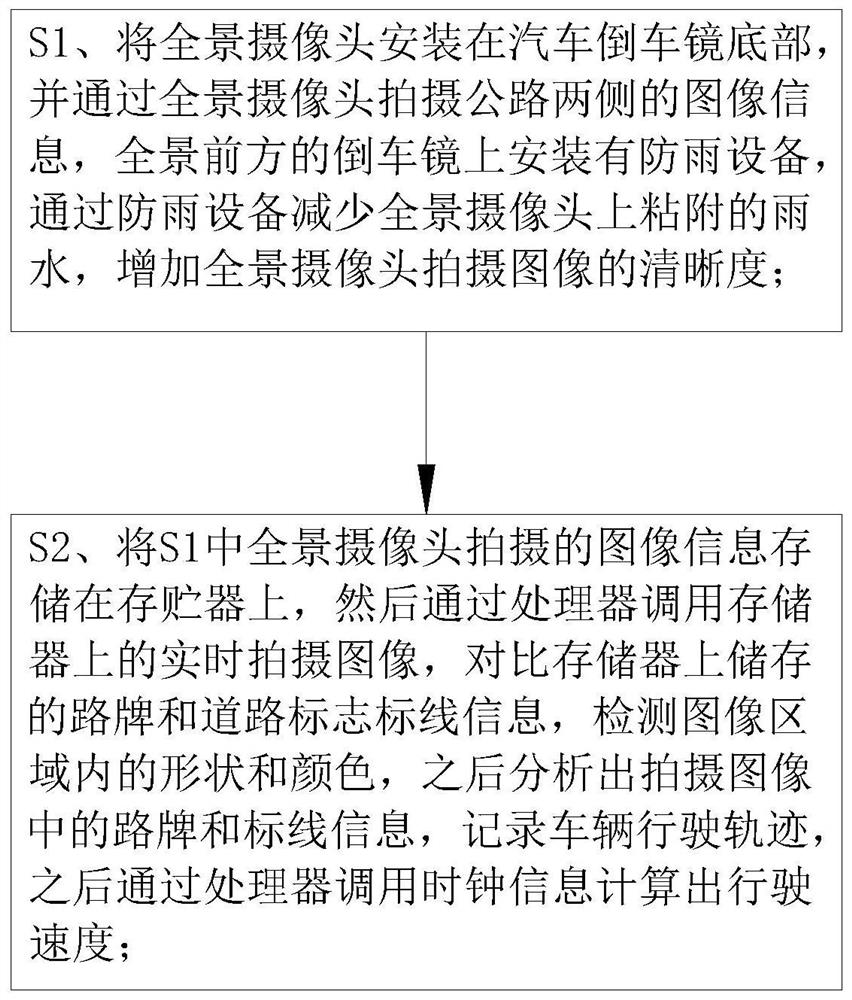

Patents

Literature

34results about How to "Guaranteed dehydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

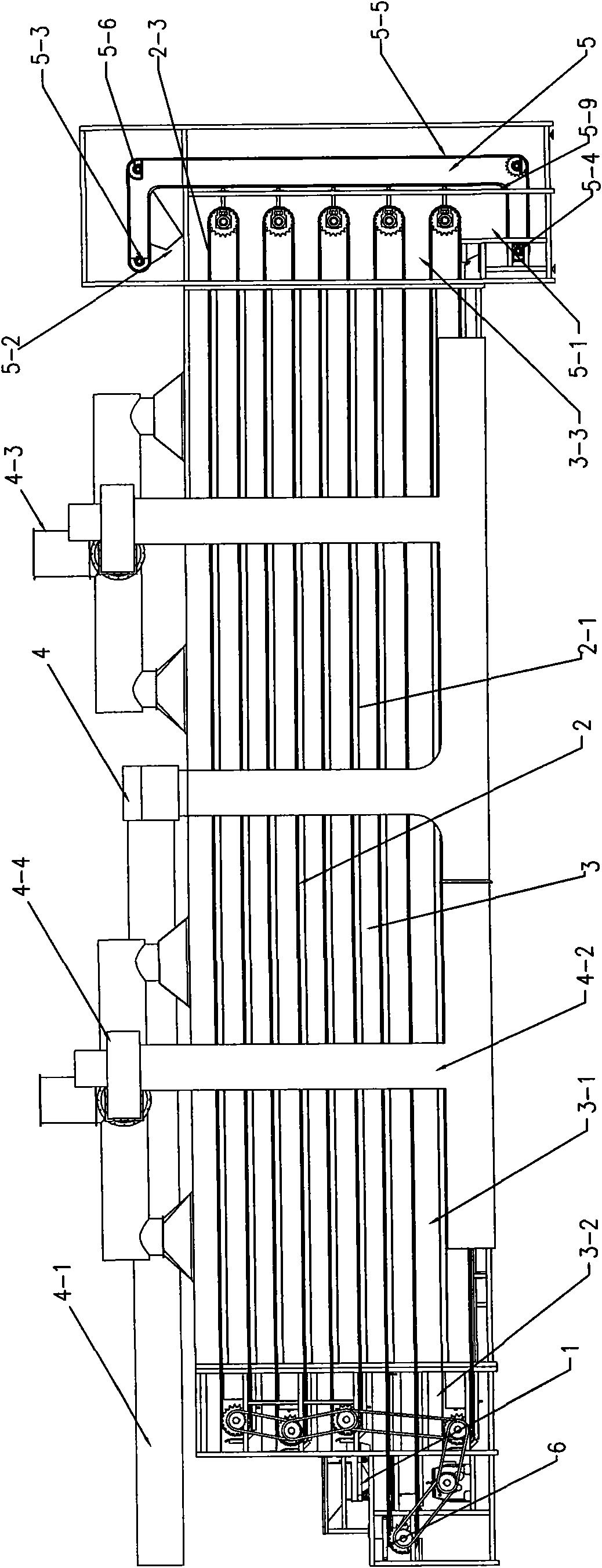

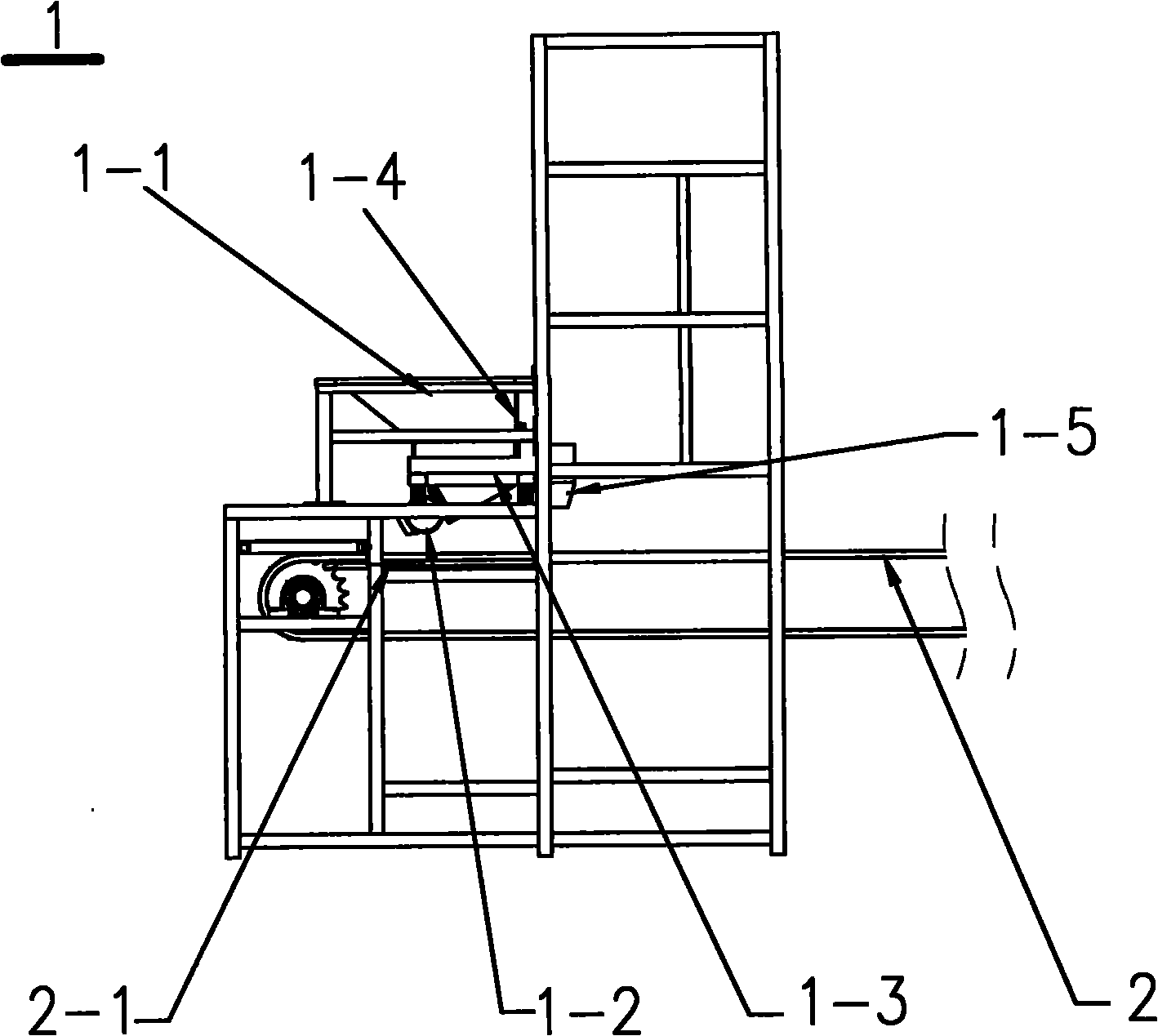

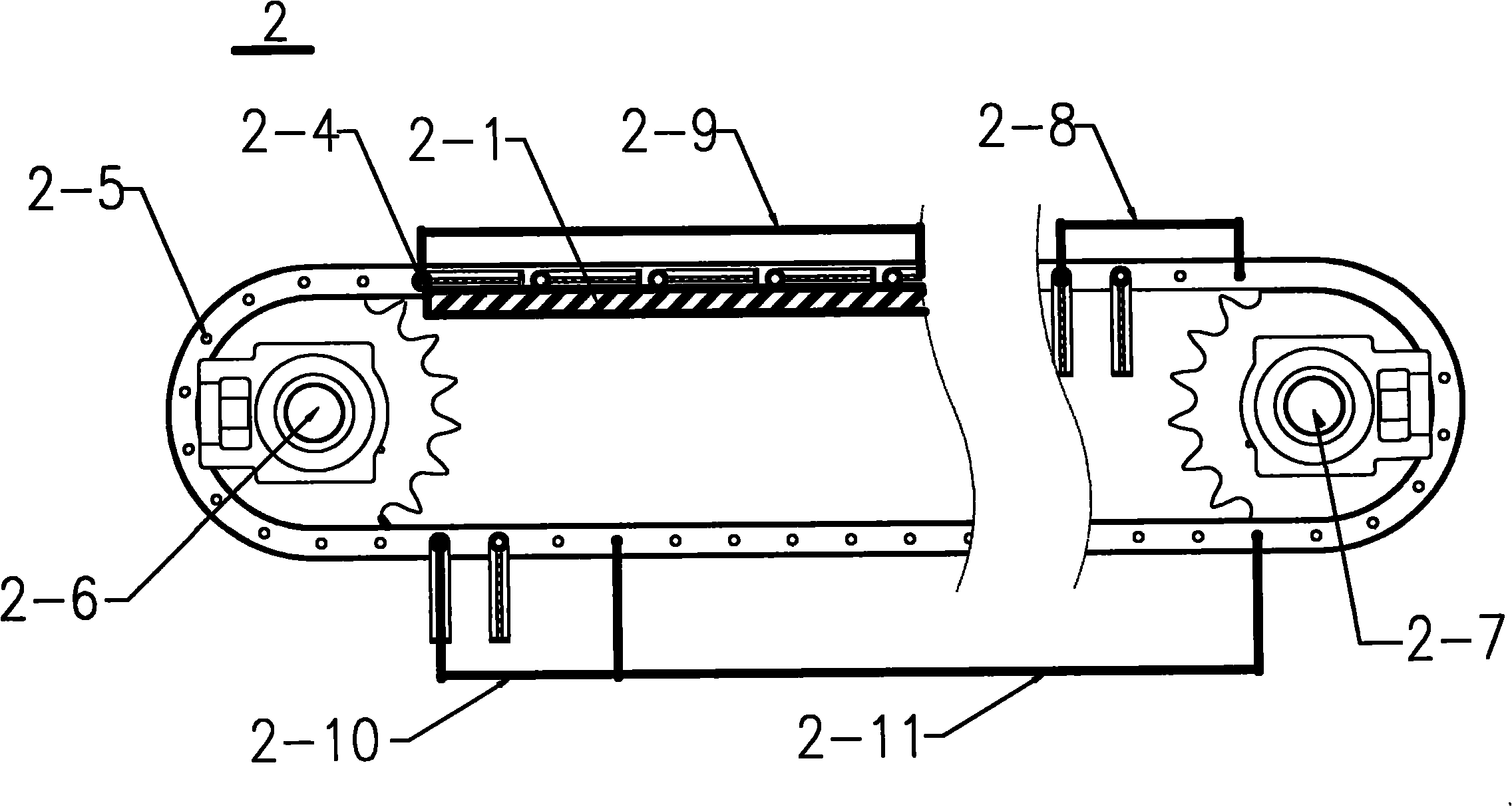

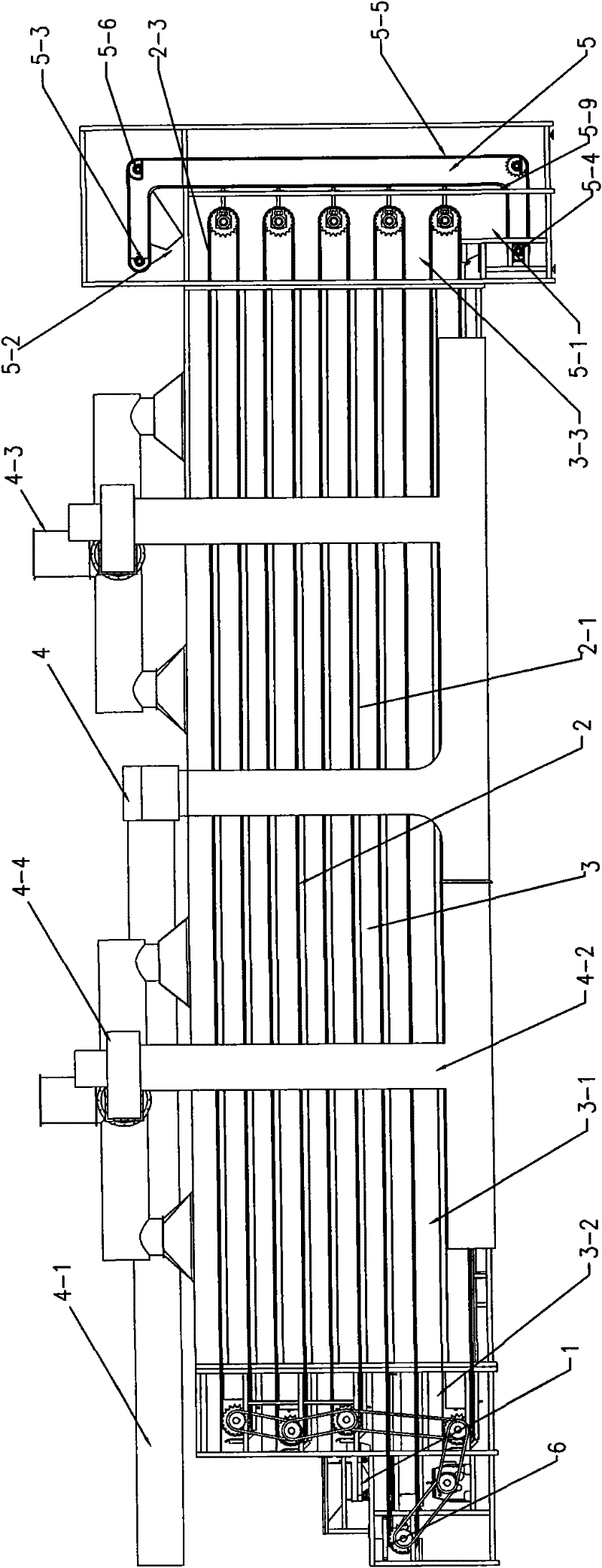

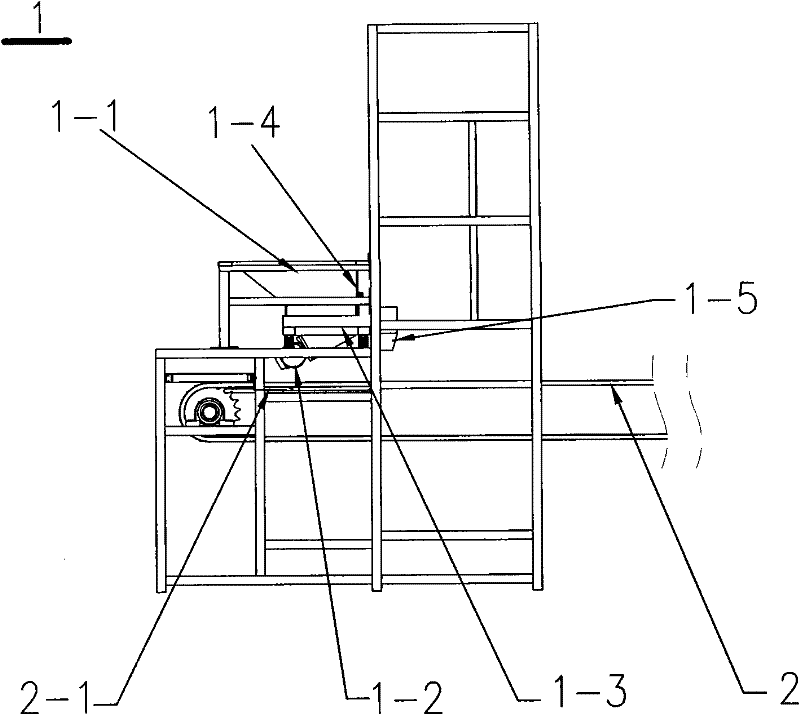

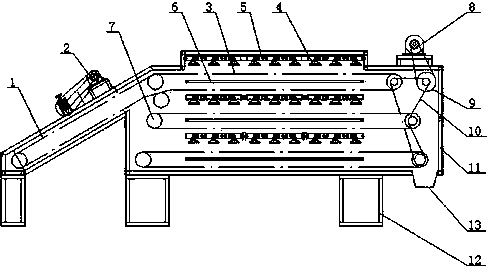

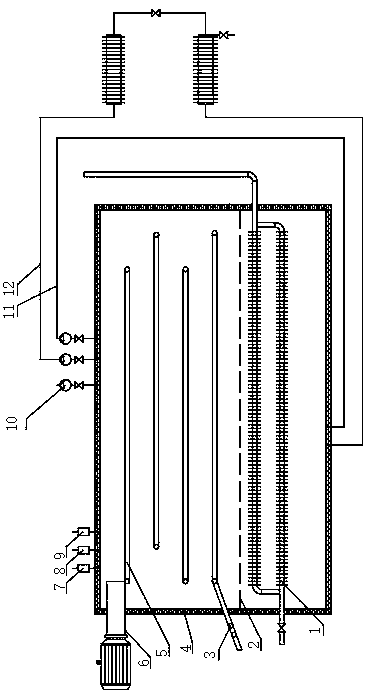

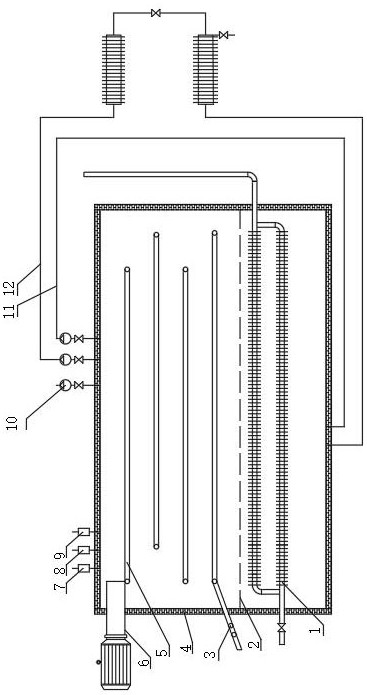

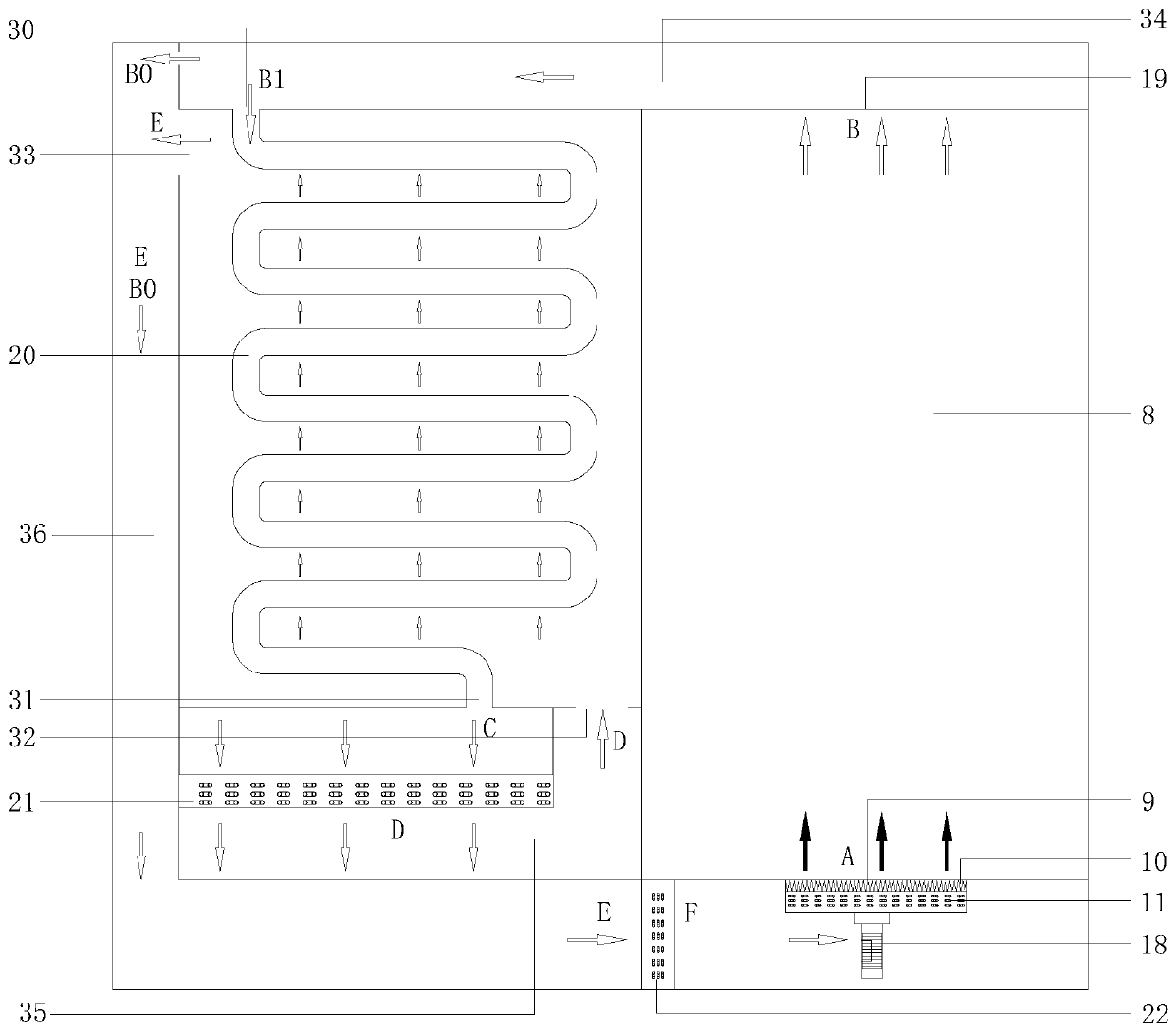

Self-circulation multi-layer slat dryer and self-circulation segmented drying method

