Air and coolant coupled electric vehicle battery pack thermal management system

A thermal management system and technology for electric vehicles, applied in the field of thermal management systems for electric vehicle battery packs, can solve the problems of low temperature consistency of battery packs, lack of battery pack thermal insulation function, poor cooling conditions at the end of pipes, etc., and achieve good heat dissipation. effect, improve high temperature heat dissipation and low temperature heat preservation ability, and improve the effect of temperature consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

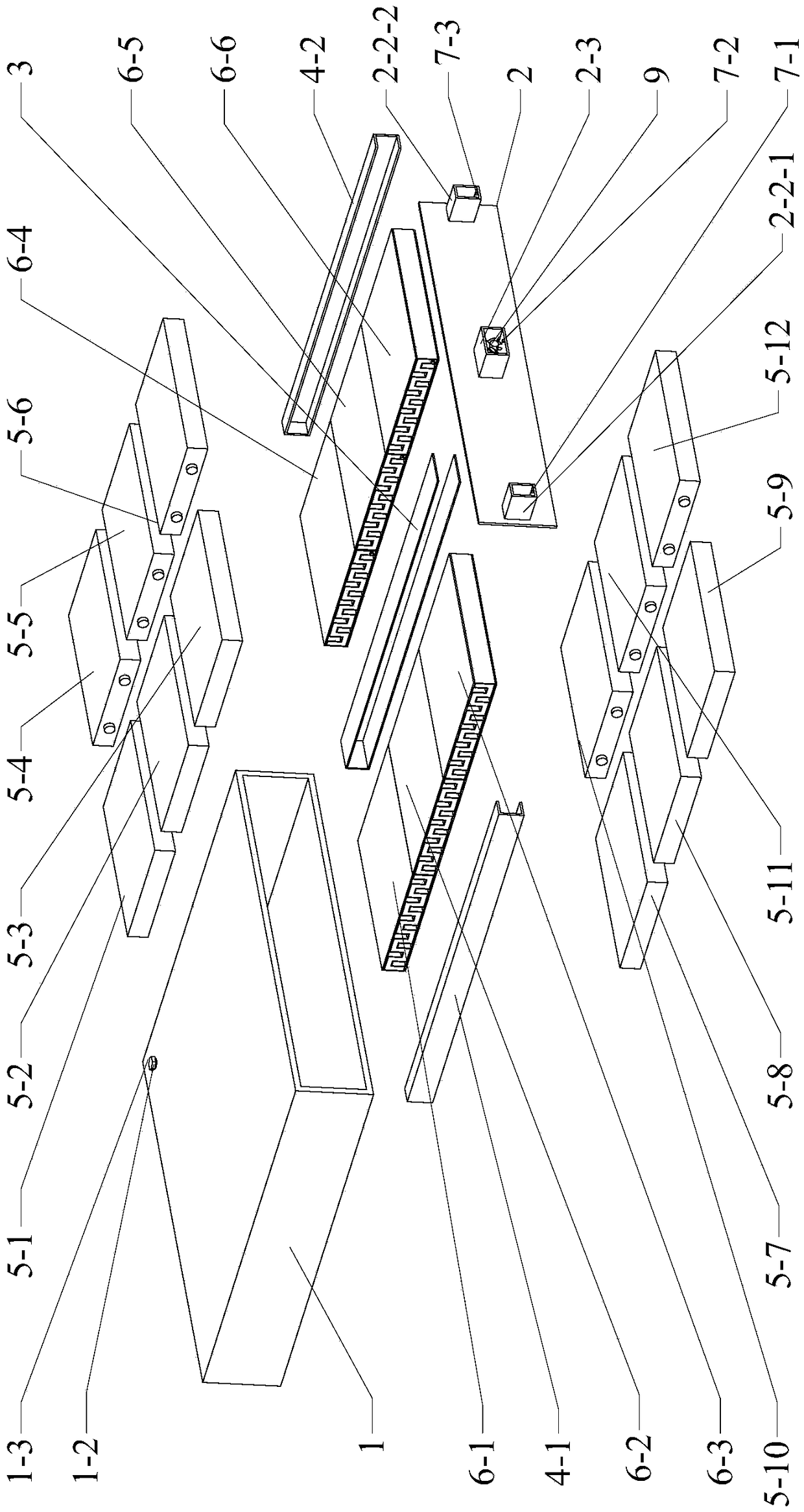

[0043]The implementation process of the present invention applied to 12 vehicle-mounted battery cells is described in detail below in conjunction with the accompanying drawings:

