Carbon sponge material and preparation method and application thereof

A carbon sponge and raw material technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems of easy saturation of adsorption and difficult regeneration, limitations on the wide application of adsorption methods, and high processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Firstly, the improved Hummers’ method was used to prepare graphite oxide from graphite powder (S. Y. Dong, J. Y. Sun, Y. K. Li, C. F. Yu, Y. H. Li, J. H. Sun, ZnSnO 3 hollow nanospheres / reduced graphene oxide nanocomposites as high-performance photocatalysts fordegradation of metronidazole, Appl. Catal. B Environ. 144 (2014) 386-393), and then the prepared graphite oxide was prepared into graphite oxide aqueous solutions with mass concentrations of 2mg / mL, 4mg / mL, 6mg / mL, 8mg / mL and 10mg / mL respectively, adding 1.5% graphite oxide The carboxymethyl cellulose of aqueous solution quality is then reduced by hydrothermal reaction at 120°C for 8 hours to obtain a carbon sponge with good plasticity, which is freeze-dried after dialysis to obtain a macroscopic monolithic carbon sponge material. After the adsorption test of n-hexane in water, the results show that the removal rates of n-hexane in water by the macroscopic monolithic block carbon fiber material are 87.49%, 99....

Embodiment 2

[0019] First, the improved Hummers' method was used to prepare graphite oxide from graphite powder, and then the prepared graphite oxide was prepared into a graphite oxide aqueous solution with a mass concentration of 4 mg / mL, and 0.5%, 1%, 1.5%, 2% and 3% were added respectively. % graphite oxide aqueous solution quality of carboxymethyl cellulose, and then hydrothermal reaction at 120 ℃ for 8 hours to obtain a carbon sponge with good plasticity, and after dialysis treatment, freeze-dry to obtain a macroscopic monolithic carbon sponge material. After the adsorption test of n-hexane in water, the results show that the removal rates of n-hexane in water by the macroscopic monolithic block carbon fiber material are 79.55%, 86.45%, 99.86%, 96.56% and 94.18%, respectively.

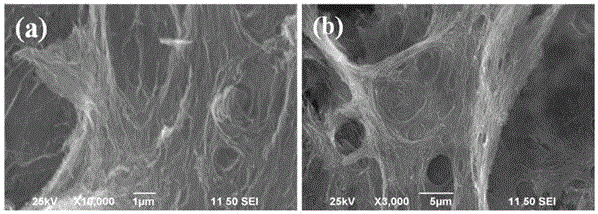

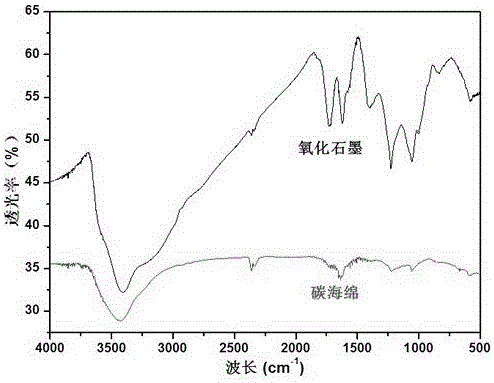

[0020] figure 1 It is the SEM picture of the carbon sponge material prepared under optimal conditions. It can be seen from the figure that the material structure is porous and the distribution range is relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com