ActiveCN101972032AGuaranteed dehydrationQuality assuranceFood treatmentFruits/vegetable preservation by dehydrationCyclic processControl system

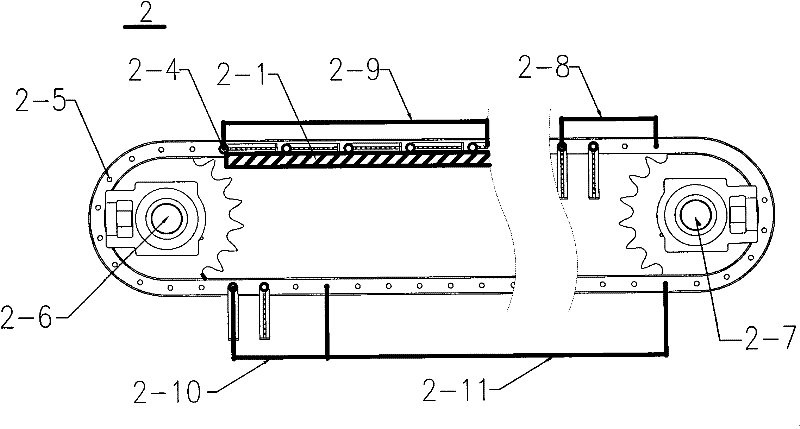

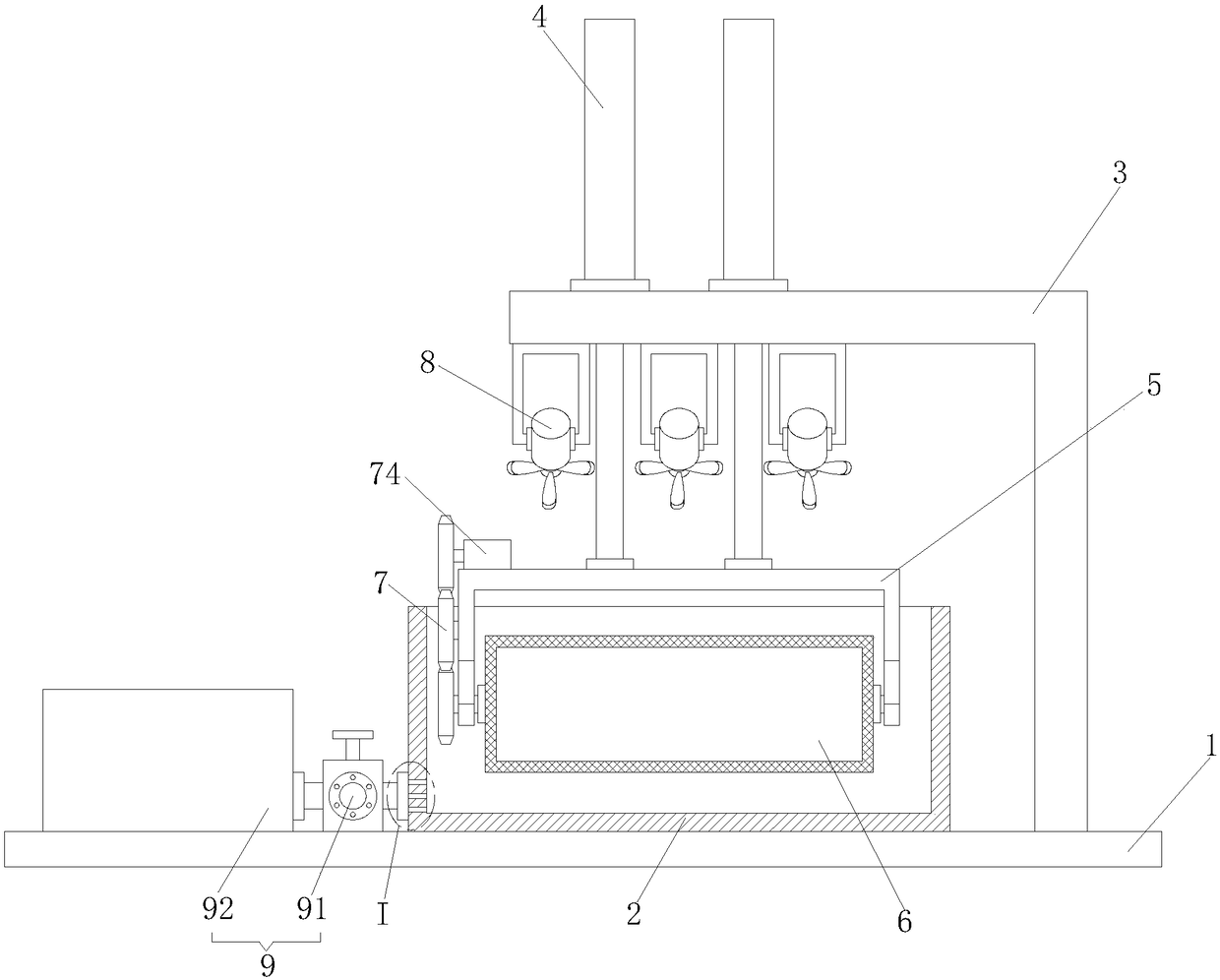

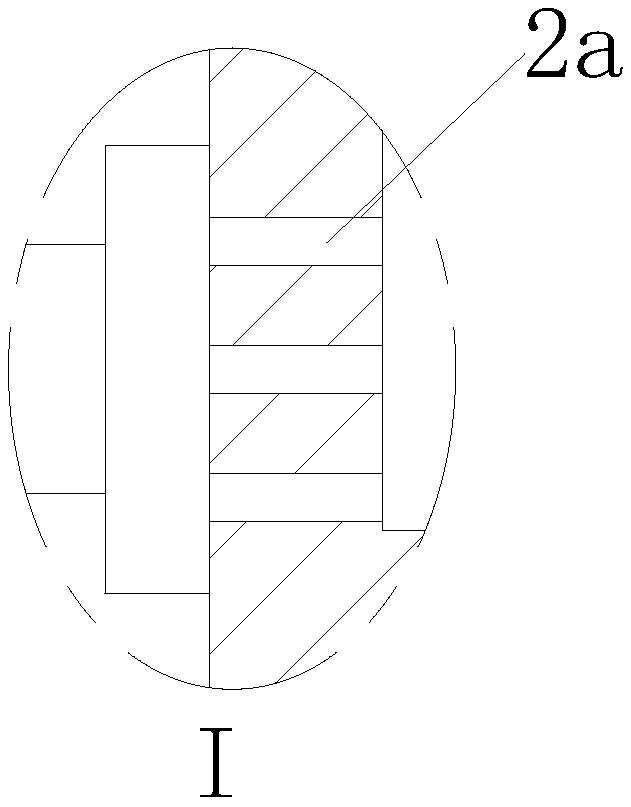

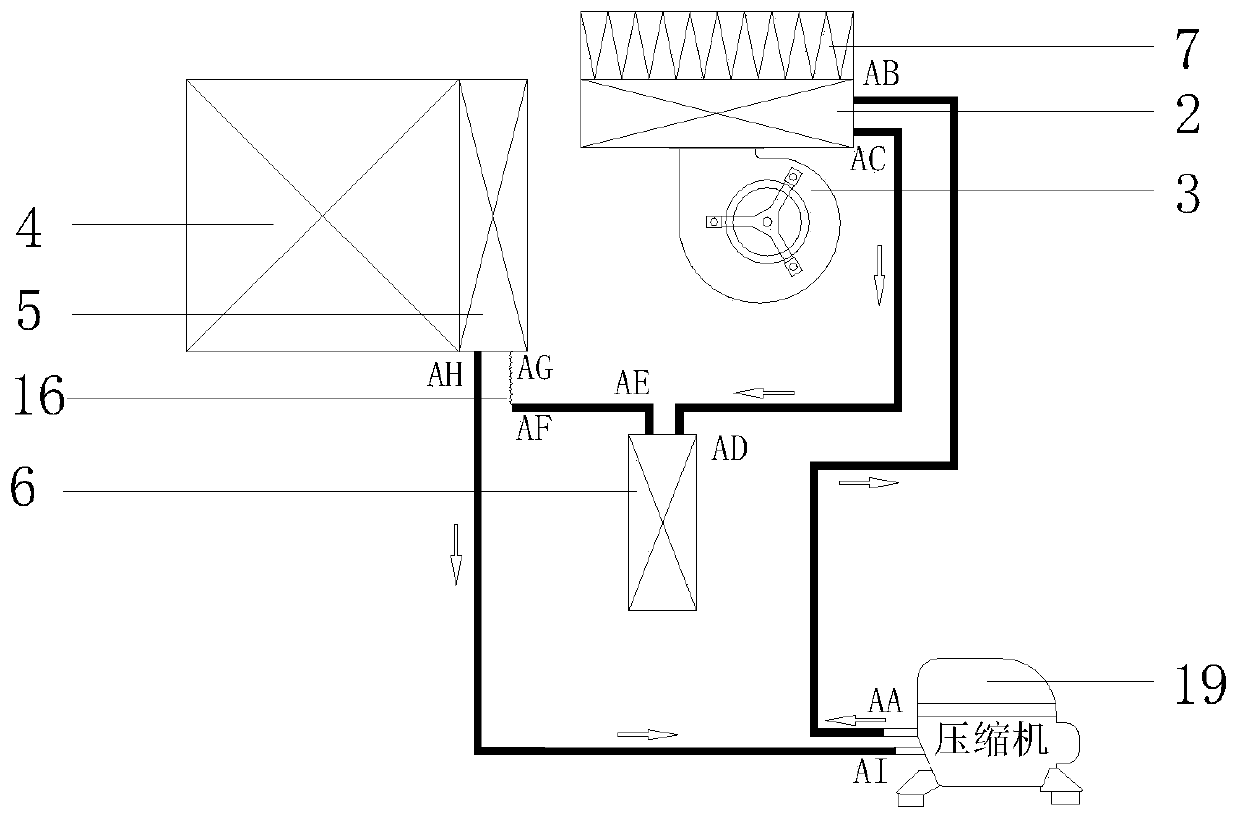

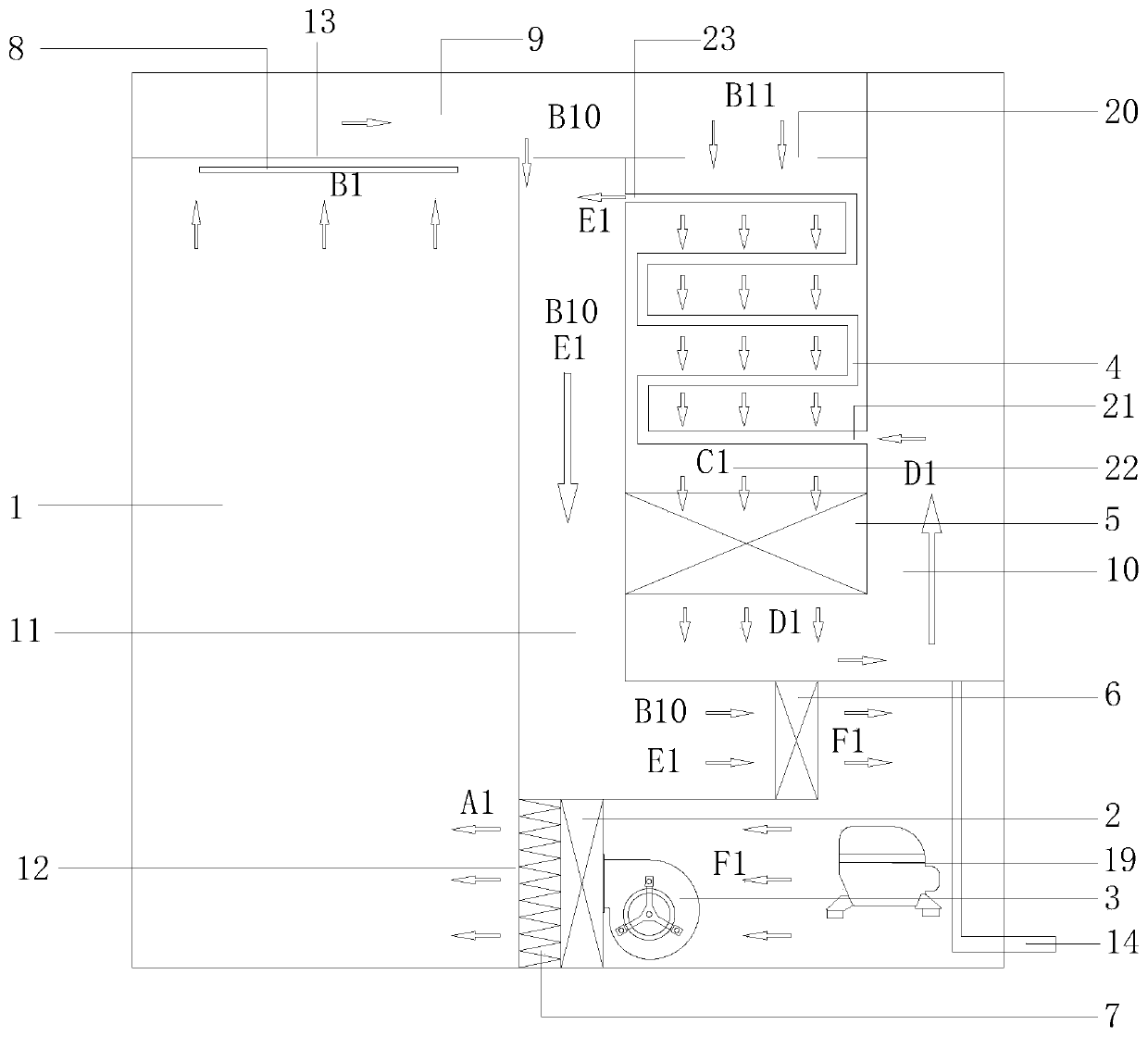

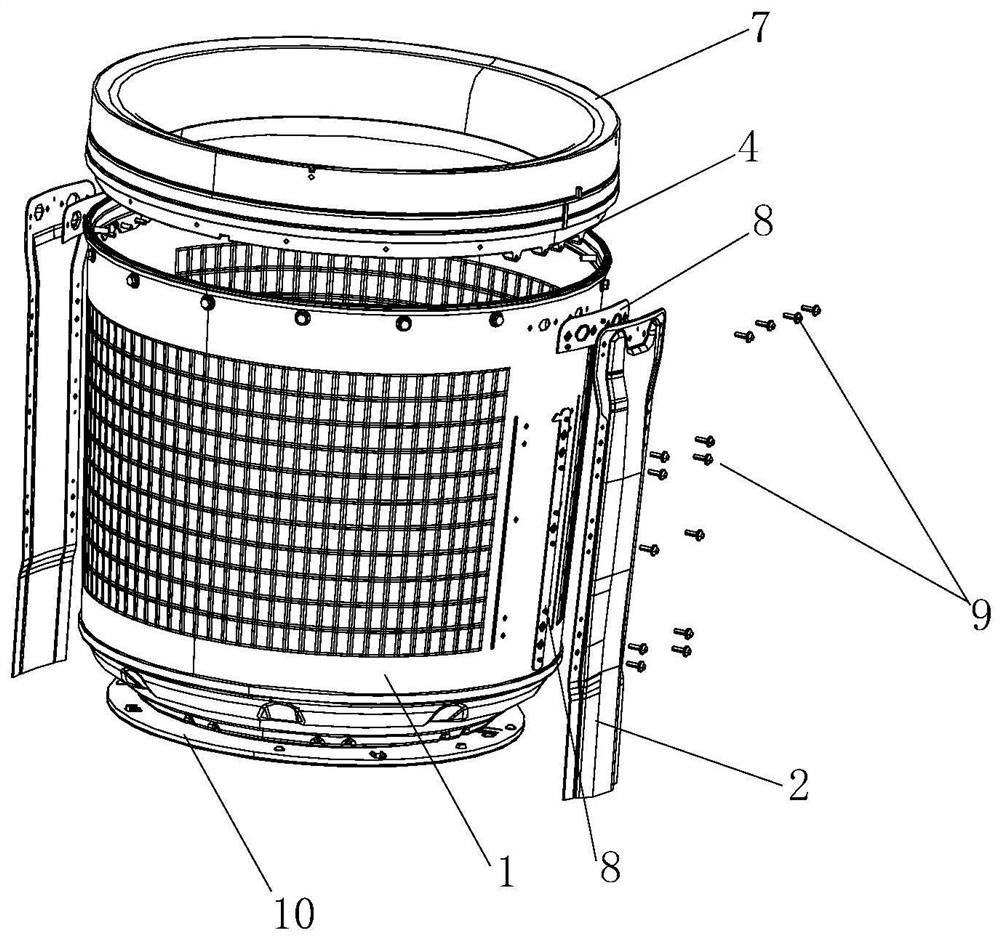

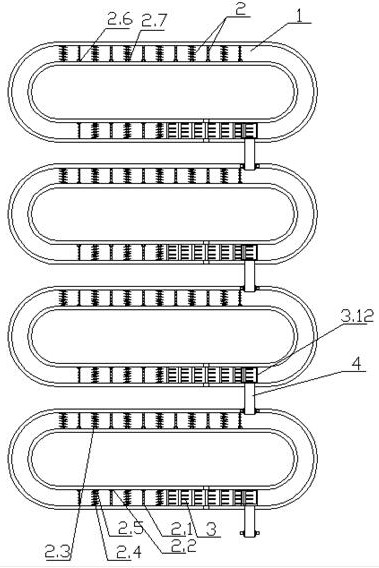

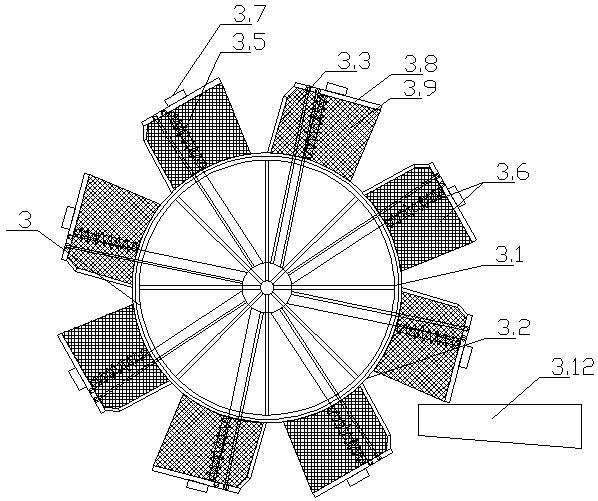

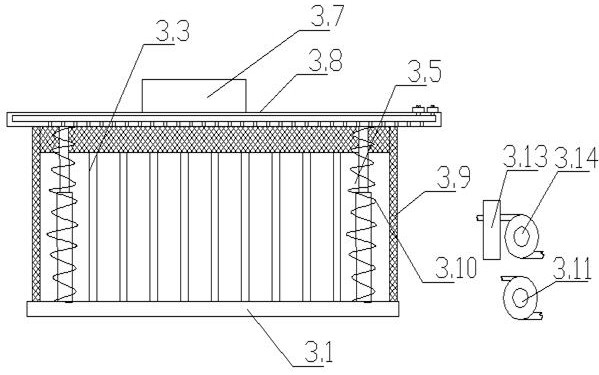

The invention discloses a self-circulation multi-layer slat dryer, which comprises a feeding and discharge device (1), a drying chamber (3) and a wind network system (4), wherein the wind network system (4) is used for supplying hot wind to the drying chamber (3) to heat materials. The self-circulation multi-layer slat dryer is characterized by further comprising a multi-layer flat conveyor device (2), a lifter (5) and a control system for controlling the dryer. In addition, the invention also discloses a self-circulation segmented drying method. The self-circulation multi-layer slat dryer and the self-circulation stepwise drying method have the advantages of realizing segmented temperature and humidity control, ensuring dehydration is performed according to the laws of a baking curve in a material drying process, ensuring the quality of dried products, ensuring the materials are uniformly heated because the multi-layer slat conveyor device is used in combination with the lifter to function in turning the materials over in the self-circulation process of the materials, meeting the materials of different characteristics, setting the temperature, humidity and time of each segment according to the characteristics of the materials and realizing discharge at any time, along with wide application range, high drying quality and capability of realizing automatic production.

