Patents

Literature

51results about How to "Reduce decomposition loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

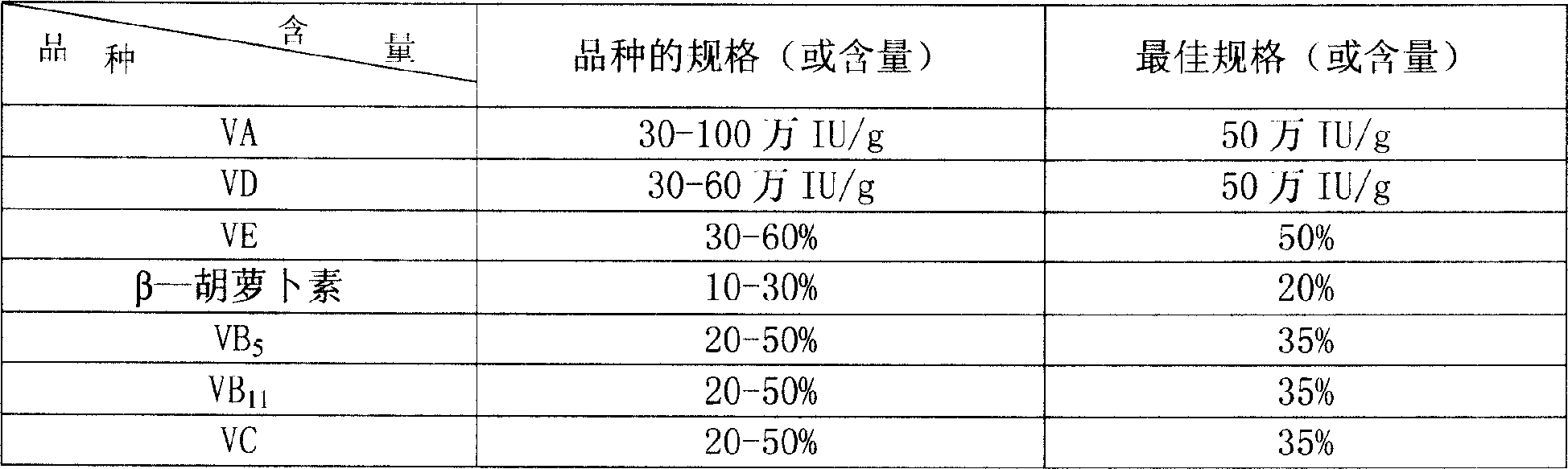

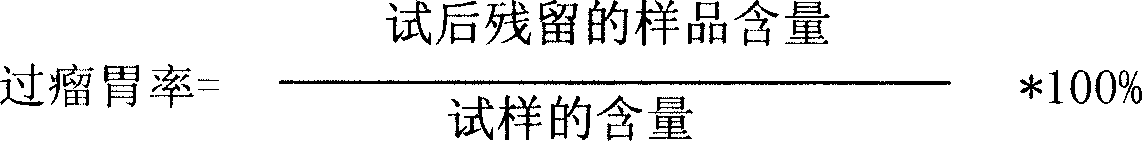

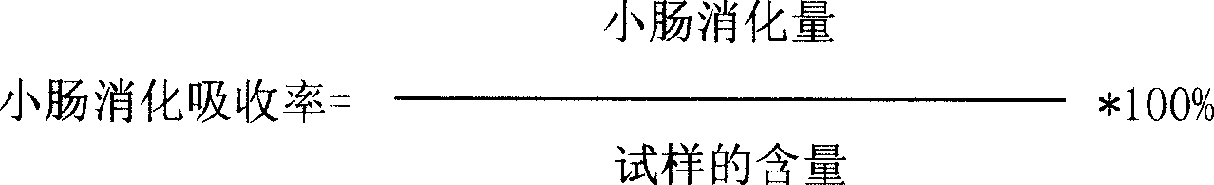

Ruminant rumen bypass vitamin nutrition adding agent and method for producing the same

InactiveCN101133777AReduce decomposition lossLess investmentAnimal feeding stuffAccessory food factorsSmall intestineRumen

The present invention relates to a cud chewer rumen-passing vitamin nutrient additive and its production method. It mainly is composed of vitamin raw material and rumen-passing fatty powder. The added vitamin can be passed through rumen, and can be digested and absorbed in small intestine, so that the utilization rate of vitamin can be effectively raised.

Owner:内蒙古多源新技术研究开发中心

2,3-dichloropyridine synthesis method

InactiveCN100357272CSuppress generationLow reaction temperatureOrganic chemistry3-AminopyridineCopper chloride

A Synthesis of 2, 3-dichloro-pyridine, including steps as follows: 1)liquating the raw material of 3-aminopyridine in decuple-twelvefold mass thick alcaine at the condition of mixing, cooling to 4-5 deg C, adding equal mol mass hydroperoxide as raw material, controlling reaction temperature between 6-8deg Cand mixing for 1-2h at the same temperature after adding the things; 2) cooling the solution below 0deg C, adding equal mol mass erinitrit solution as raw material and then preserving heat for 0. 5-1h; 3) controlling the reaction temperature below 0deg C, adding miscible liquids of 0. 15 times mol mass copper chloride as the raw material and duple mass as thick alcaine, then preserving heat for a half hour at least; 4) Returning reactant to ambient temperature and doing extraction by dichloromethane; 5) vacuum distilling the tobacco extract to dry will get product. The intermediate products of the invention are never purified and moved, all the procedures can be done in the same reaction pot and the three step reaction only uses alcaine which contains reactant as solution.

Owner:南京广通医药化工有限责任公司

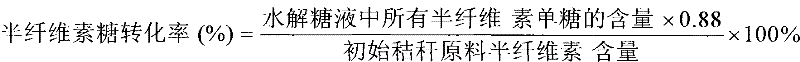

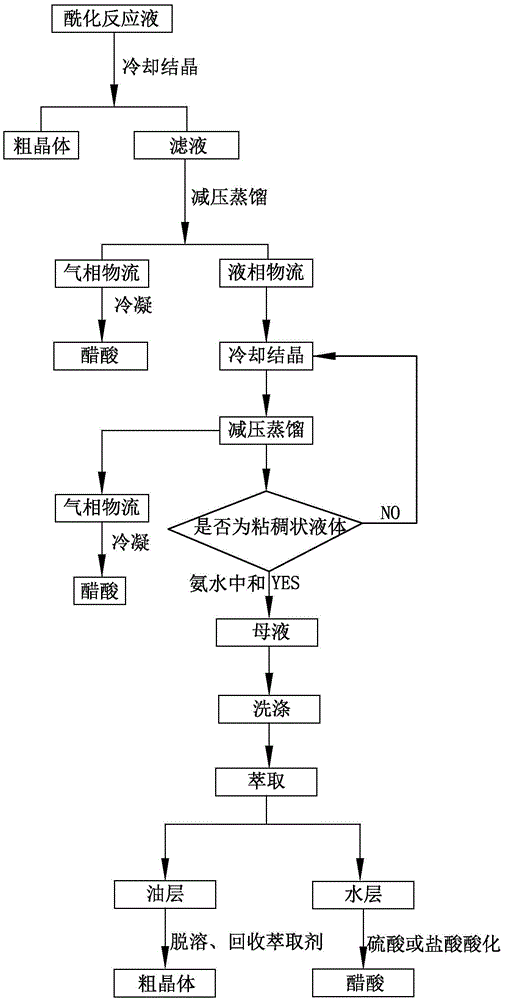

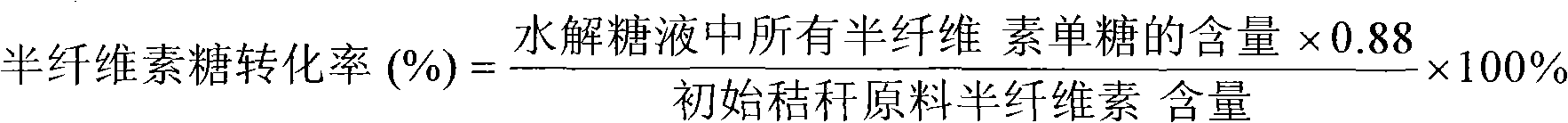

Acid and alkali combination pretreatment method of straw efficient saccharification

ActiveCN102443659ATake advantage ofEfficient removalFermentationLactose productionLiquid productLiquid glucose

The invention discloses an acid and alkali combination pretreatment method of straw efficient saccharification, which comprises the following steps that: firstly, raw material slurry consisting of straw particles, inorganic metal salt, inorganic acid and peroxide takes reaction for 1 to 50 minutes at 100 DEG C to 200 DEG C, then, the temperature is reduced, the reaction stops, finally, solid and liquid products are separated, the liquid product is hydrolytic liquid glucose, the solid product is soaked for 1 to 30 hours by alkali solution with the mass concentration being 0.1 percent to 1.5 percent, and solids obtained through solid and liquid separation after the soaking are used as enzymolysis raw materials. The acid and alkali combination pretreatment method is used, the operation flow process is simple, the treatment time is short, the energy consumption is low, the straw utilization rate is high, and the cellulase enzymolysis effect is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

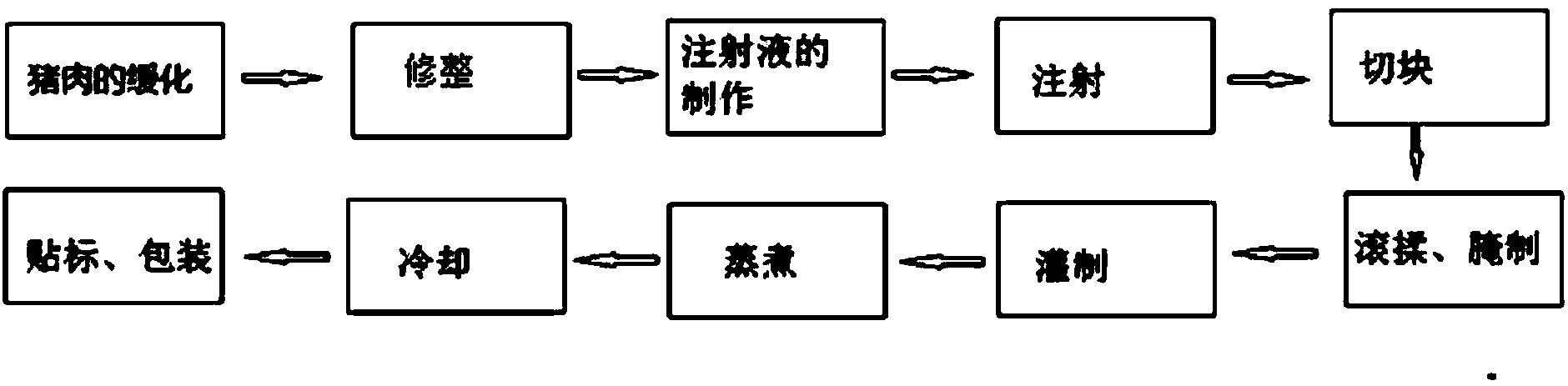

Starch-free ham

InactiveCN103932213AUniform textureClear textureSugar food ingredientsFood ingredient functionsMonosodium glutamateIce water

The invention provides a starch-free ham. The ham is prepared from the following raw materials in parts by weight: 100 parts of pork, 60 parts of ice water, 3.1 parts of ice water, 1.5 parts of white granulated sugar, 1.5 parts of glucose, 0.4 part of monosodium glutamate, 2.2 parts of a composite curing agent, 0.6 part of injection carrageenan, 0.06 part of sodium erythorbate, 0.016 part of sodium nitrite, 0.024 part of monascus red pigment, 0.12 part of natural flavor and 4 parts of soybean protein. The starch-free ham is uniform in texture, clear in section texture of shredded meat, good in slicing property, tastes elastic, smooth, tender and crisp, is natural and rich in flavor, durable in flavor durability and uniform in flavor.

Owner:TIANJIN YONGWANG FOOD

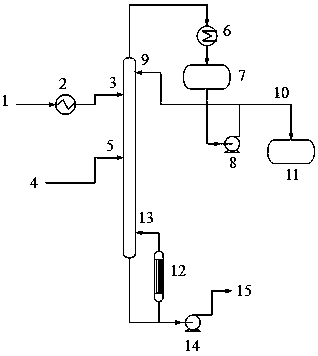

Purification method of 3-methyl-3-butene-1-ol

ActiveCN108358756AGood miscibilityImprove separation efficiencyOrganic compound preparationHydroxy compound preparationAlkaneButene

The invention discloses a purification method of 3-methyl-3-butene-1-ol. According to the method, a solvent is added, and an extractive distillation technology is adopted for separation, wherein the added solvent is high-boiling-point fatty alkane or fatty alkane containing fatty alcohol; the solvent is added from the middle upper area of a rectifying column, and raw materials containing 3-methyl-3-butene-1-ol and isoamyl alcohol are added from the middle area of the rectifying column; a part of a column bottom liquid is gasified by a heater, and obtained gas is returned into the column from agas phase inlet of the column bottom; gas at the column top is totally condensed into a liquid by a condenser and then sent into a column top return tank, and a part of liquid is sent into the columnfrom a return port at the column top by a return pump. The rectifying column is operated under the condition of reduced pressure, a pure product of 3-methyl-3-butene-1-ol is obtained at the column top, and a mixture of isoamyl alcohol and the solvent exists at the column bottom. The method has the advantages that the adopted solvent is relatively stable at the high temperature, and the product of3-methyl-3-butene-1-ol obtained from the column top is favorable for avoiding self-polymerization loss of the product.

