Patents

Literature

2200 results about "Ammonium orthophosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium phosphate is the salt of ammonium and phosphate. It is a highly unstable compound with the formula (NH4)3PO4. Because of its instability, it is elusive and of no commercial value.

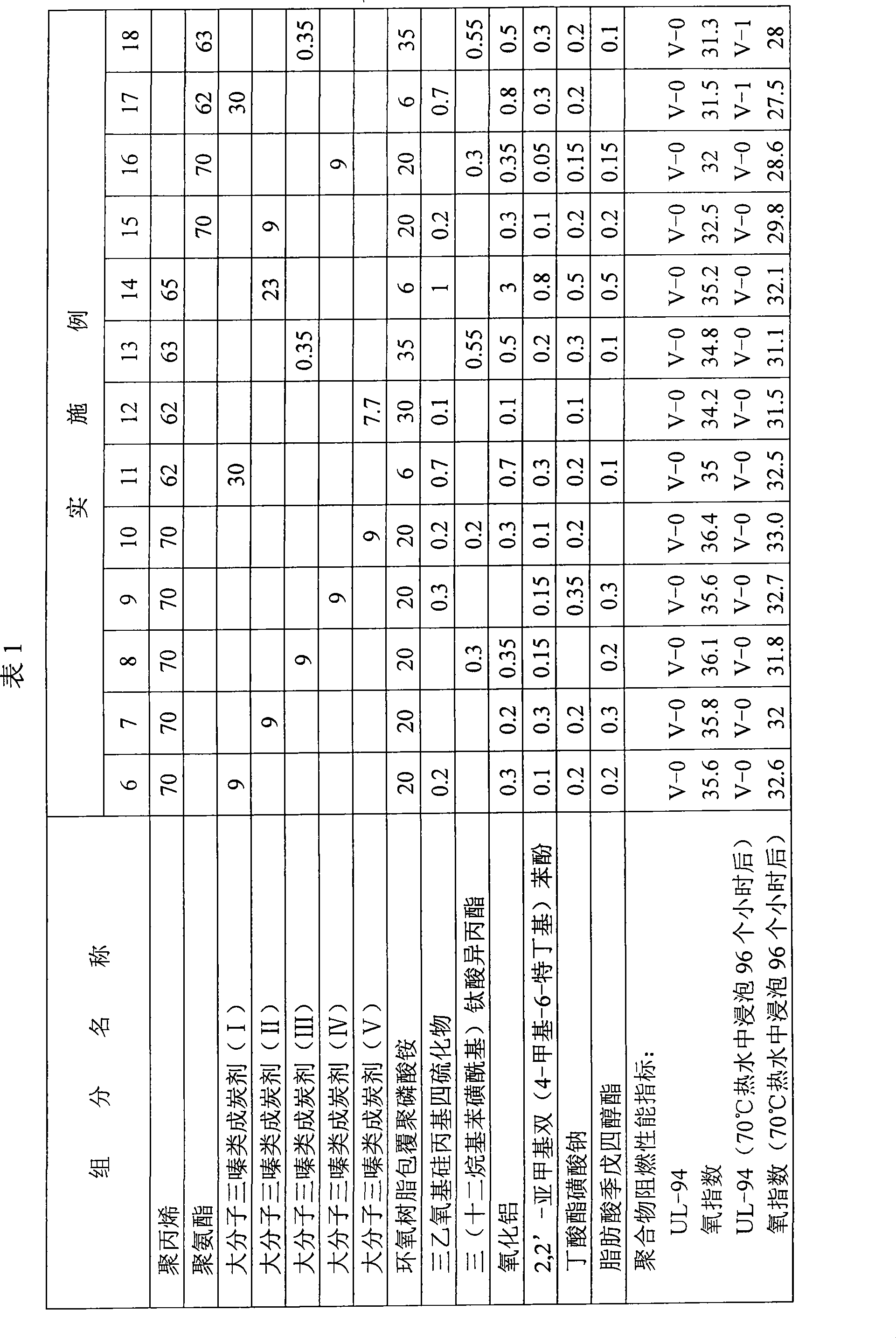

Halogen-free expansion type flame-retardant and preparation thereof

The invention relates to a halogen-free intumescent flame-retardant polypropylene composite and a preparation method thereof. Calculated by weight percentage, the composite comprises 35 to 80 percent of polypropylene, 5 to 30 percent of coated poly-ammonium phosphate, 1 to 20 percent of melamine and the derivatives, 1 to 15 percent of halogen-free macromolecular char forming flame retardant, 0.1 to 5 percent of flame retardant synergist, 1 to 20 percent of rigid inorganic particle, 0.05 to 5 percent of coupling agent, 0.1 to 10 percent of compatilizer, 1 to 20 percent of toughening agent and 0.01 to 4 percent of antioxidant. Compared with the prior art, the material of the invention has good toughness, high strength and environment-protecting flame retardance, and the composite can be widely applied in the fields such as automobile and electronic appliances.

Owner:SHANGHAI RES INST OF CHEM IND +1

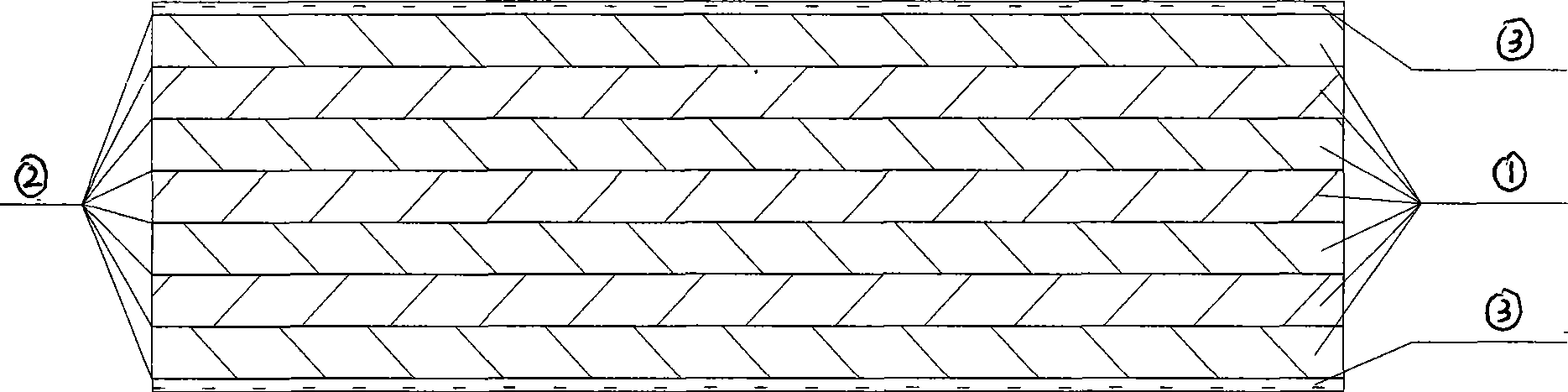

Method for producing flame-retardant glued board

ActiveCN101412231AReduce releaseImprove flame retardant performanceOther plywood/veneer working apparatusWood treatment detailsAdhesivePyrophosphate

The invention discloses a method for producing a flame-retardant veneer plywood, which comprises the following steps: placing wood veneers into a flame retardant aqueous solution to perform dipping treatment, applying the mixed adhesive to the upper surfaces and the lower surfaces of the veneers after the veneers are dried, assembling the veneers into a plate blank according to the principle that odd layers are crossed and symmetrical with even layers, and then performing the processes of cold pressing, hot pressing, cutting edge, sanding, surface treating and the like to obtain the flame-retardant veneer plywood product the thickness of which is between 2.7 and 20 millimeters. The flame retardant in the method is a mixture of low ammonium polyphosphate, ammonium phosphate, ammonium pyrophosphate, urea phosphate, boric acid and pentaerythritol, and the mixed adhesive is a uniform mixture of wood adhesive, filler, and a curing agent. The flame-retardant decorative veneer plywood prepared by the method has the advantages of excellent flame-retardant and fireproof performance, environmental prevention performance, and good mechanical properties.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Microencapsulation expansion type flame retardant and application in epoxy resin composite material thereof

The invention discloses a microencapsulation expansion type flame retardant and application in an epoxy resin composite material thereof. The microencapsulation expansion type flame retardant uses ammonium polyphosphate as a capsule core and uses a thermosetting resin melamine-formaldehyde resin as a capsule material. The microencapsulation expansion type flame retardant epoxy resin composite material consists of the epoxy resin, a curing agent, a curing accelerator, the microencapsulation expansion type flame retardant and a flame-retardant carbon-forming accelerator. The microencapsulation expansion type flame retardant and the application are economic, simple and convenient; the flame retardant has good flame-retardant synergistic effects; and under the condition of little flame retardant addition, the composite material can pass V-0 level of UL-94 test, and the oxygen index reaches over 30.0 percent.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Anti-refiring ultrafine ammonium phosphate dry chemical fire-extinguishing agent and its preparation method

InactiveCN1597024AUltrafine particle sizeLarge specific surface areaFire extinguisherSilicone oilTalc

A superfine ammonium phosphate dry chemical fire-extinguishing agent for preventing refiring is prepared from ammonium phosphate, ammonium sulfate, talc powder, mica powder, white carbon black and calcium carbonate through airflow pulverizing, proportional mixing, coating silicon oil, and coating F-C surfactant.

Owner:SICHUAN UNIV

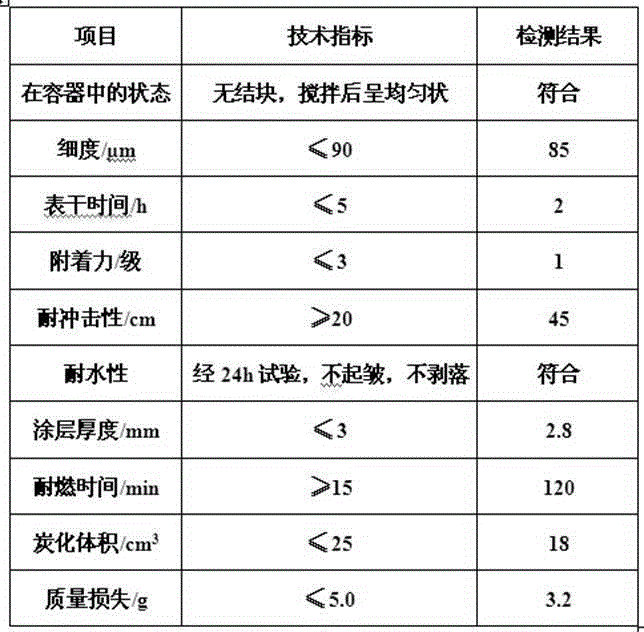

Aqueous ultrathin expansion-type fireproof coating for steel structure and preparation method thereof

ActiveCN104130671AImprove corrosion resistanceStrong adhesionFireproof paintsEpoxy resin coatingsPolymer sciencePentaerythritol

The invention discloses an aqueous ultrathin expansion-type fireproof coating for a steel structure and a preparation method thereof, and belongs to the technical field of fireproof coatings. The aqueous ultrathin expansion-type fireproof coating comprises, by mass, 10-35 parts of a modified aqueous epoxy emulsion, 1-8 parts of a curing agent, 5-15 parts of a styrene-acrylic emulsion or a silicone-acrylic emulsion, 10-20 parts of ammonium polyphosphate, 6-12 parts of melamine, 8-16 parts of pentaerythritol, 5-15 parts of a fire retardant, 5-15 parts of a pigment and a filling material, 2-8 parts of an assistant and 15-35 parts of water. The aqueous ultrathin expansion-type fireproof coating has the characteristics of low raw material cost, simple preparation process and environmental friendliness.