Owner:扬州福尔喜果蔬汁机械有限公司

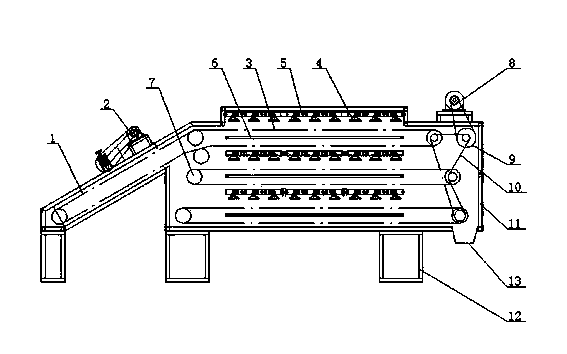

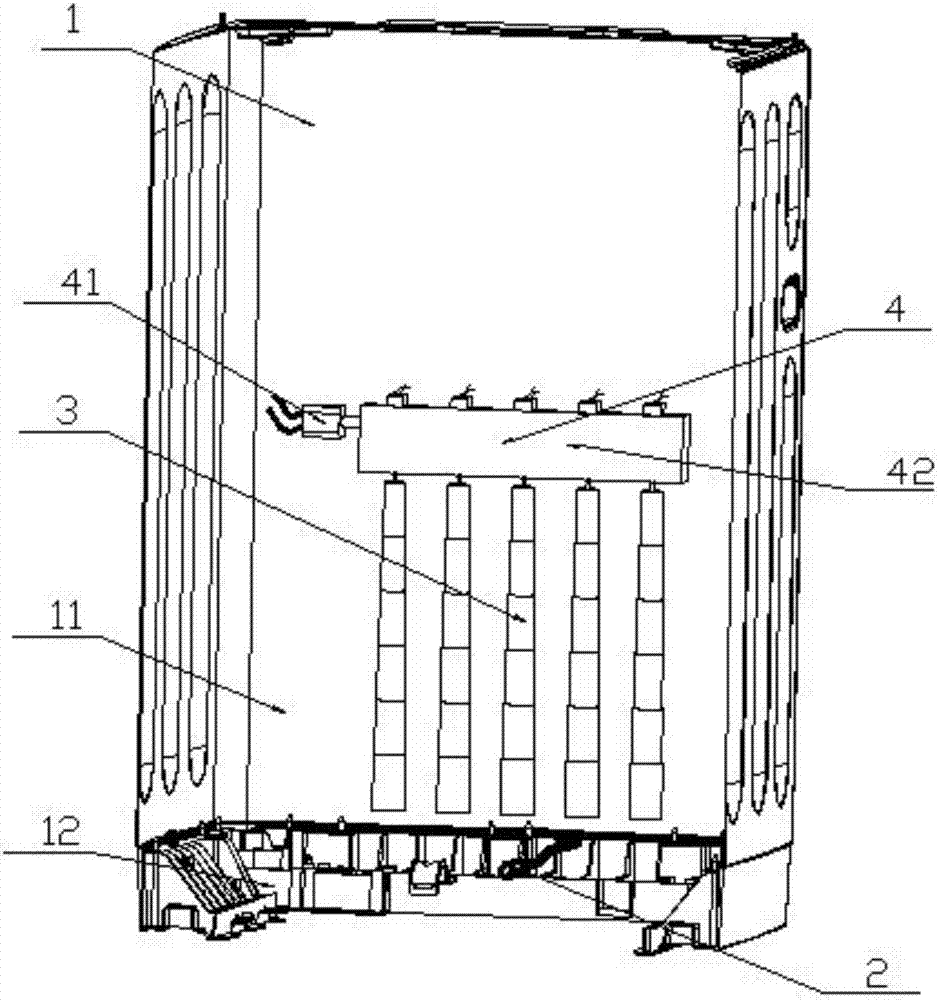

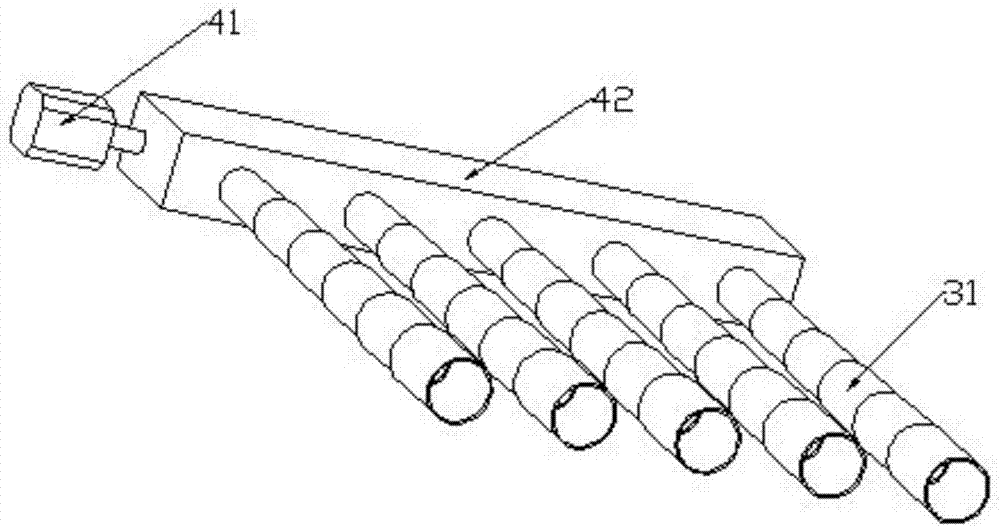

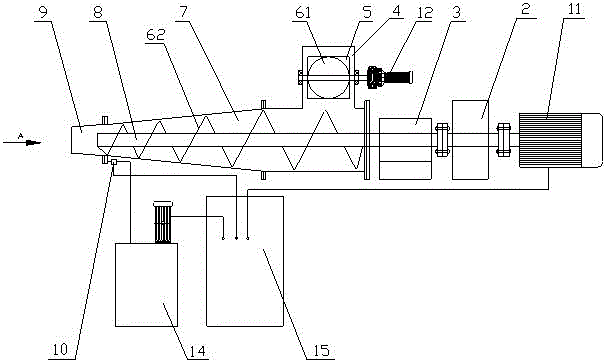

Infrared radiation static dryer

ActiveCN103478308AGuaranteed dehydrationGuaranteed colorPre-extraction tea treatmentDrying solid materials with heatInfraredPulp and paper industry

The invention relates to an infrared radiation static dryer. The infrared radiation static dryer comprises a rack and a driving device, wherein the rack is provided with a plurality of layers of staggered convey net belts, the separated convey net belts drive in opposite directions, the driving device drives the convey net belts to transmit, the inlet of the dryer is opposite to the front end of the first layer of convey net belt and is connected with a feed convey net belt, the feed convey net belt is provided with an even leaf mechanism, infrared radiation heating devices are arranged above the work surfaces of the convey net belts and are installed on a fixed plate, and the heating devices are uniformly arranged in the transverse and longitudinal directions of the convey net belts. The infrared radiation static dryer adopts infrared radiation static drying and adopts a plurality of layers of staggered convey net belts, the infrared radiation heating devices are arranged above the work surfaces of the convey net belts, so that tea leaves are dried at consistent temperature, are guaranteed to be dehydrated and have color and luster, and are not easy to break, and part of the fragrance is not brought away.

Owner:ZHEJIANG ZHUFENG MACHINERY +1

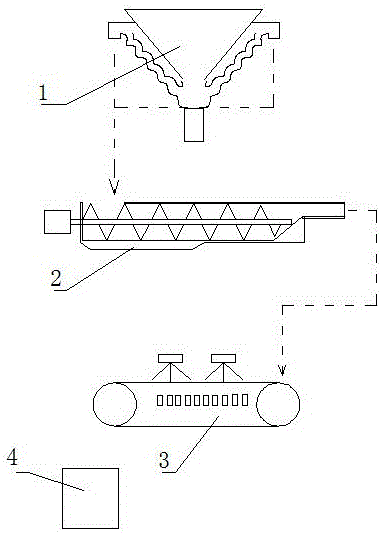

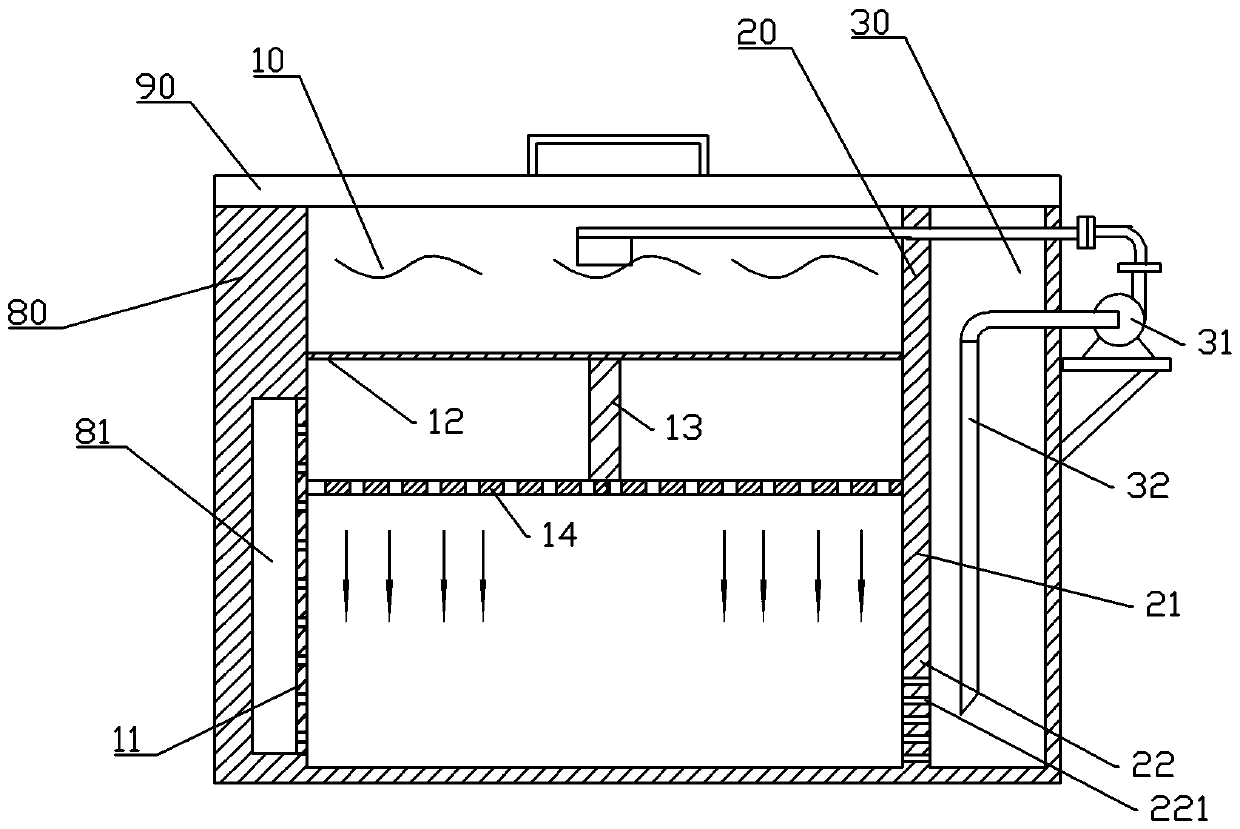

Fecal sewage treatment device

InactiveCN106219642AAchieving Security AvailabilityEasy to makeWater/sewage treatment by centrifugal separationSludge treatment by de-watering/drying/thickeningMiniaturizationEngineering

The invention relates to the field of sewage treatment, in particular to a fecal sewage treatment device. The fecal sewage treatment device comprises a filtering mechanism, a dehydration mechanism, a drying mechanism and a collecting mechanism, wherein a discharging port of the filtering mechanism is opposite to a feeding port of the dehydration mechanism, the filtering mechanism is used for centrifugal filtration of fecal residues, a discharging port of the dehydration mechanism for fecal residue dehydration is opposite to the drying mechanism, and the collecting mechanism is used for collecting dried fecal residues. The fecal residues and other granular yellow impurities in sewage are filtered to achieve the steps of dehydration,oven drying, drying and collection of faeces. Dehydration can be ensured, faeces recovery can be achieved, environmental safety can be ensured, and the device can be effectively ensured. The device is simple in structure and convenient to use, can be manufactured in a miniaturized or enlarged mode and has good universality, it can be ensured that the device facilitates conversion from faeces to fertilizers or biofuel and can further save energy and reduce consumption, and anti-microbial and sterilizing effects can be ensured and the sterilization efficiency can be improved by adopting the chlorine gas pressure design on the premise that device cost improvement is avoided.

Owner:成都测迪森生物科技有限公司

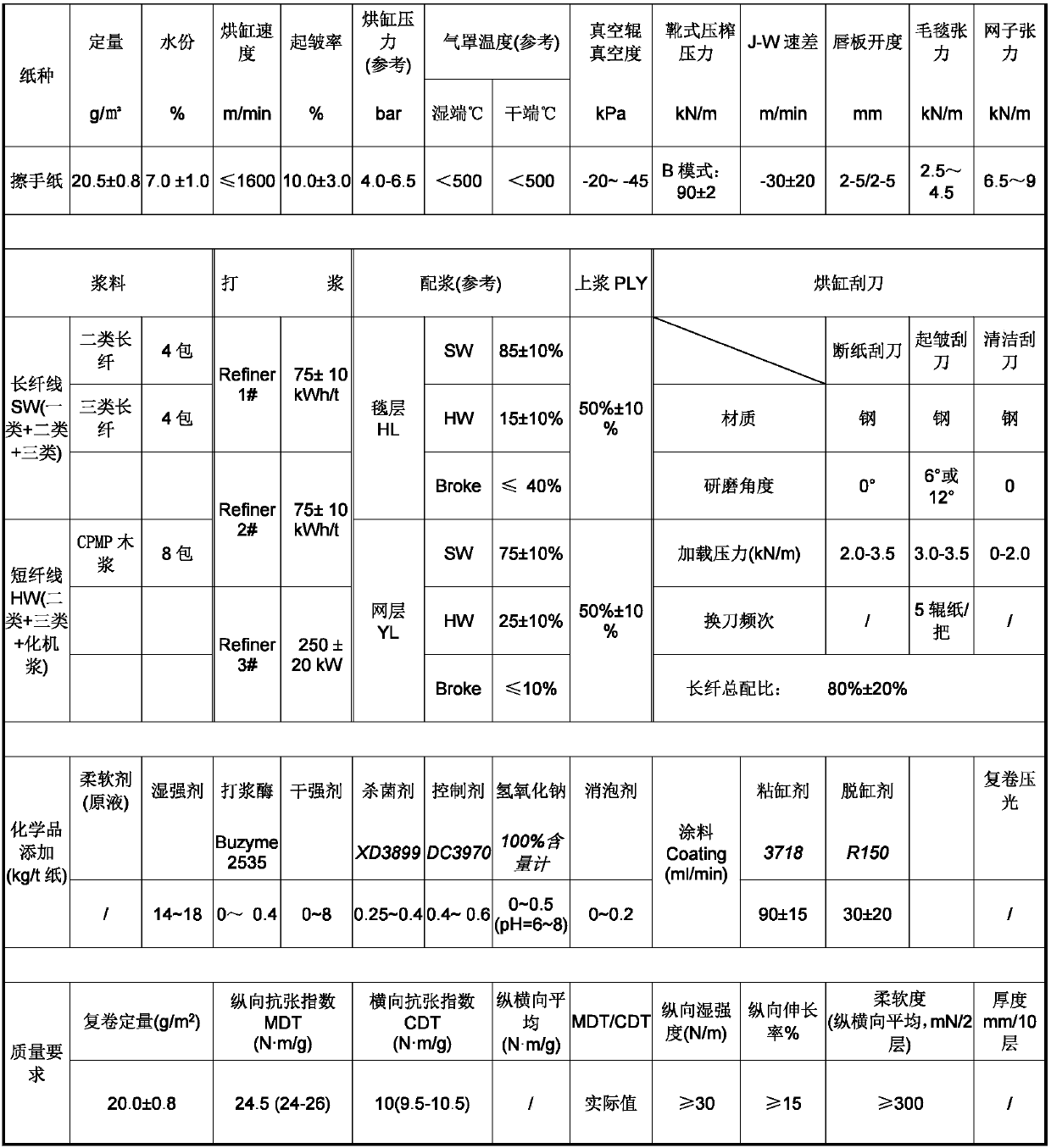

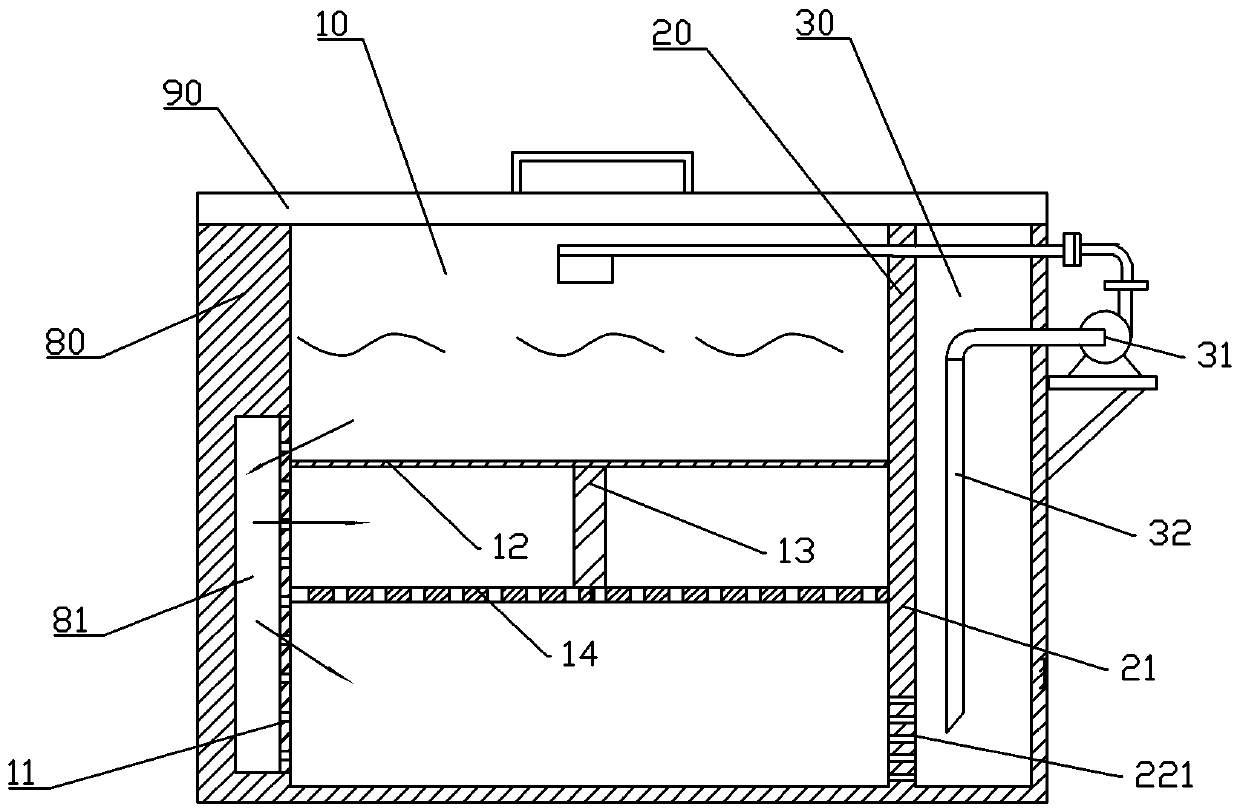

Sterile tissue and production process thereof

ActiveCN107663805AReduce porosityIncrease liquid absorptionSpecial paperPaper/cardboardFungicideSulfate

The invention discloses a sterile tissue and a production process thereof, and belongs to the technical field of tissue production. The tissue is prepared from, by weight, 20-60% of bleached sulfate softwood pulp, 30-70% of CPMP and 0-10% of broken paper pulp. According to the method, by adopting an appropriate principle and ratio, wet strength agents with low organic chlorine, biodegradable non-toxic fungicides and FDA-authenticated coatings, adopting forming equipment with a low vertical-horizontal tension ratio, a drying and sterilization process at the temperature higher than 40 DEG C andsafe non-toxic chemicals, and combining appropriate pressing printing processes, the produced tissue has the advantages of being low in quantification, low in vertical-horizontal tension ratio, sterile, environmentally friendly and high in water absorption performance.

Owner:SHANDONG HENGAN PAPER IND CO LTD

Noise reduction system and method of washing machine and washing machine

PendingCN106988085AAccurate Noise CancellationImprove noise reductionOther washing machinesSound producing devicesProcess moduleEngineering

The invention discloses a noise reduction system and method of a washing machine and the washing machine. The noise reduction system of the washing machine includes a noise collecting module, a noise processing module, a noise elimination module and a control module, wherein the noise processing module processes collected noise signals to obtain the frequency of at least one main noise, the noise elimination module includes at least one length-adjustable long pipe and eliminates the noise caused by the main noise, and the control module adjusts the length of the long pipe. The noise reduction system accurately eliminates the main noise different in frequency, especially in the dewatering stage of the washing machine, and the noise reduction effect is obvious; the noise is reduced without changing existing operation of the washing machine, the noise reduction system is not easily blocked so as to achieve the effect of noise reduction, and the noise reduction effect is obvious; the whole structure is simple, the reliability is high, and operation and maintenance are convenient.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