Owner:山东成泰新材料有限公司

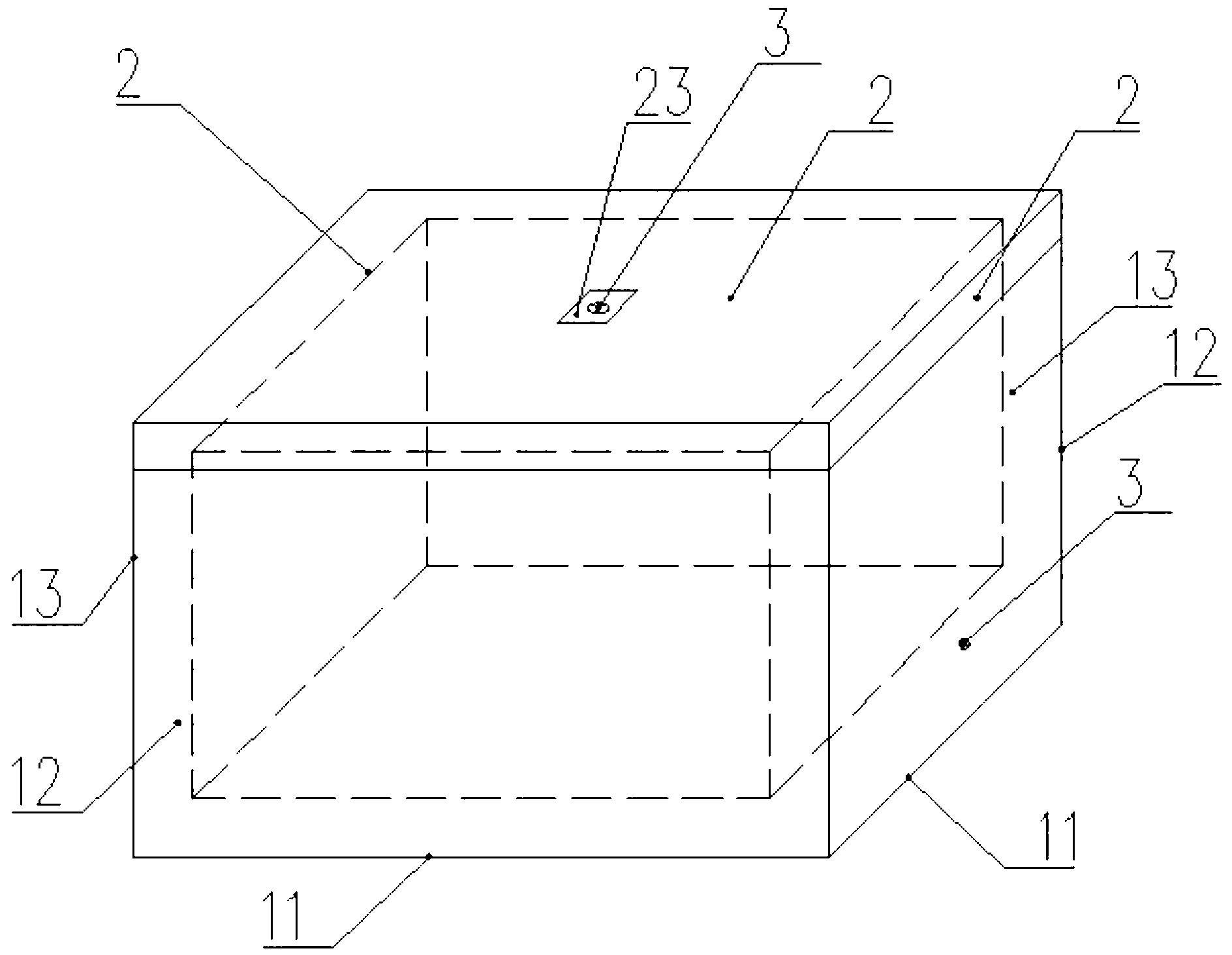

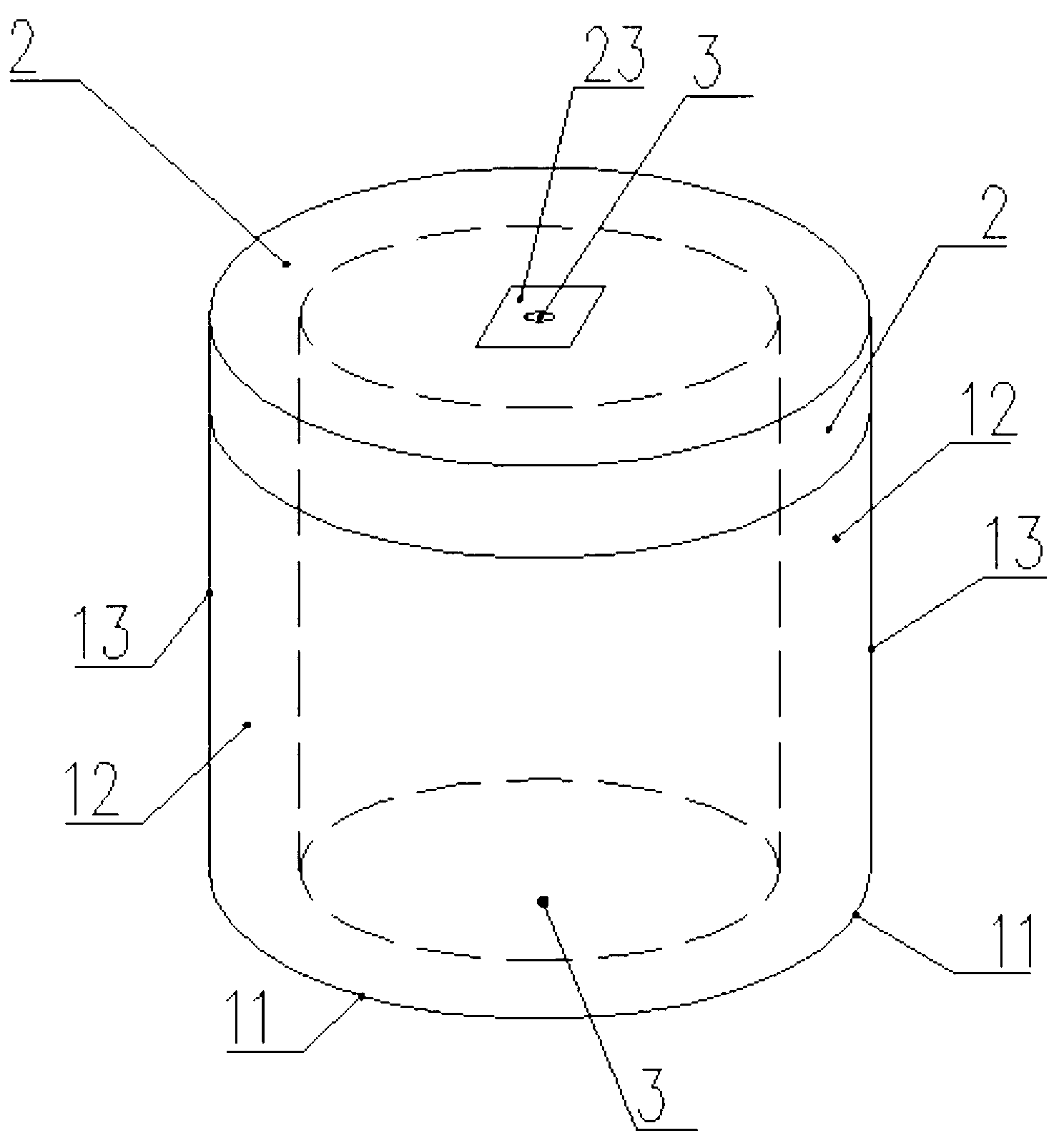

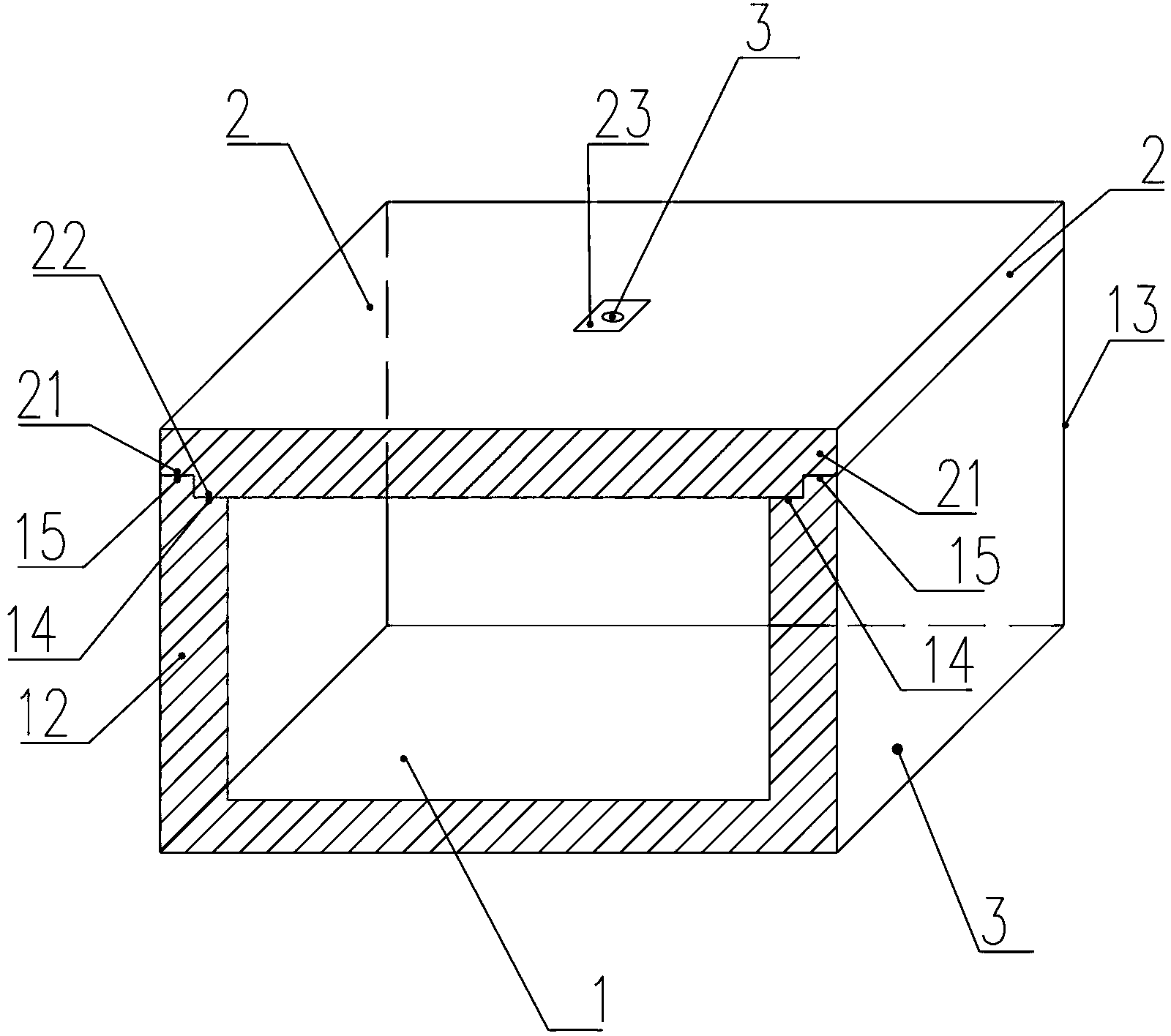

Hollow packaging box made of high-concentration ozone ice crystals

InactiveCN103318546AEffective control over decompositionEnhanced inhibitory effectLiving organism packagingFood preservationHigh concentrationPesticide residue

The invention discloses a hollow packaging box made of high-concentration ozone ice crystals, aiming to overcome defects that normal ice can only cool and suppress breeding of microorganisms and viruses and bacteria attached on surfaces of storages but cannot sterilize the same, and storages are short in preservation period, high in loss and poor in quality due to the fact that the ozone component in ozone ice is easy to decompose. The hollow packaging box made of the high-concentration ozone ice crystals comprises an ice-crystal made packaging box body, an ice-crystal made packaging box cover and an ozone and water solution pouring inlet. By utilizing double functions of bacterium inhibition and sterilization of the ozone component in the hollow ice crystals and an aseptic environment in a closed semi-vacuum state, the design purposes of prolonging the preservation period of the storages and improving green quality thereof are achieved. The hollow packaging box made of the high-concentration ozone ice crystals has the advantages of providing a proper environment capable of killing the microorganisms, viruses and moulds, decomposing harmful components, such as hormone, antibiotics, additives, pesticide residues, heavy metal, containing in the storages, and leading to the dormancy state of the storages within a short time, shortening the precooling time, prolonging the preservation period without any preservatives, improving green quality and being recycled.

