Patents

Literature

38results about How to "Uniform dehydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

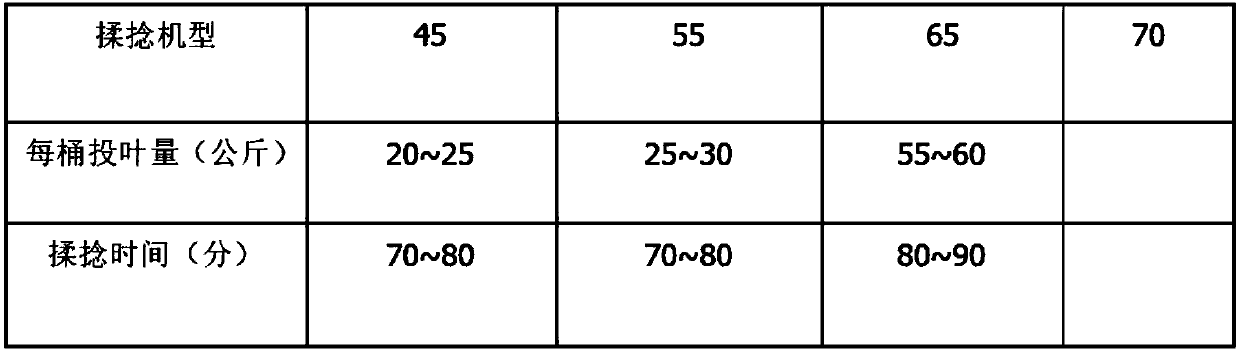

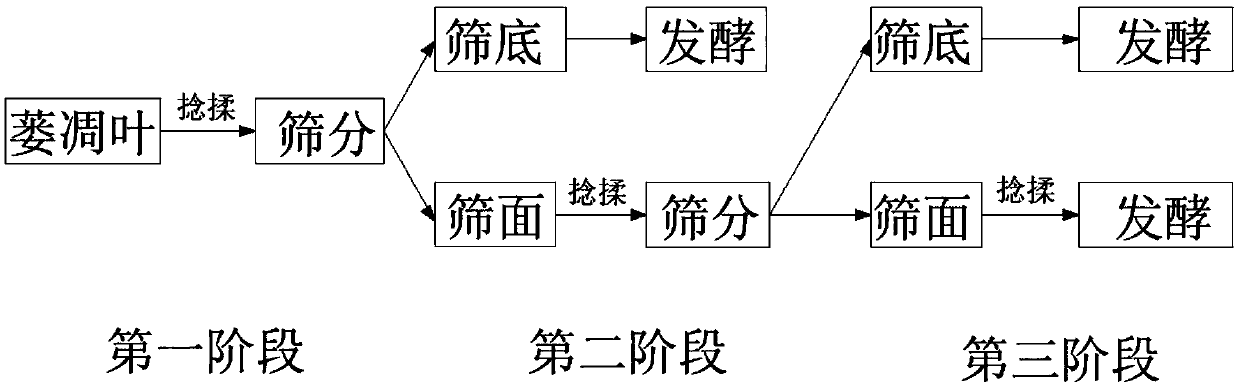

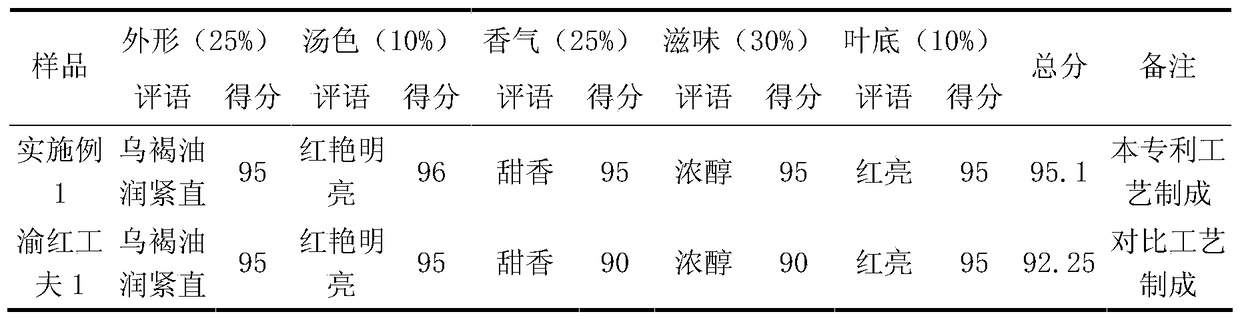

Black tea processing method

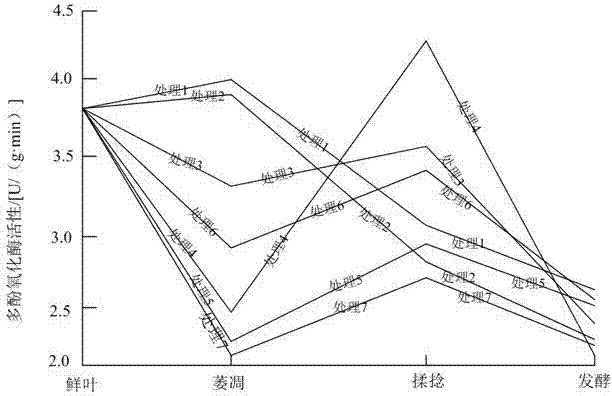

The invention discloses a black tea processing method. The method sequentially comprises the steps of raw material selection and picking, withering, rolling, fermentation, shaping and curing. In the rolling step, a rolling barrel is filled with withered tea leaves, empty rolling is carried out for 20-25 min, light pressing is carried out for 20-25 min, heavy pressing is carried out for 25-30 min, light pressing is carried out for 10-15 min, empty rolling is carried for 5 min, and then black tea is obtained, wherein the total tea rolling time is 80-100 min. Black tea obtained through the black tea processing method is compact, fine straight and upright in appearance, black and smooth in color, highly tender, red and bright in tea water color, fragrant, sweet and high in purity, mellow, brisk and sweet in taste, red, bright and fresh in leaf bottom, uniform and complete, straight and strong in appearance, red and bright in the tea water color, strong, fragrant and sweet in fragrance, bright-colored, red and bright in tea water color, and fresh, brisk and thick in taste.

Owner:CHONGQING YUNLING TEA IND TECH

Styliform tea producing method

InactiveCN101133765AUniform dehydrationIncrease temperaturePre-extraction tea treatmentEngineeringDehydration

The present invention provides a preparation method of needle tea. Said preparation method includes the following steps: steaming, dehydration, primary rolling, hot air drying, further rolling, forming and drying so as to obtain the invented finished product.

Owner:CHONGQING ACAD OF AGRI SCI

Compressed tea flower and white tea cake and preparation method thereof

InactiveCN105815477AEfficient bindingGreat tastePre-extraction tea treatmentAdditive ingredientPolyphenol

The invention relates to the technical field of white tea cake preparation, in particular to a compressed tea flower and white tea cake and a preparation method thereof .The preparation method includes the steps of tea flower preparation, white tea preparation and mixing forming .After tea flowers and white tea are mixed at the mass ratio of 0.7:1.3, stream-pressure softening treatment is carried out with a steam machine, and roasting treatment is carried out multiple times, so that nutritional ingredients in tea flowers and nutritional ingredients in white tea are effectively combined, it is ensured that tea cake leaves are oily, and inlaid with golden yellow tea flowers, the tea cake is strong and refreshing in aroma, obvious in flowery fragrance, sweet and tasty .Loss of the aroma, the beneficial substance tea polyphenol and the like in the processing process is reduced, and dehydration is uniform; the taste of the tea cake is improved.

