Ultra-soft low-smoke halogen-free flame-retardant polyolefin cable material and preparation method thereof

A technology of polyolefin cable material and polyolefin resin, which is used in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of cable bending, poor flexibility of polyolefin cables, and large amount of flame retardants. The effect of non-polar enhancement, improved mechanical properties, and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

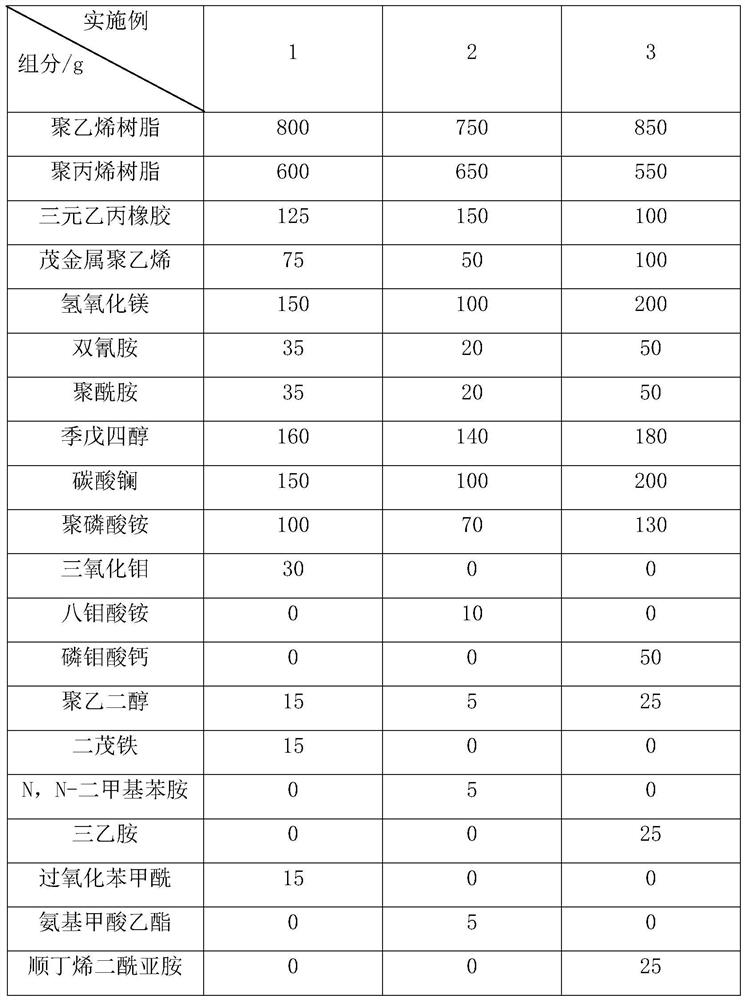

[0031] An ultra-soft low-smoke halogen-free flame-retardant polyolefin cable material, the raw material ratio of which is shown in Table 1. The preparation method of the ultra-soft low-smoke halogen-free flame-retardant polyolefin cable material includes the following steps:

[0032] (1) Weigh pentaerythritol, lanthanum carbonate, and polyphosphoramide in proportion, place them in a mixer, and stir at a speed of 955r / min for 6.5min at a temperature of 102.5°C, then add 10% of the total mass of the phosphate ester coupling agent. 1 / 3, then stirred at a speed of 955r / min for 9 minutes, and set aside;

[0033] (2) Take magnesium hydroxide in proportion, add deionized water and be mixed with the slurry that mass fraction is 5%, add 1 / 3 of the total mass of dicyandiamide, polyamide and phosphoric acid ester coupling agent wherein, with 955r / Stir at a speed of 17.5 min, vacuum filter, place the filter cake in a vacuum drying oven, dry at 105°C for 9.5 h, and pulverize through a 150...

Embodiment 2

[0036] An ultra-soft low-smoke halogen-free flame-retardant polyolefin cable material, the raw material ratio of which is shown in Table 1. The preparation method of the ultra-soft low-smoke halogen-free flame-retardant polyolefin cable material includes the following steps:

[0037] (1) Weigh pentaerythritol, lanthanum carbonate and polyphosphoramide in proportion, place them in a mixer, stir at a speed of 950r / min for 5min at a temperature of 100°C, and then add 1% of the total mass of the phosphate coupling agent. / 3, then stirred at a speed of 950r / min for 8min, and set aside;

[0038] (2) Take magnesium hydroxide in proportion, add deionized water and be mixed with the slurry that the mass fraction is 5%, add 1 / 3 of the total mass of dicyandiamide, polyamide and phosphoric acid ester coupling agent wherein, with 950r / Stir at a speed of min for 15 minutes, vacuum filter, place the filter cake in a vacuum drying oven, dry at 105°C for 9 hours, and pulverize through a 150-m...

Embodiment 3

[0041] An ultra-soft low-smoke halogen-free flame-retardant polyolefin cable material, the raw material ratio of which is shown in Table 1. The preparation method of the ultra-soft low-smoke halogen-free flame-retardant polyolefin cable material includes the following steps:

[0042] (1) Weigh pentaerythritol, lanthanum carbonate and polyphosphoramide in proportion, place them in a mixer, stir at a speed of 960r / min for 8min at a temperature of 105°C, and then add 1% of the total mass of the phosphate coupling agent. / 3, then stirred at a speed of 960r / min for 10min, and set aside;

[0043] (2) Take magnesium hydroxide in proportion, add deionized water and be mixed with the slurry that the mass fraction is 5%, add 1 / 3 of the total mass of dicyandiamide, polyamide and phosphoric acid ester coupling agent wherein, with 960r / Stir at a speed of min for 20 minutes, vacuum filter, place the filter cake in a vacuum drying oven, dry at 105°C for 10 hours, and pulverize through a 150...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com