Owner:沈阳泰丰化工有限公司

Core-shell type ammonium polyphosphate synergetic flame-retardant polyurethane elastic composite material and preparation method thereof

ActiveCN101608060AHigh flame retardant efficiencyImprove efficiencyPolyurethane elastomerFire protection

The invention discloses a core-shell type ammonium polyphosphate synergetic flame-retardant polyurethane elastic composite material and a preparation method thereof, which is characterized in that the polyurethane elastic composite material containing core-shell type ammonium polyphosphate can be obtained by melting and co-mixing 75-94.9% of polyurethane, 5-25% of core-shell type ammonium polyphosphate and 0.1-5% of synergistic agent at the temperature of 160-220 DEG C for 5-30 minutes by weight percentage. The composite material can ensure that the adding amount of flame retardant is reduced while ensuring the flame retardance effect, and the composite material has good resistance of melt drip, simultaneously improves the shortcoming of poor water resistance of the flame-retardant composite material containing the ammonium polyphosphate, enhances the compatibility of the flame retardant and a polyurethane elastomer and improves the mechanical properties of the material, such as tensile strength, fracture strength and flame retardance performance, thereby meeting the requirements of fire protection safety and engineering applications.

Owner:UNIV OF SCI & TECH OF CHINA

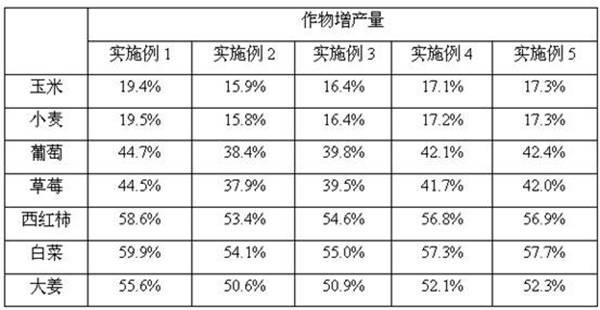

Polypeptide-ammonium polyphosphate trace element liquid chelated fertilizer and preparation method thereof

The invention discloses a polypeptide-ammonium polyphosphate trace element liquid chelated fertilizer and a preparation method of the liquid chelated fertilizer. The polypeptide-ammonium polyphosphate trace element liquid chelated fertilizer comprises the components by weight percent: 5-25% of urea, 5-15% of ammonium polyphosphate, 5-25% of potassium nitrate, 0.2-3% of potassium silicate, 0.8-5% of potassium chloride, 0.008-0.1% of polyaspartic acid, 0.8-5% of ammonium sulfate, 0.8-5% of ethylene diamine tetraacetic acid (EDTA) calcium, 0.2-3% of EDTA magnesium, 0.02-1.5% of EDTA boron, 0.005-0.1% of EDTA zinc, 0.005-0.1% of EDTA iron, 0.005-0.05% of EDTA copper, 0.005-0.05% of EDTA manganese, 0.001-0.01% of nickel sulfate, 0.001-0.01% of ammonium molybdate, 0.0008-0.01% of cobaltous sulfate, 0.008-0.1% of polyacrylamide and the balance of water. The polypeptide-ammonium polyphosphate trace element liquid chelated fertilizer disclosed by the invention is simple in technology, scientific in proportion, balanced in fertilization, low in cost and good in effect.

Owner:张朝晖

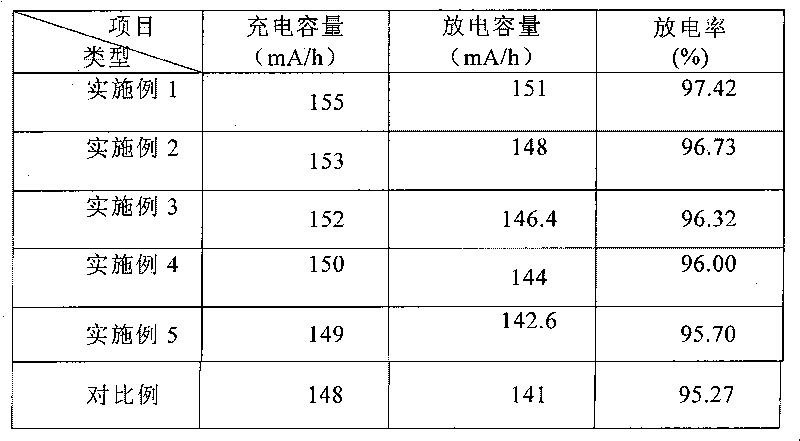

Method for forming ultrahigh-voltage anode foil for aluminum electrolytic capacitors

ActiveCN102610390AImprove compactnessIncrease costSurface reaction electrolytic coatingCapacitor electrodesConvertersPhosphorous acid

The invention relates to the production of electronic components, and discloses a method for forming anode foil for electrolytic capacitors. The ultrahigh-voltage anode foil is formed through six stages, wherein from the stage 1 to stage 5, each stage has a formation tank, and in the stage 6, three formation tanks are connected in parallel; and an acid fluid mixture containing a boric acid, a citric acid or an azelaic acid (the electric conductance and pH value thereof are adjusted by using carbon-containing inorganic salts) and ammonium hypophosphite or sodium monophosphate for improving the boiled performance of an oxidation film is filled in each formation tank. Correspondingly, the processing step is also adjusted, and the produced anode foil not only can be applied to the fields and industries of aerospace and automotive frequency converters and industrial frequency converters and the like meeting the ultrahigh voltage requirements on a withstand voltage of 700-1200V, but also is dense in oxidation film surface, high in specific volume and short in boosting time.

Owner:新疆金泰新材料技术股份有限公司

Melt slime granulating composite fertilizer and its production method

ActiveCN1762923AReduce decomposition lossIncrease profitAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersFree coolingChloride

The granular composite fertilizer consists of urea 45-50 weight portions, potassium chloride or potassium sulfate 20-25 weight portions, ammonium phosphate 20-30 weight portions and stuffing 1-5 weight portions. It is prepared by using high temperature molten urea as carrier to fuse the materials homogeneously and through tower top showering to cool and pelletize. The tower has height of 60-120 m and diameter of 8-20 m. During preparation, water is introduced continuously for adhering to pelletize without caking. The melt composite fertilizer preparing process has the advantages of no material returning, greatly raised production capacity, low power consumption, high apparatus utilization, less environmental pollution, etc.

Owner:STANLEY AGRI GRP CO LTD

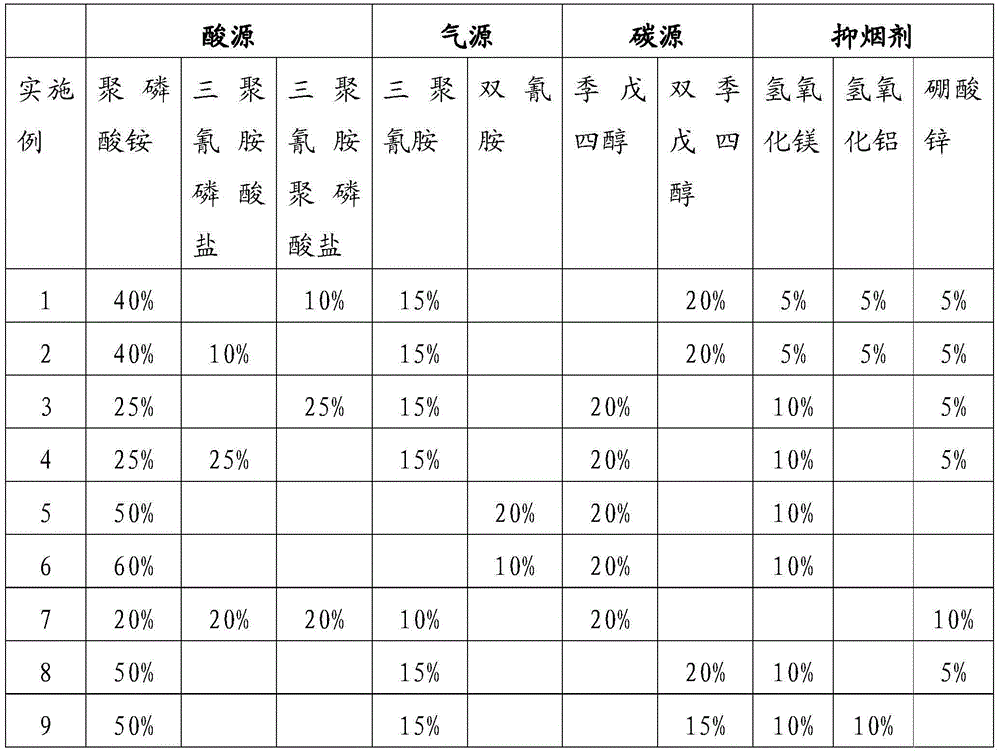

Composite intumescent flame retardant and preparation method thereof

InactiveCN104532588AReduce generationImprove flame retardant performanceFibre typesMelamine phosphateAluminium hydroxide

The invention discloses a composite intumescent flame retardant which is composed of the following components in percentage by weight: 50-65% of acid source, 10-20% of gas source, 15-20% of carbon source and 10-20% of smoke inhibitor. The acid source is composed of at least one of ammonium polyphosphate, melamine phosphate and melamine polyphosphate, wherein the ammonium polyphosphate is crystal II ammonium polyphosphate with the average degree of polymerization of greater than 1000; the gas source is composed of at least one of melamine and dicyandiamide; the carbon source is composed of at least one of pentaerythritol and bis pentaerythritol; and the smoke inhibitor is composed of at least one of magnesium hydroxide, aluminum hydroxide and zinc borate. The invention also discloses a preparation method of the composite intumescent flame retardant.

