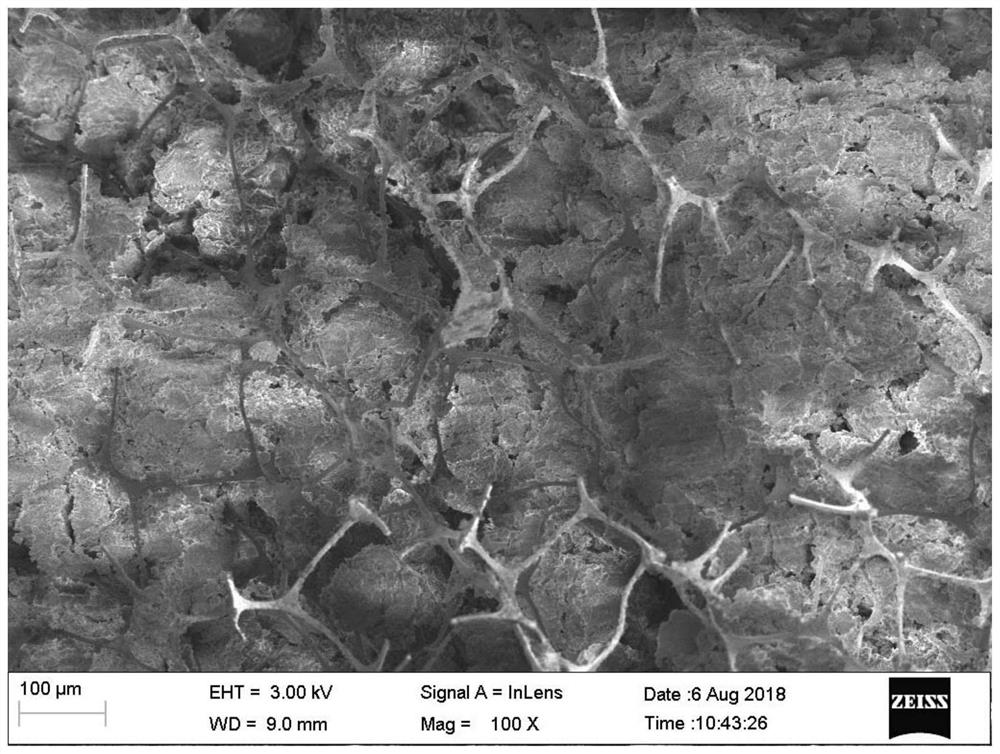

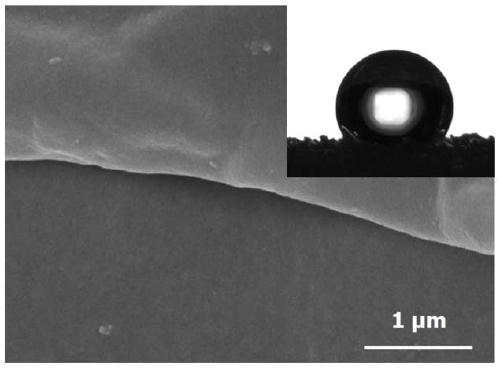

Preparation method of waste paper based recoverable aerogel used for oil-water separation

ActiveCN108686628AHydrophobic and lipophilicHigh mechanical strengthOther chemical processesLiquid separationFiberFreeze-drying

A preparation method of waste paper based recoverable aerogel used for oil-water separation comprises the following steps: crushing waste paper and dispersing in a diluted hydrochloric acid solution,filtering and collecting sediment and washing the sediment with deionized water to neutral level, and then drying the sediment for later use; dispersing the sediment in deionized water, stirring to form uniform paper pulp, adding Fe3O4 nanoparticles and chloropropylene oxide and uniformly stirring, freeze-drying, and treating by a drying oven to obtain waste paper based magnetic aerogel; impregnating the prepared aerogel in an ethanol solution of dopamine, taking out and drying at room temperature, then impregnating in a hydrophobic agent, and drying at room temperature to obtain the waste paper based recoverable aerogel used for oil-water separation. By using domestic waste paper fiber as the raw material for preparation of an oil-absorbing aerogel material, the risk of petrochemical resource shortage is alleviated, and a new approach is provided for high-value utilization of wastes.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

