Process for preparing acephate from ethenone

A technology of acephate original powder and ketene, which is applied in the field of pesticide preparation of acephate, can solve the problems of lowering product yield and purity, low total separation yield, lowering yield and the like, and achieves reduction of decomposition loss, The effect of overcoming the neutralization process and increasing the yield

Inactive Publication Date: 2010-12-01

UNIV OF JINAN

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

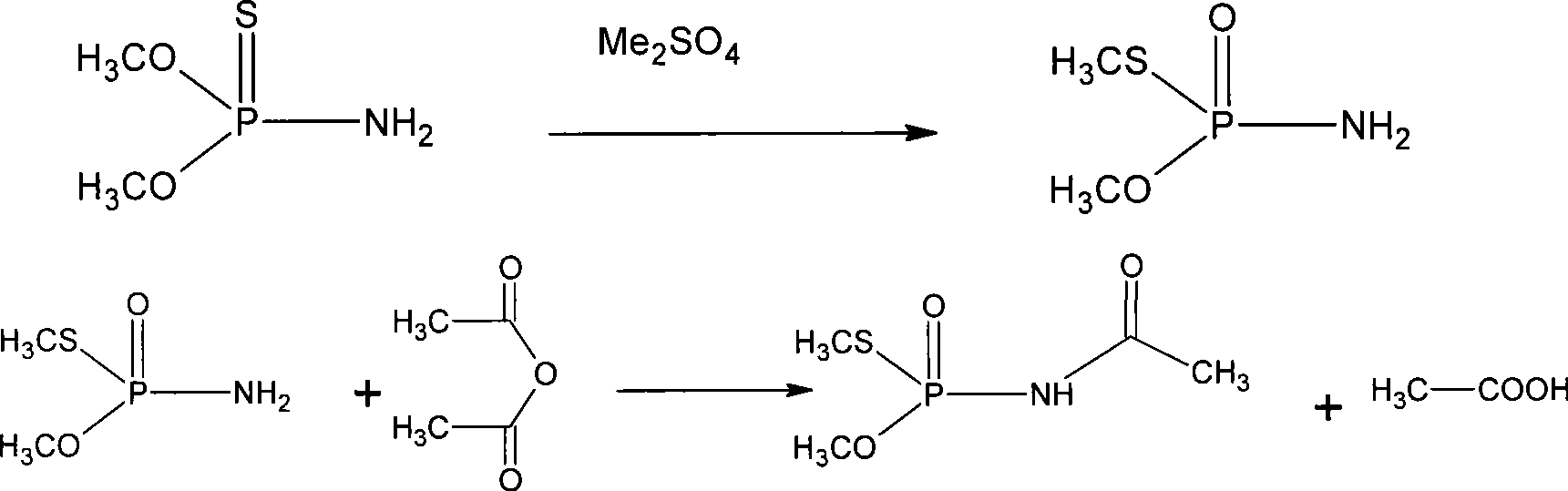

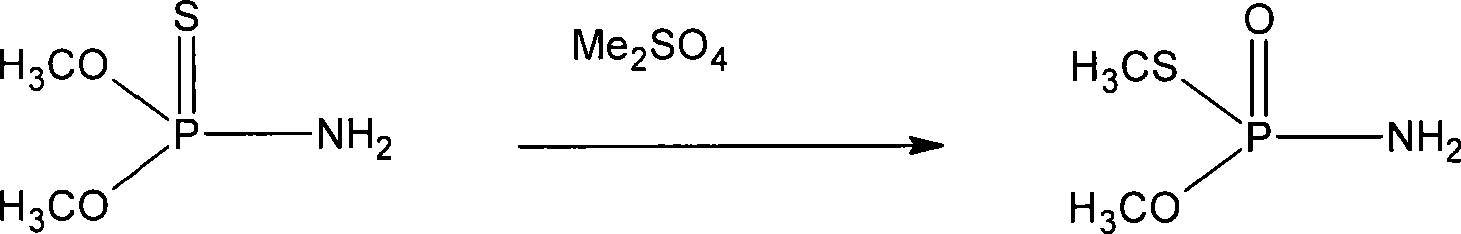

In above-mentioned these methods, all there is common problem: produce a large amount of acetic acid in the production process; Need to consume a large amount of ammoniacal liquor (or liquid ammonia) and because by-product ammonium acetate is too much in the neutralization process, ammonium acetate and acephate are easy Water-soluble substances have certain similarities in their properties, and it is difficult to completely separate them. Most production methods use ammonia water neutralization, and then use dozens of times the organic solvent to extract, as shown in Figure 1.

