Patents

Literature

62results about How to "Improve non-polarity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

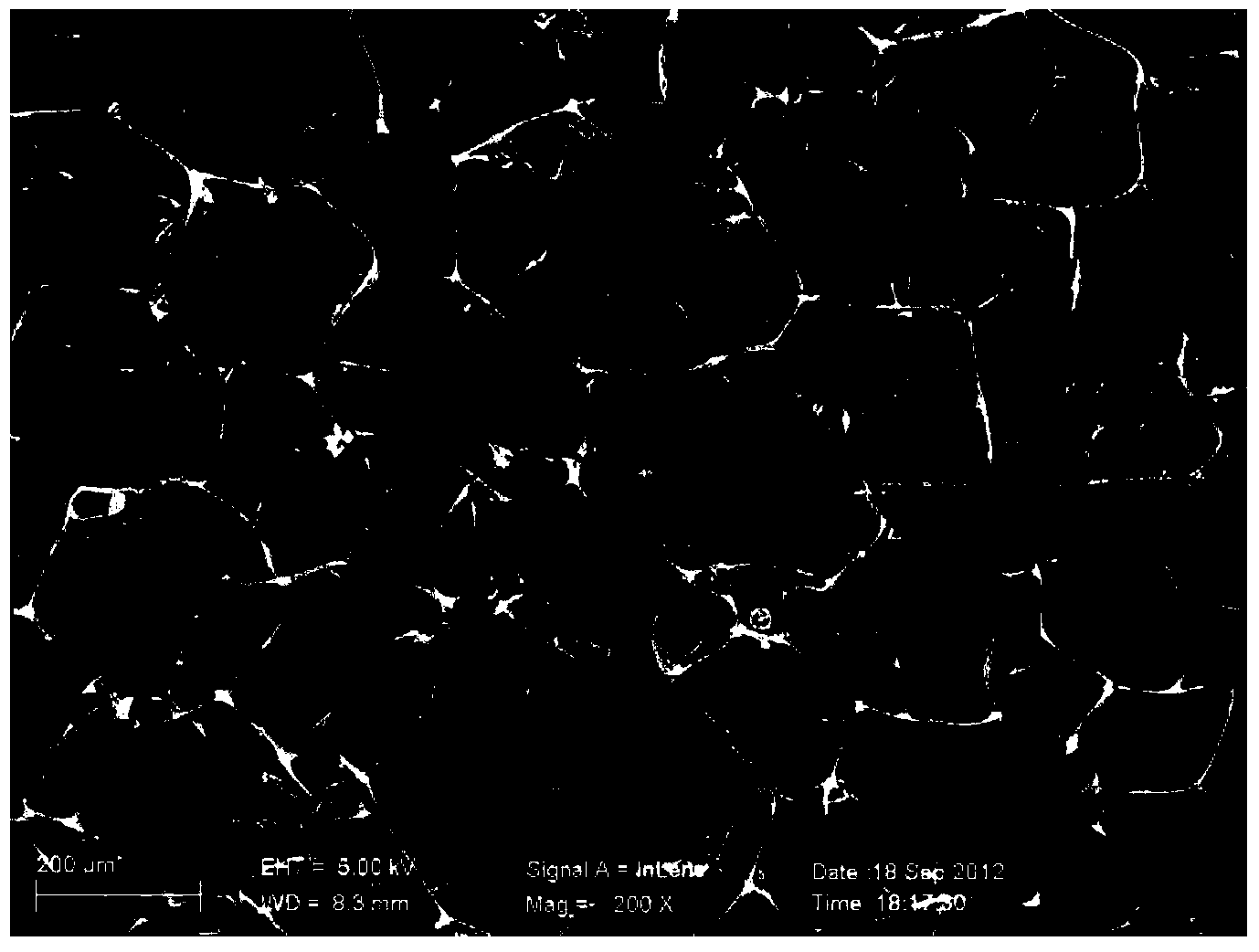

Preparation method of oil-water separation material

ActiveCN103626171AImprove oil-water separation effectEasy to separateGrapheneLiquid separationSeparation technologyMechanical stability

The invention provides a preparation method of an oil-water separation material, which comprises the following steps: soaking a sponge material in a graphene oxide solution, taking out the obtained sponge material and centrifuging the sponge material, so that a graphene oxide coated sponge material is obtained; and carrying out a reduction reaction on the graphene oxide coated sponge material under the action of a reducing agent so as to obtain the oil-water separation material. The oil-water separation material prepared by using the method provided by the invention is a reduced graphene oxide coated sponge material, is coated with a graphene layer uniformly and tightly and has good rebound resilience and mechanical stability, and the reduced graphene oxide layer provides good hydrophobicity and lipophilicity, therefore, the preparation method disclosed by the invention can be applied to oil-water separation technologies.

