Method for preparing titanium dioxide by calcining metatitanic acid in double-section rotary kiln

A rotary kiln, metatitanic acid technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of easy clogging of pipelines, inconsistent weight and speed, uneven feeding, etc., to avoid high temperature agglomeration and water loss. Uniform degree, conducive to the effect of accurate feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

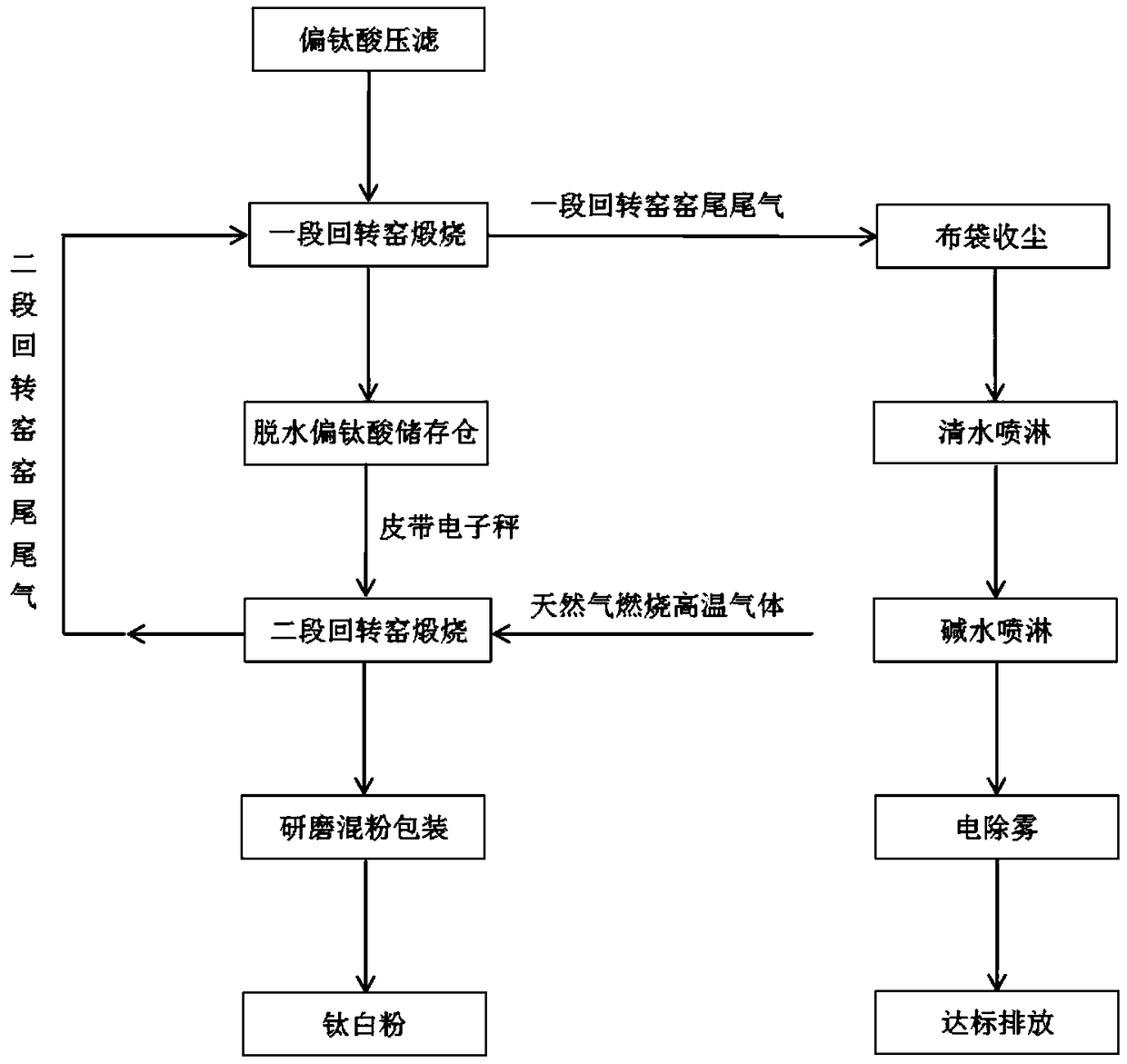

[0027] A method for preparing titanium dioxide by calcining metatitanic acid in a double-stage rotary kiln, specifically comprising the following steps:

[0028] (1) Metatitanic acid pressure filtration: the metatitanic acid after salt treatment is filtered with a diaphragm filter press, the feed pressure is 0.83mpa, the pressing pressure is 1.20mpa, and the pressure is kept for 10 minutes. The acid moisture content is 53%.

[0029] (2) One-stage rotary kiln calcination: the metatitanic acid after pressure filtration is crushed by a disintegrator, and enters the one-stage rotary kiln for calcination and dehydration through the feeding screw. , The first section of the rotary kiln has a kiln head temperature of 360°C and a kiln tail temperature of 140°C. A rotary kiln has a length of 28m and a diameter of 2.6m. The feed rate of metatitanic acid (calculated as titanium dioxide) in the first-stage rotary kiln is 4.7t / h, which is 1.68 times of the feed rate of 2.8t / h in the sing...

Embodiment 2

[0034] A method for preparing titanium dioxide by calcining metatitanic acid in a double-stage rotary kiln, specifically comprising the following steps:

[0035] (1) Metatitanic acid press filtration: The metatitanic acid after salt treatment is filtered with a diaphragm filter press, the feed pressure is 0.83mpa, the pressing pressure is 1.23mpa, and the pressure is maintained for 10 minutes. The acid moisture content is 52%.

[0036] (2) One-stage rotary kiln calcination: the metatitanic acid after pressure filtration is crushed by a disintegrator, and enters the one-stage rotary kiln for calcination and dehydration through the feeding screw. , the first section of the rotary kiln has a kiln head temperature of 380°C and a kiln tail temperature of 150°C. A rotary kiln has a length of 28m and a diameter of 2.6m. The feed rate of metatitanic acid (calculated as titanium dioxide) in the first-stage rotary kiln is 5.1t / h, which is 1.82 times of the feed rate of 2.8t / h in the s...

Embodiment 3

[0041] A method for preparing titanium dioxide by calcining metatitanic acid in a double-stage rotary kiln, specifically comprising the following steps:

[0042] (1) Metatitanic acid press filtration: The metatitanic acid after the salt treatment is press-filtered with a diaphragm filter press, the feed pressure is 0.88mpa, the pressing pressure is 1.25mpa, and the pressure is maintained for 10 minutes. The acid has a water content of 50%.

[0043] (2) One-stage rotary kiln calcination: the metatitanic acid after pressure filtration is crushed by a disintegrator, and enters the one-stage rotary kiln for calcination and dehydration through the feeding screw. , the first section of the rotary kiln has a kiln head temperature of 400°C and a kiln tail temperature of 160°C. A rotary kiln has a length of 28m and a diameter of 2.6m. The feed rate of metatitanic acid (calculated as titanium dioxide) in the one-stage rotary kiln is 5.5t / h, which is 1.96 times of the feed rate of 2.8t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tinctorial strength | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com