Owner:辽宁自然冰科技有限公司

Pretreatment method for efficiently saccharifying straws

ActiveCN102311982AAvoid removalEfficient removalBiofuelsFermentationLiquid productPretreatment method

The invention discloses a pretreatment method for efficiently saccharifying straws, which comprises the following steps: firstly, carrying out acidification reaction on raw material serum comprising straw particles, a peroxide, inorganic salt and an inorganic acid at the temperature of 150-180 DEG C for 1-15min; then, cooling to 100-130 DEG C to continue to react for 1-30min; and finally, cooling to terminate the reaction, and separating a solid-liquid product, wherein a liquid product is hydrolysis sugar liquid, and a solid is an enzymolysis raw material. The pretreatment method for efficiently saccharifying the straws has a simple operation flow, short treatment time, low energy consumption, high straw use ratio and a good saccharifying effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

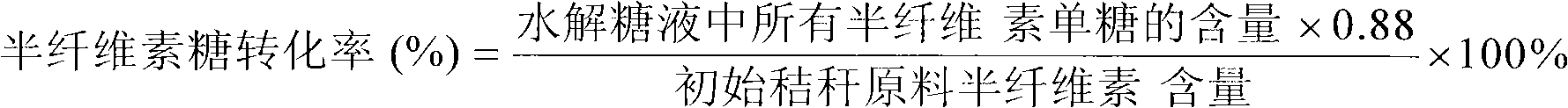

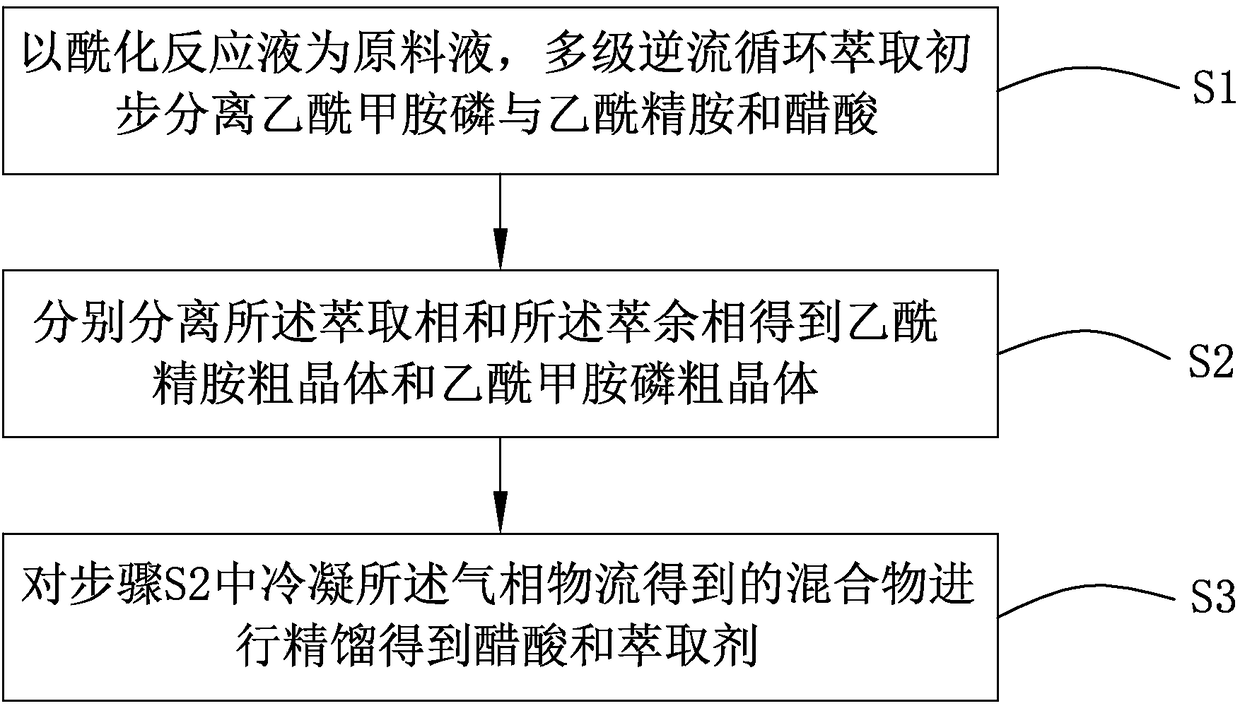

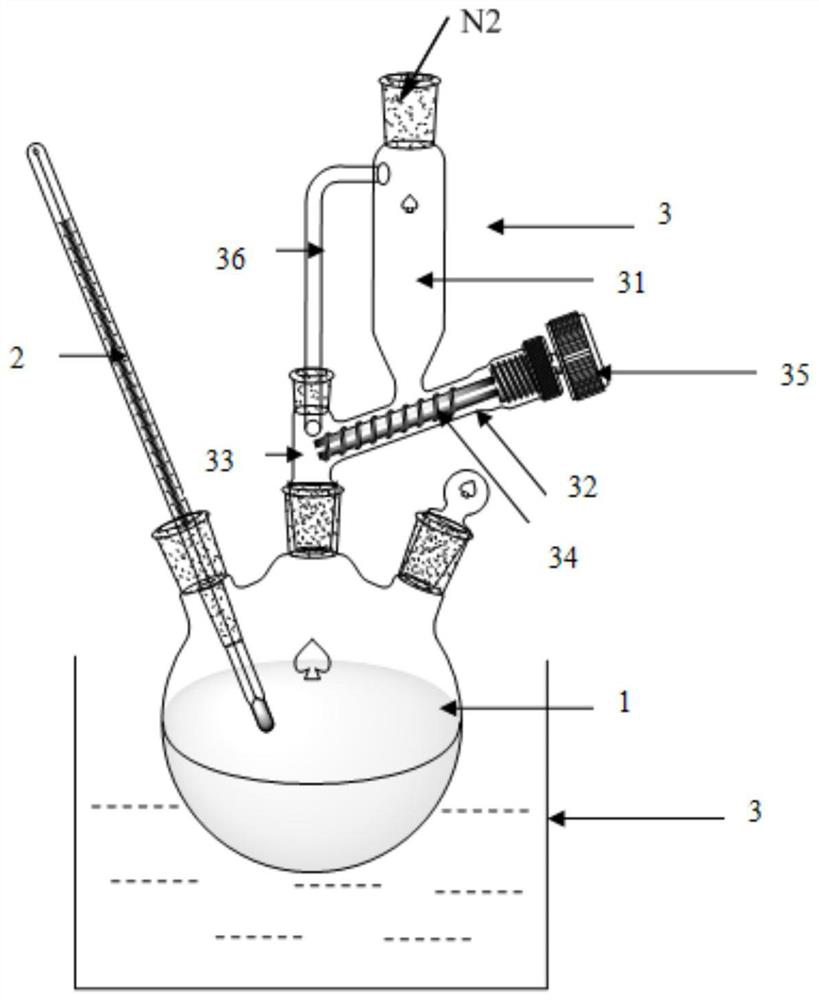

Separation method for acetic acid in acylation reaction liquid

InactiveCN105541604AEasy to separateReduce decomposition lossCarboxylic compound separation/purificationAcetic acid earDistillation

The invention provides a separation method for acetic acid in acylation reaction liquid. The method comprises the following steps of 1, performing cooling crystallization on the acylation reaction liquid to separate coarse crystals and filtrate by adopting a cooling crystallization process; 2, performing reduced pressure distillation on the filtrate to separate a gas-phase material flow and a liquid-phase material flow by adopting a reduced pressure distillation process, and condensing the obtained gas-phase material flow to obtain acetic acid; 3, recycling acetic acid from the liquid-phase material flow obtained in Step 2 by adopting an ammonia water neutralization method. According to the acetic acid separation method, most of acetic acid is directly recycled from the acylation reaction liquid by reduced pressure distillation, and a small amount of acetic acid is recycled by the ammonia water neutralization method, so that introduction of a water phase in an acetic acid direct recycling process is avoided, and production of wastewater and decomposition loss of acephate are reduced. The acetic acid separation method has a good separation effect, and an industrial requirement can be met.

Owner:XIANGTAN UNIV

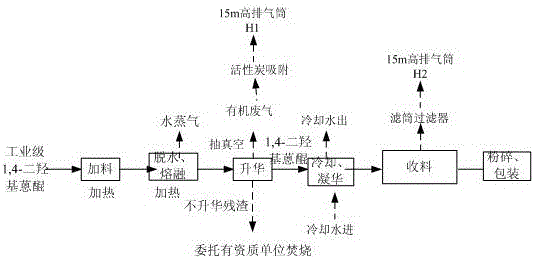

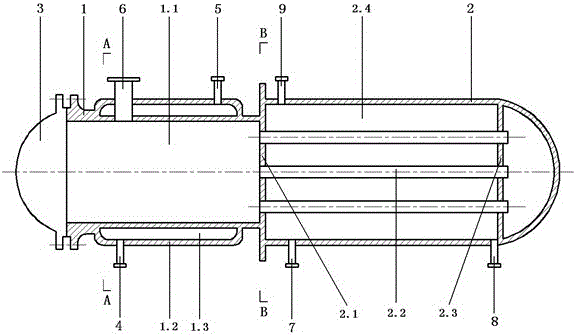

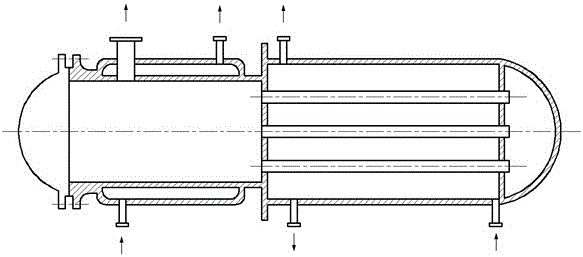

Method for purifying 1, 4-dihydroxy anthraquinone by sublimation under high vacuum

InactiveCN105884592ANo chemical reactionNo secondary pollutionQuinone separation/purificationSublimationActivated carbonChemical reaction

The invention discloses a method for purifying 1, 4-dihydroxy anthraquinone by sublimation under high vacuum. The method comprises the following preparation steps: feeding; dehydrating and fusing; purifying by sublimation; cooling and condensing; opening a tank, collecting and weighing after cooling is finished; and producing a next batch of 1, 4-dihydroxy anthraquinone. By the method provided by the invention, other chemical raw materials are not added, chemical reaction does not exist, waste water does not exist either, a small amount of waste gas can be adsorbed and removed by activated carbon, waste residues are incinerated by qualified units, and therefore, emission of the waste gas, the waste water and the waste residues is avoided basically. Compared with purification by a chemical method and a solvent method, the method has the advantages that the purity of the product is high (greater than or equal to 99%, the yield is high (greater than or equal to 97%), and is environmentally friendly; and secondary pollution is avoided. In addition, the invention further discloses a honeycomb sublimator which is designed according to the principle of infinitesimal. Compared with a reaction kettle type sublimator, the honeycomb sublimator has the features that sublimation time is shortened by more than 5 times, and energy is saved by 70%.

Owner:马骋

Energy plaster for neck, shoulder, waist and legs and preparation method of energy plaster

InactiveCN105214043AGood pain effectGood curative effectHeavy metal active ingredientsOrganic active ingredientsCentipedeSide effect

The invention discloses an energy plaster for neck, shoulder, waist and legs. The energy plaster is prepared from the following active pharmaceutical ingredients: radix aconiti kusenzoffii, radix aconite, rhizoma zingiberis, centipede, frankincense, myrrh, asarum, impatiens balsamina, radix angelicae pubescentis, rheum officinale, radix clematidis, flowers carthami, berba aristolochiae mollissimae, cassia twig, fennel, clove, pseudo-ginseng, dried body of ground beetle, tea root, mulberry bark, angelica sinensis, large-leaved gentian, ligusticum wallichii, radix aconiti carmichaeli slices, camphor, the fruit of medicinal cornel, ephedra, fructus forsythiae, the fruits of Chinese wolfberry, rhizoma cibotii, sesame oil and yellow lead. The energy plaster has a good effect in treating pains on the neck, the shoulder, the waist and the legs, can fundamentally treat pain diseases on the neck, the shoulder, the waist and the legs, and is good in curative effect, free of toxic or side effect, free of dependency, and free of relapse after healing. The energy plaster is mainly used for treating the pains on the neck, the shoulder and the legs, the osteoarthrosis, the rheumatism arthralgia, various inflammations and the like, is good in curative effect, can fundamentally treat pain diseases on the neck, the shoulder, the waist and the legs, and is good in curative effect, free of toxic or side effect, free of dependency, and free of relapse after healing.

Owner:王倩莹

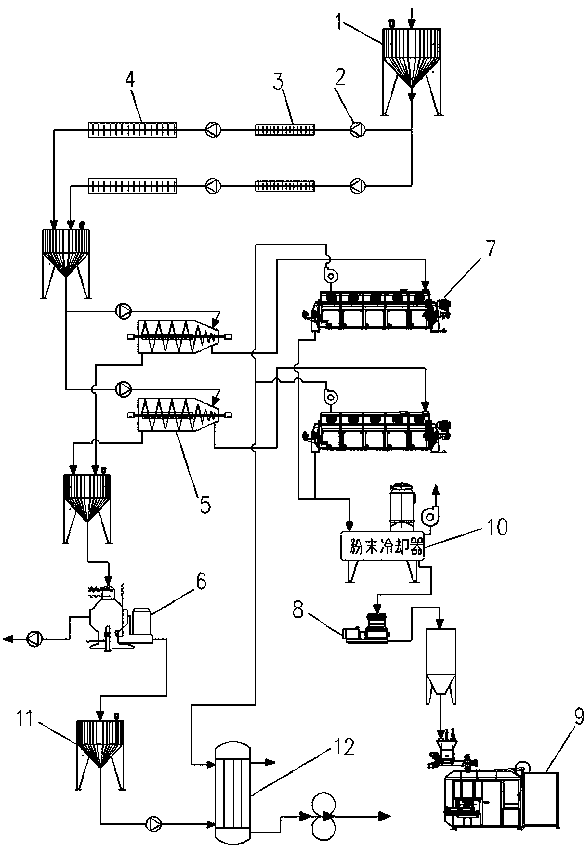

Ship-borne Antarctic krill powdering process

InactiveCN109601899AShorten cooking timeAvoid decomposition lossWaste water treatment from food industryWater/sewage treatment by heatingAstaxanthinProtein content

The invention relates to a ship-borne Antarctic krill powdering process. The process comprises the following steps: (1) material preparation: feeding Antarctic krill into a feeding pump, (2) scraper heater heating and digester heating, (3) material separation, (4) material drying, (5) material cooling, (6) material crushing, (7) liquid treatment, and (8) wastewater treatment. By adopting the production process of the invention, the yield of the product is obviously improved, the astaxanthin content and the protein content of the product are also obviously improved, and the quality of the product is significantly higher than that of shrimp powder produced by traditional methods. After the wastewater is evaporated, all resources in the entire process are fully utilized without any waste of resources.