Owner:贵州湄潭兰馨茶业有限公司

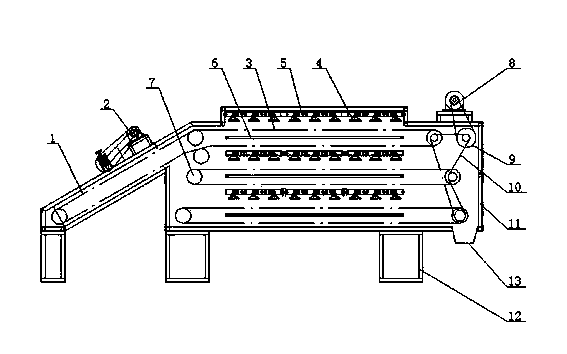

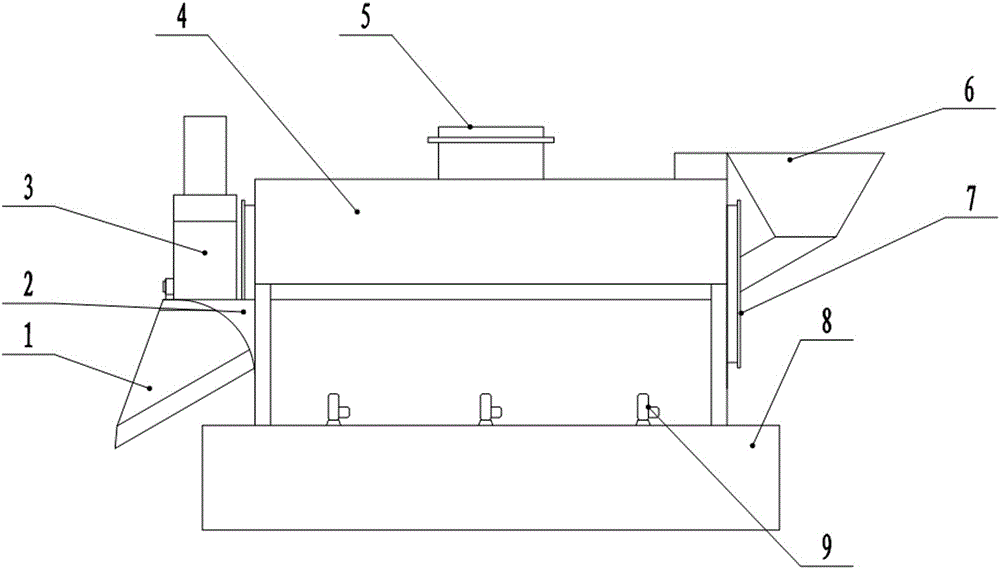

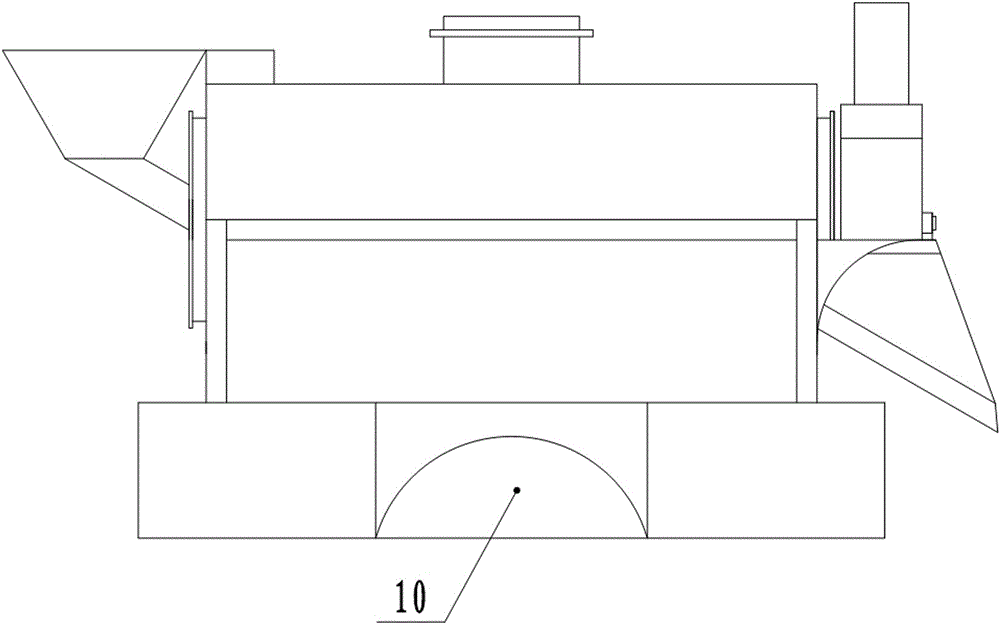

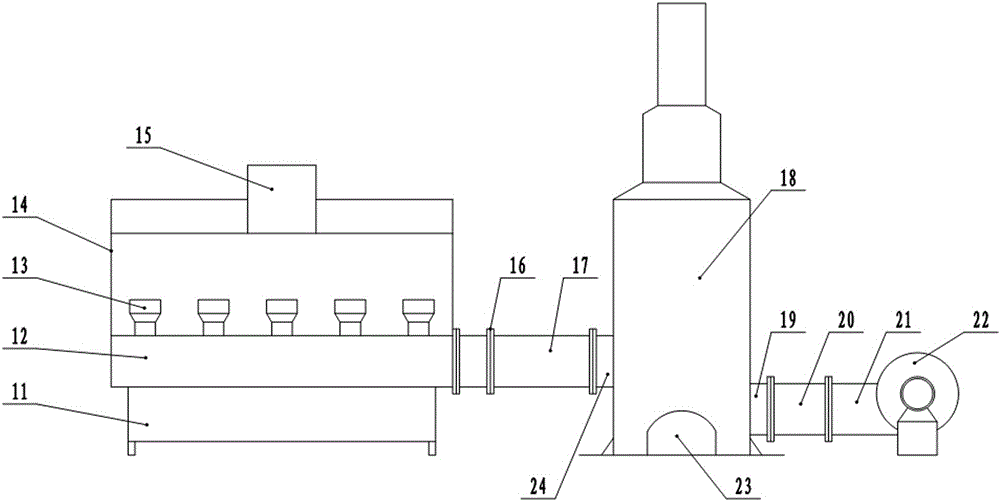

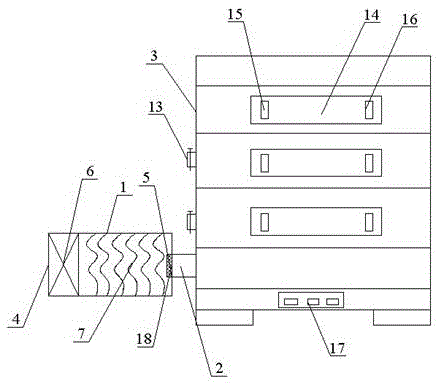

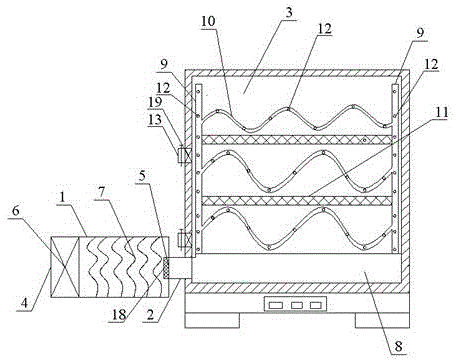

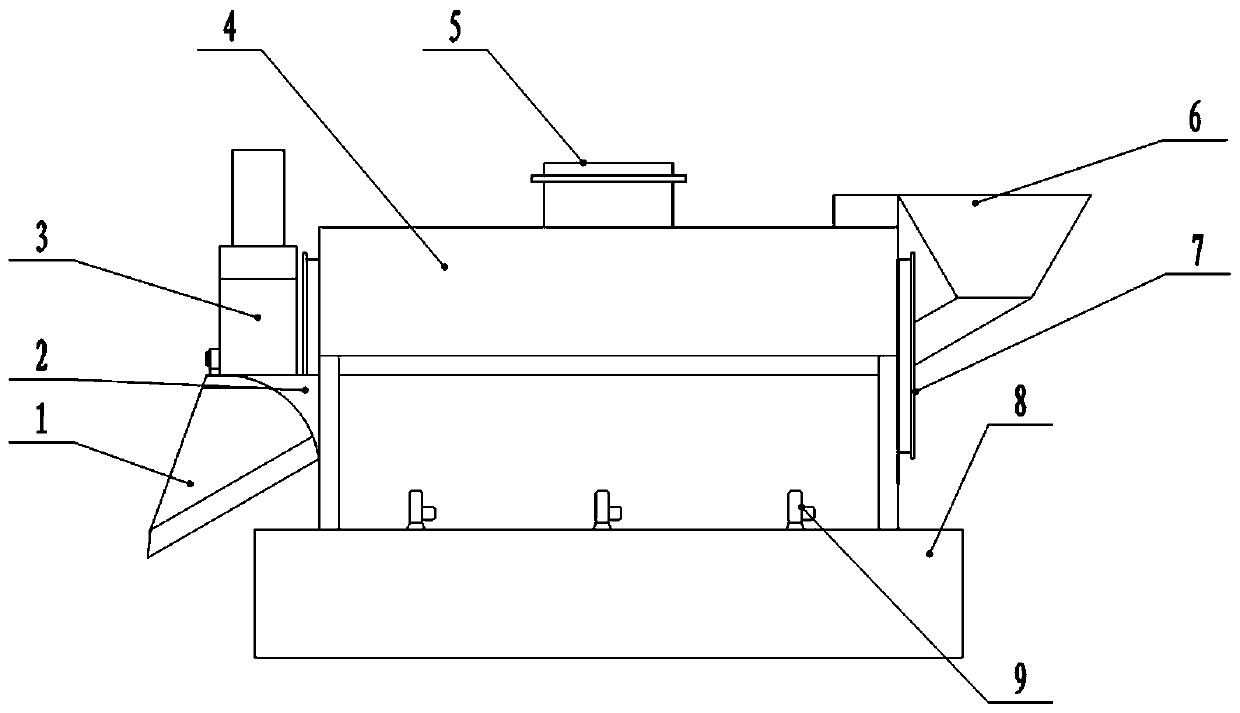

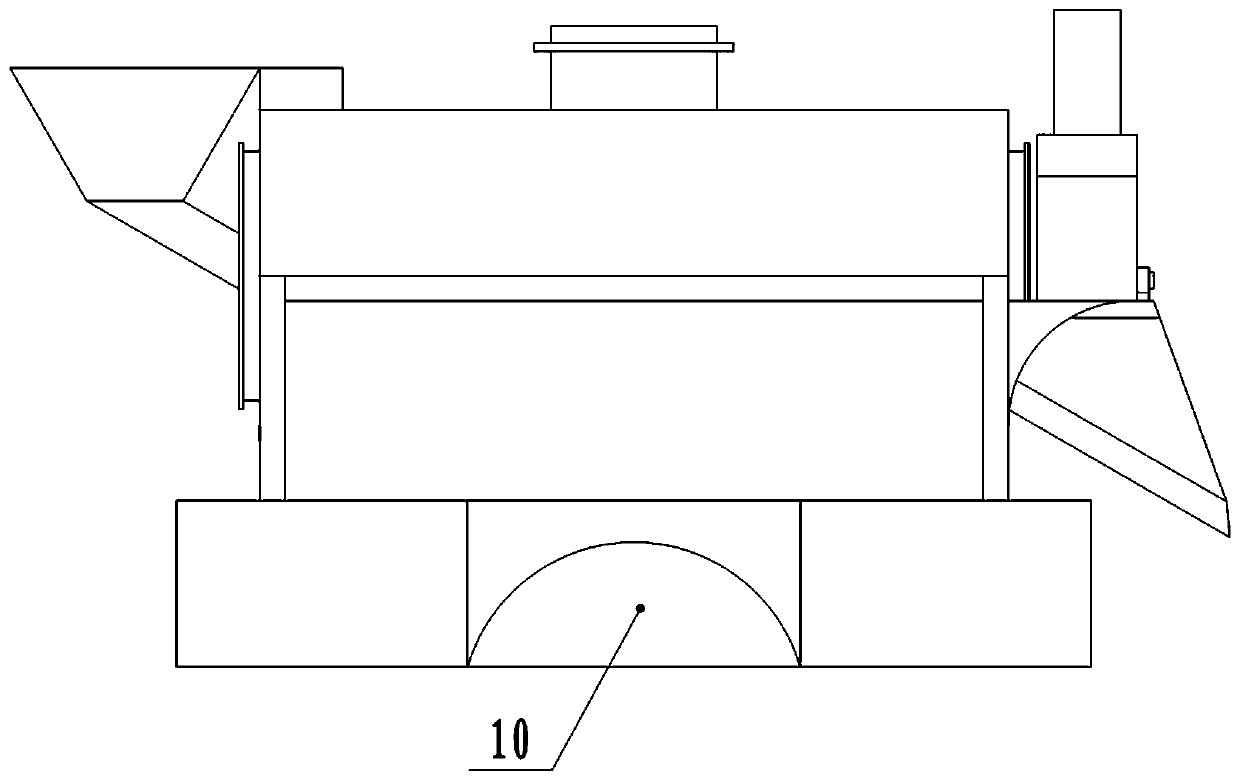

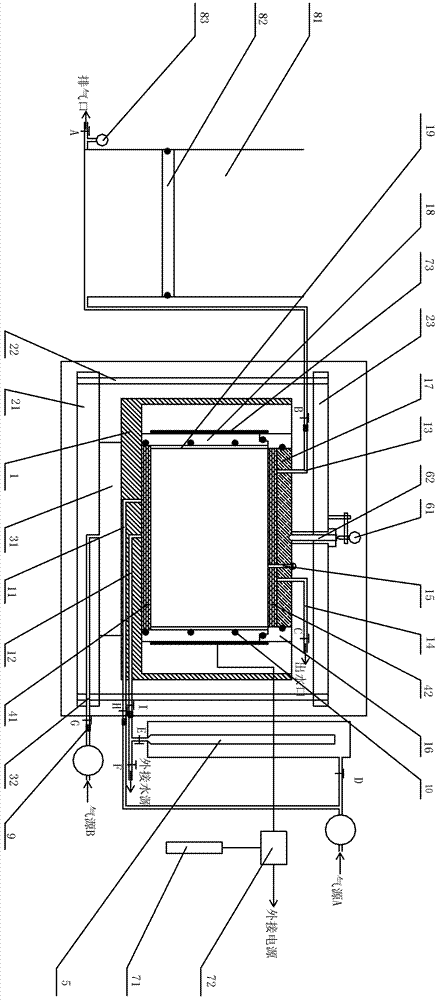

Infrared radiation static dryer

ActiveCN103478308AGuaranteed dehydrationGuaranteed colorPre-extraction tea treatmentDrying solid materials with heatInfraredPulp and paper industry

The invention relates to an infrared radiation static dryer. The infrared radiation static dryer comprises a rack and a driving device, wherein the rack is provided with a plurality of layers of staggered convey net belts, the separated convey net belts drive in opposite directions, the driving device drives the convey net belts to transmit, the inlet of the dryer is opposite to the front end of the first layer of convey net belt and is connected with a feed convey net belt, the feed convey net belt is provided with an even leaf mechanism, infrared radiation heating devices are arranged above the work surfaces of the convey net belts and are installed on a fixed plate, and the heating devices are uniformly arranged in the transverse and longitudinal directions of the convey net belts. The infrared radiation static dryer adopts infrared radiation static drying and adopts a plurality of layers of staggered convey net belts, the infrared radiation heating devices are arranged above the work surfaces of the convey net belts, so that tea leaves are dried at consistent temperature, are guaranteed to be dehydrated and have color and luster, and are not easy to break, and part of the fragrance is not brought away.