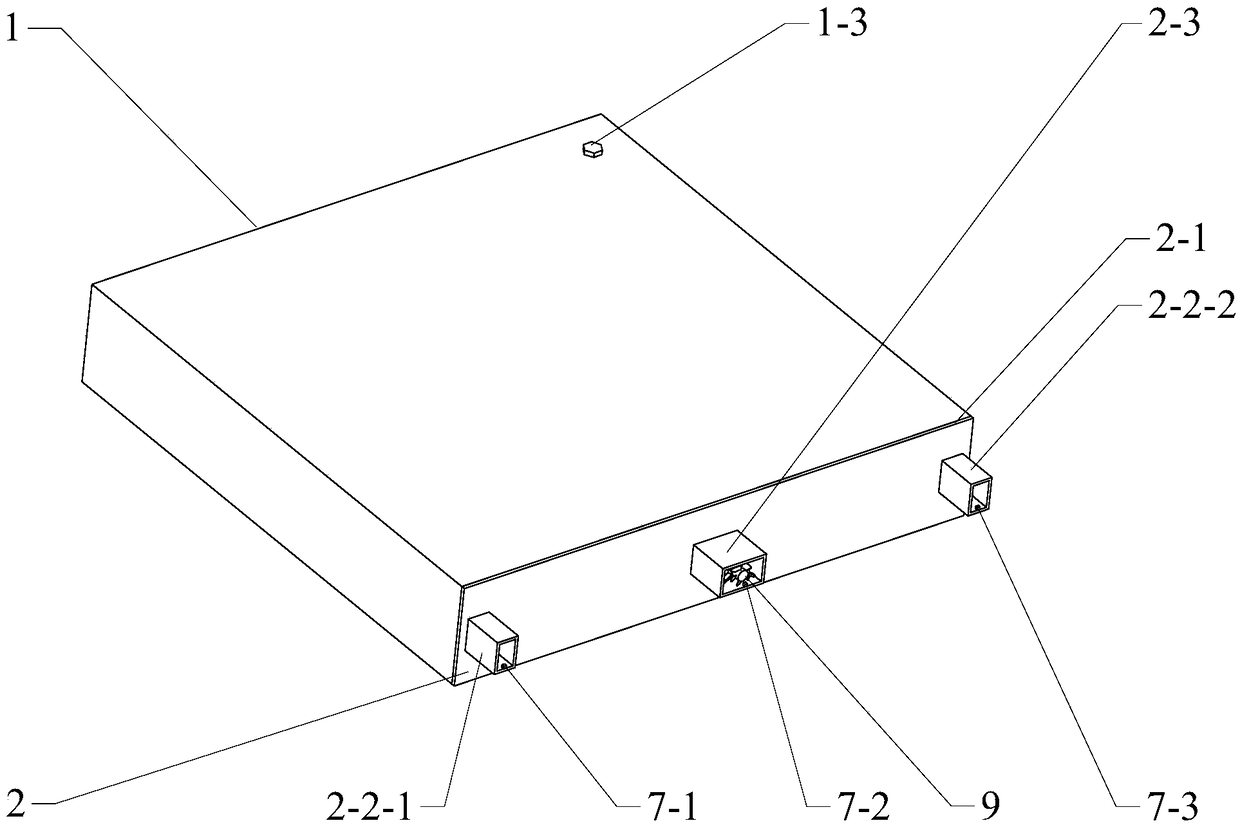

[0044] Such as figure 1 , figure 2 , Figure 14 As shown, the present invention is installed on the automobile body in combination with the vehicle-mounted battery monomer, and is connected with the electronic control unit ECU8 of the automobile. 2. Battery cooling module, air inlet guide cover 3, air outlet guide cover 4-1, air outlet guide cover 4-2, thermocouple 7-1, thermocouple 7-2, thermocouple 7-3, regulator Speed fan 9 is formed;