Owner:JIANGSU SUNLINE DEEP SEA FISHERY CO LTD

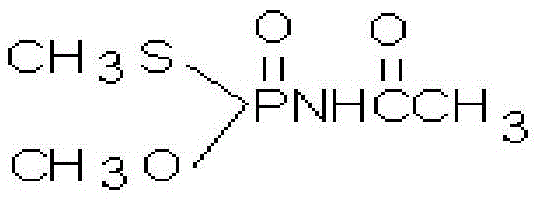

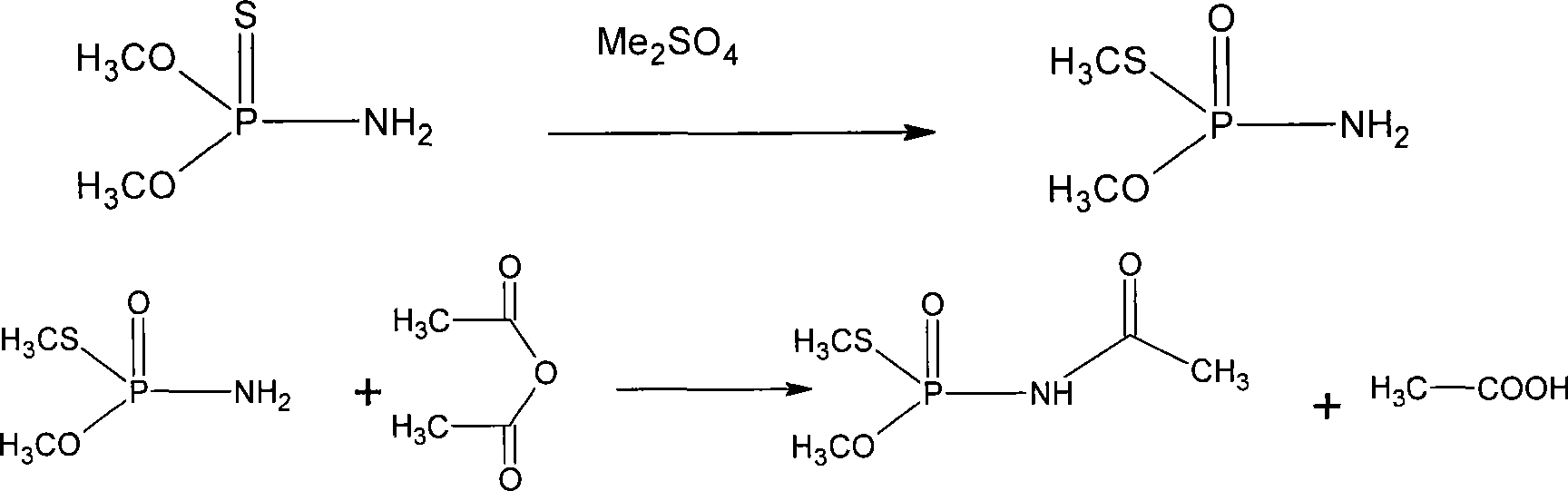

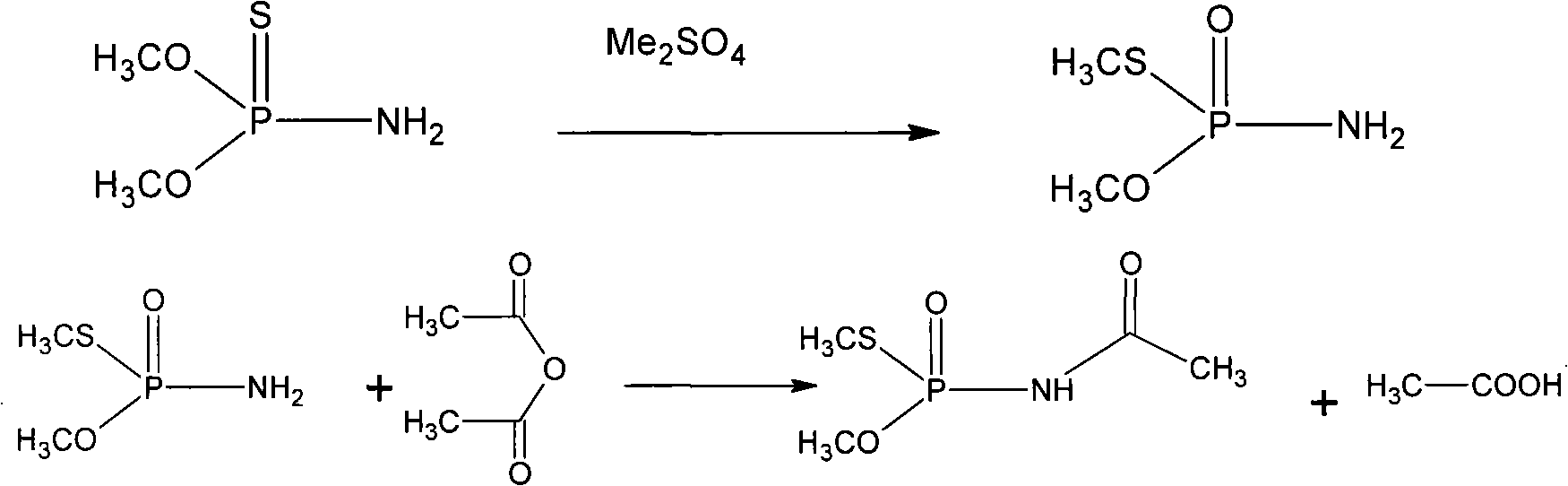

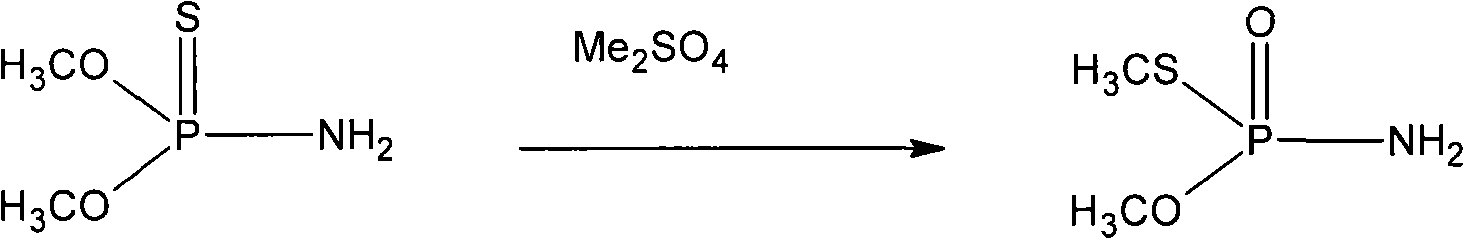

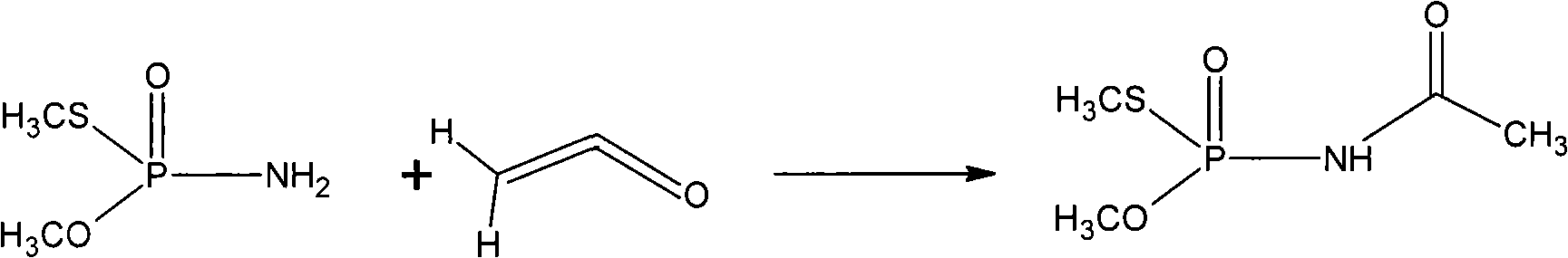

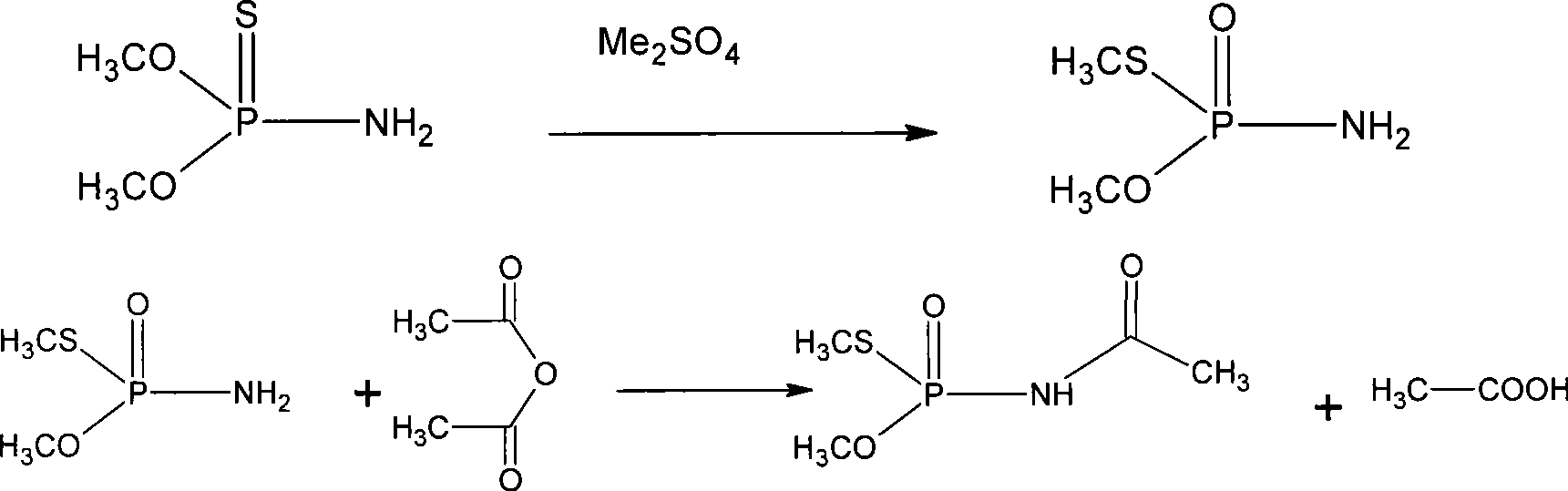

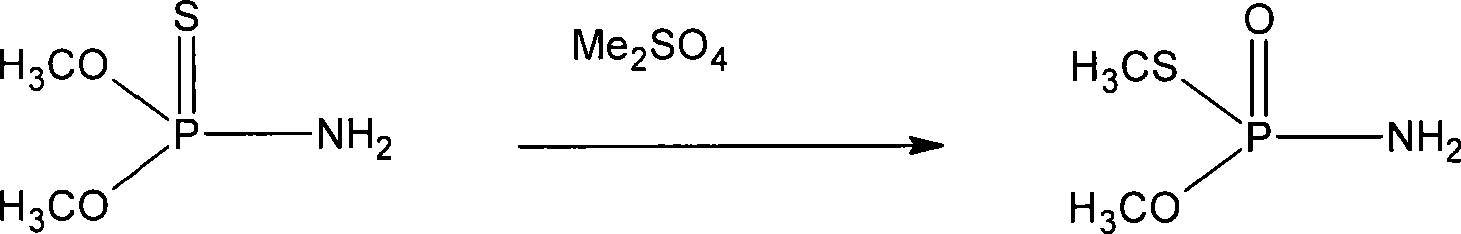

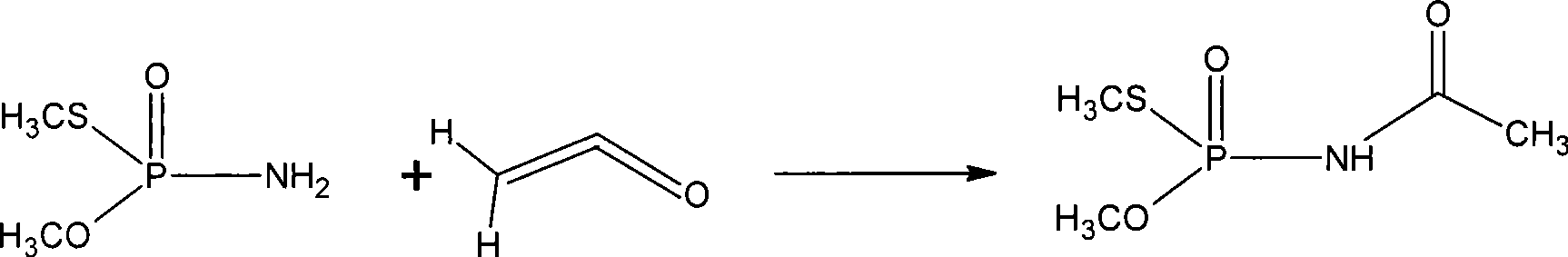

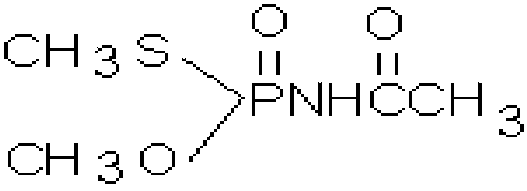

Method for preparing acephate

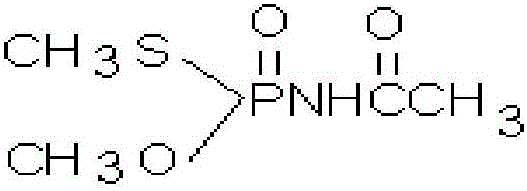

InactiveCN101074241AReduce decomposition lossHigh purityGroup 5/15 element organic compoundsOrganic solventIsomerization

Production of acephate by ketene is carried out by taking ketene and 0,0-dimethyl-thiophosphoryl triamide as raw materials, acetylating reacting ketene with 0,0-dimethyl-thiophosphoryl triamide under condition of acidation catalyst and organic solvent to obtain acetylated 0,0-dimethyl-thiophosphoryl triamide, reacting for acetylated 0,0-dimethyl-thiophosphoryl triamide under isomerization catalyst condition to prepare acephate solution, crystallizing, solid-liquid separating and drying to obtain acephate coarse powders. It has better recovery rate and purity, has less consumption and no environmental pollution.

