Halogen-free flame retardant glass-fiber reinforced polypropylene composite material and preparation method thereof

A composite material, polypropylene technology, applied in the field of halogen-free flame-retardant glass fiber reinforced polypropylene composite materials and its preparation, can solve the problems of slippery processing, ammonia gas release, poor flame retardancy, etc., to reduce energy consumption and Cost, small amount of water, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

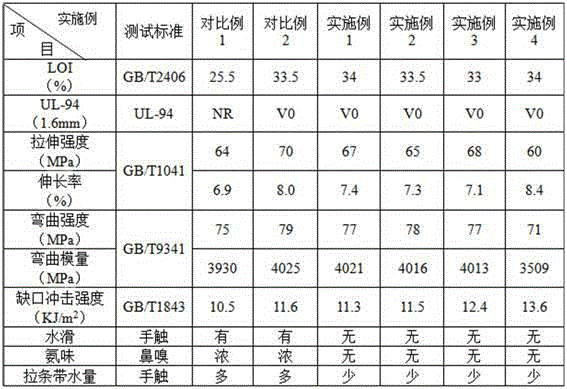

Examples

Embodiment 1

[0046] (1) Preparation of compound flame retardant: Weigh MPP and aluminum diethylphosphinate according to the mass ratio of 79:21, add to a high-speed mixer and mix evenly to obtain a compound flame retardant; it can also be added during mixing A small amount of coupling agent makes the mixing effect of the two better;

[0047] (2) Raw material premixing: according to mass percentage, weigh 33% PP resin, 25% compound flame retardant prepared in step (1), 7% maleic anhydride grafted PP, 2% zinc oxide, 1.5% Coupling agent KH550, 0.4% antioxidant 168, 0.2% antioxidant 1010, 0.6% calcium stearate, 0.3% silicone powder, fully mix the above-mentioned raw materials in a high-speed mixer;

[0048] (3) Add the raw materials mixed in step (2) into the twin-screw extruder from the feeding port, and the glass fiber is fed in from the glass fiber feeding hole. By setting the host speed and feeding frequency, the feeding amount of the glass fiber is just right was 30%, melt-mixed, e...

Embodiment 2

[0051] (1) Preparation of compound flame retardant: Weigh MPP, MCA and aluminum diethylphosphinate in a mass ratio of 50:10:40, add them into a high-speed mixer and mix evenly to obtain a compound flame retardant; When mixing, add a small amount of coupling agent to make the mixing effect better;

[0052] (2) Premixing of raw materials: by mass percentage, weigh 33% PP resin, 25% compound flame retardant prepared in step (1), 7% POE grafted maleic anhydride, 2% active magnesium oxide, 1.5 % coupling agent KH550, 0.4% antioxidant 628, 0.2% antioxidant 1010, 0.3% magnesium stearate, 0.3% calcium stearate, 0.3% silicone powder, mix the above-mentioned raw materials at high speed Fully mix in the machine;

[0053] (3) Add the raw materials mixed in step (2) into the twin-screw extruder from the feeding port, and the glass fiber is fed in from the glass fiber feeding hole. By setting the host speed and feeding frequency, the feeding amount of the glass fiber is just right w...

Embodiment 3

[0056] (1) Preparation of compound flame retardant: weigh MP and aluminum hypophosphite according to the mass ratio of 41:59, add them to a high-speed mixer and mix evenly to obtain a compound flame retardant; a small amount of coupling agent can also be added during mixing Make the two mix better;

[0057] (2) Premixing of raw materials: by mass percentage, weigh 33% PP resin, 25% compound flame retardant prepared in step (1), 7% ethylene methyl acrylate copolymer, 2% zinc oxide, 1.5% Coupling agent KH570, 0.4% antioxidant 168, 0.2% antioxidant 1010, 0.3% PE wax, 0.3% calcium stearate, 0.3% silicone powder, the raw materials weighed above are fully mixed in a high-speed mixer mix;

[0058] (3) Add the raw materials mixed in step (2) into the twin-screw extruder from the feeding port, and the glass fiber is fed in from the glass fiber feeding hole. By setting the host speed and feeding frequency, the feeding amount of the glass fiber is just right was 30%, melt-mixed, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com