Fireproof paint for super-thin steel structure and preparation method thereof

A technology of fire-resistant coatings and profiled steel, applied in fire-resistant coatings, epoxy resin coatings, coatings, etc., can solve the problems of short fire-resistant time, low fire-resistant aging, poor corrosion resistance, etc., achieve corrosion resistance and water resistance, and high carbon layer hardness , Excellent combustion expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

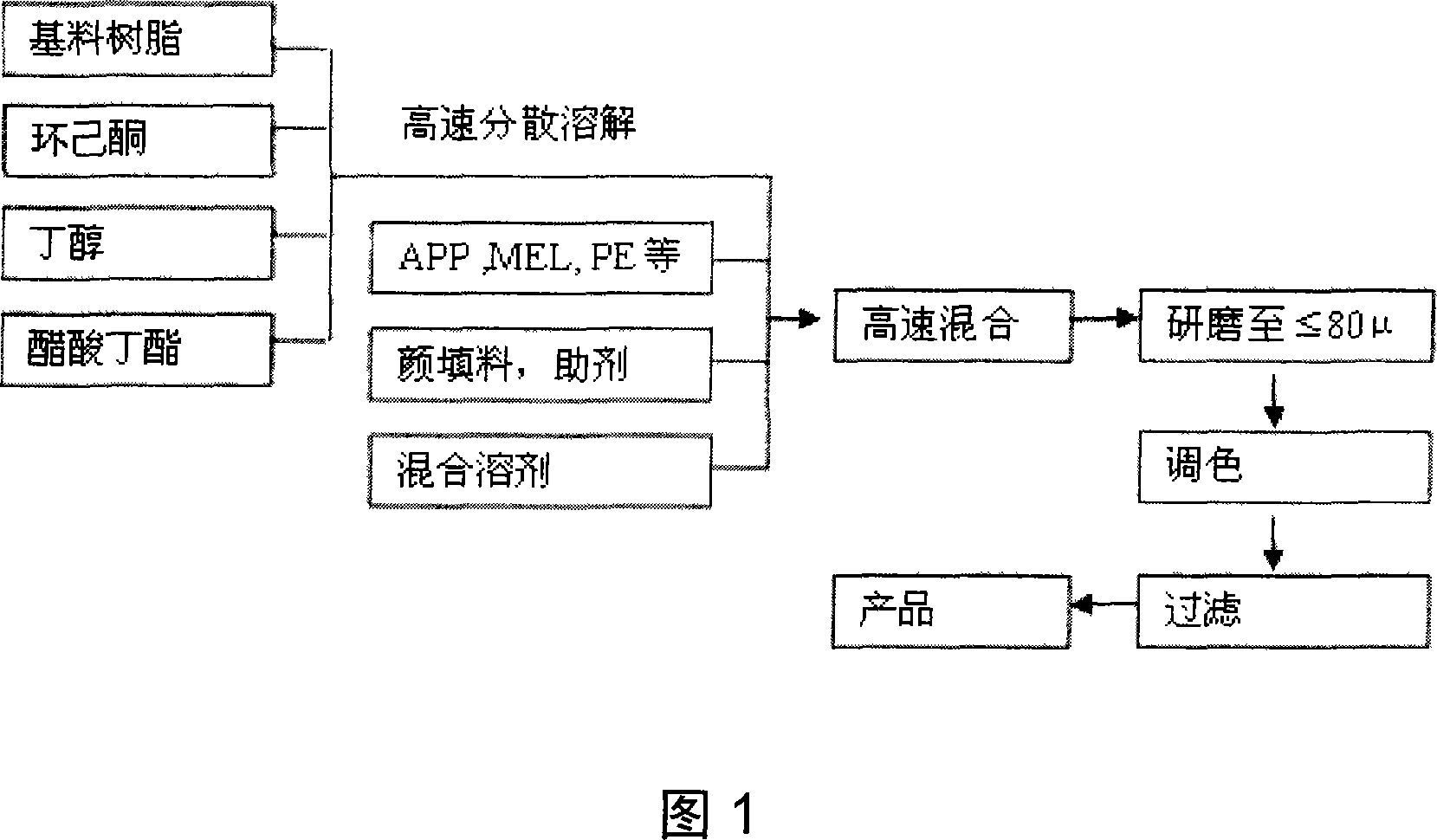

[0014] In the preparation method of the present invention, according to the formulation of the above-mentioned tetrabromobisphenol A epoxy resin, epichlorohydrin and tetrabromobisphenol A are added to the reaction kettle, start stirring and heat up to 90° C., and divide into 2 to 3 batches. Add 30% sodium hydroxide solution respectively, continue the reaction for 7.5 hours, then add water and xylene for washing, remove the generated sodium chloride, release the water phase of the lower layer, heat and steam the xylene to obtain the tetrabromobisphenol A ring Oxygen resin; Weigh tetrabromobisphenol A epoxy resin, high chlorinated polyethylene (HCPE), add mixed solvent and stir to dissolve, then add ammonium polyphosphate, melamine, pentaerythritol, titanium dioxide, antimony trioxide, aluminum hydroxide respectively , Zinc borate, finally add chlorinated paraffin, disperse evenly at high speed and then grind to obtain the coating component A, take the curing agent polyamide as t...

Embodiment 1

[0017] Add 65g epichlorohydrin and 50g tetrabromobisphenol A to the reactor, start stirring and be warming up to 90°C, add 95g 30% sodium hydroxide solution in 2 to 3 batches and react for 7.5 hours, then add water and The xylene is washed to remove the generated sodium chloride, the lower aqueous phase is released, and the xylene is distilled off by heating to obtain the tetrabromobisphenol A epoxy resin.

[0018] 20 g of the above-mentioned tetrabromobisphenol A epoxy and 60 g of high chlorinated polyethylene (HCPE) were weighed into a container, and 200 g of a mixed solvent was added to the container and stirred until the resin was dissolved. Then add 45g ammonium polyphosphate, 30g melamine, 15g pentaerythritol, 25g titanium dioxide, 5g antimony trioxide, 60g aluminum hydroxide, and finally add 10g chlorinated paraffin. After high-speed dispersion is uniform, grinding is carried out, and the fineness is controlled below 80 μm, which is the A component of the coating, the c...

Embodiment 2

[0020] 70g of epichlorohydrin and 50g of tetrabromobisphenol A were added to the reactor, started to stir and heated to 90 ° C, respectively added 100g of 30% sodium hydroxide solution in 2 to 3 batches to react for 7.5 hours, then added water and The xylene is washed to remove the generated sodium chloride, the lower aqueous phase is released, and the xylene is distilled off by heating to obtain the tetrabromobisphenol A epoxy resin.

[0021] 12 g of the above-mentioned tetrabromobisphenol A epoxy and 36 g of high chlorinated polyethylene (HCPE) were weighed into a container, and 120 g of a mixed solvent was added to the container and stirred until the resin was dissolved. Then add 28g ammonium polyphosphate, 18g melamine, 10g pentaerythritol, 15g titanium dioxide, 3g antimony trioxide, 36g aluminum hydroxide, 12g zinc borate, and finally add 6g chlorinated paraffin. After high-speed dispersion is uniform, grinding is carried out, and the fineness is controlled below 80 μm, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com