Coarse cereal step-by-step programmed extraction method and application thereof

An extraction method and a technique for miscellaneous grains, which are applied in the fields of food engineering technology and biology, and can solve problems such as the inability to establish a dose-effect relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The step-by-step programmed extraction method of embodiment 1 miscellaneous grain powder

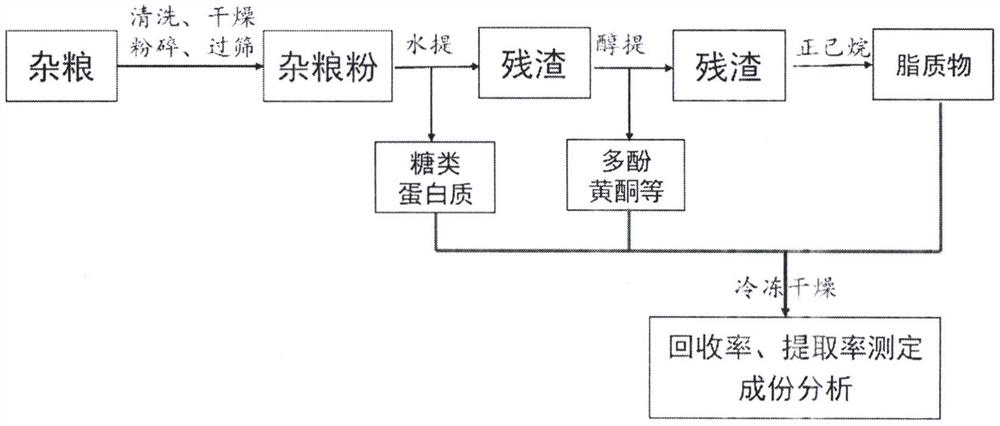

[0041] The flow chart of step-by-step programmed extraction process of miscellaneous grain powder is as follows: figure 1 shown.

[0042] (1) Pulverization of miscellaneous grains: the miscellaneous grains are crushed by a multifunctional pulverizer and passed through a 60-mesh sieve to make miscellaneous grain powder with a particle size of less than 0.3 mm;

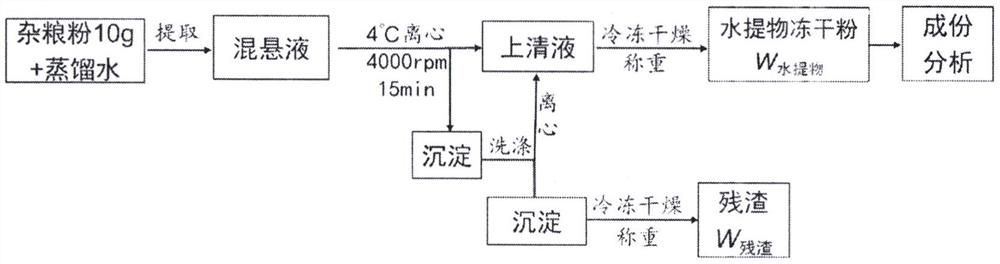

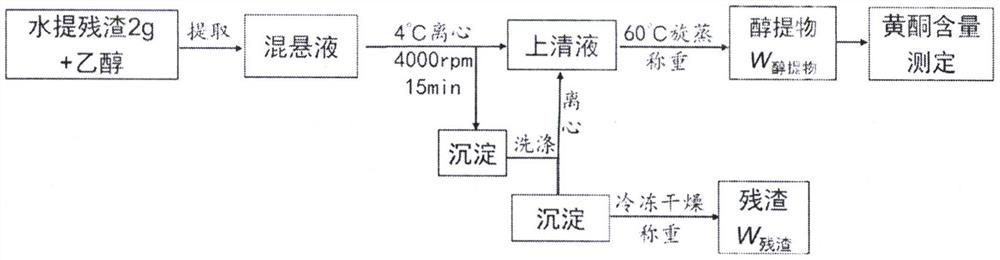

[0043] (2) the extraction of the first step water extract (as figure 2 Shown): Weigh a certain amount of grain powder dried to constant weight and place it in a 250ml Erlenmeyer flask with a stopper, add double distilled water, mix well, and then cover the plug; place it in a water bath constant temperature oscillator for incubation; the incubation is over Finally, transfer the miscellaneous grain suspension in the Erlenmeyer flask to a 50ml centrifuge tube, and centrifuge at 4000r / min for 15min at 4°C; draw the supernat...

Embodiment 2

[0047] Embodiment 2 step-by-step programmed extraction process of buckwheat

[0048] The method is consistent with that described in Example 1.

[0049] The conditions and levels of buckwheat water extraction, alcohol extraction and n-hexane extraction process are shown in Table 1, according to three factors and three levels L9 (3 3 ) table for experiments, with the quality of the extract as an investigation index, optimize the extraction process parameters; buckwheat step-by-step extraction steps are: first carry out water extraction orthogonal design experiments to obtain the optimal water extraction process, and then use the optimal water extraction residue as raw material, Optimize the alcohol extraction process by orthogonal design, finally use the optimal alcohol extraction process to obtain the alcohol extract residue, then optimize the normal hexane extraction process by orthogonal design; the conditions and levels of the orthogonal design are consistent as described i...

Embodiment 3

[0053] Example 3 Step-by-step programmed extraction process of barley

[0054] The method is consistent with that described in Example 1 and Example 2, and the conditions and levels of the orthogonal design are consistent with those described in Table 1 in Example 2.

[0055] Through the range analysis, the optimal conditions for water extraction of barley are obtained as temperature 90°C, extraction time 2h, solid-liquid ratio of 1:20 (g / ml), and the optimal conditions for alcohol extraction are temperature 70°C, extraction time 5h, solid-liquid ratio The ratio is 1: 50 (g / ml); the optimal conditions for n-hexane extraction are temperature 60°C, extraction time 10min, and the ratio of solid to liquid is 1: 10 (g / ml); the obtained water extract is off-white powder, water extraction The yield was 6.82%; the alcohol extract was light yellow solid, and the extraction yield was 4.66%; the n-hexane extract was colorless oil, and the extraction yield was 0.13%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com