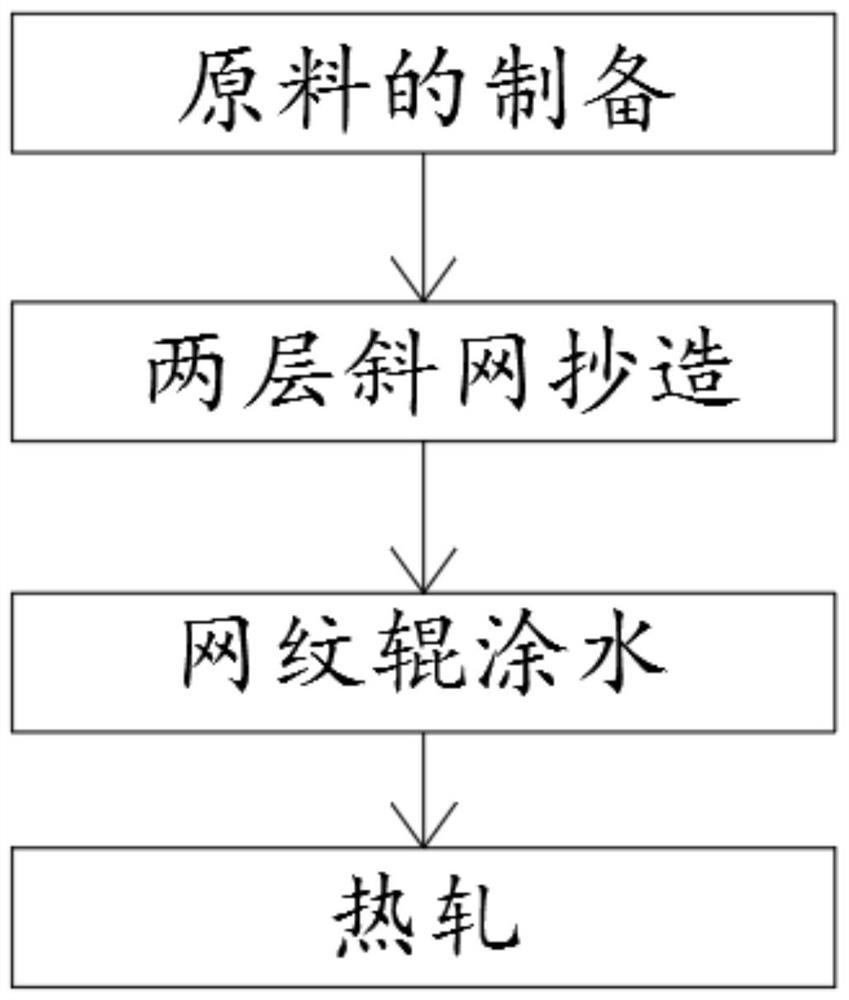

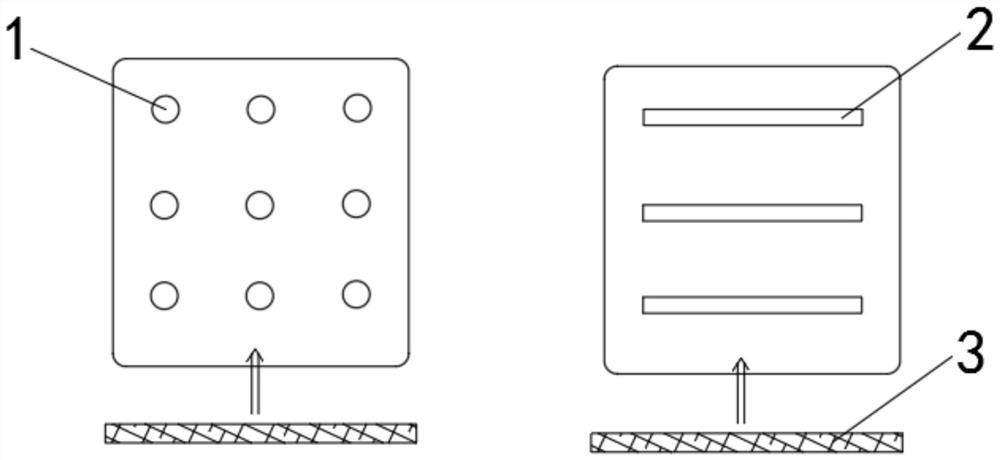

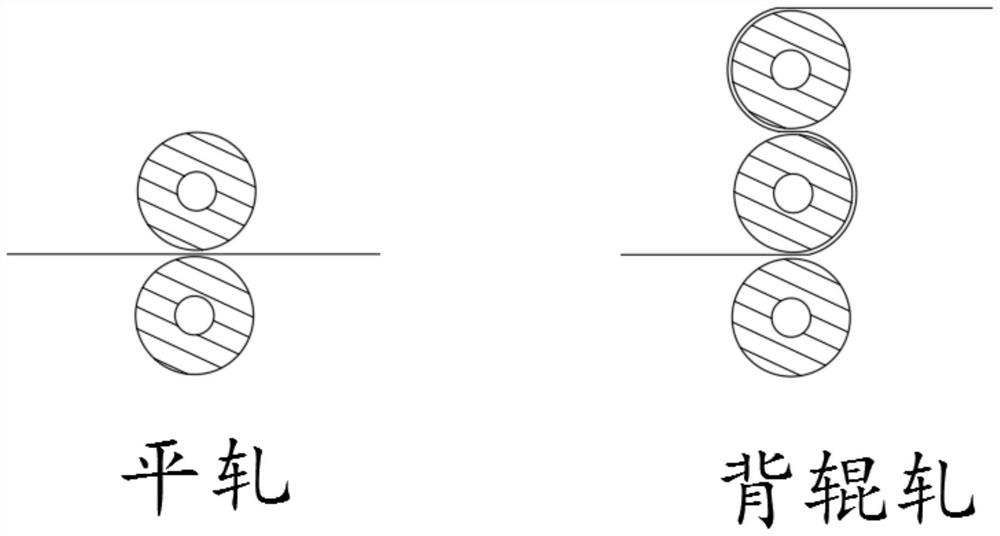

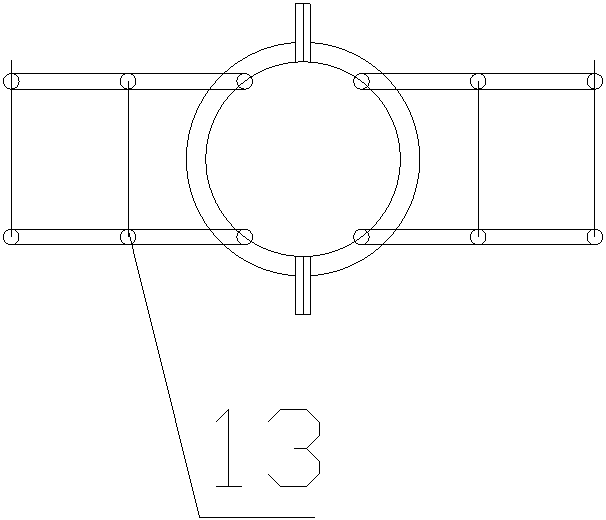

Manufacturing method of low-cost pure meta-aramid insulating composite paper

PendingCN114575176AGuaranteed film propertiesCopy speed guaranteeDryer sectionMachine wet endWater filterPapermaking

The invention discloses a manufacturing method of low-cost pure meta-aramid insulating composite paper, and belongs to the technical field of aramid paper preparation, and the manufacturing method comprises the following steps: preparing raw materials including 5-40 parts by weight of aramid chopped fiber and 60-95 parts by weight of aramid fibrid; making paper with two layers of inclined nets; deionized water is adopted for anilox roller water coating; and hot rolling is carried out in a flat rolling mode and a back rolling mode in sequence. In the invention, filiform fibrid is selected as fibrid, the specific surface area of the filiform fibrid is smaller than that of film-like fibrid, the water filtering speed is high during papermaking, the papermaking speed is also high, and the papermaking speed can be greatly improved; the ultra-low-concentration pulp is adopted, so that the dehydration amount of a forming net part is required to be large, the dehydration amount can be ensured to be sufficient when a two-layer inclined net paper machine is used for manufacturing the composite paper under the sizing concentration of 0.01%-0.02% by adopting double overlapped nets, and the quality of the composite paper is ensured; a wet rolling method is adopted for hot rolling, blank paper is humidified with deionized water, and then wet blank paper is subjected to hot rolling, so that the paper surface is high in strength and smooth.

Owner:LONGPONT

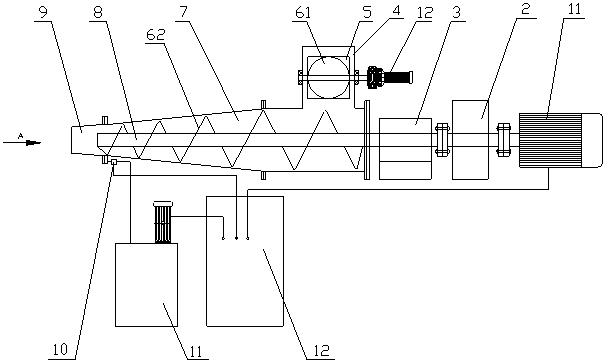

Novel straw compression forming equipment

The invention provides novel straw compression forming equipment, and relates to a compression forming device of fiber materials. The novel straw compression forming equipment comprises a main driving mechanism, a precompression mechanism and a compression mechanism. The precompression mechanism comprises a second motor, a feeding box, a precompression packing auger and a forced feeding turnover plate, a reinforcing compression cavity is formed in the outlet end of a compression cavity, and is of a left-and-right buckling structure, the two sides of the reinforcing compression cavity are connected with connecting rod mechanisms respectively, the connecting rod mechanisms are connected with a hydraulic station, the hydraulic station is controlled by an electric drive travel switch, and the hydraulic station and the electric drive travel switch are in linkage and automatic control through a PLC control cabinet. Based on the working principle that main machine volume variable physical extrusion and auxiliary machine forced feeding extrusion are combined, the materials are conveyed, extruded and dehydrated, the equipment is especially suitable for compression forming of straw type biomass, and the compressed materials are low in water content and small in density.

Owner:河南天冠纤维乙醇有限公司

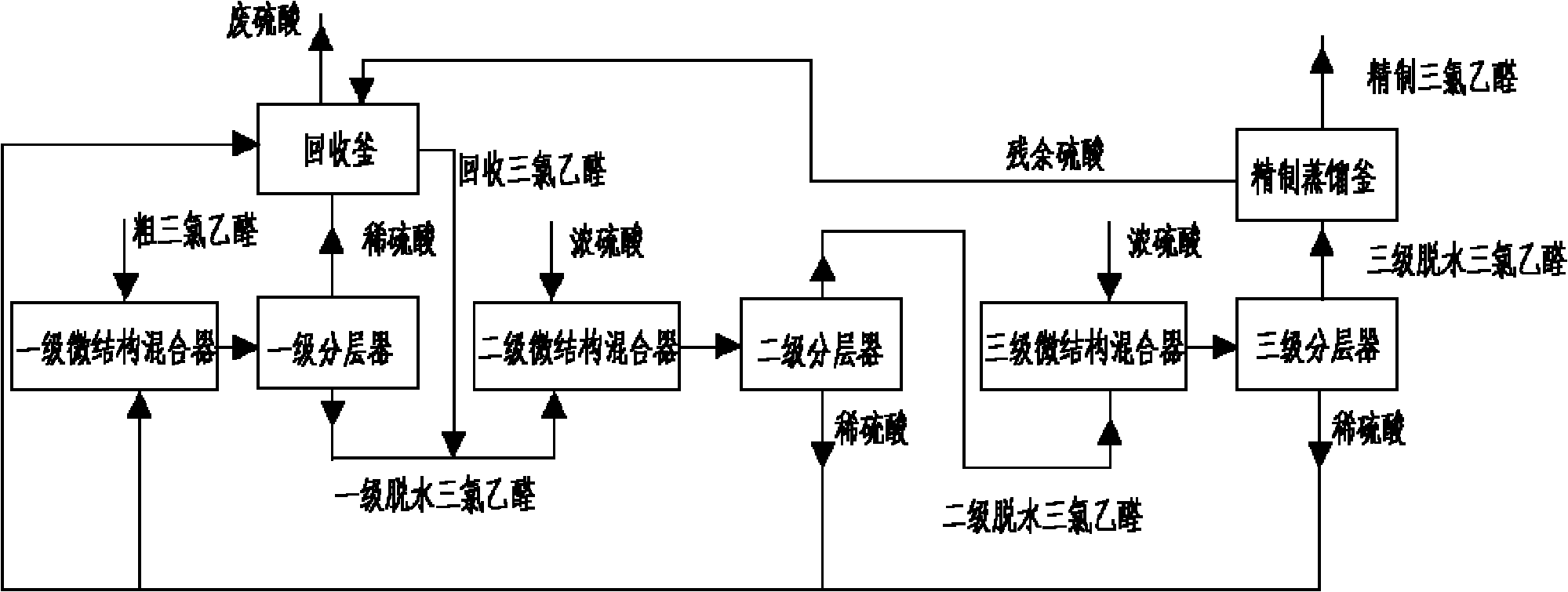

Method for purifying coarse trichloroacetaldehyde

InactiveCN102030623AEasy to dehydrateGuaranteed dehydrationCarbonyl compound separation/purificationDistillationMicrostructure

The invention discloses a method for purifying coarse trichloroacetaldehyde. The method comprises the following steps that: the coarse trichloroacetaldehyde is fully mixed with dilute sulphuric acid in a primary microstructure mixer; trichloroacetaldehyde obtained by a primary demixer is fully mixed with concentrated sulfuric acid in a secondary microstructure mixer; trichloroacetaldehyde obtained after being demixed by a secondary demixer is continuously and fully mixed with concentrated sulfuric acid in a third microstructure mixer; trichloroacetaldehyde containing a small amount of sulfuric acid obtained after being demixed by a third demixer is rectified to obtain anhydrous trichloroacetaldehyde; after sulfuric acid demixed by the secondary demixer and the third demixer is mixed, a part of sulfuric acid is used as the dilute sulphuric acid for the primary microstructure mixer, and the residual sulfuric acid is mixed with the sulfuric acid demixed by the primary microstructure mixer and the residual sulfuric acid of a refining distillation kettle to distill and recycle the residual trichloroacetaldehyde; and the recycled trichloroacetaldehyde is mixed with the trichloroacetaldehyde demixed by the primary demixer to enter the secondary microstructure mixer. By the method, the coarse trichloroacetaldehyde is purified, the consumption of steam and the sulfuric acid can be reduced, and the refining yield of the trichloroacetaldehyde is improved.

Owner:XIANGTAN UNIV

Self-circulation multi-layer slat dryer and self-circulation segmented drying method

ActiveCN101972032BGuaranteed dehydrationQuality assuranceFruits/vegetable preservation by dehydrationFood treatmentCyclic processControl system

The invention discloses a self-circulation multi-layer slat dryer, which comprises a feeding and discharge device (1), a drying chamber (3) and a wind network system (4), wherein the wind network system (4) is used for supplying hot wind to the drying chamber (3) to heat materials. The self-circulation multi-layer slat dryer is characterized by further comprising a multi-layer flat conveyor device (2), a lifter (5) and a control system for controlling the dryer. In addition, the invention also discloses a self-circulation segmented drying method. The self-circulation multi-layer slat dryer and the self-circulation stepwise drying method have the advantages of realizing segmented temperature and humidity control, ensuring dehydration is performed according to the laws of a baking curve in a material drying process, ensuring the quality of dried products, ensuring the materials are uniformly heated because the multi-layer slat conveyor device is used in combination with the lifter to function in turning the materials over in the self-circulation process of the materials, meeting the materials of different characteristics, setting the temperature, humidity and time of each segment according to the characteristics of the materials and realizing discharge at any time, along with wide application range, high drying quality and capability of realizing automatic production.

Owner:扬州福尔喜果蔬汁机械有限公司

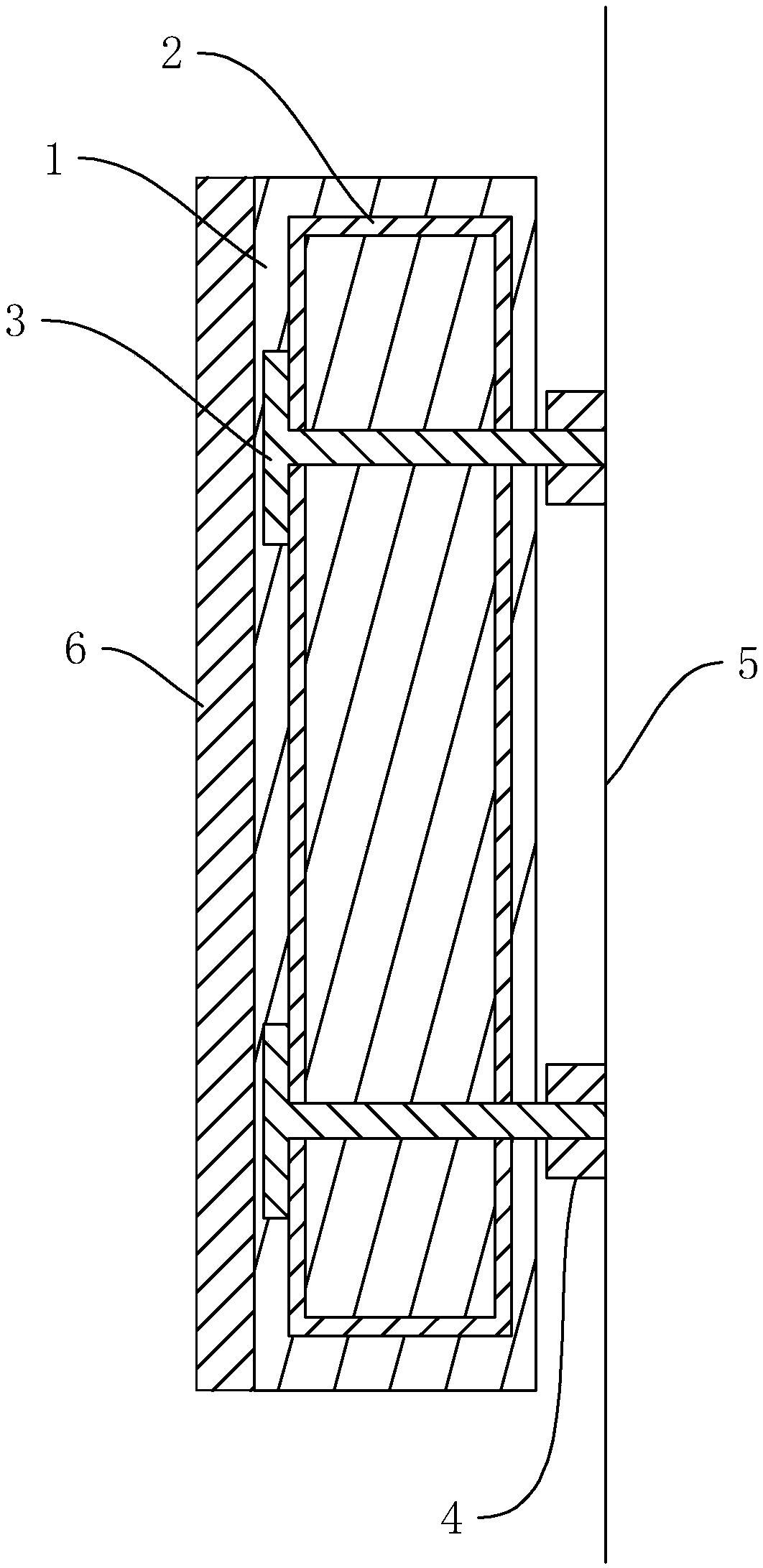

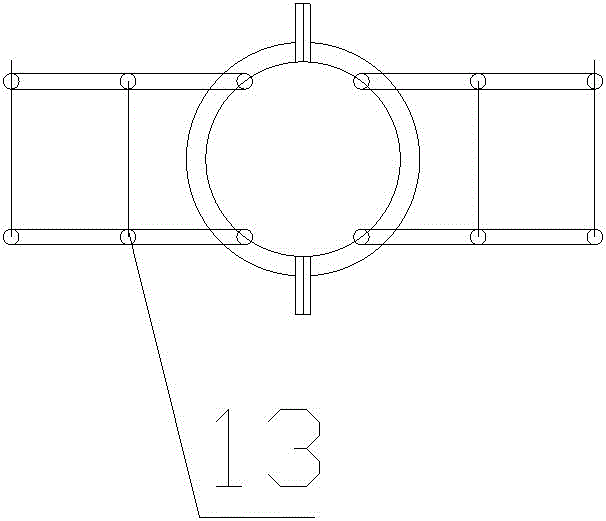

Device for cleaning and drying duck feather

InactiveCN109140949AGuaranteed qualityGuaranteed dehydrationDrying gas arrangementsDrying machines with non-progressive movementsHydraulic cylinderFixed frame

The invention relates to a device for cleaning and drying duck feather, including a bottom plate. A cleaning tank is mounted on the bottom plate. A mount frame fixed on the bottom plate is arranged above the cleaning tank, the mounting frame is provided with hydraulic cylinders symmetrically distributed along the length direction of the bottom plate. The hydraulic cylinder is connected with a fixed frame, wherein the fixed frame is connected with a cleaning frame for storing the duck feather, and a power mechanism which is matched with the cleaning frame to drive the cleaning frame for rotarycleaning. A plurality of drying fans distributed parallel along the length direction of the bottom plate are installed on the mounting frame, and a waste water collection mechanism matched with the cleaning box is also installed on the bottom plate. The invention enlarges the contact area between the duck feather and a cleaning liquid by rotating cleaning in the cleaning box through the cooperation of the power mechanism and the cleaning frame, so that the impurities of the duck feather are completely removed and the quality of the duck feather is guaranteed; and the duck feather is fully contacted with the high-temperature gas by the cooperation of the drying fan and the power mechanism and the cleaning frame, so that the duck feather is completely dehydrated.