Owner:SHANDONG HUIHAI PHARMA & CHEM

Coking technology of low-rank coal briquette raw material containing biomass

ActiveCN105733623ANot easy to pulverizeEasy to focusBiofuelsSpecial form destructive distillationBiomassAgriculture

The invention discloses a coking technology of a low-rank coal briquette raw material containing biomass. Firstly the low-rank coal briquette raw material containing the biomass is moulded, and then the raw material is coked. The raw material mainly comprises a low-rank coal briquette body formed of a low rank coal and the biomass, and a non-low-rank coal briquette layer covering the low-rank coal briquette body. The non-low-rank coal briquette layer is made of one or several coals selected from a medium rank coal, a high rank coal or a medium-high rank coal. The coking technology of the low-rank coal briquette raw material containing the biomass solves the problems that the availability of a present stamping charging coke oven is low, and the production power in the coking industry is excess, and solves the problem that the application of the low-rank coal is limited due to no large scale industrial devices. The availability of biomass energy such as straws and agriculture and forestry residues is improved, a new sludge processing mode is developed, and the influence of leachate generated by sludge sanitary landfills on the surrounding environment is solved.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

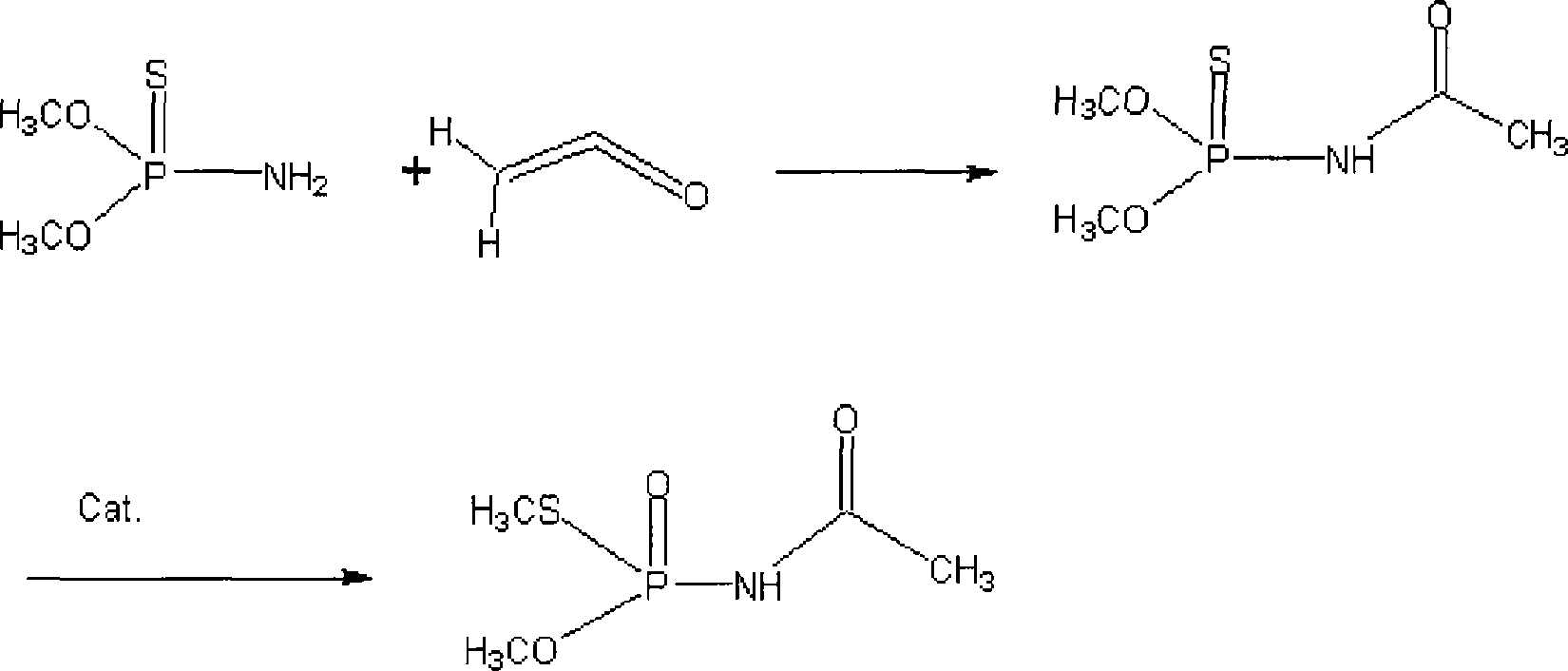

Method for purifying coarse trichloroacetaldehyde

InactiveCN102030623AEasy to dehydrateGuaranteed dehydrationCarbonyl compound separation/purificationDistillationMicrostructure

The invention discloses a method for purifying coarse trichloroacetaldehyde. The method comprises the following steps that: the coarse trichloroacetaldehyde is fully mixed with dilute sulphuric acid in a primary microstructure mixer; trichloroacetaldehyde obtained by a primary demixer is fully mixed with concentrated sulfuric acid in a secondary microstructure mixer; trichloroacetaldehyde obtained after being demixed by a secondary demixer is continuously and fully mixed with concentrated sulfuric acid in a third microstructure mixer; trichloroacetaldehyde containing a small amount of sulfuric acid obtained after being demixed by a third demixer is rectified to obtain anhydrous trichloroacetaldehyde; after sulfuric acid demixed by the secondary demixer and the third demixer is mixed, a part of sulfuric acid is used as the dilute sulphuric acid for the primary microstructure mixer, and the residual sulfuric acid is mixed with the sulfuric acid demixed by the primary microstructure mixer and the residual sulfuric acid of a refining distillation kettle to distill and recycle the residual trichloroacetaldehyde; and the recycled trichloroacetaldehyde is mixed with the trichloroacetaldehyde demixed by the primary demixer to enter the secondary microstructure mixer. By the method, the coarse trichloroacetaldehyde is purified, the consumption of steam and the sulfuric acid can be reduced, and the refining yield of the trichloroacetaldehyde is improved.

Owner:XIANGTAN UNIV

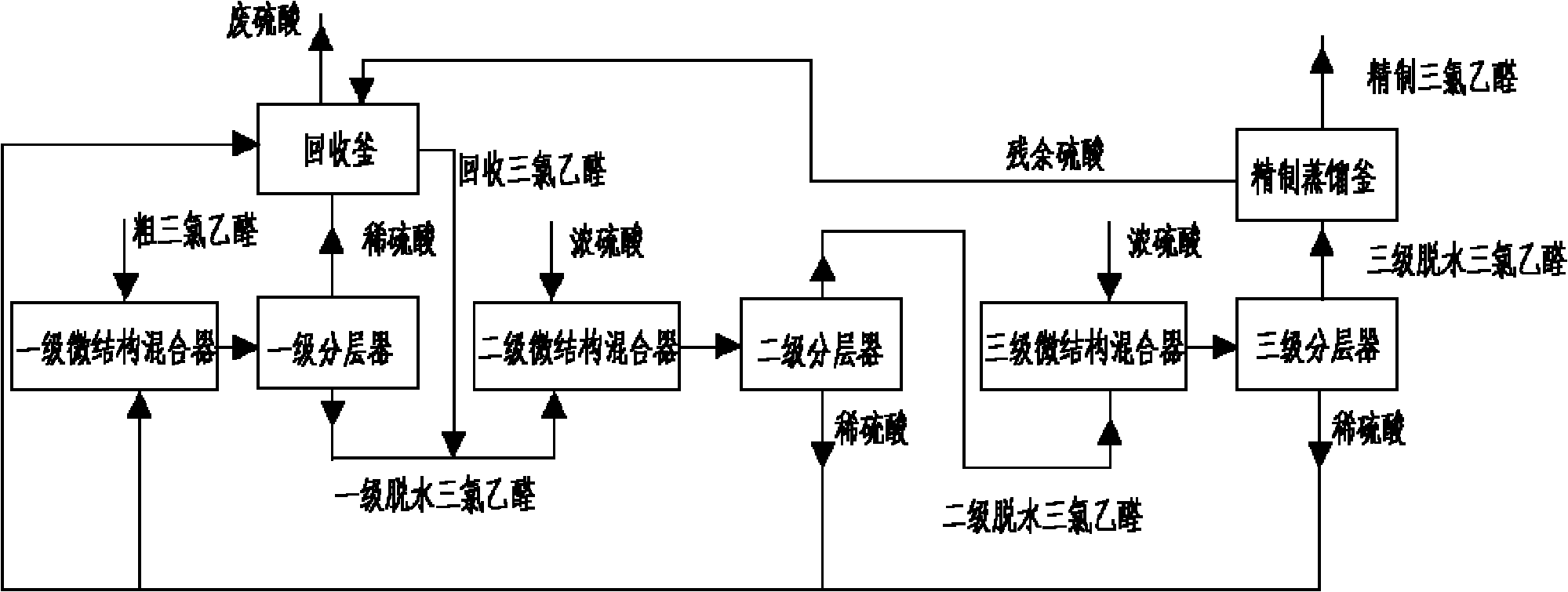

Method for extracting and separating acetyl spermine in acylation reaction liquid

ActiveCN106496061AHigh yieldHigh crystal purityGroup 5/15 element organic compoundsCarboxylic acid amide separation/purificationAcephateSpermine

The invention provides a method for extracting and separating acetyl spermine in an acylation reaction liquid. The method comprises the following steps: I, taking the acylation reaction liquid as a raw material liquid, adding an extraction agent, and performing multi-stage countercurrent continuous extraction on the raw material liquid to obtain an extraction phase and a raffinate phase, wherein the extraction phase comprises a main amount of the acetyl spermine and acetic acid of the raw material liquid, and the raffinate phase comprises a main amount of acephate in the raw material liquid; II, separating the extraction phase and the raffinate phase, thereby obtaining coarse crystal of the acetyl spermine and coarse crystal of acephate. By adopting the method provided by the invention, the crystallization purity of the acephatethe can be increased while the acetyl spermine is recycled, and moreover as the acetic acid is recycled in a rectification manner, the method is simple and convenient to operate and good in separation effect; and the acetyl spermine can be prevented from being discharged into wastewater, so that the environment pollution can be reduced.

Owner:XIANGTAN UNIV

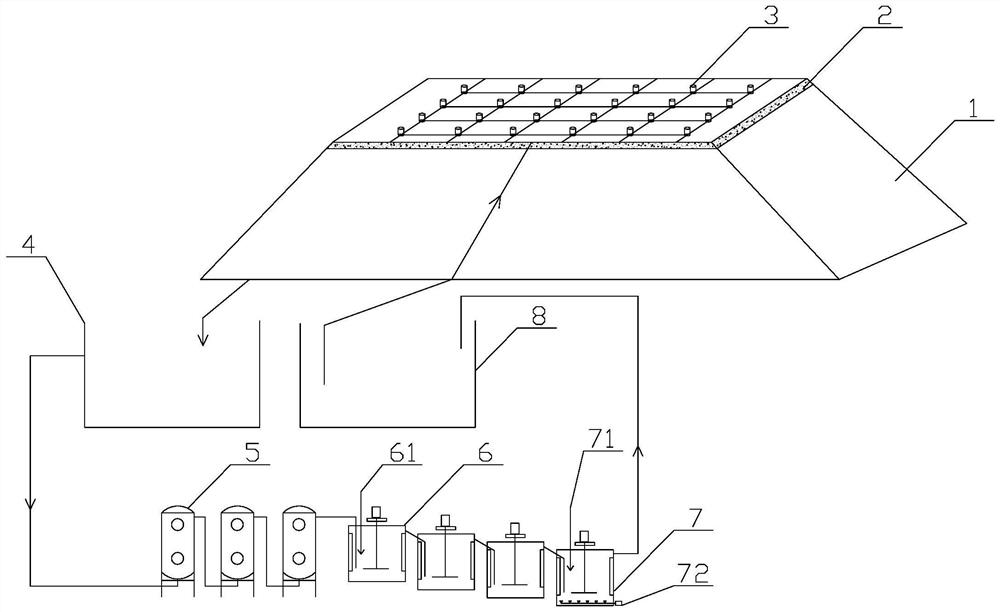

Closed-pile ecological restoration method for gold ore dump leaching field

PendingCN112058882AGood decyanation effectEfficient ecological governanceWater contaminantsContaminated soil reclamationPollutantGold ore

The invention relates to a closed-pile ecological restoration method for a gold ore dump leaching field, and belongs to pollutant treatment and ecological restoration methods in the field of environmental protection. The method comprises the following steps of heap leaching heap surface layer earthing, spraying system installation, cyanide-reducing plant planting, leachate treatment and spraying liquid preparation and spraying, and has the advantages that heap leaching heap cyanide-containing leachate treatment, heap leaching residue residual gold leaching and decyanation treatment and heap leaching heap ecological restoration treatment are fused together, efficient decyanation treatment of cyanide-containing leachate and dump leaching residues in the gold ore cyaniding dump leaching process can be achieved, recovery of gold, silver and other valuable metal elements in the leachate and the dump leaching residues can be achieved, ecological restoration and treatment of dump leaching heap can be achieved, the dump leaching field decyanation treatment and ecological restoration period is shortened, a very efficient practical method is provided for environmental governance of gold orecyaniding dump leaching process enterprises, and good application prospects are achieved.

Owner:CHANGCHUN GOLD RES INST

Cordyceps sinensis micro-powder containing cyclodextrin and preparation method and preparation of cordyceps sinensis micro-powder

InactiveCN105616451AImprove stabilityProlonged decomposition half-lifeDispersion deliveryPill deliverySolubilityCordyceps

The invention discloses cordyceps sinensis micro-powder containing cyclodextrin and a preparation method and a preparation of the cordyceps sinensis micro-powder. The cordyceps sinensis micro-powder is mainly prepared from cordyceps sinensis and cyclodextrin. The invention further discloses the preparation method of the cordyceps sinensis micro-powder, the preparation containing the cordyceps sinensis micro-powder and the preparation method of the preparation. Compared with the prior art, the prepared cordyceps sinensis micro-powder is capable of significantly promoting full release of cordyceps sinensis components, significantly improving the solubility of insoluble components and strengthening the stability of the components.