Owner:UNIV OF SCI & TECH OF CHINA

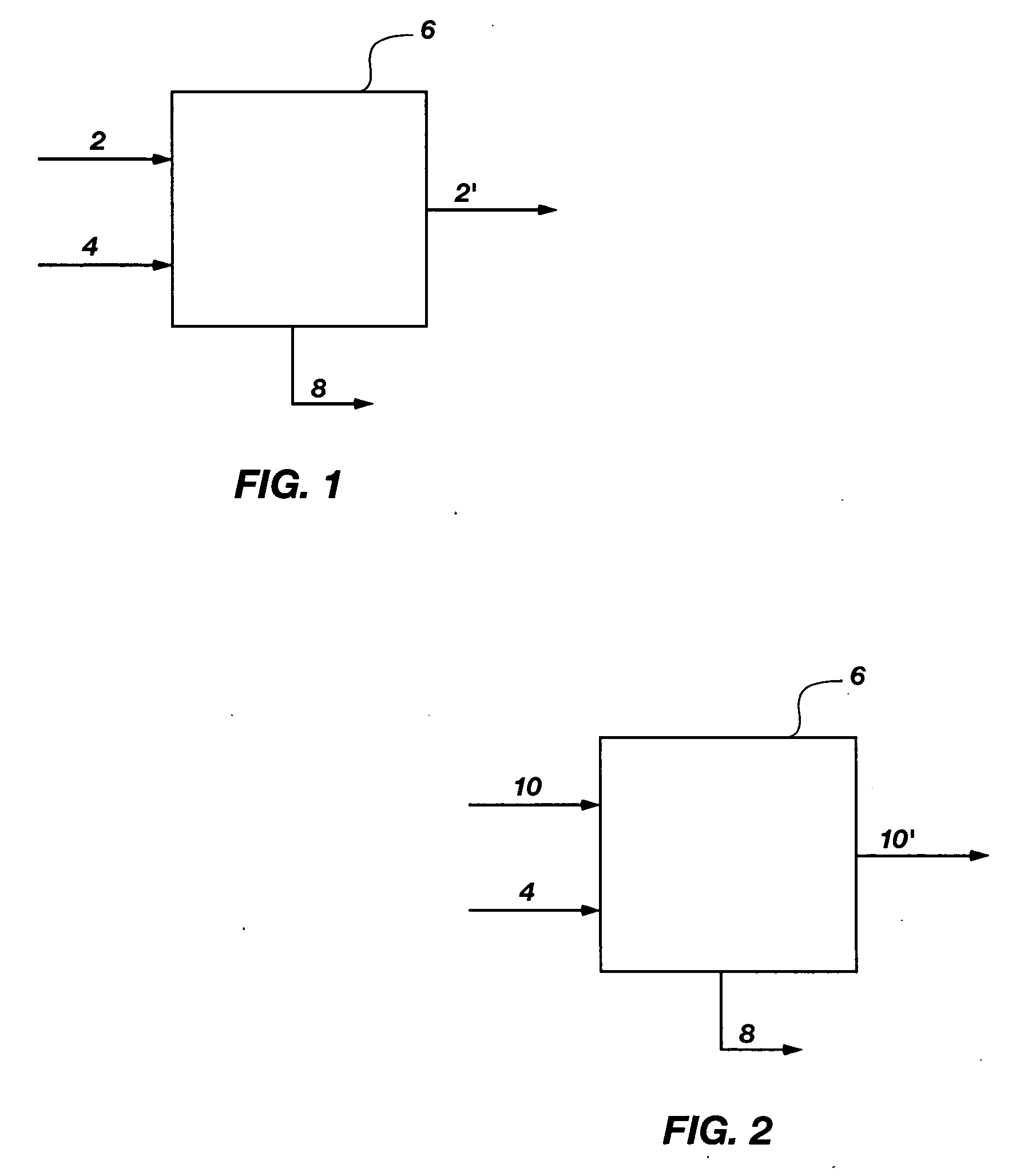

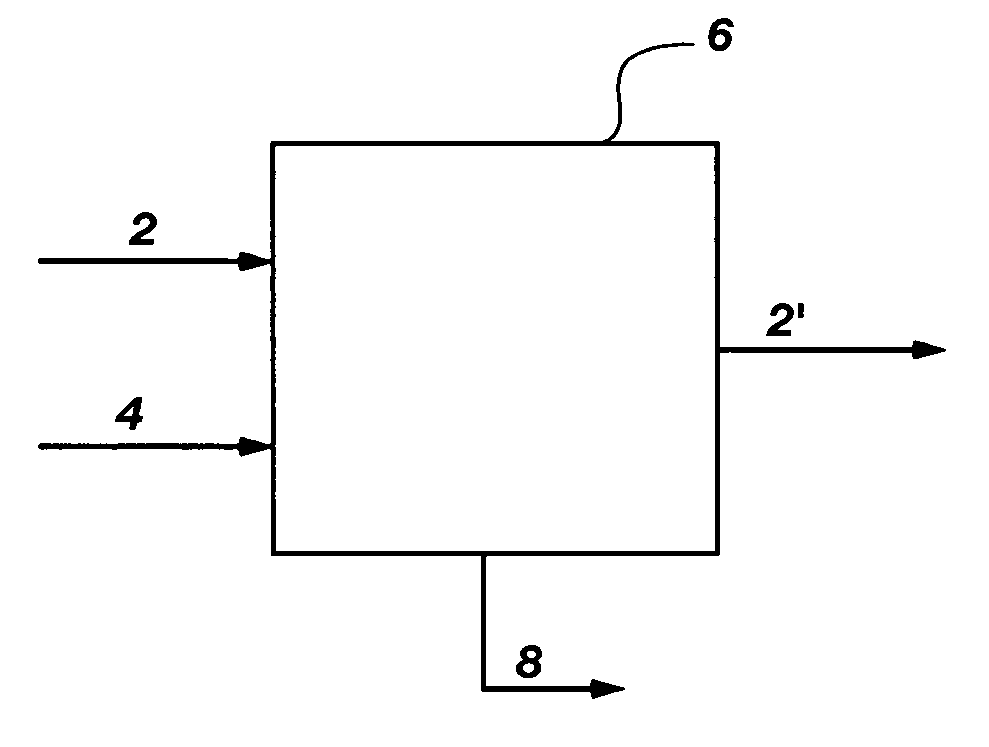

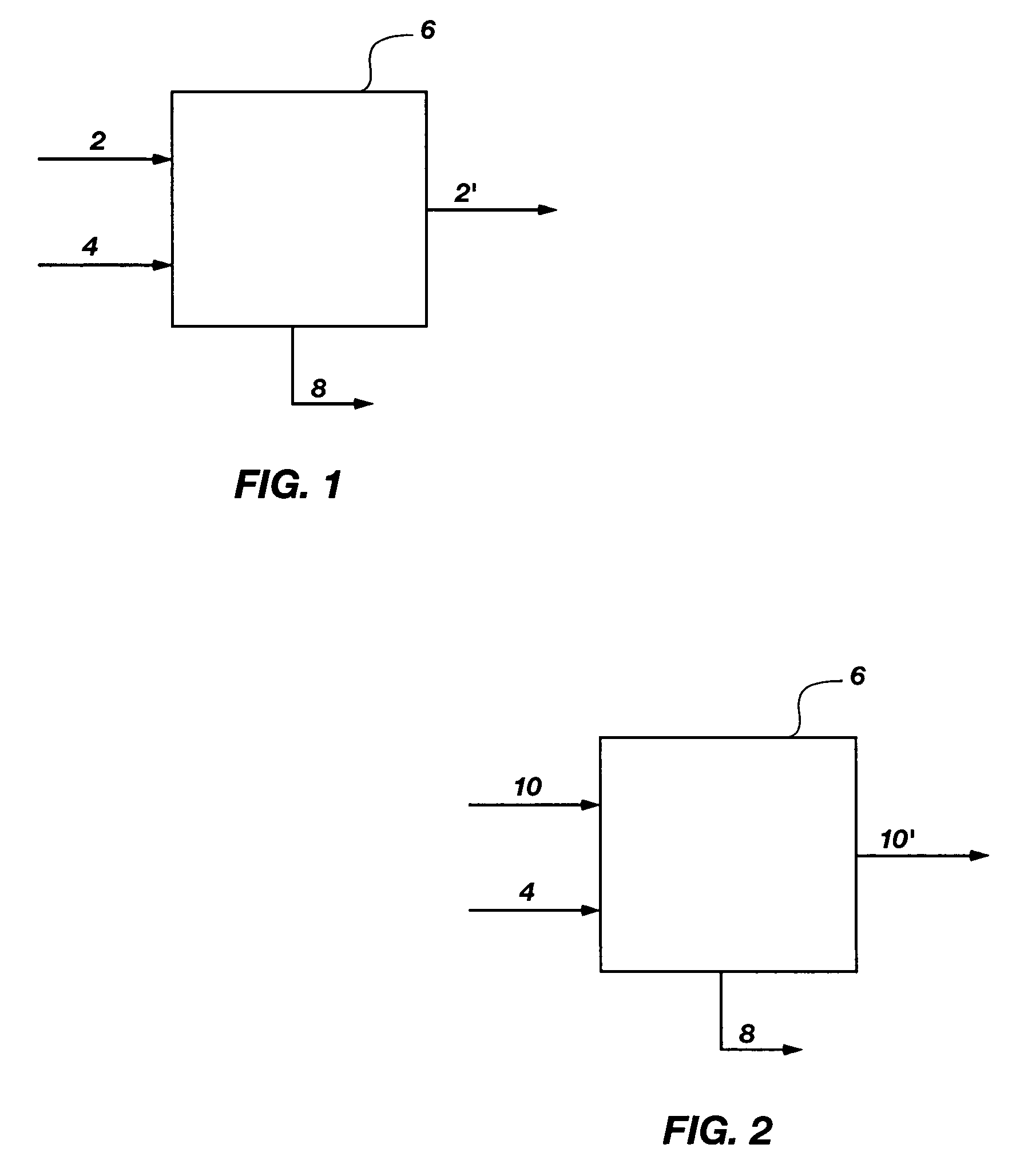

Method for removing impurities from an impurity-containing fluid stream

InactiveUS20070012621A1Reduce solubilityImprove non-polarityFatty acid chemical modificationFatty acids production/refiningSolubilitySolvent

A method of removing at least one polar component from a fluid stream. The method comprises providing a fluid stream comprising at least one nonpolar component and at least one polar component. The fluid stream is contacted with a supercritical solvent to remove the at least one polar component. The at least one nonpolar component may be a fat or oil and the at least one polar component may be water, dirt, detergents, or mixtures thereof. The supercritical solvent may decrease solubility of the at least one polar component in the fluid stream. The supercritical solvent may function as a solvent or as a gas antisolvent. The supercritical solvent may dissolve the nonpolar components of the fluid stream, such as fats or oils, while the polar components may be substantially insoluble. Alternatively, the supercritical solvent may be used to increase the nonpolarity of the fluid stream.

Owner:BATTELLE ENERGY ALLIANCE LLC

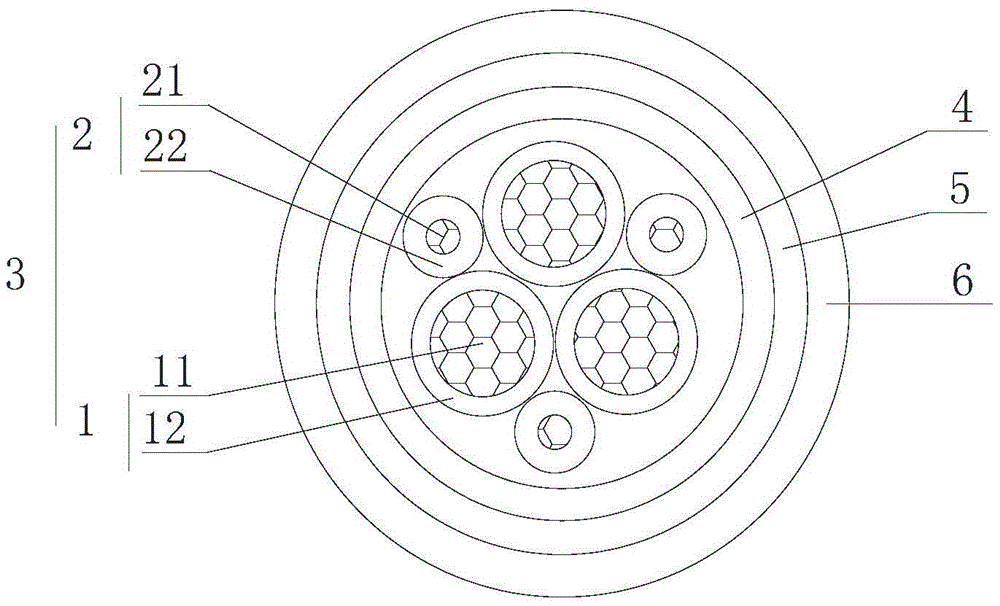

Corrosion-resistant high-temperature-resistant cable material

InactiveCN106009317AImprove heat resistanceImprove corrosion resistanceRubber insulatorsInsulated cablesEpoxyMethyl linoleate

The invention discloses a corrosion-resistant high-temperature-resistant cable material. The material is prepared from, by weight, 10-20 parts of hydrogenated butadiene-acrylonitrile rubber, 60-80 parts of ethylene propylene terpolymer, 20-40 parts of modified polyurethane, 20-40 parts of carbon black, 20-40 parts of kaolin, 4-6 parts of epoxy acetyl methyl linoleate, 40-60 parts of flame-retardant agent, 0.5-1.5 parts of gamma-aminopropyltriethoxysilane, 1-1.5 parts of dicumyl peroxide, 0.1-0.3 part of zinc stearate, 0.2-0.4 part of accelerant CZ, 4-6 parts of Ca / Zn composite stabilizer and 2-4 parts of polyethylene wax. The cable material is good in high temperature resistance, high in corrosion resistance and good in mechanical property.

