Noise reduction system and method of washing machine and washing machine

A technology of noise reduction system and washing machine, which is applied to other washing machines, washing devices, sounding equipment, etc., can solve the problems of inconvenient maintenance, complex structure, poor adaptability, etc., and achieves convenient operation and maintenance, simple overall structure, and obvious noise reduction effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

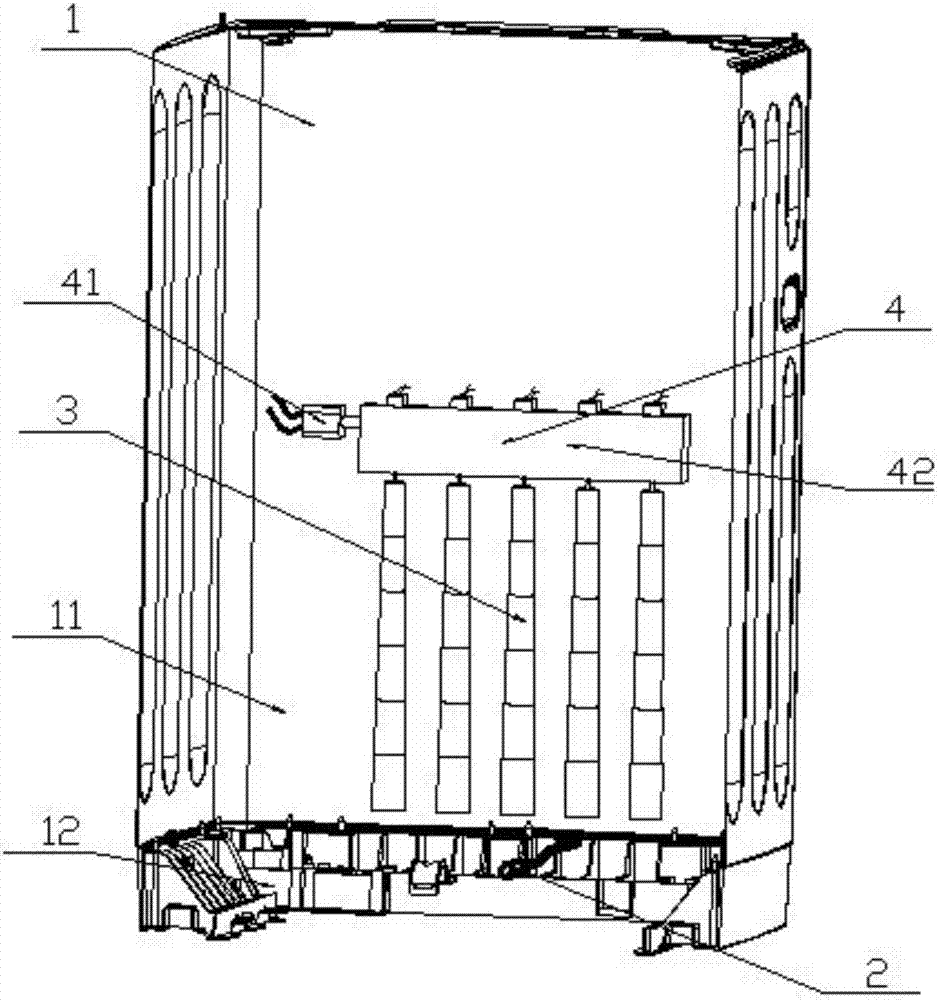

[0065] Such as Figure 1-2 As shown, in this embodiment, a noise reduction system for a washing machine 1 is provided, including

[0066] Noise collection module 2;

[0067] Noise processing module: processing the collected noise signal to obtain at least one frequency of main noise contribution;

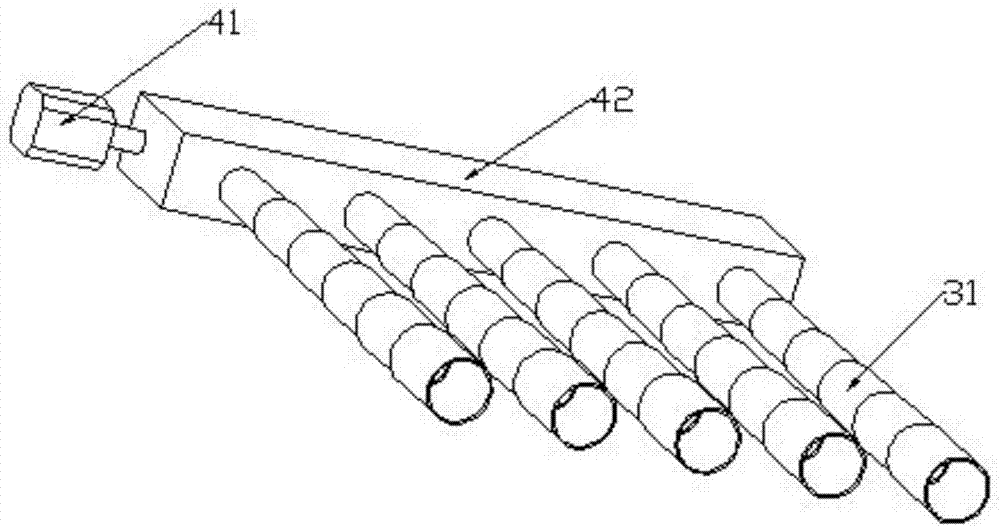

[0068] Noise elimination module 3: including at least one long pipe 31 with adjustable length, to eliminate the noise contributed by the main noise;

[0069] And control module 4: adjust the length of the long pipe 31.

[0070] The noise elimination module 3 includes five long pipes 31, and the long pipes 31 are used to eliminate the noise mainly contributed by the noise.

[0071] The long tube 31 is a tubular structure with one end closed and the other end open and connected to the noise processing module; the long tube 31 can change in length along its length direction.

[0072] The control module 4 adjusts the length of the long pipe 31 to be 1 / 4 of the wavelength of a main n...

Embodiment 2

[0083] Such as Figure 1-2 As shown, in this embodiment, a noise reduction system for a washing machine 1 is provided, including

[0084] Noise collection module 2;

[0085] Noise processing module: processing the collected noise signal to obtain at least one frequency of main noise contribution;

[0086] Noise elimination module 3: including at least one long pipe 31 with adjustable length, to eliminate the noise contributed by the main noise;

[0087] And control module 4: adjust the length of the long pipe 31.

[0088] The long tube 31 is a tubular structure with one end closed and the other end open and connected to the noise processing module; the long tube 31 can change in length along its length direction.

[0089] The control module 4 adjusts the length of the long pipe 31 to be 1 / 4 of the wavelength of a main noise sound wave. internal offset.

[0090] The long tube 31 includes at least two sets of tubes with different sizes but matching shapes, the small size tu...

Embodiment 3

[0100] Such as Figure 1-2 As shown, in this embodiment, a noise reduction system for a washing machine 1 is provided, including

[0101] Noise collection module 2;

[0102] Noise processing module: processing the collected noise signal to obtain at least one frequency of main noise contribution;

[0103] Noise elimination module 3: including at least one long pipe 31 with adjustable length, to eliminate the noise contributed by the main noise;

[0104] And control module 4: adjust the length of the long pipe 31.

[0105] The difference from the second embodiment is that at least two groups of noise elimination modules 3 are arranged in different positions inside the washing machine cabinet 11 , and each group of noise elimination modules 3 includes at least one long pipe 31 . Each group of noise elimination modules 3 is connected with a group of control modules 4, and its own control module 4 controls its noise elimination.

[0106] The long pipe 31 is a quarter corrugated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com