Owner:ZHEJIANG ZHUFENG MACHINERY +1

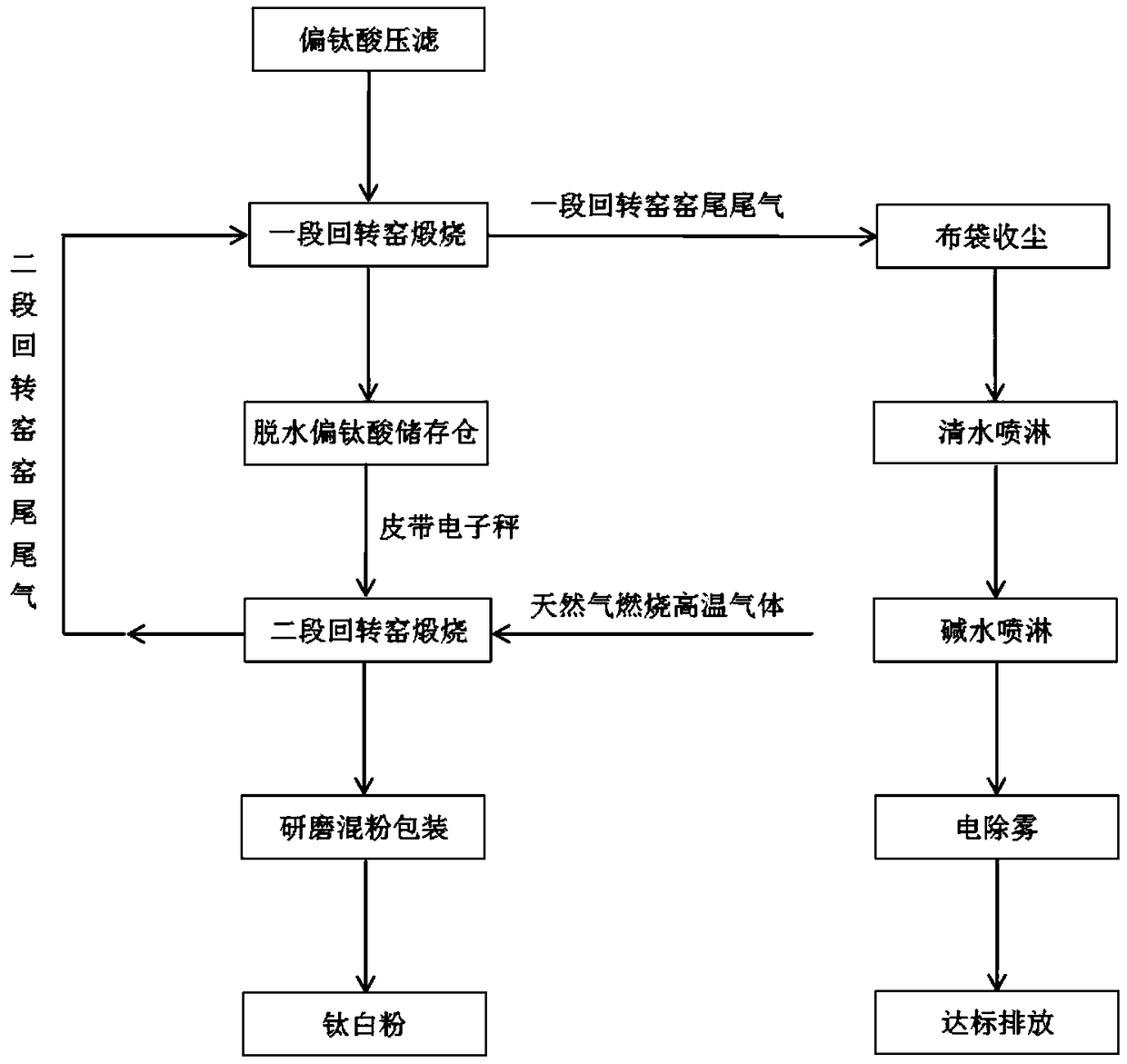

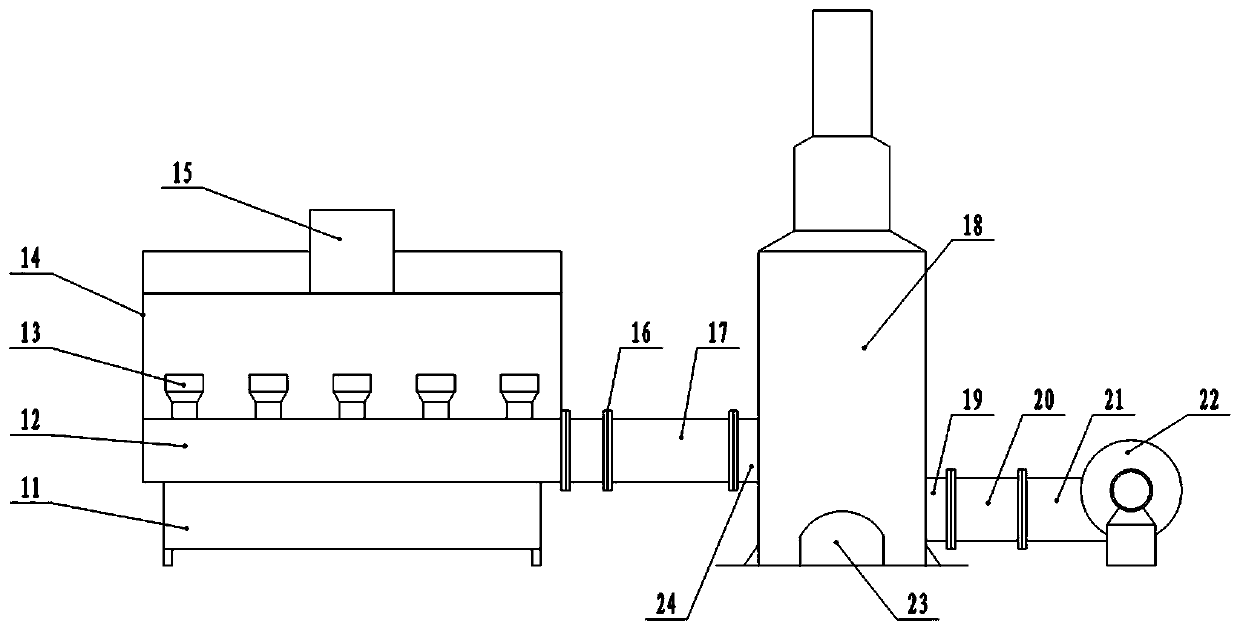

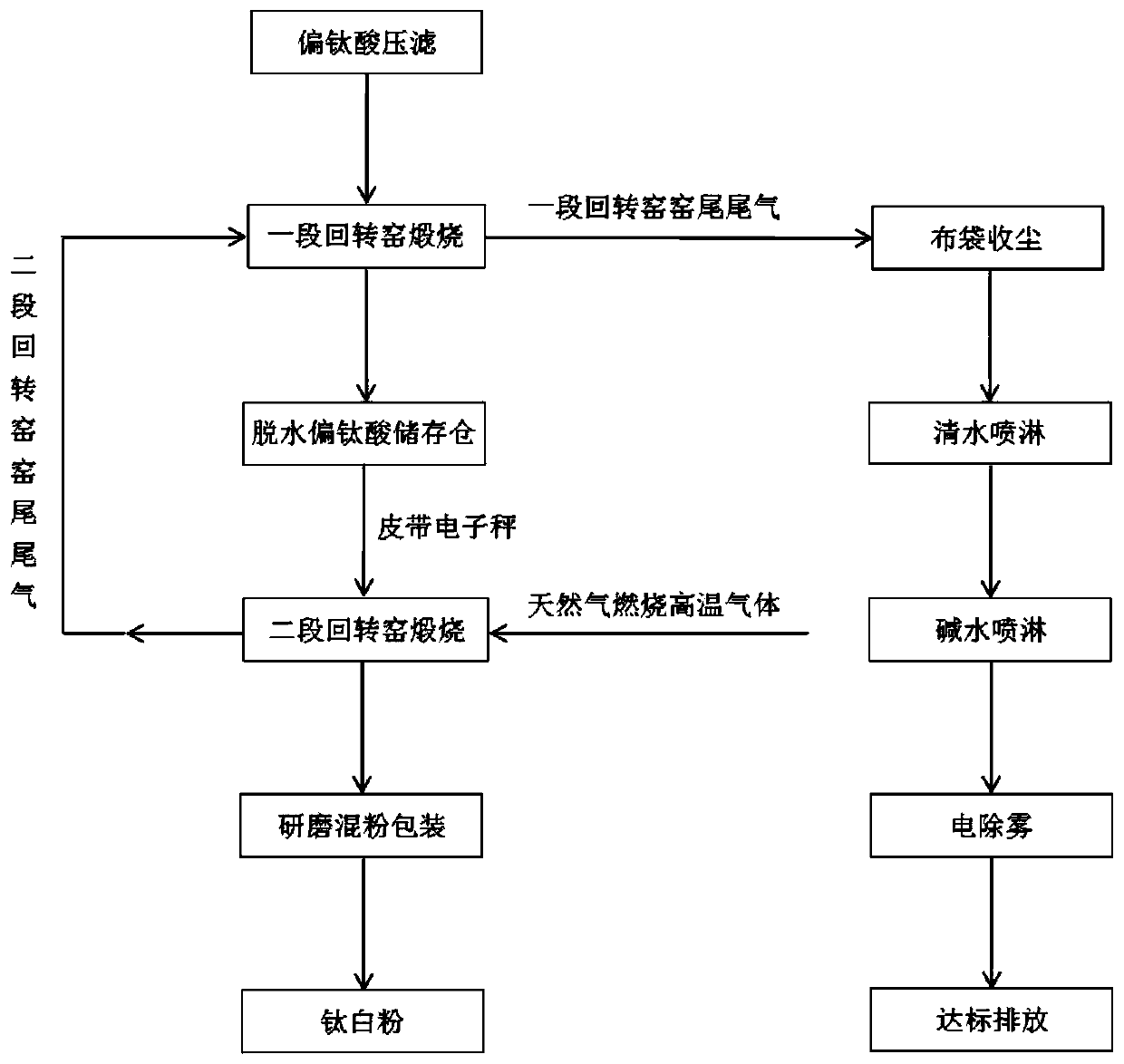

Method for preparing titanium dioxide by calcining metatitanic acid in double-section rotary kiln

ActiveCN108793244AImprove calcination recoveryEffective temperature controlTitanium dioxideGrain growthEnergy consumption

The invention discloses a method for preparing titanium dioxide by calcining metatitanic acid in a double-section rotary kiln. The method comprises the following steps: enabling metatitanic acid afterfilter pressing to successively perform dehydration in a first-section rotary kiln for calcining, and perform desulfuration, crystal type transform and grain growth in a second-section rotary kiln for calcining, to obtain a kiln falling product, and performing grinding and powder mixing on the kiln falling product, wherein a heat source of the second-section rotary kiln for calcining is from a high-temperature gas generated by calcining a natural gas, a heat source of the first-section rotary kiln for calcining is from a kiln tail gas generated by the calcining of the second-section rotary kiln, and the kiln tail gas generated by the calcining of the first-section rotary kiln successively passes through a dust collecting chamber and a bag dust collector for recovering kiln tail dust. Themethod is capable of improving the quality of the titanium dioxide, and improving a calcining recovery rate of the rotary kiln, wherein the recovery rate is up to 99.8%. The energy consumption of thenatural gas is reduced by 30-45%, and a usage amount of the natural gas is reduced.