Owner:ANHUI HAIRONG CABLE

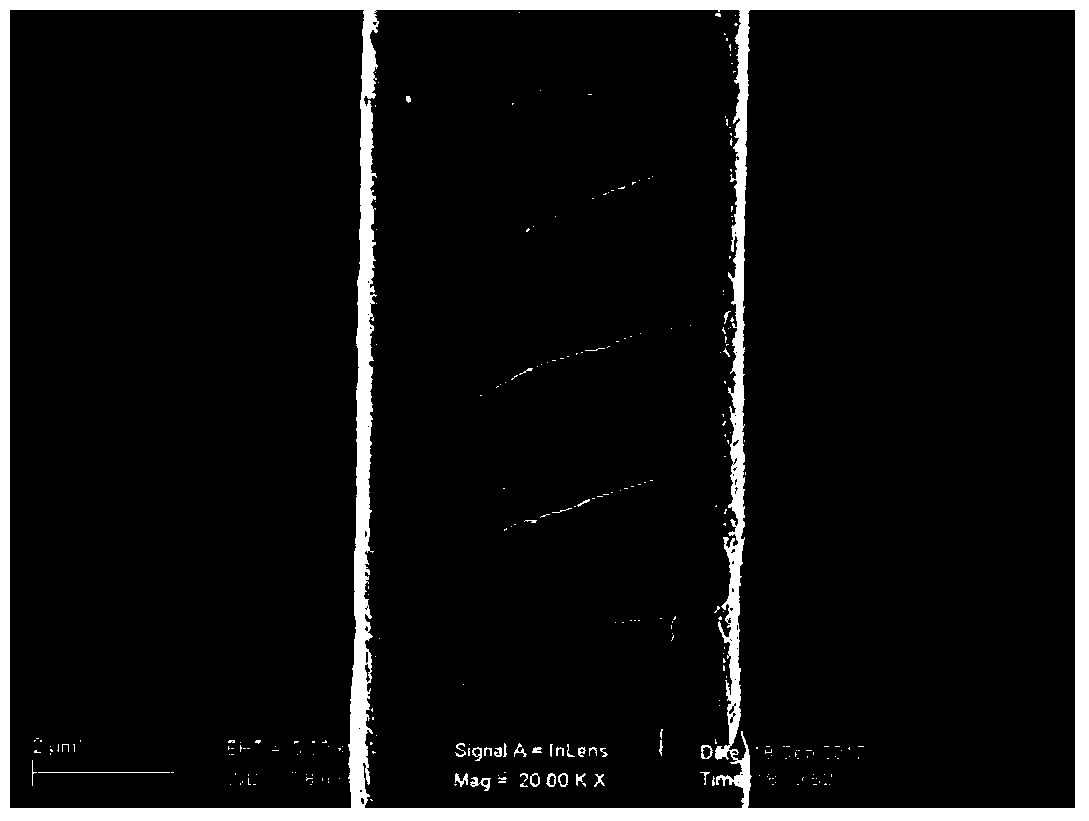

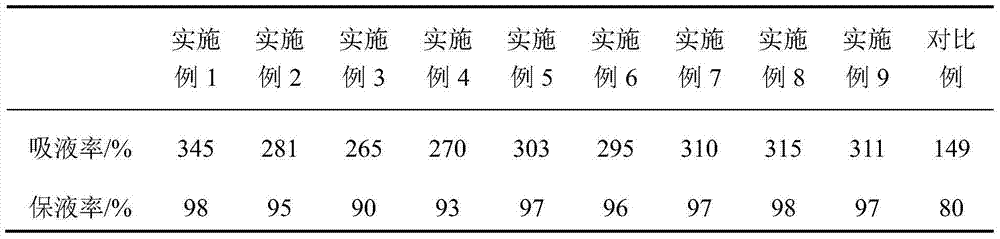

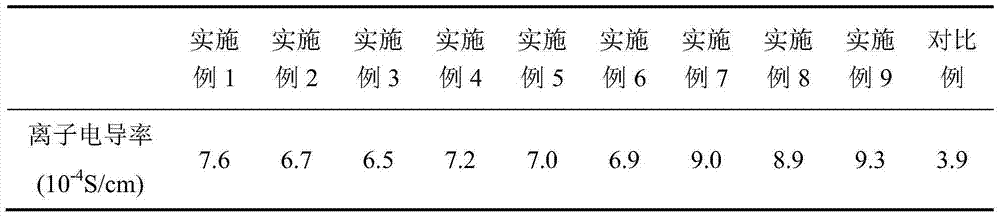

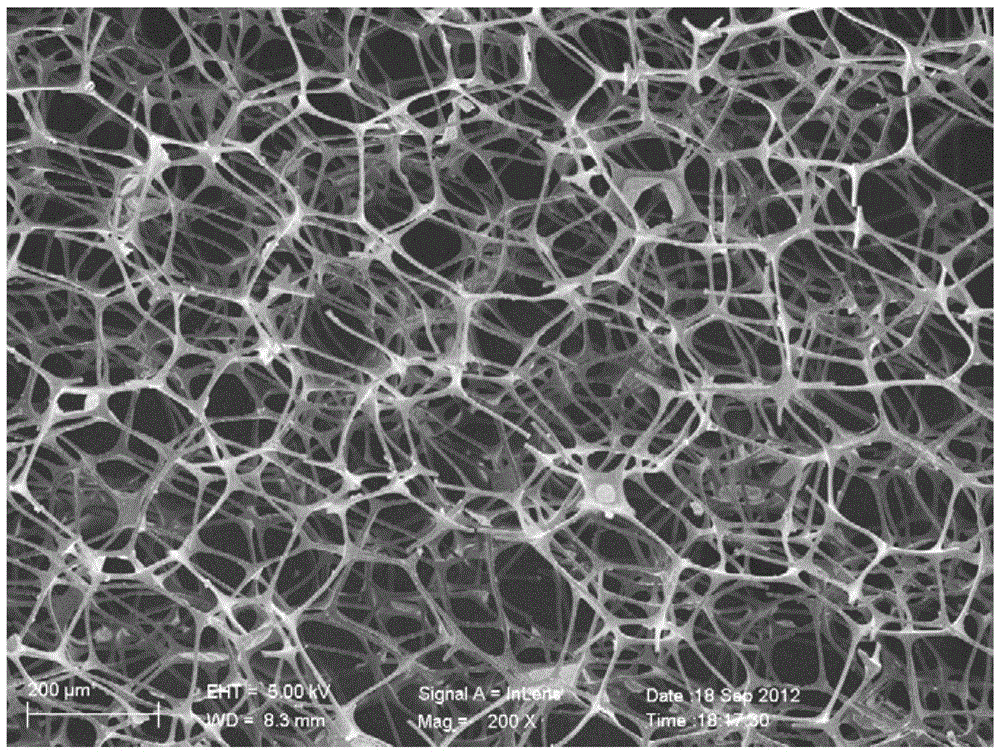

Lithium ion battery composite separation membrane and preparation method thereof

ActiveCN103715384ASimple methodSuitable for large-scale industrial production applicationsCell component detailsPolyolefinCrystallinity

The present invention discloses a lithium ion battery composite separation membrane and a preparation method thereof, and belongs to the technical field of lithium ion batteries, wherein at least a surface of a polyolefin separation membrane is coated with a modified natural rubber polymer coating. According to the invention, the polyolefin separation membrane and the modified natural rubber are combined to form the composite separation membrane, such that mechanical properties of the natural rubber can be improved, and the original pore closing characteristic of the polyolefin separation membrane can be maintained and utilized so as to improve safety of the battery, enhance bonding force between the separation membrane and the positive electrode and bonding force between the separation membrane and the negative electrode, eliminate the interface effect, and improve cycle stability of the battery; and the inorganic nanoparticles are added to the modified natural rubber latex, such that the crystallinity of the polymer can be reduced to a certain extent, the mechanical strength of the separation membrane and the carrier concentration can be increased, the interface compatibility between the separation membrane and the lithium electrode can be effectively improved, and the interface is stable.

Owner:HENAN NORMAL UNIV

Juicy food packaging biodegradable chitosan film preparation method

The invention discloses a juicy food packaging biodegradable chitosan film preparation method. The method includes dissolving chitosan powder into acetic acid solution, then adding alkylated nano cellulose, mixing completely, filtering and purifying, and obtaining alkylated nano cellulose / chitosan solution through ultrasound treatment; dissolving gallic acid or gallic acid ester substances into ethanol, adding 1-ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride and N-hydroxysuccinimide reagent for full reaction, adding the mixture into the alkylated nano cellulose / chitosan solution, stirring at low temperature, placing at room temperature, performing ultrasonic dispersion and vacuum deaeration treatment, drying, and obtaining the film; soaking with alkali solution, flushing and treating through water till neutral, drying at room temperature, and obtaining the product. The method has the advantages that the chitosan is modified through the nano cellulose and gallic acid, and the tensile strength, oxidation resistance and antibacterial properties of the chitosan film are improved greatly.

Owner:NANJING FORESTRY UNIV +1

Tear-resistant and heat-resistant silicone rubber cable

InactiveCN105623275AGood high and low temperature resistanceImprove corrosion resistanceRubber insulatorsFire retardantDibutyltin dilaurate

The invention discloses a tear-resistant and heat-resistant silicone rubber cable. The silicon rubber cable comprises a jacket layer. The jacket layer is prepared from silicone rubber, ethylene propylene diene monomer, composite filler, hydroxyl silicone oil, paraffin oil, epoxidized soybean oil, fire retardant, dicumyl peroxide, bi25, accelerant M, accelerant BZ, dibutyl tin oxide, dibutyltin dilaurate, antioxygen 1010, antioxygen 168 and silicone powder. The composite filler is prepared from vinyl triethoxysilane, nanosilicon dioxide, nanometer titania and modified expanded vermiculite. The tear-resistant and heat-resistant silicone rubber cable is good in heat resistance, high in tear resistance and good in mechanical performance.