Owner:SHIFANG TAIFENG NEW FLAME RETARDANT

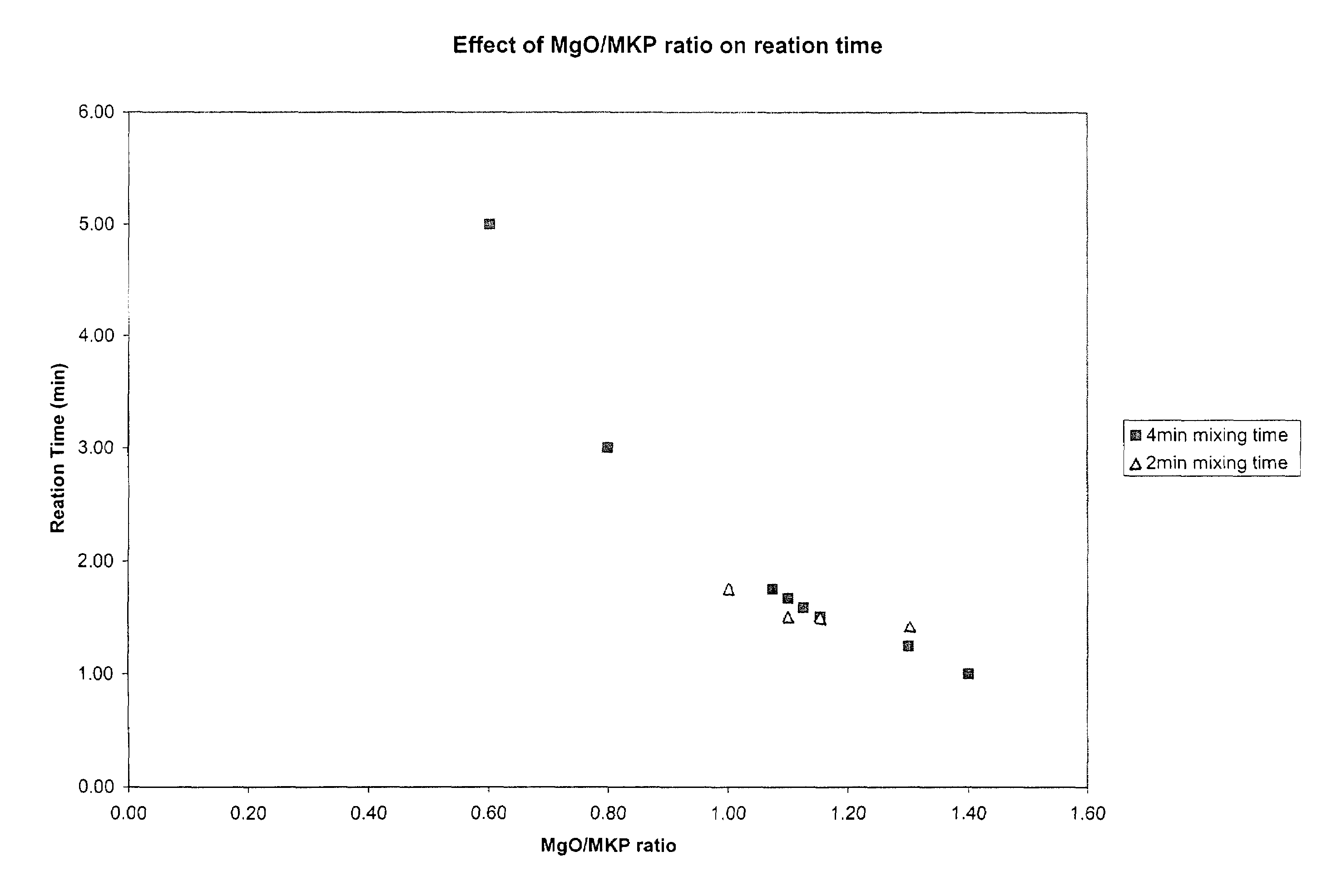

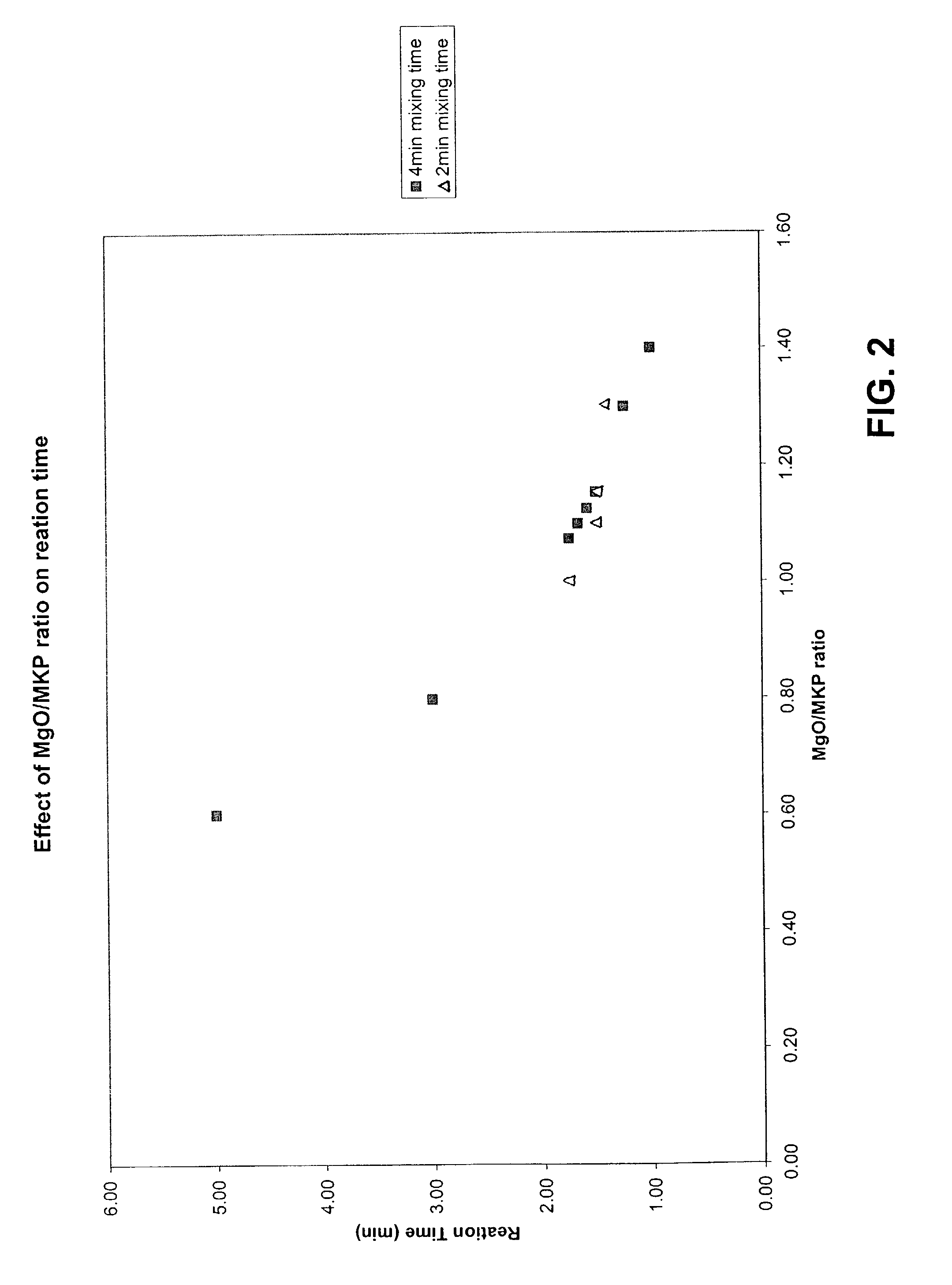

Composite materials and methods of making and using such composite materials

Composite materials made from reactive compounds such as oxides are disclosed. The materials comprise a reaction producing of metal oxide, phosphate and reactive residual materials. The metal oxide may comprise MgO, CaO, ZnO, TiO2 or the like. The phosphate may comprise mono-potassium phosphate, mono-ammonium phosphate, mono-sodium phosphate or the like. The reactive residual material may be ash, phosphate clay, phosphate residual slurry, mining waste or the like. The composite materials may be used for many applications including rapid repair materials, pre-cast structures, in-situ structures, mixes and coatings.

Owner:SECURED NOTEHOLDERS LLC

Method of economically recycling phosphor from excess sludge

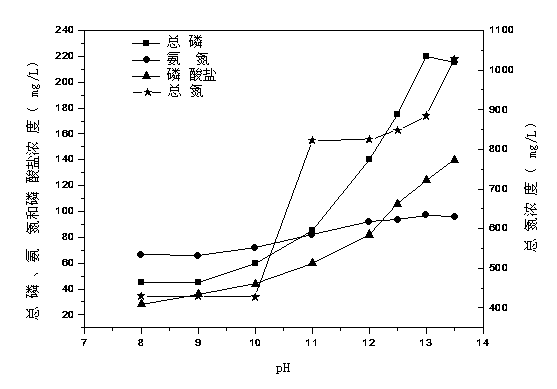

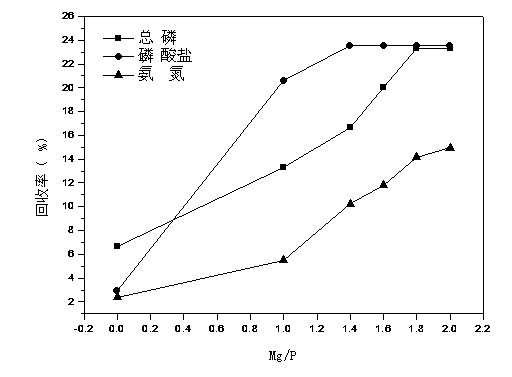

ActiveCN103641283AEasy to recycleSatisfy the requirements of sedimentationSludge treatmentO-Phosphoric AcidMagnesium salt

The invention relates to a method of economically recycling phosphor from excess sludge. The method comprises the following steps: (1), pre-treating the excess sludge; (2), carrying out alkaline hydrolysis on the excess sludge, wherein the alkaline hydrolysis is carried out by a single-stage alkaline hydrolysis method or a two-stage alkaline hydrolysis method; measuring concentration of orthophosphate and ammonia nitrogen in liquid supernatant; and (3), adding magnesium salt aqueous liquor with a Mg / P molar ratio of 0.8-2, stirring and reacting for 10 minutes-120 minutes, gravitationally or centrifugally separating precipitates, naturally drying the precipitates to obtain a magnesium ammonium phosphate crude product. Organic substances remained in the liquid supernatant can be used for producing methane by anaerobic fermentation or supplementing a carbon source by a reflux wastewater treatment system, also can be used for supplementing alkalinity needed for an anaerobic unit, so that comprehensive utilization of excess sludge is facilitated. The method disclosed by the invention has the advantages that nutrient elements in the sludge are comprehensively utilized, process is simple, and phosphor can be recycled by only adding the magnesium salt; and meanwhile, ammonia nitrogen can be partly recycled without regulating pH, and the obtained magnesium ammonium phosphate crude product can be used for producing fertilizers.