Owner:CNMC GUANGXI PGMA

Method for processing Duyun tippy tea

InactiveCN103798422AStable tasteUniform dehydrationPre-extraction tea treatmentCooling downFood processing

The invention relates to a method for processing Duyun tippy tea, and belongs to the technical field of food processing. The method comprises the following steps: a, spreading fresh leaves for cooling down; b, performing fixation; c, rolling; d, twisting the leaves into pellets; and e, highlighting the vellus. The method has the beneficial effects that the Duyun tippy tea processed by using the method is compact, fine and curly in appearance, uniform and tidy in vellus, green and smooth, yellow green and bright in soup color, uniform and tidy in leaf bottom, and vivid and light green in color.

Owner:DUYUN JIANJIANG TEA

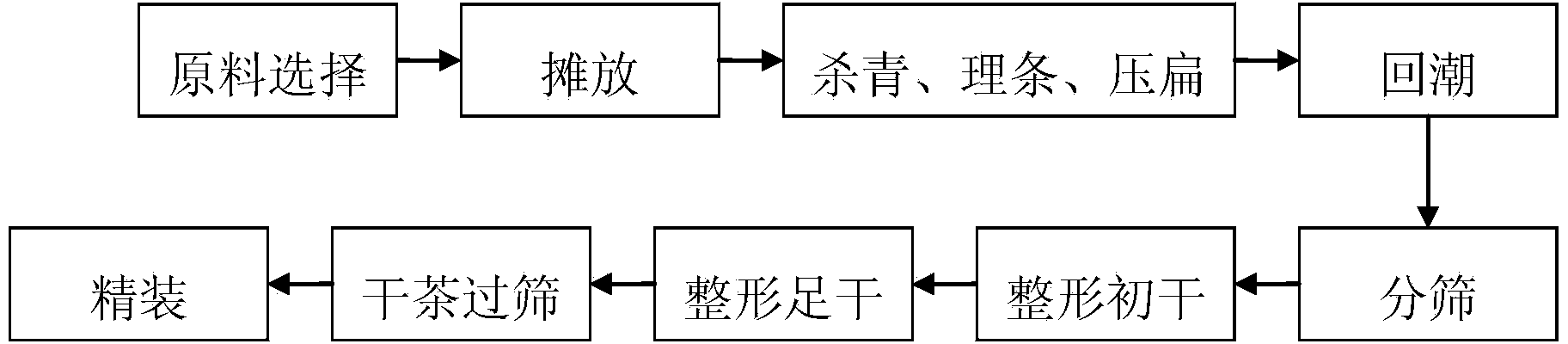

Producing and processing method of high mountain tea

The invention discloses a producing and processing method of high mountain tea. The producing and processing method is characterized by comprising the following steps: selecting raw materials, spreading, removing green, making into strips, flattening, wetting-back, sizing, shaping and drying primarily, shaping and drying enough, screening dried tea and stacking. The high mountain tea produced according to the producing and processing method is heavy in tea body, not dry, mellow and full in color, is light green, and has the advantages of being fresh and mellow in flavor.

Owner:文县玉皇茶业有限公司

Black tea processing method

The invention provides a black tea processing method. The black tea processing method comprises the following steps of firstly pretreating tea leaves, then performing withering, performing rolling, then performing fermentation, then performing a working procedure of hot blowing for quality improvement, and finally performing drying so as to obtain black tea, wherein in the working procedure of hot blowing for quality improvement, fermented tea blanks are uniformly heated by hot blowing for quality improvement equipment, and besides, peculiar smell is eliminated. According to the black tea processing method disclosed by the invention, a technology of hot blowing for quality improvement is newly added, so that the activity of enzymes is effectively restrained, besides, mixed peculiar smell of herbal flavor, wet stuffiness and the like in the tea blanks is eliminated, the tea blanks are uniformly dehydrated, and the problem that the quality of the black tea is influenced by water stifling taste and the like produced in the working procedure of drying is solved. After quick-freeze withering treatment, microwave treatment is performed, so that tea leaves are soft in leaves, the tenacity of the tea leaves is strengthened, and shaping is facilitated. In the rolling treatment process of the tea leaves, ultrasonic treatment is performed, so that the cytoclasis of the tea leaves is thorough, and later-stage fermentation treatment is facilitated. The fragrance fresh and brisk degree, the mellow degree, the brewing resistant degree and the tea soup brightness of black tea products made by the black tea processing method disclosed by the invention are obviously improved, and the green and astringency sense of the black tea products is reduced.

Owner:朱步泉 +2

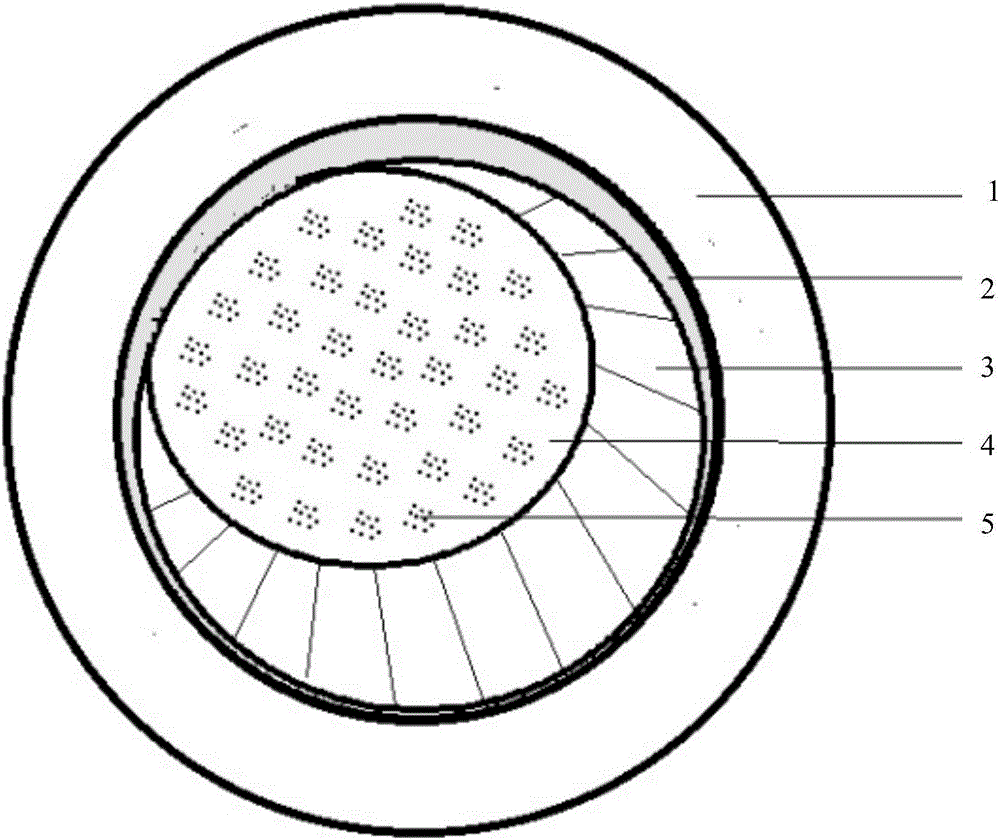

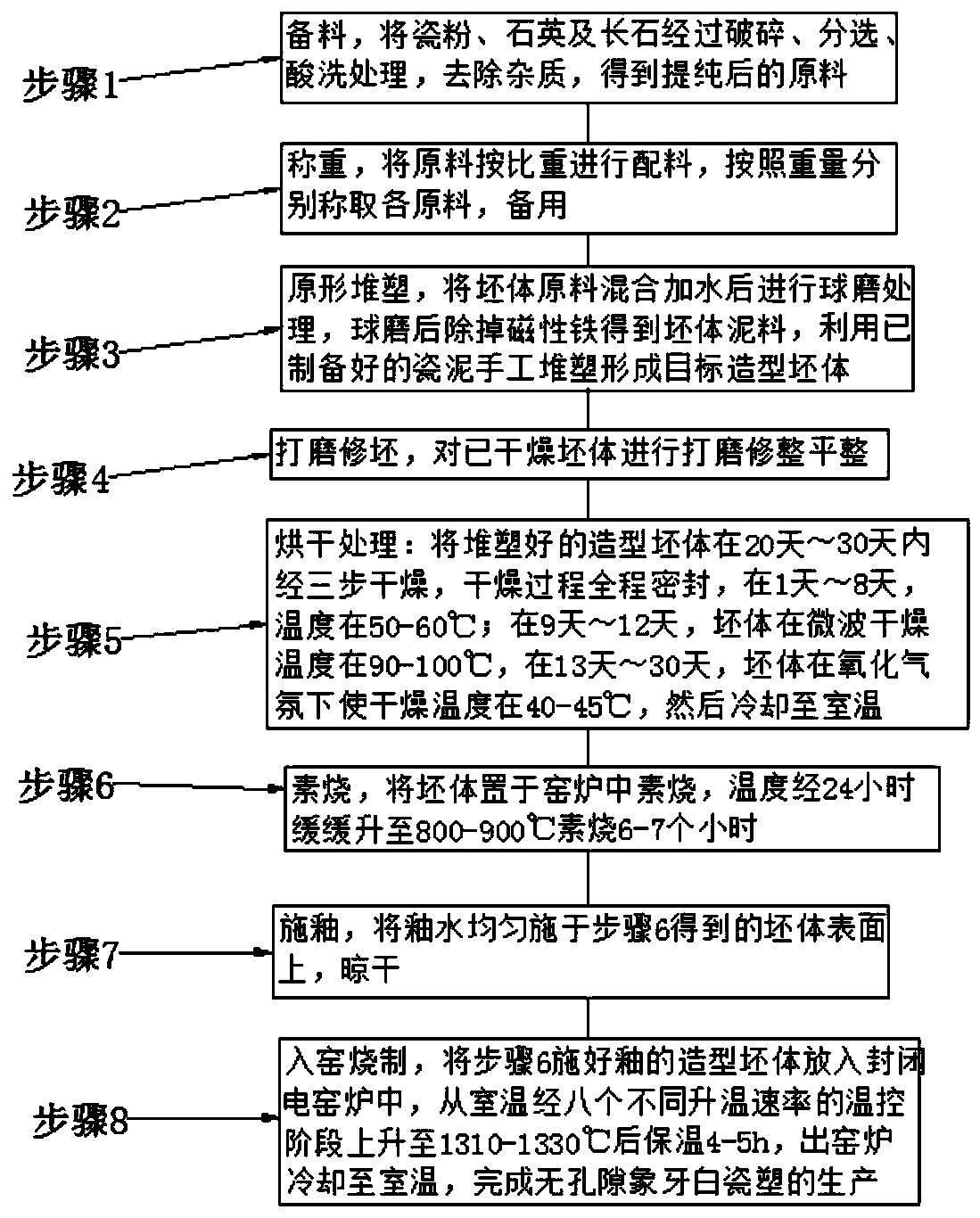

Solid porcelain plastic and preparation technology thereof

The invention particularly discloses solid porcelain plastic. The cross section of the porcelain plastic in any horizontal height comprises a plurality of independent solid faces; the radiation radius of the largest independent solid face ranges from 5cm to 35cm; and the distance of the vertical height of the solid porcelain plastic ranges from 5cm to 50cm, and the solid porcelain plastic is formed by electric heating integral baking. The invention further provides a preparation technology of the unique solid porcelain plastic. The technology comprises specific procedures of original shape paste-on-paste decoration, step-by-step drying, polishing and kiln entering for firing. The invention further provides a preparation technology of stamping back solid porcelain plastic. The technology comprises specific procedures of original shape paste-on-paste decoration, mold making, mold drying, green body printing, bonding and fettling, step-by-step drying, polishing, and kiln entering for firing. The solid porcelain plastic obtained through firing of the preparation technology is dry and even in exterior and interior, through warehouse inlet high-temperature firing, the whole body is vitreous and burnt through, no cracks, spots and pores exist on the surfaces, the mechanical property of a finished product is higher, and the plastic is not prone to being broken, is smooth and brightening in surface, and has the higher collection value and economic value.