Owner:王社兵

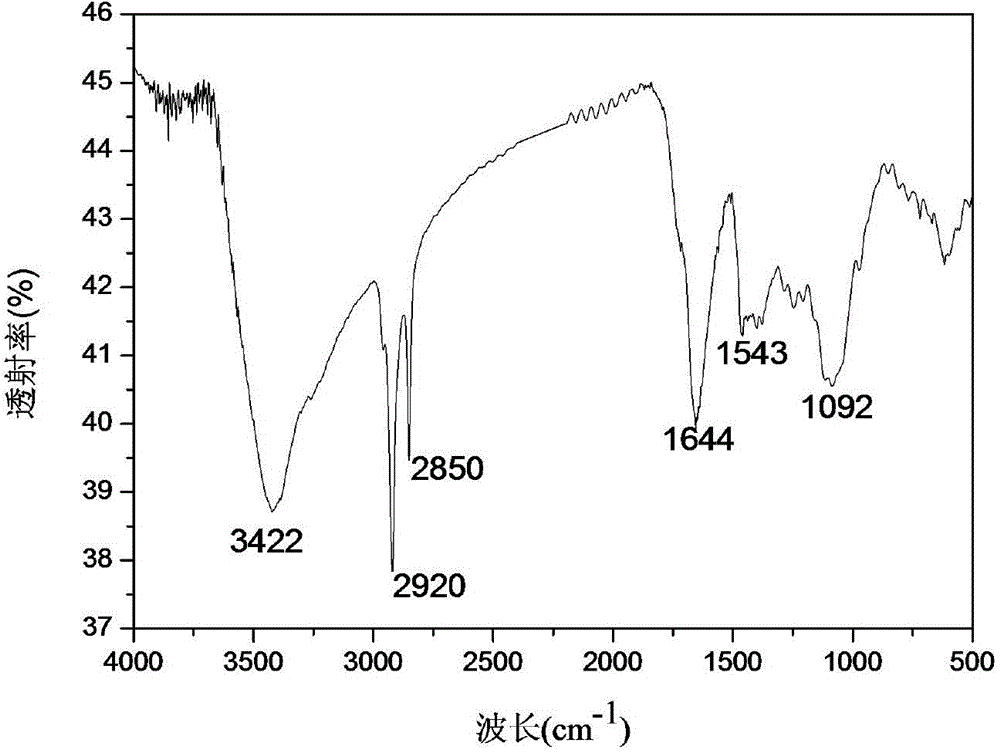

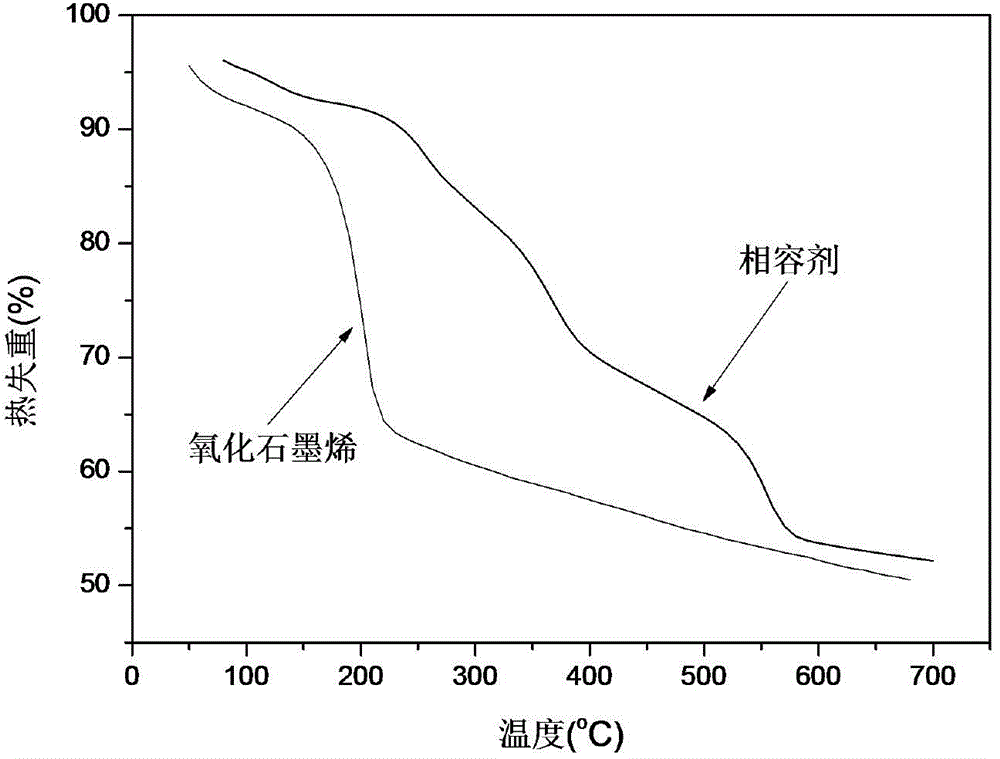

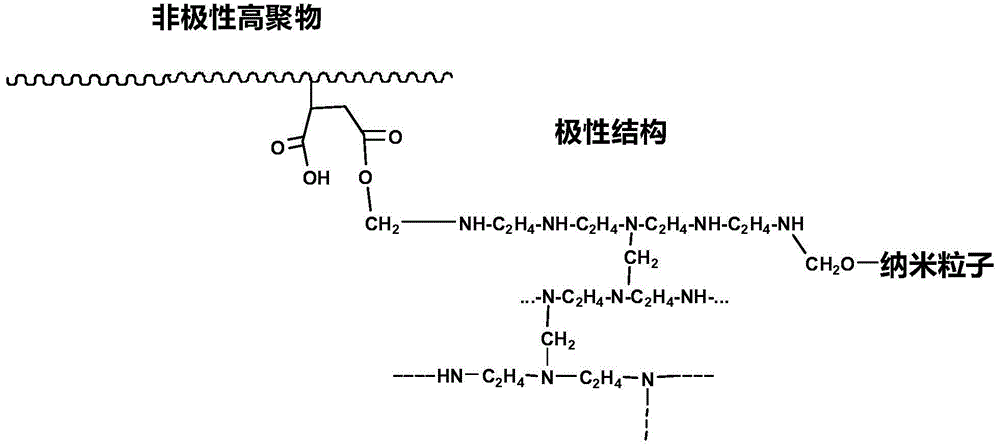

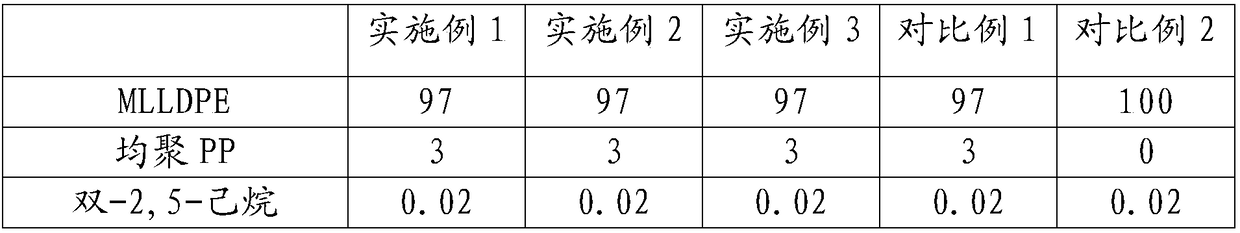

Preparing method of novel composite compatilizer

The invention relates to a preparing method of a novel composite compatilizer. The preparing method comprises the following steps of (1) adding epoxy propyl alkyl salts into a container containing a nanometer particle water solution, taking reaction at the room temperature for 0.5 to 3 hours, and carrying out filtering, washing and drying to obtain an intermediate 1; (2) mixing polyethylene polyamine and formaldehyde solution, taking reaction for 1.5 to 3 hours at a temperature below 20 DEG C to 50 DEG C, then raising the temperature to 140 DEG C to 190 DEG C, continuously taking reaction for 2 to 6 hours, lowering the temperature, and carrying out pressure reduction dewatering to obtain an intermediate 2; (3) mixing grafted non-polar polymers with the intermediate 2 in a solvent, heating the mixture to 100 to 160 DEG C, taking reaction for 4 to 10 hours, filtering the materials to obtain filter cake and obtaining an intermediate 3; (4) mixing the intermediate 1 and the intermediate 3 in the solvent, raising the temperature to 80 to 120 DEG C, taking reaction for 4 to 10 hours, and finally obtaining the novel composite compatilizer. The preparing method has the advantage that the goal of obviously improving the blending material performing by using few compatilizers is achieved.

Owner:HEBEI UNIV OF TECH

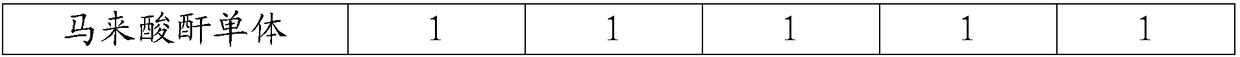

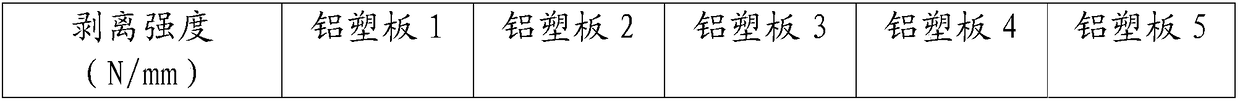

Bonding resin for aluminum-plastic board, preparation method thereof, and aluminum-plastic board

InactiveCN109321172AIncrease polarityImprove non-polaritySynthetic resin layered productsMetal layered productsUltimate tensile strengthExtrusion Granulation

The invention discloses bonding resin for an aluminum-plastic board and a preparation method thereof. The bonding resin is obtained by extrusion-granulation by a plasticizing blending process using atwin-screw extruder, and has high bonding strength, good bonding durability and film forming performance, less crystal points, and good heat and oxygen aging resistant performance, especially, by introducing HIPS, the bonding speed of the bonding resin is greatly improved, and simultaneously the bonding strength and durability are improved, so as to solve the defects of low bonding strength and poor stability caused by the untimely bonding reaction of the aluminum-plastic board in a high-speed production process, thereby greatly improving the production speed and bonding stability of the aluminum-plastic board.

Owner:HEYUAN PLG MATERIALS

Anti-carbonization concrete tubular pile and preparation method therefor

The invention discloses an anti-carbonization concrete tubular pile and a preparation method therefor. The anti-carbonization concrete tubular pile consists of the following raw materials in parts by weight: 10-16 parts of light calcium carbonate, 1-2 parts of wool grease, 0.7-2 parts of sodium lauroyl sarcosine, 20-30 parts of potassium feldspar powder, 3-4 parts of n-methyl pyrrolidone, 500-640 parts of ordinary silicate cement, 300-400 parts of yellow ground, 200-300 parts of gravels, 7-14 parts of a polycarboxylate water reducer, 0.1-0.2 part of dibenzoyl peroxide, 5-6 parts of maleic anhydride, 2-3 parts of polyethylene glycol monoethylether, 0.7-2 parts of sp-80, 50-70 parts of waste rubber powder, 0.1-0.2 part of triethylamine, 16-20 parts of polyethylene wax and 2-4 parts of polyvinyl butyral. The anti-carbonization concrete tubular pile can reduce quantity of harmful holes and defects in a concrete structure, reduces alkalinity of hydration products and promotes low-strength hydration products to transform into high-strength hydration products.

Owner:安徽三环管业有限公司

Utilization of fish leftover

InactiveCN1432300AHigh surface areaStable chemical propertiesFood preservationFood preparationProtein solutionFish oil

The present invention relates to the industrial processing of aqueous product, especially the comprehensive utilization of fish leftover. The fish leftover including fish internal organs, filtered solid matter, etc. are sorted, washed, minced, enzymolyzed and filtered to eliminate residue; fish oil in the filtrate is absorbed with modified graphite; the other part of the enzymolyzed protein solution is used as feed and food material; the filter residue is used for producing organic fertilizer; and all these constitute one comprehensive technological process.

Owner:徐少云 +2

Method for removing impurities from an impurity-containing fluid stream

InactiveUS7691270B2Reduce solubilityImprove non-polarityFatty acid chemical modificationFatty acids production/refiningSolubilitySolvent

A method of removing at least one polar component from a fluid stream. The method comprises providing a fluid stream comprising at least one nonpolar component and at least one polar component. The fluid stream is contacted with a supercritical solvent to remove the at least one polar component. The at least one nonpolar component may be a fat or oil and the at least one polar component may be water, dirt, detergents, or mixtures thereof. The supercritical solvent may decrease solubility of the at least one polar component in the fluid stream. The supercritical solvent may function as a solvent or as a gas antisolvent. The supercritical solvent may dissolve the nonpolar components of the fluid stream, such as fats or oils, while the polar components may be substantially insoluble. Alternatively, the supercritical solvent may be used to increase the nonpolarity of the fluid stream.

Owner:BATTELLE ENERGY ALLIANCE LLC

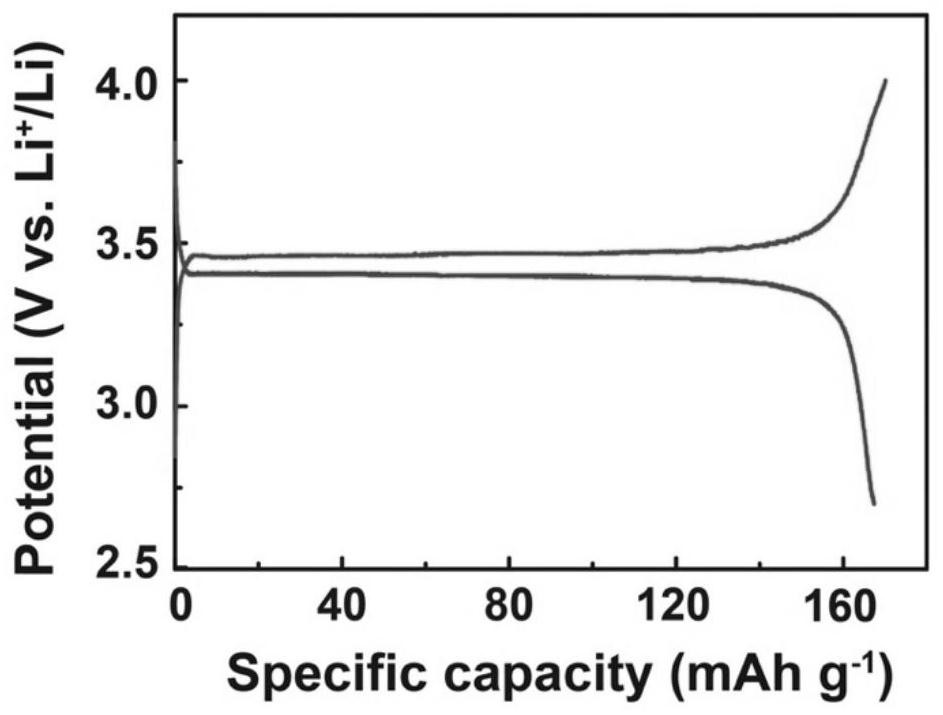

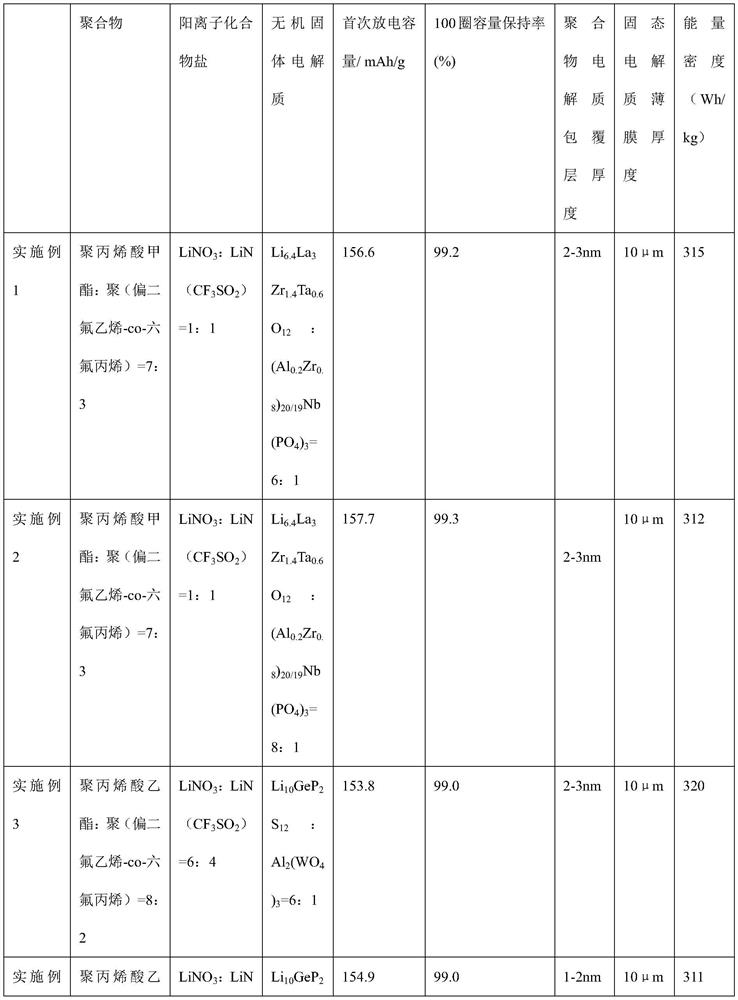

Composite solid electrolyte, preparation method thereof and application thereof in solid-state secondary battery