Owner:SOUTH CHINA UNIV OF TECH

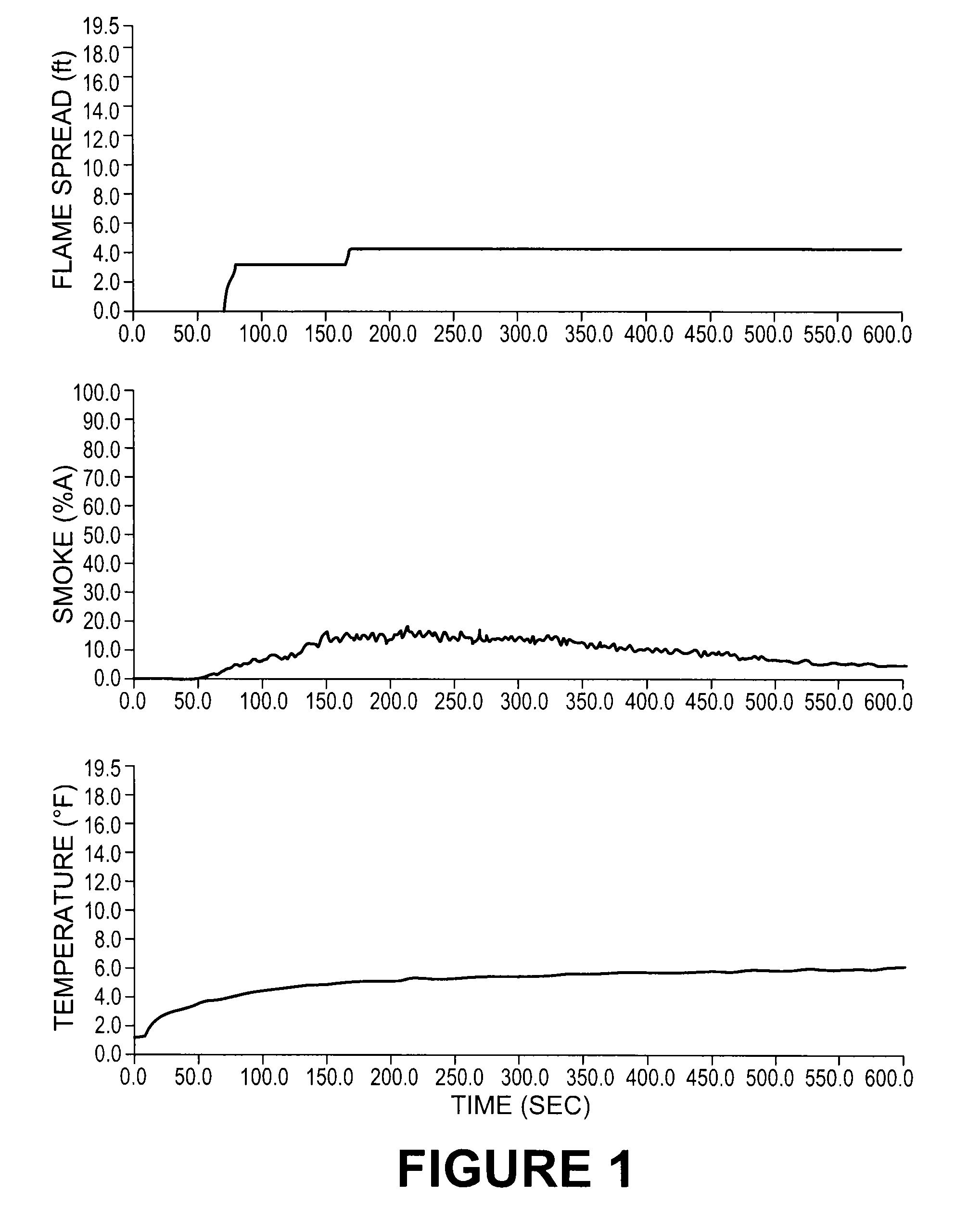

Fire resistant timber coating compositions and methods of manufacture

This application relates to compositions and methods for coating timber and the like to increase the fire resistant properties of the timber. Specifically, the compositions include water, acrylic resin, aluminum trihydrate and ammonium polyphosphate that can be used to effectively coat lumber products and impart fire-resistant properties to the lumber products. In addition, the compositions can include an anti-microbial agent to increase the anti-microbial properties of the coated timber products. The compositions can also include a coloring agent in order that coated lumber products have a recognizable tint indicating to users that the lumber products have been treated with the compositions to increase the fire-resistance and anti-microbial properties of the lumber.

Owner:CANO COATINGS

Non-halogen flame-proof urethane elastomer flame resisting agent and method of preparing the same

ActiveCN101108914ADoes not affect mechanical propertiesGood compatibilityPolyurethane elastomerPolymer science

The invention relates to a halogen-free flame retardant polyurethane elastomer flame retardant and the preparation method. The flame retardant comprises the following components and contents (weight per cent): melamine-formaldehyde coating ammonium phosphate 30 per cent to 70 per cent, triethylol isocyanurate 10 per cent to 35 per cent, melamine cyanurate 5 per cent to 20 per cent, phosphonate 10 per cent to 20 per cent, organic silane coupling agent 0.1 per cent to 0.5 per cent and antioxidant 0.1 per cent to 0.8 per cent. The preparation method of the flame retardant comprises the process steps such as the mixture of the melamine-formaldehyde coating ammonium phosphate. Compared with the prior art, the invention overcomes the defect of harm of halogen flame retardant polyurethane elastomer on the environment and the human body, endows the materials with certain difficult-flammability, has good compatibility with the polyurethane and has no effect on the mechanical properties of the polyurethane.

Owner:SHANGHAI RES INST OF CHEM IND

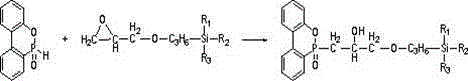

Watersoluble coating glue containing multiple coating modified poly-ammonium phosphate and uses on textile finishing

The invention discloses an aqueous coating adhesive containing multiple coating modified ammonium polyphosphate and applications thereof on fabric finishing. The single modified ammonium polyphosphate can not acquire excellent wash-resisting, immersion-resisting and durable fire retardant performance from the fabric, and can not even obtain dry and comfortable hand feeling. The invention is characterized in that the ammonium polyphosphate, which is modified by melamine, single silane or epoxy resin, is subjected to heating and backflow in an organic alcohol-like solvent, a silane coupling agent capable of being bonded with active groups in the modified ammonium polyphosphate is then added so that the surface of the ammonium polyphosphate experiences multilayer coating and has active hydrogen; the coated ammonium polyphosphate is added with a nonionic surfactant, water, a binder and aqueous closed polyurethane, the aqueous coating adhesive containing the multiple coating modified ammonium polyphosphate is obtained by means of dispersed grinding. The invention is coated on terylene or pure cotton fabrics, thus realizing the cross-linked film forming of the ammonium polyphosphate and the aqueous closed polyurethane and the aqueous binder, and obtaining waterproof and durable environmentally-friendly fire retardant coating fabric.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +1

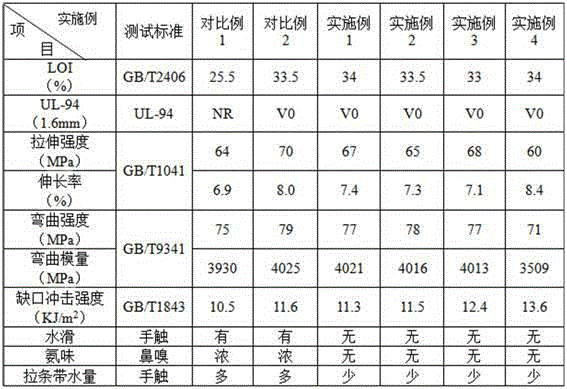

Halogen-free flame retardant glass-fiber reinforced polypropylene composite material and preparation method thereof

The invention relates to a halogen-free flame retardant glass-fiber reinforced polypropylene composite material, which comprises the following components in weight percentage: 33-59% of polypropylene resin, 15-35% of compound flame retardant, 20-30% of glass fiber, 3-10% of compatibilizing agent, 0.4-2.5% of coupling agent and 1-3% of thermal stabilizer; the compound flame retardant is prepared by mixing and compounding a main flame retardant and an auxiliary flame retardant with a mass ratio of 41-79: 21-59; the main flame retardant is one or a mixture of melamine polyphosphate, melamine phosphate and melamine cyanurate; and the auxiliary flame retardant is one or a mixture of inorganic hypophosphite, diethyl hypophosphite and diphenyl hypophosphite. The polypropylene material is good in fire retardant performance and high in fire retardant efficiency; because ammonium polyphosphate component is excluded, the polypropylene material has the advantages of non-hydroplaning in processing, no release of ammonia gas and less water in bracing.