Owner:许瑞峰

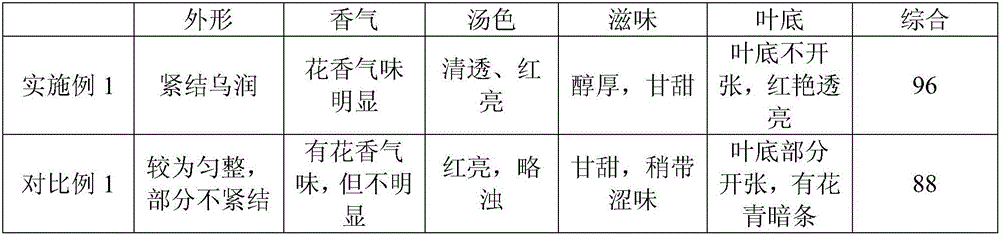

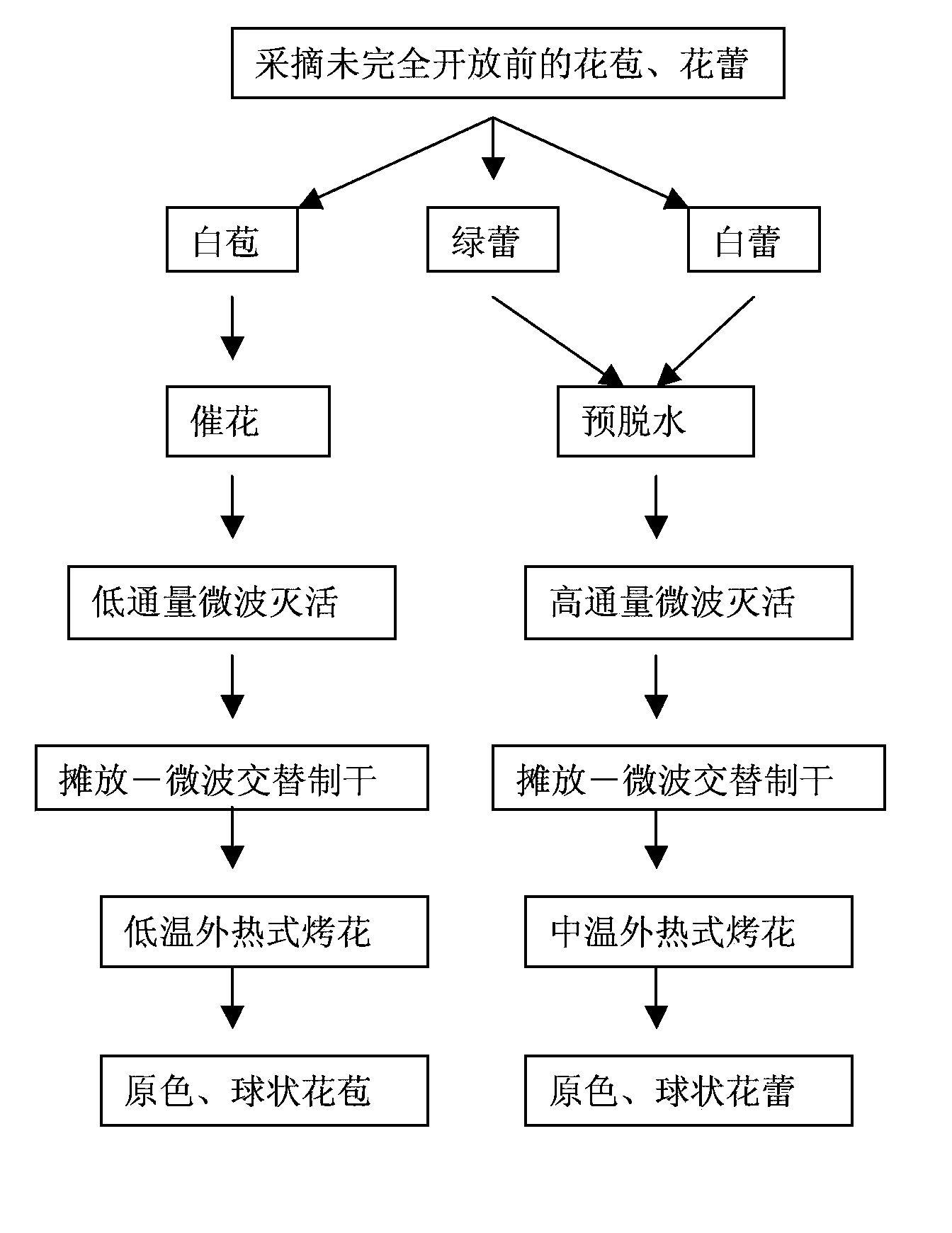

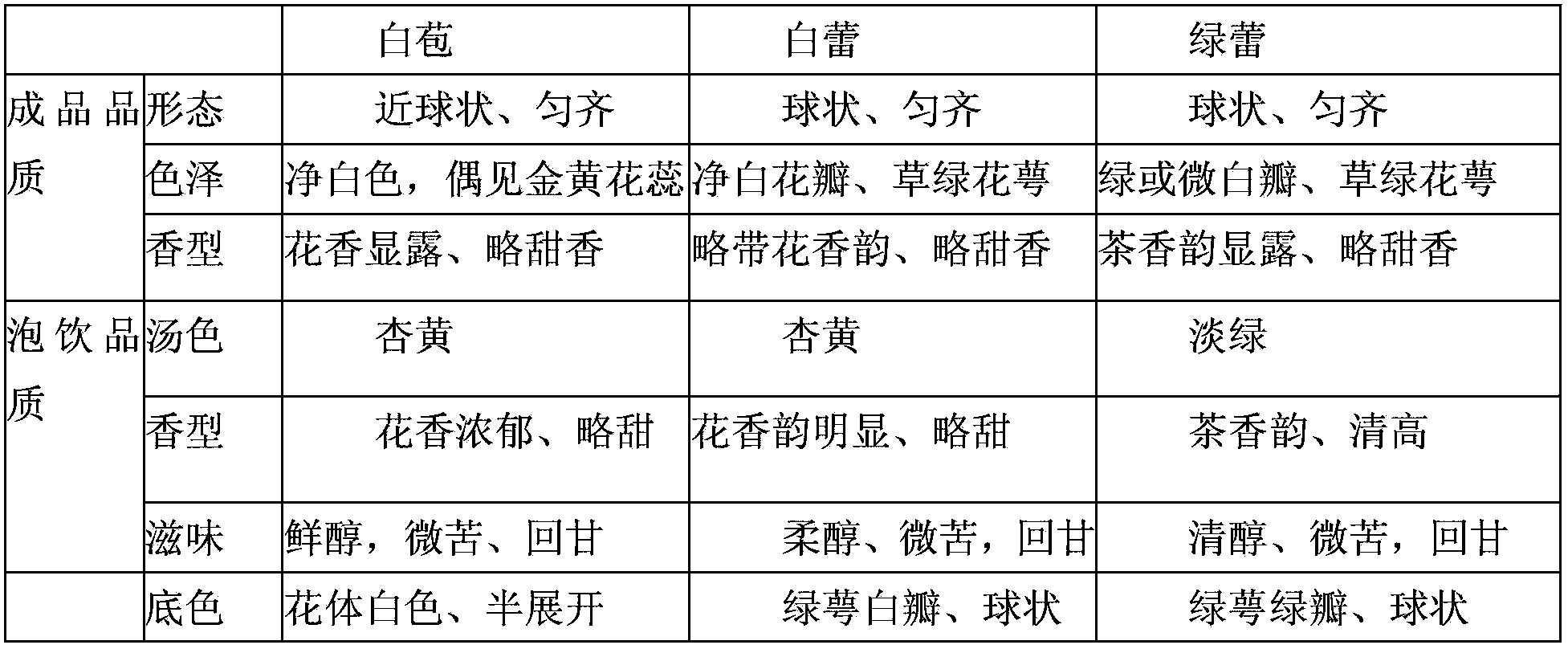

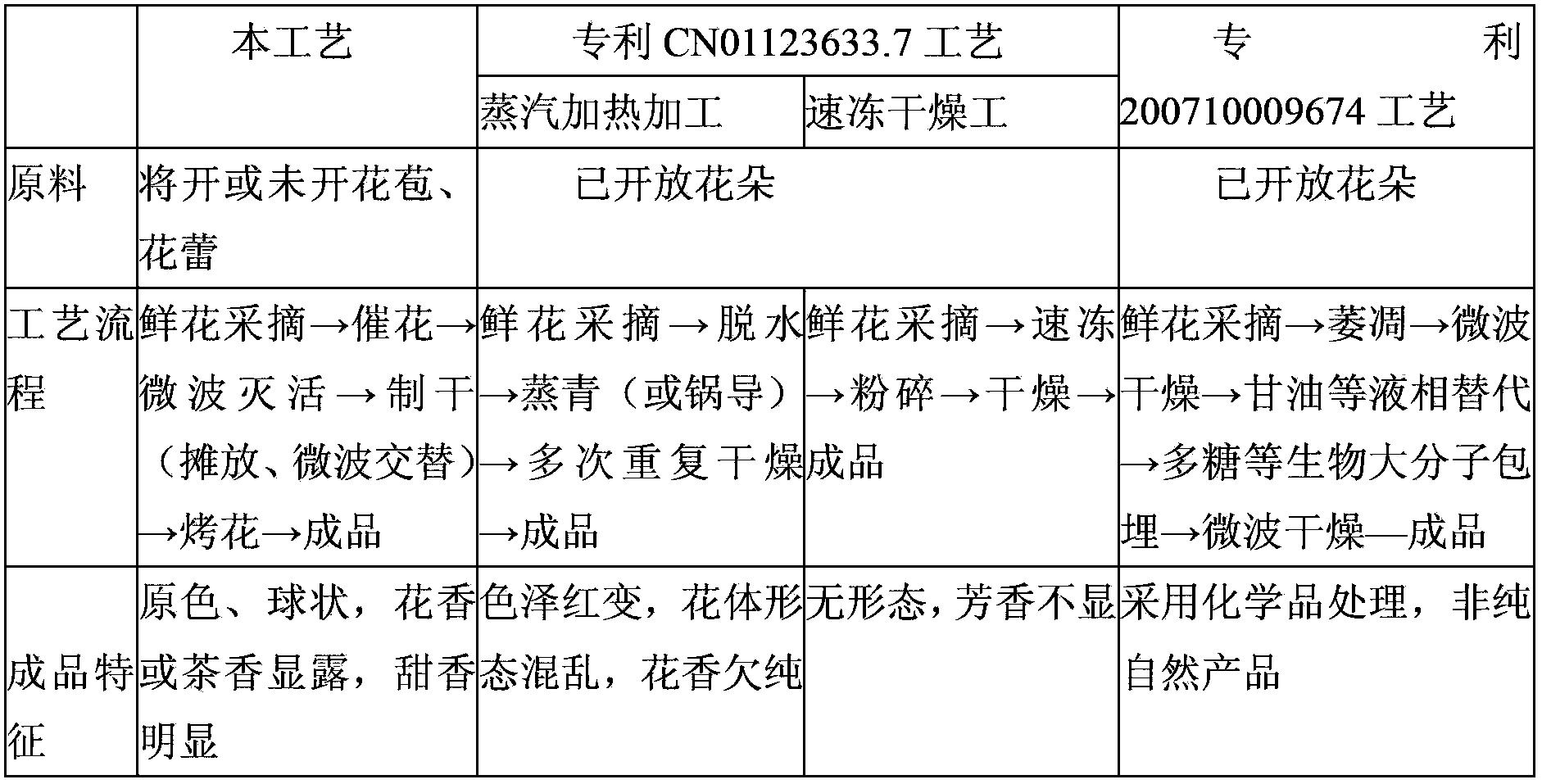

Processing method for primary-color spherical tea flowers

ActiveCN103652127AEfficient use ofImprove resource utilizationTea substituesMicrowaveResource utilization