ActiveCN112234249ASimple manufacturing processHave mechanical strengthSolid electrolytesFinal product manufactureElectrically conductiveIn situ polymerization

The invention discloses a conductive coated composite solid electrolyte, a preparation method thereof and an application of the conductive coated composite solid electrolyte in a solid-state secondarybattery. The composite solid electrolyte is composed of inorganic solid electrolyte particles and a polymer electrolyte coating layer formed on the surfaces of the inorganic solid electrolyte particles. The preparation method of the composite solid electrolyte comprises the following steps of uniformly mixing the polymer / polymer monomer, the cationic compound salt and the inorganic solid electrolyte powder according to a certain ratio to obtain a precursor solution, and adding an initiator to initiate in-situ polymerization of the polymer monomer on the surfaces of solid electrolyte particles, or adding a precipitant to separate out the polymer on the surfaces of the solid electrolyte particles, thereby preparing the composite solid electrolyte. Furthermore, the prepared composite solid electrolyte and a solvent are mixed according to a certain proportion to obtain uniform and stable slurry, and a solid electrolyte film is prepared on the surface of a base material or an electrode byusing a tape-casting coating process and is used for producing a solid-state secondary battery.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Tear-resistant heat-insulating rubber cable material and preparation method thereof

PendingCN105585754AImprove heat resistanceImprove corrosion resistanceRubber insulatorsPolymer scienceButadiene-styrene rubber

The invention discloses a tear-resistant heat-insulating rubber cable material which is prepared from the following raw materials in parts by weight: 20-30 parts of epoxidized natural rubber, 40-60 parts of styrene-butadiene rubber, 30-50 parts of ethylene propylene diene monomer rubber, 50-80 parts of modified montmorillonite, 25-35 parts of dioctyl phthalate, 25-35 parts of epoxy soybean oil, 20-40 parts of aluminum hydroxide, 10-15 parts of melamine, 10-15 parts of sodium metaborate, 1-3 parts of bis-[gamma-(triethoxysilyl)propyl]tetrasulfide, 1-2 parts of sulfur, 0.6-0.8 part of accelerator M, 0.4-0.6 part of accelerator D, 2-4 parts of Ca / Zn composite stabilizer, 1-2 parts of bis-butyl tin dichloride, 0.2-0.4 part of antioxidant BHT, 0.1-0.2 part of anti-aging agent and 2-4 parts of montanin wax. The invention also discloses a preparation method of the tear-resistant heat-insulating rubber cable material. The tear-resistant heat-insulating rubber cable material has the advantages of favorable tear resistance and favorable heating insulating property.

Owner:繁昌县菲德通讯材料设计有限公司

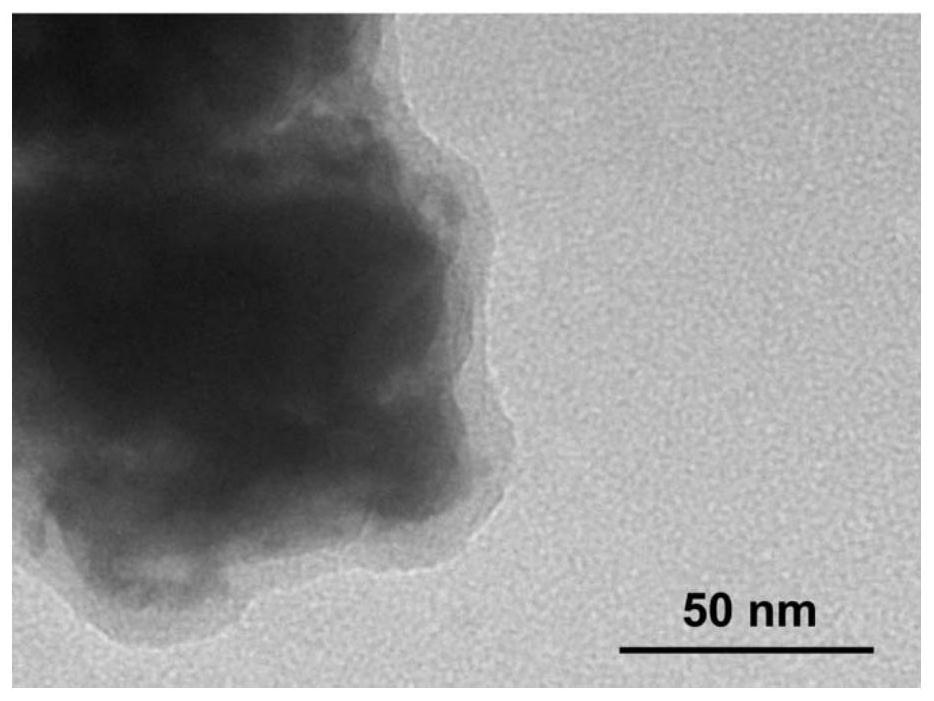

A kind of preparation method of oil-water separation material

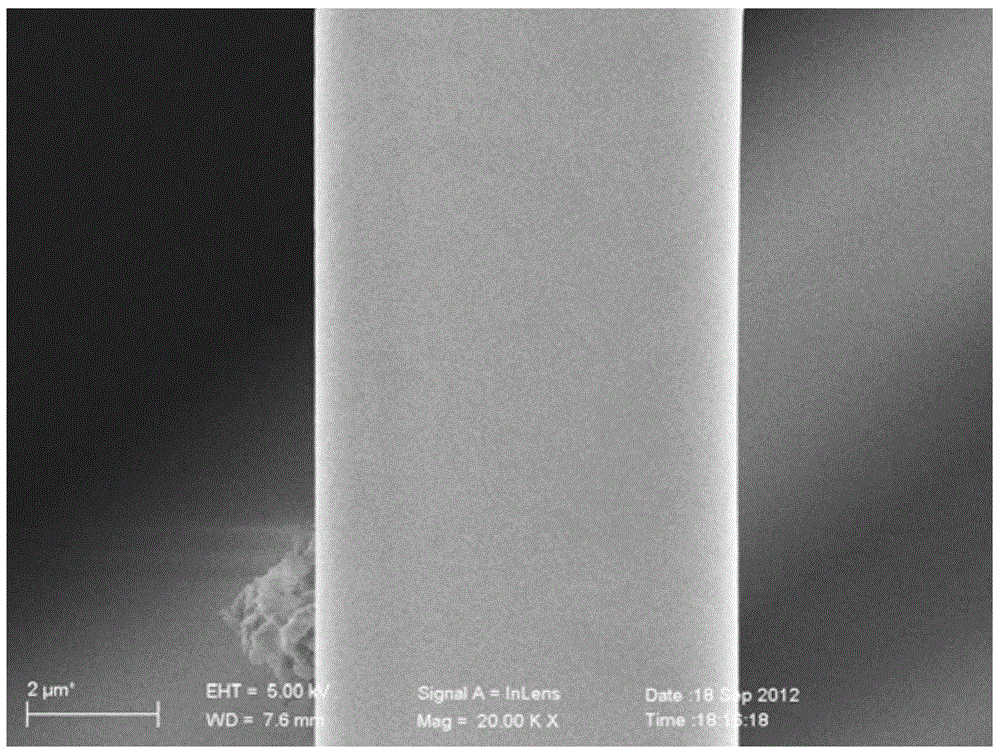

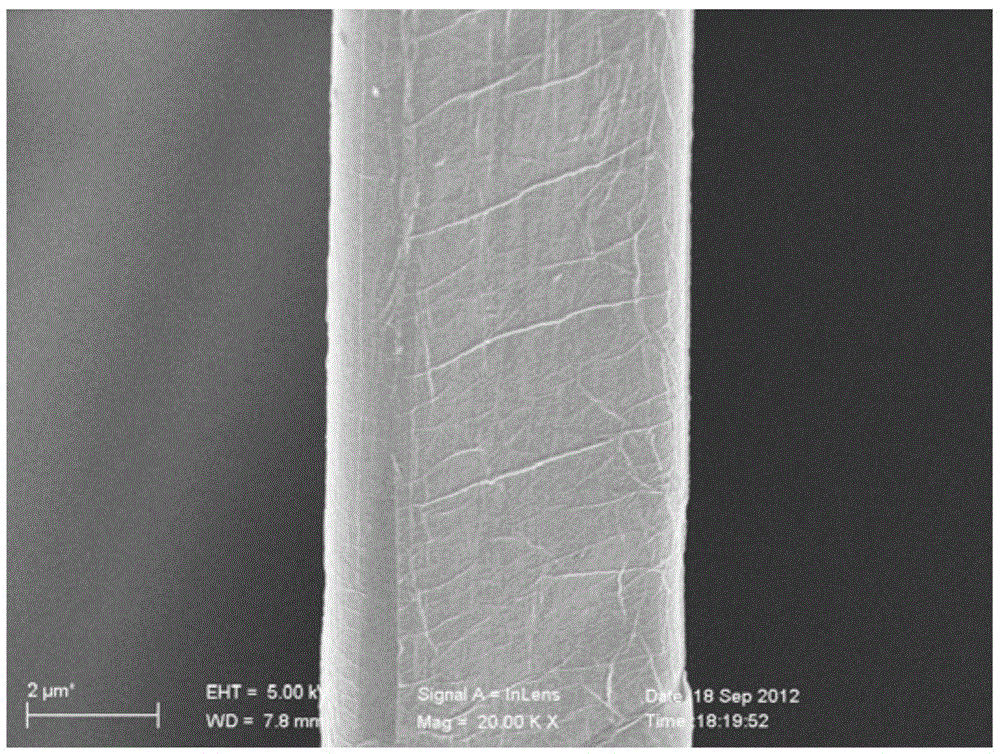

ActiveCN103626171BImprove oil-water separation effectEasy to separateGrapheneLiquid separationCentrifugationMechanical stability

The invention provides a preparation method of an oil-water separation material, comprising the following steps: soaking a sponge material in a graphene oxide solution, taking out the obtained sponge material and centrifuging to obtain a graphene oxide-coated sponge material; The graphene-coated sponge material undergoes a reduction reaction under the action of a reducing agent to obtain an oil-water separation material. The oil-water separation material prepared by the present invention is the reduced graphene oxide coated sponge, the graphene layer is evenly coated, tightly coated, has good resilience and mechanical stability, and the reduced graphene oxide layer provides good hydrophobicity and lipophilicity , can be used in oil-water separation technology.