Owner:苏州安鸿泰新材料有限公司

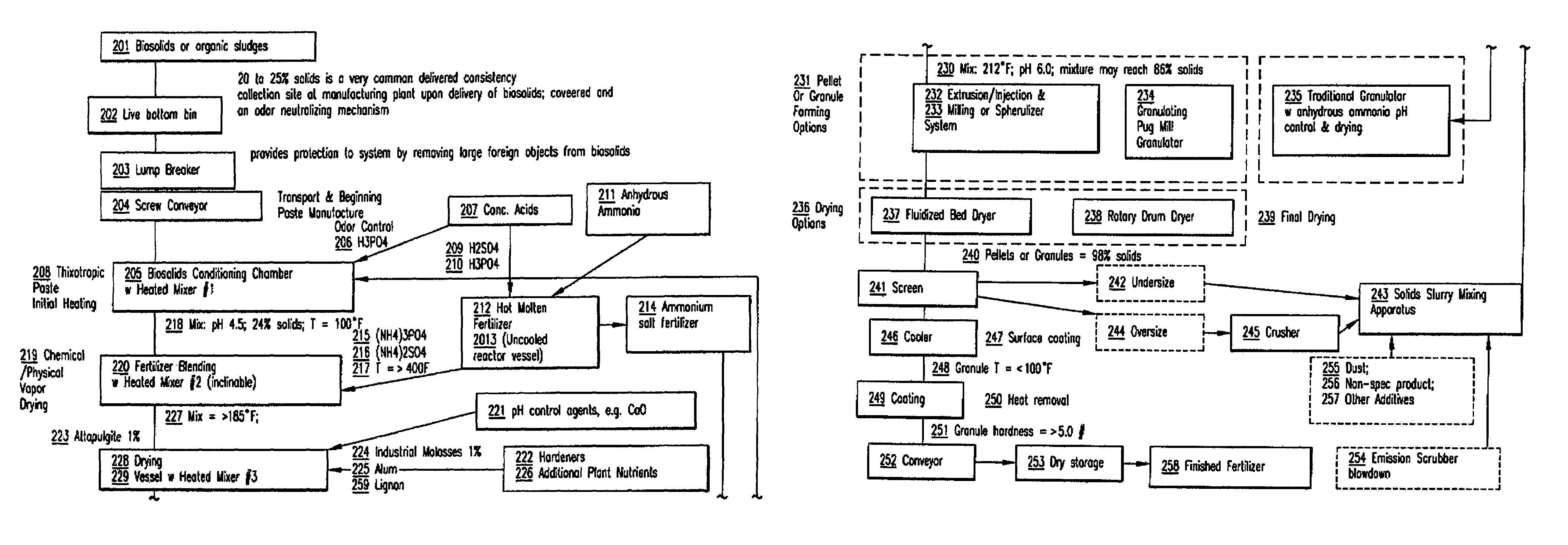

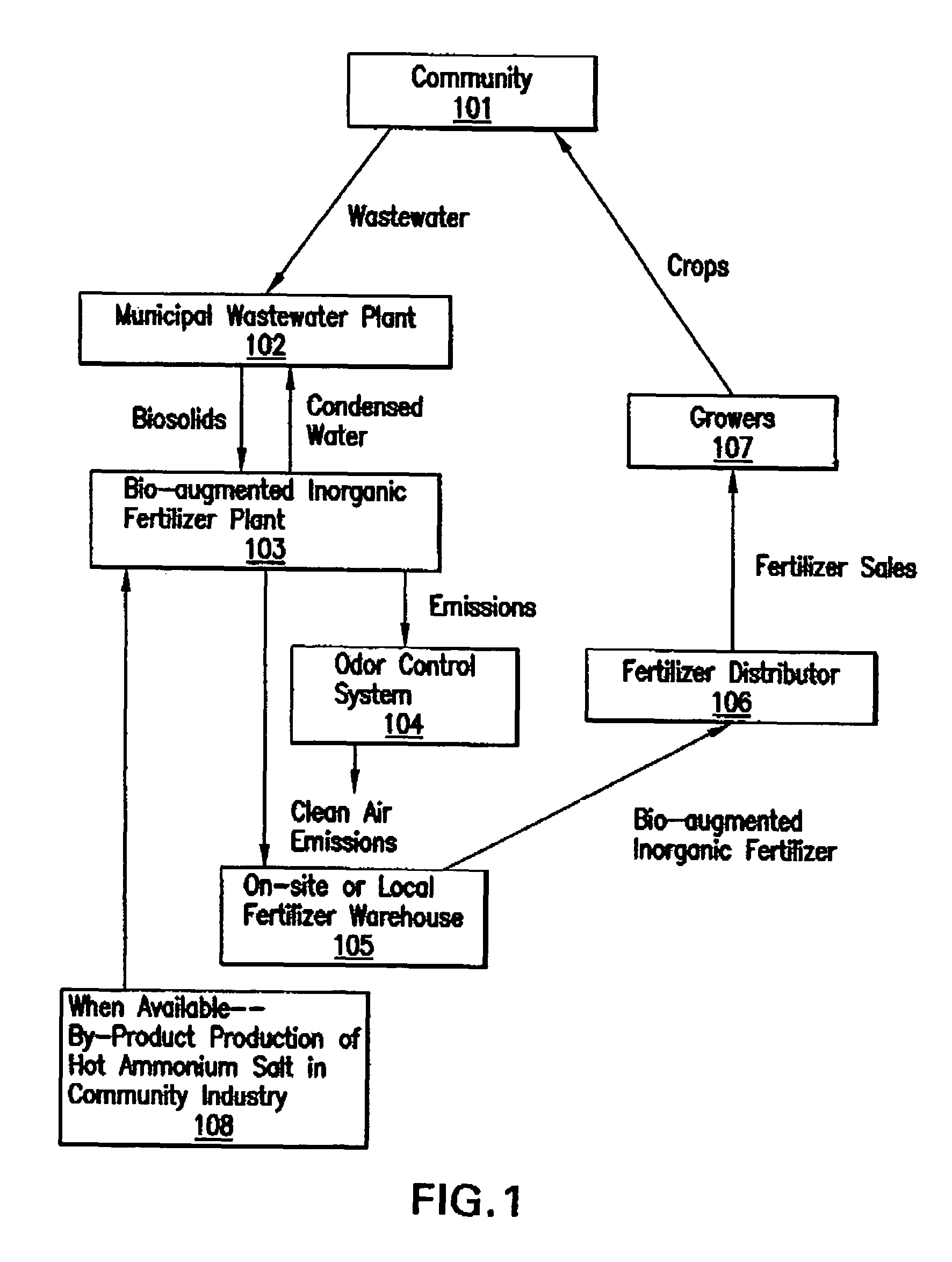

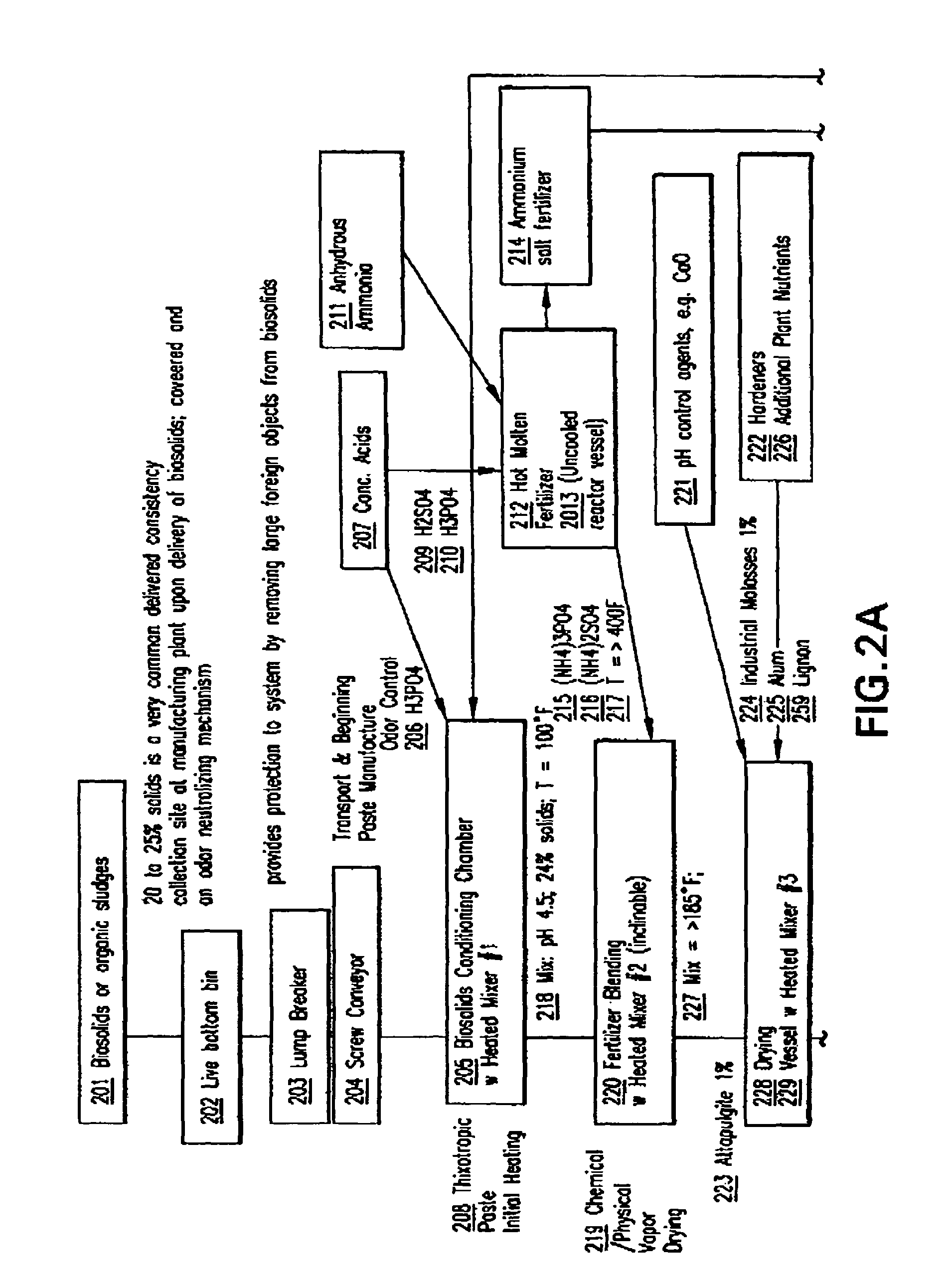

Manufacturing of bioorganic-augmented high nitrogen-containing inorganic fertilizer

The invention describes a new method for the production of high nitrogen organically-augmented inorganic fertilizer that incorporates municipal biosolids or organic sludges that can compete with traditional fertilizers such as ammonium phosphate, ammonium sulfate and urea on the commodity fertilizer marketplace. The method creates a thixotropic paste-like material from the biosolids or organic sludge that is blended with hot or molten ammonium salts, especially a mixture of ammonium phosphate and ammonium sulfate. The invention can be an add-on to commercial production of ammonium salts or it can stand alone by manufacturing ammonium salts prior to their introduction to the conditioned biosolids. The invention is oriented to be tailored to production facilities for individual municipal waste treatment plants in order to keep manufacturing plants small with a minimization of logistics and liability.

Owner:GENERATE LENDING LLC +1

Method for synthesizing iron phosphate with doped metallic elements

InactiveCN101692488AEasy to operateImprove performanceElectrode manufacturing processesPhosphoric acidReaction temperature

The invention relates to a method for synthesizing iron phosphate with doped metallic elements. The method comprises the following steps of: (1) using sulfate, chloride or nitrate of iron as an iron source, mixing any one of substances containing other metal cation elements with the iron source, accurately weighting each material in a mol ratio, and adding distilled water into the materials to prepare a mixed solution, wherein the total mol concentration of the mixed solution is 0.1 to 5 mol / L; (2) using one or a mixture of more than one of ammonium dihydrogen phosphate, ammonium phosphate, ammonium hydrogen phosphate and trisodium phosphate as a phosphorus source, and preparing phosphorus solution of which the mol concentration is 1 to 5 mol / L; (3) using ammonia water as a complexing agent and a neutralizing agent; (4) controlling the reaction temperature to between 20 and 98 DEG C, pumping the mixed solution doped with the doped metallic elements and the phosphorus solution into a reactor respectively, controlling the pH value by the ammonia water, and stirring the mixture to ensure that the mixture is continuously co-precipitated in the reactor to generate the iron phosphate with spherical doped metallic elements; and (5) aging, spin-drying, washing and drying the reaction solution to obtain the iron phosphate with the doped metallic elements. The method has the advantages of simple operation, stable performance, low manufacturing cost, sterility and no pollution.

Owner:HENAN KELONG NEW ENERGY CO LTD

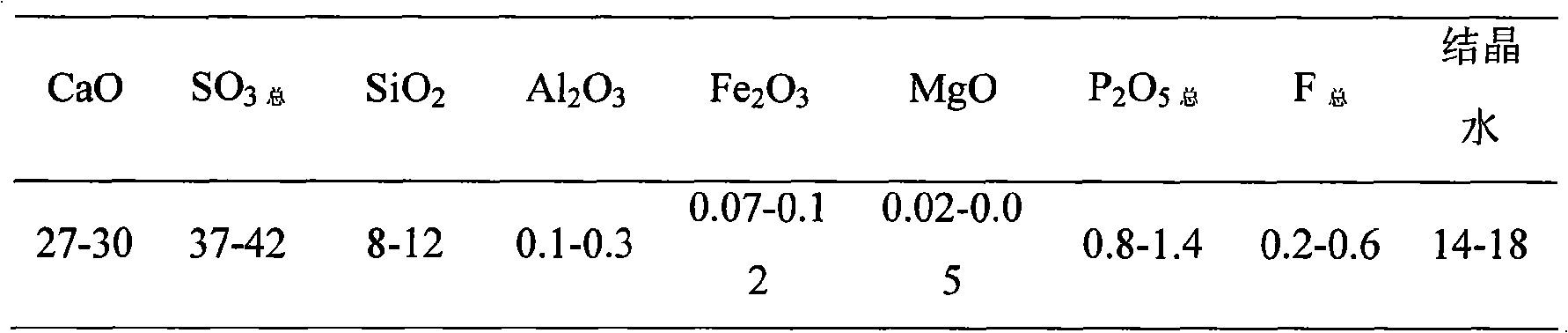

Process for producing calcium carbonate by absorbing carbon dioxide with ardealite decompose slag

InactiveCN101337685ARealize resource utilizationEmission reductionCalcium/strontium/barium carbonatesSlagDecomposition

The invention relates to a method for producing calcium carbonate by using phosphogypsum decomposition slag to absorb carbon dioxide, and provides a process for synthesizing calcium carbonate through comprehensive utilization of phosphogypsum and CO2 gas resources. The method comprises the steps of decomposing mixed phosphogypsum and coal at the temperature of 950-1200 DEG C to generate a gas which is used as sulfur to produce a feed gas; placing solid slag in a carbonizer after colling; introducing CO2 into the carbonizer for reaction under normal pressure and at the temperature of 25-80 DEG C to obtain similar strong argillo calcareous limestone with 75%-85% of CaCo3; further purifying to obtain a high purity calcium carbonate product; or directly using the similar argillo calcareous limestone as building material. Aiming at the solid waste of phosphogypsum in phosphoric acid manufacture industries, the comprehensive utilization of industrial resources in coal-fired power plants, ammonium phosphate production, etc. which has large emission of CO2, the method not only solves the pollution problem of the solid waste of phosphogypsum and recycles sulfur resources, but also recycles carbon resources and reduces CO2 emission in combination with the problem of large emission of CO2 in ammonium phosphate production in phosphoric acid industries.