The invention provides a processing method for primary-color spherical tea flowers. The processing method is characterized by comprising the following steps: picking and classifying flower buds; carrying out flower forcing and aroma promoting treatment on white buds; carrying out pre-dehydration treatment on the white buds and green buds; inactivating by adopting a microwave heat conduction manner; inactivating the white buds by using low-flux microwaves and inactivating the white buds and the green buds by using high-flux microwaves; alternatively drying by a paving step and the microwaves in a manner of slowly drying from inside to outside so as to uniformly disperse water inside and outside the flowers and achieve the processing requirements of basically drying and keeping color and luster and shape unchanged; baking the flowers in a drying machine or a drying oven by a heating manner from outside to inside; baking the white buds in a low-temperature outer heating manner; and baking the white buds and the green buds by a middle-temperature outer heating manner. The buds and the flower buds before the flower buds are primarily blossomed as used as raw materials and are treated by unique flower forcing and pre-dehydration to prepare a product with beautiful color and luster, beautiful appearance and high product safety; resources of the tea flowers are effectively utilized and the resource utilization rate is improved.

Owner:余姚市瀑布仙茗绿化有限公司

Processing method of green tea

InactiveCN107372931AIncrease internal and external temperatureImprove consistencyPre-extraction tea treatmentHorticultureDissolutionGreen tea

The invention discloses a processing method of green tea, which belongs to the technical field of tea processing. The processing method comprises the following steps: picking, withering, fixing, spreading and air-drying, kneading, removing tealeaf tips, pile-fermenting, pressing, floating, drying and improving the fragrance; the fragrance improvement is to treat a tea block which is dried and cooled to the normal temperature with steam of 100 to 120 DEG C for 6 to 12 min, then to place the tea block into a fragrance improving machine, wherein the temperature in the fragrance improving machine is adjusted to 30 to 50 DEG C, after the tea block is treated for 8 to 15 min, the temperature is increased to 60 to 80 DEG C, after the tea block is treated for 6 to 10 min, the temperature is increased to 90 to 110 DEG C, and then the tea block is treated until the water content is 3.0 to 5.5 percent, thus obtaining the green tea. According to the processing method, when the fragrance is improved, the tea block is firstly preheated with steam, so that substances contained in the tealeaves can be changed, a maturity accelerating effect can be achieved, the fragrance of the tealeaves can be significantly improved, the dissolution of tealeaf substances can be increased, and the content of water extract can be increased.

Owner:贵州苗贵客贸易发展有限公司

Preparation method of Yunnan congou black tea

The invention discloses a preparation method of Dianhong Gongfu tea. The method comprises the following steps: a. withering, b. rolling, c. fermentation, d. drying. The premise of forming the excellent quality of black tea. On the one hand, rolling is to form cords, and on the other hand, it is to break leaf cells. It is an important process for shaping the shape and forming the inner quality of Gongfu black tea. Fermentation is a process in which the tea polyphenols in tea are oxidized violently under the action of enzymes, and at the same time affect the changes of other ingredients in the tea, forming the unique color and aroma of black tea. Fermentation is the key process to form the quality of Gongfu black tea. Drying is the last process to fix and improve the quality of black tea, which has a great influence on the quality. These four key steps directly affect the quality of tea. By refining the production process of Dianhong Gongfu tea, it can obtain a better taste and save costs.

Owner:BAOSHAN GUDAOCHUN TEA BUSINESS LIMITED

Preparation method of green tea

ActiveCN106551016AMaximize incentive valueImprove use valuePre-extraction tea treatmentCooking & bakingGreen tea

The invention discloses a preparation method of green tea. The preparation method comprises the following steps of selecting planting lands; performing picking; performing baking of tea leaves; performing rolling; performing pyrolysis; performing drying twice; performing careful choosing; obtaining primary finished products; and obtaining finished products and the like. According to the preparation method disclosed by the invention, the efficacies of the green tea can be furthest arouse out, the utilization value of the green tea can be increased, the prepared green tea is bright in color, brewed tea leaves are still green and rich in fragrance, and tea soup has the characteristics of being rich, mellow, fresh and brisk, sweet in aftertaste and the like.

Owner:湖南长健农业发展有限责任公司

Processing method for improving quality of white tea

InactiveCN109430445AImprove qualityUniform dehydrationPre-extraction tea treatmentTemperature controlFlavor

The present invention discloses a processing method for improving the quality of white tea. The processing method comprises steps of picking, withering in a first stage, rapid freezing in a first stage, enzyme treatment, withering in a second stage, withering post-treatment, rapid freezing in a second stage, drying, etc. The sectional type withering and temperature-controlled drying are used, so that tea leaves slowly complete a material conversion process, the withered leaves are uniform in water loss, various intrinsic biochemical components of the withered leaves change normally, and good white tea quality is formed; the drying is all conducted in a relatively low temperature, besides, from low temperature to high temperature, the drying time is suitable, so that the tea leaves have a unique aroma and taste; after the withering is ended and before the drying process is conducted, the tea leaves are also subjected to a stacking process, so that the tea leaves normally complete necessary physical and chemical changes of contents of the withered leaves, water distribution of each part of the withered leaves is regulated again, and the processing method promotes leaf cells to continue to be oxidized and ensures fresh, sweet, mellow and refreshing white tea quality flavor.

Owner:湖北圣浩现代农业科技发展有限公司

Manufacturing method of black tea

The invention provides a manufacturing method of black tea. The manufacturing method comprises the following steps: (1) withering: adopting spreading, sunning and airing manners; (2) rolling by adopting a rolling machine; (3) putting tea leaves into a fermentation chamber for fermentation, and controlling the fermentation temperature to be 24 to 28 DEG C, the relative humidity to be 95% to 98% and the fermentation time to be 2 to 4 hours; and (4) drying with charcoal fire, and drying until the water content of the tea leaves reaches 5% to 8% so as to obtain dried black tea. In virtue of a green tea withering method (spreading, sunning and airing), uniform water loss for the tea leaves is guaranteed, and the rolled tea leaves are uniform in shapes and good in forming effect; through drying with charcoal fire, charcoal flavored black tea is obtained; and by adopting the manufacturing method, the quality of the black tea is improved.

Owner:HUBEI XINGMENG TEA CO LTD

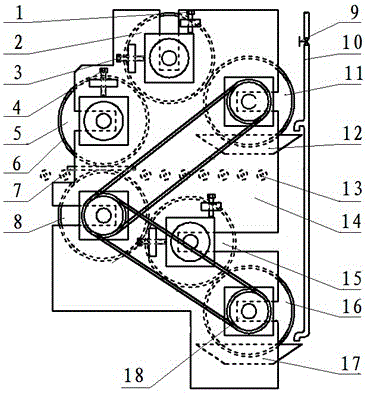

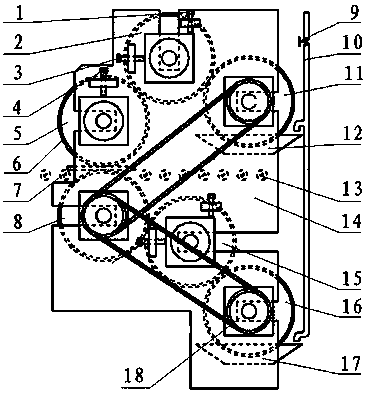

Environment-friendly material-saving device for sulfuric acid rolling of smeared unformed plates through rolling dipping of rich solution with barren solution

ActiveCN105938895ANo wasteReduce pollutionElectrode rolling/calenderingLead-acid accumulator electrodesEngineeringSulfuric acid

The invention discloses an environment-friendly material-saving device for sulfuric acid rolling of smeared unformed plates through rolling dipping of a rich solution with a barren solution. The device comprises an upper rolling dipping roll, a lower rolling dipping roll, an upper transfer roll, a lower transfer roll, an upper rolling roll, and a lower rolling roll, wherein the upper rolling dipping roll is rolled through an upper rolling dipping acid tank below the upper rolling dipping roll in a soaked manner, and the lower rolling dipping roll is rolled through a lower rolling dipping acid tank below the lower rolling dipping roll in a soaked manner; the upper rolling dipping roll and the lower rolling dipping roll are respectively in contact with the upper transfer roll and the lower transfer roll to transfer rolling; the upper transfer roll and the lower transfer roll are respectively in contact with the upper rolling roll and the lower rolling roll to transfer rolling; a gap is formed between the upper rolling roll and the lower rolling roll; an unformed plate delivery rollway is arranged in the gap; roll surfaces of the upper rolling dipping roll, the lower rolling dipping roll, the upper transfer roll, the lower transfer roll, the upper rolling roll and the lower rolling roll are all wrapped with acid-resistant and acid-absorbent roll cloth. When the unformed plates are rolled through the device, dripping of dilute sulfuric acid and lead mud is prevented, so that the acid rolling lead mud and the acid are not wasted, and a surface acid layer is thin and uniform.

Owner:TIANNENG GRP JIANGSU TECH

Black tea withering method

InactiveCN107319020AUniform dehydrationThe withering process is simplePre-extraction tea treatmentBlack teaBud

The invention belongs to the technical field of tea processing, and specifically relates to a black tea withering method. Fresh tea leaves with one bud and two leaves are picked as raw materials for withering. ‑8°C, the freezing time is 30‑38 minutes, and the fresh raw leaves obtained by freezing are sent to the evaporation chamber for instant evaporation treatment. The instant evaporation temperature is 200‑220 °C, and the instant evaporation time is 1‑1.2 seconds. Spray a layer of wort evenly on the surface of fresh original leaves, place it at 26-28°C for 40-50 minutes, and then knead. Nutrient loss also ensures low aroma loss, so that the finally obtained black tea is not only rich in influence, but also has the advantages of high and lasting aroma.

Owner:安徽汇灵农业科技有限公司

Needle-shaped green tea preparation method

InactiveCN1197471CIncrease temperaturePassivation activityPre-extraction tea treatmentGreen-lightGreen tea

Owner:CHONGQING YUNLING TEA IND TECH

Pork drying machine

InactiveCN106689331AIncrease the number of rootsAvoid cloggingMeat/fish preservation by heatingMeat/fish preservation by dryingWater depletionAgricultural engineering

The invention discloses a pork drying machine. The pork drying machine comprises a heater, wherein the heater is connected with a drying box through a heating transporting pipe; a wind inlet and a wind outlet are separately formed in two ends of the heater; a wind sucking fan is arranged at the wind inlet; at least two heating wires are arranged between the wind outlet and the wind sucking fan; the drying box comprises a hot wind chamber; at least two layers of meat laying frames are arranged above the hot wind chamber; the hot wind chamber is connected with hot wind heating pipes; the hot wind heating pipes are vertically arranged on the inner walls of the drying box; sub hot wind heating pipes are arranged on the hot wind heating pipes, and the sub hot wind heating pipes are distributed on the inner walls of the drying box in a sinusoidal manner; wing outlets are formed in the hot wind heating pipes and the sub hot wind heating pipes; wind releasing holes are formed in the side wall of the drying box; a wind releasing fan is arranged on each wind releasing hole; observation windows are also formed in the drying box; a temperature sensor and a humidity sensor are arranged on each observation window; and a controller is also arranged on the drying box. According to the pork drying machine disclosed by the invention, temperature is easy to control, the drying efficiency is high, the water depletion of pork is uniform, and the labor intensity is low.