Owner:UNIV OF SCI & TECH OF CHINA

Anti-ultraviolet coating

InactiveCN105802429AImprove non-polarityImproves UV resistanceRadiation-absorbing paintsEmulsionChemistry

The invention discloses an anti-ultraviolet coating. The anti-ultraviolet coating is prepared from, by weight, 80-100 parts of modified epoxy resin emulsion, 15-25 parts of water, 3-5 parts of propylene glycol methyl ether acetate, 8-12 parts of light calcium carbonate, 20-25 parts of kaolin, 2-3 parts of dodecyl ethoxy sulfo glycine betaine, 1-2 parts of sodium dodecyl sulfate, 0.03-0.05 part of dimethicone, 0.05-0.07 part of defoamer Tego Foamex 843, 0.2-0.4 part of wetting agent Wet265, 0.1-0.2 part of wetting agent Wet500, 0.4-0.5 part of leveling agent, 0.3-0.5 part of polyacrylamide, 0.1-0.2 part of methylcellulose, 0.02-0.04 part of 1,2-benzoisothiazolinone-3-ketone and 0.1-0.3 part of ultraviolet absorbent UV-P. The anti-ultraviolet coating is high in anti-ultraviolet property, good in bactericidal performance and good in corrosion resistance.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

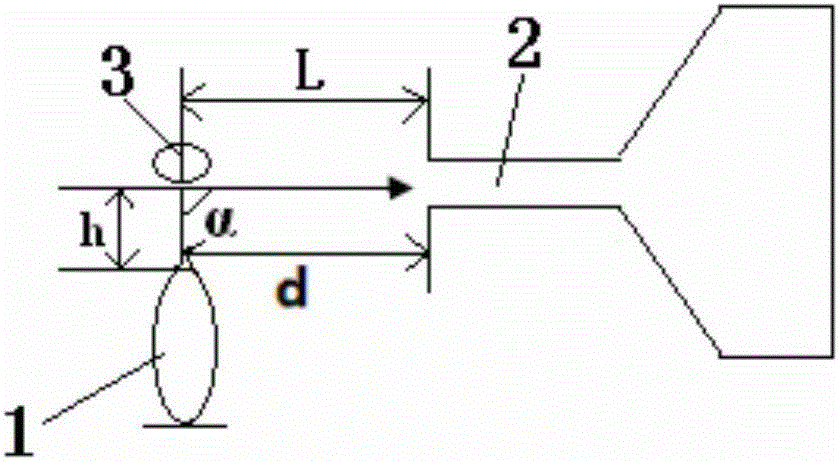

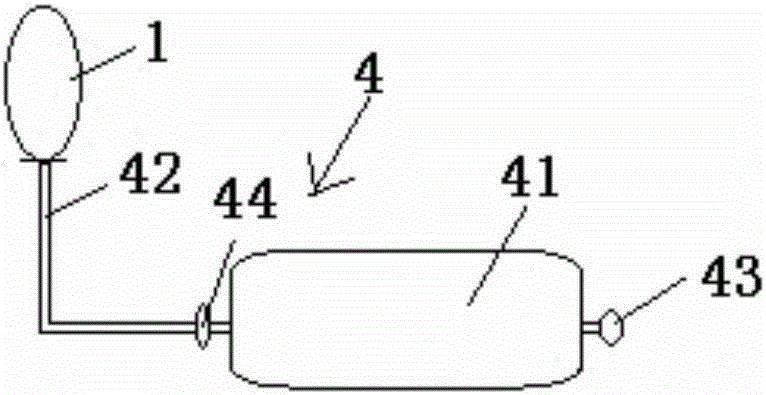

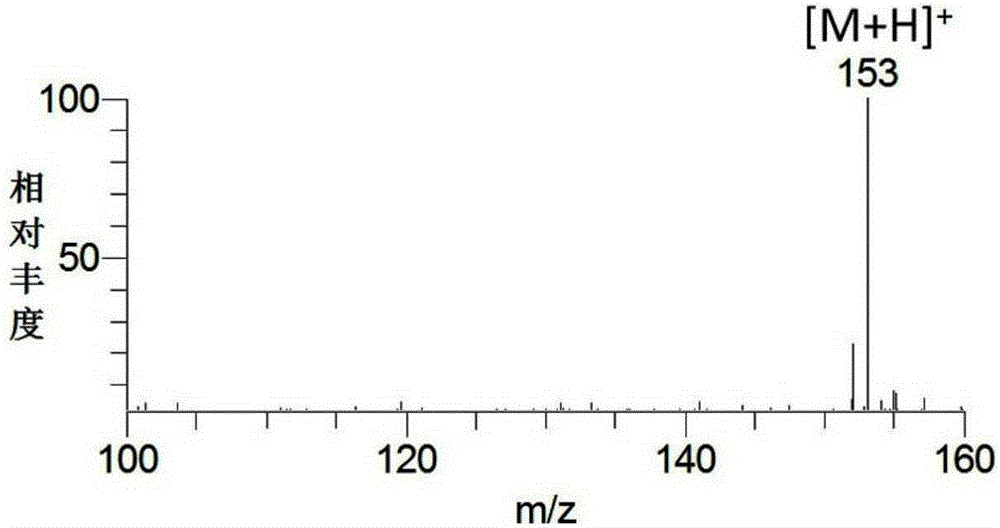

Ionization method and ionization device

ActiveCN105355536AEasy to implementEasy to operateMaterial analysis by electric/magnetic meansIon sources/gunsPhysical chemistryMass Spectrometry-Mass Spectrometry

The invention discloses an ionization method and an ionization device. The ionization method comprises an ion source, a sample, and a mass spectrum feeding channel, and is characterized in that the ion source is a flame. By using a flame as an ion source, the ionization technology is easy to implement and simple in operation, the analysis cost is reduced greatly, the ionization technology is of high compatibility and can meet the ionization resolution temperature requirement of compounds of different molecular sizes, the ionization efficiency is high for gaseous, liquid and solid samples and actual samples, the ionization technology is of high sensitivity, actual samples can be analyzed directly, substances such as polar, highly polar, non-polar and metal organic compounds can be well ionized, and the ionization technology has a wide application range, can be used together with a portable mass spectrometry to make natural in-situ analysis more convenient and is of significant practical value.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

High temperature resistant insulation composite insulator

InactiveCN105001563AImprove corrosion resistanceGood oil resistanceRubber insulatorsSuspension/strain insulatorsRubber materialComposite insulators

The invention discloses a high temperature resistant insulation composite insulator which comprises an insulation core rod, an umbrella skirt and a metal fitting. The umbrella skirt coats the insulation core rod. The metal fitting coats two ends of the insulation core rod and is connected to two ends of the umbrella skirt. The umbrella skirt is made from a rubber material. The high temperature resistant insulation composite insulator is resistant to high temperature, has good electrical insulation property, high mechanical strength, corrosion resistance and radiation resistance, is simple and convenient to operate and has short processing time.

Owner:ANHUI CHUANGYU ELECTRIC POWER EQUIP CO LTD

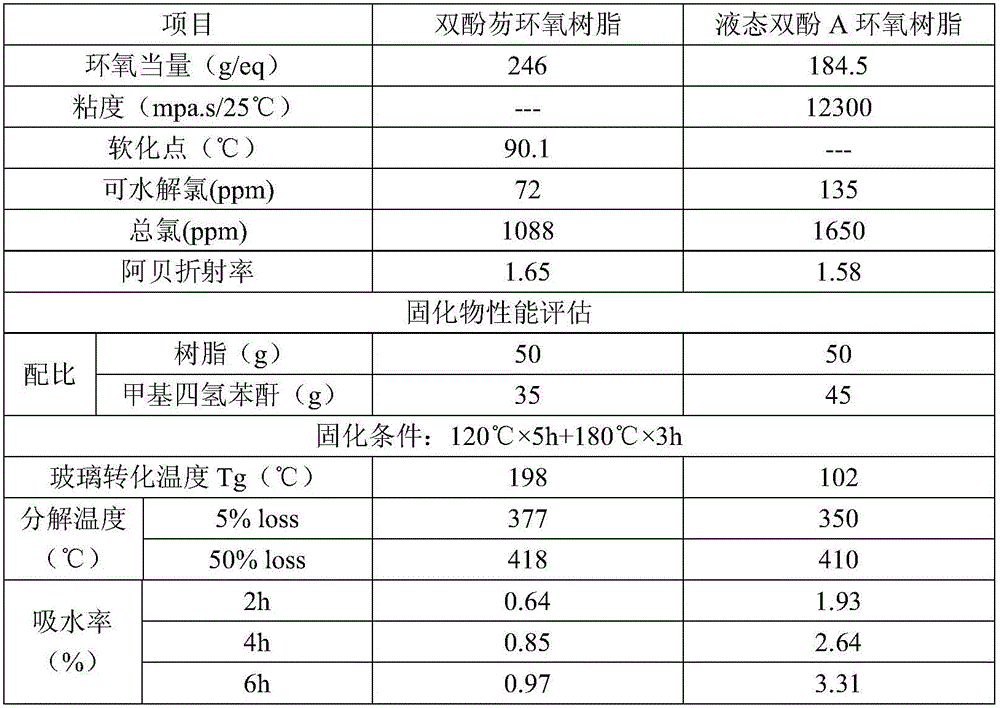

Preparation technology of bisphenol fluorene epoxy resin

The invention relates to the field of epoxy resin and particularly discloses a preparation technology of bisphenol fluorene epoxy resin. The preparation technology of bisphenol fluorene epoxy resin comprises the processes of catalytic grafting reaction, ring-closure reaction, refining reaction, desalting, concentration and brine treatment. The bisphenol fluorene epoxy resin obtained by the preparation technology disclosed by the invention has the properties of low water absorption, low total chlorine content and high heat resistance; the byproduct brine generated in the preparation process and the organic solvent of certain concentration contained in the brine are recycled, and the wastewater is treated to avoid direct discharge to the environment; the obtained sodium chloride can be sold as industrial salt, thereby turning waste into wealth; and the water obtained by condensation can be repeatedly used, thus the water consumption is reduced, and the energy is saved while the emission is reduced.

Owner:EPOXY BASE ELECTRONICS MATERIAL

High-strength insulating pipeline and preparation method thereof

The invention provides a high-strength insulating pipeline and a preparation method thereof. The pipeline is prepared by the following components: styrene butadiene rubber, ethylene propylene diene monomer, hollow glass beads, dioctyl phthalate, epoxy soybean oil, titanium dioxide, thermoplastic resin, an attapulgite compound, modified montmorillonite, filling powder, an inorganic fiber, a halogen-free flame retardant and an antioxidant. The insulating pipeline prepared by the method has good insulation performance, has advantages of high density, good toughness, high strength, environmental protection, non-toxicity, easy availability of raw materials and simple preparation method, and is suitable for large-scale industrial production.