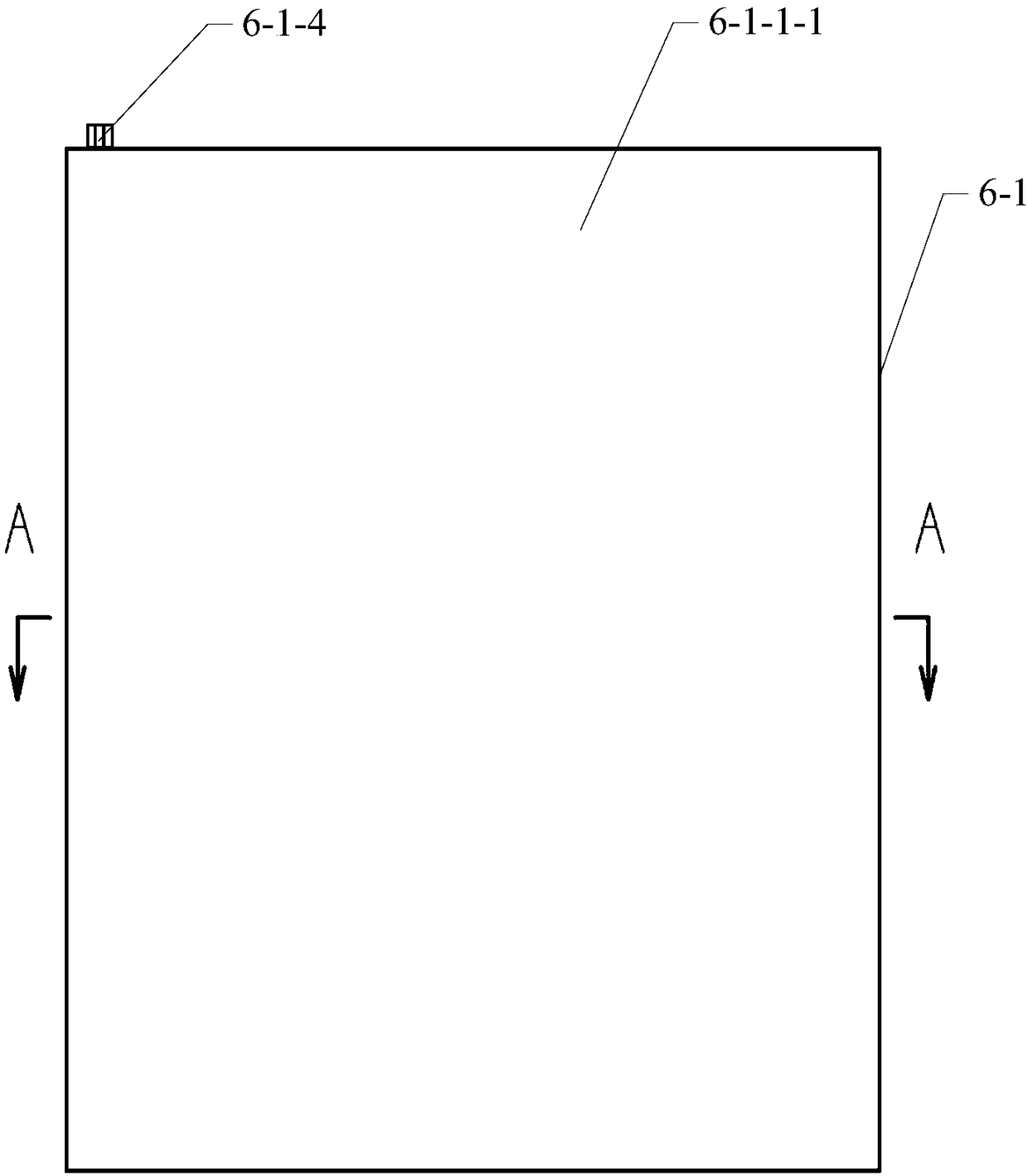

[0045] Such as figure 1 , figure 2 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 10 , Figure 11 , Figure 12 , Figure 13 As shown, the battery box 1 is a rectangular parallelepiped open shell with a double-layer shell, a cavity is formed between the two layers of the double-layer shell, and a phase-change material injection hole 1-1 i...

Embodiment 2

[0055] The implementation process of the present invention applied to 16 vehicle-mounted battery cells is described in detail below in conjunction with the accompanying drawings:

[0056] Such as figure 2 , Figure 14 , Figure 15 As shown, the present invention is combined with the vehicle-mounted battery monomer and installed on the automobile body, and is connected with the electronic control unit ECU8 of the automobile. End cover 2, battery cooling module, air inlet guide cover 3, air outlet guide cover 4-1, air outlet guide cover 4-2, thermocouple 7-1, thermocouple 7-2, thermocouple 7-3 , speed-regulating fan 9 components;

[0057] Such as figure 2 , Figure 5 , Figure 6 , Figure 7 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 15 , Figure 16 As shown, the battery box 1 is a rectangular parallelepiped open shell with a double-layer shell, a cavity is formed between the two layers of the double-layer shell, and a phase-change material injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com