Owner:贵州省福泉市安运腌制食品有限责任公司

Non-porous ivory white porcelain plastic and preparation method thereof

InactiveCN110563446AAvoid crackingUniform dehydrationCeramic materials productionClaywaresWhole bodyKaolin clay

The invention provides a non-porous ivory white porcelain plastic and a preparation method thereof. The non-porous ivory white porcelain plastic comprises the following materials in percentage by weight, 31%-49% of kaolin, 12%-18% of porcelain powder, 6%-10% of quartz, 3%-6% of limestone, 9.5%-14% of clay, 5%-9% of feldspar, 3.5%-7% of calcium oxide, 1.5%-5% of magnesium oxide, 4.5%-9% of silicondioxide, 2%-7% of aluminum oxide and 1%-3% of ferric oxide. Beneficial effects are as following, kaolin, quartz, feldspar, clay and porcelain powder are used as raw materials of a green body; all theraw materials are fully mixed, the middle of the porcelain plastic body is solid and free of pores, the hardness, abrasion resistance and water resistance of fired porcelain plastic products are improved by improving the density of the fired porcelain plastic products, the whole body is porcelainized and burnt through, the surface is free of cracks, spots and pores, the surface is smooth and bright, and very high collection value and economic value are achieved.

Owner:兰全盛

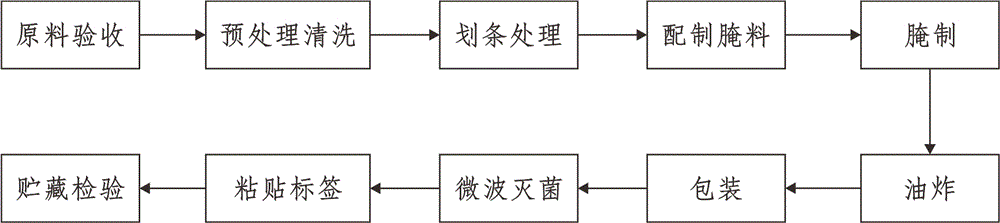

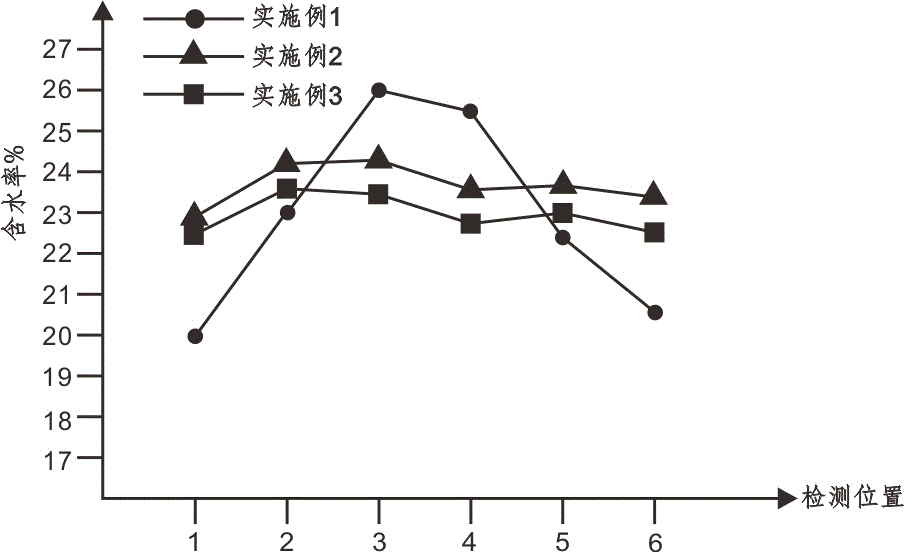

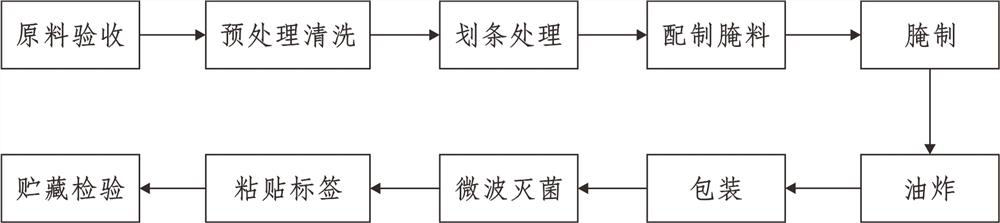

Method for preparing diced pork in pot by use of microwave heating sterilization

ActiveCN106509652AKeep the original flavorKeep the tasteMeat/fish preservation by heatingFood ingredient as mouthfeel improving agentFlavorDeep frying

The invention discloses a method for preparing diced pork in pot by use of microwave heating sterilization. The method comprises the following steps of: performing pretreatment to obtain primal cut; performing pickling to obtain pickled pork; and performing deep frying to obtain deep-fried port, performing microwave sterilization, and optimizing process conditions of microwave high-temperature sterilization, wherein the microwave power is 10-15KW, the frequency is 3000-4000MHz, the temperature is 70-90 DEG C, and the processing time is 2-5min. The diced pork in pot is complete in strip shape, golden and bright in skin color, unique in pickling flavor, and fragrant but not oily in oil, and is fresh, fragrant and delicious. A traditional preparation method of the diced pork in pot is improved; after semi-finished products are packaged, microwave heating sterilization is used, and the sterilization effect of microwave heating sterilization is good, so that the amount of bacteria in pork is greatly reduced, and furthermore, the pork quality, taste and appearance of the diced pork in pot are preserved. A transparent high-temperature retort pouch is adopted for package, the traditional diced pork in pot is easily polluted during a taking process; compared with a traditional package preservation method, the diced pork in pot, which is prepared by the method, is beautiful in package appearance, convenient to carry, good in preservation effect and beneficial to storage.

Owner:雅安职业技术学院 +1

Moisturizing method capable of improving cucumber and loofah grafting survival rate

InactiveCN105493905AImprove water absorptionUniform dehydrationGraftingGrowth substratesGraft survivalBiology

The invention provides a moisturizing method capable of improving the cucumber and loofah grafting survival rate. A cucumber seedling with 2-4 true leaves is selected, and the stem base is cut into a wedge shape in the position at 0.5-0.8 cm under the leaf at the lowest bottom end of the cucumber seedling; a loofah interior leaf is cut, the lower crotch between two seed leaves of a loofah seedling is directly cut into a grafting opening, the cut wedge-shape stem base of the cucumber seedling is rapidly inserted into the grafting opening, after fixing, the grafting opening is wrapped with ramie or fiax soaked with water for one hour and tightened, the advantages that the hydroscopicity of the with ramie or fiax is good, the moisture retention is good and the water loss is uniform are fully used, water loss of the grafting opening is prevented, the cucumber seedling and loofah seedling are ensured to heal rapidly and recover growth, the grafting survival rate can reach 98.5% or above, the operation is simple, convenient and reliable, a cucumber and a loofah are ensured to be grafted successfully under the premise that the cost is not increased, the disadvantage that a cucumber has to survive in wet, fertile and suitable soil is overcome, the expense consumption is reduced, and the income is increased.

Owner:DONGGUAN GUANGXIN INTPROP SERVICES CO LTD

An environment-friendly and energy-saving smear raw plate rich liquid rolling dipping lean liquid rolling sulfuric acid device

ActiveCN105938895BNo wasteReduce pollutionElectrode rolling/calenderingLead-acid accumulator electrodesMaterials scienceEnvironmentally friendly

The invention discloses an environment-friendly material-saving device for sulfuric acid rolling of smeared unformed plates through rolling dipping of a rich solution with a barren solution. The device comprises an upper rolling dipping roll, a lower rolling dipping roll, an upper transfer roll, a lower transfer roll, an upper rolling roll, and a lower rolling roll, wherein the upper rolling dipping roll is rolled through an upper rolling dipping acid tank below the upper rolling dipping roll in a soaked manner, and the lower rolling dipping roll is rolled through a lower rolling dipping acid tank below the lower rolling dipping roll in a soaked manner; the upper rolling dipping roll and the lower rolling dipping roll are respectively in contact with the upper transfer roll and the lower transfer roll to transfer rolling; the upper transfer roll and the lower transfer roll are respectively in contact with the upper rolling roll and the lower rolling roll to transfer rolling; a gap is formed between the upper rolling roll and the lower rolling roll; an unformed plate delivery rollway is arranged in the gap; roll surfaces of the upper rolling dipping roll, the lower rolling dipping roll, the upper transfer roll, the lower transfer roll, the upper rolling roll and the lower rolling roll are all wrapped with acid-resistant and acid-absorbent roll cloth. When the unformed plates are rolled through the device, dripping of dilute sulfuric acid and lead mud is prevented, so that the acid rolling lead mud and the acid are not wasted, and a surface acid layer is thin and uniform.

Owner:TIANNENG GRP JIANGSU TECH

A kind of preparation method of green tea

ActiveCN106551016BMaximize incentive valueImprove use valuePre-extraction tea treatmentGreen teaEpigallo-catechin gallate

The invention discloses a preparation method of green tea. The preparation method comprises the following steps of selecting planting lands; performing picking; performing baking of tea leaves; performing rolling; performing pyrolysis; performing drying twice; performing careful choosing; obtaining primary finished products; and obtaining finished products and the like. According to the preparation method disclosed by the invention, the efficacies of the green tea can be furthest arouse out, the utilization value of the green tea can be increased, the prepared green tea is bright in color, brewed tea leaves are still green and rich in fragrance, and tea soup has the characteristics of being rich, mellow, fresh and brisk, sweet in aftertaste and the like.

Owner:湖南长健农业发展有限责任公司

Method for preparing titanium dioxide by calcining metatitanic acid double-stage rotary kiln

ActiveCN108793244BImprove calcination recoveryEffective temperature controlTitanium dioxideThermodynamicsProcess engineering

The invention discloses a method for preparing titanium dioxide by calcining metatitanic acid in a double-section rotary kiln. The method comprises the following steps: enabling metatitanic acid afterfilter pressing to successively perform dehydration in a first-section rotary kiln for calcining, and perform desulfuration, crystal type transform and grain growth in a second-section rotary kiln for calcining, to obtain a kiln falling product, and performing grinding and powder mixing on the kiln falling product, wherein a heat source of the second-section rotary kiln for calcining is from a high-temperature gas generated by calcining a natural gas, a heat source of the first-section rotary kiln for calcining is from a kiln tail gas generated by the calcining of the second-section rotary kiln, and the kiln tail gas generated by the calcining of the first-section rotary kiln successively passes through a dust collecting chamber and a bag dust collector for recovering kiln tail dust. Themethod is capable of improving the quality of the titanium dioxide, and improving a calcining recovery rate of the rotary kiln, wherein the recovery rate is up to 99.8%. The energy consumption of thenatural gas is reduced by 30-45%, and a usage amount of the natural gas is reduced.