Owner:安徽万利达羽绒制品有限公司

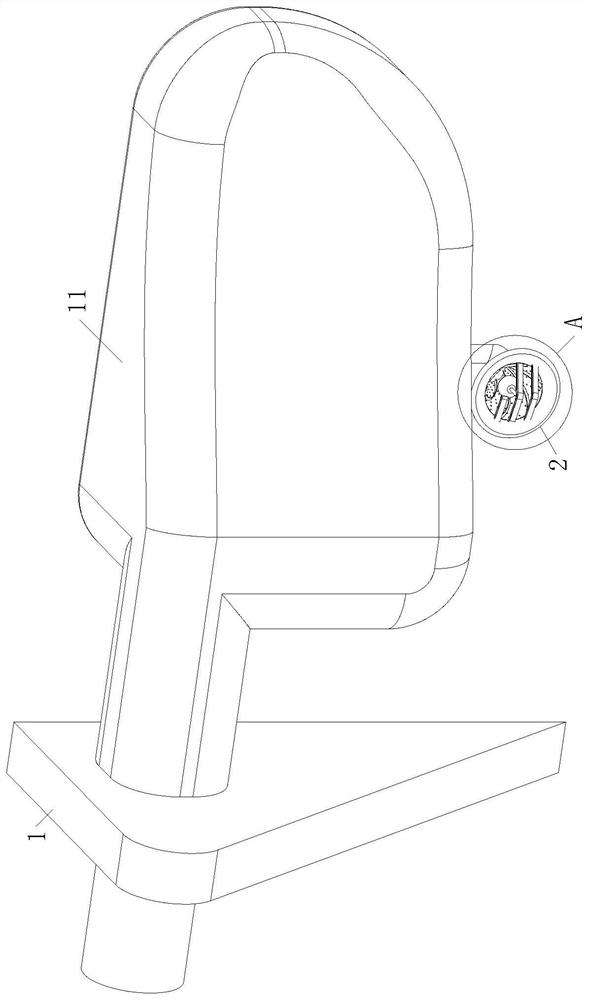

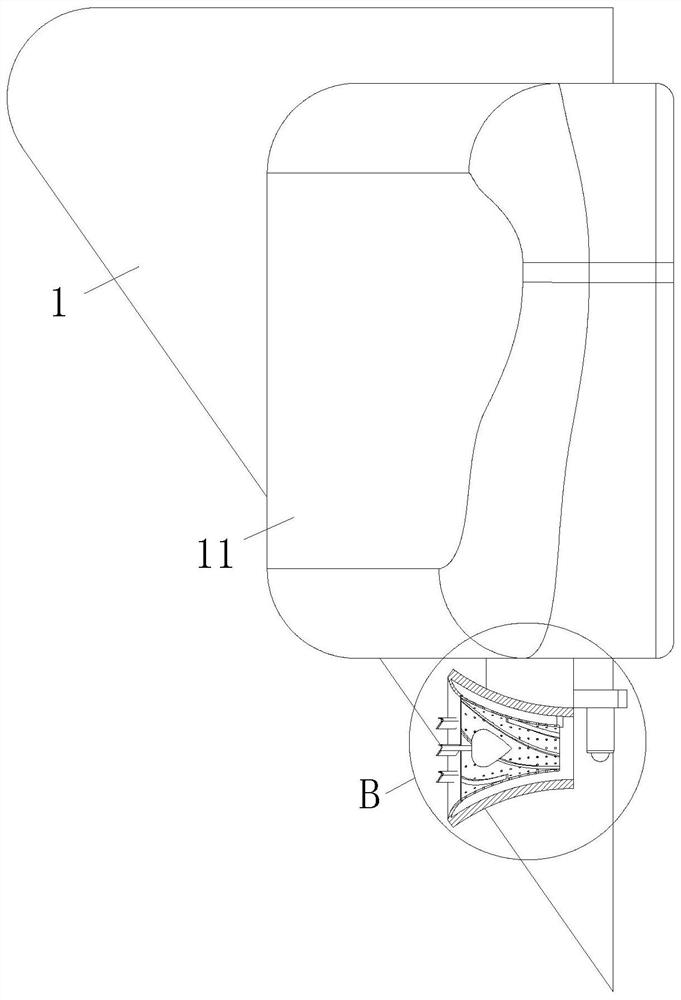

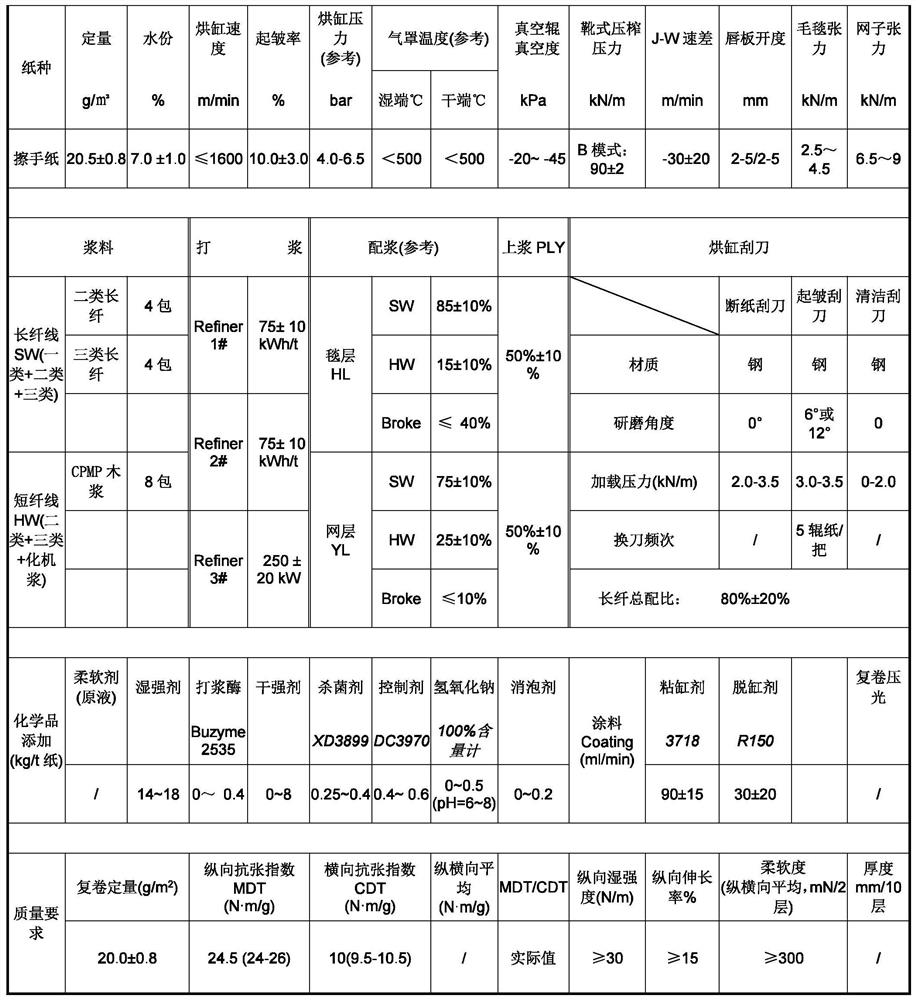

Vehicle driving image recognition method

ActiveCN111660949AImprove clarityIncreased dispersionTelevision system detailsColor television detailsPhysicsRear-view mirror

The invention belongs to the technical field of image processing, and particularly relates to a vehicle driving image recognition method. Rain-proof equipment adopted in the invention comprises a mounting frame; a mirror body of a rearview mirror is fixedly connected to the mounting frame; a panoramic camera is fixedly connected to the bottom of the mirror body through a support; an atomization cover is fixedly connected to the mirror body in front of the panoramic camera; the atomization cover is horn-shaped; and the diameter of the end, close to the panoramic camera, of the atomization coveris smaller than that of the other end. By means of the horn-shaped atomization cover, air flow passing through the position near the panoramic camera is accelerated when an automobile runs, so that raindrops are atomized by the air flowing at a high speed when passing through the end, with the small diameter, of the atomization cover, and therefore, large-drop rainwater adhering to the panoramiccamera is reduced, and the focusing precision and the shooting image definition of the panoramic camera are improved.