Owner:NANJING NORMAL UNIVERSITY +1

A coking process for briquettes comprising biomass and low-rank coal

ActiveCN105733624BImprove utilizationSolve application limitationsBiofuelsSpecial form destructive distillationCoal briquetteSludge

The invention discloses a coking process for a coal briquette comprising biomass and low-grade coal. The coking process includes the steps of: moulding a low-grade coal briquette raw material containing biomass; and coking the low-grade coal briquette raw material, wherein the coal briquette comprising the biomass and low-grade coal includes a non-low-grade coal briquette layer formed from one or more of medium-grade coal, high-grade coal or mid-high-grade goal, and a low-grade coal briquette layer which is arranged on the non-low-grade coal briquette layer and includes low-grade coal and biomass. The coking process solves the problems of low utilization rate of a tamping coke oven in the prior art and excessive productivity in the coking industry, and solves a problems of limited application of the low-grade coal since no large-scale industrial device is provided. The utilization rate of biomass resources, such as straw and agricultural and forestry wastes, is improved. The invention develops a novel sludge treatment method and solves the influence on surrounding environment due to garbage leachate generated from sludge sanitary landfill.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Melt slime granulating composite fertilizer and its production method

ActiveCN100503524CReduce decomposition lossIncrease profitAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSlurryCaking

A melt slurry tower granulation compound fertilizer and a manufacturing method thereof. A melt slurry tower granulation compound fertilizer is composed of the following components by weight ratio: urea: 45-50 parts; potassium chloride or Potassium sulfate: 20-25 parts; ammonium phosphate: 20-30 parts; filler: 1-5 parts. The invention discloses a method for manufacturing compound fertilizer with melted slurry tower granulation. In the manufacturing process, high-temperature molten urea is used as a carrier, the raw materials are evenly fused, and then sprayed and cooled at the top of the tower to form granules. The height of the tower is 60-120 meters, and the diameter of the tower is 8-20 meters. During the preparation process, no moisture is introduced into the system to bond and granulate, which can prevent agglomeration due to excess moisture. The advantages of the present invention are: the melt method compound fertilizer prepared by the present invention adopts high tower spraying natural cooling and one-time granulation molding technology in the preparation process. This technology does not have returning materials, so that the production capacity is greatly improved. It avoids the problems of low granulation rate and many returning materials due to the traditional method, saves energy and improves equipment utilization. At the same time, because there is almost no dust pollution from returned materials, the working environment is cleaner and the discharge of three wastes is avoided.

Owner:STANLEY AGRI GRP CO LTD

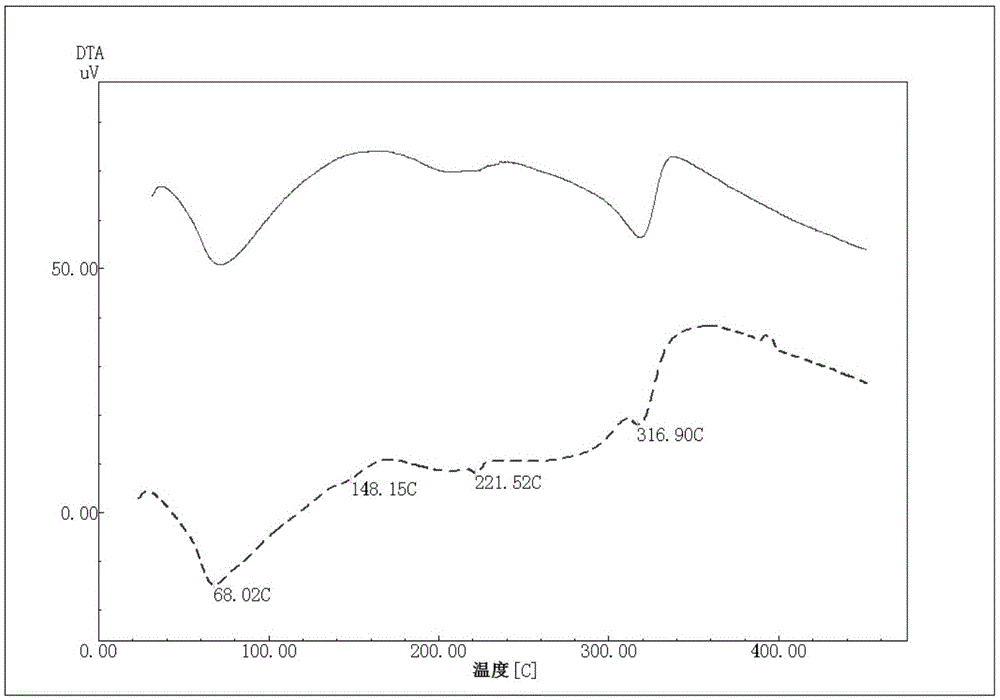

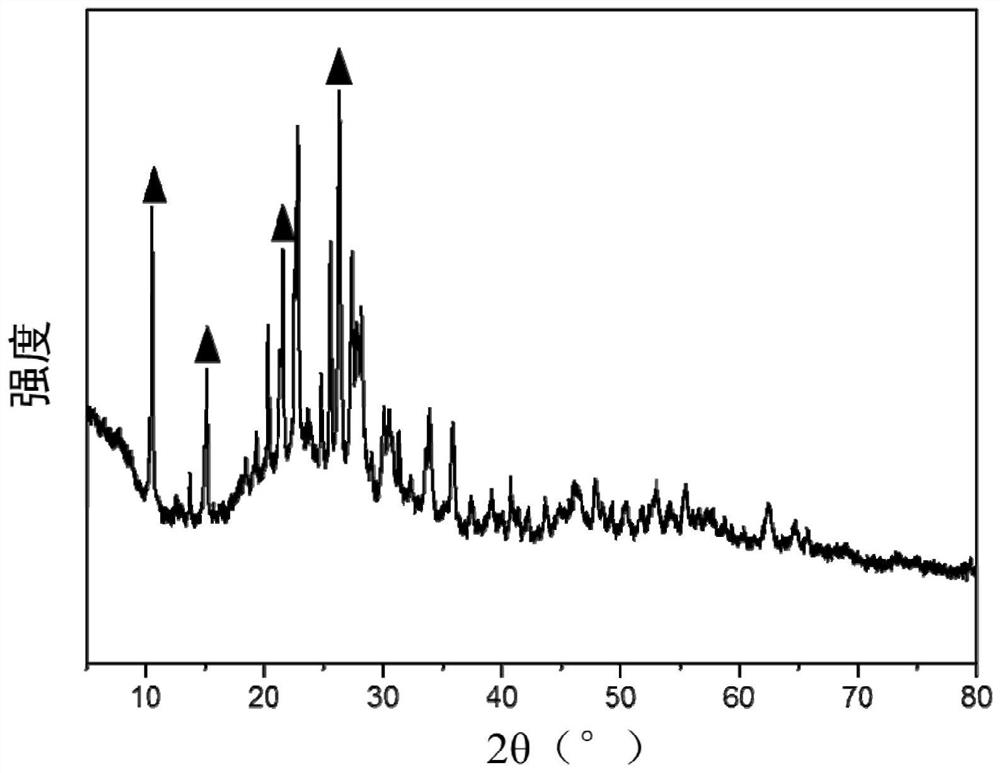

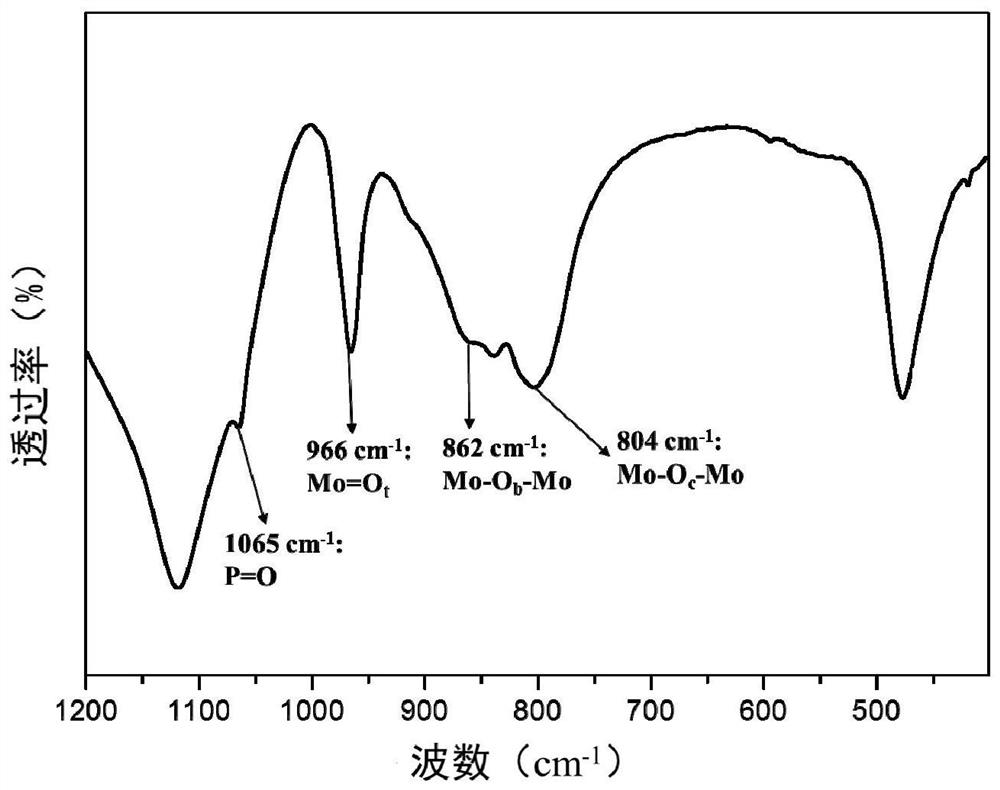

Composite catalyst for manufacturing methacrylic acid and preparation method thereof

PendingCN114471530AHigh selectivityRaw material conversion rate is highOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystHeteropoly acid

The invention provides a catalyst for directly preparing methacrylic acid by taking isobutene as a raw material through a one-step method and a preparation method of the catalyst. The catalyst comprises two different active components, namely Mo-Bi metal oxide and mesoporous Mo-P heteropolyacid, and can selectively oxidize isobutene into methylacrolein and further oxidize methylacrolein into methacrylic acid respectively. The preparation method of the catalyst comprises two steps: after Mo-Bi metal oxide particles are prepared, dispersing the Mo-Bi metal oxide particles in a Mo-P heteropolyacid precursor solution containing a surfactant and a silicon dioxide precursor to obtain the composite catalyst. The heat treatment method of the catalyst is also divided into two steps, that is, roasting is carried out in inert gas and oxidizing gas atmospheres respectively, and finally the catalyst with good heat stability is obtained. The catalyst can directly oxidize isobutene into methacrylic acid by a one-step method, and has good reaction activity and thermal stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

