Cu-Ti2SnC self-lubricating conductive coating and preparation method thereof

A technology of tin carbide and titanium, conductive coating, applied in the direction of coating, metal material coating process, fusion spraying, etc., can solve the problem that it is difficult to meet the requirements and limitations of sliding electrical contact performance, pure copper room temperature strength and high temperature strength and hardness Insufficient and other problems, to achieve the effect of less oxide content and unmelted particles, low porosity, and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

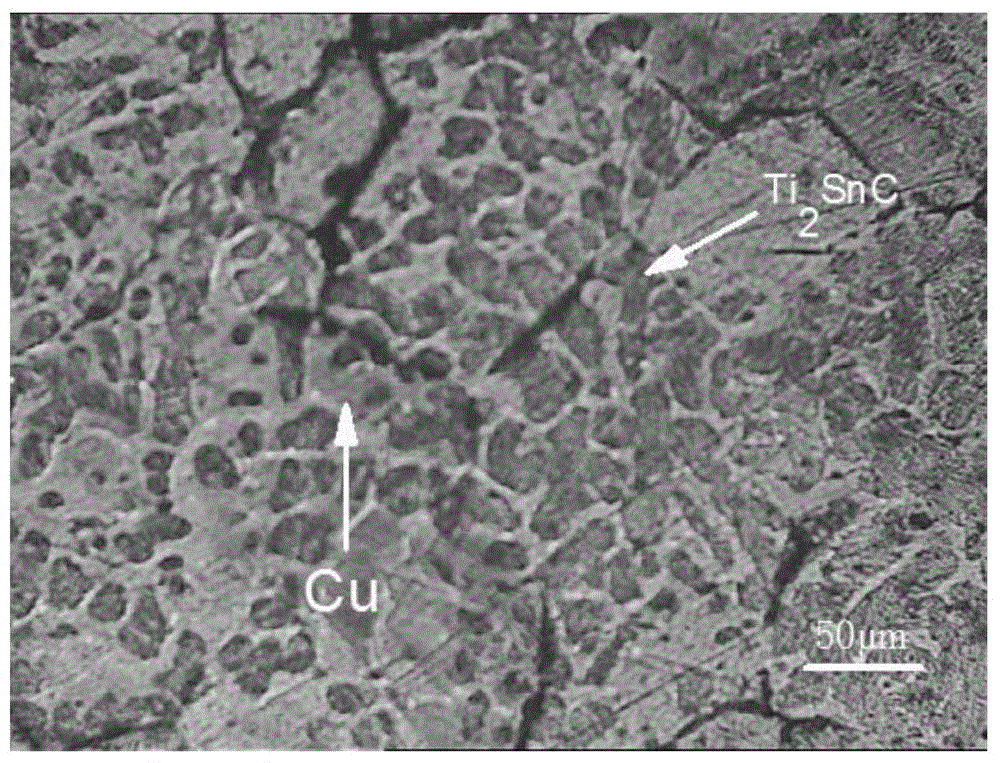

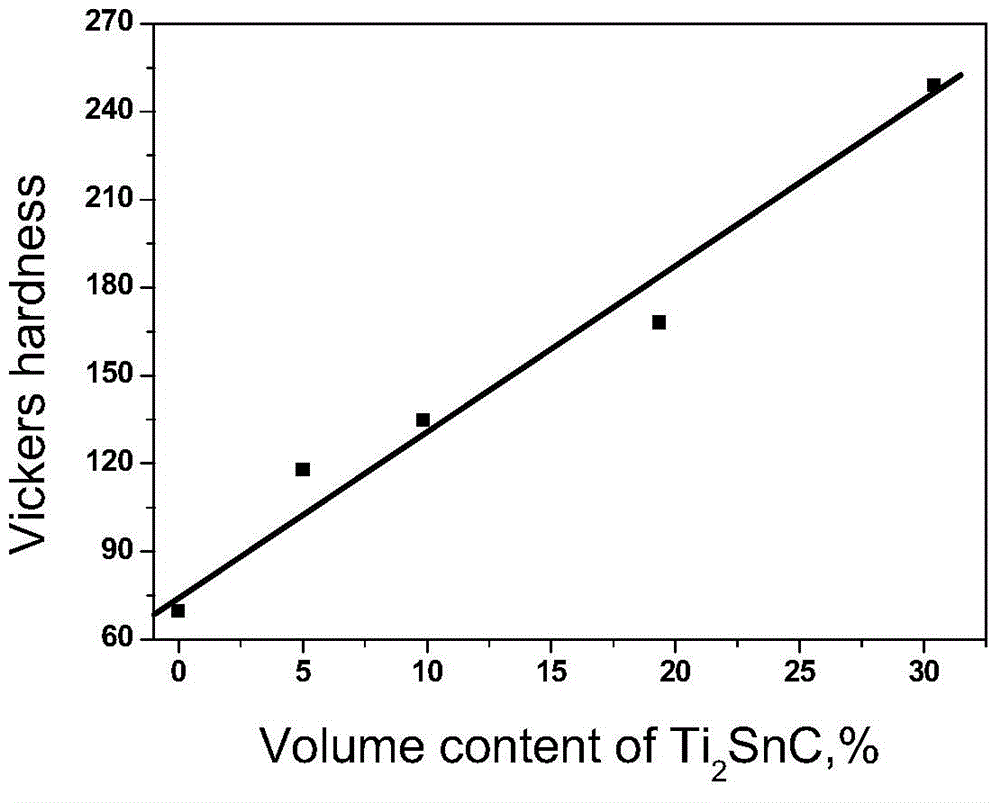

Embodiment 1

[0034] Tin carbide titanium powder is selected as the base material, high-purity copper sulfate is used as the main salt, high-purity zinc powder is used as the reducing agent, and soft water is used as the solvent. Copper-coated carbonization is obtained by plating copper on the surface of tin carbide titanium particles by chemical replacement. Tin titanium powder material.

[0035] Pure copper powder (average particle size 50μm) and copper-coated tin carbide titanium powder (average particle size 30μm) are mass Cu:Ti 2 SnC=90:10 batching and wet grinding mixing in absolute ethanol medium. The grinding medium is agate ball, the ball milling speed is 120r / min, and the mixing time is 30h;

[0036] The powder obtained after ball milling is mixed with polyvinyl alcohol solution (PVA) as a binder, and then granulated by agglomeration method, and sieved to obtain a powder that meets the spraying requirements. The average particle size of the selected powder is 75 μm;

[0037] CH...

Embodiment 2

