Infrared radiation static dryer

A technology of infrared radiation and drying machine, applied in the direction of drying machine, drying, drying solid materials, etc., can solve problems such as uneven distribution of hot air, broken tea leaves, affecting dehydration and color of tea leaves, and achieves fewer turning times and loss of color. Uniform water, guaranteed dehydration and color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

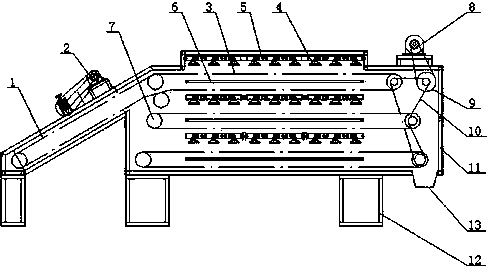

[0013] figure 1 Among them, an infrared radiation static dryer includes a frame 12 and a driving device. The frame 12 is provided with multi-layered interlaced conveying mesh belts 3, and the transmission directions of the separated conveying mesh belts 3 are opposite, and the driving device Drive the conveying mesh belt 3 to drive, the inlet of the dryer corresponds to the front end of the first layer of conveying mesh belt 3 connected with the feeding conveying mesh belt 1, the feeding conveying mesh belt 1 is provided with a uniform leaf mechanism 2, and the conveying mesh belt 3 An infrared radiation heating device 4 is arranged above the working surface. The infrared radiation heating device 4 is installed on a fixed plate 5 . The first layer of conveying mesh belt 3 and the feeding conveying mesh belt 1 are integrally connected, the first layer of conveying mesh belt 3 and the feeding conveying mesh belt 1 are driven circularly by the transmission roller 7, and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com