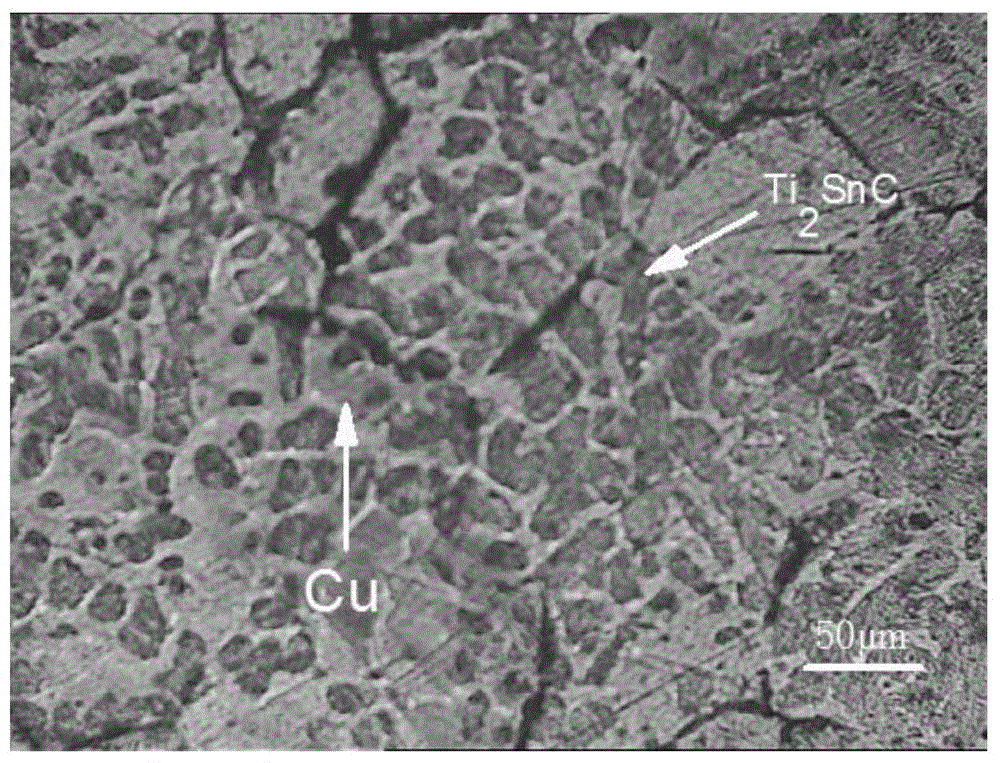

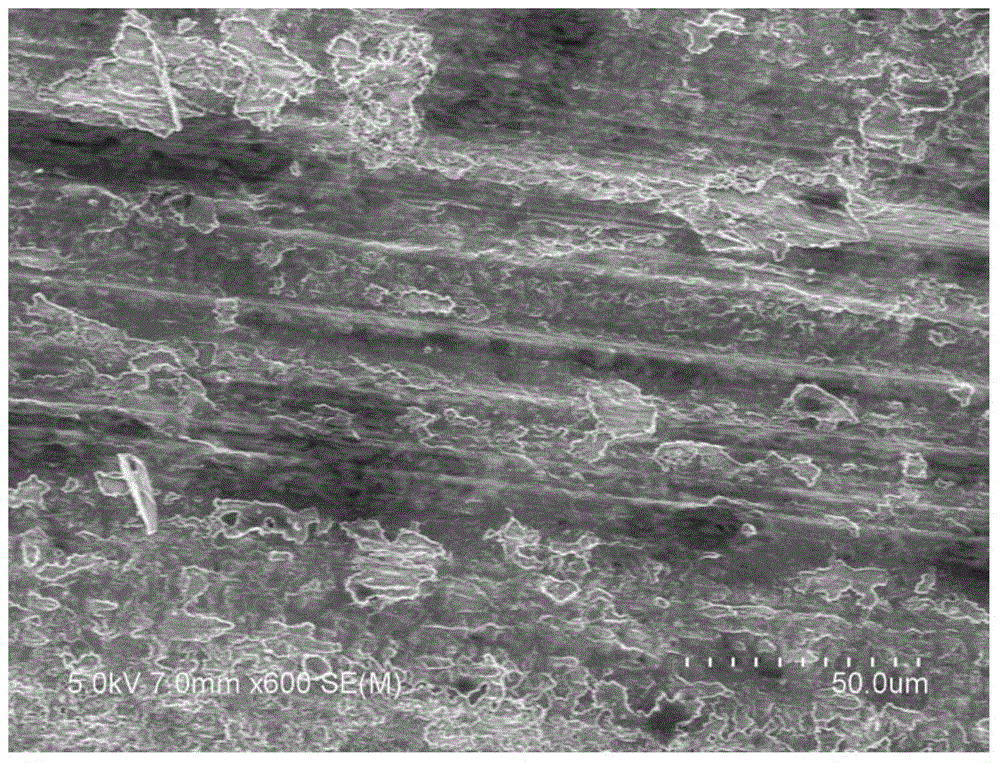

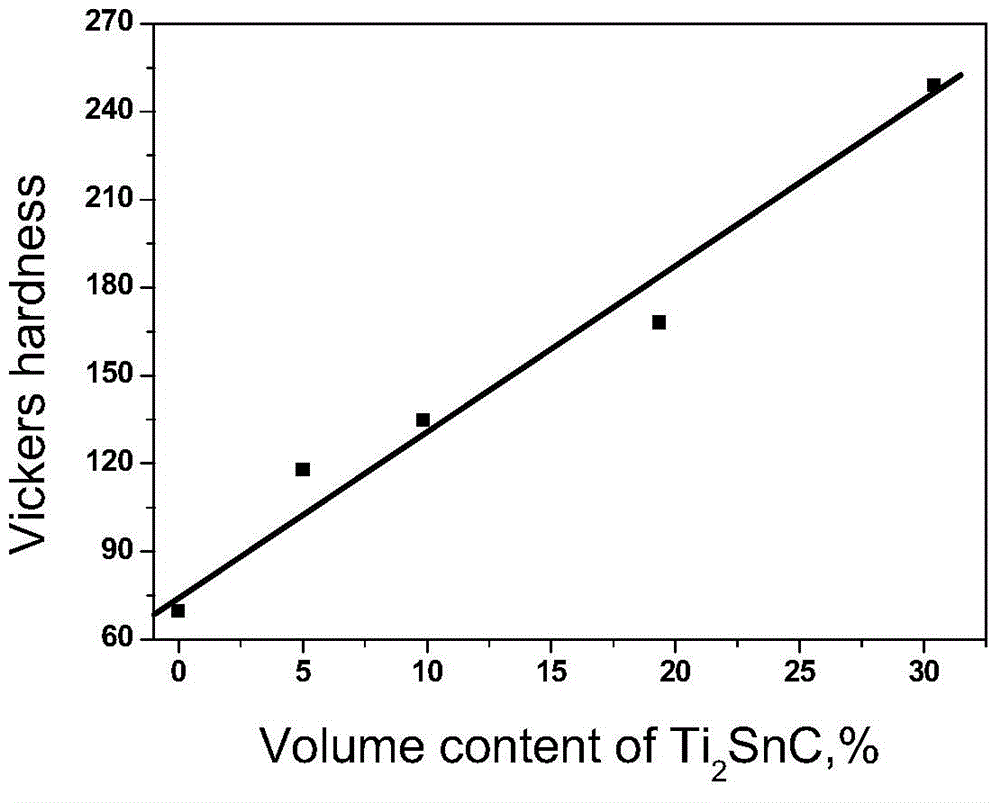

Cu-Ti2SnC self-lubricating conductive coating and preparation method thereof

ActiveCN104805327AImprove wear resistanceImprove the lubrication effectMolten spray coatingConductive coatingMass ratio

The invention discloses a Cu-Ti2SnC self-lubricating conductive coating and a preparation method thereof. The mass ratio of raw materials of the coating is as follow: Cu:Ti2SnC=(65-97):(3-35); the mass ratio of components of the formed coating is as follow: Cu:Ti2SnC:the balance=(65-97):(2-30):(1-5); the balance consists of Cu2O as well as decomposition products TiC and Sn of the Ti2SnC, wherein the mass ratio of the TiC and Sn is 1: (1.5-2), and the Cu2O is 1-3% of the mass of the formed coating. Through spraying by a high velocity oxy-fuel technology, good wear-resisting, self-lubricating and electrical properties are achieved, the Cu-based strength and the wear resistance are improved, and meanwhile the high conductivity is maintained.

Owner:盐城东方汽车广场投资发展有限公司

Coking process for coal briquette comprising biomass and low-grade coal

ActiveCN105733624ASolve the low utilizationSolve the problem of overcapacity in the coking industryBiofuelsSpecial form destructive distillationCoal briquetteSludge

The invention discloses a coking process for a coal briquette comprising biomass and low-grade coal. The coking process includes the steps of: moulding a low-grade coal briquette raw material containing biomass; and coking the low-grade coal briquette raw material, wherein the coal briquette comprising the biomass and low-grade coal includes a non-low-grade coal briquette layer formed from one or more of medium-grade coal, high-grade coal or mid-high-grade goal, and a low-grade coal briquette layer which is arranged on the non-low-grade coal briquette layer and includes low-grade coal and biomass. The coking process solves the problems of low utilization rate of a tamping coke oven in the prior art and excessive productivity in the coking industry, and solves a problems of limited application of the low-grade coal since no large-scale industrial device is provided. The utilization rate of biomass resources, such as straw and agricultural and forestry wastes, is improved. The invention develops a novel sludge treatment method and solves the influence on surrounding environment due to garbage leachate generated from sludge sanitary landfill.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Blueberry juice product on-line clarification technique and blueberry juice pectization agent

InactiveCN103385523BRealize online centrifugal clarificationHigh yieldFood scienceSolubilityFruit juice

The invention discloses a blueberry juice product on-line clarification technique and a blueberry juice pectization agent. The technique comprises the following steps successively: a) cleaning blueberry fruits; b) squeezing; c) preserving heat for enzymolysis; d) preparing a sol; e) mixing; f) fast-cooling; g) centrifugating; and h) producing finished products, etc. The complex pectization agent can coagulate with suspensions in juice rapidly and form denser coagulation products under the coordination of fast-cooling technology, so that the juice is clarified by on-line centrifugation. Residues separated from the blueberry juice by a centrifuge only account for about 1% of the total juice by weight, which means that the yield rate of the juice is largely improved and waste of resources is reduced. The amount of the pectization agent used is minimized, as it only accounts for 0.01 to 0.03% of the total juice, and thus the pectization agent cost is reduced. EDTA-2Na is combined in the formulation of the pectization agent, so that the water-solubility of gels in the pectization agent is improved, and the use of the gels is decreased. Meanwhile, some of the heavy metals in the juice are bound through complexation during pectization, and thus decomposition and loss of anthocyanins are significantly reduced, and nutritional values of the blueberry juice is guaranteed.

Owner:ZHEJIANG LANMEI AGRI +1

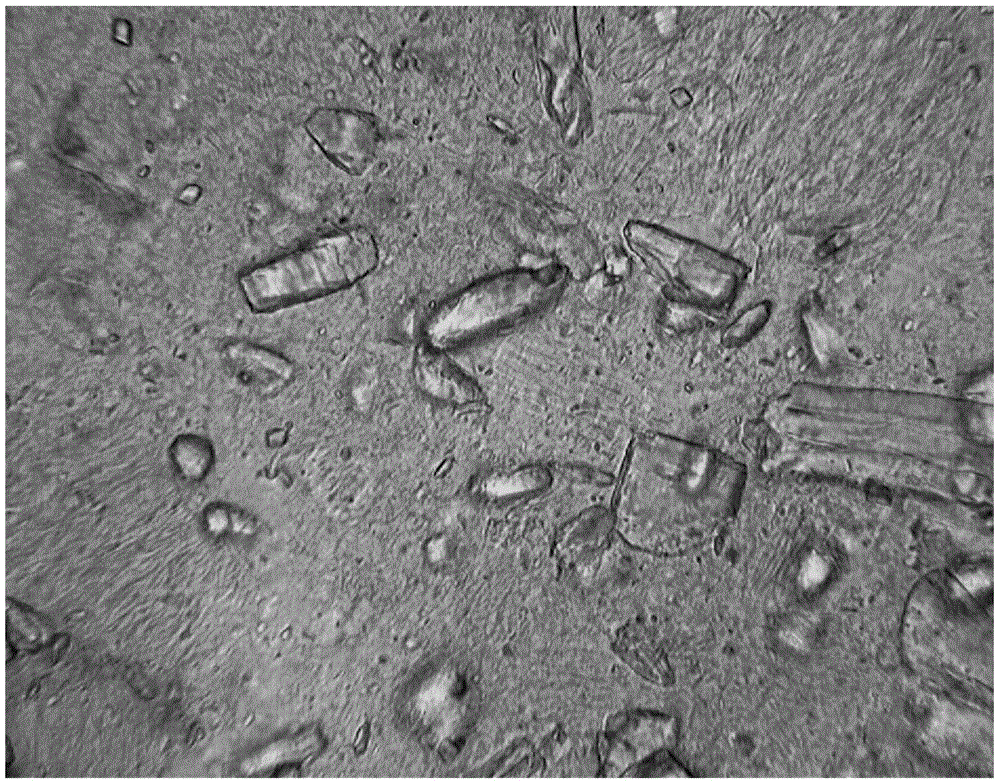

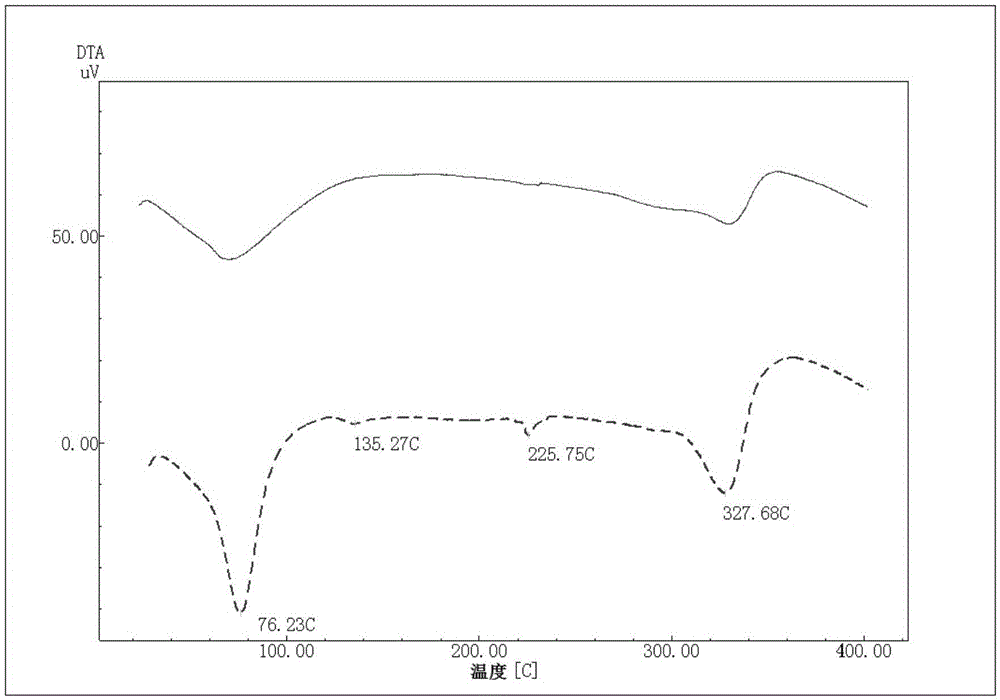

Process for preparing acephate from ethenone

InactiveCN101289462AReduce decomposition lossHigh purityGroup 5/15 element organic compoundsEthenoneAcetylation

The invention discloses a new method for using a ketene acetylation method to synthesize high purity acephate raw powder, which includes the following steps: O, O-dimethyl thiophosphoryl is used as raw material; the O, O-dimethyl thiophosphorus is isomerized to prepare O, S-dimethyl thiophosphoryl amine (methamidophos), the ketene and the O, S-dimethyl thiophosphoryl amine is caused to generate acetylation reaction at a proper speed, under the condition of a solvent and a catalyst and the temperature of minus 20 to 50 DEG C, the reaction time is 2 to 8 hours; and acephate raw powder is prepared through the processes of crystallization, solid-liquid separation and drying. The yield rate of the acephate raw powder prepared by the new method is high up to 90 percent (accounted by methamidophos), and the purity is up to 98 percent, without discharging waste liquid and polluting the environment.