[0044] Prepare copper-coated tin carbide titanium powder (average particle size 50 μm, the preparation method is the same as Example 1). Pure copper powder (average particle size 25μm) and copper-coated tin carbide titanium powder are mass Cu:Ti 2 SnC = 80:20 ingredients were wet milled in absolute ethanol medium. The grinding medium is agate ball, the ball milling speed is 100r / min, and the mixing time is 36h;

[0045] The powder obtained after ball milling is mixed with polyvinyl alcohol solution (PVA) as a binder, and then granulated by agglomeration method, and sieved to obtain a powder that meets the spraying requirements. The average particle size of the selected powder is 50 μm;

[0046] CH-2000 HVOF spraying equipment is used for spraying, propane is used as fuel gas, high-pressure oxygen is used as combustion-supporting gas, and nitrogen is used as powder delivery gas. When spraying, the propane pressure is 0.60MPa, the oxygen pressure is 0.68MPa, and the nitrogen ...

Embodiment 3

[0052] Prepare copper-coated tin carbide titanium powder (average particle size 80 μm, the preparation method is the same as Example 1). Pure copper powder (average particle size 10μm) and copper-coated tin carbide titanium powder are mass Cu:Ti 2 SnC=70:30 ingredients were mixed with wet milling in absolute ethanol medium. The grinding medium is agate ball, the ball milling speed is 150r / min, and the mixing time is 36h;

[0053] The powder obtained after ball milling is mixed with polyvinyl alcohol solution (PVA) as a binder, and then granulated by agglomeration method, and sieved to obtain a powder that meets the spraying requirements. The average particle size of the selected powder is 100 μm;

[0054] CH-2000 HVOF spraying equipment is used for spraying, propane is used as fuel gas, high-pressure oxygen is used as combustion-supporting gas, and nitrogen is used as powder delivery gas. When spraying, the propane pressure is 0.60MPa, the oxygen pressure is 0.68MPa, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com