Owner:SUZHOU QINGZHI NETWORK TECH CO LTD

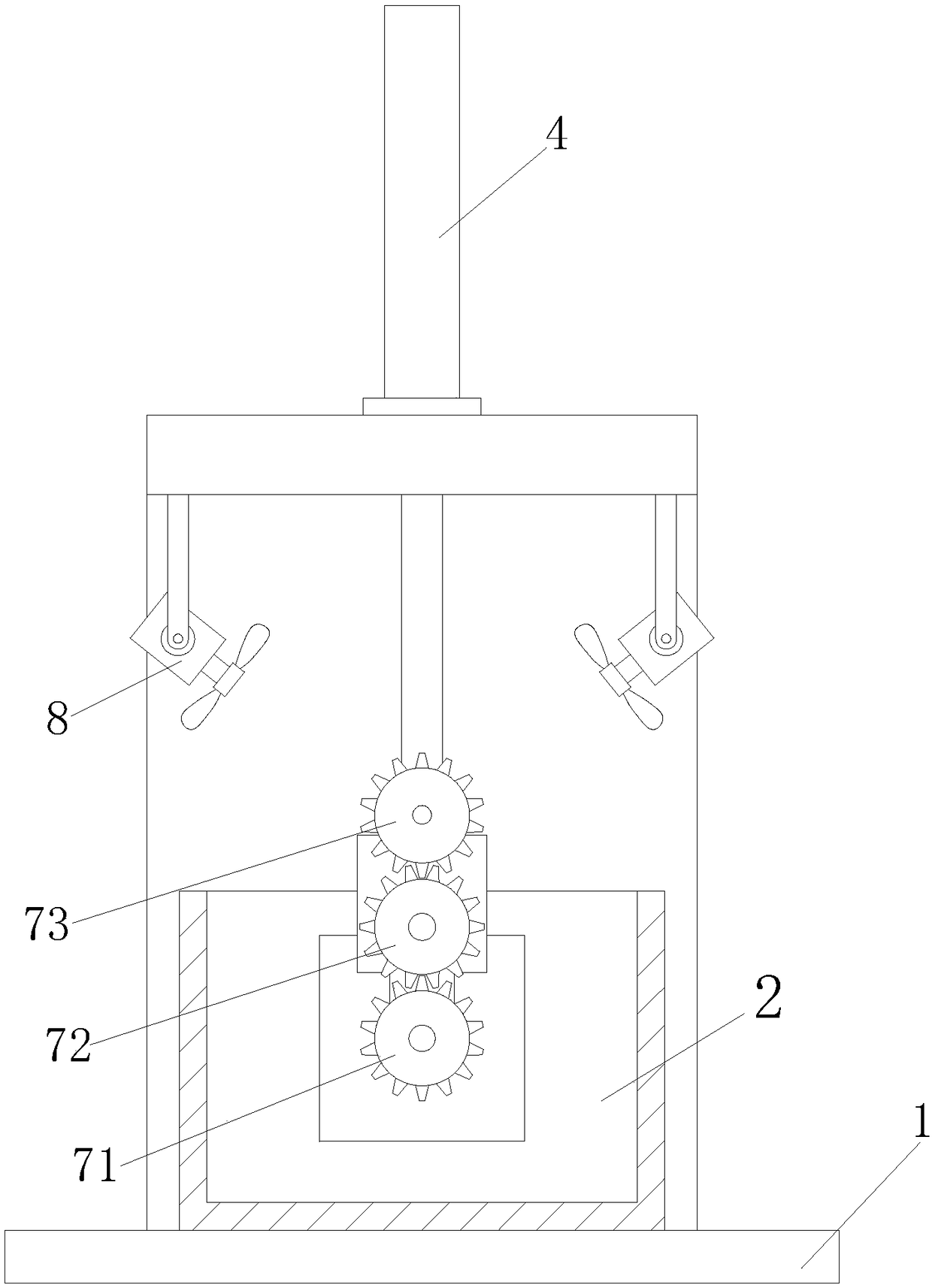

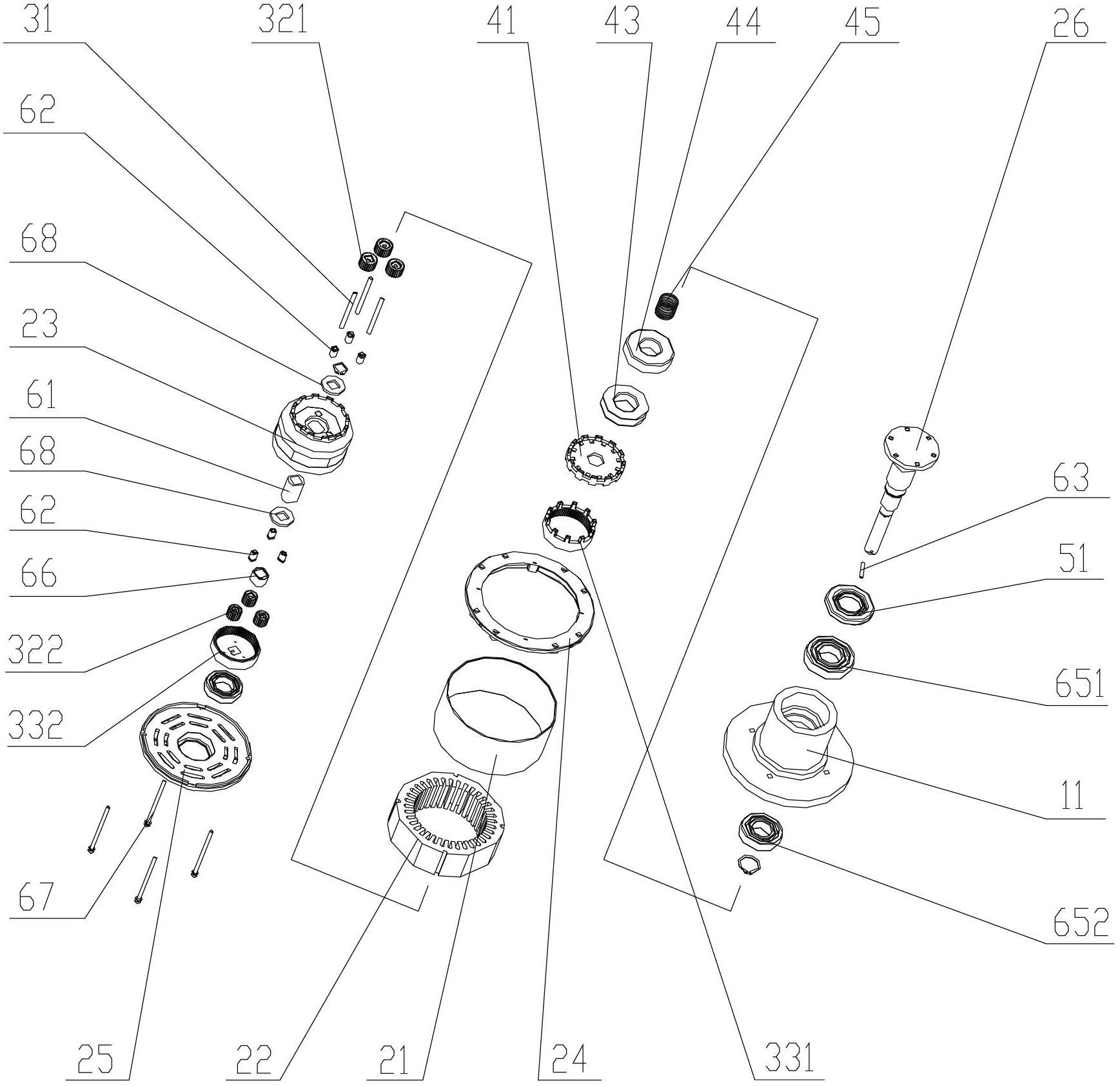

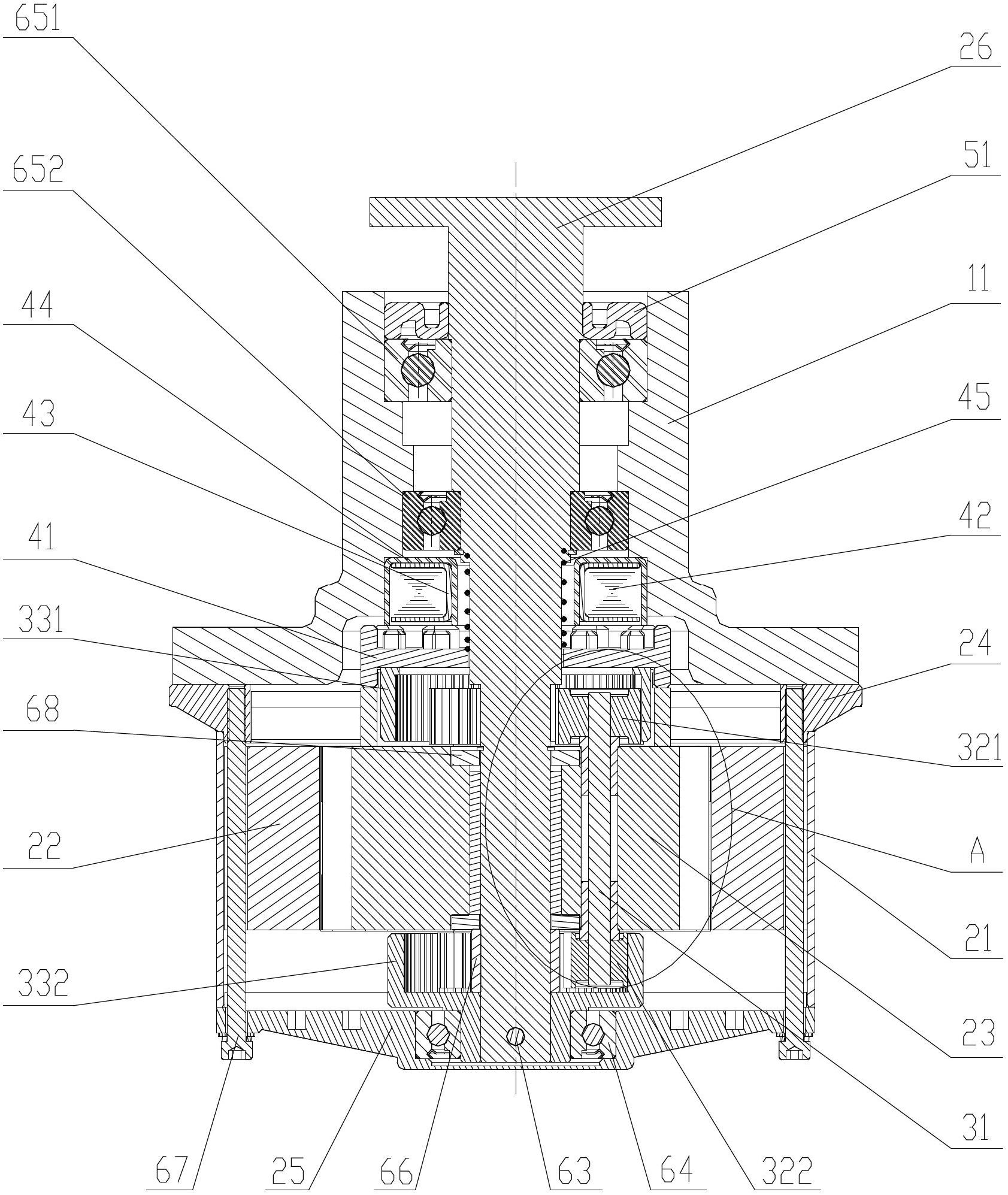

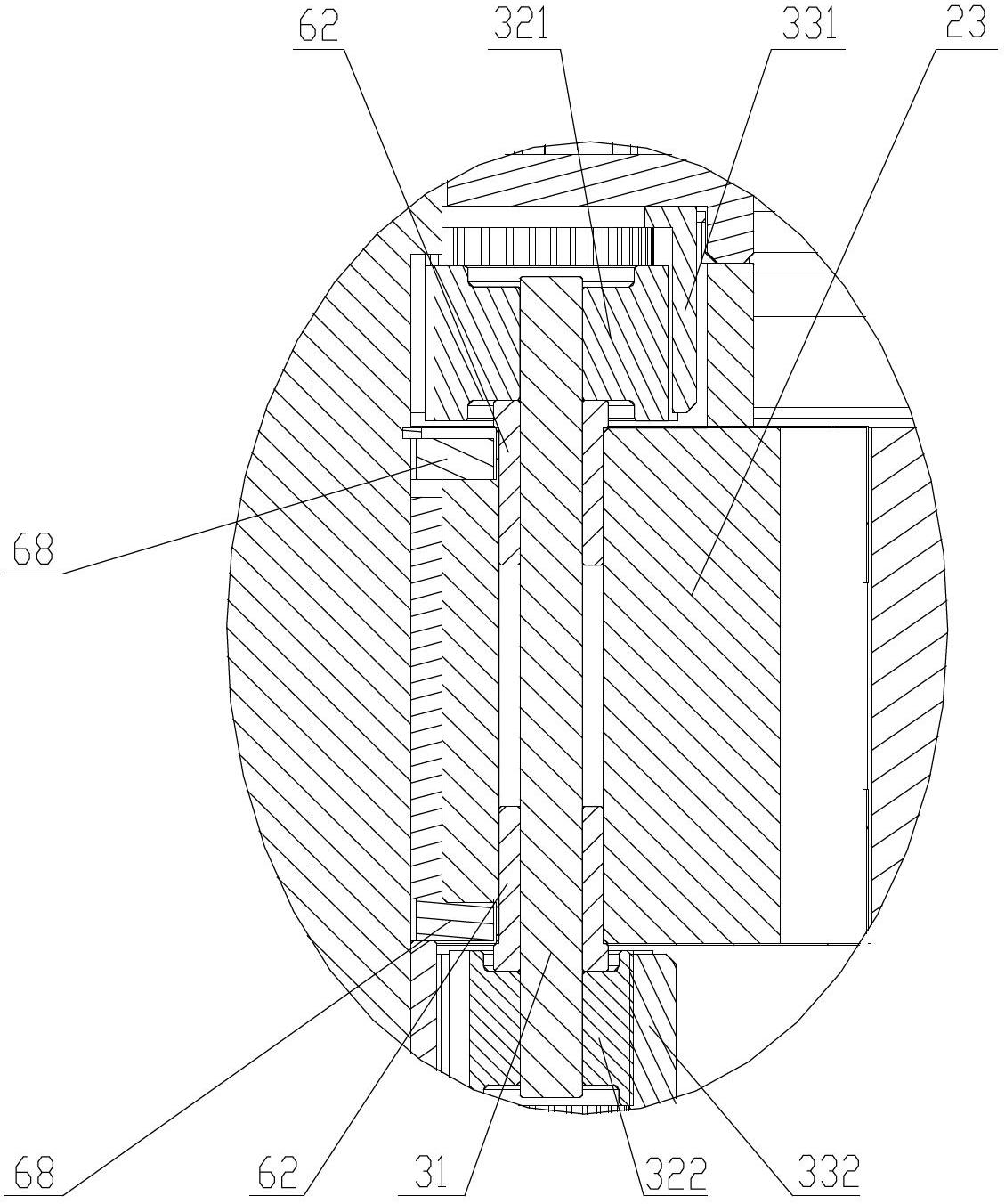

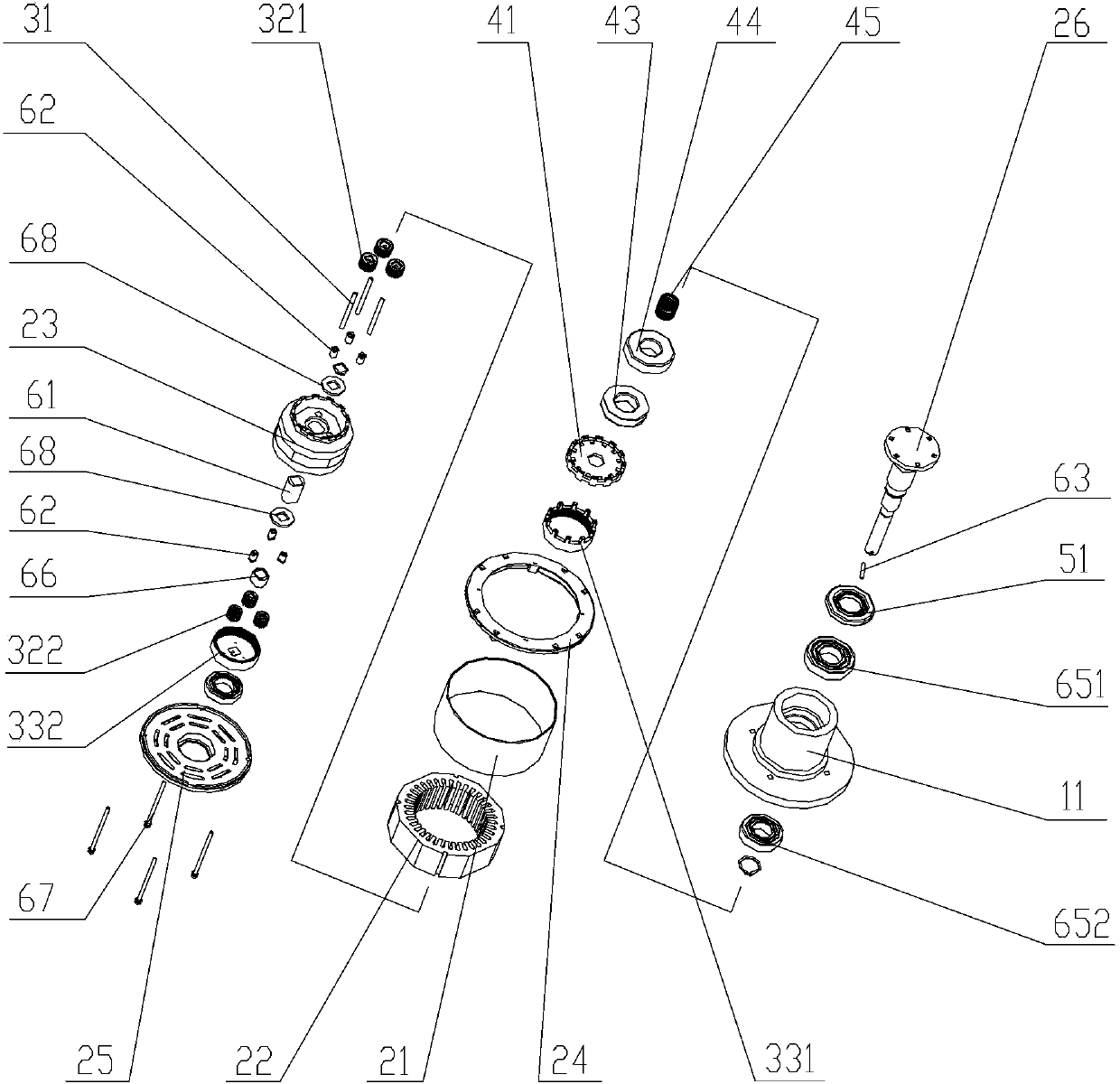

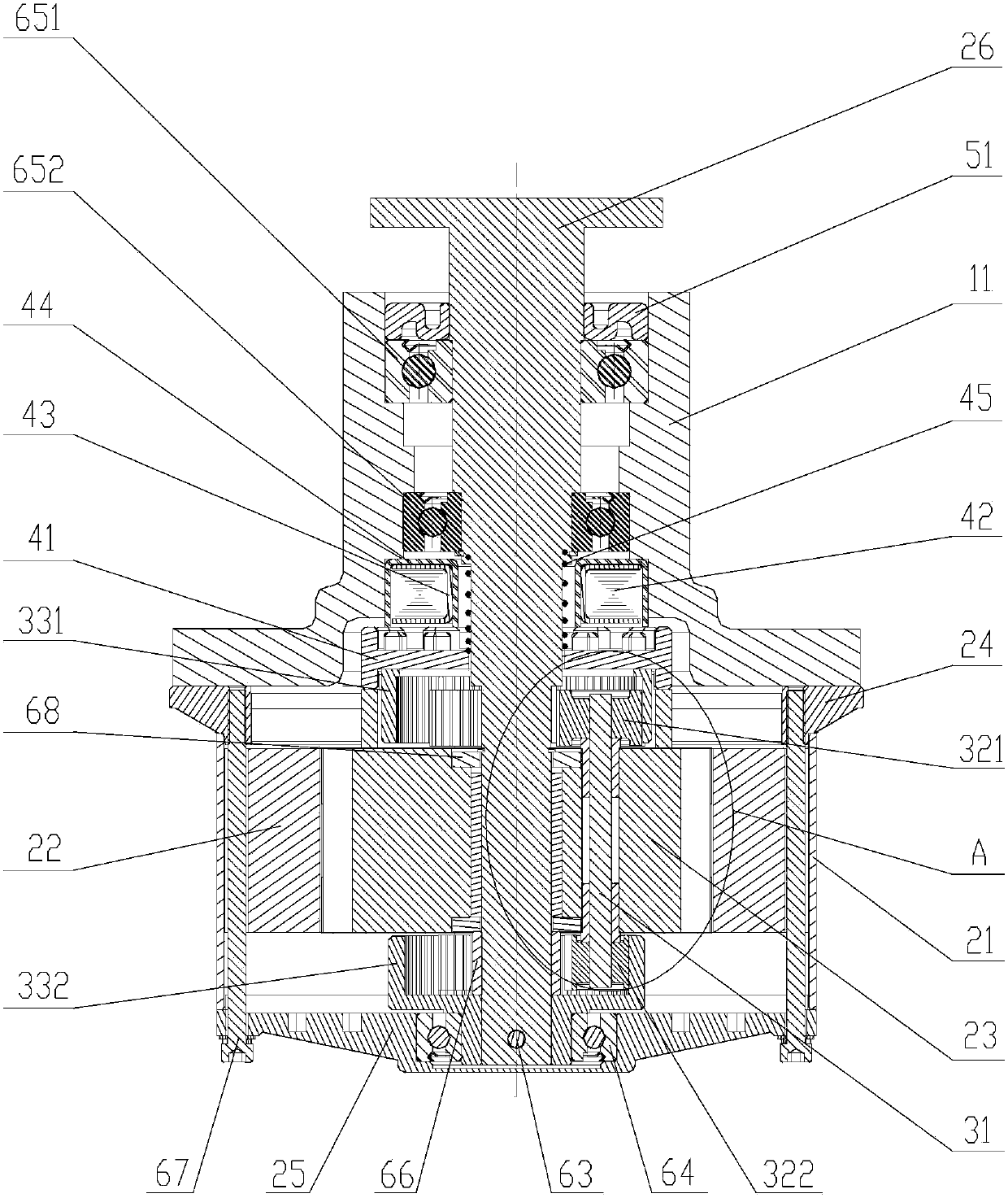

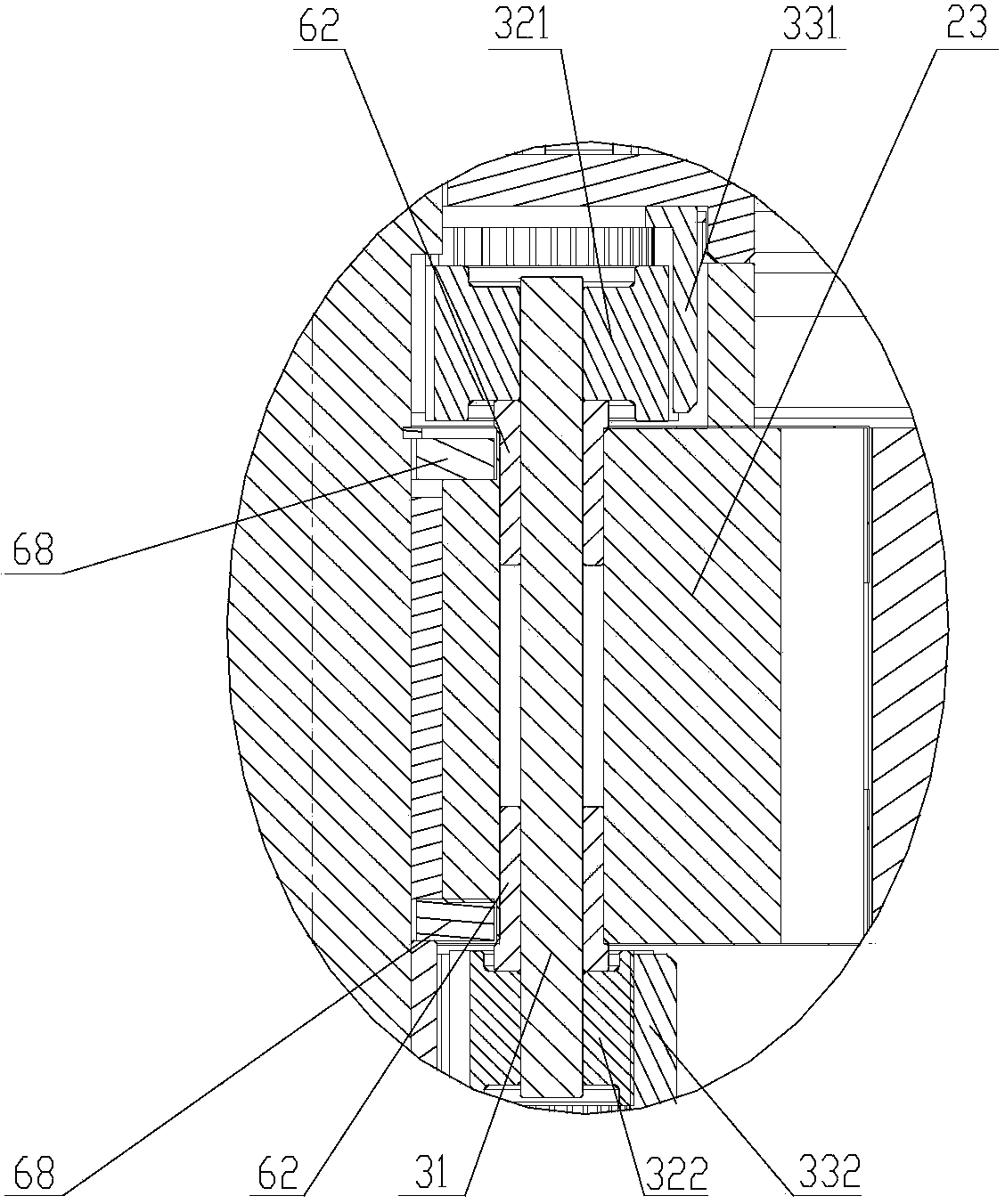

Driver of drum washing machine

InactiveCN102660856ACompact structureSmall footprintOther washing machinesTextiles and paperEngineeringMechanical engineering

The invention discloses a driver of a drum washing machine, comprising a motor and an output shaft, and further comprising a gear reduction mechanism, wherein the output shaft is coaxially installed in an electronic rotor of the motor and fixedly connected with an output gear of the gear reduction mechanism, and an input gear shaft of the gear reduction mechanism is inserted-installed in a shaft hole of the motor rotor. Via the arrangement of the gear reduction mechanism, the driver of a drum washing machine provided by the invention can realize the low-speed output of the output shaft via the gear reduction mechanism during the high-speed rotation of the motor, and ensure the high-speed running of the motor in the case that the drum washing machine is in a washing working condition, thus increasing the use efficiency of the motor. Additionally, the gear reduction mechanism provided by the invention is installed on the motor, the motor rotor is used as a gear rack, and the motor and the gear reduction mechanism are effectively integrated, so that the driver is simple and compact in structure, and small in occupied space.

Owner:CHANGZHOU XINYA ELECTROMOTOR

Infrared radiation static dryer

ActiveCN103478308BImprove temperature consistencyGuaranteed dehydrationPre-extraction tea treatmentDrying solid materials with heatInfraredPulp and paper industry

The invention relates to an infrared radiation static dryer. The infrared radiation static dryer comprises a rack and a driving device, wherein the rack is provided with a plurality of layers of staggered convey net belts, the separated convey net belts drive in opposite directions, the driving device drives the convey net belts to transmit, the inlet of the dryer is opposite to the front end of the first layer of convey net belt and is connected with a feed convey net belt, the feed convey net belt is provided with an even leaf mechanism, infrared radiation heating devices are arranged above the work surfaces of the convey net belts and are installed on a fixed plate, and the heating devices are uniformly arranged in the transverse and longitudinal directions of the convey net belts. The infrared radiation static dryer adopts infrared radiation static drying and adopts a plurality of layers of staggered convey net belts, the infrared radiation heating devices are arranged above the work surfaces of the convey net belts, so that tea leaves are dried at consistent temperature, are guaranteed to be dehydrated and have color and luster, and are not easy to break, and part of the fragrance is not brought away.

Owner:ZHEJIANG ZHUFENG MACHINERY +1

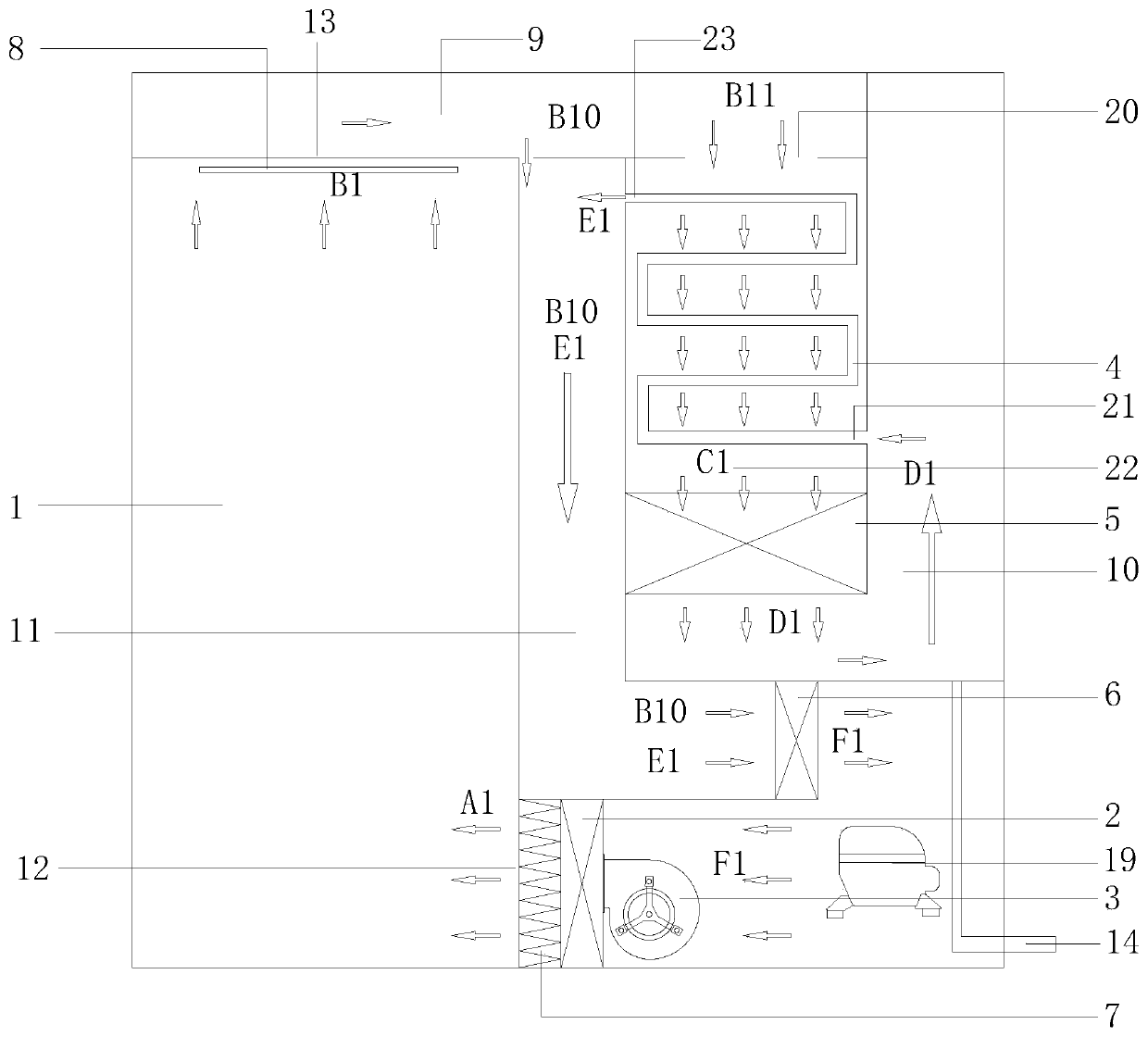

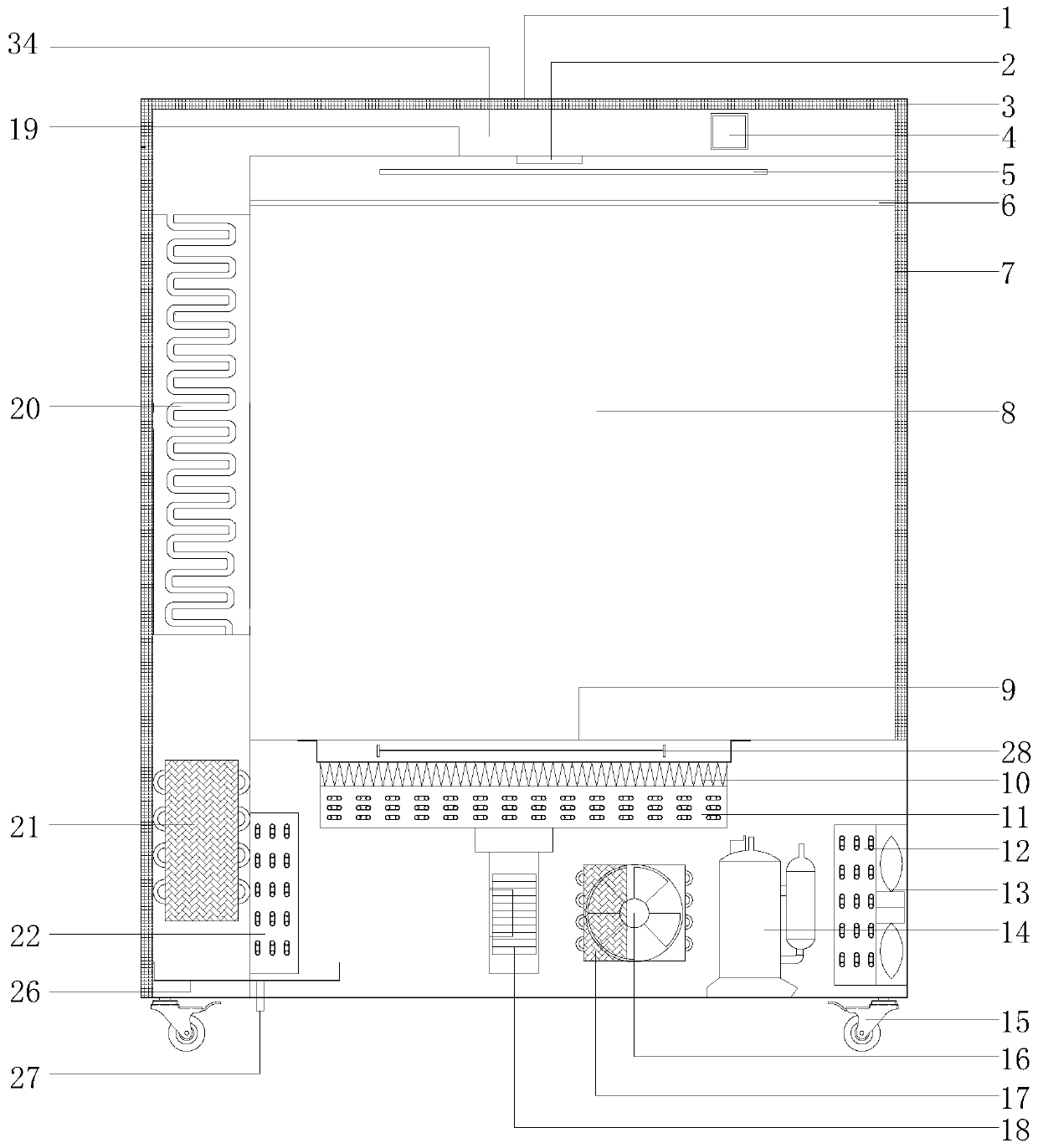

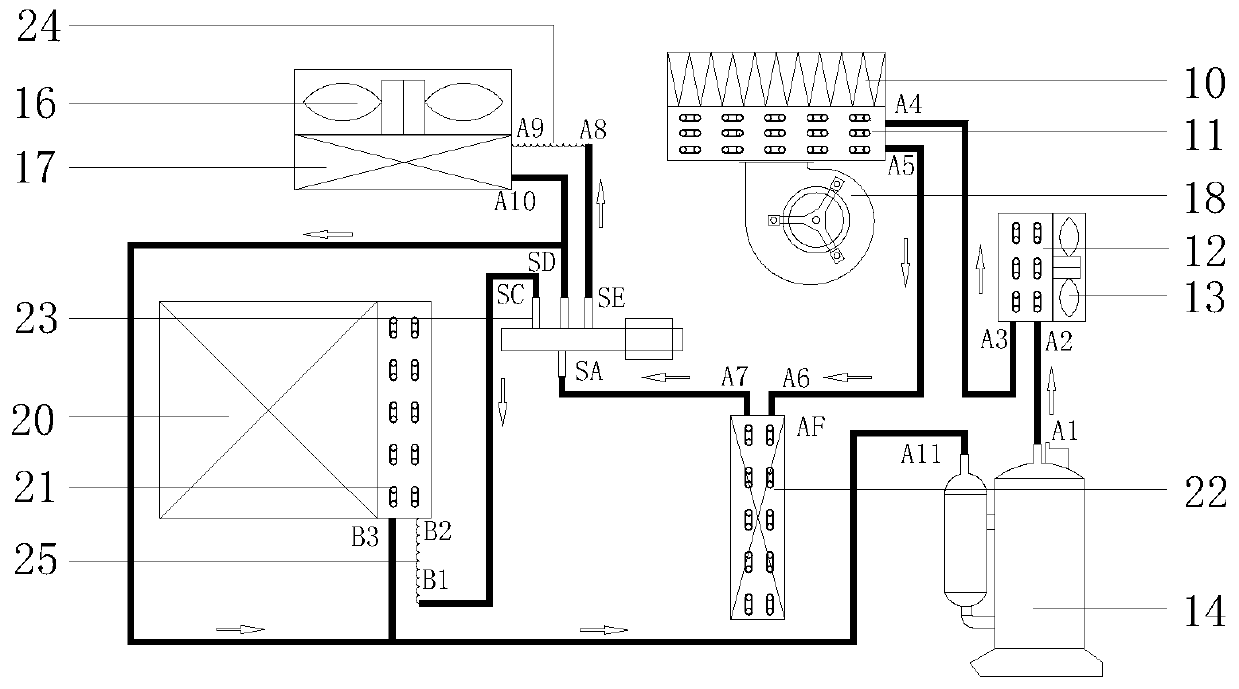

Drying method and energy-saving drying equipment

PendingCN109974411AImprove energy efficiencyWide range of energy utilizationDrying gas arrangementsDrying solid materialsProcess engineeringProduct gas

The invention discloses a drying method. Heating gas is utilized for drying objects. The drying method specifically comprises the following steps that firstly, the objects are placed in the preset drying area, and the drying area is provided with a heating gas inlet and a heating gas outlet; secondly, the heating gas is led into the drying area from the heating gas inlet, and after the objects inthe drying area are heated, the heating gas is discharged out of the drying area from the heating gas outlet, and the heating gas discharged out of the drying area is divided into two paths; thirdly,after one of the two paths of the heating gas is sequentially dehumidified and heated, the heating gas is led into the drying area again; and fourthly, the other one of the two paths of the heating gas is heated and then is led into the drying area again. According to the low-humidity drying method, energy saving is obvious, water in the gas in the drying area is removed two times, and it is guaranteed that the water removal phenomenon is generated to the objects needing to be dried in the drying area in the low-humidity environment.