Owner:CNMC GUANGXI PGMA

Device and method for measuring swelling representation parameters of swelling soil

InactiveCN102401778BEasy to control temperatureUniform dehydrationPermeability/surface area analysisVertical loadPermeation

The invention discloses a device and method for measuring swelling representation parameters of swelling soil. The device for measuring the swelling representation parameters of the swelling soil comprises a sample container, a soil body permeation coefficient measurement part, a jacking cylinder applying a vertical load, a dial indicator for testing a swelling soil sample to generate vertical deformation, and a deformation pipe used for testing water seepage coefficients of the swelling soil. The method comprises the steps of: immersing the swelling soil sample into water for swelling stably, measuring the water seepage coefficients; and then electrically heating the swelling soil sample to ensure that the swelling soil sample is dehydrated and contracted stably, and measuring the permeation coefficients of the swelling soil. Therefore, the invention can be used for measuring water seepage and permeation coefficients of the swelling soil in a repeatedly-swelling deformation process by controlling temperature and water content changes of the swelling soil sample in the sample container so as to reflect the change of a fracture and a soil body structure inside the soil body of the swelling soil in the repeatedly-swelling deformation process. In addition, the sample container of the device is connected with an external pipeline through each joint arranged on the sample container, therefore, data measurement in an experiment process is facilitated, and measurement precision of data is increased.

Owner:HOHAI UNIV

A method for preparing jar meat by microwave heating and sterilization

ActiveCN106509652BKeep the original flavorKeep the tasteMeat/fish preservation by heatingFood ingredient as mouthfeel improving agentBiotechnologyBacterial counts

The invention discloses a method for preparing jar meat by microwave heating and sterilization, which includes pretreatment to obtain selected meat; marinating to obtain marinated meat; frying to obtain fried meat and microwave sterilization, and optimizing the process of microwave high-temperature sterilization Process conditions: microwave power 10~15KW, frequency 3000~4000MHz, temperature 70℃~90℃, processing time 2min~5min. The jar meat in the present invention has a complete strip shape, golden and bright skin color, unique pickled taste, oily fragrance but not greasy, fresh and delicious. The invention improves the traditional production method of jar meat. By packaging the semi-finished products and using microwave heating and sterilization, the sterilization effect of microwave heating and sterilization is good, so that the number of bacteria in the meat is greatly reduced, and the meat quality and taste of the jar meat are maintained. shape. The present invention uses a transparent high-temperature retort bag for packaging, and the traditional jar meat is very easy to cause pollution in the process of taking it. Compared with the traditional packaging and preservation method, the present invention has a beautiful appearance, is easy to carry, has a good preservation effect, and is more conducive to storage.

Owner:雅安职业技术学院 +1

Production method for waterproof pig-skin shoe upper leather

InactiveCN107488757AReduce lossesGood degreasing effectPre-tanning chemical treatmentLeather degreasingHexamethylenetetramineChlorinated paraffins

The invention relates to the technical field of animal fur processing, in particular to a production method for waterproof pig-skin shoe upper leather. Specifically, sodium carboxymethyl cellulose, borax, diethylene glycol and water are mixed to obtain depilation liquid, and pigskin is depilated; urotropine, nitroglycerin, salt, polyferric sulfate, diethylene glycol monooctyl ether and water are mixed to obtain a degreasing agent, and the pigskin is degreased; nitrocellulose, chlorinated paraffin, ethanol with the concentration being 80-82% and epoxy soybean oil are uniformly mixed to obtain a waterproof agent, and the pigskin is subjected to filling watertightness; the pigskin obtained through filling is hung and subjected to still standing under the environment that the humidity is relatively 50-52% and the temperature is 33-36 DEG C till the wet content of the pigskin is 18-20%; and the pigskin is dried. The production method for the waterproof pig-skin shoe upper leather is simple, the obtained pigskin has the excellent waterproofness, soft and full hand feelings, a certain elasticity and the good mercerizing sense, and the leather obtaining rate is 92.88% or above.

Owner:安徽乐踏鞋业有限公司

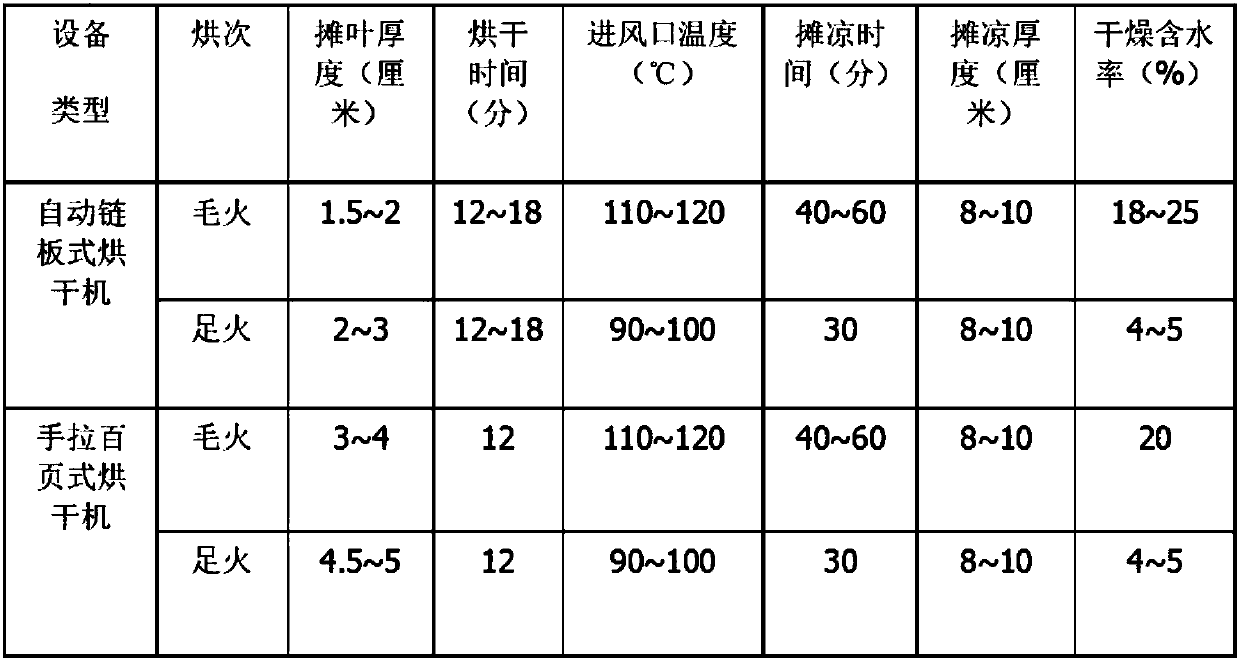

A kind of processing method of high-quality black tea

ActiveCN105028716BConsistent qualityEasy to shapePre-extraction tea treatmentCooking & bakingFixation time

The invention discloses a processing method of a black tea. The processing method sequentially comprises the following steps: selecting raw materials; picking; withering; kneading; fermenting; steaming and dehydrating; re-kneading; shaping; primarily baking; stacking and re-baking, wherein the processing method is characterized in that a steam-heating fixation machine is adopted for steaming and dehydrating; when the steam temperature reaches 150-160 DEG C and the hot air temperature reaches 100-110 DEG C, leaves are evenly fed; the leaf feeding amount is 1Kg / min; the fixation time is controlled within 35-40 seconds; the hot air dehydration time is controlled within 90-120 seconds; and the moisture content of the dehydrated leaves is 55%-65%. The black tea obtained by the processing method of the black tea is tight, fine and straight in appearance, black in color and luster, visible in golden tip, red and bright in soup, sweet, fragrant, high in purity, mellow and brisk in taste, sweet in aftertaste, bright and living in infused leaf, regular and intact; the dry tea is straight and robust in appearance; the tea soup is red and bright in color and luster; the fragrance is strong and sweet; the soup is strong, red and bright; and the taste is fresh and strong.

Owner:CHONGQING YUNLING TEA IND TECH

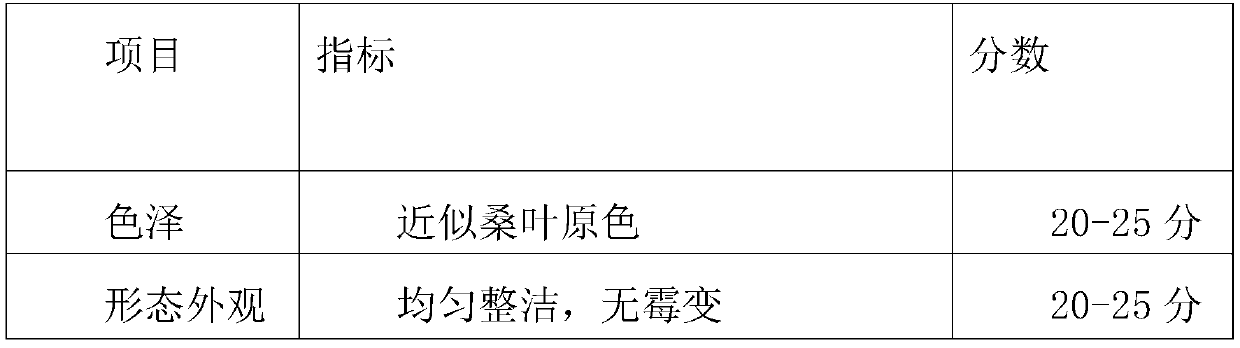

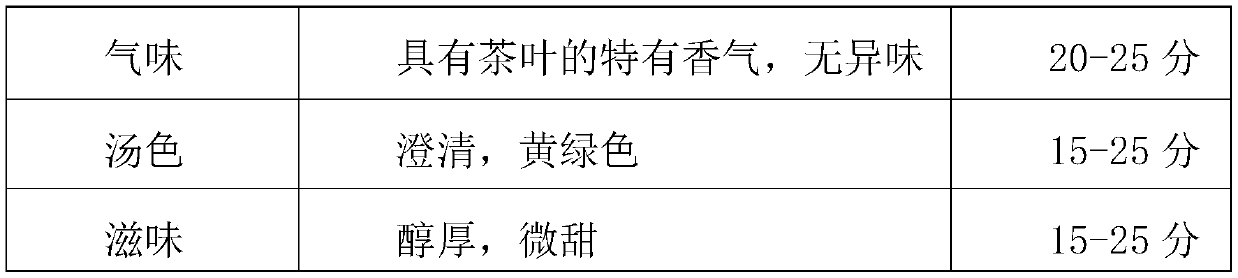

Production process of mulberry leaf tea cakes

A production process of mulberry leaf tea cakes comprises the following steps: picking fresh mulberry leaves, performing cleaning, performing drying in a cool and ventilated place for withering; afterthe mulberry leaves are withered, sorting old leaves and tender leaves, selecting the tender leaves, performing slicing, performing enzyme deactivation on the sliced mulberry leaves, performing twisting on the enzyme-deactivated mulberry leaves, performing strip making and shaping by using a strip making machine to form curved mulberry leaf tea; pressing the curved mulberry leaf tea to form a cake, and performing packaging by using cotton paper after the water content of the secondary-dried mulberry tea cakes is 8% or below; performing wrapping by using bamboo shoot shells to form tea cylinders (every tea cylinder is composed of seven tea cakes) or performing packaging by using paper bags to form tea cylinders, performing quality inspection, performing packaging and performing sales. In the preparation process of the mulberry leaf tea, the mulberry leaf tea cakes are adjusted to a suitable moisture content for compression, so that the loss of the aroma and beneficial substances of thetea leaves in the processing process is reduced, the water loss is uniform, the taste of the tea cakes is improved, the grassy smell of mulberry leaves is removed, and although the production processis not easy to control, the prepared mulberry leaf tea has high quality; and the finished mulberry leaf tea has a fresh taste, a bright green color, and various optimized biochemical and physical andchemical indicators after being drunk.

Owner:刀兴魁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com