Owner:UNIV OF JINAN

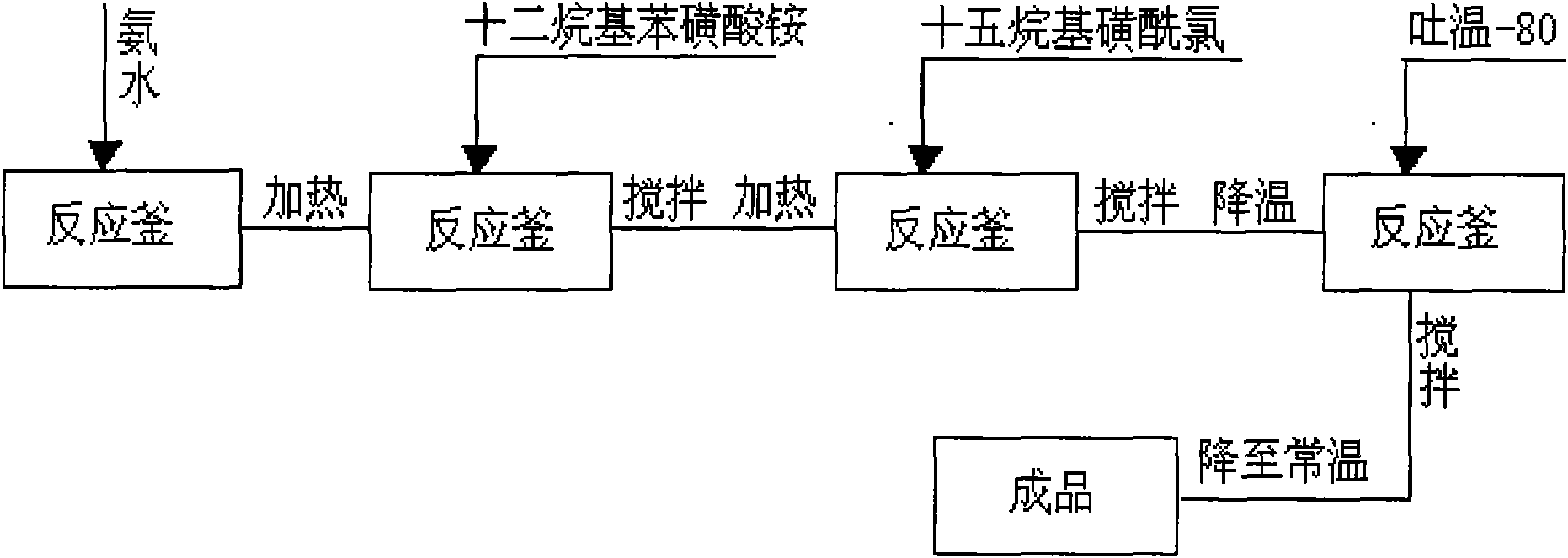

Compound ammonium bicarbonate additive and production method thereof

InactiveCN101591027AEasy to useReduce moisture contentAmmonium carbonates/bicarbonatesSodium bicarbonateDecomposition

The invention provides a compound ammonium bicarbonate additive and a production method thereof. The ammonium bicarbonate additive is compounded with the following materials: ammonia with mass concentration of 4 to 8 percent, ammonium dodecylbenzenesulfonate, 1-pentadecanesulfonyl chloride and Tween 80. The weight portion ratio of the compounded materials is 45-55:13-15:28-32:3-6. The compounding method comprises the following steps: preparing materials according to the weight portion ratio; adding the ammonia into a reaction kettle, and adding the ammonium dodecylbenzenesulfonate when the ammonia temperature in the kettle is between 58 and 62 DEG C; stirring the mixture of the two, adding the 1-pentadecanesulfonyl chloride when the temperature in the kettle is between 70 and 78 DEG C, stirring for 60 minutes, and slowly reducing temperature; and adding the Tween 80 when the temperature in the kettle is between 58 and 62 DEG C, evenly stirring, cooling to normal temperature, and obtaining a finished product. The ammonium bicarbonate additive prepared by the invention reduces the moisture content of the ammonium bicarbonate finished product to below 3 percent, improves the nitrogen content to over 17 percent, increases crystalline particles, reduces decomposition loss, is not easy to cake, facilitates the storage and transportation of ammonium bicarbonate, and reduces the production cost of the ammonium bicarbonate.

Owner:JIANGSU HEYOU CHEM

Process for preparing acephate from ethenone

InactiveCN101289462BReduce decomposition lossHigh purityGroup 5/15 element organic compoundsEthenoneAcetylation

The invention discloses a new method for using a ketene acetylation method to synthesize high purity acephate raw powder, which includes the following steps: O, O-dimethyl thiophosphoryl is used as raw material; the O, O-dimethyl thiophosphorus is isomerized to prepare O, S-dimethyl thiophosphoryl amine (methamidophos), the ketene and the O, S-dimethyl thiophosphoryl amine is caused to generate acetylation reaction at a proper speed, under the condition of a solvent and a catalyst and the temperature of minus 20 to 50 DEG C, the reaction time is 2 to 8 hours; and acephate raw powder is prepared through the processes of crystallization, solid-liquid separation and drying. The yield rate of the acephate raw powder prepared by the new method is high up to 90 percent (accounted by methamidophos), and the purity is up to 98 percent, without discharging waste liquid and polluting the environment.

Owner:UNIV OF JINAN

A method for extracting and separating acetylspermine in acylation reaction liquid

ActiveCN106496061BHigh yieldHigh crystal purityGroup 5/15 element organic compoundsCarboxylic acid amide separation/purificationDiacetylspermineAcephate

The invention provides a method for extracting and separating acetyl spermine in an acylation reaction liquid. The method comprises the following steps: I, taking the acylation reaction liquid as a raw material liquid, adding an extraction agent, and performing multi-stage countercurrent continuous extraction on the raw material liquid to obtain an extraction phase and a raffinate phase, wherein the extraction phase comprises a main amount of the acetyl spermine and acetic acid of the raw material liquid, and the raffinate phase comprises a main amount of acephate in the raw material liquid; II, separating the extraction phase and the raffinate phase, thereby obtaining coarse crystal of the acetyl spermine and coarse crystal of acephate. By adopting the method provided by the invention, the crystallization purity of the acephatethe can be increased while the acetyl spermine is recycled, and moreover as the acetic acid is recycled in a rectification manner, the method is simple and convenient to operate and good in separation effect; and the acetyl spermine can be prevented from being discharged into wastewater, so that the environment pollution can be reduced.

Owner:XIANGTAN UNIV

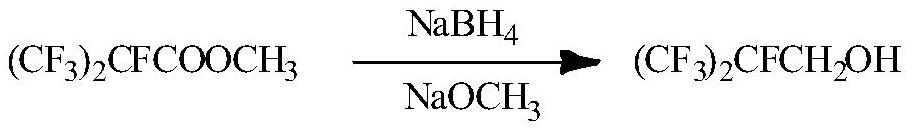

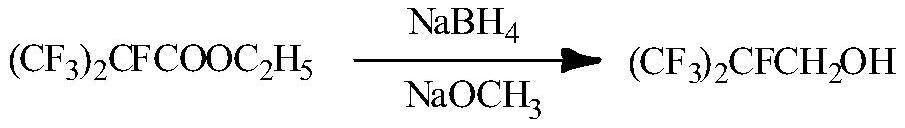

Preparation method of heptafluoroisobutyl alcohol

PendingCN111978147AReduce usageWide variety of sourcesOrganic compound preparationHydroxy compound preparationChemical industryOrganic base

The invention belongs to the field of fluorine chemical industry, and particularly relates to a preparation method of heptafluoroisobutyl alcohol. The preparation method comprises the following steps:adding raw material perfluoroisobutyrate, solvent methanol and organic base assistant into a reaction vessel; performing cooling in an ice-water bath, then adding solid sodium borohydride by using aspiral feeder to react, and after the feeding is completed, recovering the room temperature to carry out stirring reaction; and after the reaction is finished, performing distilling to remove the solvent in the reaction solution, performing washing with saline solution, drying with sodium sulfate, and performing concentrating to obtain the product. Through the conventional chemical reduction reaction, no dangerous reagent is used, the synthetic route is short, the post-treatment is simple, and the reaction yield is high, so that the product can be produced on a large scale, and is low in priceand convenient to popularize.

Owner:天津长芦新材料研究院有限公司

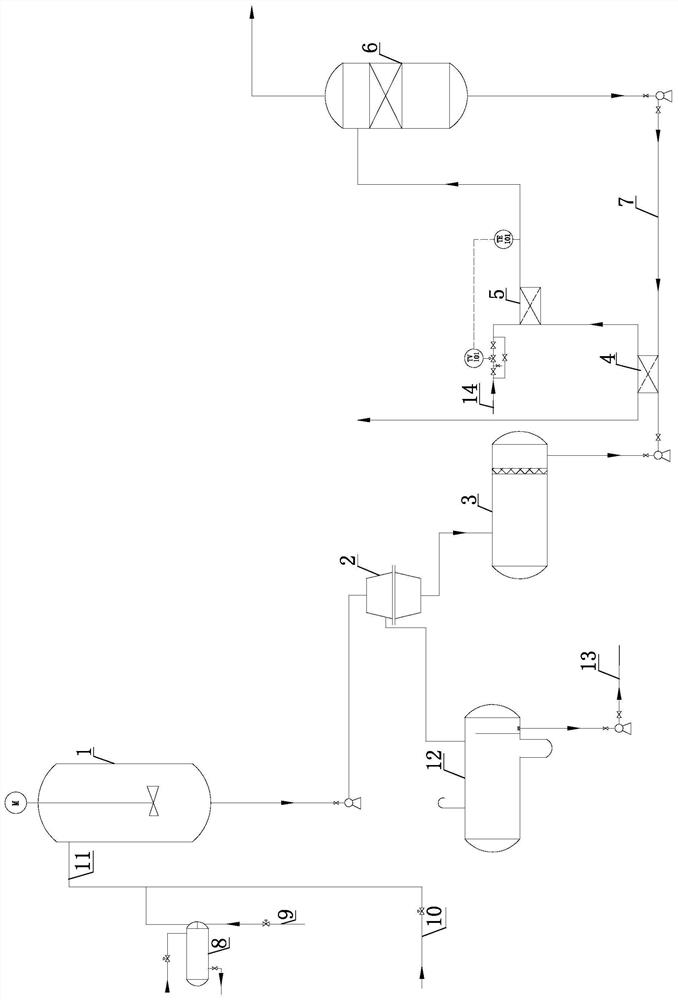

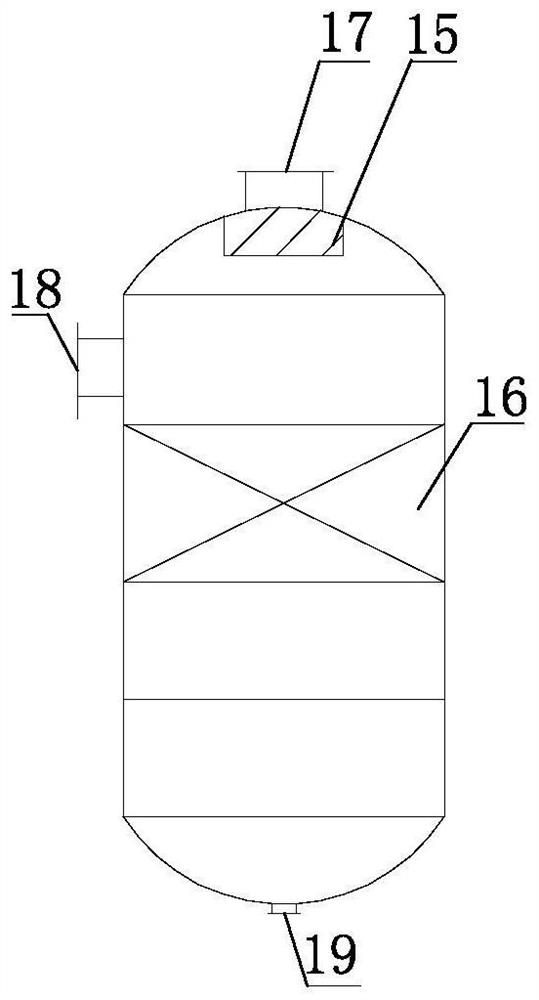

Maleic anhydride plant solvent dehydration drying process and equipment

The invention belongs to the technical field of maleic anhydride solvent recovery, and in particular relates to a solvent dehydration and drying process and equipment for a maleic anhydride plant. The desalted water is mixed with the organic solvent and then centrifuged. The obtained organic phase is preheated by the flash tank heat exchanger, and then enters the flash tank heater to be heated to 95-100°C, and then enters the solvent flash tank for flash evaporation , so that the moisture content in the solvent is ≤0.02%, and the obtained dry solvent enters the maleic anhydride absorption tower for recycling. The maleic anhydride device solvent dehydration drying process and equipment of the present invention, for the solvent discharged from the bottom of the centrifuge, after the solvent is dried and flashed by heating, the water brought into the absorption section by the solvent washing section is further reduced, and the decomposition of maleic anhydride is reduced. Loss, reducing the formation of impurities, to ensure that the solvent absorption and analysis system can run smoothly for a long period of time.

Owner:淄博海益精细化工有限公司

Acid and alkali combination pretreatment method of straw efficient saccharification

ActiveCN102443659BTake advantage ofEfficient removalSaccharides productionLiquid productLiquid glucose

The invention discloses an acid and alkali combination pretreatment method of straw efficient saccharification, which comprises the following steps that: firstly, raw material slurry consisting of straw particles, inorganic metal salt, inorganic acid and peroxide takes reaction for 1 to 50 minutes at 100 DEG C to 200 DEG C, then, the temperature is reduced, the reaction stops, finally, solid and liquid products are separated, the liquid product is hydrolytic liquid glucose, the solid product is soaked for 1 to 30 hours by alkali solution with the mass concentration being 0.1 percent to 1.5 percent, and solids obtained through solid and liquid separation after the soaking are used as enzymolysis raw materials. The acid and alkali combination pretreatment method is used, the operation flow process is simple, the treatment time is short, the energy consumption is low, the straw utilization rate is high, and the cellulase enzymolysis effect is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com