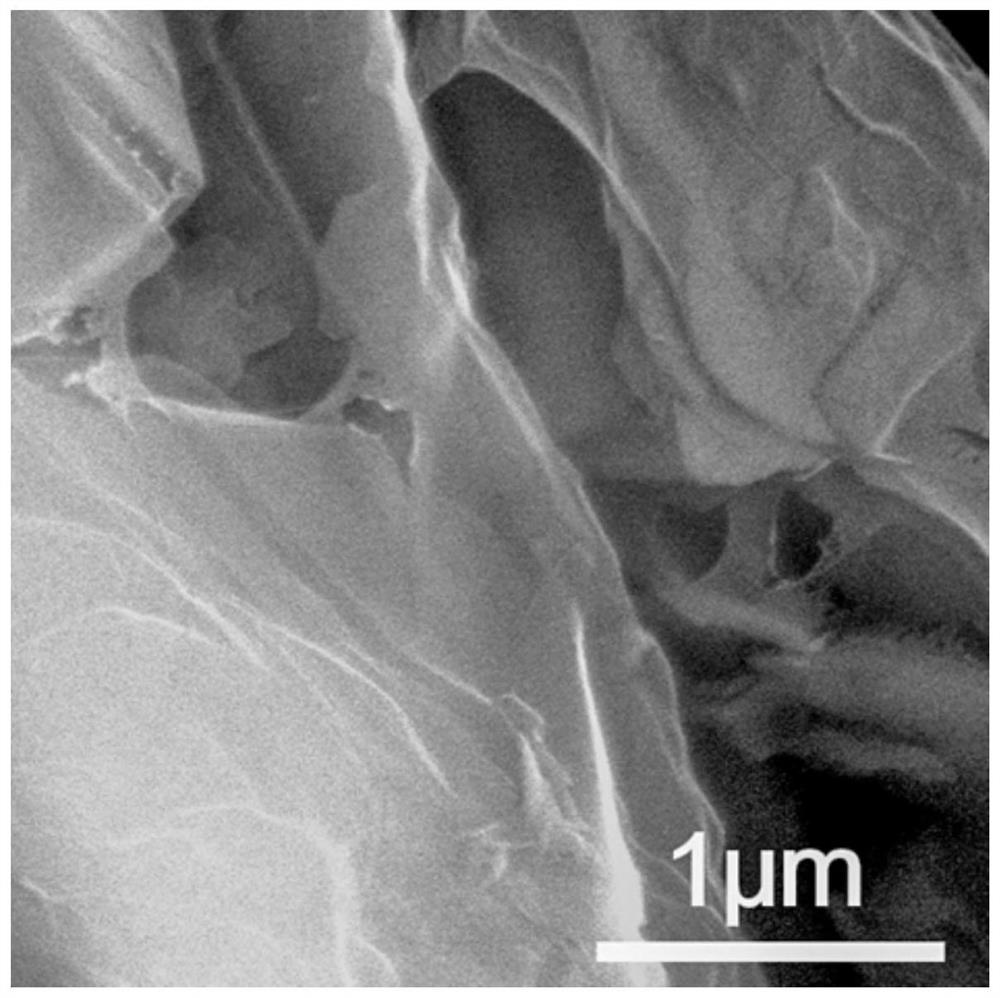

Preparation method of graphene hybrid perfluoropolymer hollow fiber membrane

InactiveCN110614040AHigh porosityHydrophobic and lipophilicMembranesSemi-permeable membranesCvd grapheneEmulsion

The invention discloses a preparation method of a graphene hybrid perfluoropolymer hollow fiber membrane. Polyperfluorinated ethylene propylene or poly (tetrafluoroethylene-perfluoroalkoxy vinyl ether) long filaments prepared by a melt spinning method are used as weaving raw materials; wherein the graphene hybrid perfluoropolymer hollow fiber membrane for oil-water separation is obtained by meansof a perfluoropolymer concentrated dispersion emulsion and graphene as membrane casting solution raw materials and polyvinyl alcohol as an adhesive through the processes of weaving, membrane casting solution preparation, coating, curing, sintering and the like. The method is simple in process, short in flow, high in controllability, convenient to operate, low in energy consumption, high in production efficiency and easy for industrial production. The graphene hybrid perfluoropolymer hollow fiber membrane prepared by the method is not subjected to secondary modification treatment, and only thehydrophobic and oleophylic characteristics of the perfluoropolymer and the graphene are utilized, so that the prepared hollow fiber membrane is good in mechanical property, excellent in chemical reagent resistance and aging resistance, good in hydrophobic and oleophylic properties and high in oil-water mixture separation efficiency.