Owner:KUNMING UNIV OF SCI & TECH

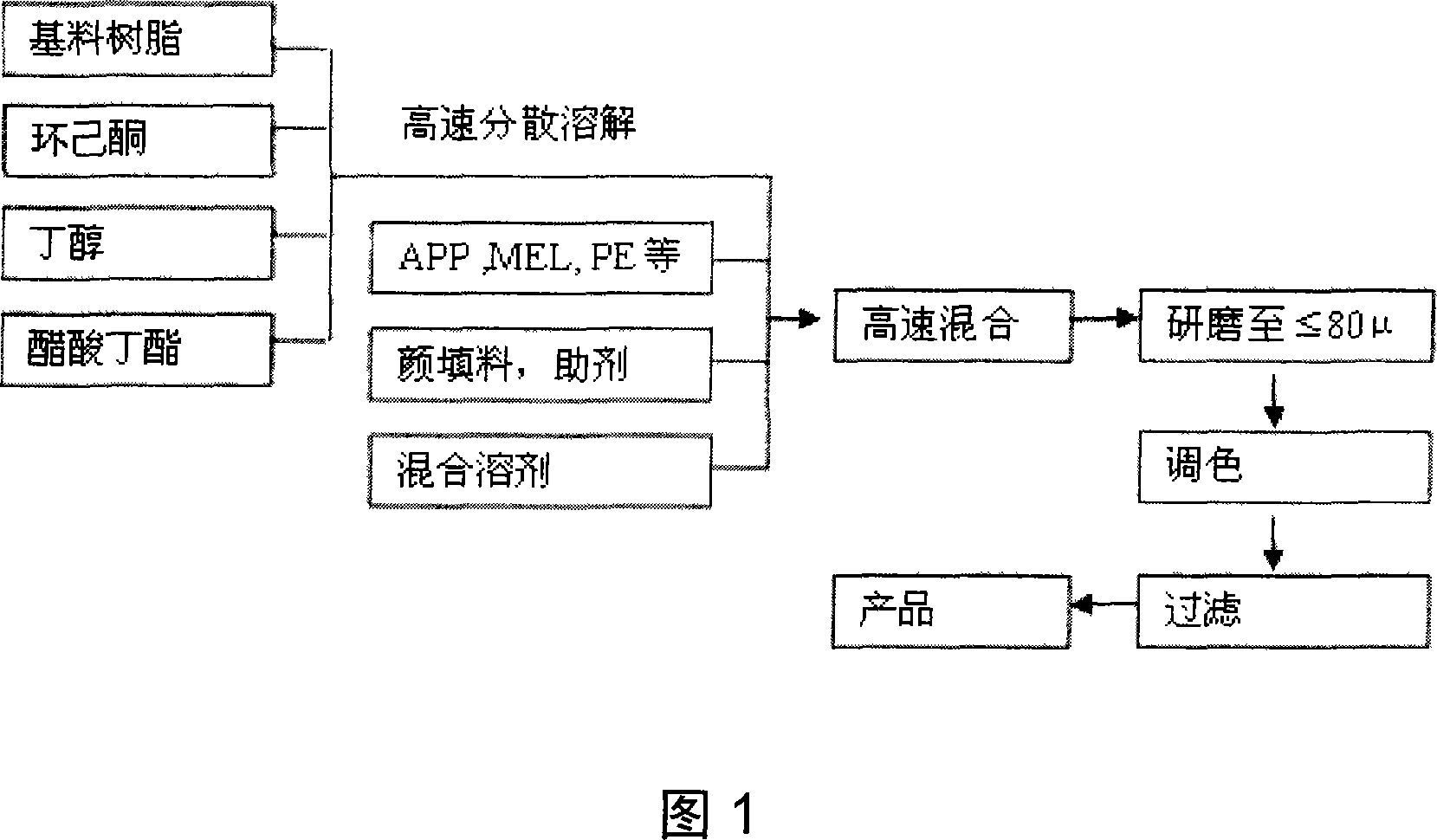

Fireproof paint for super-thin steel structure and preparation method thereof

InactiveCN101058693AStrong adhesionGood film formingFireproof paintsLiquid surface applicatorsTetrabromobisphenol APolyvinyl chloride

The invention discloses a method preparing for an ultra-thin inflatable steel structure fire-proof paint, which is characterized by the following: the allocation of tetrabromo-bisphenol A epoxide resin contains epichlorohydrin and tetrabromo-bisphenol A with weight rate at 1. 3-1. 5:1 and epichlorohydrin and sodium hydroxide with weight rate at 1. 0-1. 05:1; the allocation of fireproof painting is tetrabromo-bisphenol A epoxide resin and hyperchlorinated polyvinyl chloride with weight rate at 3: 1, polyphosphate, melamine, pentaerythritol with weight rate at 3:2:1, antimony trioxide and paraffin chloride with weight rate at 3:7, aluminium hydroxide and zinc borate smoke suppressor with weight rate at 10: 3. The method comprises the following steps: adding epichlorohydrin and tetrabromo-bisphenol A to the autoclave; mixing and heating at 90 Deg. C; adding caustic soda solution; keeping 7. 5 hours; washing and removing thylbenzene by heating;getting tetrabromo-bisphenol A epoxide resin; adding the mixed solvent to tetrabromo-bisphenol A epoxide resin and perchlorinated polyethylene; mixing and dissolving; adding ammonium polyphosphate, melamine, pentaerythrite, titanium dioxide, antimony oxide, aluminum hydroxide, zinc borate separately, adding chlorcosane; grinding after high-speed dispersing uniformly; mixing polyamide uniformly according to 10:1; getting the fire-proof paint.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

