Maleic anhydride plant solvent dehydration drying process and equipment

A technology for drying treatment and solvent is applied in the field of solvent dehydration and drying treatment process and equipment of maleic anhydride plant, which can solve the problems of poor absorption, reduced maleic anhydride yield, difficulty in solvent treatment and increased loss, and achieves reduction of decomposition loss, The effect of reducing the generation of impurities and smooth and long-term operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

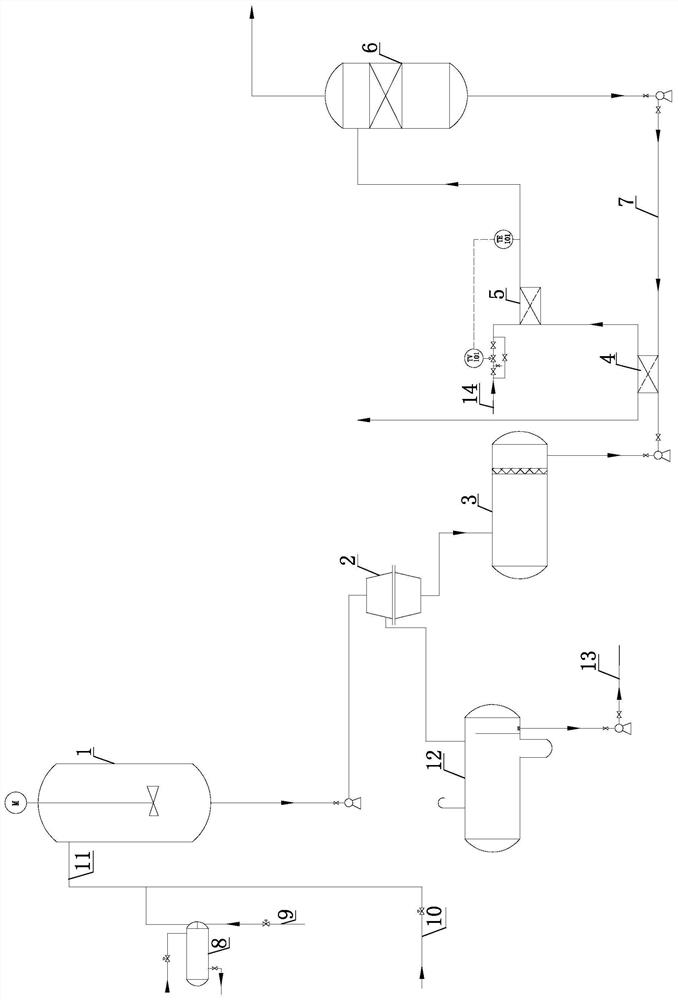

[0047] A solvent dehydration and drying treatment process of a maleic anhydride unit. The desalted water is mixed with an organic solvent and then centrifuged. The obtained organic phase is preheated by a flash tank heat exchanger and heated to 100°C in a flash tank heater, and then enter the solvent flash tank for flash evaporation, so that the water content in the solvent is ≤0.02%, and the obtained dry solvent enters the maleic anhydride absorption tower for recycling.

[0048] in:

[0049] The mixing of desalted water and organic solvent is carried out in a stirring tank, and then centrifuged for centrifugation, wherein: the mixing volume ratio of desalted water and organic solvent is 6:4; desalted water is preheated to 75°C; the stirring time of the stirring tank 30min, the operating temperature of the stirring tank is 68°C; the speed of the centrifuge is 4800r / min.

[0050] The mass flow rate of the solvent phase at the bottom of the centrifuge is 8000kg / h, and the temp...

Embodiment 2

[0065] A maleic anhydride device solvent dehydration drying treatment process, the desalted water is mixed with the organic solvent and then centrifuged, the obtained organic phase is preheated by the flash tank heat exchanger, heated to 95°C in the flash tank heater, and then enter the solvent flash tank for flash evaporation, so that the water content in the solvent is ≤0.02%, and the obtained dry solvent enters the maleic anhydride absorption tower for recycling.

[0066] in:

[0067] The mixing of desalted water and organic solvent is carried out in a stirring tank, and then centrifuged for centrifugation, wherein: the mixing volume ratio of desalted water and organic solvent is 6:4; desalted water is preheated to 70°C; the stirring time of the stirring tank 30min, the operating temperature of the stirring tank is 65°C; the speed of the centrifuge is 4800r / min.

[0068] The mass flow rate of the solvent phase at the bottom of the centrifuge is 8000kg / h, and the temperatur...

Embodiment 3

[0079] A maleic anhydride device solvent dehydration drying treatment process, the desalted water is mixed with the organic solvent and then centrifuged, the obtained organic phase is preheated by the flash tank heat exchanger, heated to 98°C in the flash tank heater, and then enter the solvent flash tank for flash evaporation, so that the water content in the solvent is ≤0.02%, and the obtained dry solvent enters the maleic anhydride absorption tower for recycling.

[0080] in:

[0081] The mixing of desalted water and organic solvent is carried out in a stirring tank, and then centrifuged for centrifugation, wherein: the mixing volume ratio of desalted water and organic solvent is 6:4; desalted water is preheated to 80°C; the stirring time of the stirring tank 30min, the operating temperature of the stirring tank is 70°C; the speed of the centrifuge is 4800r / min.

[0082] The mass flow rate of the solvent phase at the bottom of the centrifuge is 8000kg / h, and the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com