Owner:TIANJIN POLYTECHNIC UNIV

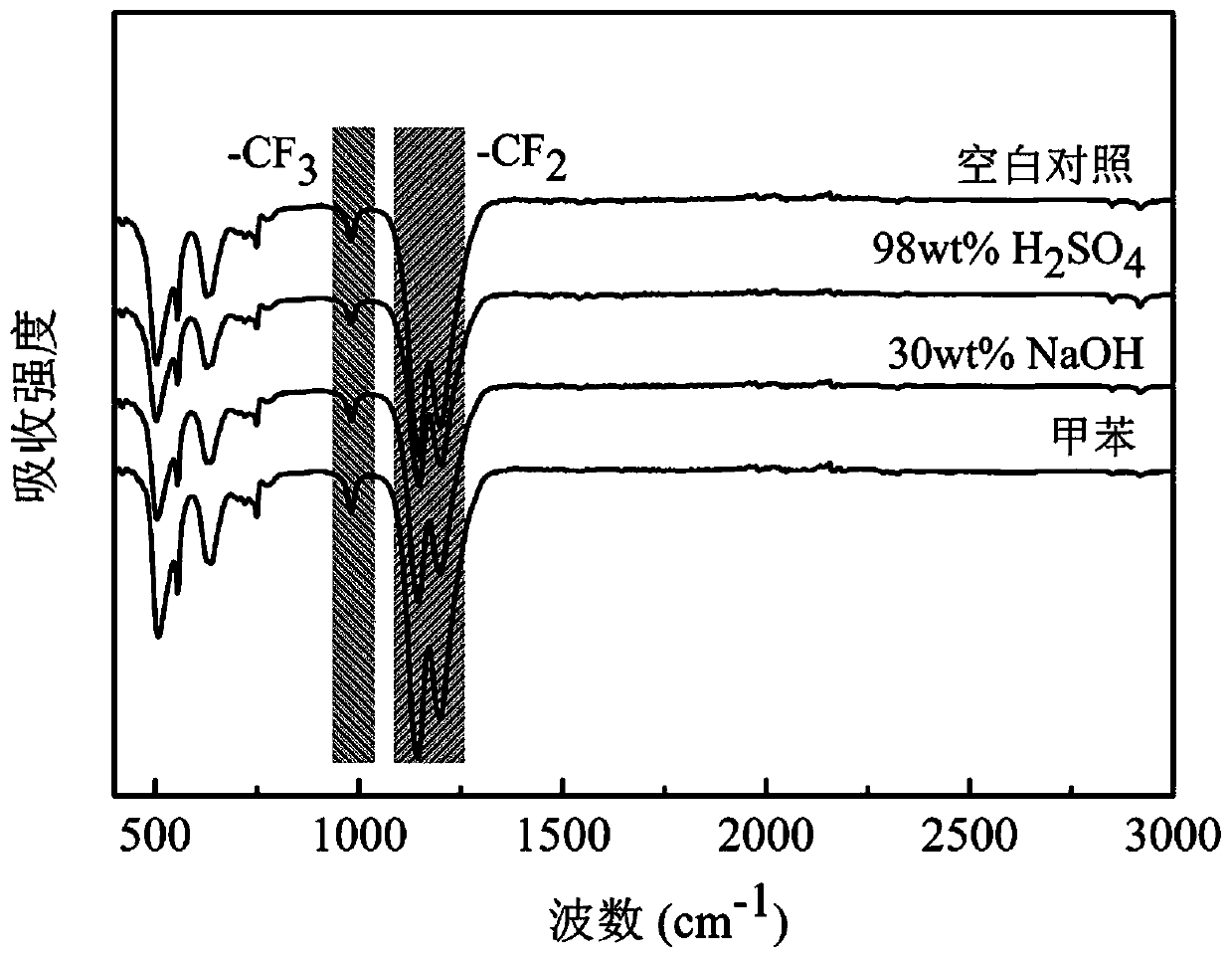

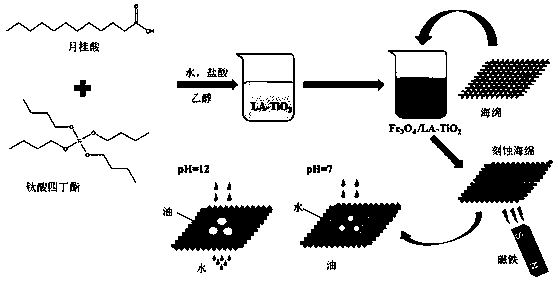

Magnetic oil-water separation material and preparation method thereof and oil-water separation sponge

InactiveCN111495314ASimple preparation processLow equipment requirementsOther chemical processesAlkali metal oxides/hydroxidesEnvironmental geologyOil water

