Method for purifying 1, 4-dihydroxy anthraquinone by sublimation under high vacuum

A dihydroxyanthraquinone and high-vacuum technology, which is used in the purification of pharmaceutical intermediates and dyes, can solve the problems of long sublimation time, energy waste, and exposed heating surface, and achieve no secondary pollution, high product purity, and exhaust rate big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Raw material selection in this example: industrial grade 1, 4-dihydroxyanthraquinone; production unit: Jiangsu Yabang; purity: 94%, moisture: ≤1%, appearance brick red; testing unit: Jiangsu Yabang; feeding Jiangsu Yabang 2015-6-25 batch; feeding quality 400Kg;

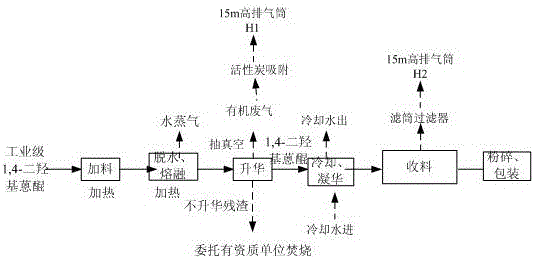

[0044] Such as figure 1 Shown, the method for high vacuum sublimation purification 1,4-dihydroxyanthraquinone is prepared as follows:

[0045] Step 1) Feeding: put industrial grade 1, 4-dihydroxyanthraquinone into the trough, after compacting and scraping, put it into the sublimation tube of 10 or 12 parallel honeycomb sublimators;

[0046] The parallel honeycomb sublimator refers to the vacuum system on the adjacent honeycomb sublimator, and the heating system and the cooling system are arranged in parallel;

[0047] Step 2) Dehydration and melting: heat the industrial grade 1, 4-dihydroxyanthraquinone in the sublimation tube under non-vacuum conditions, turn on the heating system, control the temperature at...

Embodiment 2

[0059] The method for purifying 1, 4-dihydroxyanthraquinone by high vacuum sublimation, and the used honeycomb sublimator;

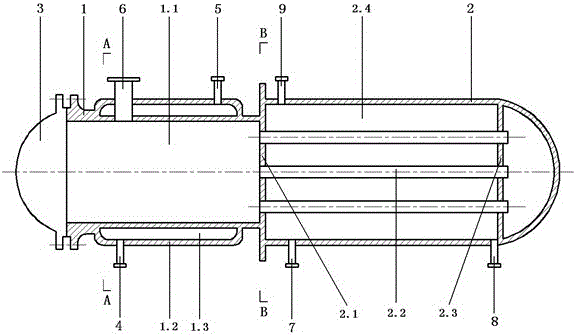

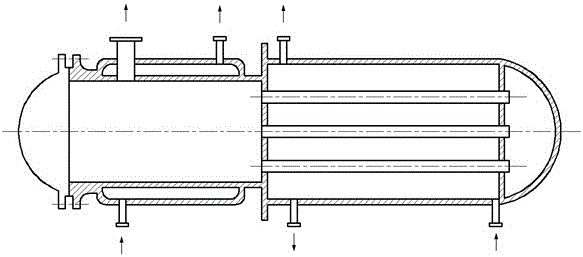

[0060] Such as figure 2 , image 3 , Figure 4 and Figure 5 As shown, the honeycomb sublimator includes a crystallization tank body 1, a heating tank body 2, a tank cover 3, a tube plate 2.1, a sublimation tube 2.2, a support plate 2.3 and a trough; in the crystallization tank body 1 A crystallization chamber 1.1 is provided; a heating chamber 2.4 is provided in the heating tank body 2; one end of the crystallization tank body 1 is connected to the non-closed end of the heating tank body 2 through a tube plate 2.1; the crystallization tank body 1 is another One end is hinged with the tank cover 3; the tube plate 2.1 is provided with a honeycomb through hole; the heating chamber 2.4 is provided with a support plate 2.3; the support plate 2.3 is provided with a honeycomb through hole with the tube plate 2.1 Corresponding through holes; the sublimatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com