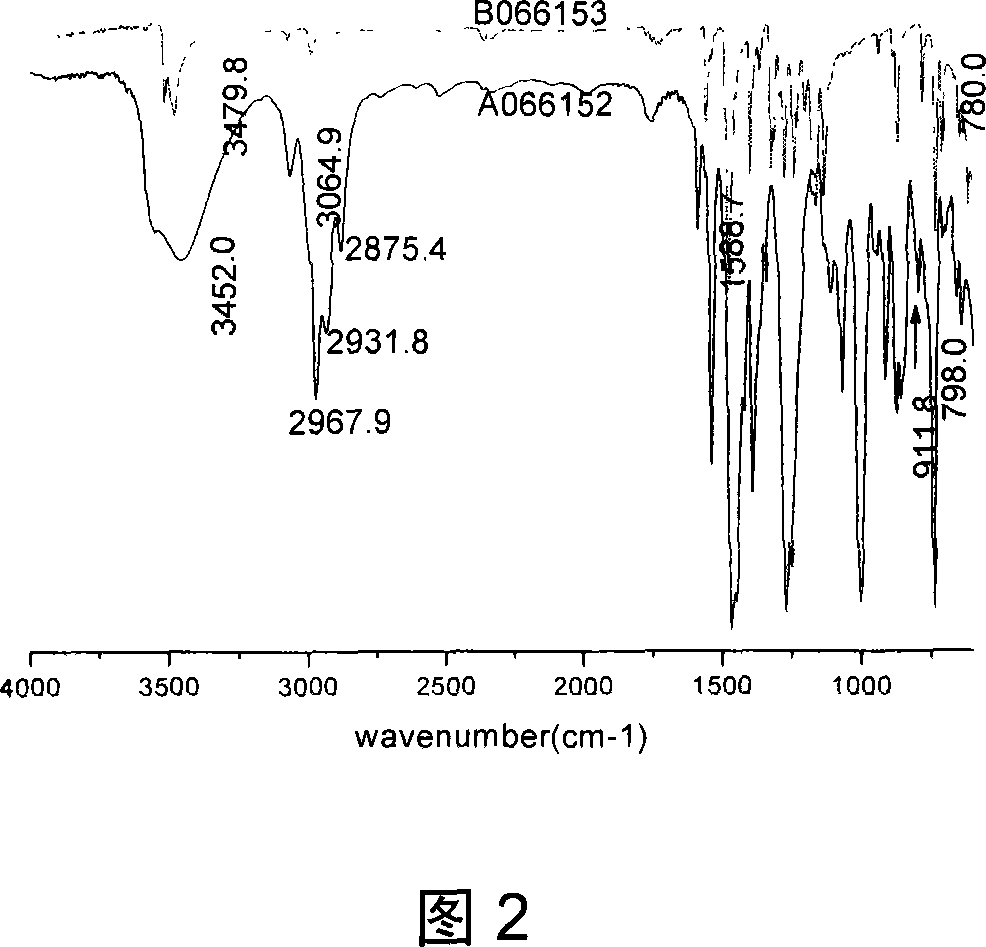

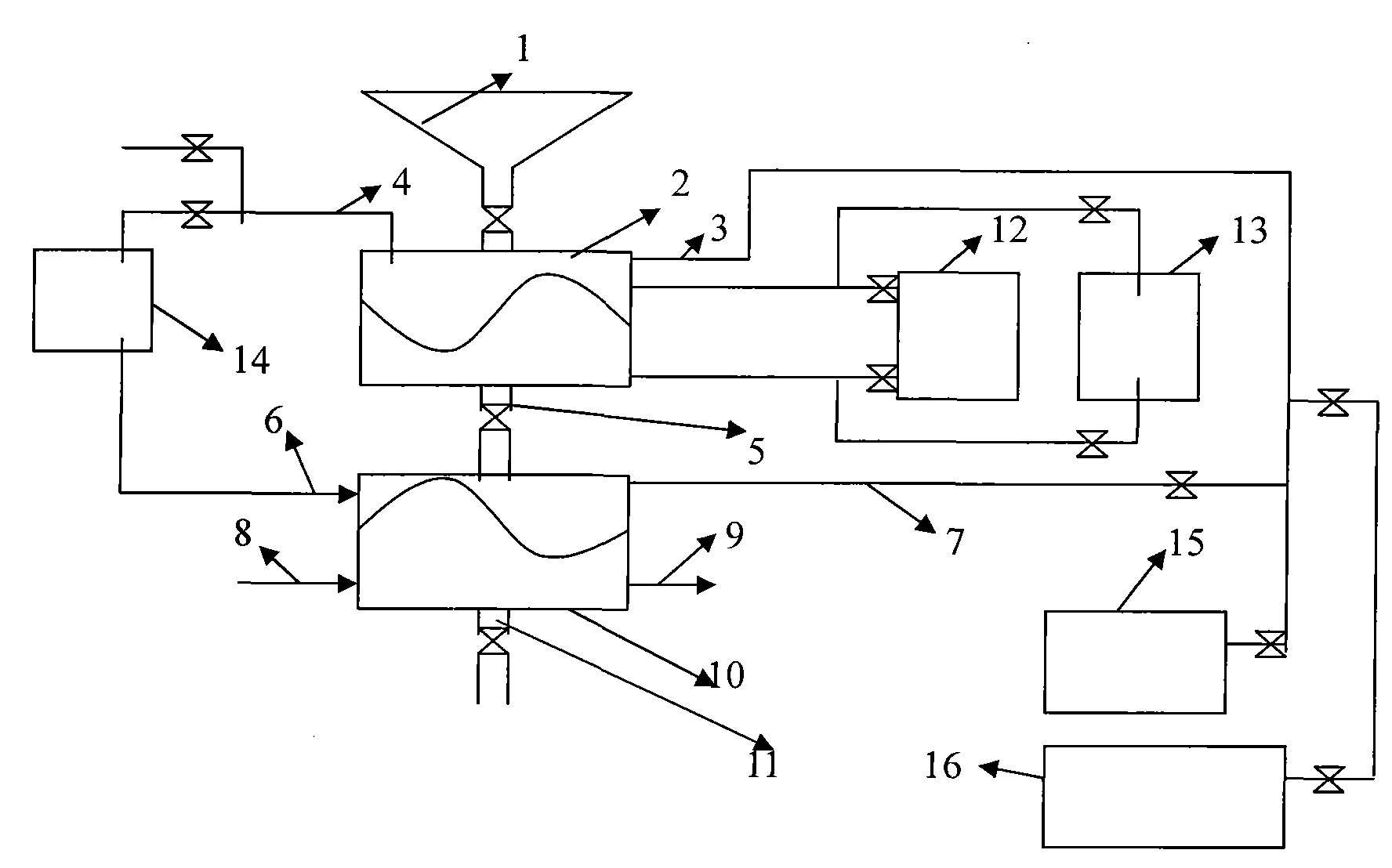

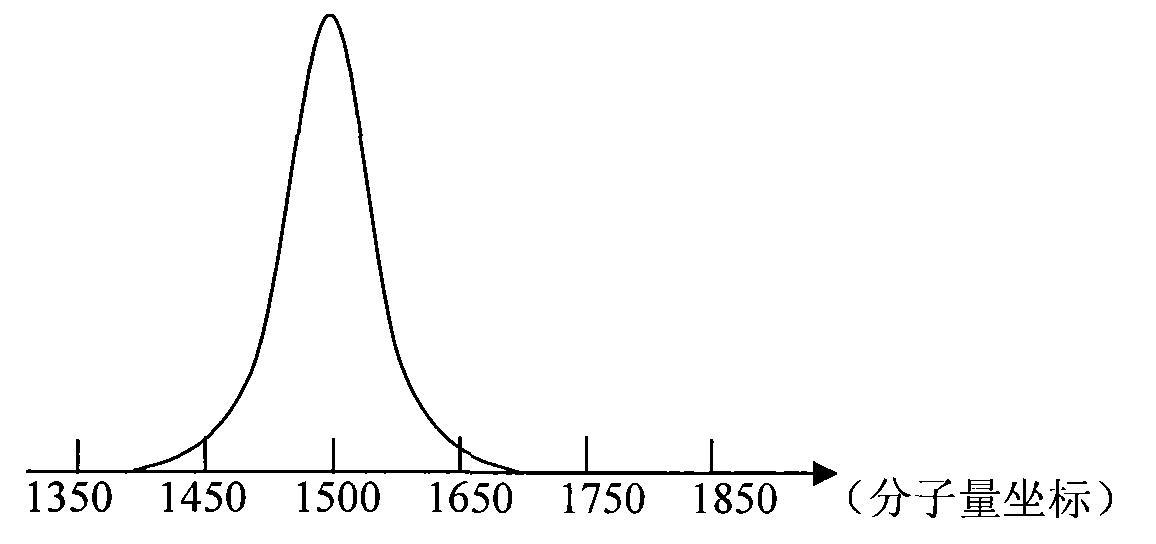

Method for preparing crystal II-type ammonium polyphosphate with distribution of high polymerization degree and narrow molecular weight

ActiveCN101597044AEliminate the effects ofTemperature controlPhosphorus compoundsSolubilityPolymerization

The invention discloses a method for preparing crystal II-type ammonium polyphosphate with distribution of high polymerization degree and narrow molecular weight. The method comprises the following steps: putting phosphorus pentoxide and diammonium phosphate which have equal molar ratio into a malaxator which can accurately control a temperature and heated by conducting oil for mixing; under the protection of inert gas, heating the materials in the malaxator to between 100 and 250 DEG C through the circulatory conducting oil; stopping introducing the inert gas; performing ammonification on the materials and heating the materials under an atmosphere of ammonia gas till the materials are totally molten down; stopping introducing the ammonia gas; after homogenization, introducing the ammonia gas again and heating the materials; throwing a surface treating agent into the malaxator; after material throwing is completed, continuously introducing the ammonia gas, keeping warm and mixing the materials; after reaction is finished, transferring the materials to a closed vessel and reducing the temperature; simultaneously, continuously introducing the ammonia gas till the temperature of the materials is below 100 DEG C; and obtaining a finished product. The method can prepare the crystal II -type ammonium polyphosphate with the distribution of the high polymerization degree and the narrow molecular weight; and the product has the characteristics of uniform granularity shape, small water-solubility, good heat resistance, high polymerization degree, narrow distribution of molecular weight and high crystal II-type purity.

Owner:GUANGDONG JUSHI CHEM CO LTD

Multifunctional re-mixed organic-inorganic fertilizer and its prepn process

The multifunctional re-mixed organic-inorganic fertilizer consists of castor cake or bean cake powder, humic acid, Chinese medicinal stone, effective EM microbe, urea, ammonium phosphate, potassium chloride and water preserving agent. The preparation process includes compounding, fermentation, powdering, re-mixing and other steps. The key point of the present invention is that the organic material is treated with microbe colony to produce multifunctional biological fertilizer, which can provide plant with required nutrients, improve soil, fix nitrogen, decompose residual pesticide and preserve water in fast and high efficiency.

Owner:王泽利

Water super-thin steel structure fire-proof paint and preparation method thereof

An aqueous fire proofing coating with ultra-thin steel structure and its production are disclosed. The fire proofing coating consists of acrylic acid emulsion, amine poly-phosphate, tetramethylolmethane, melamine, expanding graphite, aluminum hydrate, antifoaming agent, leveling agent, dispersant, plasticizer, coupling agent, thickening agent. The process is carried out by adding amine poly-phosphate, tetramethylolmethane, melamine, aluminum hydrate and partial accessories into ball grinder, agitating, grinding, adding expanding graphite and residual accessories into ball grinder, agitating and filtering to obtain final product. It's cheap, simple and convenient, has better flame retardant performance, short drying time and no environmental pollution.

Owner:HUNAN UNIV

Flame retardant polyurethane composite material and preparation method thereof

The invention relates to a flame retardant polyurethane composite material and a preparation method thereof. The traditional flame retardant polyurethane foamed material has a poor use effect. The flame retardant polyurethane composite material provided by the invention is a mixed system comprising 70-99wt% of flame retardant polyurethane and 1-30% of blending type fire retardant, wherein the blending type fire retardant is one or more than one of ammonium polyphosphate, melamine, melamine cyanurate acid, polysiloxane, graphine, a carbon nano tube and kaolin, the fire retardant polyurethane is a random copolymer consisting of a polycarbonate unit, a polyether and an isocyanate unit. The preparation method of the flame retardant polyurethane composite material comprises the following steps of: firstly, preparing fire retardant polyalcohol; then, mixing the fire retardant polyalcohol and the blending type fire retardant into a mixed system; and then adding polyisocyanates into the mixed system and reacting to finally obtain the flame retardant polyurethane composite material. The flame retardant polyurethane composite material prepared by using the preparation method disclosed by the invention has the advantages of excellent fire retardance, low-fogging performance and low-gas-releasing performance.

Owner:JIANGSU ZHONGKE JINLONG CHEM

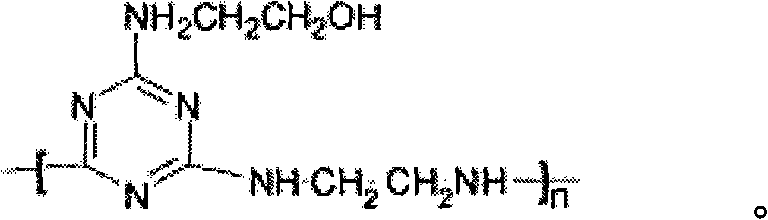

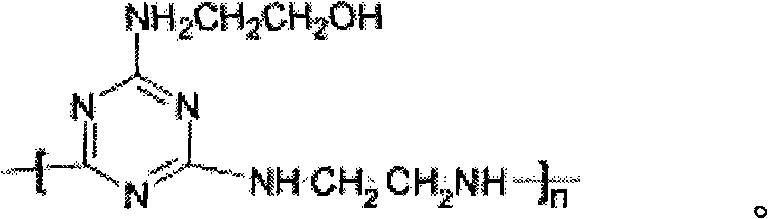

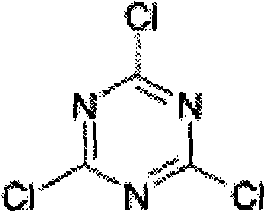

Halogen-free expansion type flame retardant containing macromole triazine charring agent and preparation thereof

ActiveCN101434843AThe synthesis reaction process is continuousThe synthesis process is simpleFireproof paintsDiamineSolvent

The invention provides a halogen-free expansion type flame retardant containing large molecular triazine char-forming agent, and a preparation method thereof; the expansion type flame retardant consists of large molecular triazine char-forming agent, epoxy resin cladding ammonium polyphosphate and auxiliary agent; the large molecular triazine char-forming agent is the reaction product of cyanuric chloride and diamine. The preparation of the flame retardant comprises the steps as follows: synthesis of the large molecular triazine char-forming agent, preparation of the flame retardant, and the like. The large molecular triazine char-forming agent has high yield and thermal-stability, continuous reaction process, simple synthesis process, convenient recovery of the solvent; furthermore, the prepared flame retardant has high polymer flame retardance, good mechanical performance, strong humidity resistance, low smoke, no toxin, and the like, and meets the requirement of environmental protection.