The invention discloses a magnetic oil-water separation material and a preparation method thereof and oil-water separation sponge, and relates to the technical field of oil-water separation materials;the preparation method of the oil-water separation material and the oil-water separation sponge comprises the steps: firstly, slowly dropwise adding tetrabutyl titanate into an ethanol solution of lauric acid and stirring; secondly, adding a proper amount of deionized water and 0.2 M HCl solution into the mixed solution obtained in the first step, and violently stirring; dropwise adding the Fe3O4ethanol suspension into the mixed solution obtained in the step S2, and stirring to obtain an oil-water separation magnetic material Fe3O4 / La-TiO2; and then soaking the treated polyurethane sponge inan oil-water separation magnetic material Fe3O4 / La-TiO2 to obtain the oil-water separation sponge. The prepared oil-water separation sponge is high in separation efficiency and large in flux, and canbe widely applied to separation of various oil-water mixtures.

Owner:LANZHOU JIAOTONG UNIV

Anti-fouling and anti-cracking artificial marble and preparation method thereof

The invention relates to anti-fouling and anti-cracking artificial marble and a preparation method thereof, and belongs to the technical field of artificial stone preparation. The preparation method comprises the following steps: firstly, bamboo splits are used as a raw material, steam explosion fiber breaking is performed to obtain steam explosion fibers rich in hydroxyl groups on the surfaces, then surface corona treatment is performed on the steam explosion fibers to obtain modified fibers, then the modified fibers are used as a template, and calcium sulfate whiskers are deposited on the surfaces of the modified fibers to obtain fibrous calcium sulfate whiskers; then sodium silicate and hydrochloric acid react to generate orthosilicic acid precipitates which are adhered to the surfaces of the fibrous calcium sulfate whiskers, then hydrolysis is carried out at high temperature and high pressure to generate nano silicon dioxide, the nano silicon dioxide coats the surfaces of the fibrous calcium sulfate whiskers, and silicon-coated modified fibrous calcium sulfate whiskers are obtained; and curing is performed under the action of a curing agent, finally, the anti-fouling and anti-cracking artificial marble is prepared, and the anti-fouling and anti-cracking artificial marble has excellent anti-fouling and anti-cracking performance and is wide in application prospect.

Owner:深圳市新佰人建筑材料科技有限公司

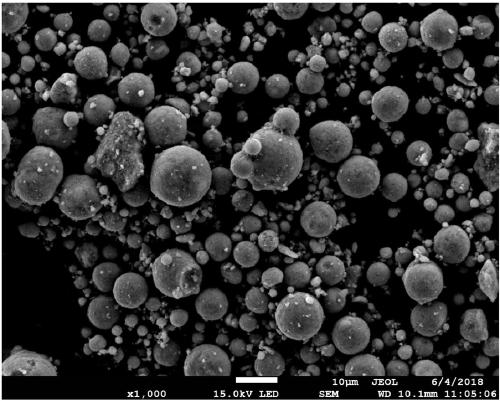

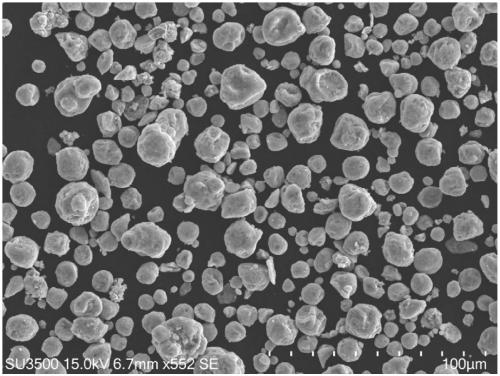

Method for preparing lipophilic spherical zinc oxide dry powder by ultrasonic wet grinding

ActiveCN111303666ASmall particle sizeHydrophobic and lipophilicPigment treatment with macromolecular organic compoundsPigment physical treatmentPhysical chemistrySpray dried

The invention discloses a method for preparing lipophilic spherical zinc oxide dry powder through ultrasonic wet grinding. The method comprises the following steps: emulsifying and dispersing a dispersing coupling agent dissolving solution, primary zinc oxide powder and deionized water by using an emulsifying machine; carrying out ultrasonic wet grinding by adopting an ultrasonic sand mill to reduce the particle size of the primary zinc oxide powder while spheroidize the powder; and finally drying the diluted grinding liquid into zinc oxide dry powder by adopting a centrifugal dryer or a spraydryer. According to the method, primary zinc oxide powder can be spheroidized under the low-temperature condition while the surface of the primary zinc oxide powder is filled and coated with a dispersing coupling agent, so that the spherical powder formed after drying is good in hydrophobicity and lipophilicity, can float on the water surface and can be widely applied to various oleophylic polymer matrix materials.