Owner:苏州达善净化科技有限公司

Washing machine inner barrel component and washing machine

ActiveCN111850973AAvoid cloggingAvoid damageOther washing machinesTextiles and paperLaundry washing machineEnvironmental engineering

The invention discloses a washing machine inner barrel component and a washing machine. The washing machine inner barrel component includes an inner barrel; when washing / rinsing, the inner barrel is awater barrel; the side wall of the inner barrel is provided with a drainage channel communicating with the inner barrel for draining water thrown out of the inner barrel; and the water inlet of the drainage channel is provided with a stop structure to prevent clothing from entering the drainage channel. The stop structure includes a protruding part, the protruding part protrudes inward from the outer circumference of the water inlet, and the protruding part blocks a part of the water inlet to prevent clothing from entering. The washing machine inner barrel component disclosed by the inventionis provided with the stop structure at the water inlet of the drainage channel to prevent the clothing from entering the drainage channel; and the stop structure has a simple structure and is easy toinstall, which can effectively prevent the clothing from clogging the drainage channel, and can also prevent the clothing from rubbing against the water inlet to damage the clothing.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Automatic scrap recovery device and recovery process

ActiveCN113478692AImprove cleanlinessGuaranteed dehydrationPlastic recyclingCleaning using liquidsProcess engineeringDehydration

The invention discloses an automatic scrap recovery device. The automatic scrap recovery device comprises cleaning pools, cleaning fluid guide mechanisms, scum collection rolling screens and scrap dehydration mechanisms, each cleaning pool is an annular cleaning pool, the plurality of cleaning pools are sequentially arranged side by side, the cleaning fluid guide mechanisms are arranged in each cleaning pool, the scum collecting roller screens are arranged in each cleaning pool, the scum collecting roller screens are seamlessly connected with the cleaning pools, and a plurality of dust dehydration mechanisms are arranged on the scum collecting roller screens. Recovery is carried out on waste plastic bag scraps in the cleaning pools in an automatic salvage mode, and water in the scraps is removed during recycling, so that cleanliness and dehydration of the scraps are guaranteed, and the scraps do not need to be dried by a drying device.

Owner:湖南安福环保科技股份有限公司

Van type vacuum drying device for urban sludge

ActiveCN110395873AImprove drying rateWon't spillSludge treatment by de-watering/drying/thickeningSludgeProcess engineering

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Lightweight composite concrete external wall and production method

ActiveCN108975814ALow densityImprove stress resistanceForms/shuttering/falseworksCeramicwarePortland cementCrushed stone

The invention relates to lightweight concrete external walls and discloses a lightweight composite concrete external wall and a production method. The lightweight composite concrete external wall comprises a steel bar bracket, an embedded part fixed in the steel bar bracket, a concrete matrix which is used for filling and cladding the steel bar bracket and a coating layer which is coated on the outer side of the concrete matrix; the lightweight composite concrete external wall is prepared from the following raw materials in parts by mass: 100 parts of portland cement, 100 parts of water, 80 parts of crushed stone aggregate, 8 to 12 parts of strongly acidic action exchange resin, 30 to 40 parts of natural sand and 7 to 10 parts of polytetrafluoroethylene filler. The production method comprises the following steps: pouring lightweight composite concrete obtained by mixing the raw materials into an external wall mold provided with the steel bar bracket and the embedded part; after the lightweight composite concrete is solidified and cured, obtaining the concrete matrix; coating the concrete matrix with a coating layer, so as to obtain the lightweight composite concrete external wall.The carrying load of an external wall fixing bracket is reduced, and the compression resistance and bending strength of the lightweight composite concrete are improved; the possibility that the external wall is fractured or crushed when being impacted is reduced.

Owner:浙江高盛钢结构有限公司

Method and equipment for making pickled peppers

The invention relates to fermenting equipment for pickled peppers, specifically to a making method and apparatus for pickled peppers. The making apparatus comprises a pickling pool and a seal cover capable of enclosing the pickling pool, wherein the pickling pool is provided with a separator plate which divides the pickling pool into a pickling zone and a circulating zone; the upper part of the separator plate is a separation part while the lower part of the separator plate is a filtering part which is provided with penetration holes; a circulating device and pipelines are in the circulating zone, and the circulating device is communicated with the lower part of the circulating zone and the upper part of the pickling zone via the pipelines; the pickling zone is provided with a valve plate, joint pins, a floating plate and a filter plate; the sidewalls of the valve plate and the floating plate are hermetically and slidably connected with the inner wall of the pickling zone; the floating plate is located below the valve plate and fixedly connected with the valve plate via the joint pins; the pool wall of the pickling zone is provided with a communicating hole; and the filter plate covers the communicating hole. The objective of the invention is to provide the method and apparatus for realizing full mixing of salt water and peppers.

Owner:贵州遵义新佳裕食品有限公司

A kind of sterile paper towel and its production process

ActiveCN107663805BReduce porosityIncrease liquid absorptionSpecial paperPaper/cardboardTextile printerFungicide

Owner:SHANDONG HENGAN PAPER IND CO LTD

A method for vehicle driving image recognition

ActiveCN111660949BIncreased dispersionReduce adhesionTelevision system detailsColor television detailsImaging processingEngineering

Owner:SUZHOU QINGZHI NETWORK TECH CO LTD

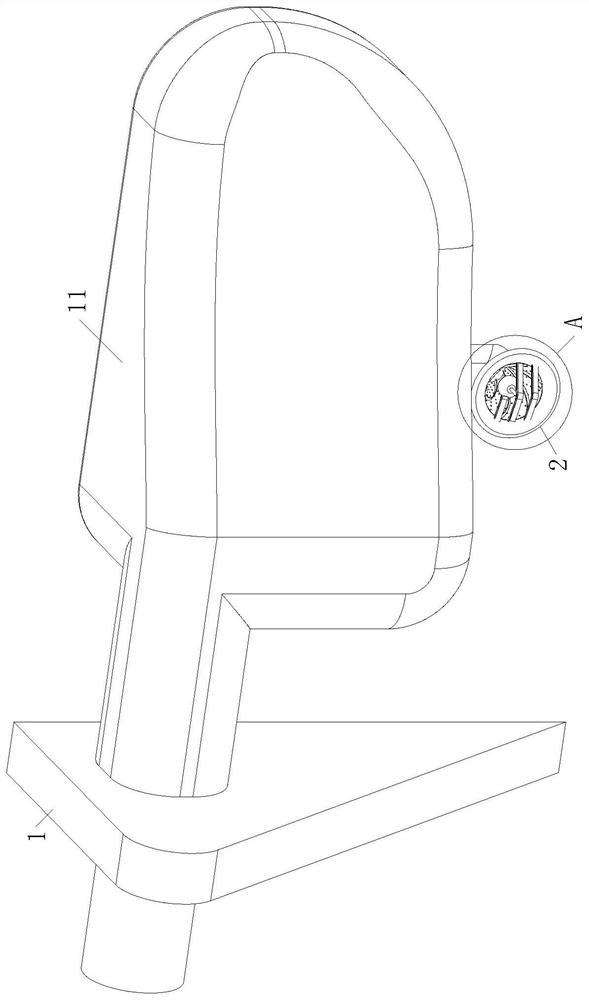

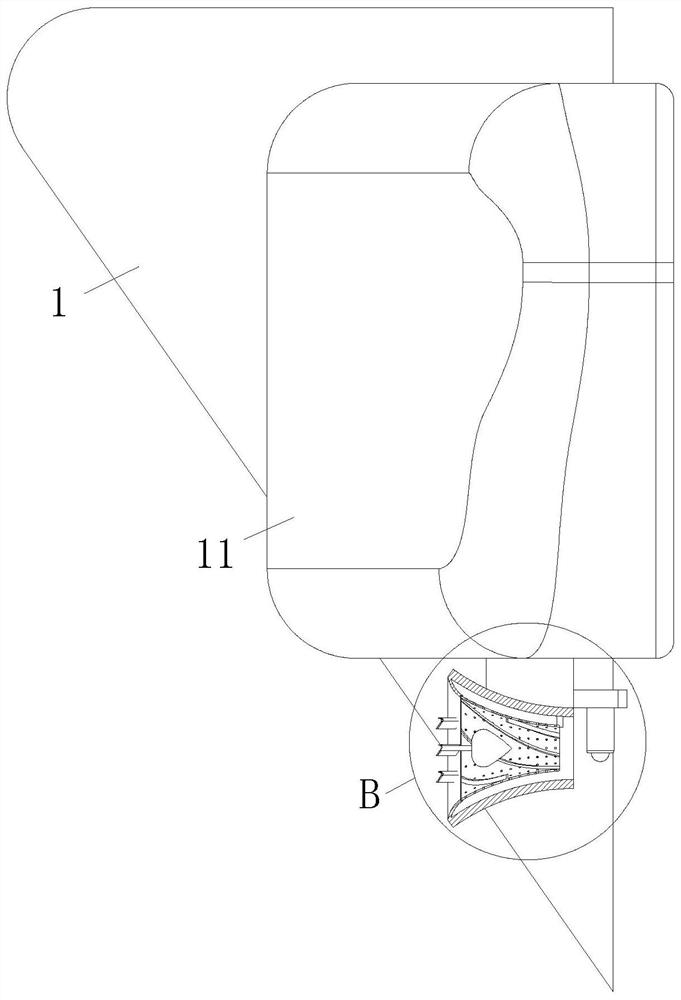

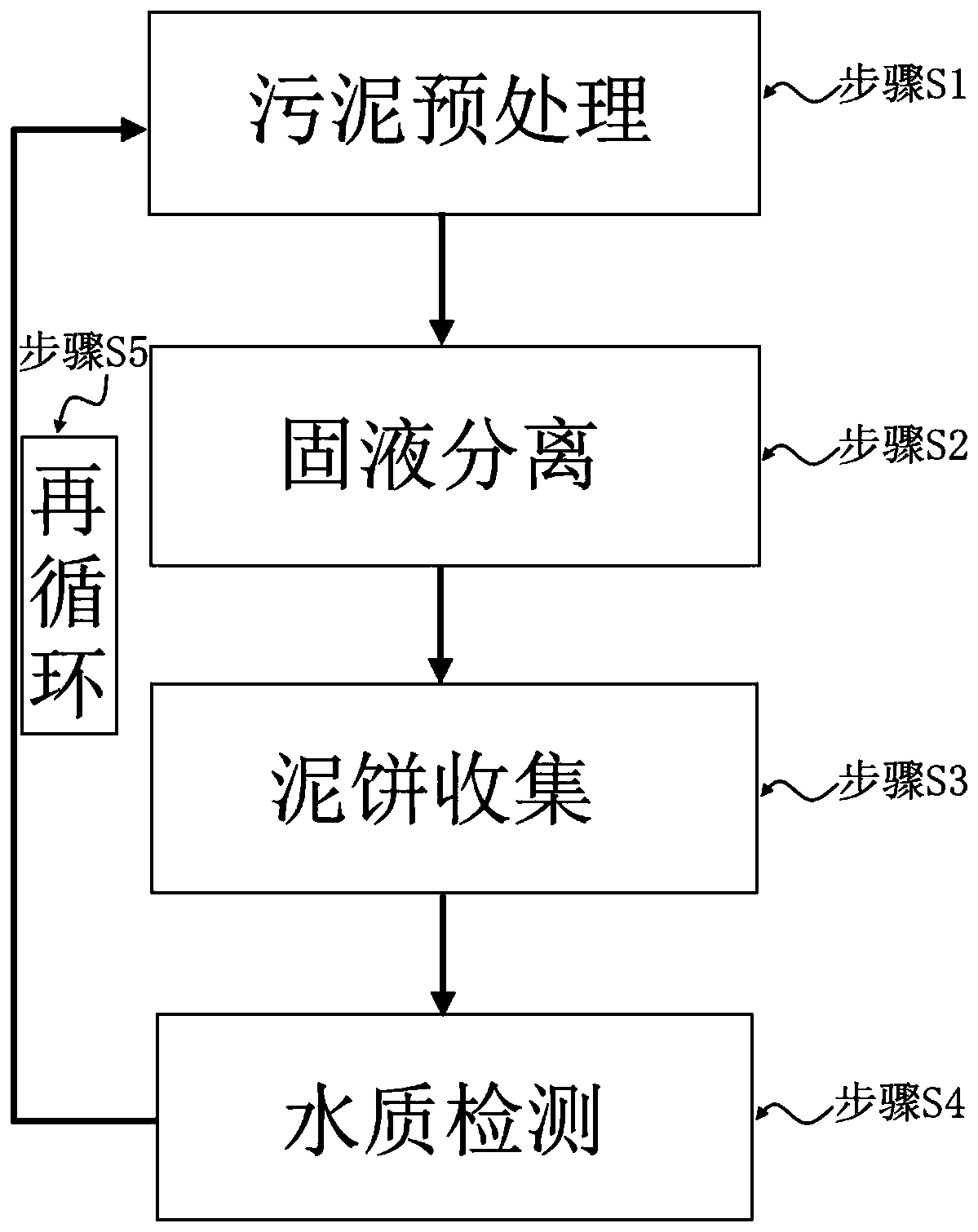

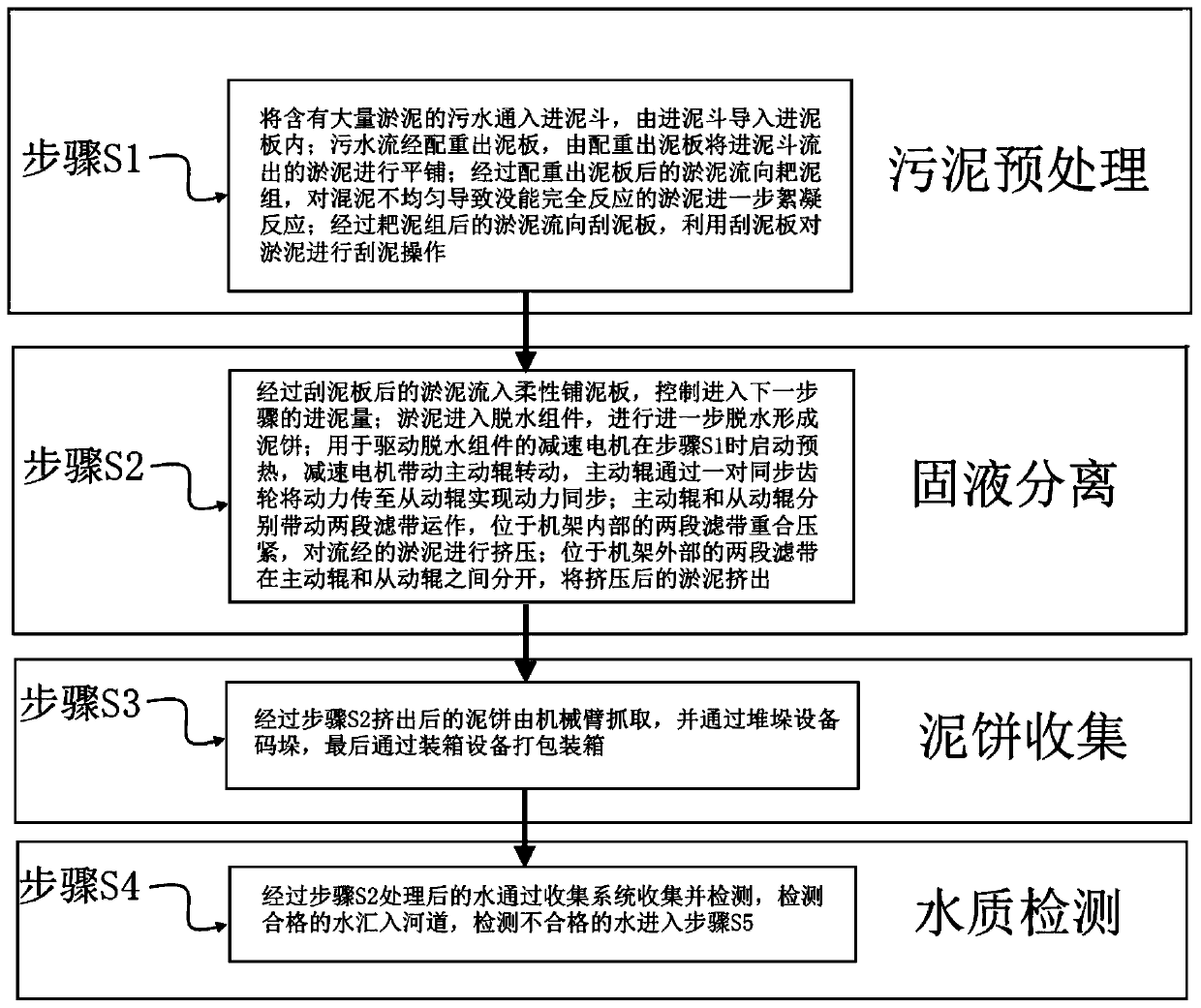

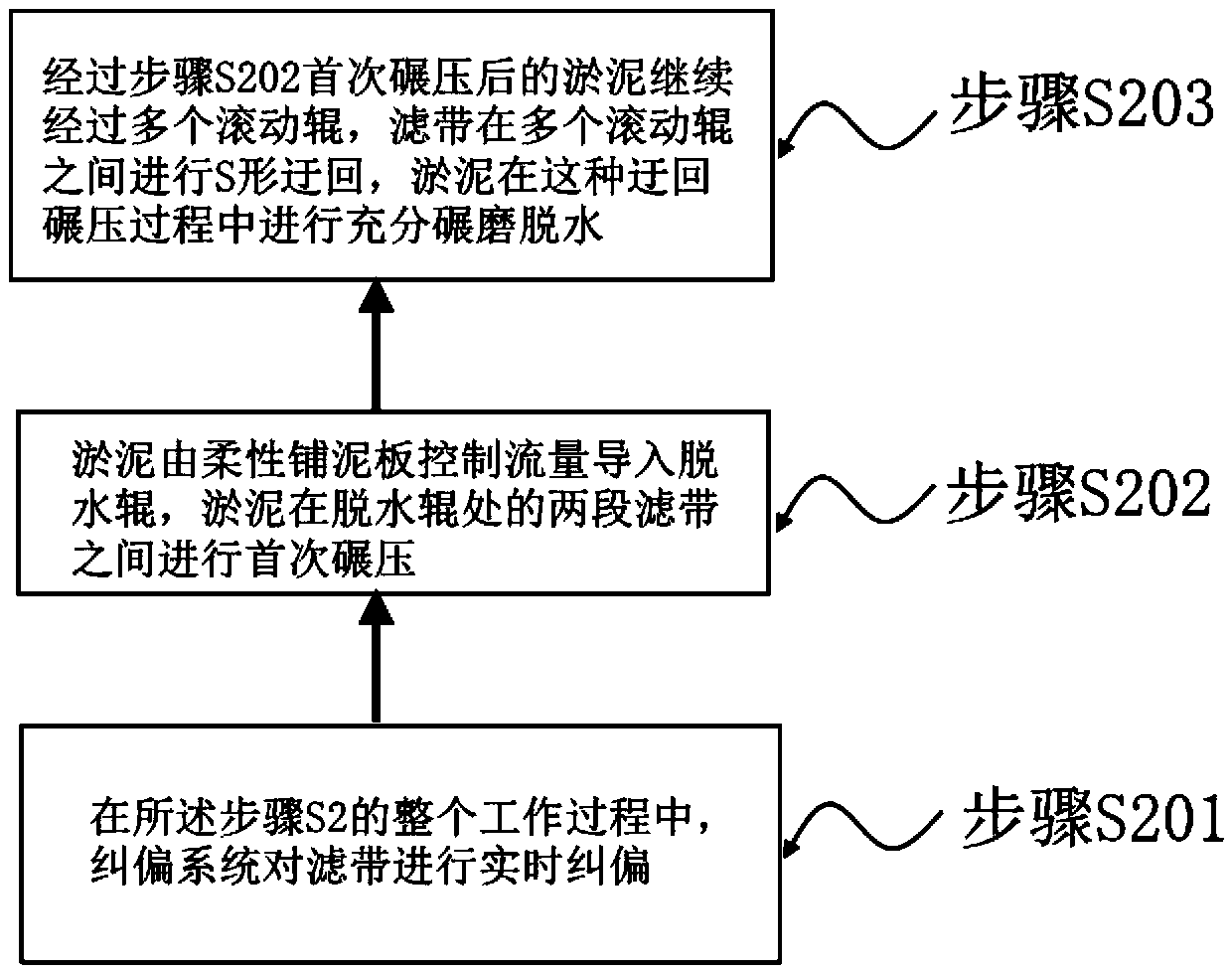

A kind of sewage sludge treatment and recovery and recycling method

ActiveCN110078351BRich in nutrientsGuaranteed dehydrationSludge treatment by de-watering/drying/thickeningSludge cakeFertigation

The invention relates to a sewage sludge treatment, recovery and recycling method. sewage containing sludge sequentially passes a sludge inlet hopper, a balance weight sludge discharging plate, sludgeraking assemblies, a sludge scraping plate and a flexible sludge paving plate and enters a dewatering assembly, two sections of a filter belt are driven to operate by a driving roll and a driven roll, and the two sections of the filter belt located in a rack coincide and are tightly pressed to squeeze passing sludge; two sections of the filter belt outside the rack are separated between the driving roll and the driven roll, the squeezed sludge is squeezed out. The filter belt circles in an S shape among multiple rolling rolls, sludge is sufficiently ground in the circular grinding process, and further dewatering of the sludge is guaranteed. The water content of a sludge cake finally squeezed through the steps meets the corresponding requirements. By means of the sewage sludge treatment method, sludge and other sediments with inorganic matter as main components in sewage can be efficiently compressed and ground and finally form the sludge cake, the treated water is clear, the producedsludge cake contains rich nutritional elements and the treated water and the sludge cake can be used for irrigation and fertilization of crops and are high in utilization rate.