The disadvantages of using ammonia neutralization process are:

1. Almost all the acephate obtained by the reaction meets with water (JP-B48-34583 is to use chloroform to extract acephate crude oil and then treat it with brine; JP-A64-75494 is to directly neutralize acephate with aqueous alkali solution Acephate crude oil), and acephate is easily decomposed in aqueous solution (especially in alkaline solution), so the loss of acephate may be larger in the separation process, resulting in a low total yield of separation

2. Methamidophos is easily soluble in water, difficult to extract and has high solvent consumption; and when recovering the solvent, acephate is decomposed due to distillation, which reduces the yield and purity of the product

3. A large amount of industrial wastewater is generated during the production process. The water cannot be recycled during the separation process and can only be discharged as wastewater in the end. This may cause the discharge loss of organic solvents and acephate, further increasing the separation cost

4. Although neutralization with liquid ammonia can partially solve the above problems, such as CN1362415, the by-product ammonium acetate is too much, and it is difficult to separate. A part of acephate is entrained in the ammonium acetate, and solid-liquid separation and desorption are also required in the production process. High-purity acephate raw powder was obtained through complex processes such as dissolution and crystallization separation, and coarse crystal purification, resulting in a decrease in yield

Since the emulsifiable concentrate prepared with mother liquor contains more impurities, the stability is generally poor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

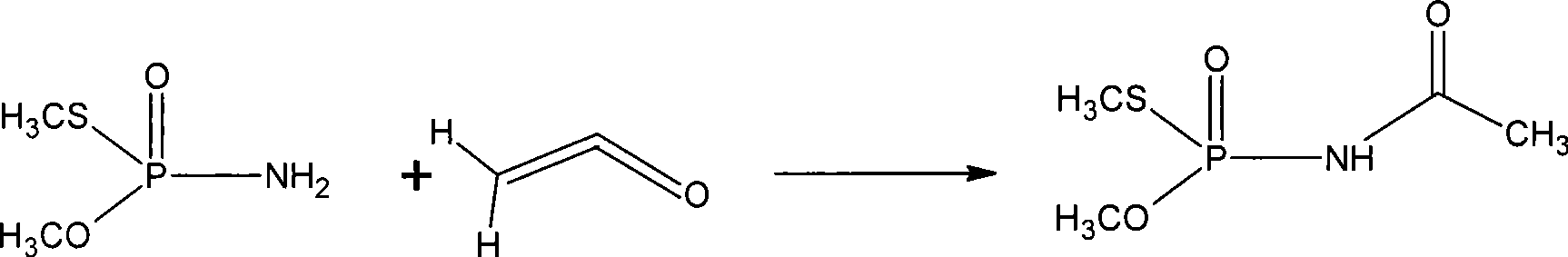

The invention discloses a new method for using a ketene acetylation method to synthesize high purity acephate raw powder, which includes the following steps: O, O-dimethyl thiophosphoryl is used as raw material; the O, O-dimethyl thiophosphorus is isomerized to prepare O, S-dimethyl thiophosphoryl amine (methamidophos), the ketene and the O, S-dimethyl thiophosphoryl amine is caused to generate acetylation reaction at a proper speed, under the condition of a solvent and a catalyst and the temperature of minus 20 to 50 DEG C, the reaction time is 2 to 8 hours; and acephate raw powder is prepared through the processes of crystallization, solid-liquid separation and drying. The yield rate of the acephate raw powder prepared by the new method is high up to 90 percent (accounted by methamidophos), and the purity is up to 98 percent, without discharging waste liquid and polluting the environment.

Description

Method for preparing acephate from ketene 1. Technical field The invention belongs to the field of pesticides and relates to a method for preparing the pesticide acephate, in particular to a new method for preparing high-purity acephate from ketene. 2. Background technology Acephate is an acetylated derivative of the insecticide methamidophos. It is a good high-efficiency, low-toxicity, and low-residue broad-spectrum insecticide. It is effective against major pests of rice, cotton, vegetables, and fruit trees. It has good control effect and is one of the ideal varieties to replace highly toxic and high residue pesticides. Especially in the current social and economic development, some highly toxic pesticides such as methamidophos, parathion (1605), methyl parathion (methyl 1605), monocrotophos, ammonium phosphate and other five highly toxic pesticides Since January 1, 2007, the use in agriculture has been completely prohibited, and the structural adjustment of the agricul...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C07F9/24

Inventor 郑庚修王秋芬卢言建

Owner UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com