Method for preparing superhydrophobic polyurethane sponge by biomineralization method

A technology of polyurethane sponge and biomineralization, applied in chemical instruments and methods, and other chemical processes, can solve the problems of expensive raw materials and secondary pollution of the environment, and achieve simple and cheap devices, less environmental pollution, and cheap and easy-to-obtain raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

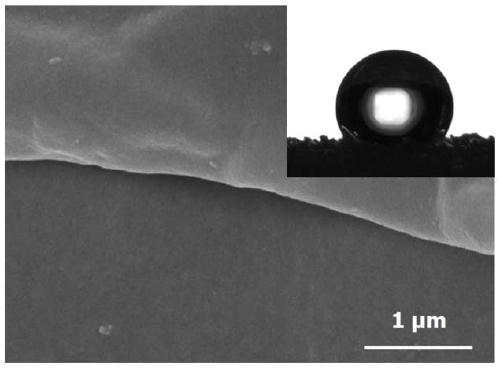

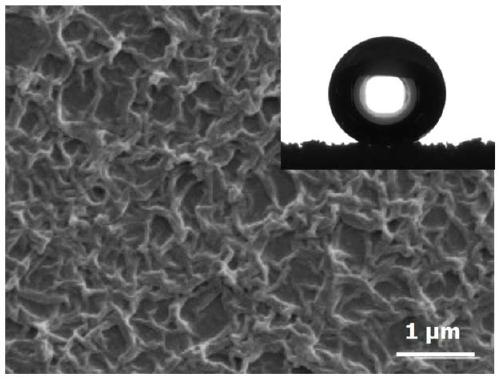

[0030] First cut the ordinary polyurethane sponge into a 2*2*2cm square, and ultrasonically clean it with ethanol for 30 minutes, then wash it with water three times and then dry it. (i) after drying, soak the sponge in 2mol / LNaOH solution for 10 minutes, take it out and clean it with clear water, (ii) put the polyethyleneimine (PEI) (PEI) and 50mol / L calcium acetate aqueous solution for 30 minutes, then take it out and rinse it with water for 5 times, and then (iii) submerge the sponge in 5g / L polystyrene sodium sulfonate (PSS) solution for 30 minutes. Repeat step (ii) and step (iii) twice and then repeat step (ii) again, finally obtain the sponge whose outer surface is PEI and calcium acetate solution, put this sponge together with ammonium bicarbonate into an airtight container (such as glass desiccator) and placed in an oven set at 30°C for 48 hours. Then take it out and dry it thoroughly, put it into 0.01mol / L palmitic acid / dichloromethane solution and soak it for 24 hou...

Embodiment 2

[0032] First cut the ordinary polyurethane sponge into a 2*2*2cm square, and ultrasonically clean it with ethanol and water for 30 minutes, then wash it with water three times and then dry it. (i) after drying, soak the sponge in 2mol / LNaOH solution for 10 minutes, take it out and clean it with clear water, (ii) put the polyethyleneimine (PEI) (PEI) and 20mol / L calcium acetate aqueous solution for 60 minutes, then take it out and rinse it with water for 5 times, then (iii) submerge the sponge in 2g / L polystyrene sodium sulfonate (PSS) solution with a molecular weight of 70000g / mol 60 minutes. Repeat step (ii) and step (iii) twice and then repeat step (ii) again, finally obtain the sponge whose outer surface is PEI and calcium acetate solution, put this sponge together with ammonium bicarbonate into an airtight container (such as glass desiccator) and placed in an oven set at 30°C for 24 hours. Then take it out and dry it thoroughly, put it into 0.01mol / L lauric acid / dichloro...

Embodiment 3

[0035] First cut the ordinary polyurethane sponge into a 2*2*2cm square, and ultrasonically clean it with ethanol and water for 30 minutes, then wash it with water three times and then dry it. (i) after drying, soak the sponge in 2mol / LNaOH solution for 10 minutes, take it out and clean it with clear water, (ii) put the polyethyleneimine (PEI) (PEI) and 30mol / L calcium acetate aqueous solution for 20 minutes, then take it out and rinse it with water for 3 times, then (iii) submerge the sponge in 3g / L polystyrene sodium sulfonate (PSS) solution with a molecular weight of 70000g / mol 20 minutes. Repeat step (ii) and step (iii) twice and then repeat step (ii) again, finally obtain the sponge whose outer surface is PEI and calcium acetate solution, put this sponge together with ammonium bicarbonate into an airtight container (such as glass desiccator) and placed in an oven set at 40°C for 36 hours. Then take it out and dry it thoroughly, put it in 0.01mol / L hexadecyltrimethoxysil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com