Owner:瑞美智能设备江苏有限公司

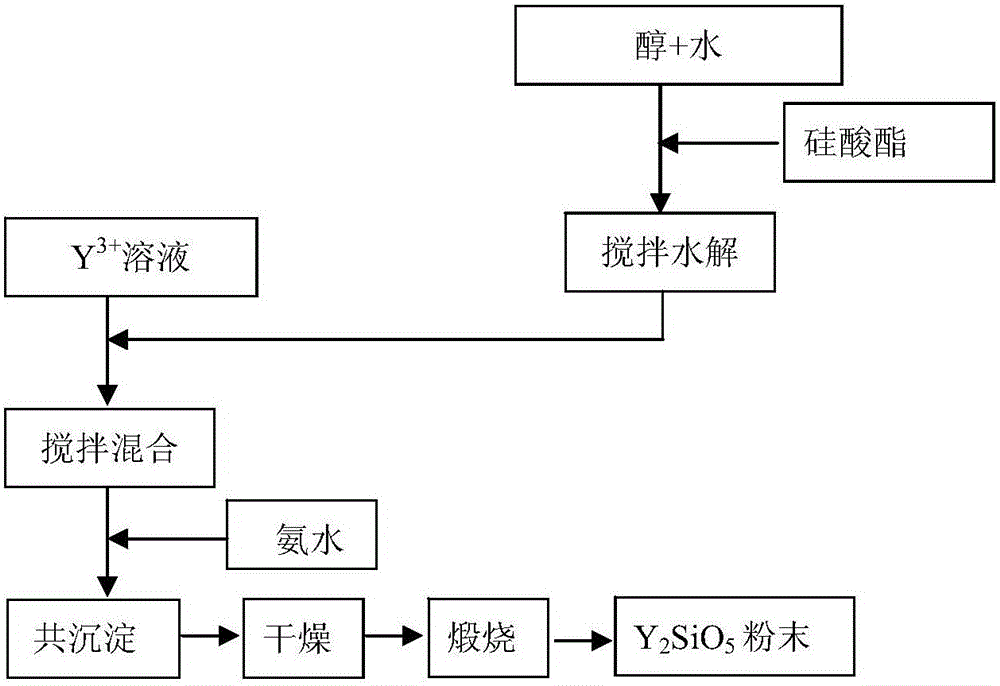

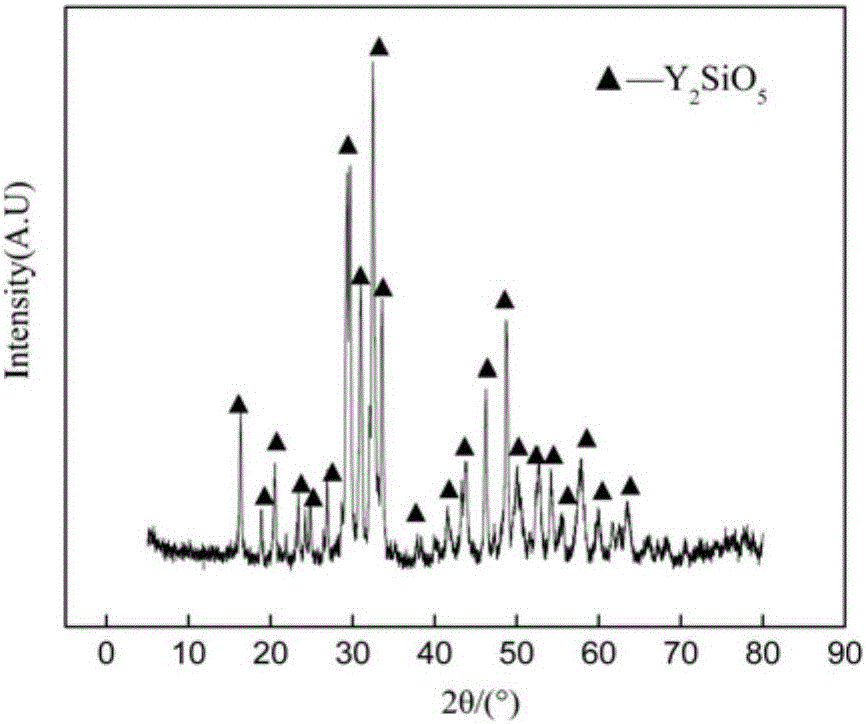

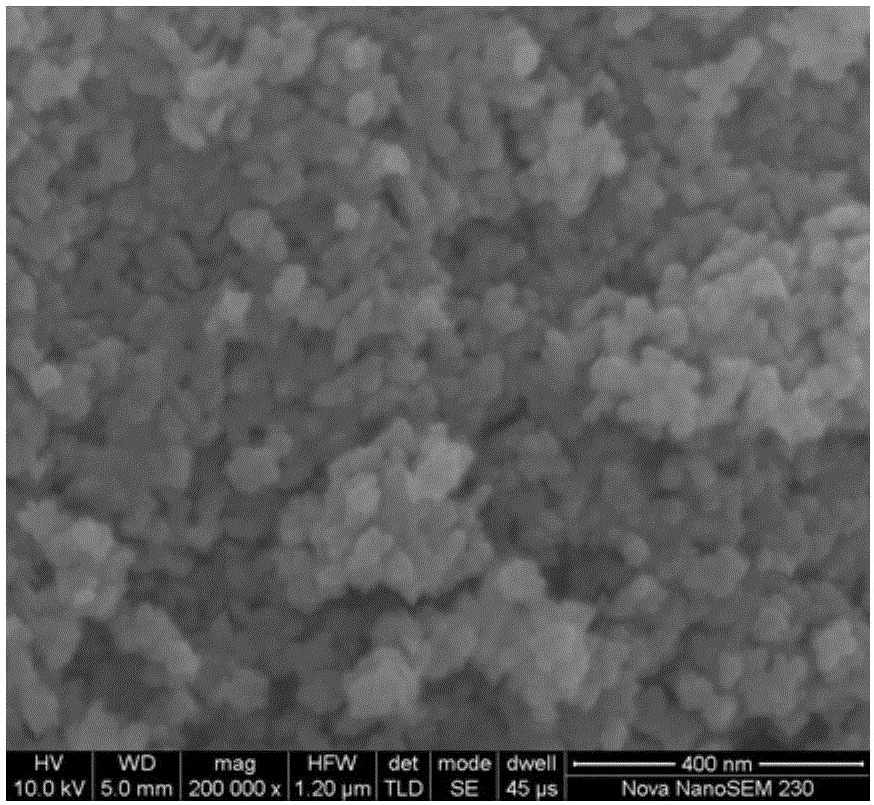

A kind of preparation method of yttrium silicate ceramic powder

ActiveCN104003699BStable pHGuaranteed GranularityMolten spray coatingOxide ceramicMaterials preparation

The invention relates to a preparation method of yttrium silicate ceramic powder, in particular relates to a preparation method of yttrium silicate ceramic powder for environment barrier coating, and belongs to the technical field of oxide ceramic material preparation. The method comprises the following steps: using a yttrium solution with Y<3+> ion concentration of 0.6-1.5 mol / L as solution A; weighing silicate ester according to a molar ratio of Y to Si being 2: 1; adding alcohol and water in the weighed silicate ester according to a volume ratio of the silicate ester to alcohol to water being 1: 1-2: 2-6 to obtain solution B; uniformly mixing the solutions A and B solution to obtain the mixed solution containing aluminum and silicon; adding the mixed solution containing aluminum and silicon into ammonium hydroxide with pH value of 9-10 at a speed of dropwise adding 0.2-0.5 L of the mixed solution containing aluminum and silicon in 1L of precipitator every minute, and stirring to obtain the co-precipitate; after the reaction is finished, standing, filtering, washing and drying the residue, calcining for at least 4 hours at 800-1000 DEG.C to obtain the Y2SiO5 ceramic composite powder. The method provided by the invention is short in reaction period and good in repeatability; and the obtained product is high in purity and is of a single crystal form.

Owner:CENT SOUTH UNIV

Intumescent flame-retardant coating for cables and preparation method of intumescent flame-retardant coating

InactiveCN112940576AGuaranteed foaming ratioThe contradiction of ensuring that the foaming ratio is reducedFireproof paintsPolymer sciencePhthalocyanine

The invention discloses an intumescent flame-retardant coating for cables and a preparation method of the intumescent flame-retardant coating. The intumescent flame-retardant coating for cables comprises the following raw materials: a component A including a base material, namely, 20.0-25.0 parts by weight of silicone acrylic emulsion; a component B including an acid source, namely, 25.0-27.5 parts by weight of ammonium polyphosphate, a carbonizing agent, namely, 15.0-16.5 parts by weight of pentaerythritol, a foaming agent, namely, 15.0-16.5 parts by weight of melamine, and auxiliaries, namely, 3.0-5.0 parts by weight of expandable graphite, 6.0-8.0 parts by weight of phthalocyanine and 12.0-16.0 parts by weight of silane coupling agent modified Fe2O3; and a component C including 4.0-6.0 parts by weight of a curing agent. The preparation method of theintumescent flame-retardant coating for cables comprises the steps of a, preparing silane coupling agent modified Fe2O3; b, uniformly mixing silane coupling agent modified Fe2O3, expandable graphite, phthalocyanine, ammonium polyphosphate, pentaerythritol and melamine to obtain a component B; c, adding the component B into the component A, uniformly stirring to obtain a component A and component B mixture, and sealing; d, sealing the component C; and e, mixing the mixture of the component A and the component B with the component C during use to obtain the intumescent flame-retardant coating for cables.

Owner:STATE GRID CORP OF CHINA +1

Straw compression molding equipment

The invention provides novel straw compression forming equipment, and relates to a compression forming device of fiber materials. The novel straw compression forming equipment comprises a main driving mechanism, a precompression mechanism and a compression mechanism. The precompression mechanism comprises a second motor, a feeding box, a precompression packing auger and a forced feeding turnover plate, a reinforcing compression cavity is formed in the outlet end of a compression cavity, and is of a left-and-right buckling structure, the two sides of the reinforcing compression cavity are connected with connecting rod mechanisms respectively, the connecting rod mechanisms are connected with a hydraulic station, the hydraulic station is controlled by an electric drive travel switch, and the hydraulic station and the electric drive travel switch are in linkage and automatic control through a PLC control cabinet. Based on the working principle that main machine volume variable physical extrusion and auxiliary machine forced feeding extrusion are combined, the materials are conveyed, extruded and dehydrated, the equipment is especially suitable for compression forming of straw type biomass, and the compressed materials are low in water content and small in density.

Owner:河南天冠纤维乙醇有限公司

Lycii fructus and flos chrysanthemi medicinal tea and preparation method thereof

InactiveCN109938128AImprove product aestheticsPrevent stamens from turning blackPre-extraction tea treatmentToxicityLiver and kidney

The invention discloses a fructus lycii and flos chrysanthemi medicinal tea and a preparation method thereof. The fructus lycii and flos chrysanthemi medicinal tea is prepared from fructus lycii, floschrysanthemi, black tea and the like. The fructus lycii and flos chrysanthemi medicinal tea has the advantages that the fructus lycii in the medicinal tea is sweet in taste and neutral in nature, theaction of the fructus lycii is associated with the liver and kidney channels, and the fructus lycii has the effects of nourishing liver and kidney and replenishing vital essence to improve eyesight;the flos chrysanthemi is bitter and sweet in taste and slightly cold, the action of the flos chrysanthemi is associated with the lung and liver, and the flos chrysanthemi has the effects of dispersingwind to clear heat, calming the liver, improving eyesight, clearing heat and removing toxicity; the fructus lycii is combined with the flos chrysanthemi, on the basis of fragrance of the black tea, the aroma of the flos chrysanthemi and the sweetness of the fructus lycii are added, the nature and the taste are complementary, the fructus lycii and flos chrysanthemi medicinal tea has the effects ofnourishing the liver and protecting the eyes, and is conductive to detoxifying the body after long-term use, processing parameters of the raw materials are scientifically optimized, the preparation method is simple, drinking is convenient, and industrialization production can be achieved.

Owner:安徽神农素食品有限公司

A box-type vacuum drying device for urban sludge

ActiveCN110395873BImprove drying rateWon't spillSludge treatment by de-watering/drying/thickeningSludgeSewage

The invention discloses a box-type vacuum drying device for urban sludge, which comprises a drying box connected with a vacuum pump; the drying box is provided with an air distribution plate to divide it into an upper material delivery area and a lower air supply area The air distribution channel is arranged on the air distribution plate; the material conveying system is arranged in the material conveying area, and the heat exchanger is installed in the air supply area. The air channel leads into the material conveying area to heat and dry the materials conveyed by the material conveying system; the drying box is also connected with a hot air circulation system. The invention is suitable for drying urban sludge, provides favorable material conveying conditions and heat medium pressure, temperature, and wind conditions for sludge drying, improves sludge drying rate, and has good environmental protection without foul smell in the drying process.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Driver of drum washing machine

InactiveCN102660856BCompact structureSmall footprintOther washing machinesTextiles and paperLow speedGear wheel

The invention discloses a driver of a drum washing machine, comprising a motor and an output shaft, and further comprising a gear reduction mechanism, wherein the output shaft is coaxially installed in an electronic rotor of the motor and fixedly connected with an output gear of the gear reduction mechanism, and an input gear shaft of the gear reduction mechanism is inserted-installed in a shaft hole of the motor rotor. Via the arrangement of the gear reduction mechanism, the driver of a drum washing machine provided by the invention can realize the low-speed output of the output shaft via the gear reduction mechanism during the high-speed rotation of the motor, and ensure the high-speed running of the motor in the case that the drum washing machine is in a washing working condition, thus increasing the use efficiency of the motor. Additionally, the gear reduction mechanism provided by the invention is installed on the motor, the motor rotor is used as a gear rack, and the motor and the gear reduction mechanism are effectively integrated, so that the driver is simple and compact in structure, and small in occupied space.

Owner:CHANGZHOU XINYA ELECTROMOTOR

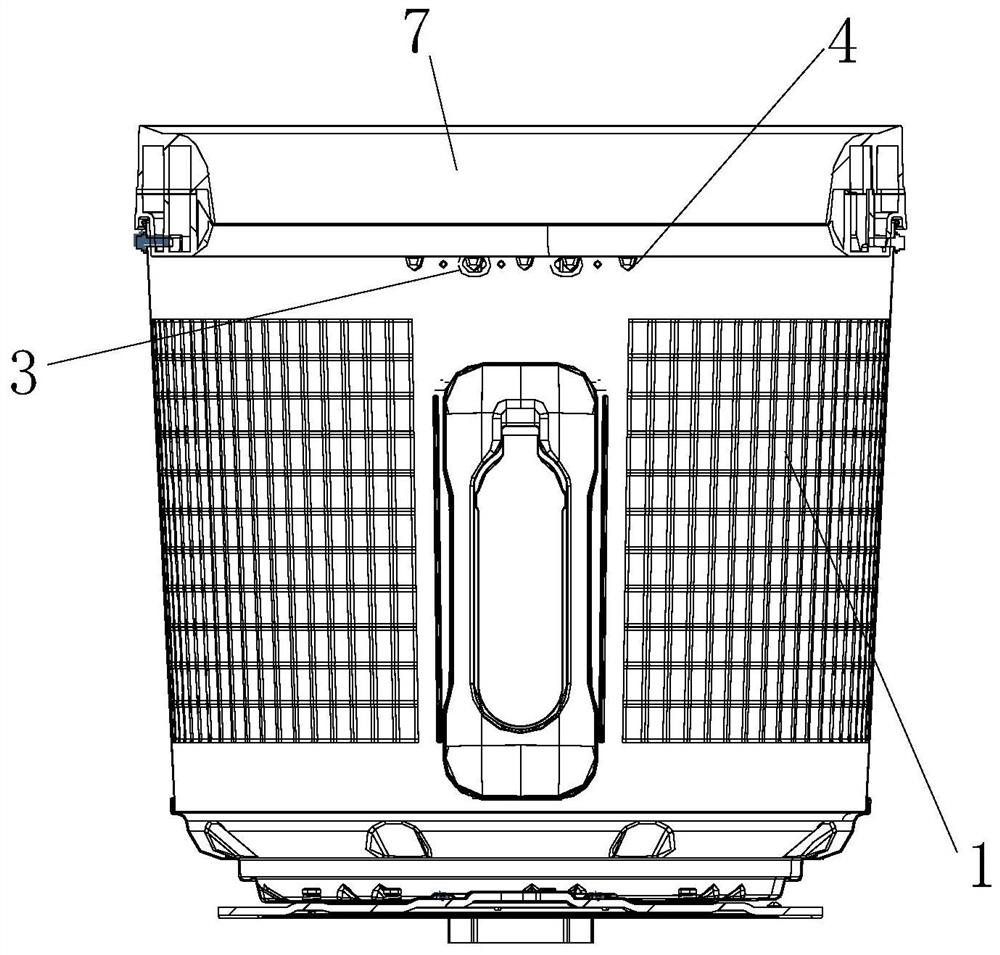

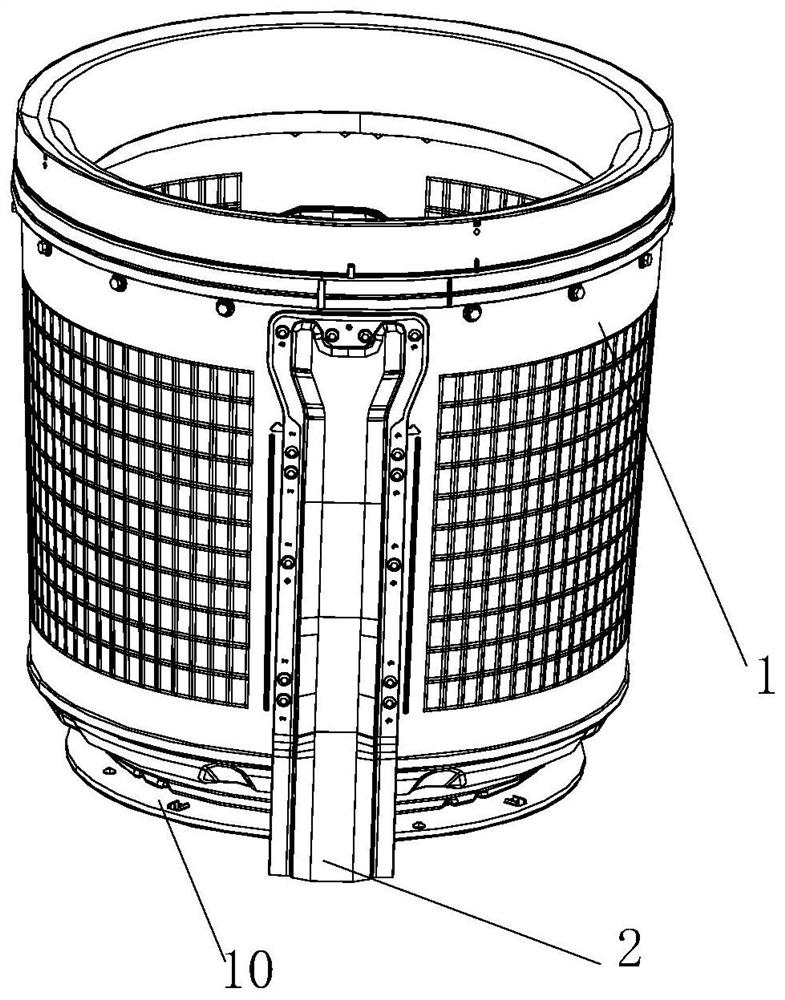

Dehumidification and energy-saving drying device and method

PendingCN109974412AIncrease temperatureImprove energy efficiencyDrying gas arrangementsDrying solid materialsFour-way valveProcess engineering

The invention discloses a dehumidification and energy-saving drying device. The dehumidification and energy-saving drying device comprises a compressor, a refrigerant pipeline connected with the compressor, a refrigerant operating in the refrigerant pipeline, a drying chamber for placing to-be-dried objects, a heating device for heating air to form heated air, an air supply device for delivering the heated air to the drying chamber, a cooling capacity releasing device for releasing the cooling capacity of the refrigerant, a heat recovery device for cooling the heated air discharged from the drying chamber, and a cooling device for condensing and dehumidifying the air; the refrigerant pipeline is provided with a four-way valve, a first expansion valve is arranged between the four-way valveand the cooling capacity releasing device, and a second expansion valve is arranged between the four-way valve and the cooling device; and the heat recovery device comprises a first heat exchange channel and a second heat exchange channel, and the drying chamber is internally provided with a drying area. According to the dehumidification drying device, the cooling capacity and heat are all utilized, and energy saving is more significant.

Owner:苏州达善净化科技有限公司

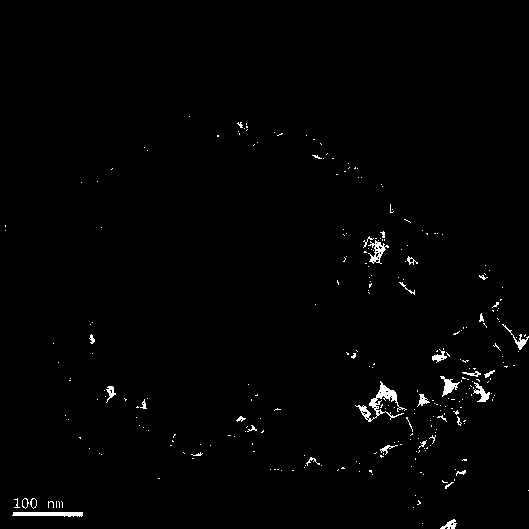

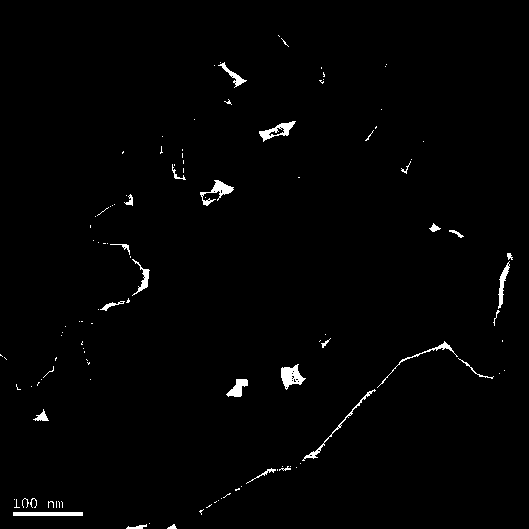

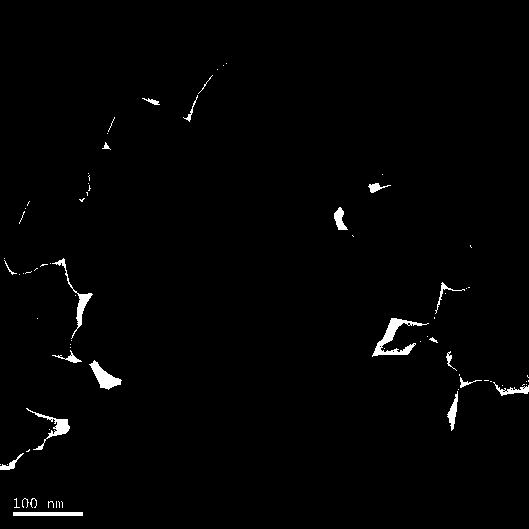

A method for adjusting the length of tungsten oxide nanorods by oxygen

ActiveCN105948128BHigh viscosityGuaranteed dehydrationTungsten oxides/hydroxidesNanotechnologyCarbon nanotubeHeat treated

The invention provides a method for adjusting the length of a tungsten oxide nano-rod by means of oxygen and belongs to the technical field of tungsten-based nano-materials. According to the method, tungsten metal salt serves as a tungsten source, a carbon nano-tube serves as a carrier, ethanediol serves as a dispersant, hydrochloric acid is added into the reaction system, tungstic acid is directly separated out of the surface of the carbon nano-tube and covers the surface of the carbon nano-tube, tungstic acid grows along the surface of the carbon nano-tube, and then a tungstic acid / carbon nano-tube rodlike composite is formed. Then, the composite is put in a high-temperature reaction region for heat treatment, an oxidizing atmosphere is introduced, the carbon nano-tube is burnt, the burning degree of the carbon nano-tube and the generation speed of carbon dioxide are controlled by controlling the gas flow and the oxygen content, the breakage degree and surface shrinkage degree of the tungsten oxide nano-rod are controlled accordingly, and therefore the purpose of shearing the tungsten oxide nano-rod is achieved.

Owner:JIANGXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com