Method for extracting and separating acetyl spermine in acylation reaction liquid

A technique for acetylspermine and acylation reaction, applied in chemical instruments and methods, separation/purification of carboxylic acid amides, separation/purification of carboxylic acid compounds, etc., can solve waste of resources, reduce crystal purity of acephate, and pollution Environmental and other issues, to achieve the effect of reducing waste water production, chemical stability and thermal stability, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

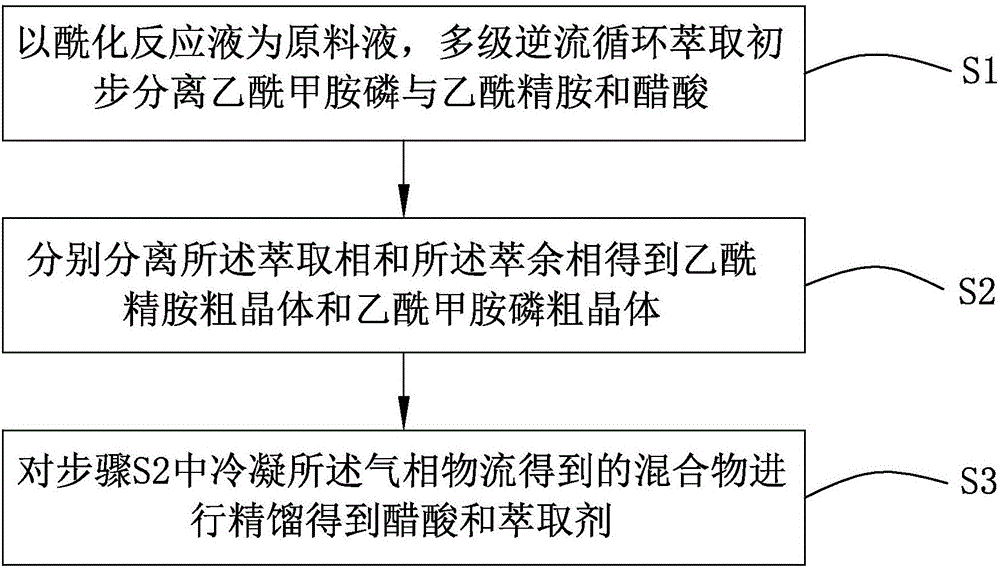

Method used

Image

Examples

Embodiment 1

[0053] Take 150g of acephate content and be 49.57%, acetic acid content is 27.85%, and the acylation reaction solution that acetylspermine content is 5.74% is put into the mixing tank of extraction device, and 150g petroleum ether extractant is carried out 5 grades of countercurrent extraction experiments After extraction, 186.6 g of the upper extract phase and 97.4 g of the lower raffinate phase were obtained. Through liquid chromatography analysis, the mass percentages of the upper layer of the extract phase are respectively 13.03% of acephate, 16.60% of acetic acid, and 3.08% of acetylspermine, and the mass percentages of the lower raffinate phase are respectively 51.14% of acephate and 10.92% of acetic acid. %, acetylspermine 2.97%. Compared with acephate, the selectivity coefficient of acetic acid was calculated to be 5.97, and the selectivity coefficient of acetylspermine to be 4.07. The total recovery rate was 94.67%. Put the extract phase in a rotary evaporator with ...

Embodiment 2

[0055] Getting 150g acephate content is 53.40%, and acetic acid content is 31.72%, and the acylation reaction liquid that acetylspermine content is 5.86% is put into the mixing tank of extraction device, carries out 5 grades of countercurrent extraction experiments with 150g toluene extractant, After extraction, 176.3 g of the upper extract phase and 104.6 g of the lower raffinate phase were obtained. Through liquid chromatography analysis, the mass percentages of the upper layer extract phase are respectively 13.15% of acephate, 18.76% of acetic acid, and 4.07% of acetylspermine, and the mass percentages of the lower raffinate phase are respectively 54.36% of acephate and 13.41% of acetic acid. %, acetylspermine 1.62%. Compared with acephate, the selectivity coefficient of acetic acid is 5.78, the selectivity coefficient of acetylspermine is 10.39, and the total recovery rate is 93.63%. Put the extraction phase in a rotary evaporator with a rotating speed of 70rmp, and disti...

Embodiment 3

[0057] Get 150g of acephate content and be 49.68%, acetic acid content is 34.24%, and the acylation reaction solution that acetyspermine content is 5.32% is put into the mixing tank of extraction device, carries out 5 grades of countercurrent continuous extractions with 150g xylene extractant In the experiment, 180.1 g of the upper extract phase and 106.7 g of the lower raffinate phase were obtained after extraction. Through liquid chromatography analysis, the mass percentages of the upper layer of the extract phase are respectively 8.76% of acephate, 20.12% of acetic acid, and 3.41% of acetylspermine, and the mass percentages of the lower raffinate phase are respectively 54.84% of acephate and 14.15% of acetic acid. %, acetylspermine 1.08%. Compared with acephate, the selectivity coefficient of acetic acid is 8.30, the selectivity coefficient of acetylspermine is 12.11, and the total recovery rate is 95.6%. Put the extract phase in a rotary evaporator with a rotating speed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com