Owner:SHANGHAI RES INST OF CHEM IND

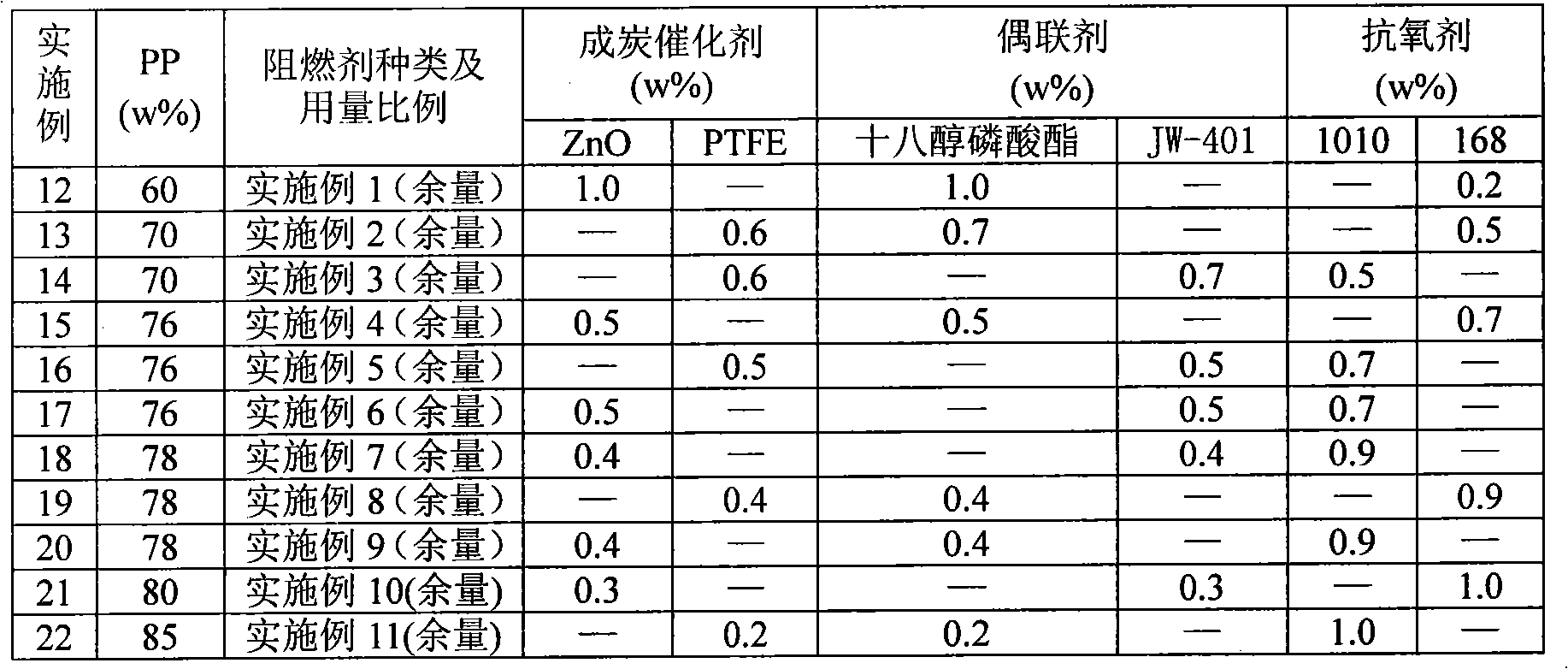

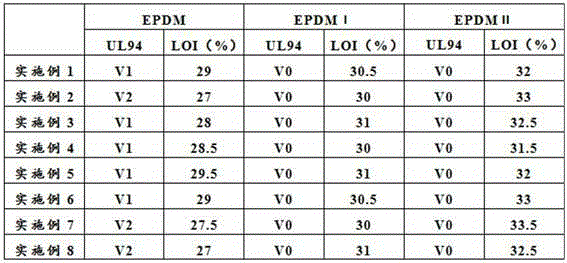

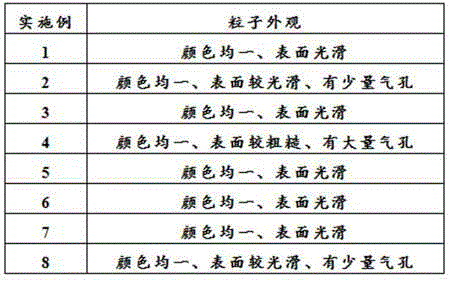

Halogen-free expansion type fire retardant and flame-proof polypropylene material

InactiveCN101260202AReduce the impact of physical and mechanical propertiesAdd lessPhosphatePolyphosphate

The invention relates to halogen-free expansion-type fire retardant and fire-retarding polypropylene material. The fire retardant is a composite expansion-type fire retardant consisting of melamine salt of bis (melabis) expansion-type fire retardant component, poly ammonium phosphate, triethylolisocyanurate, melamine cyanurate and melamine polyphosphate. Halogen-free expansion-type fire-retarding polypropylene material is made from polypropylene component, antioxidant, char-forming catalyst, phosphate ester coupling agent and the halogen-free expansion-type fire retardant through common milling. The halogen-free expansion-type fire retardant adopts MC or THEIC as one of the gas sources of the fire retardant, and is matched with melabis to substantially increase fire-retarding performance; moreover, the dosage of the halogen-free expansion-type fire retardant is less while ensuring fire-retarding performance, thereby furthest reducing the influence on the physical and mechanical properties of body materials such as polypropylene.

Owner:应急管理部四川消防研究所

Halogen-free flame-retardant masterbatch for ethylene-propylene-diene monomer and preparation method of halogen-free flame-retardant masterbatch

The invention relates to a halogen-free flame-retardant masterbatch. The raw material formula of the halogen-free flame-retardant masterbatch comprises the following components in percentage by weight: 5 to 20% of carrier resin, 75 to 90% of compounding flame retardant, and free antioxidants, lubricants and surface modification agents, wherein the carrier resin is LDPE (Low-Density Polyethylene) or EVA (Ethyleno Vinyl Acetale Copolymetr) or the mixture of LDPE and EVA; the compounding flame retardant comprises a fire retardant, a charring agent, a smoke inhibitor and a synergist; the fire retardant is one or the combination of some of micro-capisulazed red phosphorus, micro-capisulazed ammonium polyphosphate, a melamine-phosphate compound and melamine cyanurate. The masterbatch has the advantages of being smooth in appearance, high in flame retardant content, and free of slag falling; the problem of large dust caused by adding common fire retardant in the ethylene-propylene-diene monomer melting process can be solved, thus the melting efficiency can be increased, the productivity can be improved, and moreover, the vulcanization of ethylene-propylene-diene monomer is not influenced.

Owner:苏州安鸿泰新材料有限公司

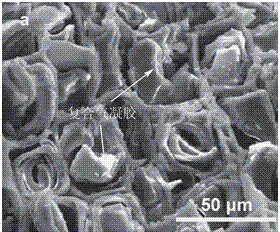

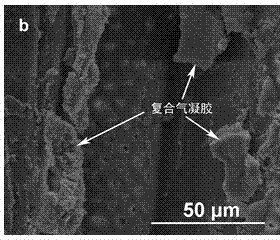

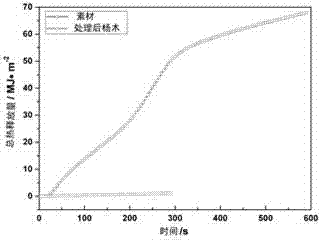

Ammonium polyphosphate/SiO2 composite aerogel flame-retardant reinforced timber and preparation method thereof

ActiveCN104760103AImprove permeabilityEvenly dispersedRadiation/waves wood treatmentWood treatment detailsSolid woodCorrosion prevention

The invention discloses an ammonium polyphosphate / SiO2 composite aerogel flame-retardant reinforced timber which comprises a timber and an ammonium polyphosphate / SiO2 composite aerogel in timber pores. The invention also discloses a preparation method of the flame-retardant reinforced timber, which comprises the following steps: pretreating the timber with microwaves to form new flow channels in the timber, thereby enhancing the timber permeability; hydrolyzing the previously prepared ammonium polyphosphate and silicon source by pressure dipping treatment, and introducing the generated uniform sol solution into the timber; and carrying out condensation reaction and normal-pressure drying to generate the ammonium polyphosphate / SiO2 composite aerogel in the timber pore structure in situ. The ammonium polyphosphate / SiO2 composite aerogel flame-retardant reinforced timber has favorable flame-retardant and smoke-inhibition functions, and can effectively prevent the flame retardant from loss. The composite aerogel in the timber pores has the effect of enhancing wear resistance and corrosion resistance. The method can be widely used in flame retardancy, reinforcement and corrosion resistance of the solid wood or composite wood, has the advantages of feasible technical process, cheap raw materials and favorable effect, and is worthy of popularization.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Wide-range flame-retarding canvas and preparation method thereof

The invention discloses a wide-range flame-retarding canvas. The wide-range flame-retarding canvas includes a fire retardant fabric base material; a layer of flame-retarding primer is coated on the fire retardant fabric base material, and the flame-retarding coating is coated on the flame-retarding primer; the formula and dosage of the flame-retarding primer according to part by weight are: 20-40 parts of ammonium polyphosphate APP, 5-15 parts of melamine MEL, 10-20 parts of dipentaerythritol DPER, 0.5-2 parts of wetting agent, 0.5-2 parts of antifoaming agent, 10-30 parts of pure acrylic emulsion, 40-50 parts of ethylene-vinyl acetate copolymer emulsion, 20-30 parts of 70% of titanium dioxide powder syrup, 0.5-2 parts of brightening agent, 100-110 parts of water, and 5-8 parts of thickening agent. The wide-range flame-retarding canvas can be printed by compatible solvent type, weak solvent type and UV solidifying type inks, and has excellent smoothness and fineness, coating firmness, good weather resistance, moisture-resisting humidity and exquisite grain line and inkjet resolution rate. Meanwhile, the wide-range flame-retarding canvas can satisfy the foreign canvas flame-retarding standard and reach the highest flame-retarding standard B1 grade at home.

Owner:江苏耐斯数码科技股份有限公司

Flexible high thermomechanical stress-resistant and fireproof halogen-free thermoplastic compositions

ActiveUS7897673B2No excessive viscosity increaseImprove performanceFireproof paintsPlastic/resin/waxes insulatorsThermoplasticPhosphate

The invention concerns flexible high thermomechanical stress-resistant and fire retardant halogen-free thermoplastic compositions, comprising a polyamide block-graft copolymer consisting of a trunk and on average at least one polyamide graft, wherein the grafts are bound to the trunk by the residues of an unsaturated monomer (X) having a function capable of reacting with a polyamide at the amine-terminal, the unsaturated monomer residues (X) being bound on the trunk by grafting or copolymerization from the double bond thereof. The invention is characterized in that the compositions comprise a mixture: 50 to 70 wt. % of polyamide block copolymer, 25 to 35 wt. % of a flame-retardant agent selected among ammonium phosphates, phosphinates, pyrophosphates, and polyphosphates, about 2 wt. % of zeolite, or hydrotalcitemolecular sieves. Said compositions are particularly useful for making electric cables, electric components, for molding electrotechnical housings, or for making coating layers or thermal protection sleeves for fluid transfer lines in the automotive industry.

Owner:ARKEMA FRANCE SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com