Owner:介休市博创纳米材料科技有限公司

A method of producing high-quality filter material by using discarded walnut shells

Owner:DANFENG FENGLIN BIOTECH DEV

A kind of superhydrophobic sponge and its preparation method and application

ActiveCN109608689BLow priceHydrophobic and lipophilicOther chemical processesLiquid separationSuperhydrophobeAnhydrous ethanol

The invention discloses a superhydrophobic sponge, its preparation method and application. The method is to put the prepared polydivinylbenzene into absolute ethanol, stir ultrasonically to prepare a polydivinylbenzene suspension, soak the cleaned and dried sponge for 3 min, and then put it in an oven to dry to obtain Superhydrophobic sponge. Compared with other processes, the preparation process of the present invention is simple and feasible, the environment is mild, and there is no requirement for complicated equipment and instruments. The contact angle can reach 154.4°, showing superhydrophobic and superlipophilic properties, which can effectively separate oil-water mixtures and also have good adsorption for volatile organic compounds. The superhydrophobic sponge prepared by the invention can be widely used in the fields of water pollution control, air pollution control and the like.

Owner:SOUTH CHINA UNIV OF TECH

A kind of extraction method and application of taro starch

InactiveCN103242457BHigh purityThe effect of deproteinization is obviousCooking & bakingFreeze thawing

Owner:NINGBO UNIV

Method for preparing superhydrophobic polyurethane sponge by biomineralization method

ActiveCN106700122BMild preparation conditionsReduce harmOther chemical processesGas phaseMultiple layer

The invention relates to a method for preparing a super-hydrophobic and super-oleophilic polymeric sponge through a biological mineralization method. The preparation method includes the steps that polyethyleneimine, Ca2+ ions and sodium polystyrenesulfonate are attached to a sponge on multiple layers through electrostatic force, under the effect of polyethyleneimine and sodium polystyrenesulfonate, the Ca2+ ions and CO2 are induced for a gas phase mineralization reaction, thus, a coarse surface structure is provided for the polymeric sponge, finally low-surface-energy matter is used for surface modification, and then the super-hydrophobic and super-oleophilic polymeric sponge is obtained. The process is simple, the reaction conditions are mild, the adopted raw materials are cheap and easy to obtain, and the prepared sponge can selectively absorb floating oil on the water surface, can be compressed multiple times to be reused, and is a novel material expected to be applied to marine floating oil pollution treatment.

Owner:TIANJIN UNIV

A kind of zif-8/non-woven composite material and preparation method thereof

ActiveCN110777537BEvenly distributedHas a multi-level pore structureLiquid repellent fibresNon-woven fabricsWoven fabric compositeNonwoven fabric

The invention discloses a ZIF-8 / nonwoven fabric composite material and a preparation method thereof. The preparation method includes following steps: preparing a ZIF-8 primary solution; putting nonwoven fabric into the ZIF-8 primary solution; drying to obtain the ZIF-8 / nonwoven fabric composite material. ZIF-8 particles are deposited on the surface of the nonwoven fabric in situ by soaking the nonwoven fabric into the ZIF-8 primary solution and standing for aging and uniformly distributed on the surface of the nonwoven fabric, and the ZIF-8 / nonwoven fabric composite material with a multistagehole structure is obtained by adopting the ZIF-8 particles to fill the nonwoven cloth; the composite material has good adsorption performance and excellent hydrophobicity and lipophilicity. Methods ofin-situ deposition and low-temperature drying are adopted, so that the preparation method is simple in process, low in cost and energy consumption and suitable for popularization and implementation.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Methyl tert-butyl ether cracking catalyst for isobutylene and preparation method thereof

ActiveCN103071519BImprove pore structureReduce adsorptionMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveMethyl tert-butyl ether

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of super-hydrophobic textile fabric and its preparation method and application

ActiveCN109629232BLow priceHydrophobic and lipophilicLiquid repellent fibresLiquid separationSuperhydrophobePolymer science

The invention discloses a superhydrophobic textile cloth, a preparation method and application thereof. The method is as follows: under the action of initiator azobisisobutyronitrile, divinylbenzene is polymerized on textile cloth in an organic solvent to generate polydivinylbenzene and superhydrophobic textile cloth. The contact angle of the woven fabric can reach 155.7°, showing superhydrophobic and superoleophilic properties, which can effectively and selectively separate oil-water mixtures. The superhydrophobic textile fabric prepared by the invention can be prepared by a hydrothermal method, has stable structure and performance, and good reproducibility, and can be widely used in the fields of water pollution control, volatile organic compound adsorption and the like.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com