Owner:HEFEI ZHENXUN LOW TEMPERATURE TECH CO LTD

High temperature resistance and impact resistance variable frequency cable

InactiveCN105585851AGood high and low temperature resistanceImprove corrosion resistanceRubber insulatorsInsulated cablesPhosphateStearic acid

The invention discloses a high temperature resistance and impact resistance variable frequency cable which comprises a sleeve layer. The sleeve layer is prepared from silicone rubber, composite filler, hydroxyl silicone oil, acetyl tributyl citrate, trioctyl phosphate, fire retardant, vinyltriethoxysilane, dicumyl peroxide, sulphur, zinc oxide, stearic acid, accelerant DETU, lauric acid dibutyltin maleate, octyl tin mercaptide, an anti-aging agent 4020, an anti-aging agent TMQ, an anti-aging agent RD and polyethylene wax. The composite filler is prepared from superfine glass fiber cotton, nanometer silicon carbide and modified expanded vermiculite. The high temperature resistance and impact resistance variable frequency cable is good in high temperature resistance and high in mechanical performance.

Owner:王社兵

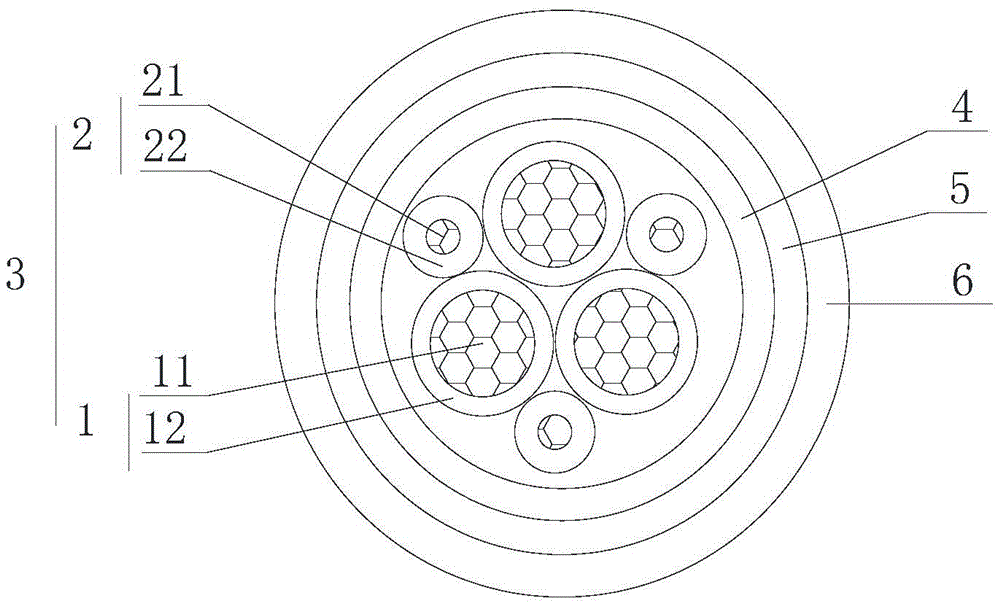

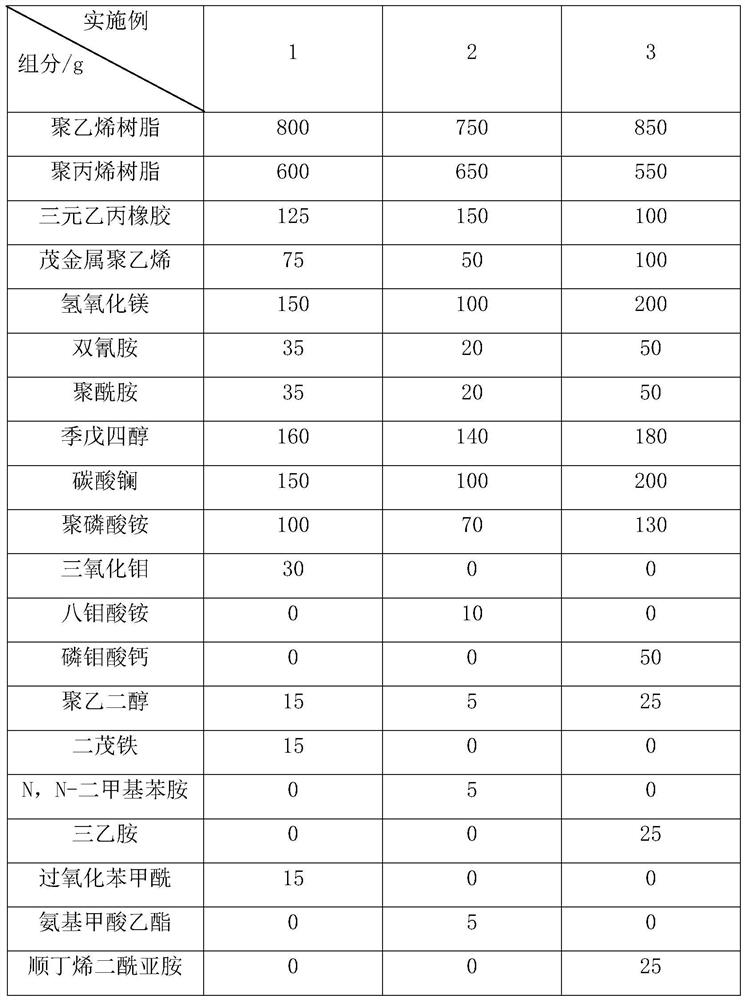

Ultra-soft low-smoke halogen-free flame-retardant polyolefin cable material and preparation method thereof

PendingCN111647218AIncrease the viscosity of the systemImprove compactnessPlastic/resin/waxes insulatorsPolyamidePolyolefin

The invention relates to an ultra-soft low-smoke halogen-free flame-retardant polyolefin cable material and a preparation method thereof, and relates to the technical field of cable materials. Raw materials of the ultra-soft low-smoke halogen-free flame-retardant polyolefin cable material specifically comprise the following components (by weight): 135-145 parts of polyolefin resin, 15-25 parts ofan elastomer, 10-20 parts of magnesium hydroxide, 2-5 parts of dicyandiamide, 2-5 parts of polyamide, 14-18 parts of pentaerythritol, 10-20 parts of lanthanum carbonate, 7-13 parts of ammonium polyphosphate, 1-5 parts of a smoke suppressant, 0.5-2.5 parts of a dispersing agent, 0.5-2.5 parts of an accelerant and 0.5-2.5 parts of a vulcanizing agent. The cable material provided by the invention hasgood flexibility, so that the polyolefin cable material is convenient to bend in the use process; and in addition, the cable material provided by the invention has good flame retardant property and smoke suppression property.

Owner:上海方之德新材料有限公司

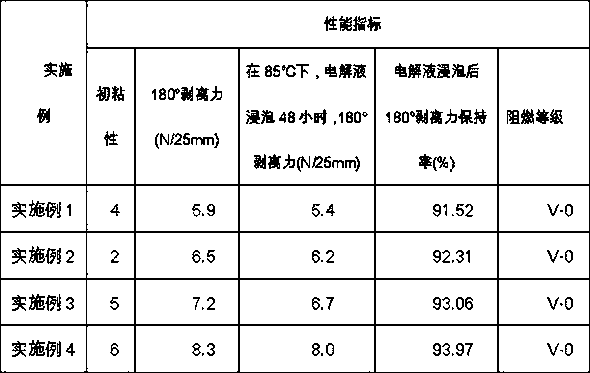

Lithium battery electrolyte-proof flame-retardant adhesive, preparation method thereof, and adhesive tape

ActiveCN109385237ASolve the problem of poor electrolyte resistanceImprove performanceFinal product manufactureMacromolecular adhesive additivesPolymer scienceAcrylonitrile

The invention relates to a lithium battery adhesive tape, and more specifically relates to a lithium battery special-purpose electrolyte-proof flame-retardant adhesive, a preparation method thereof, and an electrolyte-proof flame-retardant adhesive tape. The lithium battery electrolyte-proof flame-retardant adhesive comprises, by mass, 10 to 60 parts of octadecyl acrylate, 1 to 10 parts of 4-methacryloxyethyl trimellitic anhydride, 1 to 5 parts of acrylonitrile, 1 to 15 parts of a phosphorus-containing acrylate monomer, 0.001 to 0.5 part of radical initiator tertial butyl peroxymaleic acid, 0.001 to 1 part of ferric trichloride, 0.01 to 2 parts of triphenylphosphine, 50 to 250 parts of an organic solvent, 1 to 10 parts of epoxidized polybutadiene, and 0.1 to 1 part of a curing accelerator.The preparation method is capable of solving a problem in the prior art that the electrolyte resistance of conventional acrylate pressure-sensitive adhesive is poor. According to the preparation method, the electrolyte resistance of the adhesive tape at high temperature environment is improved; and the flame-retardant function monomer and flame-retardant film are introduced, so that the flame resistance of the acrylate pressure-sensitive adhesive tape is improved further.

Owner:佛山市顺德区永创翔亿电子材料有限公司

Heat conductive cable material

InactiveCN106084497AImprove heat resistanceImprove insulation performanceRubber insulatorsPolymer scienceModified carbon

The invention discloses a heat conductive cable material which comprises, by weight, 100-120 parts of modified ethylene-propylene-diene monomer rubber, 10-30 parts of talcum powder, 20-50 parts of carbon black, 1-3 parts of epoxidized soybean oil, 20-30 parts of magnesium hydrate, 10-20 parts of micro-capsulated red phosphorus, 5-10 parts of expansible graphite, 1-2 parts of sulphur, 0.1-0.3 part of zinc oxide, 0.2-0.4 part of stearic acid, 0.2-0.4 part of accelerant M, 4-6 part of Ca / Zn composite stabilizer and 2-4 parts of montan wax. In the preparation process of the modified ethylene-propylene-diene monomer rubber, phenolic resin is added into ethyl alcohol to be dissolved, silane coupling agent modified carbon nanotubes are added, stirring is carried out, rotary evaporation is carried out to remove ethyl alcohol, and drying is carried out to obtain a material A; the material A and ethylene-propylene-diene monomer rubber are mixed to be uniform, the temperature is increased, heat insulation and stirring are carried out, and the modified ethylene-propylene-diene monomer rubber is obtained. The heat conductive cable material is good in heat conductivity and high in mechanical performance.

Owner:ANHUI HAIRONG CABLE

Flame-retardant and wear-resistant polypropylene cable material

InactiveCN105924768AImprove non-polarityEvenly dispersedPlastic/resin/waxes insulatorsInsulated cablesCorrosion resistantPolypropylene

The invention discloses a flame-retardant and wear-resistant polypropylene cable material. The flame-retardant wear-resistant polypropylene cable material comprises the following raw materials in parts by weight: 60 to 80 parts of polypropylene, 30 to 40 parts of modified polyurethane, 20 to 30 parts of carbon black, 15 to 25 parts of lightweight calcium carbonate, 10 to 15 parts of kaolin, 3 to 4 parts of trioctyl acetylcitrate, 1 to 2 parts of epoxidized soybean oil, 20 to 30 parts of microencapsulated red phosphorous, 5 to 10 parts of zinc borate, 1 to 2 parts of 3-aminopropyltriethoxysilane, 1 to 3 parts of dicumyl peroxide, 0.2 to 0.4 part of sulfur, 0.1 to 0.3 part of an accelerator D, 0.3 to 0.5 part of an accelerator CZ, 1 to 2 parts of a Ca / Zn composite stabilizing agent, 1 to 2 parts of a rare-earth stabilizing agent, 1 to 2 parts of dibutyl tin dichloride, 0.2 to 0.3 part of an anti-aging agent MB, 0.1 to 0.3 part of an anti-aging agent RD and 2 to 4 parts of silicone powder. The flame-retardant and wear-resistant polypropylene cable material provided by the invention has good wear resistance and flame retardance and high impact resistance and toughness, and is corrosion-resistant.

Owner:ANHUI WANTAI CABLE

High-temperature-resistant and impact-resistant cable material

InactiveCN106084781AGood high and low temperature resistanceImprove corrosion resistanceRubber insulatorsDibutyltin oxideTemperature resistance

The invention discloses a high-temperature-resistant and impact-resistant cable material. The high-temperature-resistant and impact-resistant cable material is prepared from, by weight, 70-90 parts of silicone rubber, 30-40 parts of modified polyurethane, 20-30 parts of kaolin, 40-60 parts of organized montmorillonoid, 2-4 parts of tributyl citrate, 30-40 parts of aluminum hydroxide, 8-10 parts of zinc borate, 0.8-1.5 parts of 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, 0.1-0.2 part of sulphur, 0.1-0.3 part of an accelerant BZ, 3-5 parts of dibutyltin oxide and 3-5 parts of paraffin oil. The high-temperature-resistant and impact-resistant cable material is high in impact resistance, high temperature resistance and mechanical property.

Owner:ANHUI HAIRONG CABLE

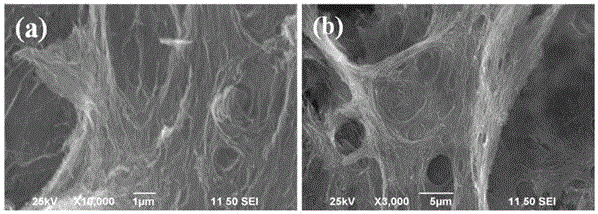

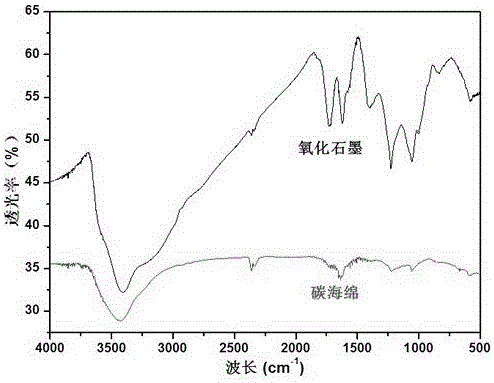

Carbon sponge material and preparation method and application thereof

InactiveCN106732412AHydrophobic and lipophilicAdjust the shape arbitrarilyOther chemical processesWater contaminantsFreeze-dryingAqueous solution

The invention discloses a carbon sponge material and a preparation method and an application thereof, and belongs to the synthetic technical field of oil absorption materials. The key points of the technical scheme of the invention are as follows: firstly, using an improved Hummers method to prepare graphite oxide with graphite powder as a raw material, preparing a graphite oxide aqueous solution with a mass concentration of 2-10 mg / mL by using the prepared graphite oxide, adding carboxymethylcellulose accounting for 0.5-3% of the mass of the graphite oxide aqueous solution, performing hydrothermal reaction at 120 DEG C for 8h in a hydrothermal reactor to obtain plasticity carbon sponge, and performing dialysis treatment and freeze drying to obtain a macroscopic bulk carbon sponge material, wherein the carbon sponge material can be applied to treatment of oily wastewater. The macroscopic bulk carbon sponge material with large adsorption capacity and easy regeneration property is synthesized, and a method for obtaining a recyclable adsorption material by a simpler preparation process is provided.

Owner:HENAN NORMAL UNIV

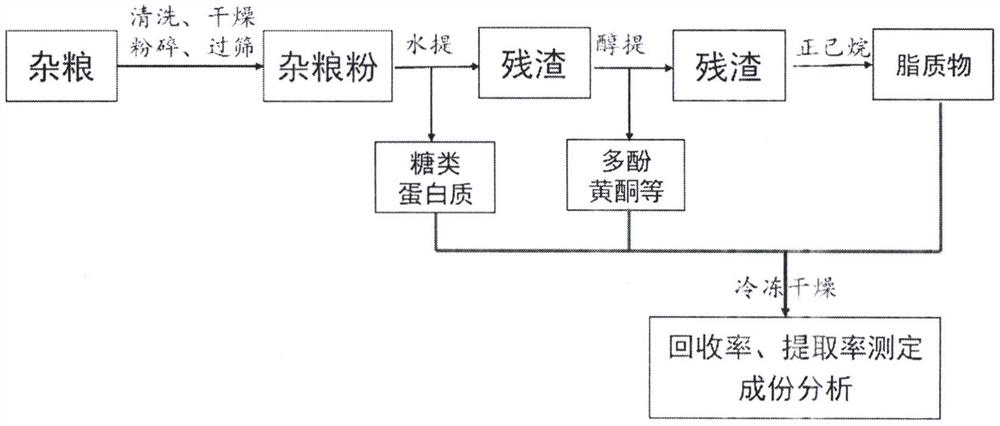

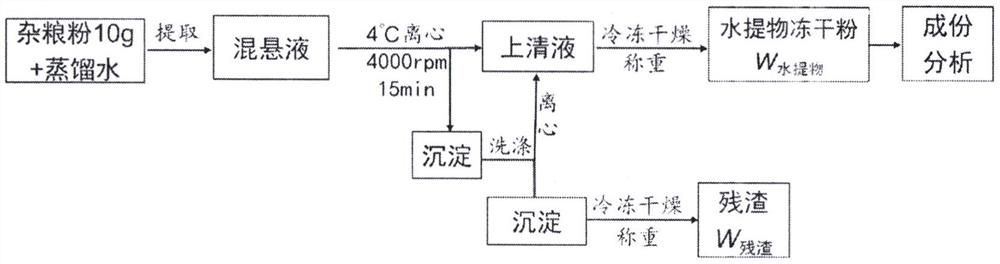

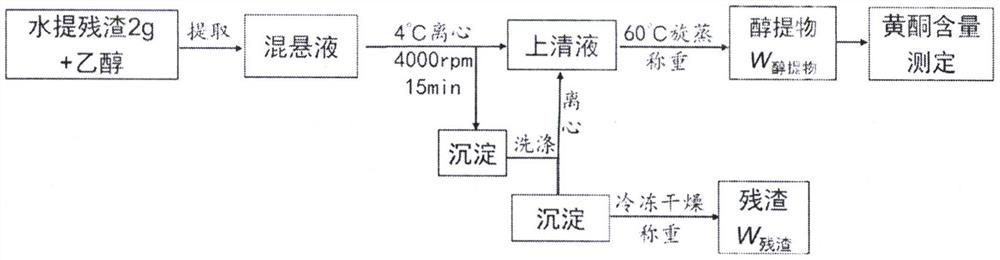

Coarse cereal step-by-step programmed extraction method and application thereof

InactiveCN112629961ABreakthrough extraction processImprove non-polarityComponent separationPreparing sample for investigationBiotechnologyPolygonum fagopyrum

The invention belongs to the field of food engineering technology and biotechnology. The invention discloses a coarse cereal step-by-step programmed extraction method and application thereof, which are used for obtaining all soluble substances of coarse cereals and determining components and contents of the soluble substances. The coarse cereals comprise but are not limited to buckwheat, peas and coix seeds. According to the invention, the solvents used in the step-by-step programmed extraction of coarse cereals are successively a polar aqueous solvent, a semi-polar solvent ethanol and non-polar n-hexane, wherein the residue extracted in the previous step is used as the raw material for the next step of extraction. The invention discloses the step-by-step extraction process of three coarse cereals, namely buckwheat, pea and coix seed, wherein the yield is highest, soluble full components of the coarse cereals can be obtained, and reliable material guarantee is provided for establishing a quantitative relation between coarse cereal components and biological efficacy. The method has important guiding significance for reasonably eating the coarse cereals.

Owner:PEKING UNIV

Low-cost fly ash concrete pile, and preparation method therefor

The present invention discloses a low-cost fly ash concrete pile. The pile consists of the following raw materials in parts by weight: 5-6 parts of maleic anhydride,40-50 parts of fly ash, 1.5-3 parts of Butyl-p-hydroxybenzoate, 0.1-0.2 parts of diazolidinyl urea, 0.1-0.3 parts of two thioglycolic acid dimethyl diisooctyl tin, 0.2-0.4 parts of polysorbate 80, 4-7 parts of kynar, 500-640 parts of ordinary Portland cement, 300-400 parts of yellow sand, 200-300 parts of crushed stone, 7-15 parts of polycarboxylate superplasticizer, 16-20 parts of polyethylene wax, 0.1-0.2 parts of dibenzoyl peroxide, 2-3 parts of polyethylene glycol monomethyl ether, 0.7-2 parts of sp-80, and 50-70 parts of waste rubber powder. The pile of the invention, with fly ash being used as a filler, is low in cost, good in surface resistance, high in strength, strong in impermeability, and superior in overall performance.

Owner:安徽三环管业有限公司

Carbon-silicon reinforced concrete tubular pile and production method thereof

InactiveCN106116371AImprove non-polarityImprove compatibilitySolid waste managementStructural systemCarbon dioxide

The present invention discloses a carbon-silicon reinforced concrete tubular pile; since ethoxylated rubber fiber is doped, inner pore structure of concrete can be effectively improved and mass closed pores can be formed so as to prevent capillary pores from forming a continuous through meshed structural system, an 'anti-carbonization belt' is formed, inhibition on carbon dioxide invasion is further enhanced, and it is also additionally possible to reduce harmful pores and defects in the concrete structure, reduce alkality of hydrates and promote the conversion of low-strength hydrates to high-strength hydrates.

Owner:ANHUI XINRUN NEW MATERIALS

Concrete pipe pile and preparation method thereof

InactiveCN105016682AImprove hydrophilicityHigh strengthSolid waste managementFiberPolyethylene glycol

The invention discloses a concrete pipe pile which is prepared from the following raw materials in parts by weight: 500-640 parts of common silicate cement, 300-400 parts of yellow sand, 200-300 parts of gravels, 14-20 parts of aluminum phosphate, 7-15 parts of a poly carboxylic acid water reducing agent, 16-20 parts of polyethylene wax, 0.1-0.2 part of dibenzoyl peroxide, 5-6 parts of maleic anhydride, 2-3 parts of methoxy polyethylene glycol, 4-7 parts of ethyecellulose, 0.7-2 parts of sp-80, 50-70 parts of waste rubber powder and 0.1-0.2 part of triethylamine. According to the concrete pipe pile disclosed by the invention, by doping the ethoxylated rubber fiber, the inner pore structure of the concrete can be effectively improved to form a lot of closed pores to prevent pores from forming a continuous penetrating netty structure system so as to play a role of further enhancing inhibition of invasion of carbon dioxide. In addition, the content of harmful pores and defects in the concrete structure can be further reduced, the alkalinity of hydration products is reduced, and the low-strength hydration products are promoted to be converted into high-strength hydration products.

Owner:安徽三环管业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com